Energy and Economic Efficiency of Maize Agroecosystem under Three Management Strategies in the Frailesca, Chiapas (Mexico)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Location of the Study Area

2.2. Selection of the Study Region and the Farming Styles

2.3. Analysis and Description of the Farming System

2.4. Energy Balance

2.5. Calculation of Indicators for Energy Balance

2.6. Economic Efficiency of the Farming System

3. Results and Discussion

3.1. Characteristics of the Maize Production Modes

3.2. Productive Cycle and Types of Management

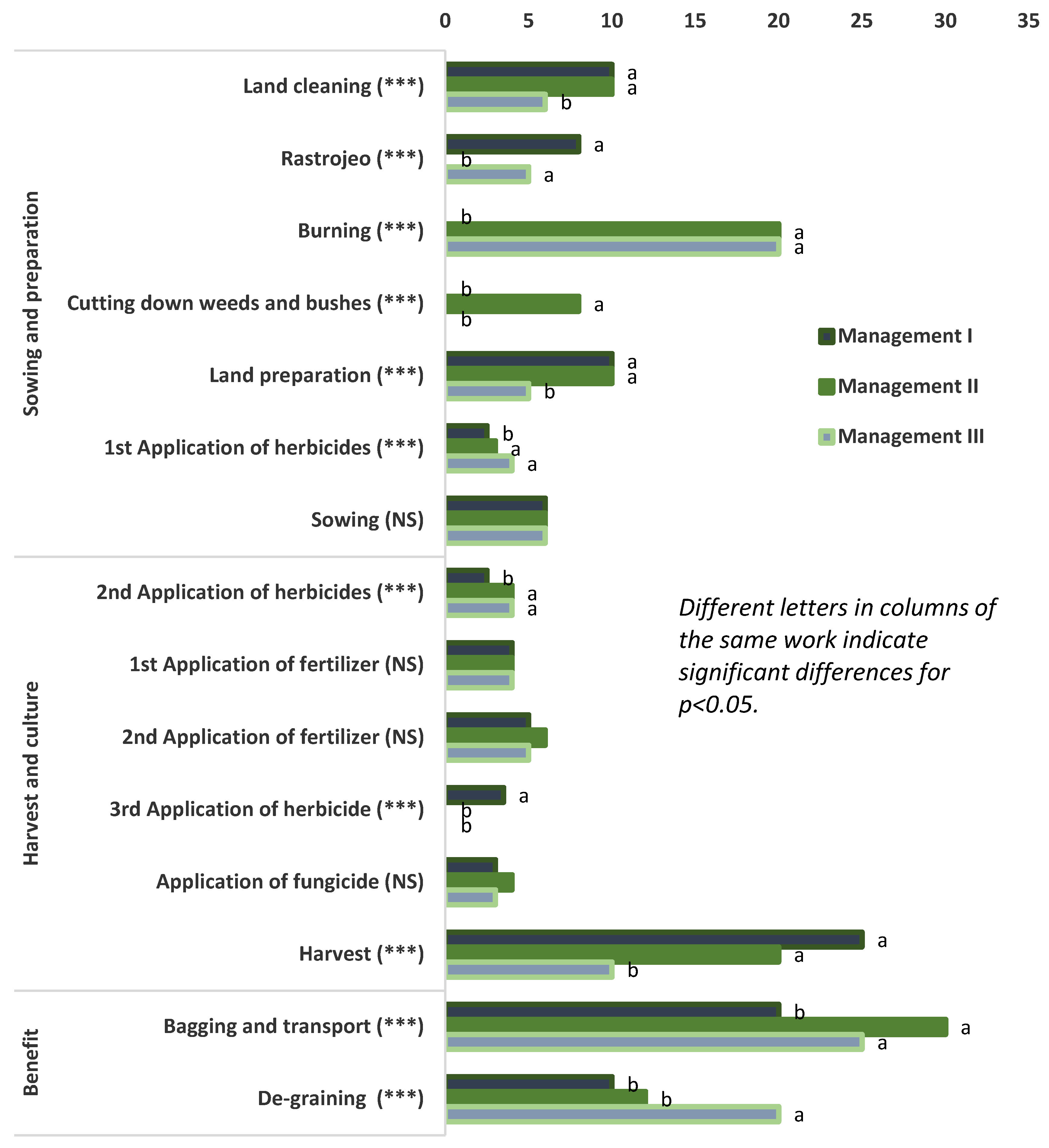

3.3. Use of Labour

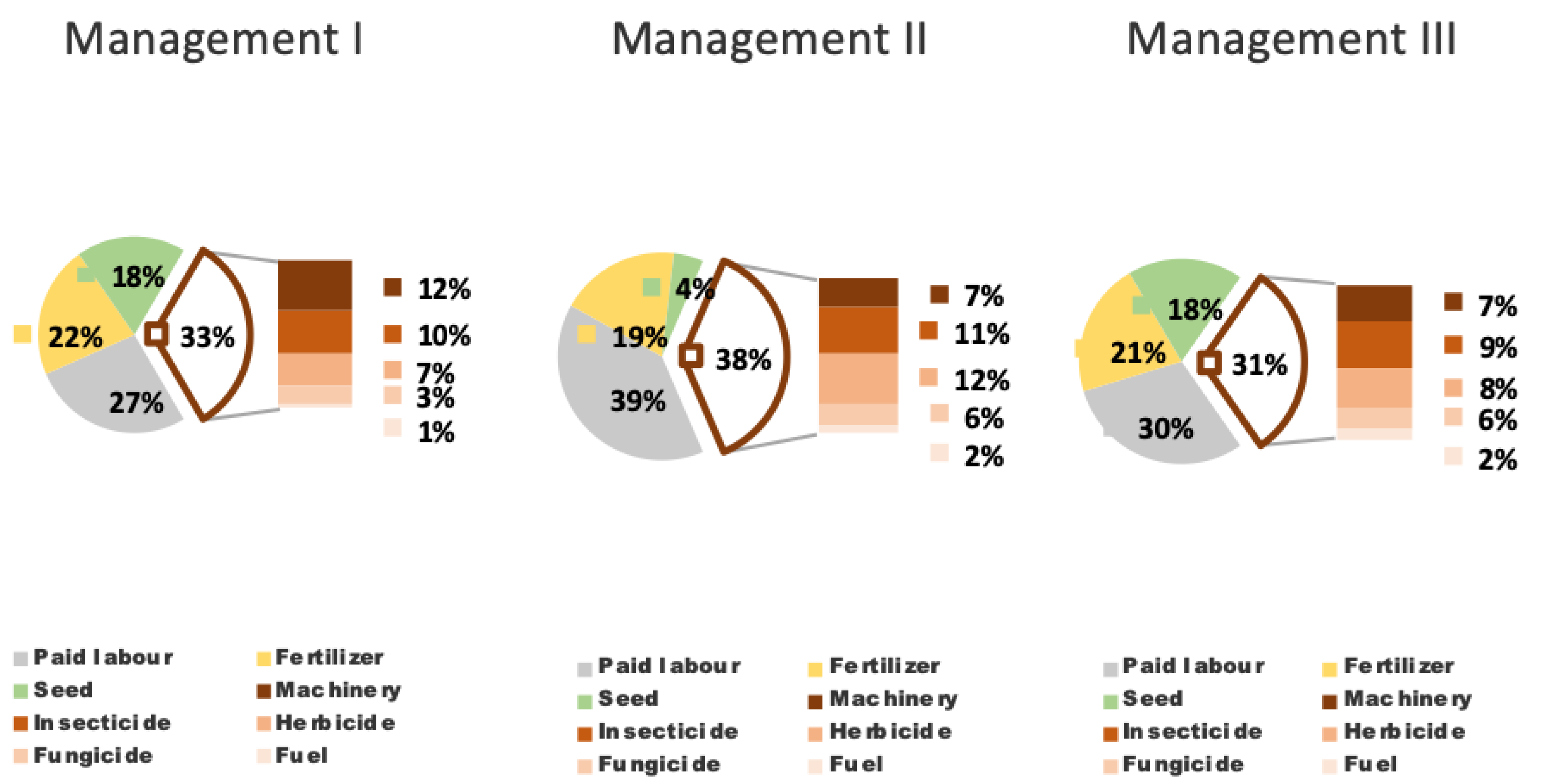

3.4. Energy Balance

3.5. Benefit-Cost Ratio

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Perales, H.R.; Benz, B.F.; Brush, S.B. Maize diversity and ethnolinguistic diversity in Chiapas, Mexico. Proc. Natl. Acad. Sci. USA 2005, 102, 949–954. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ferraro, O.D. Energy use in cropping systems: A regional long-term exploratory analysis of energy allocation and efficiency in the Inland Pampa (Argentina). Energy 2012, 44, 490–497. [Google Scholar] [CrossRef]

- Hellin, J.; Erenstein, O.; Beuchelt, T.; Camacho, C.; Flores, D. Maize stover use and sustainable crop production in mixed crop–livestock systems in Mexico. Field Crops Res. 2013. [Google Scholar] [CrossRef] [Green Version]

- Servicio de Información Agroalimentaria y Pesquera (SIAP). Atlas Agroalimentario Servicio de Información Agroalimentaria y Pesquera; Secretaría de Agricultura, Ganadería, Desarrollo Rural, Pesca y Alimentación (SAGARPA): Mexico City, Mexico, 2017; Available online: http://www.siap.gob.mx/ (accessed on 2 February 2020).

- Hernández-Ramos, M.A.; Rodríguez-Larramendi, L.A.; Guevara-Hernández, F.; Rosales-Esquinca, M.D.L.Á.; Pinto-Ruiz, R.; Ortiz-Pérez, R. Molecular characterization of local maize varieties from the Biosphere Reserve La Sepultura, Mexico. Agron. Mesoam. 2017, 28, 69–83. [Google Scholar] [CrossRef] [Green Version]

- Ocaña, J.M.J. Estudio Socioeconómico y Ambiental del uso y Manejo del Rastrojo en los Sistemas Maíz-ganadería en la Region Frailesca, Chiapas. Master’s Thesis, Universidad Autónoma de Chiapas, Tuxtla Gutiérrez, Mexico, 2015; p. 110. [Google Scholar]

- Guevara, H.F.; Delgado, R.F.; Arias, L.M.; Rodríguez, L.L.; Ortiz, P.R.; Delgado, R.J.A.; Venegas, V.J.A.; Pinto, R.R. Comparative energy-economic analysis of the maize agroecosystem under conventional and conservation practices in the Frailesca región, Chiapas, Mexico. Rev. Fac. Agron. Univ. Zulia 2018, 35, 343–364. [Google Scholar]

- Denoia, J.; Monticos, S. Energy balance in field vegetable crops in Rosario (Santa Fe, Argentina). Cienc Docencia Tecnol. 2010, XXI, 145–157. Available online: http://www.redalyc.org/articulo.oa?id=14515335007 (accessed on 3 December 2019).

- Denoia, J.; Vilche, M.; Montico, S.; Bonel, B.; Di Leo, N. Descriptive Analysis of the Evolution of the Technological Models Prevalent in Zavalla District (Santa Fe), from an Energetic Perspective. Cienc. Docencia Tecnol. 2006, XVII, 211–226. [Google Scholar]

- Bonel, B.; Montico, S.; di Leo, N.; Denoia, J.; Vilche, M. Energy analysis of the land units in a rural basin. Rev. FAVE Cienc. Agrar. 2006, 4, 37–47. [Google Scholar]

- Rodríguez-Larramendi, L.; Guevara-Hernández, F.; Ovando-Cruz, J.; Marto-González, J.R.; Ortiz-Pérez, R. Growth and harvest index of local maize varieties (Zea mays L.) in communities of the Frailesca region of Chiapas, Mexico. Cultiv. Trop. 2016, 37, 137–145. [Google Scholar] [CrossRef]

- Delgado-Ruiz, F.; Guevara-Hernández, F.; Acosta-Roca, R. Farmers’ criteria for maize (Zea mays L.) selection in Villaflores and Villa Corzo, Chiapas, Mexico. Cienc. UAT 2018, 13, 123–134. [Google Scholar] [CrossRef]

- Corporación Educativa para el Desarrollo Costarricense (CEDECO). Emisión de Gases con Efecto Invernadero y Agricultura Orgánica; CEDECO: San José, Costa Rica, 2007; p. 59. [Google Scholar]

- Vergara, R.D.R.G.; Díaz, R.Á.; Alvarez, P.A. Effect of Nitrogen Fertilization on Maize Crop to Characterize Greenhouse Gas Emissions; Working Papers; Universidad Nacional Abierta y a Distancia: Bogotá, Colombia, 2017. [Google Scholar]

- Vilche, S.M.; Denoia, J.; Montico, S.; Bonel, B.; Dileo, N. Energy usage in agropecuarian systems at the Argentinian district of Zavalla, Santa Fe. Rev. Científica Agropecu. 2006, 10, 7–19. [Google Scholar]

- Guevara-Hernández, F.; Rodríguez-Larramendi, L.A.; Hernández-Ramos, M.A.; Fonseca-Flores, M.A.; Ruiz, R.P.; Reyes-Muro, L. Energy and economic efficiency of maize in the buffer zone of the Biosphere Reserve “La Sepultura”, Chiapas, Mexico. Rev. Mex. Cienc. Agrícolas 2015, 6, 1929–1941. [Google Scholar] [CrossRef] [Green Version]

- Hernández, R.M.A.; Hernández, F.G.; Larramendi, L.A.R.; Esquinca, M.Á.R.; Castro, H.G.; López, A.H.; Ruiz, R.P.; Jonapá, F.J.M. Eficienciaenergética y económica del proceso de producción del sistema maíz en una comunidad rural. In Naturaleza-Sociedad: Reflexiones Desde la Complejidad; Flores, A.C., Báez, P.A.O., Rodríguez, A.D., Rábago, F.G., Eds.; CIISDER, Centro de Investigaciones Interdisciplinarias sobre Desarrollo Regional, Universidad Autónoma de Tlaxcala: Tlaxcala, Mexico, 2003; pp. 130–150. ISBN 978-607-7698-98-2. [Google Scholar]

- Dussi, M.C.; Fernández, C.; Flores, L. Towards sustainable use of energy in agroecosystems. Cuad. Agroecol 2018, 13, 9. [Google Scholar]

- Cervantes, O.A. Transformación agroecológica en el cantón de Mora en Costa Rica y emigraciónindígenahuetar (1900–1955). Rev. Hist. 2016, 74, 116. [Google Scholar]

- Sánchez-Morales, P.; Romero-Arenas, O. Fossil fuels and CO2 traditional milpa and monoculture maize systems in Tlaxcala, Mexico. Rev. Mex. Cienc. Agrícolas 2017, 4, 919–932. [Google Scholar]

- Pérez, R.A.; Flores, J.C.B. Balance energetic en dos sistemas de producción de maíz en las condiciones de Cuba. Cent. Agrícola. 2003, 30, 84–87. [Google Scholar]

- Pervanchon, F.; Bockstaller, C.; Girardin, P. Assessment of energy use in arable farming systems by means of an agro-ecological indicator: The energy indicator. Agric. Syst. 2002, 72, 149–172. [Google Scholar] [CrossRef]

- Corporación Educativa para el Desarrollo Costarricense (CEDECO). Agricultura Orgánica y Gases con EfectoInvernadero; CEDECO: San José, Costa Rica, 2005; p. 27. [Google Scholar]

- Instituto Nacional de Estadística, Geografía e Informática (INEGI). Anuario Estadístico de los Estados Unidos Mexicanos 2011/Instituto Nacional de Estadística, Geografía e Informática; INEGI: Aguascaliente, Mexico, 2012; p. 155. [Google Scholar]

- Hagmann, J.; Guevara, H. Aprendiendo Juntos Para el Cambio: La Facilitación de Innovaciones Para el Manejo Sustentable de Recursos Naturales y el Desarrollo Rural a Través de Procesos Participativos; Serie Estudios de Caso; Red de Estudios para el Desarrollo Rural A.C. y Fundación Rockefeller, Oaxaca de Juárez: Oaxaca, Mexico, 2004; p. 153. [Google Scholar]

- Guevara-Hernández, F. ¿Y después qué?: Action-Research and Ethnography on Governance, Actors and Development in Southern Mexico; Technology and Agrarian Development Group, Department of Social Sciences, Wageningen University and Research Centre: Wageningen, The Netherlands, 2007; p. 223. [Google Scholar]

- Guevara, H.F.; Rodríguez, L.L.; Arias, L.M.; Gómez, C.H.; Fonseca, F.M.; Pinto, R.R.; Ponce, P.I.; Jonapá, M.F.; Carbonell, C.J.; Hernández, L.A.; et al. Metodología Para el Desarrollo de Procesos de Innovación Local a Través de la Investigación Acción; IIA Jorge Dimitrov: Bayamo, Cuba, 2011; p. 27. [Google Scholar]

- Geilfus, F. 80 Herramientas Para el Desarrollo Participativo; Diagnóstico, Planificación Monitoreo y Evaluación; IICA: San José, CA, USA, 1997; p. 217. [Google Scholar]

- Meul, M.; Nevens, F.; Reheul, D.; Hofman, G. Energy use efficieny of specialised dairy, arable and pig farms in Flanders. Agric. Ecosyst. Environ. 2007, 199, 135–144. [Google Scholar] [CrossRef]

- Funes, M.F. Agricultura con Futuro, la Alternativa Agroecológica Para Cuba; Estación Experimental Indio Hatuey, Universidad de Matanzas: Matanzas, Cuba, 2009; p. 176. [Google Scholar]

- Márquez, M.; Valdés, N.; Ferro, M.E.; Paneque, I.; Rodríguez, Y.; Chirino, E.; Gómez, L.M.; Vargas, D. Análisis agroenergético de tipologías agrícolas en La Palma. In Innovación Agroecológica, Adaptación y Mitigación del Cambio Climático; Ríos, L.H., Vargas, V.D., Funes, M.F., Eds.; Instituto Nacional de Ciencias Agrícolas (INCA): San José de las Lajas, Cuba, 2011; p. 248. [Google Scholar]

- Bowers, W. Agricultural field equipment. In Energy in the World Agriculture, Energy in Farm Production; Fluck, R.C., Ed.; Elsevier: Amsterdam, The Netherlands, 1992; Volume 6, pp. 117–129. [Google Scholar]

- Funes, M.F. Sistema Para el Análisis de la Eficiencia Energética de Fincas Integrales; IIPF (Instituto de Investigación de Pastos y Forrajes): Matanzas, Cuba, 2001. [Google Scholar]

- Pimentel, D. Environmental and economic costs of the application of pesticides primarly in the United States. Environ. Dev. Sustain. 2005, 7, 229–252. [Google Scholar] [CrossRef]

- Masera, O.; Astier, M. Energía y Sistema Alimentario en México: Aportaciones de la Agricultura Alternativa, en Agroecología y Desarrollo Agrícola en México; Universidad Autónoma Metropolitana: Xochimilco, Mexico, 1993. [Google Scholar]

- Instituto para la Diversificación y Ahorro de la Energía (IDAE). Ahorro, Eficiencia Energética y Fertilización Nitrogenada; IDAE: Madrid, Spain, 2007; p. 44. [Google Scholar]

- Fluck, C.R. Energy in World Agriculture: Energy in Farm Production; Agricultural Engineering Department, Institute of Food and Agricultural Sciencies, University of Florida: Gainesville, FL, USA, 1992; p. 384. [Google Scholar]

- Funes, F.; Monzote, F. Eficiencia Energetica en Sistemas Agropecuarios: Elementos Teoricos y Practicos Para el Calculo y Análisis Integrado; Estación experimental “Indio Hatuey”, Universidad de Matanzas, Ministerio de Educación Superior: Matanzas, Cuba, 2009; p. 38. [Google Scholar]

- Centro Internacional de Mejoramiento de Maíz y Trigo (CIMMyT). La Formulación de Recomendaciones a Partir de Datos Agronómicos: Un Manual Metodológico de Evaluación Económica; CIMMyT: Mexico City, Mexico, 1988; p. 86. ISBN 968-6127-24-0. [Google Scholar]

- Damián, H.M.; Ramírez, V.B.; Aragón, G.A.; Huerta, L.M.; Sangerman, J.; Romero, A. Handling of maize in the state of Tlaxcala, Mexico: Between the conventional and the agroecological. Rev. Latinoam. Recur. Nat. 2010, 6, 67–76. [Google Scholar]

- Iermanó, M.J.; Sarandón, S.J. Eficiencia energética de cultivos anuales en dos tipos de agroecosistemas de la Región Pampeana Argentina. In Proceedings of the Memorias del V Congreso Latinoamericano de Agroecología, La Plata, Argentina, 7–9 October 2015; p. 5. [Google Scholar]

- Aguilar, J.C.E. Informe final del estudiotécnico: Validación de semilla y del proceso de mantenimiento de agroecosistemaen los ejidos de California, Nueva Esperanza y Flores Magónlocalizadosen la zona de amortiguamiento de la reserva de la Biosfera la Sepultura; UNACH: Municipio de Villaflores, Mexico, 2010. [Google Scholar]

- Purroy-Vázquez, R.; Ortega-Vargas, E.; Hernández-Santiago, Q.; Del Ángel-Piña, O.; Meza-Hernández, J.; Reyes-Santiago, B.; Nicolás-Vicente, F. Maize small-scale agroecosystems in the high Huasteca region of Veracruz: Economic-energetic efficiency and poverty. Rev. Agric. Soc. Desarro. 2019, 16, 105–121. [Google Scholar]

- Funes, M.F.; Suarez, J.; Blanco, D.; Reyes, F.; Cepero, L.; Rivero, J.L.; Rodríguez, E.; Savran, V.; del Valle, Y.; Cala, M.; et al. Initial evaluation of integrated systems for food and energy production in Cuba. Pastos Forrajes 2011, 34, 445–462. [Google Scholar]

- Funes, F.; Monzote, M.; Lantinga, E.A.; van Keulen, H. Conversion of specialised dairy farming systems into sustainable mixed farming systems in Cuba. Environ. Dev. Sustain. 2008, 11, 765–783. [Google Scholar] [CrossRef] [Green Version]

- Pimentel, D. Handbook of Energy Utilization in Agriculture; CRC Press: Boca Raton, FL, USA, 1980. [Google Scholar]

- Purroy-Vasquez, R.; Gallardo-Lopez, F.; Diaz-Rivera, P.; Ortega-Jimenez, E.; Lopez-Ortiz, S.; Torres-Hernandez, G. Energetic-economic flow as a tool to typify agroecosystems in the center of the state of Veracruz, Mexico. Ecosistemas Recur. Agropecu. 2016, 3, 91–101. [Google Scholar]

- Stark, F.; Moulin, C.H.; Cangiano, C.; Vigne, M.; Vayssières, J.; González, G.E. Methodologies for evaluating farming systems. Part I. Generalities. Life cycle analysis (LCA) and ecological network analysis (ENA). PastosForrajes 2016, 39, 81–88. [Google Scholar]

- Pimentel, D.; Pimentel, M. El uso de la energía en la agricultura, una visión general. LEISA Rev. Agroec. 2005, 21, 5–8. [Google Scholar]

- Valdés, N.; Pérez, D.; Márquez, M.; Angarica, L.; Vargas, D. Funcionamiento y balance energetic en agroecosistemas diversos. Cultiv. Trop. 2009, 30, 36–42. [Google Scholar]

- Schiere, J.B.; Ibrahim, M.N.M.; Van Keulen, H. The role of livestock for sustainability in mixed farming: Criteria and scenario studies under varying resource allocation. Agric. Ecosyst. Environ. 2002, 90, 139–153. [Google Scholar] [CrossRef]

- Miranda, T.; Rey, M.; Hilda, M.; Julio, B.; Pedro, D. Economic valuation of environmental goods and services in two ecosystems of cattle use. Zootec. Trop. 2008, 26, 187–189. [Google Scholar]

- Mandal, K.G.; Saha, K.P.; Ghost, K.M.; Hati, K.M.; Bandyopadhyay, K.K. Bioenergy and economic analysis of soybean-based crop production systems in central India. Biomas Energy. 2002, 23, 337–345. [Google Scholar] [CrossRef]

- Purroy, V.R.; Gallardo, L.I.; Ortega, J.E.; Díaz, R.P.; López, O.S.; Torres, H.G. Energetic and economic efficiency, family welfare and productivity in tropical agroecosystems. Rev. Agric. Soc. Desarro. 2016, 13, 513–527. [Google Scholar]

- Comisión Económica para América Latina y el Caribe (CEPAL). Informe Nacional de Monitoreo de la Eficiencia Energética de México; Organización de las Naciones Unidas: Ciudad de México, México, 2018; p. 195. [Google Scholar]

- Instituto Para la Diversificación y Ahorro de Energía (IDAE). Ahorro y Eficiencia Energética en los Cultivos Energéticos y Agricultura; IDAE: Madrid, Spain, 2009; p. 35. ISBN 978-84-96680-43-2. [Google Scholar]

- Chamorro, M.A.; Golik, I.S.; Bezus, R.; Pellegrini, E.A. Energetic analysis of four crop sequences in Buenos Aires Province, Argentina. Chil. J. Agric. Anim. Sci. (Ex Agro-Ciencia) 2015, 32, 20–31. [Google Scholar] [CrossRef] [Green Version]

- Vences-Pérez, J.; Morales-Almaraz, E.; Martínez-Garcia, C.G.; Albarran-Portillo, B.; Garcia-Martínez, A. Energy efficiency and sustainability. The case of corn cultivation in dual purpose livestock systems in the state of Mexico. In Proceedings of the XLIV Reunion Cientifica de la Asociación Mexicana Para la Producción Animal y Seguridad Alimentaria, A.C. Clima y Ganaderia: Productividad Sustentable, Tuxtla Gutiérrez, Mexico, 6–8 September 2017; pp. 526–531. [Google Scholar]

| Type of Management and Technology | Management I | Management II | Management III |

|---|---|---|---|

| Soil preparation | Use of small agricultural machinery plus herbicide | Does not remove soil plus herbicide | Use of small agricultural machinery plus herbicide |

| Type of seed used | Hybrid | Local 1 | Hybrid |

| Labour | Family and paid | Family, paid and by invitation 2 | Family and paid |

| Synthetic inputs | Intensive use of herbicides High amounts of chemical fertilizers Generalised use of insecticides and fungicides | Less use of herbicides Lower amount of synthetic fertilizers and use of local manures Use of botanical techniques for pest and diseases control, and minimal use of synthetic pesticides | Intensive use of herbicides High amounts of chemical fertilizers Generalised use of insecticides and fungicides |

| Other practices | Small agricultural machinery for soil preparation Monoculture | Soil conservation practices Intercropping and crop rotation Manual tools for weed management and planting Local knowledge on moon phases for sowing and harvesting | Soil conservation practices Small agricultural machinery for soil preparation Monoculture |

| Socio-economic | |||

| Labour | Paid and family | Family, paid and by invitation | Family and paid |

| Cropping objective (in order of importance) | Sale and family consumption | Family consumption, animals and sale | Sale and family consumption |

| Profit | Medium | High | High |

| Cropping area (average) | 5.70 hectares | 2.66 hectares | 2.53 hectares |

| Land tenure | Ejidal (social) and private | Ejidal (social) | Ejidal and rented |

| Level of protein produced kg/ha/year | High | Low | Medium |

| Protected forest area | Scarce | High | Medium |

| Input | Uni | MJ Unit−1 † | Source |

|---|---|---|---|

| Human work | Workday | 1.05 | [33] |

| Animal work | Workday | 7.54 | [33] |

| Seed (in general) | Kg | 107.66 | [34] |

| Diesel | L | 38.70 | [35] |

| Gasoline | L | 34.12 | [35] |

| Ammonium sulphate (21%) | Kg | 45.03 | [36] |

| Herbicide | L | 238.65 | [33] |

| Insecticide | L | 184.22 | [33] |

| Machinery | Hours | 87.92 | [34] |

| Farm tractor | Hours | 4.25 | [37] |

| Product (Maize, dry grain) | Kg | 15.31 | [30] |

| Input | Unit of Measure | Amount of Inputs Used ha−1 | Sig. | |||||

|---|---|---|---|---|---|---|---|---|

| Management I | Management II | Management III | ||||||

| Mean | S.E. | Mean | S.E. | Mean | S.E. | |||

| Seed (maize) | Kg | 20 | 0.000 | 20 | 0.000 | 20 | 0.000 | ns |

| Diesel | L | 10 | 1.612 | 8 | 2.646 | 10 | 1.648 | ns |

| Gasoline | L | 15 a | 3.435 | 10 b | 1.936 | 15 a | 2.392 | 0.00 |

| Ammonium Sulphate 21% | Kg | 800 a | 63.246 | 600 b | 75.00 | 800 a | 70.711 | 0.00 |

| Glyphosate | L | 3.5 a | 0.5477 | 1.5 b | 0.500 | 3 a | 0.6814 | 0.00 |

| Paraquat | L | 5 a | 0.922 | 1 c | 0.500 | 3 b | 0.756 | 0.00 |

| 2-4 D amine | L | 3 a | 0.447 | 1 c | 0.000 | 2 b | 0.655 | 0.00 |

| Paraquat + Diuron | L | 0 c | 0.000 | 3 a | 0.500 | 2 b | 0.655 | 0.00 |

| Methyl parathion | L | 2 b | 0.742 | 1 c | 0.433 | 3 a | 0.463 | 0.00 |

| Aluminium phosphorus | Tablet | 3 a | 0.632 | 0 c | 0.000 | 2 b | 0.756 | 0.00 |

| Cypermethrin | L | 3 a | 0.775 | 1 c | 0.707 | 2 b | 0.756 | 0.00 |

| Mancozeb | kg | 3 a | 0.632 | 1 c | 0.707 | 2 b | 0.756 | 0.00 |

| Production Factors | Management I | Management II | Management III | Sig. | |||

|---|---|---|---|---|---|---|---|

| Mean S.E. | Mean S.E. | Mean S.E. | |||||

| Planted area (ha) | 1 | 1 | 1 | ns | |||

| Yield (kg ha−1) | 4727.2 a | 368.75 | 3411.1 b | 407.66 | 4033.3 a | 315.77 | 0.069 |

| Energy produced (EP) (MJha−1) | 73,760.18 | 6044.17 | 54,982.67 | 6682.08 | 65,387.8 | 5175.92 | ns |

| Protein produced (Kg ha−1) | 465.85 | 41.77 | 362.53 | 46.17 | 434.30 | 35.77 | ns |

| Number of people fed ha−1/year | |||||||

| Maize | 24.06 a | 1.88 | 17.36 c | 2.08 | 20.53 b | 1.36 | 0.069 |

| Protein sources | 23.40 | 2.09 | 18.21 | 2.31 | 21.82 | 1.79 | ns |

| Energy consumed (EC) | 12,177.13 a | 439.98 | 11,831.18 a | 486.42 | 10,099.83 b | 376.78 | 0.002 |

| Human and animal work (MJ ha−1) | 260.72 | 24.05 | 268.66 | 26.59 | 304.73 | 20.60 | ns |

| Inputs used (MJ ha−1) | 11,916.4 a | 430.74 | 11,562.51 a | 476.20 | 9795.44 b | 368.86 | 0.001 |

| Energy intensity (MJkg−1) | 2.87 a | 0.30 | 3.61 a | 0.33 | 2.63 b | 0.25 | 0.034 |

| Energy yield (kgMJ−1) | 0.395 a | 0.00 | 0.305 b | 0.00 | 0.430 a | 0.00 | 0.039 |

| Energy use efficiency (EP/EC) | 6.04 a | 0.52 | 4.65 b | 0.57 | 6.47 a | 0.44 | 0.038 |

| Mode of Production | Yield (kg/ha) | Quantity Commercialised (kg) | % | Price/kg (pesos) | Income/ha (pesos) |

|---|---|---|---|---|---|

| Management I | 4727.2 | 4500 | 95.1 | 4.00 | 18,000 |

| Management II | 3411.1 | 3200 | 93.8 | 4.20 | 13,440 |

| Management III | 4033.3 | 4000 | 99.1 | 4.10 | 16,400 |

| Management I | Management II | Management III | |

|---|---|---|---|

| Income ($) | 18,000 | 13,400 | 16,400 |

| Expenditure ($) | 11,485 | 8565.8 | 11,002.7 |

| Benefit/cost | 1.56 | 1.56 | 1.49 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martínez, F.B.; Guevara, F.; Aguilar, C.E.; Pinto, R.; La O, M.A.; Rodríguez, L.A.; Aryal, D.R. Energy and Economic Efficiency of Maize Agroecosystem under Three Management Strategies in the Frailesca, Chiapas (Mexico). Agriculture 2020, 10, 81. https://doi.org/10.3390/agriculture10030081

Martínez FB, Guevara F, Aguilar CE, Pinto R, La O MA, Rodríguez LA, Aryal DR. Energy and Economic Efficiency of Maize Agroecosystem under Three Management Strategies in the Frailesca, Chiapas (Mexico). Agriculture. 2020; 10(3):81. https://doi.org/10.3390/agriculture10030081

Chicago/Turabian StyleMartínez, Franklin B., Francisco Guevara, Carlos E. Aguilar, René Pinto, Manuel A. La O, Luis A. Rodríguez, and Deb R. Aryal. 2020. "Energy and Economic Efficiency of Maize Agroecosystem under Three Management Strategies in the Frailesca, Chiapas (Mexico)" Agriculture 10, no. 3: 81. https://doi.org/10.3390/agriculture10030081

APA StyleMartínez, F. B., Guevara, F., Aguilar, C. E., Pinto, R., La O, M. A., Rodríguez, L. A., & Aryal, D. R. (2020). Energy and Economic Efficiency of Maize Agroecosystem under Three Management Strategies in the Frailesca, Chiapas (Mexico). Agriculture, 10(3), 81. https://doi.org/10.3390/agriculture10030081