1. Introduction

Soilless plant production is widely used to obtain efficient and economic plant production in greenhouses and in private small-scale plant production [

1]. Handling, diverse soil types, and climate conditions complicate plant production. Some of the challenges are temperature fluctuations, the water holding capacity, the cation exchange capacity of the soil, contamination of soils with heavy metals, nutrient supply disorder, soil-borne diseases, and pests. These challenges are reduced in soilless media with better control of growth factors, resulting in uniform plant growth [

2]. Moreover, increasing concerns about the environmental effects of the overconsumption of utilized materials such as peat have driven plant producers to recognize and survey more sustainable materials. In recent decades, there has been increasing focus on recycling natural organic waste as soilless media for containerized plant production [

1]. There has been attention towards inexhaustible materials from farming and metropolitan waste streams. While a significant number of these seem useful at a trial level, few have been taken up on a larger scale. To develop and support soilless agriculture, sustainable and environmentally friendly materials need to be investigated and developed [

3].

The soilless media can either be organic, inorganic, or both. Organic media include sawdust, peat moss, and compost, whereas inorganic substrates, for example, include perlite and vermiculite [

4]. Sawdust is a derivative of the wood industry, which is a principal economic activity in regions with extensive woodlands [

5]. Sawdust is intensively produced in timber processing and industrialized areas, and some sawdust sources can be used as a growth medium due to the low price, ease of accessibility, light weight, and good drainage [

6]. Sawdust is a dry wood material consisting of cellulose, lignin, hemicelluloses, and 5–10% other materials [

7]. Sawdust has usually low bulk density, high water porosity, low air porosity, and low cation exchange capacity [

8]. Abad et al. [

1] proposed that the ideal soilless substrate should contain the following chemical properties: pH = 5.2 – 6.3; EC (dS m

−1) = 0.75 – 3.49; organic matter (%) > 80; NO

3 (µg mL

−1) = 100 – 199; K

+ (µg mL

−1) = 150 – 249; Na

+ (µg mL

−1) ≤ 115; Cl

− (µg mL

−1) ≤ 180. Domtar sawdust (commercially prepared) mixed with organic (atlas fish emulsion, bone meal, and chicken manure) and inorganic materials (clay, loam soil, and vermiculite) and NH

4NO

3 enhanced the growth and production of greenhouse tomatoes (

Solanum lycopersicum L.) and ornamental flowers, coleus (

Coleus scutellarioides (L) Benth,, and gloxinias (

Sinningia speciose (lodd.) Hiern) plants [

9]. Okalebo et al. [

10] argued that the composition of nutrient contents of sawdust limits the population of the microorganisms, making sawdust an almost sterile medium for growth, with a slow decomposition rate and temporary shortage of nitrogen to plants. Some types of sawdust may be toxic to plants and are not suitable as plant growth substrates [

11]. Meanwhile, other types of sawdust favor the plants. Nielsen and Lewis [

12] found that entomopathogenic nematodes were negatively impacted by redwood sawdust, reducing the infection of

Steinernema riobrave and

Heterorhabditis bacteriophora.

Several types of sawdust have proven to be beneficial to plants as a container substrate. Douglas fir sawdust has been used as a benifical substrate in glasshouse production [

13]. In Argentina and Alberta, sawdust has been used as a regular growth medium for plants in glasshouses [

14]. Oxygen-fumigated Douglas fir sawdust was filled in plastic bags to produce cucumbers (

Cucumis sativus L.) in a glasshouse, resulting in 20% more fresh weight yield [

13]. Comparison between sawdust and coir as growth media showed that tomatoes retained better calcium and manganese concentrations in sawdust media [

15]. When sawdust was compared with coir for the growth of English cucumber, coir proved to be a better medium, but sawdust gave a better nutrient supply to bell pepper (

Capsicum annuum L.) [

16]. The yield of strawberries ((

Fragaria ananassa L.) increased when the plants were grown in a mixture of sawdust and pumice (50:50 ratio) compared to growth in 100% sawdust, but the leaf number doubled in 100% sawdust [

17]. In a study conducted by Ruifen et al. [

18], tomato yield was up to 48% larger in a mixture of carbonized rice hulls and sawdust (ratio, 2:1 vol/vol) than in soil or 100% sawdust. Moreover, flower and fruit number, plant height, root dry weight, the quantity of green foliage, chlorophyll content, and root length were higher in the mixture than in the soil. Mixing different components carefully in appropriate proportions may create attractive physical and chemical characteristics of the growth medium to improve the development of plants [

1].

Okra is a common vegetable crop grown under tropical and subtropical conditions. Okra is especially valued for its tender, delicious fruits and is a good source of essential vitamins (e.g., Vitamin C) and minerals, such as calcium, phosphorus, magnesium, and iron [

19]. Okra is generally grown in locations where the crop receives full sunlight throughout the day. Soil types for okra production can vary, with loams and sandy loams preferred, but even heavier soils can produce well if the soil drains well enough to prevent waterlogging. Okra is tolerant of a wide range of soil pH, but prefers soil with a pH between 6.0 and 6.8. If the soil pH is below 5.8, it should be limed to increase the pH to 6.0 or more. Soils at or below 5.8 can result in okra with poorly developed pods [

20].

We chose okra as a container plant in our experiments and soilless sawdust from chinaberry (Melia azedarach L.) as a growth substrate to provide an option to urban people to grow okra—for example, in containers on rooftops. Melia azedarach is a species of deciduous tree in the mahogany family, Meliaceae. The main utility of chinaberry is its timber.

Banana peels and eggshells were selected and amended as potential sources of organic fertilizers. In some densely populated areas, it is possible to collect banana and eggshell efficiently and use them as fertilizers for small-scale vegetable production. Panwar [

21] claimed that banana peels contained essential plant nutrients, particularly potassium, and Gaonkar and Chakraborty [

22] declared eggshells as the best source of calcium for tomato plants suffering from calcium deficiency.

In this study, we investigated whether amendments of banana peels (as a source of potassium), eggshells (as a source of calcium), and urea (as a source of nitrogen) in non-composted (fresh) Melia azedarach sawdust may enhance its potential as a growth medium for okra.

2. Materials and Methods

2.1. Selection of Growth Substrate

The growth substrate consisted of sawdust mixed with banana peel powder, eggshell powder, and urea fertilizer. Banana peels were collected from fresh fruit juice shops and household kitchens. It was sun-dried and ground into powder by using a spice grinding mill. The eggshells were collected from hatcheries, bakeries, fast food shops, and household kitchens. Eggshells were also sun-dried and ground into powder using a spice grinding mill. The average chip size of

M. azedarach sawdust was 8−16 µm, obtained using a wood sawdust crusher machine (Zhengzhou Yuxi wood sawdust crusher machine, Zhengzhou Yuxi Machinery Equipment Co., Ltd., Zhengzhou, China). Healthy and young

M. azedarach trees approximately 23 feet tall and around 6 years old were selected. We used fresh non-composted sawdust. The banana peels and eggshells were dried and ground into powder to be used as organic fertilizers. The treatments were: T

1—100% sandy clay loam unfertilized soil from a fellow field (control) (vol/vol, herafter equal to v/v), T

2—100%

M. azedarach sawdust (v/v) non-composted, T

3—80%

M. azedarach sawdust +20% banana peel (v/v) non-composted, T

4—60%

M. azedarach sawdust +20% banana peel +20% eggshells (v/v) non-composted, T

5—60%

M. azedarach sawdust +20% banana peel +20% eggshells (v/v) + urea (91 kg N hectare

−1 as recommendation for okra [

19]) non-composted. Fertilizer was mixed manually in the substrate.

2.2. Experimental Design

Two pot experiments (exp-1 and exp-2) placed at different locations with different light and climate conditions were conducted during summer 2019 at a research area of the Department of Agronomy, College of Agriculture, University of Sargodha, Pakistan (32.07° N, 72.68° E).

The experiments were completely randomized designs (CRD) with five treatments and four replications. We used plastic pots (21 × 20 cm) with two small holes at the bottom to facilitate proper water drainage. Pots were filled with 5.6 liters of growth substrates. Each growth substrate had a different density and weight. The total mass and composition of the sawdust substrate mixtures are shown in

Table 1. The basic physio-chemical properties of the soil and non-composted

M. azedarach sawdust mixtures are shown in

Table 2. Okra (

Abelmoschus esculentus L. Moench) (cultivar: Punjab Selection) was used as a test plant. Four seeds per pot were sown at 2−3 cm depth. The number of seedlings was reduced to two per pot 15 days after sowing (DAS). One plant was further uprooted 30 days after sowing (S

1). Hence, one plant remained in the pots. Plant growth at S

1 was recorded. The plants were harvested 110 DAS (S

2). Weeds were removed from control pots after emergence. No weeds emerged from pots with sawdust.

Irrigation was applied to provide proper moisture for seed germination. Each pot was placed on a plastic tray filled with water. The base of each plastic pot remained submerged in water until all the substrate mixtures and the soil in the pots were wetted completely through the holes in the bottom.

Subsequent irrigations were applied regularly from the top of each pot, ensuring that water never became a limiting factor for the plant growth.

2.3. Phenological Development

The number of days to plant emergence was recorded for each pot. Plant height was measured at S1 and S2. Stem diameter was recorded with an electronic digital vernier caliper (Mitutoyo 500-196-20 Digital Vernier Caliper, Mitutoyo Corporation; 20-1, Sakado 1-Chome, Takatsu-Ku, Kawasaki-shi, Kanagawa 213-8533, Japan) at S1 and S2. One plant of okra from each treatment was uprooted, and the above-ground biomass and root fresh and dry weight (oven: Model DGH-9240A; 540 S Brea Blvd. Brea, California 92821, USA; biomass dried at 85 °C for 48 h) were measured at S1 and S2 using a digital weight balance (Sartorius Model No. BSA2235, Made by Sartorius Scientific Instruments (Beijing) Co., Ltd. 33 Yu An Road, Airport Industrial Park Zone B, Shunyi District, Beijing 101300, China). At S1 and S2, root length (cm) was measured. The average number of days to the first flower was estimated for each treatment. The number of pods per plant was counted at S2. The fresh and oven-dry weight of pods from each plant were weighed separately, and the average weight was calculated. The length of each pod was measured. The average diameter of pods per plant was measured by using a digital vernier caliper (Electronic Digital Caliper by Hangzhou Maxwell Tools Co., Ltd. Zhejiang, China). Seeds were counted manually by removing the seeds from each pod and the average number of seeds per pod was calculated.

2.4. Physiological Parameters

Chlorophyll content index (CCI) was measured by using a CCI meter (“CCI Meter”, Beijing Yaxinliyi Science and Technology Co., Ltd.; No. F707 Jiahua Building, No. 9 3th Street Shangdi, Haidian District 10085, Beijing, China) at S

1 and S

2. The single leaf area (mm

2) was calculated at S

1 and S

2 using a Leaf Area Meter (Yaxin-1241 Leaf Meter, Beijing Yaxinliyi Science and Technology Co., Ltd.; No. F707 Jiahua Building, No.9 3th Street Shangdi, Haidian District 10085, Beijing, China). Relative leaf water content (RWC) (%) was determined according to the method described by Smart [

23]. One leaf from each plant was selected randomly from the middle of the canopy from each replication and detached from the plant using a scissor. Leaves were cleaned with tissue paper, and fresh weight was recorded (FW). Then, the leaves were dipped in distilled water for four hours in dim light to obtain a turgid weight (TW). Afterward, the leaves were dried in an oven (Model DGH-9240A; 540 S Brea Blvd. Brea, California 92821, USA) at 85 °C for 24 h, and the dry weight (DW) of the leaves was recorded. Relative leaf water content was measured by using the following formula:

The membrane stability index (MSI) (%) was measured according to the method described by Sairam [

24]. One hundred mg leaf discs from each replicate were taken and thoroughly washed with distilled water. Thereafter, leaf discs were heated in 10 mL distilled water for 30 min at 40 °C. Electrical conductivity (C1) was measured by the EC meter (DDS-307 Conductivity Meter by Ningbo Hinotek Technology Co., Ltd. Qiancheng Building, Ningbo Hi-Tech Zone, Ningbo 315040, China). The samples were placed in a boiling water bath for 10 min, and electrical conductivity (C2) was measured again, and the MSI index was calculated:

2.5. Statistical Analysis

The two experiments were analyzed separately. The data recorded were subjected to one-way analysis of variance (ANOVA) and presented as the mean of four replicates ± standard error (SE). Significance between the treatments was checked at p ≤ 0.05. In a post hoc procedure, all pair-wise comparisons were made, and significance levels were assessed using the Least Significant Difference (LSD) test at the 5% probability level.

3. Results

All mixtures of

M. azedarach sawdust substrate significantly reduced the growth and development of okra. The roots became stunted compared to plants grown in the soil (control) (

Figure 1).

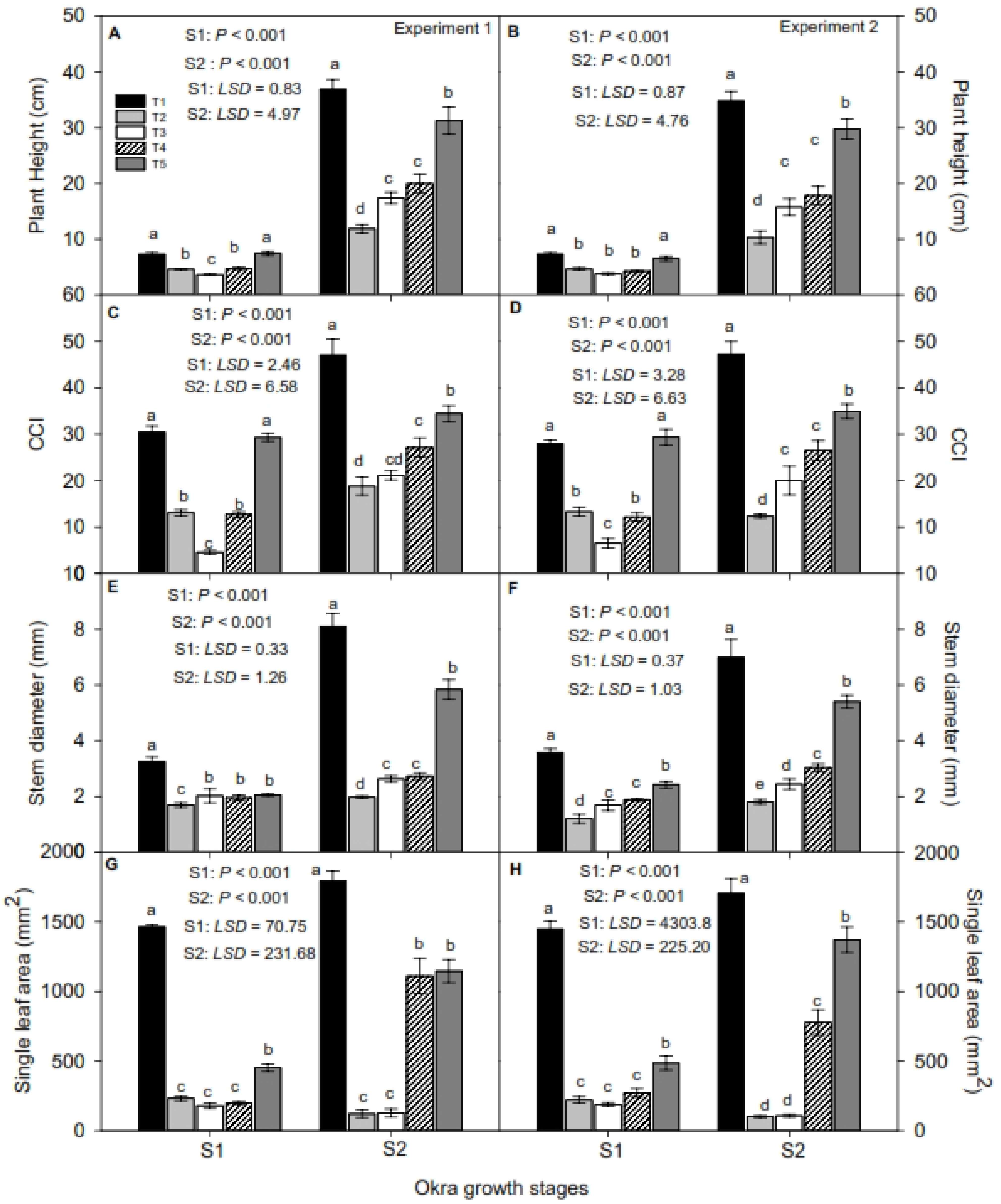

Plant height varied significantly between treatments at S

1 and S

2 (

Figure 2A,B). In exp-1, at S

1, the maximum plant height (7.42 cm) was recorded in T

5, and it was statistically on par with T

1 (7.25 cm). The shortest plant height was recorded in T

3 (3.62 cm).

In exp-2, at S

1, plants grown in soil were tallest (7.27 cm), followed by plants grown in T

5 (6.5 cm). The same was observed at S

2 in both experiments. The shortest plants were found in T

2 with plant heights of 11.85 cm and 10.30 cm in exp-1 and exp-2, respectively (

Figure 2A,B). In exp-1, the chlorophyll content index (CCI) at S

1 was largest (30.47) for plants grown in soil and T

5 (29.30) (

Figure 2C,D) and smallest (4.57) for plants grown in T

3 in exp-1. For exp-2, at S

1, the largest CCI (29.37) was measured in T

5 and was statistically on par with T

1 (CCI = 28) (

Figure 2C,D). At S

2, maximum CCI was measured in T

1, followed by T

5, in both experiments. The lowest CCI was recorded in T

2 (

Figure 2C,D).

At S

1, the largest stem diameter (SD) (3.25 mm) was measured in T

1, followed by T

5 (2.05 mm) (

Figure 2E,F). Plants exposed to T

2 had the smallest SD (1.19 mm). In both experiments, SDs at S

2 showed the same trends as at S

1 (

Figure 2E,F).

The average single leaf area (SLA) significantly differed for the various sawdust treatments (

p ≤ 0.001). In both experiments, the single leaf area was the largest for plants exposed to T

1, followed by plants exposed to T

5. The lowest SLA was recorded in T

3 (

Figure 2G,H).

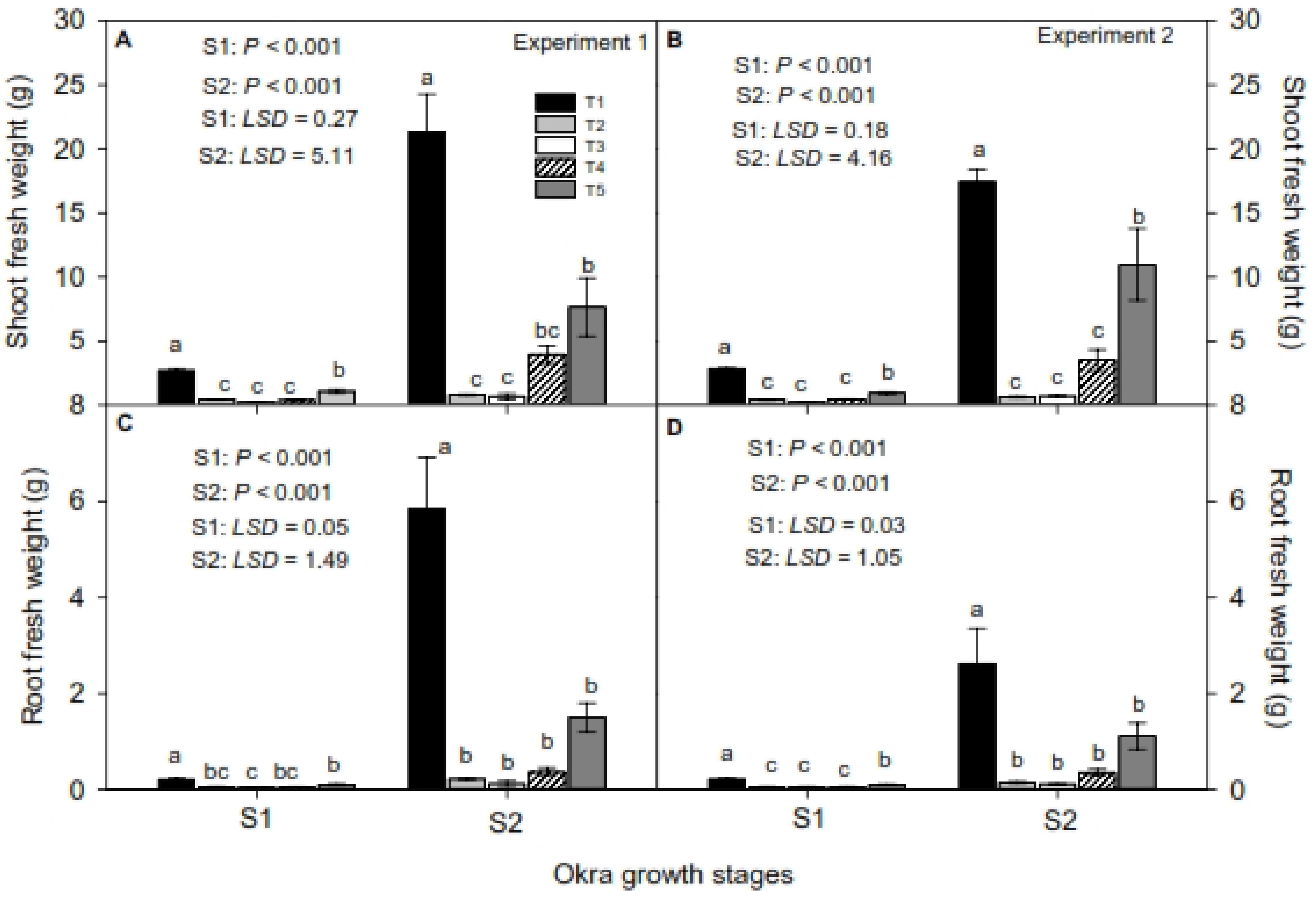

The shoot fresh weight (SFW) in both experiments at S

1 and S

2 was largest for T

1, followed by T

5. Plants exposed to T

3 had the smallest SFW (

Figure 3A,B). The root fresh weight (RFW) showed the same trend as SFW (

Figure 3 C,D).

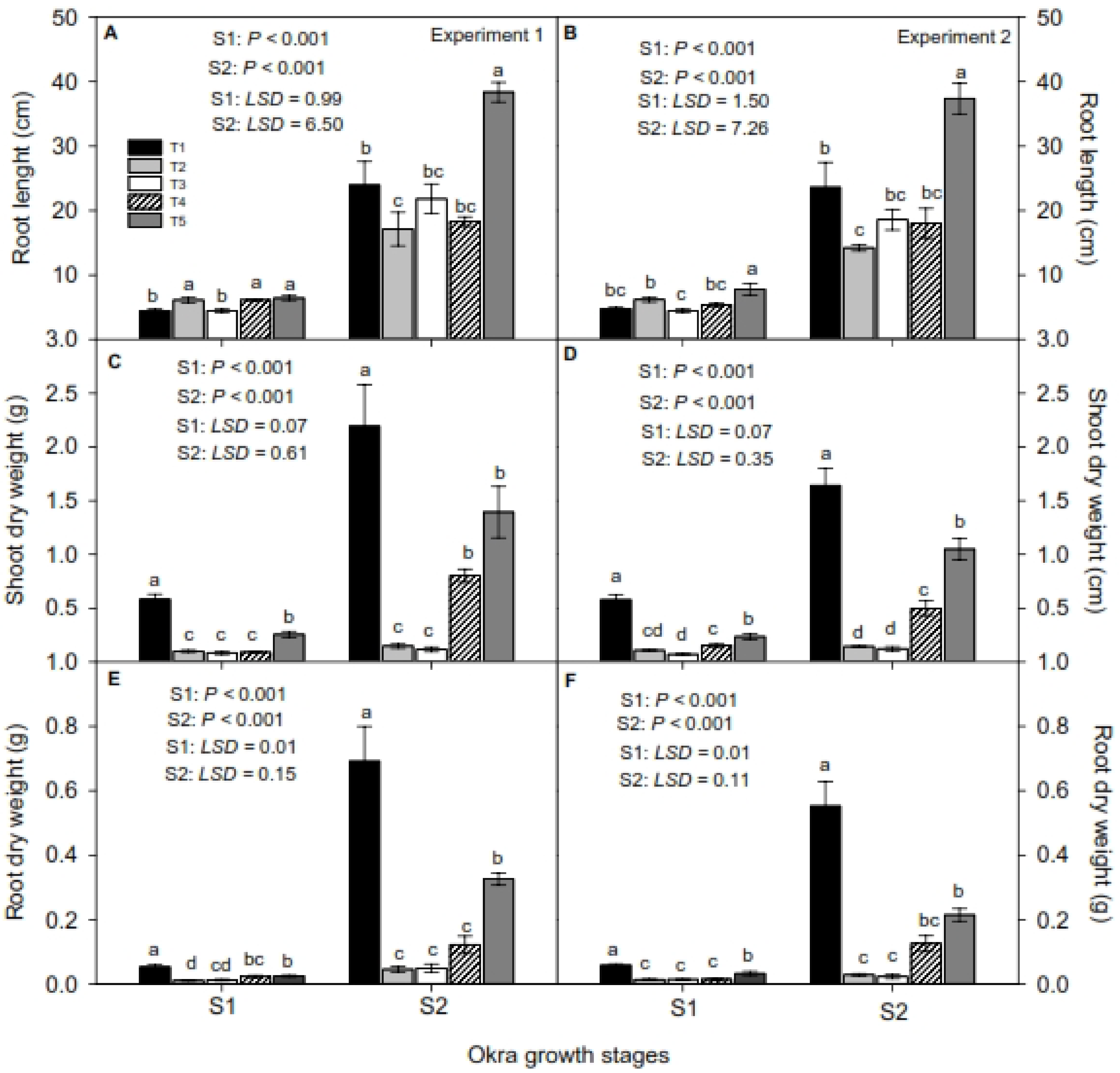

For root length (RL) in exp-1, at S

1, T

5, T

4, and T

2 were statistically on par (6.42, 6.15, and 6.12 cm, respectively) (

Figure 4A,B). In exp-2, at S

1, the largest RL (7.8 cm) was measured in T

5, followed by T

2 (6.17 cm). At S

2, in exp-1, the largest RL was recorded in T

5 (38.35 cm), followed by T

1 (23.95 cm) and T

3 (21.82 cm). In exp-2, T

5 had the largest RL (37.37 cm), followed by T

1 (23.6 cm), while plants exposed to T

2 had the shortest RL (18.57 cm) (

Figure 4A,B). In exp-1, at S

1, the maximum shoot dry weight (SDW) was measured in T

1, followed by T

5. In T

2 and T

4, SDW was estimated to be 0.09 g, and plants exposed to T

3 had the lowest SDW (0.08 g) (

Figure 4C,D). In exp-2, at S

1, the largest SDW (0.57 g) was measured in T

1, followed by 0.23 g in T

5 (

Figure 4C,D). At S

2, similar trends were observed for SDW in both experiments as in S

1 (

Figure 4C,D).

In both experiments at S

1, the largest root dry weight (RDW) was measured in T

1, followed by T

5 and T

4 (

Figure 4E,F). In both experiments, we saw the same trends at S

2 (

Figure 4E,F).

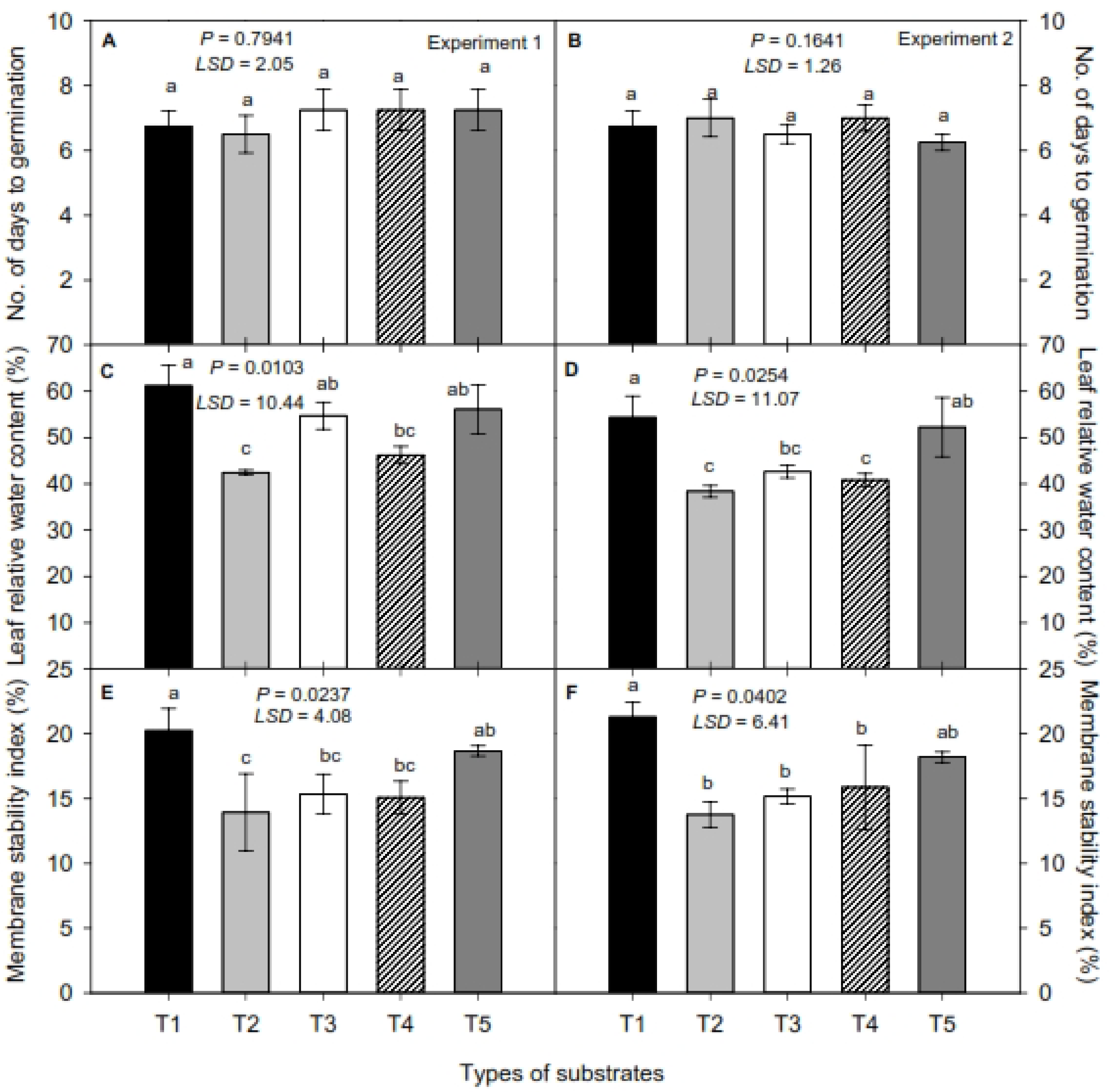

In both experiments, there was no significant difference in the number of days to emergence of plants among the treatments (

Figure 5A,B). The leaf relative water content (RWC) was, in both experiments, the highest for plants exposed to T

1, followed by T

5 and T

3, respectively (

Figure 5C,D). The membrane stability index (MSI) was, in both experiments, the largest for T

1, followed by T

5, and the lowest for T

2 (

Figure 5E,F).

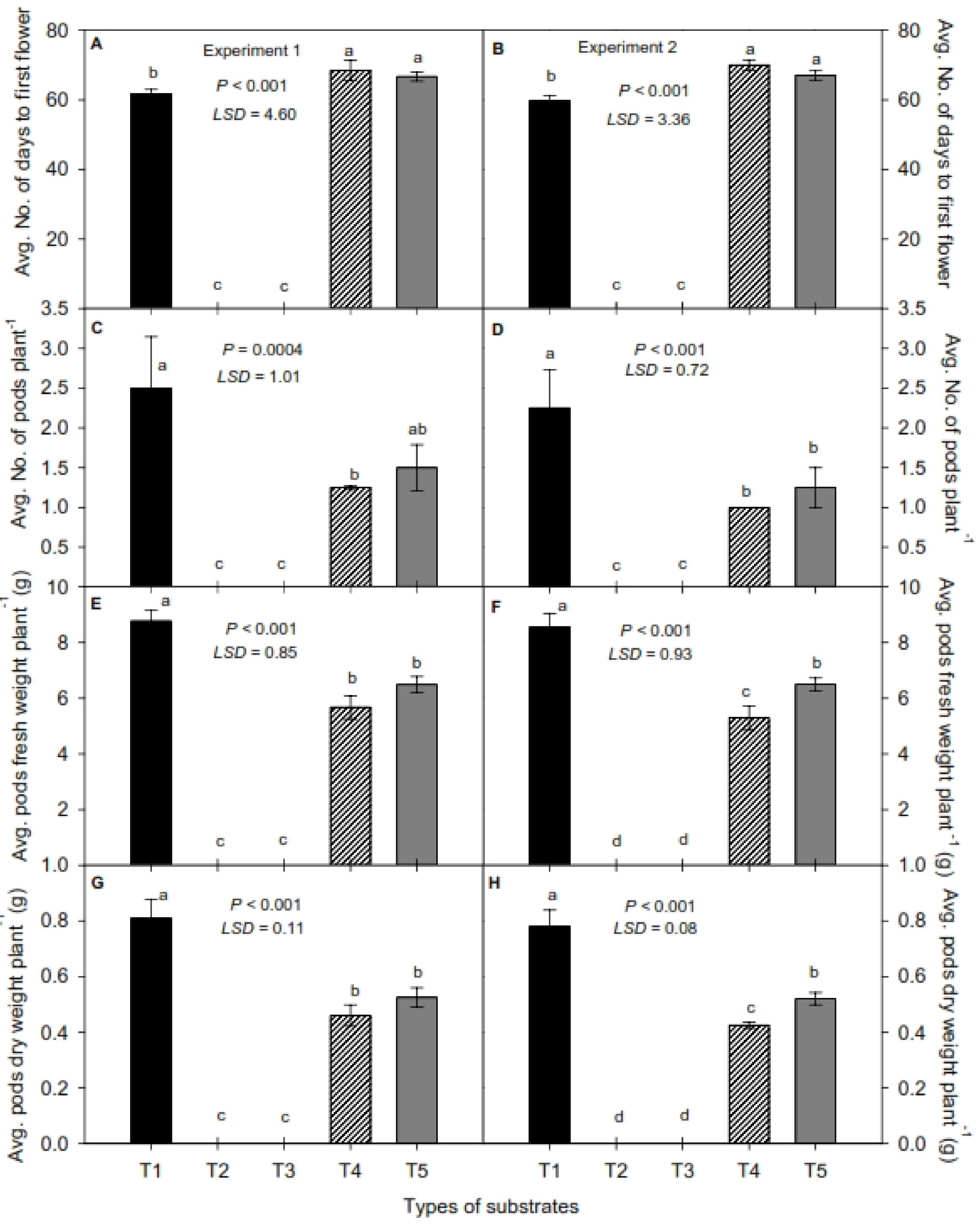

Plants grown in the soil had the least number of days to first flower in both experiments (

Figure 6A,B). No blooming occurred in T

2 and T

3 in both experiments (

Figure 6A,B). Most pods were found in T

1, followed by T

5, in both experiments, while the smallest number was found in T

4 (

Figure 6C,D). The treatments had the same effect on the average pod’s fresh weight (

Figure 6E,F) and the average pod’s dry weight per plant

−1 (

Figure 6G,H).

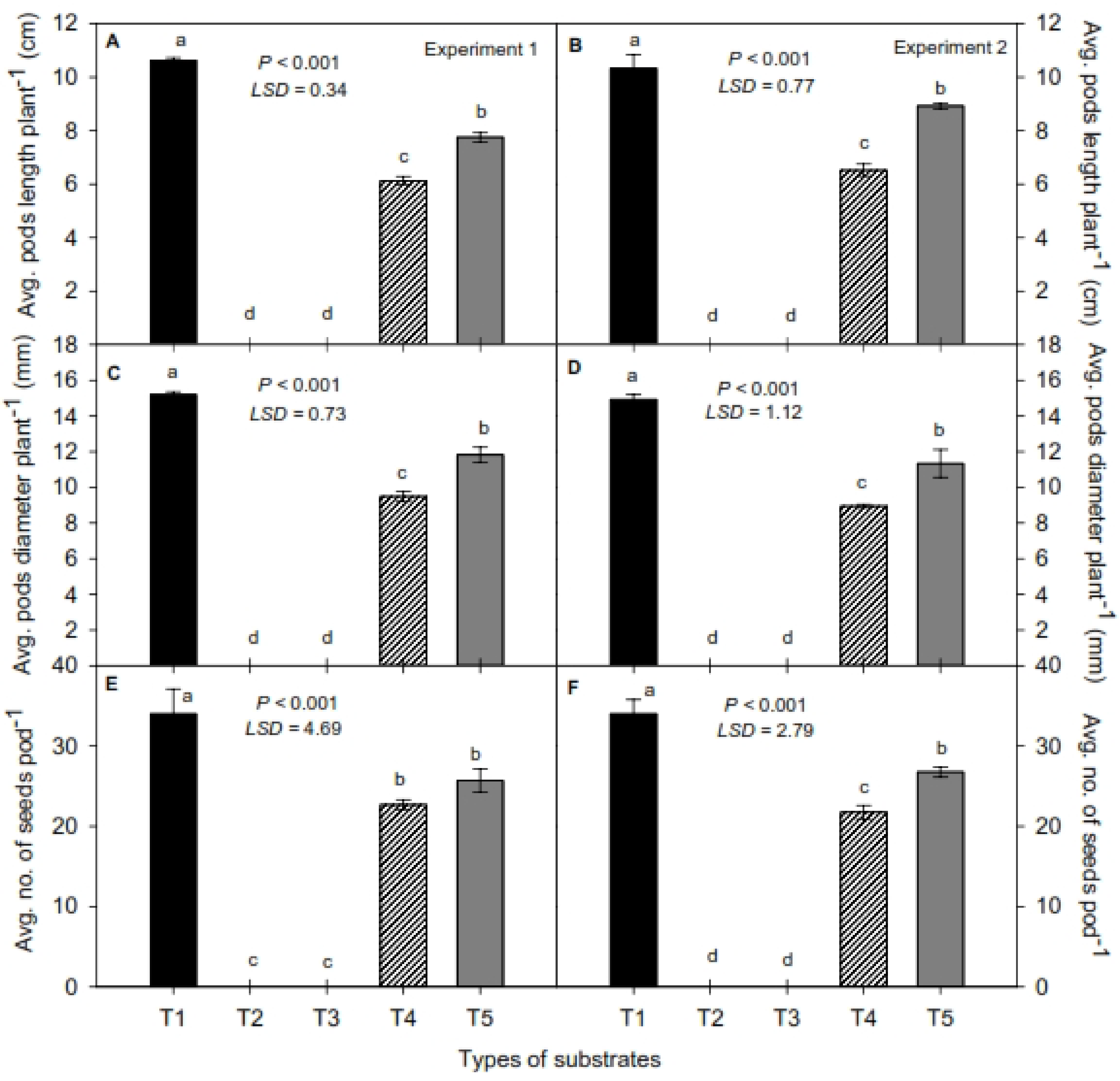

Plants that were grown in the soil produced pods with a greater average pod length in both experiments (

Figure 7A,B). Similarly, the average pod diameter (

Figure 7C,D) and the average number of seeds per pod

−1 (

Figure 7E,F) were higher in okra plants grown in soil. There was no blooming and hence no pod settings in T

2 and T

3 in both experiments. The greatest pod length, diameter, and number of seeds were found in T

1, followed by T

5 and T

4 in both experiments.

4. Discussion

In general, the non-composted Melia azedarach sawdust substrate mixtures with and without organic amendments reduced the growth and yield of okra compared with unfertilized sandy clay loam soil (control). However, there was no significant difference between the treatments for the number of days it took okra to emergence. During germination and emergence, plants are usually solely dependent on the nutrients stored in the seed. Hence, M. azedarach sawdust substrates have the potential to be used as a nursery germination medium for okra seed germination due to their porosity and good water drainage.

In T

5, 91 kg N hectare

−1 as urea was added because many studies have reported nitrogen deficiency in sawdust growth substrates due to nitrogen immobilization [

25,

26,

27]. The amount of N incorporated into the sawdust mixture was not sufficient to attain the same growth of okra as in the soil, probably because of nitrogen immobilization in the non-composted sawdust. A lack of plant nutritents reduces the plants’ abilty to achieve their full yield potential, and affects the plants below and above the ground, reducing root growth, shoot biomass, and fruit and seed production. These yield components are highly correlated.

We used non-composted

M. azedarach sawdust to grow okra plants to avoid 10−24 weeks of composting time of the sawdust and speed up the process for commercial manufacturing of sawdust as a growth substrate. Maas and Adamson [

28] showed that

Pseudotsuga menziesii and

Tsuga heterophylla non-composted sawdust could be used as a growth substrate for various plants in Canada. However, fresh sawdust could result in reduced plant yields compared to other substrates.

Along with low fertility, phytotoxicity may be another reason for the reduced growth of okra and yield in non-composted

M. azedarach sawdust mixtures. However, we did not study the phytotoxicity of

M. azedarach sawdust. Ortega et al. [

29] stated that forest waste can contain phytotoxic phenolic compounds that reduce plants’ growth. They studied cork oak bark’s phytotoxic effects on tomato and lettuce. Nichols [

30] stated that the growth of many containerized plants was impaired due to the phytotoxicity of fresh

Pinus radiate D. Don bark used as a growth medium.

Yasin et al. [

6] reported that garlic cloves’ emergence was on par when grown in soil and six different types of sawdust substrates (

Eucalyptus albens,

Morus alba,

Bombax ceiba,

Azadirachta indica,

Acacia nilotica, and

Mangifera indica), but garlic growth was better in

A. indica and

B. ceiba sawdust, probably because sawdust has good porosity, which allowed radicals and root tips to penetrate deep into the medium during garlic cloves’ emergence and bulb establishment.

All growth and physiological parameters (i.e., plant height, leaf area, shoot and root fresh and dry weight, stem diameter, pod number, diameter of plant

−1, average pod length per plant

−1, total yield, and CCI) after emergence were negatively affected by the non-composted

M. azedarach sawdust mixtures compared to soil, probably because of the reduced availability of plant nutrients in the sawdust mixtures. Palacios et al. [

31] reported that phytotoxic compounds were present in

M. azedarach fruit extract. When this extract was mixed with soil, they observed the inhibition of seed germination and reduced radicle and shoot length of

Avena sativa L. and

Sorghum halepense (L.). The lower leaf area and CCI might be due to N immobilization and N deficiency in non-composted

M. azedarach sawdust soilless mixtures. Nitrogen increases the photosynthetic process, resulting in greater leaf production and chlorophyll content [

32]. Poor dry matter accumulation might be due to the poor nutritional status and unfavorable pH of sawdust substrate mixtures, which restricted the nutrient supply to the plants and therefore reduced photosynthetic activity, resulting in a lower plant dry biomass in our experiments.

The root length in T5 was longer than in the soil. This might be due to the higher porosity of the sawdust substrate, which permitted easy penetration and enhanced root length, whereas the compactness of the clay soil in the control pots influenced the root penetration.

Leaf relative water content percentage was observed to be higher in plants grown in soil, maybe because the sawdust substrates had larger pore spaces and less water holding capacity compared to clay soil. Okra grown in the soil had the highest membrane stability index, meaning that the plants retained more water in leaves and suffered less leaf cuticle membrane injury during summer by heat.

No blooming or fruiting were observed in T2 and T3, and the blooming was delayed in T4 and T5 compared to soil. A lack of sufficient plant nutrients and immobilization of nutrients caused an imbalanced C:N ratio in non-composted M. azedarach sawdust mixtures, which could be the reasons for the reduction in all yield components.