Filtration Characterization Method as Tool to Assess Membrane Bioreactor Sludge Filterability—The Delft Experience

Abstract

:1. Introduction

2. Results and Discussion

2.1. Available Methods to Measure Filterability

| Method | Critical flux determination by flux-step method [6] | Delft Filtration Characterization Method (DFCm) [7] | MBR-VITO fouling measurement [8] | Berlin Filtration Method (BFM) [9] | Sludge Filtration Index (SFI) [10] |

|---|---|---|---|---|---|

| Fouling Parameter | Critical flux | Filterability | Resistance | Critical flux | Filterability |

| Principle | Flux (J) is increased stepwise until critical flux is obtained | Single TMP filtration measurement at constant supra-critical J | Sequence of filtrations steps at constant TMP followed by physical cleaning steps | Flux is increased and subsequently decreased stepwise | Single dead-end filtration through paper filter, relying on gravity filtration |

| Definitions | Critical flux (Jc): highest flux for which the trans-membrane pressure remains constant | Filterability: fouling potential from the MBR activated sludge. ΔR20: additional membrane resistance obtained when 20 L·m−2 of permeate are produced, following the DFCm. Scale defined between ΔR20 and sludge filtration quality | Reversible fouling: obtained when operating at an air flow rate of 40 mL·min−1; removed by 10 min relaxation and air flow rate of 100 mL·min−1.Irreversible fouling: obtained by operating at an air flow rate of 80 mL·min−1 | Critical flux (Jc): highest flux for which the permeate pressure remains constant.Irreversible fouling: existence of irreversible fouling when hysteresis loop does not present similar values | Filterability: defined as the specific value of the SFI, calculated as the measured time, divided by the MLSS concentration of the sample |

| Data processing | TMP based parameters in each flux-step: initial TMP increase (ΔP0); rate of TMP increase dP/dt; average TMP (Pave) | Data processed as increased membrane resistance, based on Darcy’s law, see Section 2.2.1. | Data processed as permeability subsequently used to obtain total resistance, further subdivided according to the resistance in series model | Pressure of permeate and applied J | Required time to produce specific volume of supernatant; Mixed Liquid Suspended Solids (MLSS) determination |

| Application | Ex situ | Ex situ (also possible in situ, see Section 2.2.4.1) | Ex situ and In situ | In situ | Ex situ |

| Applicability | Measures removable fouling | Measures removable fouling | Measures removable fouling and attempts to quantify the irremovable fouling | Measures removable fouling and qualifies irremovable fouling | Attempt to quantify filterability-removable fouling |

| Duration | 5 h | 30 min | 1–2 h | 2–3 h | 10 min |

| Usefulness | Guide value for suitable operating flux | Quantify fouling potential | Establishes fouling potential; info concerning need of physical or chemical cleaning | Guide value for suitable operating flux; info concerning irreversible fouling | Information on dewatering properties of the sludge |

| Method | Critical flux determination by flux-step method [6] | Delft Filtration Characterization Method (DFCm) [7] | MBR-VITO fouling measurement [8] | Berlin Filtration Method (BFM) [9] | Sludge Filtration Index (SFI) [10] |

|---|---|---|---|---|---|

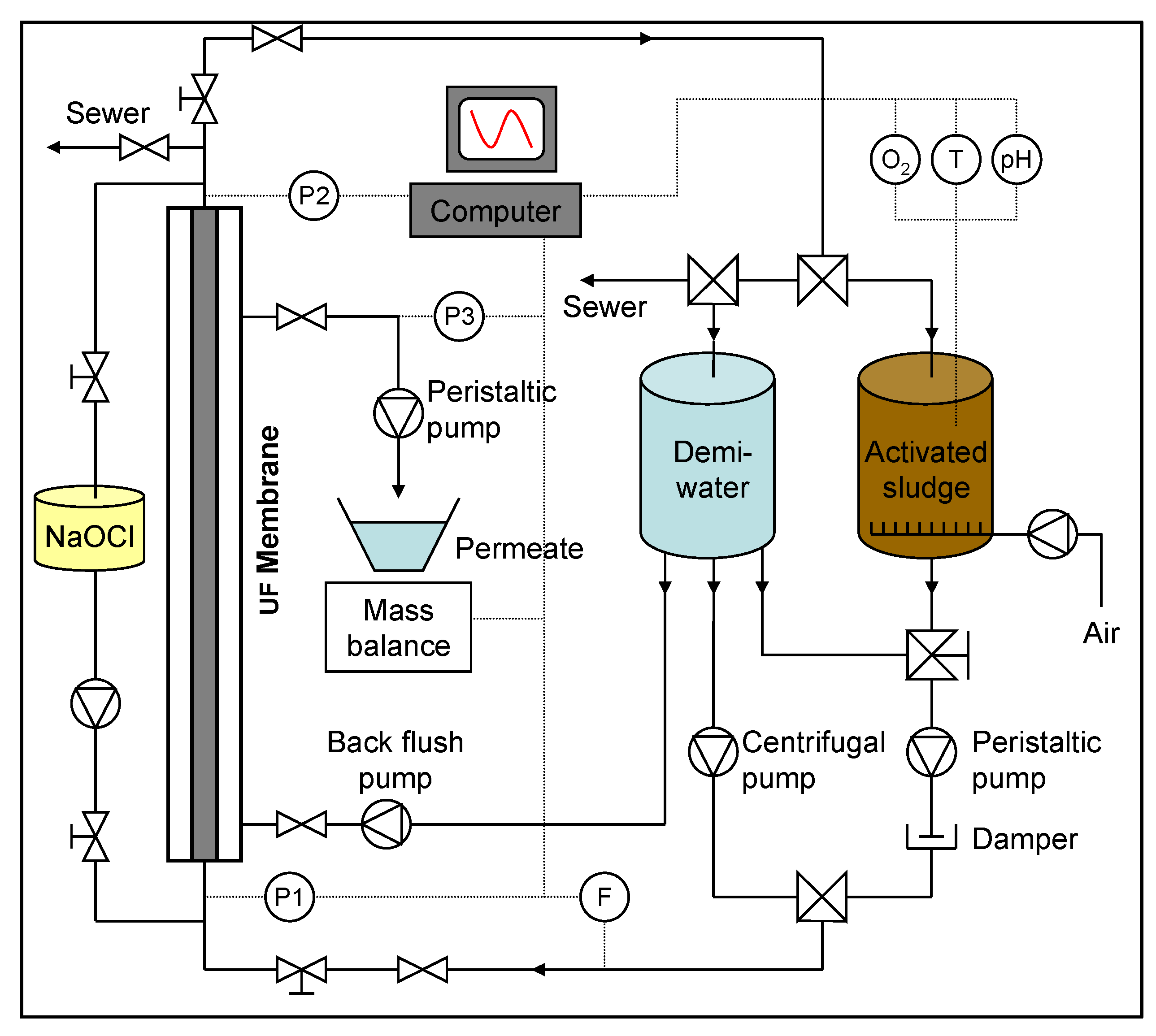

| Installation | 40 L bioreactor. Vertical mounted submerged tubular membrane; pore size 0.2 µm. Constant cross-flow of air: bioreactor air-flow 4 L·min−1 and module air-flow 6 L·min−1 | 40 L bioreactor. Side-stream membrane; pore size 0.03 µm | Submerged membrane. Presently, several types of tubular membranes are proposed with a pore size from 0.1 to 0.01 µm. Cross-flow of air; fixed values varying according to filtration and physical cleaning steps | Submerged Ultra-filtration flat-sheet membranes with a total filtration surface of 0.025 m2 and space between plates of 7 mm; flat-sheet module supplied with aeration | Buchner funnel, with specific paper filter. The sample is mixed through a blade agitator. Volume of produced supernatant is measured and time of production recorded |

| Method operation | Permeation rate incrementally increased and the pressure change continuously monitored. Step duration: 15 min Step height: 2 L·m−2·h−1 | Sludge filtration at J of 80 L·m−2·h−1 and sludge cross-flow velocity of 1 ms−1 | (1) Start up: air flow rate of 100 mL·min−1; (2) Filtration step to establish membrane resistance and removable fouling: constant TMP of 0.1 bar; air flow rate of 40 mL·min−1; (3) Physical cleaning: 10 min relaxation; air flow rate of 100 mL·min−1; (4) Filtration steps to establish irremovable fouling: constant TMP of 0.1 bar; air flow rate of 80 mL·min−1; (5) At least 10 cycles to establish irremovable fouling with physical cleaning of 3 min relaxation and air flow of 100 mL·min−1 in between | Sequence of 5 min filtration steps at constant flux and aeration Specific aeration demand (SAD) of 3.5 m3/m2·h; Relaxation between filtration steps of 2 min; Flux steps of 3 L·m−2·h−1 with variable initial step of 5 to 8 L·m−2·h−1 | A 500 mL sludge sample, previously tempered to 20 °C, is placed on the filter and mixed at 40 rpm. The time to produce 100 mL to 150 mL of supernatant is used to calculate the specific value of the SFI. The MLSS concentration of the sample is measured |

| Cleaning protocol | Backwash with permeate for 5 min at 50–75 mbar. Ex situ chemical cleaning with NaOCl (0.5 wt %) at 50 °C for 20 h | Forward flush of water at cross-flow velocity >5 ms−1. In situ chemical cleaning with Na OCl 500 ppm | Physical cleaning with fixed duration and air flow rate of 100 mL·min−1 depending on the operation step. Ex situ chemical cleaning, NaOCl at 500 ppm for 2 h | Ex situ chemical cleaning with solution of 1% active chlorine | No cleaning protocol |

| Fouling type | Fouling rate (mbar/min) | Time interval | Cleaning |

|---|---|---|---|

| Reversible fouling | 0.1–1 | 10 min | Mechanical |

| Irreversible fouling | 0.001–0.1 | Weeks, months | Chemical |

| Long-term irreversible fouling | 0.0001–0.001 | Several years | Impossible |

2.2. Delft Filtration Characterization Method

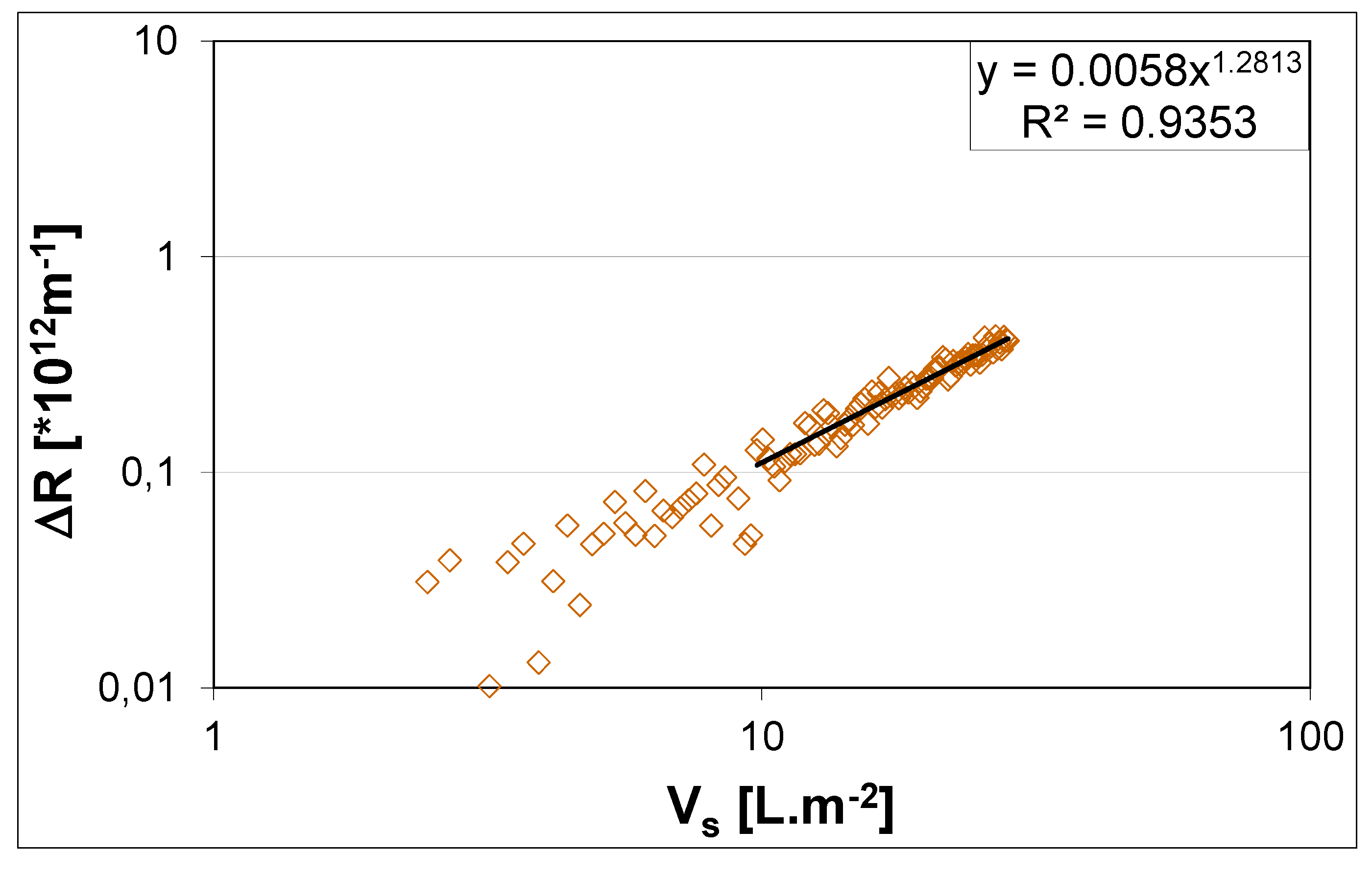

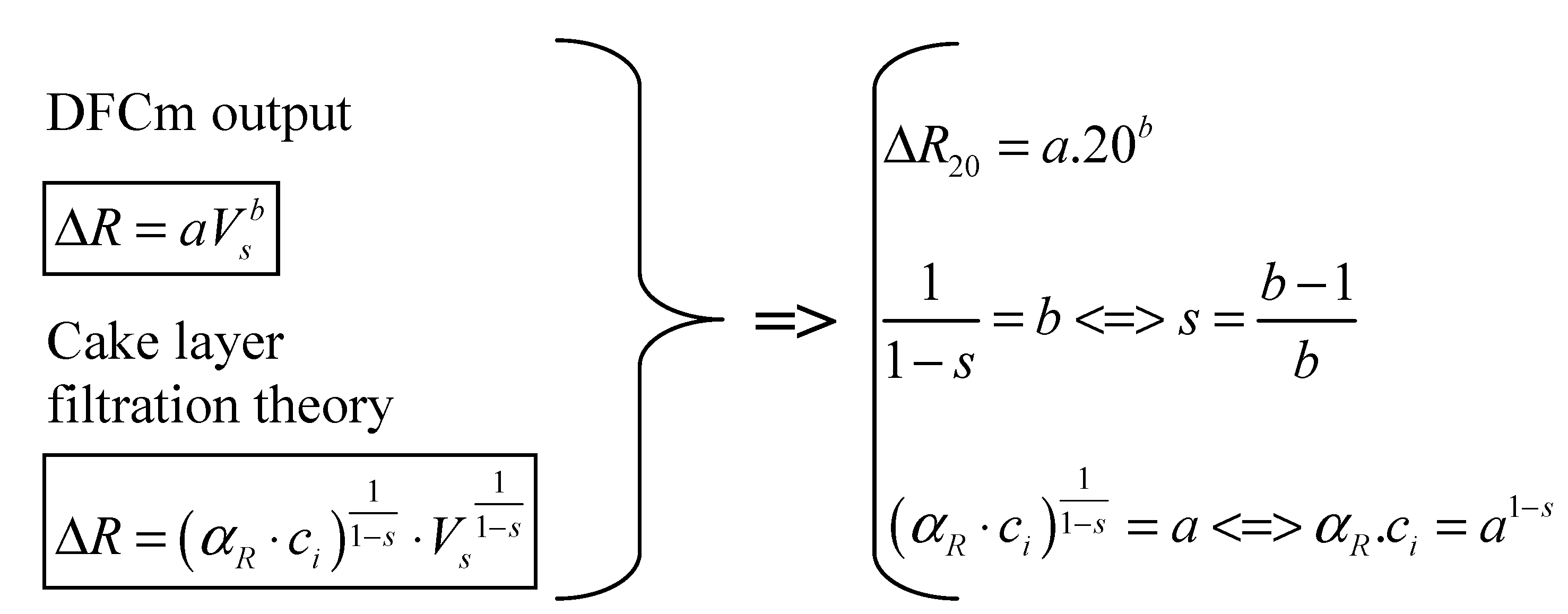

2.2.1. Output and Data Processing

| Sludge quality | ΔR20 (×10 12 m−1) | |

|---|---|---|

| Minimum | Maximum | |

| Good | 0 | 0.1 |

| Moderate | 0.1 | 1 |

| Poor | 1 | – |

2.2.2. Installations and Locations

2.2.3. Sampling

2.2.4. Evaluation

2.2.4.1. Accuracy

| Date | 4 July 2007 | 5 July 2007 | 6 July 2007 |

|---|---|---|---|

| Activated sludge | – | – | – |

| MLSS g/L | 14.5 | 14.6 | 14.4 |

| Permeability L/m2·h·bar | 193 | 199 | 186 |

| Permeate | – | – | – |

| COD mg/L | 21.7 | 15.9 | 18.1 |

| NH4-N mg/L | 0.01 | 0.02 | 0.02 |

| NO3-N mg/L | 3,3 | 3,7 | 4 |

| PO4-P mg/L | 0.18 | 0.28 | 0.36 |

| Day-Month-Year | Hour:Minute | ΔR20 (1012 m−1) | ΔR20 Standard deviation(daily) | pH | T (°C) |

|---|---|---|---|---|---|

| 4 July 2007 | 8:27 | 0.05 | 0.098 | 7.1 | 19.7 |

| 4 July 2007 | 9:31 | 0.06 | 7.2 | 19.7 | |

| 4 July 2007 | 10:51 | 0.08 | 7.2 | 19.7 | |

| 4 July 2007 | 11:48 | 0.22 | 7.1 | 19.6 | |

| 4 July 2007 | 13:09 | 0.26 | 7.1 | 19.5 | |

| 5 July 2007 | 8:27 | 0.21 | 0.06 | 6.7 | 17.8 |

| 5 July 2007 | 10:18 | 0.08 | 6.4 | 17.7 | |

| 5 July 2007 | 12:05 | 0.08 | 6.1 | 17.8 | |

| 5 July 2007 | 12:59 | 0.07 | 6.3 | 17.8 | |

| 5 July 2007 | 13:42 | 0.16 | 6.4 | 17.8 | |

| 6 July 2007 | 8:30 | 0.11 | 0.025 | 6.6 | 18.9 |

| 6 July 2007 | 9:32 | 0.16 | 6.5 | 18.9 | |

| 6 July 2007 | 10:21 | 0.13 | 6.5 | 18.9 |

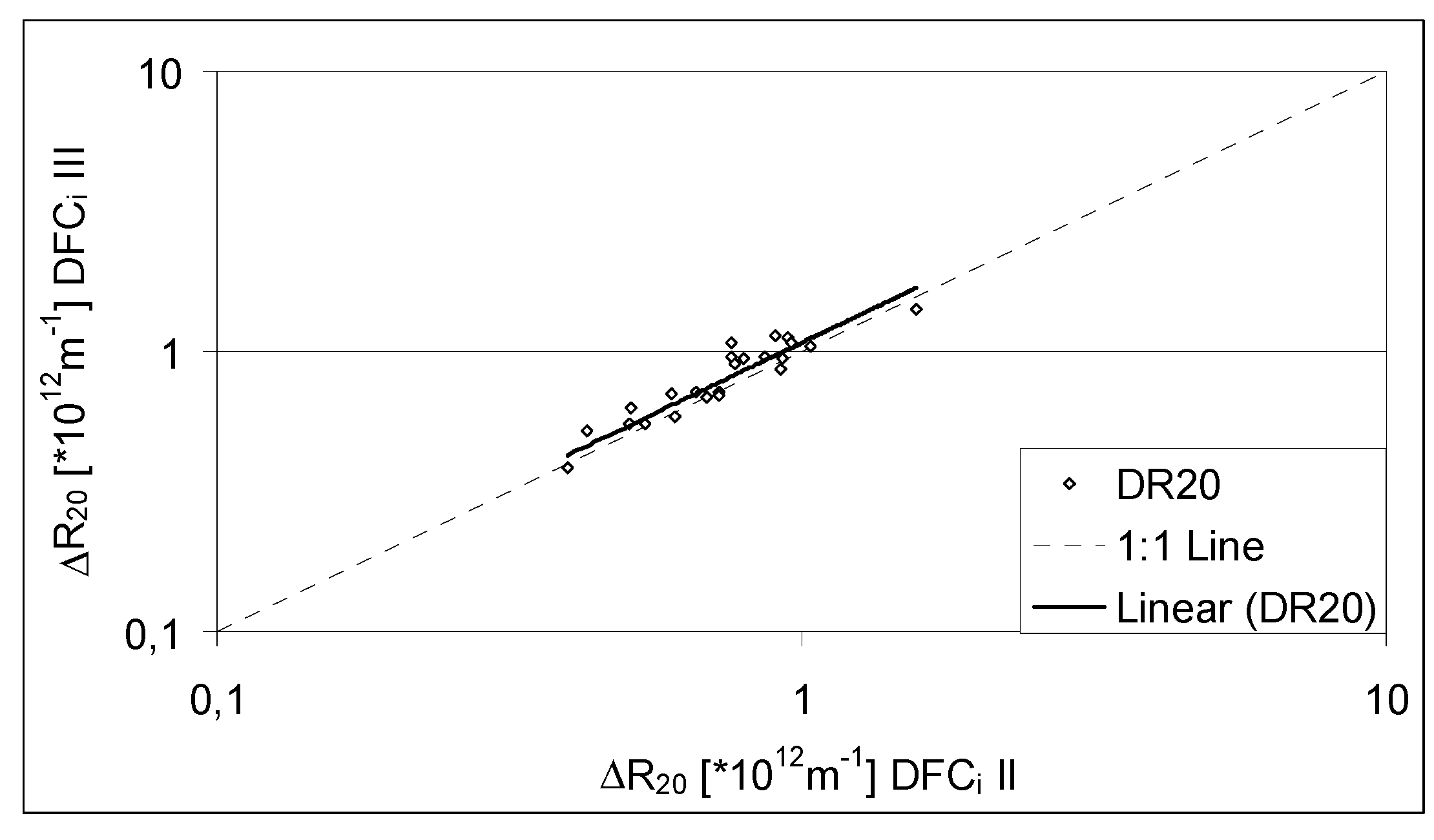

2.2.4.2. Reproducibility

2.2.4.3. Reliability

| MBR installation | Month Year | ΔR20 (1012 m−1) | MBR operation stability | |

|---|---|---|---|---|

| Average | Standard deviation | |||

| A | February 2007 | 0.97 | 0.11 | Steady |

| April 2008 | 3.01 | 1.47 | Unsteady | |

| August 2008 | 0.31 | 0.07 | Steady | |

| B | March 2007 | 0.56 | 0.04 | Steady |

| September 2008 | 0.08 | 0.02 | Steady | |

| C | July 2007 | 0.12 | 0.07 | Steady |

| November 2008 | 0.43 | 0.07 | Steady | |

| D | February 2007 | 0.31 | 0.12 | Steady |

| June 2008 | 0.05 | 0.05 | Steady | |

| January 2009 | 0.30 | 0.12 | Steady | |

| July 2009 | 0.14 | 0.07 | Steady | |

| February 2010 | 0.77 | 0.14 | Steady | |

| E | June 2008 | 0.18 | 0.04 | Steady |

| February 2009 | 2.72 | 0.41 | Unsteady | |

| August 2009 | 0.04 | 0.01 | Steady | |

| March 2010 | 0.95 | 0.13 | Steady | |

| F | June 2008 | 0.17 | 0.04 | Steady |

| February 2009 | 3.46 | 0.37 | Unsteady | |

| August 2009 | 0.04 | 0.00 | Steady | |

| March 2010 | 0.75 | 0.11 | Steady | |

2.2.4.4. Applicability

3. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Judd, S. The MBR Book-Principles and Applications of Membrane Bioreactors for Water and Wastewater Treatment, 2nd ed.; Elsevier: Oxford, UK, 2011. [Google Scholar]

- Krzeminski, P.; van der Graaf, J.H.J.M.; van Lier, J.B. Specific energy consumption of membrane bioreactor (MBR) for sewage treatment. Water Sci. Technol. 2012, 65, 380–392. [Google Scholar] [CrossRef]

- Kraume, M.; Wedi, D.; Schaller, J.; Iversen, V.; Drews, A. Fouling in MBR: What use are lab investigations for full scale operation? Desalination 2009, 236, 94–103. [Google Scholar] [CrossRef]

- Geilvoet, S. The Delft Filtration Characterisation Method, Assessing Membrane Bioreactor Activated Sludge Filterability; Technical University of Delft: Delft, The Netherlands, 2010. [Google Scholar]

- Judd, S. The MBR Book-Principles and Applications of Membrane Bioreactors for Water and Wastewater Treatment, 1st ed.; Elsevier: Oxford, UK, 2006. [Google Scholar]

- Le Clech, P.; Jefferson, B.; Chang, I.S.; Judd, S.J. Critical flux determination by the flux-step method in a submerged membrane bioreactor. J. Membr. Sci. 2003, 227, 81–93. [Google Scholar] [CrossRef]

- Evenblij, H.; Geilvoet, S.; van der Graaf, J.H.J.M.; van der Roest, H.F. Filtration characterisation for assessing MBR performance: Three cases compared. Desalination 2005, 178, 115–124. [Google Scholar] [CrossRef]

- Huyskens, C.; Brauns, E.; van Hoof, E.; de Wever, H. A new method for the evaluation of the reversible and irreversible fouling propensity of MBR mixed liquor. J. Membr. Sci. 2008, 323, 185–192. [Google Scholar] [CrossRef]

- De la Torre, T.; Mottschall, M.; Lesjean, B.; Drews, A.; Iheanaetu, A.; Kraume, M. Filterability assessment in membrane bioreactors using an in-situ filtration test cell. Water Sci. Technol. 2010, 61, 2809–2816. [Google Scholar] [CrossRef]

- Thiemig, C. The importance of measuring the sludge filterability at an MBR-introduction of a new method. Water Sci. Technol. 2012, 66, 9–14. [Google Scholar] [CrossRef]

- De la Torre, T. The Quest for a Universal Indicator for MBR Fouling; Technischen Universität Berlin: Berlin, Germany, 2013. [Google Scholar]

- Lousada-Ferreira, M. Filterability and Sludge Concentration in Membrane Bioreactors; Technical University of Delft: Delft, The Netherlands, 2011. [Google Scholar]

- Evenblij, H. Filtration Characteristics in Membrane Bioreactors; Technical University of Delft: Delft, The Netherlands, 2006. [Google Scholar]

- Krzeminski, P. Activated Sludge Filterability and Full-Scale Membrane Bioreactors Operation; Technical University of Delft: Delft, The Netherlands, 2013. [Google Scholar]

- Geilvoet, S.P.; Moreau, A.A.; Lousada-Ferreira, M.; van Nieuwenhuijzen, A.F.; van der Graaf, J.H.J.M. Filtration Characterization and Sludge Quality Monitoring at a Full-Scale MBR during its First Year of Operation; IWA International Conference on Membranes for Water and Wastewater Treatment: Harrogate, UK, 2007; p. 8. [Google Scholar]

- Moreau, A.A. Filterability Assessment of Membrane Bioreactors at European Scale; Technical University of Delft: Delft, The Netherlands, 2010. [Google Scholar]

- Krzeminski, P.; Langhorst, W.; Schyns, P.; de Vente, D.; van den Broeck, R.; Smets, I.Y.; van Impe, J.F.M.; van der Graaf, J.H.J.M.; van Lier, J.B. The optimal MBR configuration: Hybrid vs. stand-alone-Comparison between three full-scale MBRs treating municipal wastewater. Desalination 2011, 284, 341–384. [Google Scholar]

- Gil, J.A.; Krzeminski, P.; van Lier, J.B.; van der Graaf, J.H.J.M.; Wijffels, T.; Prats, D. Analysis of the filterability in industrial MBRs. Influence of activated sludge parameters and constituents on filterability. J. Membr. Sci. 2011, 385, 96–109. [Google Scholar]

- Lousada-Ferreira, M.; Moreau, A.; van Lier, J.B.; van der Graaf, J.H.J.M. Particle counting as a tool to predict filterability in membrane bioreactors activated sludge? Water Sci. Technol. 2011, 64, 139–146. [Google Scholar] [CrossRef]

- Krzeminski, P.; Gil, J.A.; van Nieuwenhuijzen, A.F.; van der Graaf, J.H.J.M.; van Lier, J.B. Flat sheet or hollow fibre-comparison of full-scale membrane bio-reactor configurations. Desalin. Water Treat. 2012, 42, 100–106. [Google Scholar] [CrossRef]

- Krzeminski, P.; Iglesias-Obelleiro, A.; Madebo, G.; Garrido, J.M.; van der Graaf, J.H.J.M.; van Lier, J.B. Impact of temperature on raw wastewater composition and activated sludge filterability in full-scale MBR systems for municipal sewage treatment. J. Membr. Sci. 2012, 423, 348–361. [Google Scholar]

- Geilvoet, S.P.; Remy, M.; Evenblij, H.; Temmink, H.; van der Graaf, J.H.J.M. Tracing membrane foulants in membrane bioreactors by filtration characterisation and fractionation. Water Sci. Technol. 2005, 6, 165–172. [Google Scholar]

- Lousada-Ferreira, M.; Geilvoet, S.; Moreau, A.; Atasoy, E.; Krzeminski, P.; van Nieuwenhuijzen, A.; van der Graaf, J. MLSS concentration: Still a poorly understood parameter in MBR filterability. Desalination 2010, 250, 618–622. [Google Scholar] [CrossRef]

- Moreau, A.A.; Ratkovich, N.; Nopens, I.; van der Graaf, J.H.J.M. The (in)significance of apparent viscosity in full-scale municipal membrane bioreactors. J. Membr. Sci. 2009, 340, 249–256. [Google Scholar] [CrossRef]

- Van den Broeck, R.; Krzeminski, P.; van Dierdonck, J.; Gins, G.; Lousada-Ferreira, M.; van Impe, J.F.M.; van der Graaf, J.H.J.M.; Smets, I.Y.; van Lier, J.B. Activated sludge characteristics affecting sludge filterability in municipal and industrial MBRs: Unraveling correlations using multi-component regression analysis. J. Membr. Sci. 2011, 330–338. [Google Scholar]

- Van den Broeck, R.; van Dierdonck, J.; Nijskens, P.; Dotremont, C.; Krzeminski, P.; van der Graaf, J.H.J.M.; van Lier, J.B.; van Impe, J.F.M.; Smets, I.Y. The influence of solids retention time on activated sludge bioflocculation in a membrane bioreactor. J. Membr. Sci. 2012, 401, 48–55. [Google Scholar]

- Evenblij, H.; Verrecht, B.; van der Graaf, J.H.J.M.; van der Bruggen, B. Manipulating filterability of MBR activated sludge by pulsed substrate addition. Desalination 2005, 178, 193–201. [Google Scholar] [CrossRef]

- Gil, J.A.; Krzeminski, P.; van Lier, J.B.; van der Graaf, J.H.J.M.; Wijffels, T.; van den Broeck, R.; Smets, I.Y.; van Impe, J.F.M.; Prats, D. MBR performance: Operational problems in industry. Filtr. Separ. 2011, 48, 36–41. [Google Scholar]

- Jiang, T.; Kennedy, M.D.; van der Meer, W.G.J.; Vanrolleghem, P.A.; Schippers, J.C. The role of blocking and cake filtration in MIBR fouling. Desalination 2003, 157, 335–343. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Lousada-Ferreira, M.; Krzeminski, P.; Geilvoet, S.; Moreau, A.; Gil, J.A.; Evenblij, H.; Van Lier, J.B.; Van der Graaf, J.H.J.M. Filtration Characterization Method as Tool to Assess Membrane Bioreactor Sludge Filterability—The Delft Experience. Membranes 2014, 4, 227-242. https://doi.org/10.3390/membranes4020227

Lousada-Ferreira M, Krzeminski P, Geilvoet S, Moreau A, Gil JA, Evenblij H, Van Lier JB, Van der Graaf JHJM. Filtration Characterization Method as Tool to Assess Membrane Bioreactor Sludge Filterability—The Delft Experience. Membranes. 2014; 4(2):227-242. https://doi.org/10.3390/membranes4020227

Chicago/Turabian StyleLousada-Ferreira, Maria, Pawel Krzeminski, Stefan Geilvoet, Adrien Moreau, Jose A. Gil, Herman Evenblij, Jules B. Van Lier, and Jaap H. J. M. Van der Graaf. 2014. "Filtration Characterization Method as Tool to Assess Membrane Bioreactor Sludge Filterability—The Delft Experience" Membranes 4, no. 2: 227-242. https://doi.org/10.3390/membranes4020227

APA StyleLousada-Ferreira, M., Krzeminski, P., Geilvoet, S., Moreau, A., Gil, J. A., Evenblij, H., Van Lier, J. B., & Van der Graaf, J. H. J. M. (2014). Filtration Characterization Method as Tool to Assess Membrane Bioreactor Sludge Filterability—The Delft Experience. Membranes, 4(2), 227-242. https://doi.org/10.3390/membranes4020227