Development and Application of a Crossed Multi-Arch Greenhouse in Tropical China

Abstract

:1. Introduction

2. Development Idea

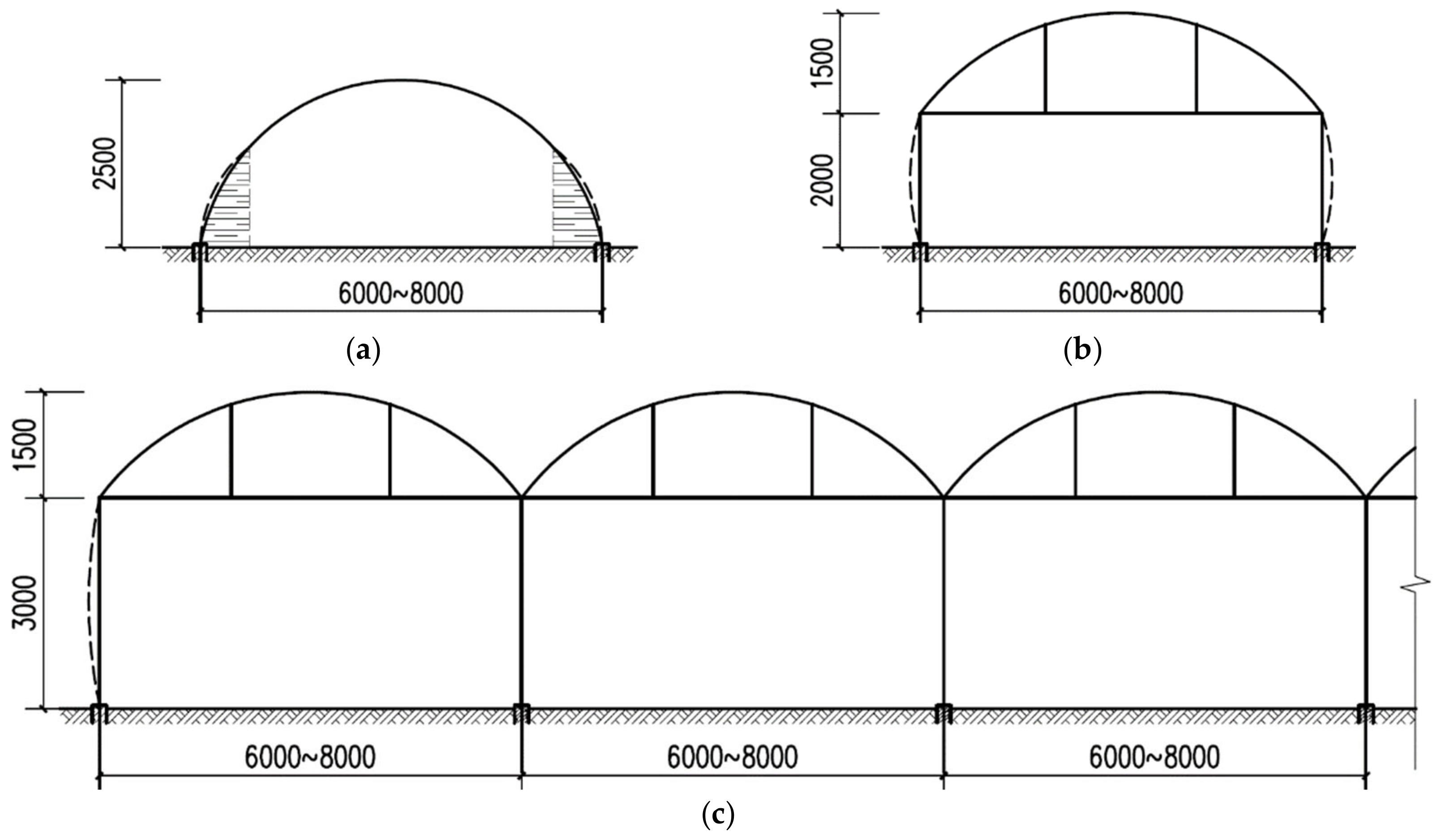

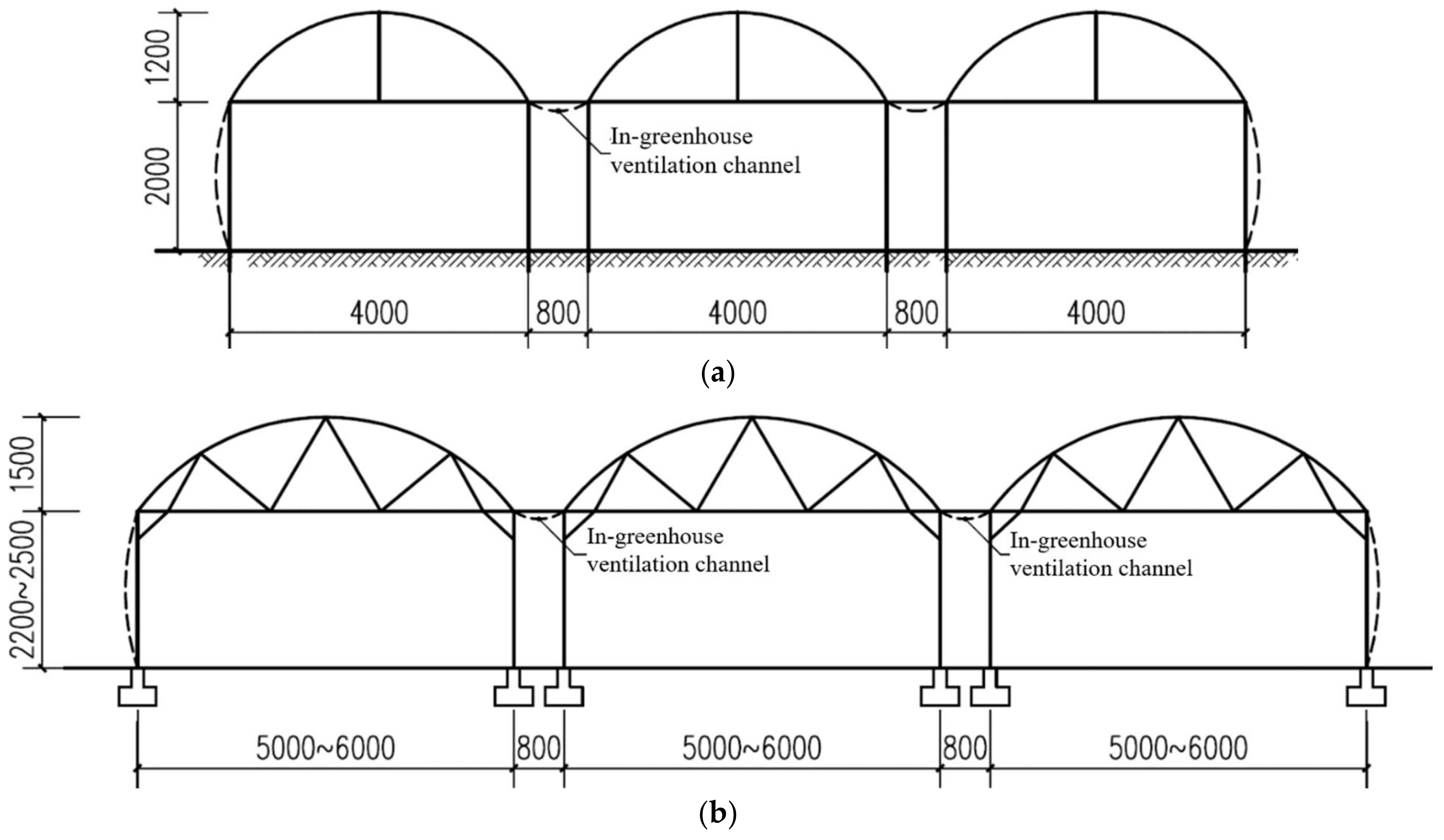

2.1. Evolution of the Round Arc Greenhouse Structure

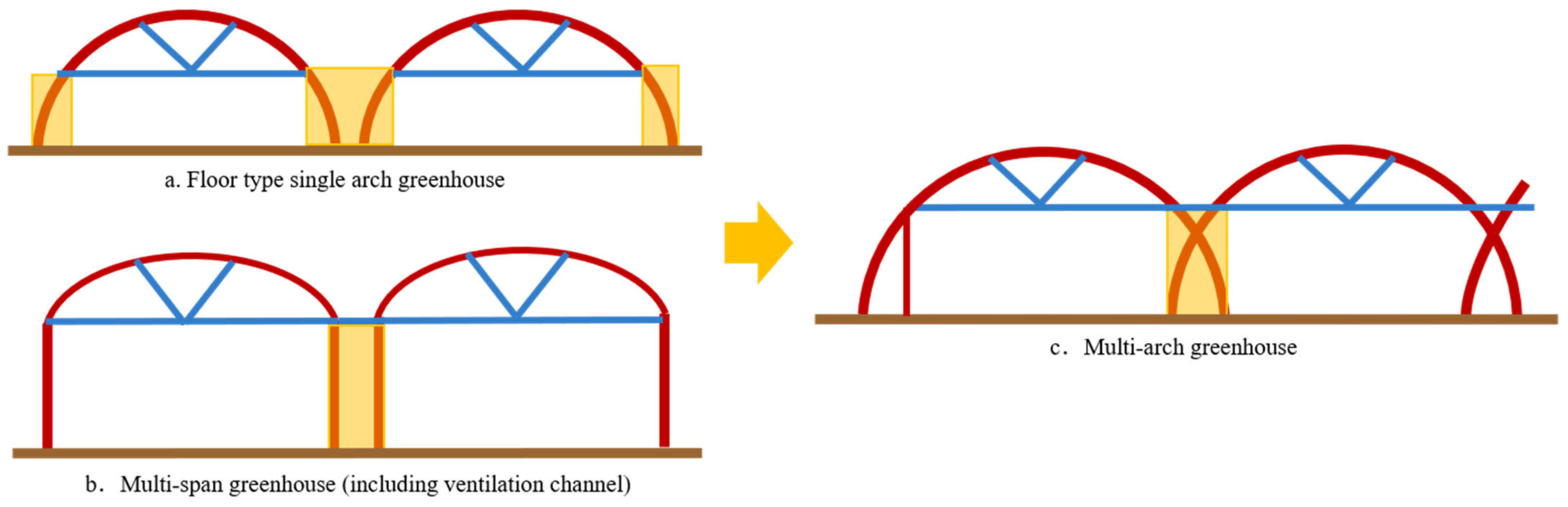

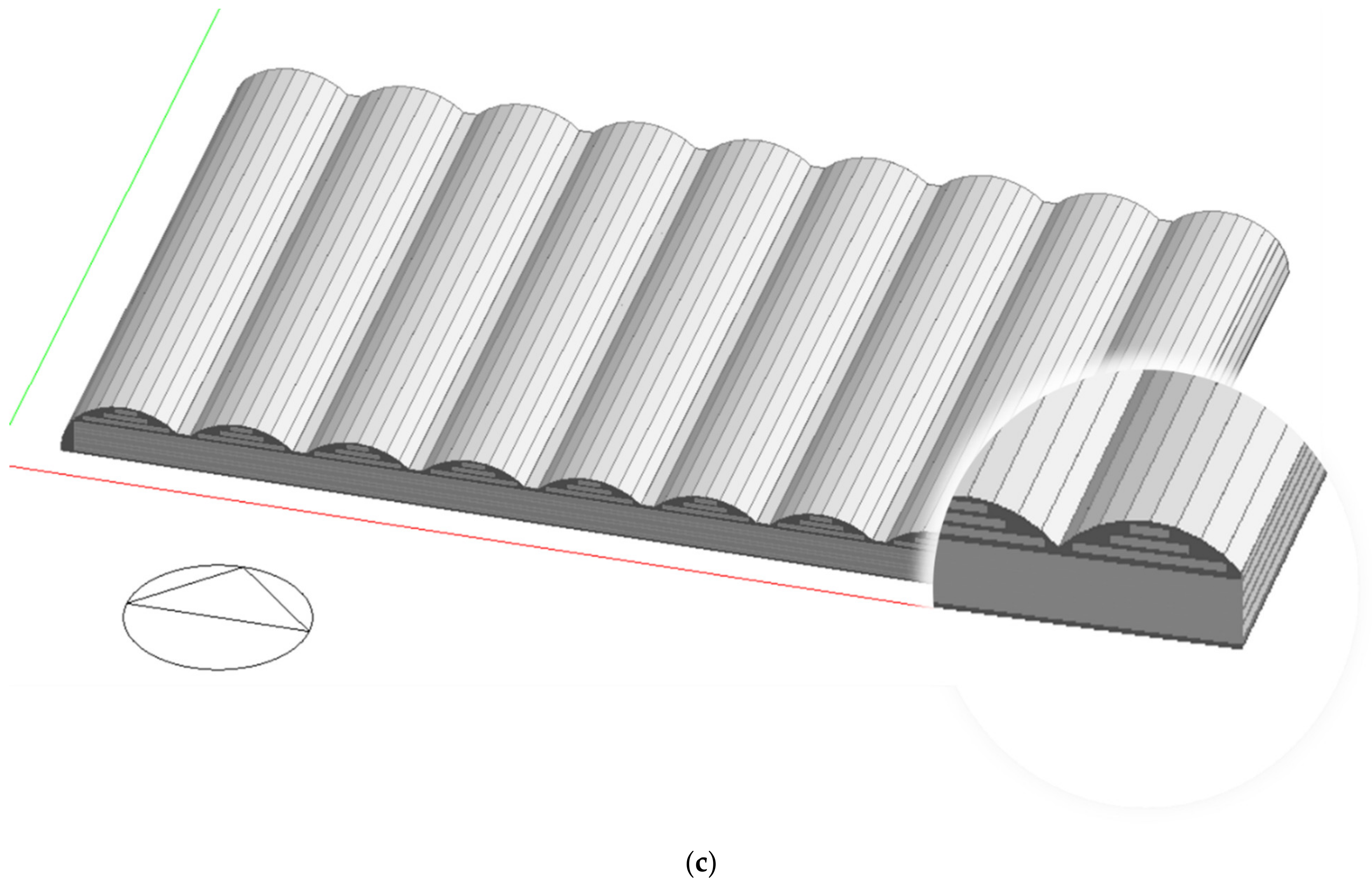

2.2. Structural Concept Design

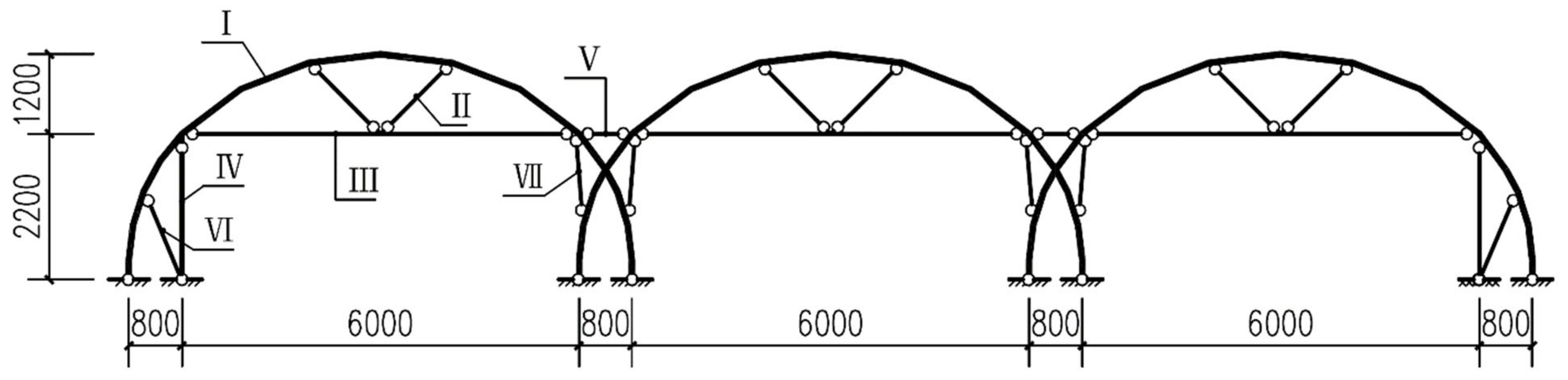

2.3. Architectural and Structural Design

2.4. Functional Design

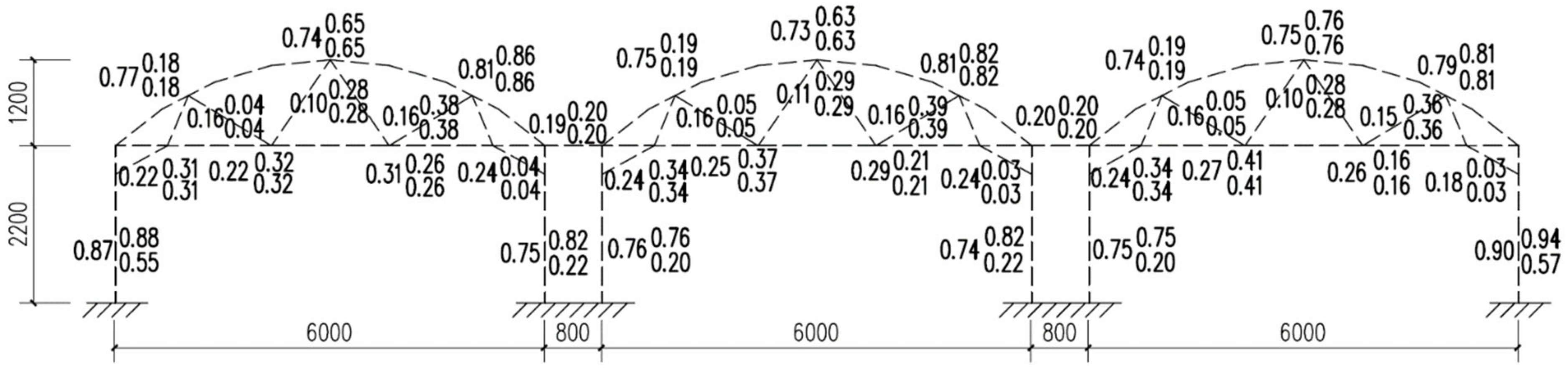

3. Structural Calculation and Material Specifications

3.1. Load Parameters

- The permanent load, taking the self-weight of the frame, is 0.025 kN/m2. For light steel greenhouses with wind resistance requirements, the self-weights of the structure and the equipment are both favorable loads, and only the self-weight of the frame structure is taken into account during the calculation;

- The variable load, including the wind load and other variable loads. Multi-arch greenhouses are developed for year-round vegetable production in Hainan, which takes leafy vegetables as the production object, without considering the lifting weight of the crop.

- (1)

- Other variable loads: 0.15 kN/m2;

- (2)

- Wind load: basic wind load (W0), 0.79 kN/m2.

3.2. Calculation of the Load Standard Value and Design Value

- (1)

- Constant load design value: = 0.9 × 1 × 0.025 × 4 = 0.09 kN/m;

- (2)

- Wind load design value: = 0.9 × 1 × (−0.4503) × 4 = −1.6211 kN/m;

- (3)

- Live load design value: = 0.9 × 1.2 × 0.7 × 0.15 × 4 = 0.4536 kN/m.

3.3. Structural Calculation

3.4. Comparison of Structural Properties

4. Ventilation Simulation

4.1. Greenhouse Modeling

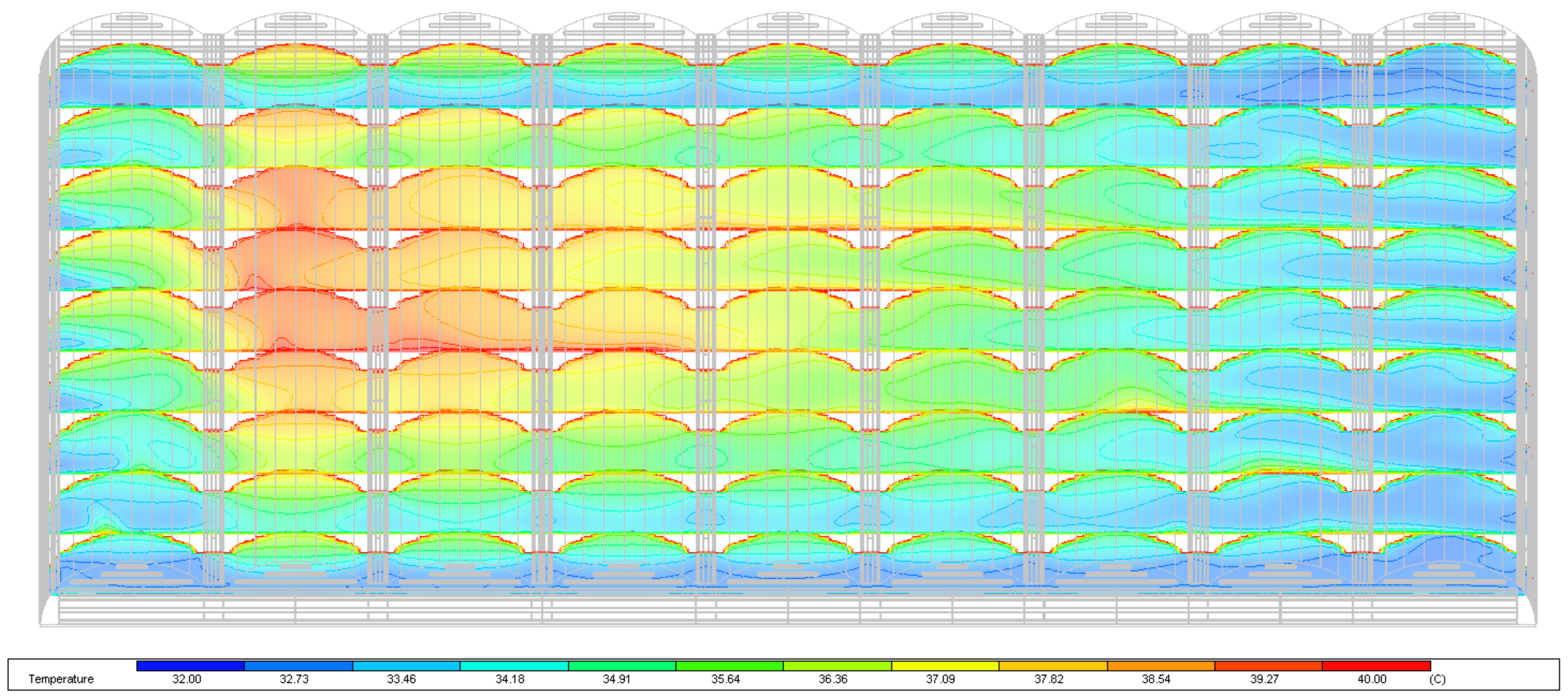

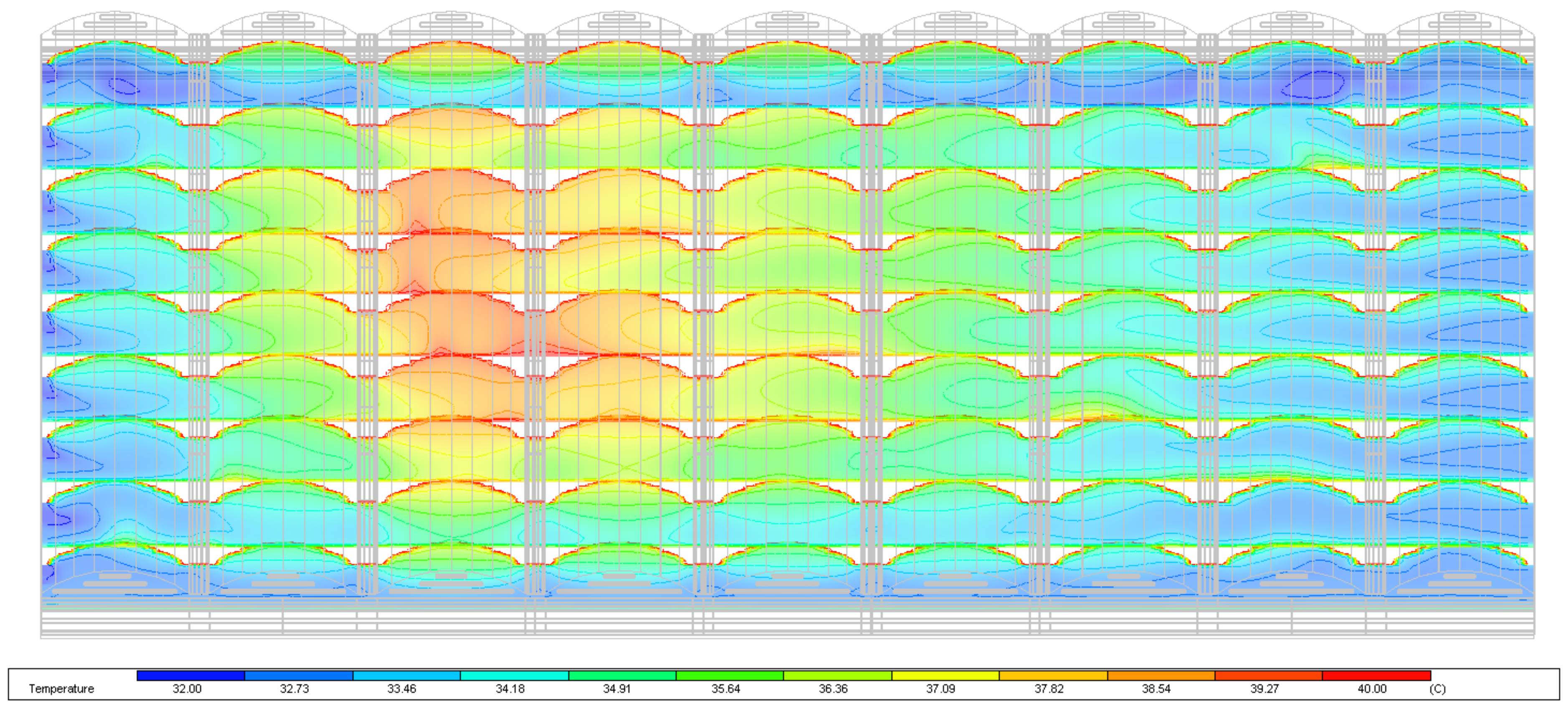

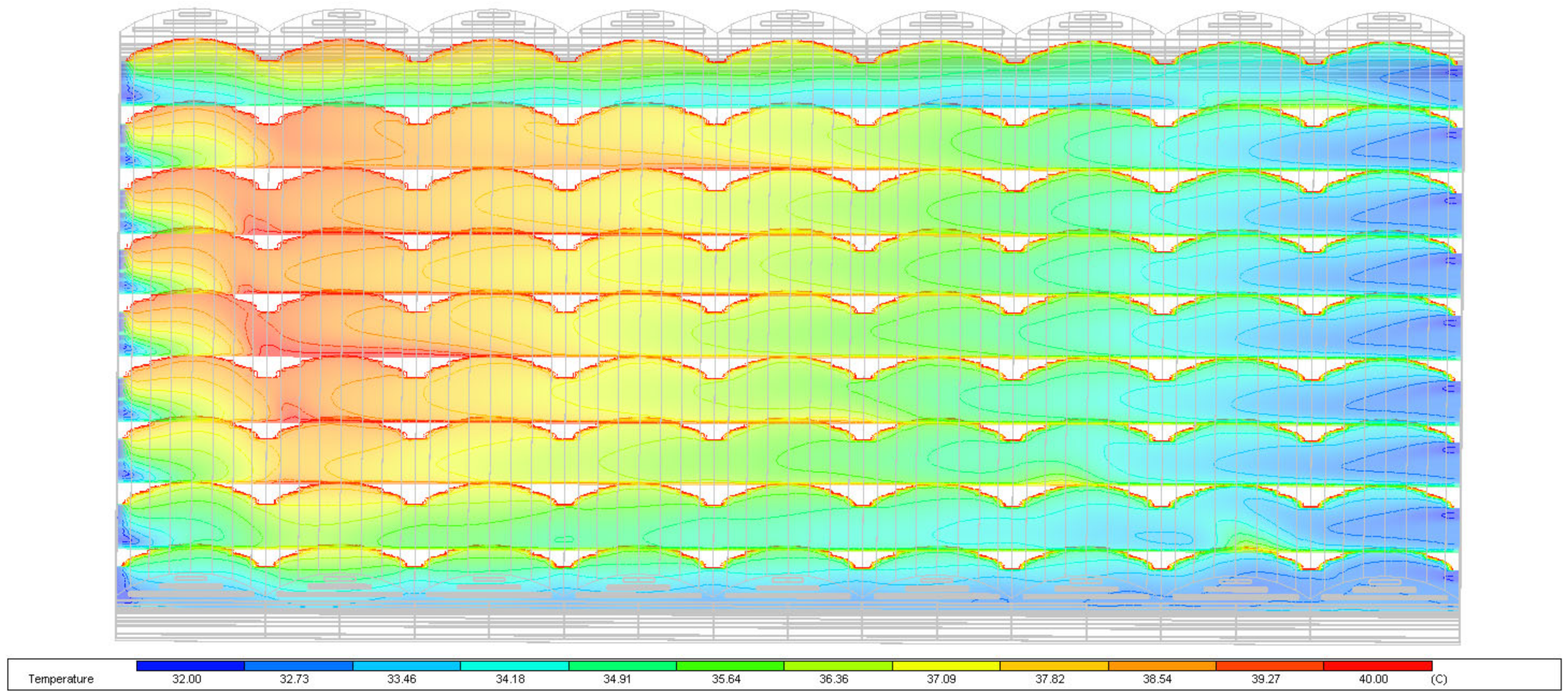

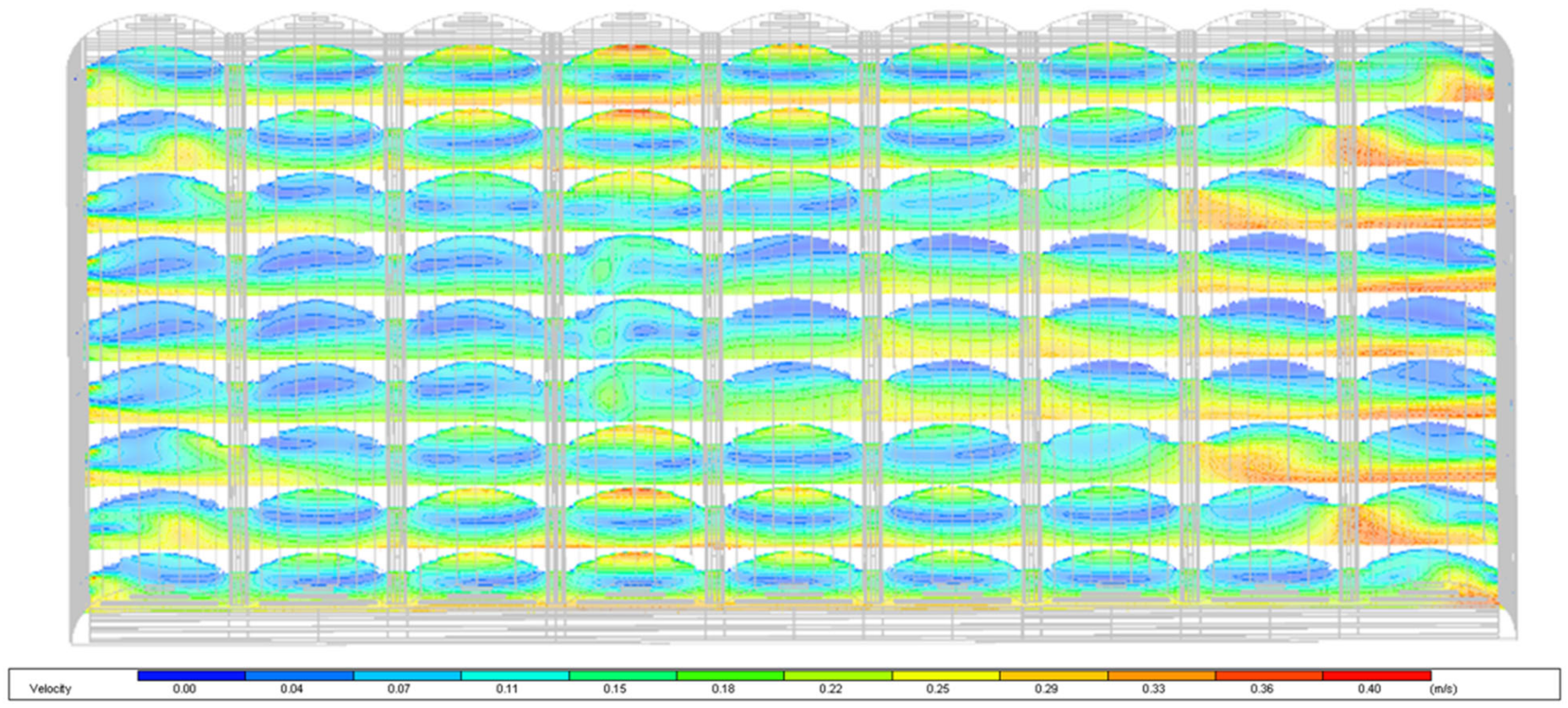

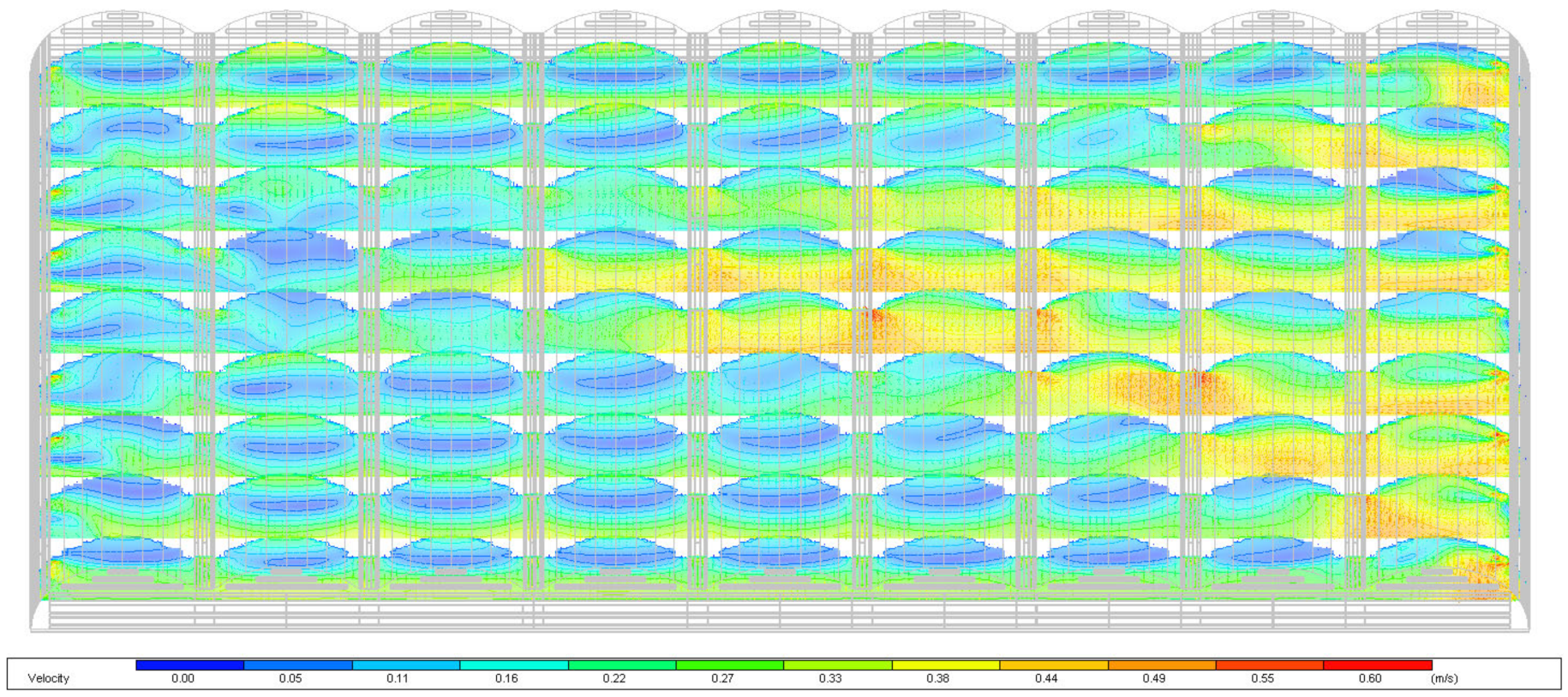

4.2. Simulation Environment Setting and Simulation Results Analysis

5. Conclusions

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, J. Development and application of several typhoon-resistant vegetable planting greenhouses in Hainan. Agric. Eng. Technol. (Greenh. Hortic.) 2018, 38, 32–38. [Google Scholar] [CrossRef]

- Zhuang, H.; Chen, L.; Du, C.; Gao, F.; Zheng, H.; Li, H. Efficient cultivation techniques of leafy vegetables under rain proof shelter in summer or fall in South China. Guangdong Agric. Sci. 2014, 41, 86–88. [Google Scholar] [CrossRef]

- Zhou, C. Dr. Zhou’s Field Investigation (34) Greenhouse in Taiwan ⑤ Continuous window opening method in plastic film greenhouse with round arch roof. Agric. Eng. Technol. (Greenh. Hortic.) 2014, 6, 26–28+30. [Google Scholar] [CrossRef]

- Liu, J.; Huang, Y. Influence of Super Typhoon Sarika on facility agriculture in Hainan and suggestions. Appl. Eng. Technol. 2017, 37, 34–37. [Google Scholar] [CrossRef]

- Yang, X.; Li, J.; Yang, M.; Huang, Z.; Cao, M.; Yang, G. Influence of Typhoon “Shanshen” on facility agriculture in south Hainan and reflections. Agric. Eng. Technol. (Greenh. Hortic.) 2013, 1, 20–25. [Google Scholar] [CrossRef]

- Yang, X.; Li, J.; Yang, M.; Chen, M.; Liang, Z. Investigation and analysis of Typhoon Conson’s damage on facility agriculture in Sanya, Hainan. Agric. Eng. Technol. (Greenh. Hortic.) 2011, 2, 20–21. [Google Scholar] [CrossRef]

- Yang, X.; Li, J.; Yang, M.; Chen, M. Influence of Typhoon Ketsana on protected agriculture in south Hainan. Chin. J. Trop. Agric. 2009, 29, 68–69+74. [Google Scholar]

- Yang, X.; Liu, J.; Cao, M.; Yang, G.; Zhang, X.; Huang, X. Structural optimization design of economical steel tube plastic greenhouse with typhoon resistance in tropical region. J. Chin. Agric. Mech. 2016, 37, 48–52. [Google Scholar] [CrossRef]

- Wang, C.; Nan, B.; Wang, T.; Bai, Y.; Li, Y. Wind pressure acting on greenhouses: A review. Int. J. Agric. Biol. Eng. 2021, 4, 1–8. [Google Scholar] [CrossRef]

- Ren, Y.; Wang, M.; Saeeda, I.A.; Chen, X.; Gao, W. Progress, problems and prospects for standardization of greenhouse-related technologies. Int. J. Agric. Biol. Eng. 2018, 11, 40–48. [Google Scholar] [CrossRef]

- Wang, J. Optimal Design and Ventilative Test of Mutual Insert Multi-Span Greenhouse; Nanjing Agricultural University: Nanjing, China, 2007; Available online: https://webvpn.hainanu.edu.cn/https/77726476706e69737468656265737421fbf952d2243e635930068cb8/kcms/detail/detail.aspx?dbcode=CDFD&dbname=CDFD9908&filename=2008031525.nh&uniplatform=NZKPT&v=MQBqjRkXn37A932ISKhjE92f2XspsP72tVdPHJq1DqErtrHQaIEbUtzY5A3O4IjE (accessed on 14 July 2022).

- Zhou, C. The current use of the main greenhouse type and performance (I). Pract. Eng. Technol. Rural. Areas 2000, 1, 8–9. [Google Scholar]

- Zhou, C. The current use of the main greenhouse type and performance (II). Pract. Eng. Technol. Rural. Areas 2000, 2, 8–9. [Google Scholar]

- Zhou, C. The current use of the main greenhouse type and performance (III). Pract. Eng. Technol. Rural. Areas 2000, 3, 8–9. [Google Scholar]

- Zhou, C. The current use of the main greenhouse type and performance (IV). Pract. Eng. Technol. Rural. Areas 2000, 4, 8–9. [Google Scholar]

- Zhou, C. Handbook of Greenhouse Engineering Design; China Agriculture Press: Beijing, China, 2007. [Google Scholar]

- Zhang, Z.; Zhou, C. Zhou’s Field Investigation (26) Investigation report of facility horticulture development status in Hainan Province. Agric. Eng. Technol. (Greenh. Hortic.) 2013, 11–18. [Google Scholar] [CrossRef]

- Liu, J.; Wang, B.; Chen, Y.; Zhu, G. A Fully Assembled Crossed Multi-Arch Greenhouse Structure. CN212696864U, 16 March 2021. [Google Scholar]

- GB/T 51183-2016; Code for the Design Load of Horticultural Greenhouse Structures. China Planning Press: Beijing, China, 2016.

- GB 51022-2015; Technical Specification for Steel Structure of Lightweight Buildings with Gabled Frames. China Construction Industry Press: Beijing, China, 2015.

- Yan, D.; Xu, K.; Zhang, Q.; Li, X. Experimental study on wind load of insect control screen with different mesh sizes. Agric. Eng. Technol. 2020, 40, 57–63. [Google Scholar] [CrossRef]

- Emekli, N.; Kendirli, B.; Kurunc, A. Structural analysis and functional characteristics of greenhouses in the Mediterranean region of Turkey. Afr. J. Biotechnol. 2010, 9, 3131–3139. [Google Scholar]

- Wu, Y.; Li, H. Structure and design analysis of ventilation and cooling facilities in greenhouse in south china. Mod. Agric. Equip. 2013, 12, 60–62. Available online: https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=CJFD&dbname=CJFDHIS2&filename=GDLJ201305020&uniplatform=NZKPT&v=77BL2gXUDMo6Ay7YkUufIXW3Bp3SfqV5Q7MHIMc9nQSt_NbHCVBbdzzf2m_cq9SE (accessed on 14 July 2022).

- Hou, S. Research on Microclimate Environment Prediction and Control of Facility Greenhouse Based on CFD Model; Nanjing Agricultural University: Nanjing, China, 2016. [Google Scholar]

- Floresvelazquez, J.; Montero, J.; Baeza, E.; Lopez, J. Mechanical and natural ventilation systems in a greenhouse designed using computational fluid dynamics. Int. J. Agric. Biol. Eng. 2014, 7, 1–16. [Google Scholar] [CrossRef]

- Maraveas, C. Wind Pressure Coefficients on Greenhouse Structures. Agriculture 2020, 10, 149. [Google Scholar] [CrossRef]

- Molina-Aiz, F.; Fatnassi, H.; Boulard, T.; Roy, J.; Valera, D. Comparison of finite element and finite volume methods for simulation of natural ventilation in greenhouses. Comput. Electron. Agric. 2010, 72, 69–86. [Google Scholar] [CrossRef]

- Wu, F.; Zhang, L.; Xu, F.; Chen, J.; Chen, X. Application and Development of Computational Fluid Dynamics in Ventilation for Greenhouses. J. Agric. Mech. Res. 2008, 6, 1–5. [Google Scholar] [CrossRef]

- Zhang, F.; Fang, H.; Yang, Q.; Cheng, R.; Zhang, Y.; Ke, X.; Lu, W.; Liu, H. Ventilation Simulation in a Large-scale Greenhouse Based on CFD. Chin. J. Agrometeorol. 2017, 38, 221–229. [Google Scholar] [CrossRef]

- Lee, G.; Kim, J.; Kim, J.; Lee, S.; Ha, H.; Kang, T. A study of the triangular cross section type greenhouse using fluid-structure interaction. J. Korean Soc. Vis. 2019, 17, 17–24. [Google Scholar]

- GB/T 50178-93; Standard of Climatic Regionalization for Architecture. China Planning Press: Beijing, China, 1993.

- Fang, H.; Yang, Q.; Zhang, Y.; Cheng, R.; Zhang, F.; Lu, W. Simulation on ventilation flux of solar greenhouse based on the coupling between stack and wind effects. Chin. J. Agrometeorol. 2016, 37, 531–537. [Google Scholar] [CrossRef]

- López-Martínez, A.; Granados-Ortiz, F.; Molina-Aiz, F.; Lai, C.; Moreno-Teruel, M.; Valera-Martínez, D. Analysis of Turbulent Air Flow Characteristics Due to the Presence of a 13 × 30 Threads·cm−2 Insect Proof Screen on the Side Windows of a Mediterranean Greenhouse. Agronomy 2022, 12, 586. [Google Scholar] [CrossRef]

- López-Martínez, A.; Molina-Aiz, F.; Valera-Martínez, D.; López-Martínez, J.; Peña-Fernández, A.; Espinoza-Ramos, K. Application of semi-empirical ventilation models in a mediterranean greenhouse with opposing thermal and wind effects. Use of non-constant cd (pressure drop coefficient through the vents) and cw (wind effect coefficient). Agronomy 2019, 9, 736. [Google Scholar] [CrossRef] [Green Version]

- López, A.; Molina-Aiz, F.; Valera, D.; Peña, A. Wind tunnel analysis of the airflow through insect-proof screens and comparison of their effect when installed in a Mediterranean greenhouse. Sensors 2016, 16, 690. [Google Scholar] [CrossRef]

- Dong, H.; Yan, Z.; Ji, Y.; Tan, X.; Shen, Y. Effects of Covering with Insect Proof Net on Growth and Anti-insect Efficiency of Brassica campestris ssp. chinensis Makino. J. Chang. Veg. 2013, 20, 63–65. [Google Scholar] [CrossRef]

- Espinoza, K.; Lopez, A.; Valera, D.; Molina-Aiz, F.; Torres, J.; Pena, A. Effects of ventilator configuration on the flow pattern of a naturally-ventilated three-span Mediterranean greenhouse. Biosyst. Eng. 2017, 164, 13–30. [Google Scholar] [CrossRef]

| No. | Item | Specification | Length (m) | Quantity | Unit Weight (kg) | Total Weights (kg) |

|---|---|---|---|---|---|---|

| 1 | Arch bar | φ42 × 1.5 mm | 11.2 | 3 | 16.78 | 50.33 |

| 2 | Web member | φ25 × 1.5 mm | 1.5 | 6 | 1.30 | 7.82 |

| 3 | Tie beam | φ42 × 1.5 mm | 6 | 3 | 8.99 | 26.96 |

| 4 | Side wind-resisting column | φ42 × 1.5 mm | 2.1 | 2 | 1.82 | 3.65 |

| 5 | In-greenhouse beam | φ25 × 1.5 mm | 0.8 | 2 | 0.70 | 1.39 |

| 6 | Side reinforcement bar | φ25 × 1.5 mm | 1.3 | 2 | 1.13 | 2.26 |

| 7 | Reinforcement bar | φ25 × 1.5 mm | 1.3 | 4 | 1.13 | 4.52 |

| 8 | Total | 96.94 | ||||

| No. | Item | Specification | Length (m) | Quantity | Unit Weight (kg) | Total Weights (kg) |

|---|---|---|---|---|---|---|

| 1 | Column | □80 × 60 × 2 mm | 2.2 | 6 | 9.39 | 56.36 |

| 2 | Arch bar | φ50 × 1.5 mm | 6.62 | 3 | 11.88 | 35.63 |

| 3 | Web member | φ25 × 1.5 mm | 7.2 | 3 | 6.26 | 18.77 |

| 4 | Tie beam | φ42 × 1.5 mm | 6 | 3 | 8.99 | 26.96 |

| 5 | In-greenhouse beam | φ25 × 1.5 mm | 0.8 | 2 | 0.70 | 1.39 |

| 6 | Reinforcement bar | φ25 × 1.5 mm | 0.83 | 6 | 0.72 | 4.33 |

| 7 | Total | 143.45 | ||||

| Location | Latitude and Longitude | Simulation Date | Outdoor Wind Speed (m/s) | Wind Direction (°) | Outdoor Temperature (°C) |

|---|---|---|---|---|---|

| Haikou, Hainan | East longitude 110°33′, Northern latitude 20°05′ | 8 July, 13:00 | 1 | 90 | 32.7 |

| 12 July, 15:00 | 0 | -- | 35.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Wu, X.; Sun, F.; Wang, B. Development and Application of a Crossed Multi-Arch Greenhouse in Tropical China. Agriculture 2022, 12, 2164. https://doi.org/10.3390/agriculture12122164

Liu J, Wu X, Sun F, Wang B. Development and Application of a Crossed Multi-Arch Greenhouse in Tropical China. Agriculture. 2022; 12(12):2164. https://doi.org/10.3390/agriculture12122164

Chicago/Turabian StyleLiu, Jian, Xuyong Wu, Fangyuan Sun, and Baolong Wang. 2022. "Development and Application of a Crossed Multi-Arch Greenhouse in Tropical China" Agriculture 12, no. 12: 2164. https://doi.org/10.3390/agriculture12122164

APA StyleLiu, J., Wu, X., Sun, F., & Wang, B. (2022). Development and Application of a Crossed Multi-Arch Greenhouse in Tropical China. Agriculture, 12(12), 2164. https://doi.org/10.3390/agriculture12122164