Novel Two-Slope Equations to Predict Amino Acid Concentrations Using Crude Protein Concentration in Soybean Meal

Abstract

1. Introduction

2. Materials and Methods

2.1. Soybean Meal Samples

2.2. Chemical Analysis

2.3. Statistical Analysis

3. Results

3.1. Nutrient Composition in Different Sources of Soybean Meal

3.2. Correlation Coefficients between Crude Protein and Amino Acids and Simple Linear Regressions

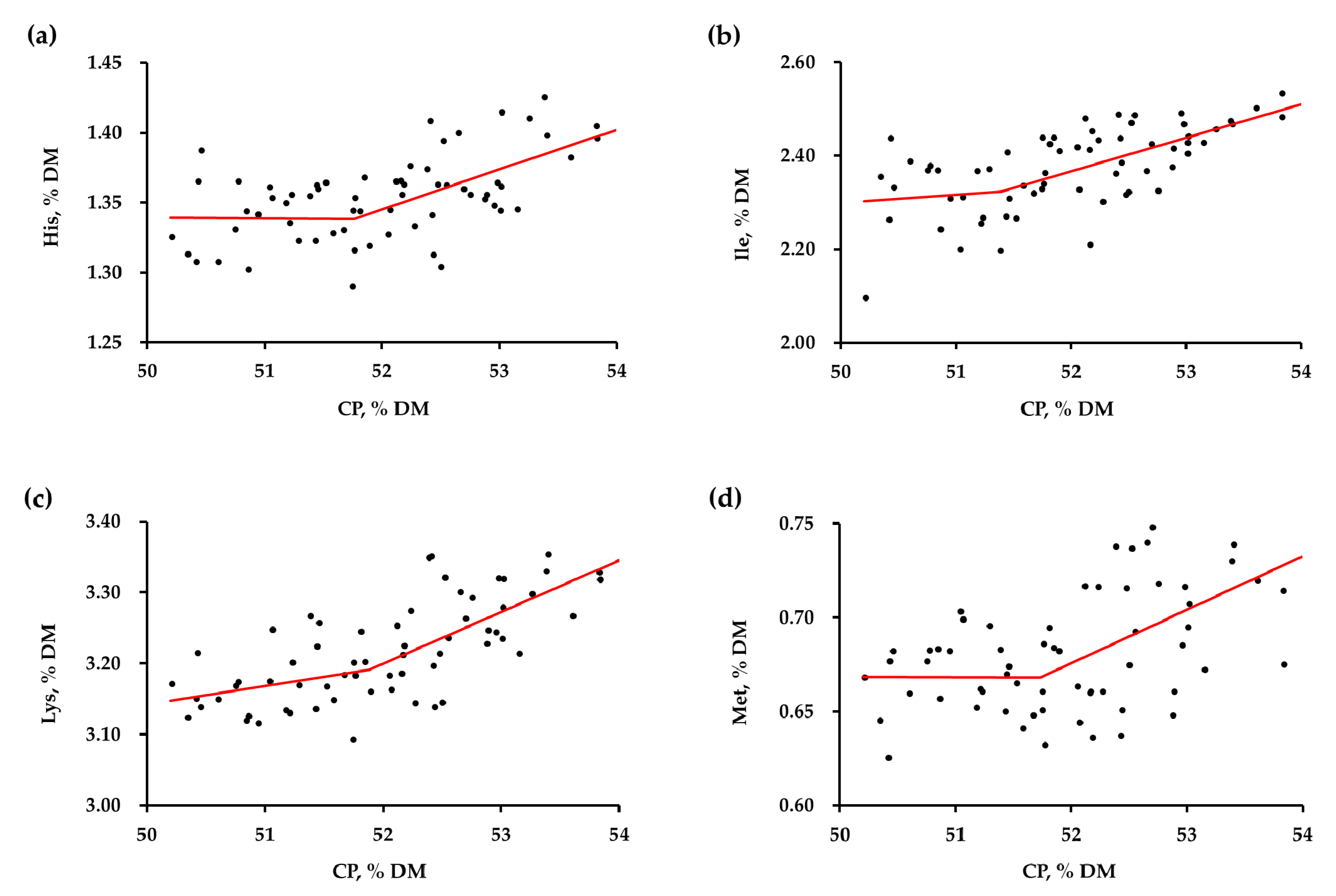

3.3. Novel Equations to Predict Amino Acids Using Crude Protein in Soybean Meal

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- AAFCO. AAFCO Official Publication; The Association of American Feed Control Officials: Oxford, IN, USA, 2016. [Google Scholar]

- NRC. Nutrient Requirements of Swine, 11th ed.; Natl. Acad. Press: Washington, DC, USA, 2012. [Google Scholar]

- AMINODat. Amino Acid Regression Equation of Soybean Meal. In AminoDat® 4.0, Platinum Version; Evonik Degussa GmbH: Hanau-Wolfgang, Germany, 2010. [Google Scholar]

- USSEC. The Nutritional Value of U.S. Soybean Meal; Reports & Whitepapers: St. Louis, MO, USA, 2012. [Google Scholar]

- Messad, F.; Létourneau-Montminy, M.P.; Charbonneau, E.; Sauvant, D.; Guay, F. Prediction of standardized ileal digestibility and essential amino acid content of ingredients in swine: A meta-analysis. Anim. Feed Sci. Technol. 2015, 207, 204–221. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of AOAC INTERNATIONAL, 18th ed.; AOAC International: Gaithersburg, MD, USA, 2005. [Google Scholar]

- AOCS. Official Methods and Recommended Practices of the AOCS, 6th ed.; AOCS: Champaign, IL, USA, 2009. [Google Scholar]

- Robbins, K.R.; Saxton, A.M.; Southern, L.L. Estimation of nutrient requirements using broken-line regression analysis. J. Anim. Sci. 2006, 84 (Suppl. E), e155–e165. [Google Scholar] [CrossRef]

- Lee, S.A.; Kim, B.G. Classification of copra meal and copra expellers based on ether extract concentration and prediction of energy concentrations in copra byproducts. J. Anim. Plant Sci. 2017, 27, 34–39. [Google Scholar]

- Li, Z.; Wang, X.; Guo, P.; Liu, L.; Piao, X.; Stein, H.H.; Li, D.; Lai, C. Prediction of digestible and metabolisable energy in soybean meals produced from soybeans of different origins fed to growing pigs. Arch. Anim. Nutr. 2015, 69, 473–486. [Google Scholar] [CrossRef] [PubMed]

- Lopez, D.A.; Lagos, L.V.; Stein, H.H. Digestible and metabolizable energy in soybean meal sourced from different countries and fed to pigs. Anim. Feed Sci. Technol. 2020, 268, 114600. [Google Scholar] [CrossRef]

- Sauvant, D.; Perez, J.-M.; Tran, G. Tables of Composition and Nutritional Value of Feed Materials; Acad. Publ.: Wageningen, The Netherlands, 2004. [Google Scholar] [CrossRef]

- Frikha, M.; Serrano, M.P.; Valencia, D.G.; Rebollar, P.G.; Fickler, J.; Mateos, G.G. Correlation between ileal digestibility of amino acids and chemical composition of soybean meals in broilers at 21 days of age. Anim. Feed Sci. Technol. 2012, 178, 103–114. [Google Scholar] [CrossRef]

- Sotak-Peper, K.M.; González-Vega, J.C.; Stein, H.H. Concentrations of digestible, metabolizable, and net energy in soybean meal produced in different areas of the United States and fed to pigs. J. Anim. Sci. 2015, 93, 5694–5701. [Google Scholar] [CrossRef]

- Cromwell, G.L.; Calvert, C.C.; Cline, T.R.; Crenshaw, J.D.; Crenshaw, T.D.; Easter, R.A.; Ewan, R.C.; Hamilton, C.R.; Hill, G.M.; Lewis, A.J.; et al. Variability among sources and laboratories in nutrient analyses of corn and soybean meal. J. Anim. Sci. 1999, 77, 3262–3273. [Google Scholar] [CrossRef]

- Maillard, L.C. Action of amino acids on sugars. Formation of melanoidins in a methodical way. Comptes Rendus Acad. Sci. 1912, 154, 66–68. [Google Scholar]

- González-Vega, J.C.; Kim, B.G.; Htoo, J.K.; Lemme, A.; Stein, H.H. Amino acid digestibility in heated soybean meal fed to growing pigs. J. Anim. Sci. 2011, 89, 3617–3625. [Google Scholar] [CrossRef]

- Kim, B.G.; Kil, D.Y.; Zhang, Y.; Stein, H.H. Concentrations of analyzed or reactive lysine, but not crude protein, may predict the concentration of digestible lysine in distillers dried grains with solubles fed to pigs. J. Anim. Sci. 2012, 90, 3798–3808. [Google Scholar] [CrossRef]

- Sung, J.Y.; Kim, B.G. Prediction equations for digestible and metabolizable energy concentrations in feed ingredients and diets for pigs based on chemical composition. Anim. Biosci. 2021, 34, 306–311. [Google Scholar] [CrossRef]

- Son, A.R.; Park, C.S.; Kim, B.G. Determination and prediction of digestible and metabolizable energy concentrations in byproduct feed ingredients fed to growing pigs. Asian Australas. J. Anim. Sci. 2017, 30, 546–553. [Google Scholar] [CrossRef]

- Choi, H.; Sung, J.Y.; Kim, B.G. Neutral detergent fiber rather than other dietary fiber types as an independent variable increases the accuracy of prediction equation for digestible energy in feeds for growing pigs. Asian Australas. J. Anim. Sci. 2020, 33, 615–622. [Google Scholar] [CrossRef]

- Sung, J.Y.; Kim, B.G. Prediction models for apparent and standardized total tract digestible phosphorus in swine diets. Anim. Feed Sci. Technol. 2019, 255, 114224. [Google Scholar] [CrossRef]

- Park, C.S.; Son, A.R.; Kim, B.G. Prediction of gross energy and digestible energy in copra meal, palm kernel meal, and cassava root fed to pigs. J. Anim. Sci. 2012, 90 (Suppl. S4), 221–223. [Google Scholar] [CrossRef]

- Lee, G.I.; Kim, K.; Kim, J.H.; Kil, D.Y. Growth performance of early finishing gilts as affected by different net energy concentrations in diets. Asian Australas. J. Anim. Sci. 2015, 28, 1614–1623. [Google Scholar] [CrossRef]

- Ewan, R.C. Predicting the energy utilization of diets and feed ingredients by pigs. In Energy Metabolism. European Association of Animal Production Bulletin No. 43; van der Honing, Y., Close, W.H., Eds.; Wageningen Pudoc: Wageningen, The Netherlands, 1989; pp. 271–274. [Google Scholar]

- Hong, B.; Kim, B.G. Prediction equations for urinary energy concentration based on urinary carbon and nitrogen concentration. In Proceedings of the the 18th AAAP Animal Science Congress, Kuching, Malaysia, 1–5 August 2018; p. 497. [Google Scholar]

- Karr-Lilienthal, L.K.; Grieshop, C.M.; Merchen, N.R.; Mahan, D.C.; Fahey, G.C. Chemical composition and protein quality comparisons of soybeans and soybean meals from five leading soybean-producing countries. J. Agric. Food Chem. 2004, 52, 6193–6199. [Google Scholar] [CrossRef]

- Evans, S.M.; Sinclair, E.A.; Poore, A.G.; Bain, K.F.; Vergés, A. Genotypic richness predicts phenotypic variation in an endangered clonal plant. PeerJ 2016, 4, e1633. [Google Scholar] [CrossRef]

- Skogerson, K.; Harrigan, G.G.; Reynolds, T.L.; Halls, S.C.; Ruebelt, M.; Iandolino, A.; Pandravada, A.; Glenn, K.C.; Fiehn, O. Impact of genetics and environment on the metabolite composition of maize grain. J. Agric. Food Chem. 2010, 58, 3600–3610. [Google Scholar] [CrossRef]

- Park, C.S.; Helmbrecht, A.; Htoo, J.K.; Adeola, O. Comparison of amino acid digestibility in full-fat soybean, two soybean meals, and peanut flour between broiler chickens and growing pigs. J. Anim. Sci. 2017, 95, 3110–3119. [Google Scholar] [CrossRef]

- Son, A.R.; Park, C.S.; Park, K.R.; Kim, B.G. Amino acid digestibility in plant protein sources fed to growing pigs. Asian Australas. J. Anim. Sci. 2019, 32, 1745–1752. [Google Scholar] [CrossRef]

| Item, % | Average | SD 2 | Minimum | Maximum | CV 2, % |

|---|---|---|---|---|---|

| Moisture | 12.05 | 0.63 | 9.38 | 13.41 | 5.3 |

| Crude protein | 51.88 | 1.07 | 49.04 | 54.61 | 2.1 |

| Crude fiber | 6.45 | 1.13 | 3.65 | 9.09 | 17.6 |

| Ether extract | 1.50 | 0.67 | 0.35 | 5.62 | 44.4 |

| Ash | 7.35 | 0.99 | 5.56 | 11.44 | 13.5 |

| Indispensable amino acids | |||||

| Arg | 3.71 | 0.07 | 3.52 | 3.86 | 2.0 |

| His | 1.35 | 0.03 | 1.29 | 1.43 | 2.2 |

| Ile | 2.37 | 0.09 | 2.10 | 2.53 | 3.7 |

| Leu | 4.00 | 0.09 | 3.81 | 4.30 | 2.1 |

| Lys | 3.22 | 0.07 | 3.09 | 3.35 | 2.1 |

| Met | 0.68 | 0.03 | 0.63 | 0.76 | 5.0 |

| Phe | 2.65 | 0.16 | 2.51 | 3.81 | 6.0 |

| Thr | 2.02 | 0.06 | 1.92 | 2.15 | 2.9 |

| Val | 2.47 | 0.08 | 2.21 | 2.57 | 3.3 |

| Dispensable amino acids | |||||

| Ala | 2.25 | 0.05 | 2.13 | 2.35 | 2.0 |

| Asp | 5.84 | 0.14 | 5.60 | 6.20 | 2.3 |

| Cys | 0.71 | 0.04 | 0.63 | 0.78 | 5.3 |

| Glu | 9.43 | 0.22 | 8.91 | 9.78 | 2.3 |

| Gly | 2.19 | 0.04 | 2.10 | 2.29 | 2.0 |

| Pro | 2.58 | 0.07 | 2.45 | 2.75 | 2.8 |

| Ser | 2.55 | 0.09 | 2.40 | 2.77 | 3.4 |

| Tyr | 1.72 | 0.07 | 1.53 | 1.85 | 4.0 |

| Item, % | Average | SD 2 | Minimum | Maximum | CV 2, % |

|---|---|---|---|---|---|

| Indispensable AAs-to-CP | |||||

| Arg | 0.071 | 0.001 | 0.068 | 0.074 | 1.7 |

| His | 0.026 | 0.001 | 0.025 | 0.027 | 2.0 |

| Ile | 0.046 | 0.001 | 0.042 | 0.048 | 2.9 |

| Leu | 0.077 | 0.002 | 0.074 | 0.080 | 2.0 |

| Lys | 0.062 | 0.001 | 0.060 | 0.064 | 1.6 |

| Met | 0.013 | 0.001 | 0.012 | 0.015 | 4.4 |

| Phe | 0.051 | 0.003 | 0.048 | 0.074 | 6.0 |

| Thr | 0.039 | 0.001 | 0.037 | 0.041 | 3.0 |

| Val | 0.047 | 0.001 | 0.044 | 0.050 | 2.9 |

| Dispensable AAs-to-CP | |||||

| Ala | 0.043 | 0.001 | 0.041 | 0.045 | 1.9 |

| Asp | 0.112 | 0.002 | 0.109 | 0.117 | 1.6 |

| Cys | 0.014 | 0.001 | 0.012 | 0.015 | 4.6 |

| Glu | 0.181 | 0.003 | 0.176 | 0.188 | 1.6 |

| Gly | 0.042 | 0.001 | 0.041 | 0.044 | 1.9 |

| Pro | 0.050 | 0.001 | 0.047 | 0.054 | 2.6 |

| Ser | 0.049 | 0.002 | 0.046 | 0.054 | 3.7 |

| Tyr | 0.033 | 0.001 | 0.029 | 0.036 | 4.0 |

| Item | Crude Protein (r) | p-Value |

|---|---|---|

| Indispensable amino acids | ||

| Arg | 0.627 | <0.001 |

| His | 0.517 | <0.001 |

| Ile | 0.622 | <0.001 |

| Leu | 0.506 | <0.001 |

| Lys | 0.693 | <0.001 |

| Met | 0.479 | <0.001 |

| Phe | 0.158 | 0.212 |

| Thr | 0.224 | 0.075 |

| Val | 0.496 | <0.001 |

| Dispensable amino acids | ||

| Ala | 0.498 | <0.001 |

| Asp | 0.741 | <0.001 |

| Cys | 0.522 | <0.001 |

| Glu | 0.726 | <0.001 |

| Gly | 0.523 | <0.001 |

| Pro | 0.437 | <0.001 |

| Ser | 0.068 | 0.593 |

| Tyr | 0.213 | 0.093 |

| Regression Coefficient Parameter | Statistical Parameter | ||||

|---|---|---|---|---|---|

| Item | Intercept | Slope (Crude Protein) | RMSE 1 | R-Square | p-Value |

| Arg | 1.05 | 0.051 | 0.058 | 0.41 | <0.001 |

| SE 2 | 0.41 | 0.008 | |||

| p-value | 0.013 | <0.001 | |||

| His | 0.468 | 0.017 | 0.026 | 0.27 | <0.001 |

| SE | 0.19 | 0.004 | |||

| p-value | 0.014 | <0.001 | |||

| Ile | −0.695 | 0.059 | 0.069 | 0.39 | <0.001 |

| SE | 0.49 | 0.009 | |||

| p-value | 0.161 | <0.001 | |||

| Leu | 1.54 | 0.047 | 0.075 | 0.26 | <0.001 |

| SE | 0.53 | 0.01 | |||

| p-value | 0.005 | <0.001 | |||

| Lys | 0.527 | 0.052 | 0.050 | 0.48 | <0.001 |

| SE | 0.36 | 0.007 | |||

| p-value | 0.144 | <0.001 | |||

| Met | −0.281 | 0.019 | 0.030 | 0.25 | <0.001 |

| SE | 0.21 | 0.004 | |||

| p-value | 0.191 | <0.001 | |||

| Phe | 1.29 | 0.026 | 0.160 | 0.02 | 0.233 |

| SE | 1.14 | 0.022 | |||

| p-value | 0.262 | 0.233 | |||

| Thr | 1.34 | 0.013 | 0.057 | 0.05 | 0.095 |

| SE | 0.40 | 0.008 | |||

| p-value | 0.002 | 0.095 | |||

| Val | 0.11 | 0.045 | 0.070 | 0.27 | <0.001 |

| SE | 0.50 | 0.01 | |||

| p-value | 0.825 | <0.001 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.A.; Park, C.S.; Kim, B.G. Novel Two-Slope Equations to Predict Amino Acid Concentrations Using Crude Protein Concentration in Soybean Meal. Agriculture 2021, 11, 280. https://doi.org/10.3390/agriculture11040280

Lee SA, Park CS, Kim BG. Novel Two-Slope Equations to Predict Amino Acid Concentrations Using Crude Protein Concentration in Soybean Meal. Agriculture. 2021; 11(4):280. https://doi.org/10.3390/agriculture11040280

Chicago/Turabian StyleLee, Su A, Chan Sol Park, and Beob Gyun Kim. 2021. "Novel Two-Slope Equations to Predict Amino Acid Concentrations Using Crude Protein Concentration in Soybean Meal" Agriculture 11, no. 4: 280. https://doi.org/10.3390/agriculture11040280

APA StyleLee, S. A., Park, C. S., & Kim, B. G. (2021). Novel Two-Slope Equations to Predict Amino Acid Concentrations Using Crude Protein Concentration in Soybean Meal. Agriculture, 11(4), 280. https://doi.org/10.3390/agriculture11040280