Influence of Process Parameters on the Efficiency of Pervaporation Pilot ECO-001 Plant for Raw Ethanol Dehydration

Abstract

1. Introduction

2. Experimental

- i.

- A thin selective skin layer is prepared using cross-linked PVA. This top layer is responsible for the membrane selectivity and permeability. The mode of PVA deposition and crosslinking degree determines the membrane properties. The thickness of this layer is up to 10 μm.

- ii.

- Intermediate ultrafiltration support. This layer (40–60 μm thick) is prepared by a phase inversion method usually from polyacrylonitrile (PAN).

- iii.

- The polyester non-woven backing fabric. This layer (80–120 μm thick) does not influence either selectivity or permeate flux.

3. Results and Discussion

4. Conclusions

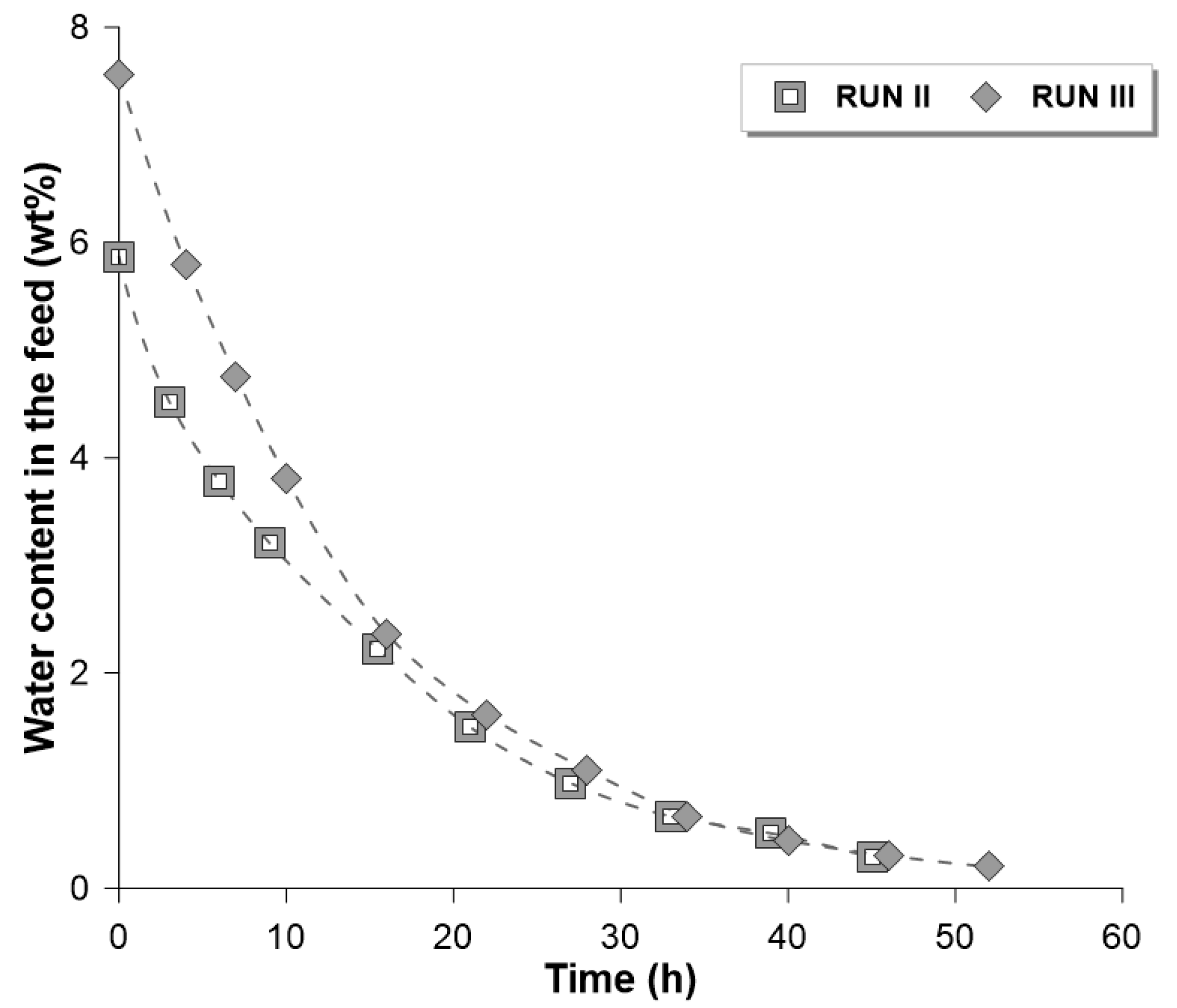

- During the dehydration of ethanol by using the pervaporation ECO-001 unit, up to 99 wt% of water was removed from the feed mixture, reaching the final water content in the product solution equal to 0.1 wt% (average separation factor β was equal to 700). It has to be underlined that pervaporation allows one to obtain an even lower level of water content in the feed mixture; however, in such a case, the PV process should be performed longer. Moreover, an additional increase in the process efficiency would be obtained if the modules equipped with membranes of larger membrane areas were applied.

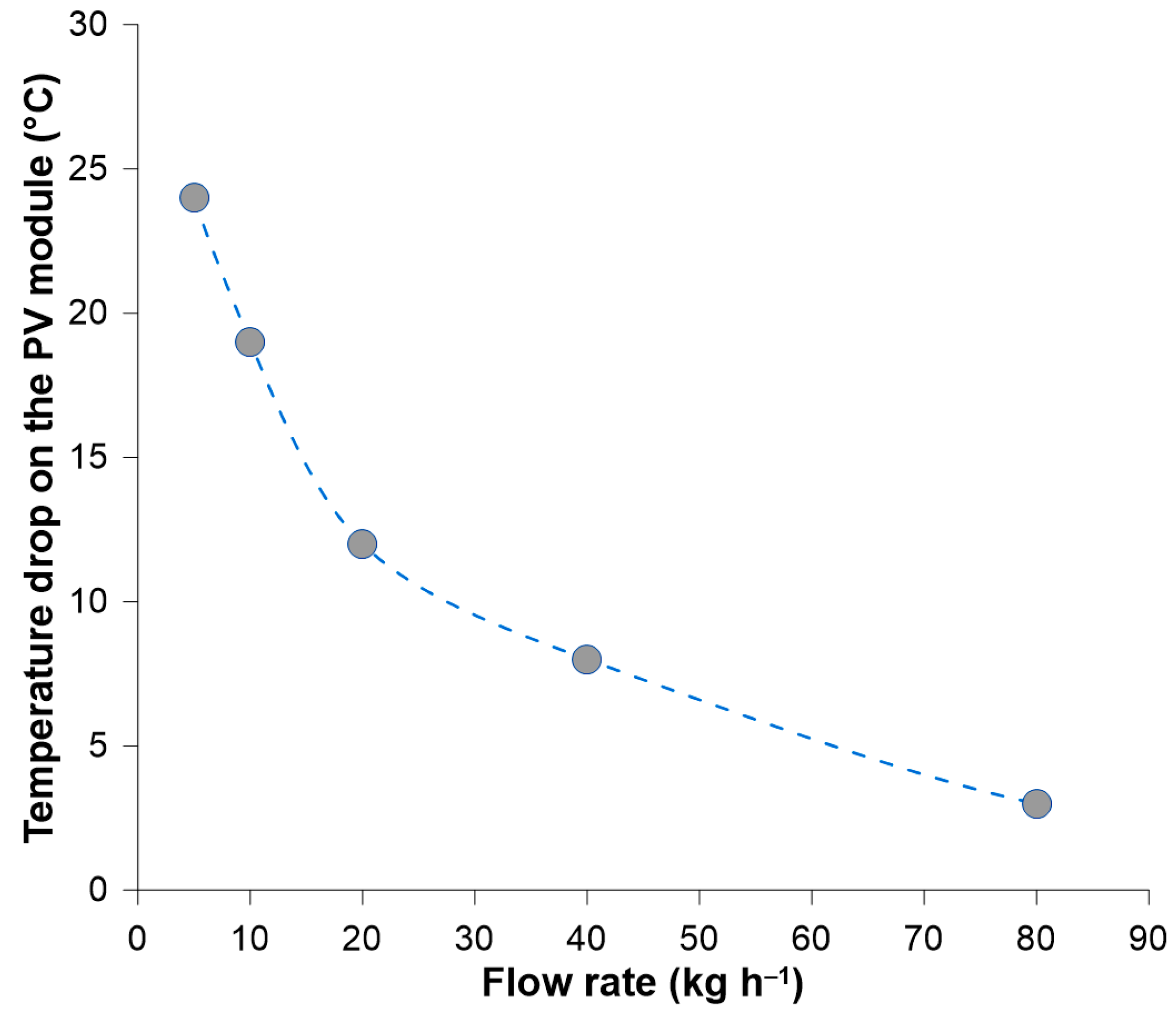

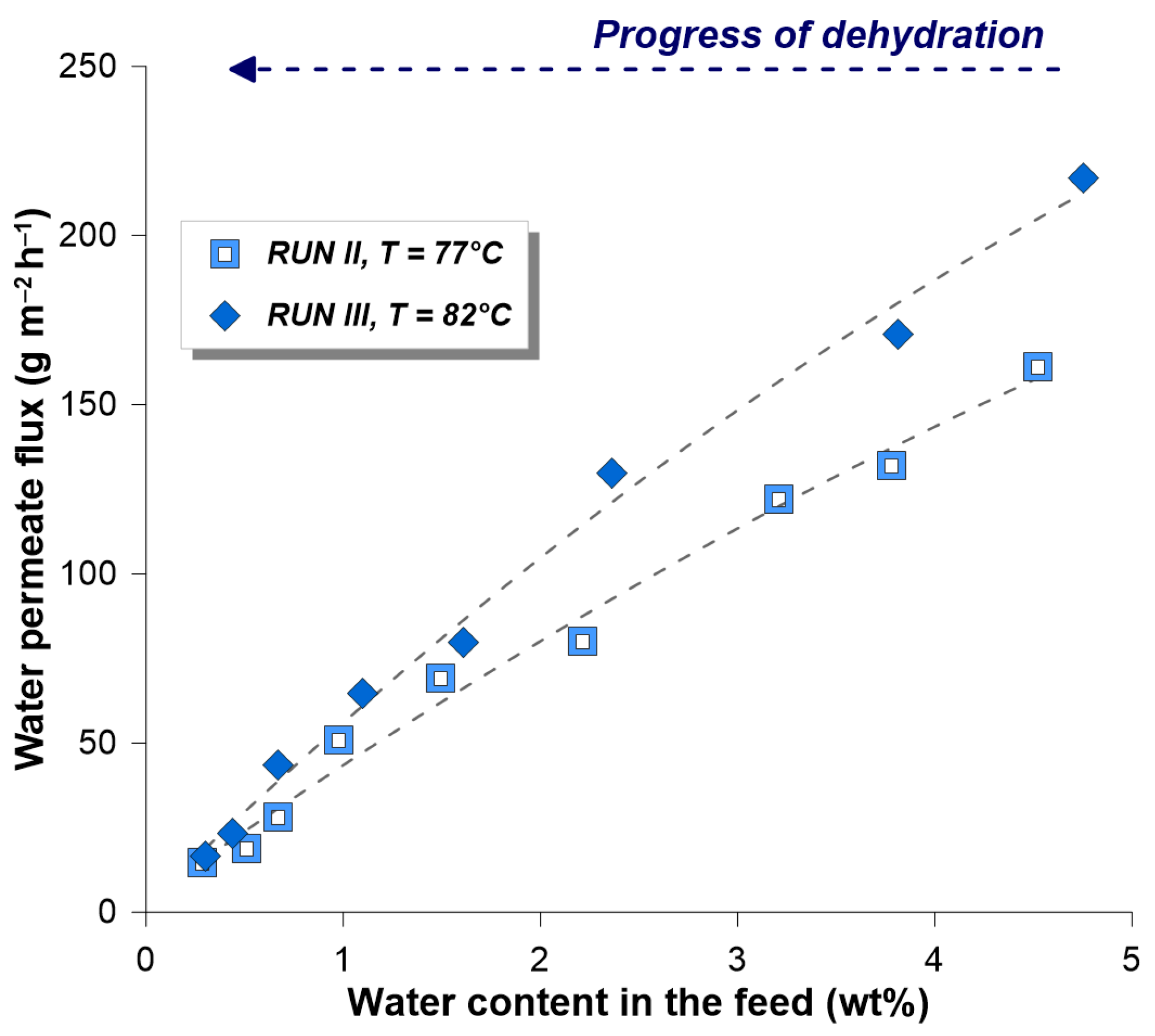

- The feed temperature and the initial water content were the most important parameters influencing the efficiency of the process. The permeate flux increased substantially with temperature increase, reducing the time necessary to reach the assumed final water level.

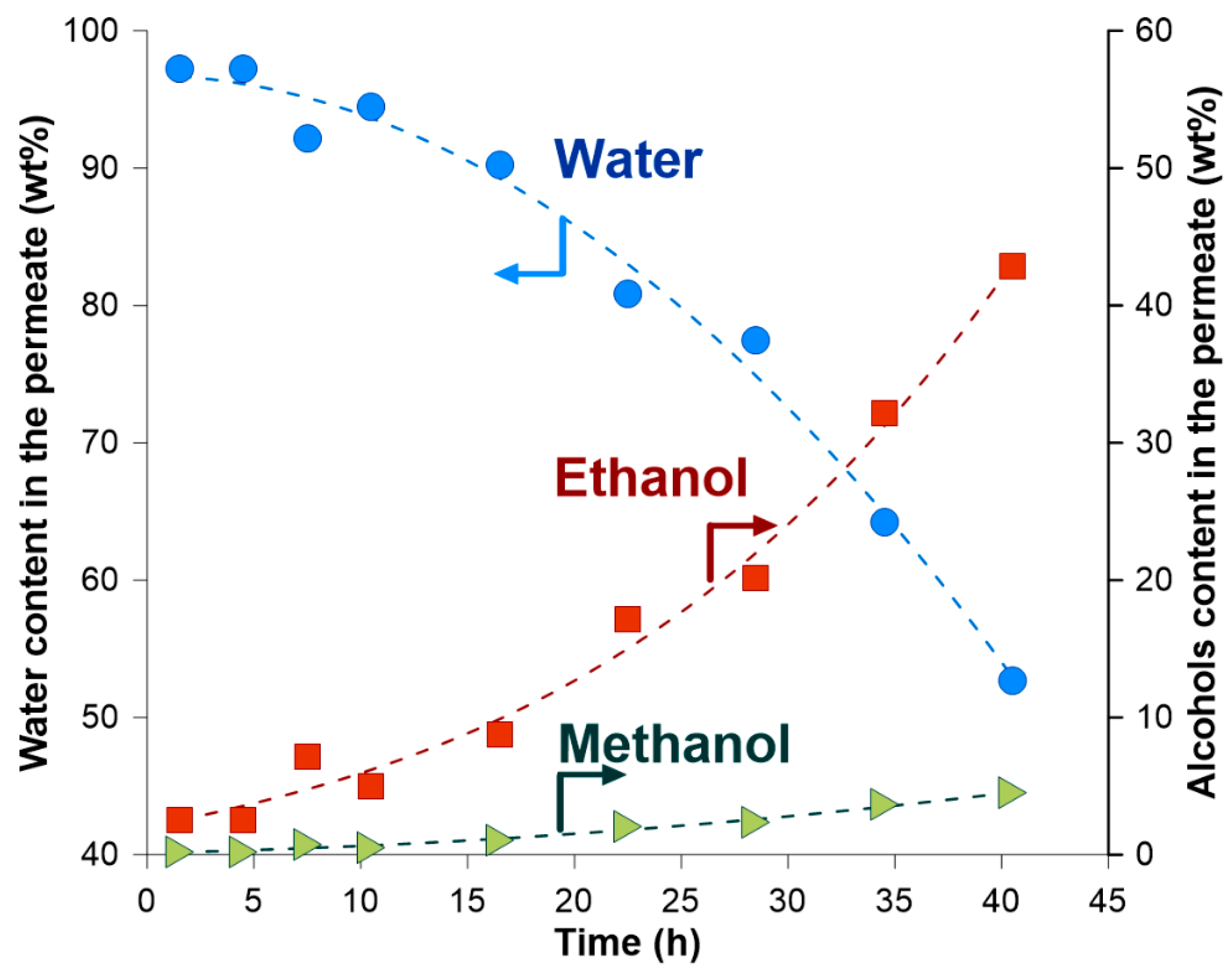

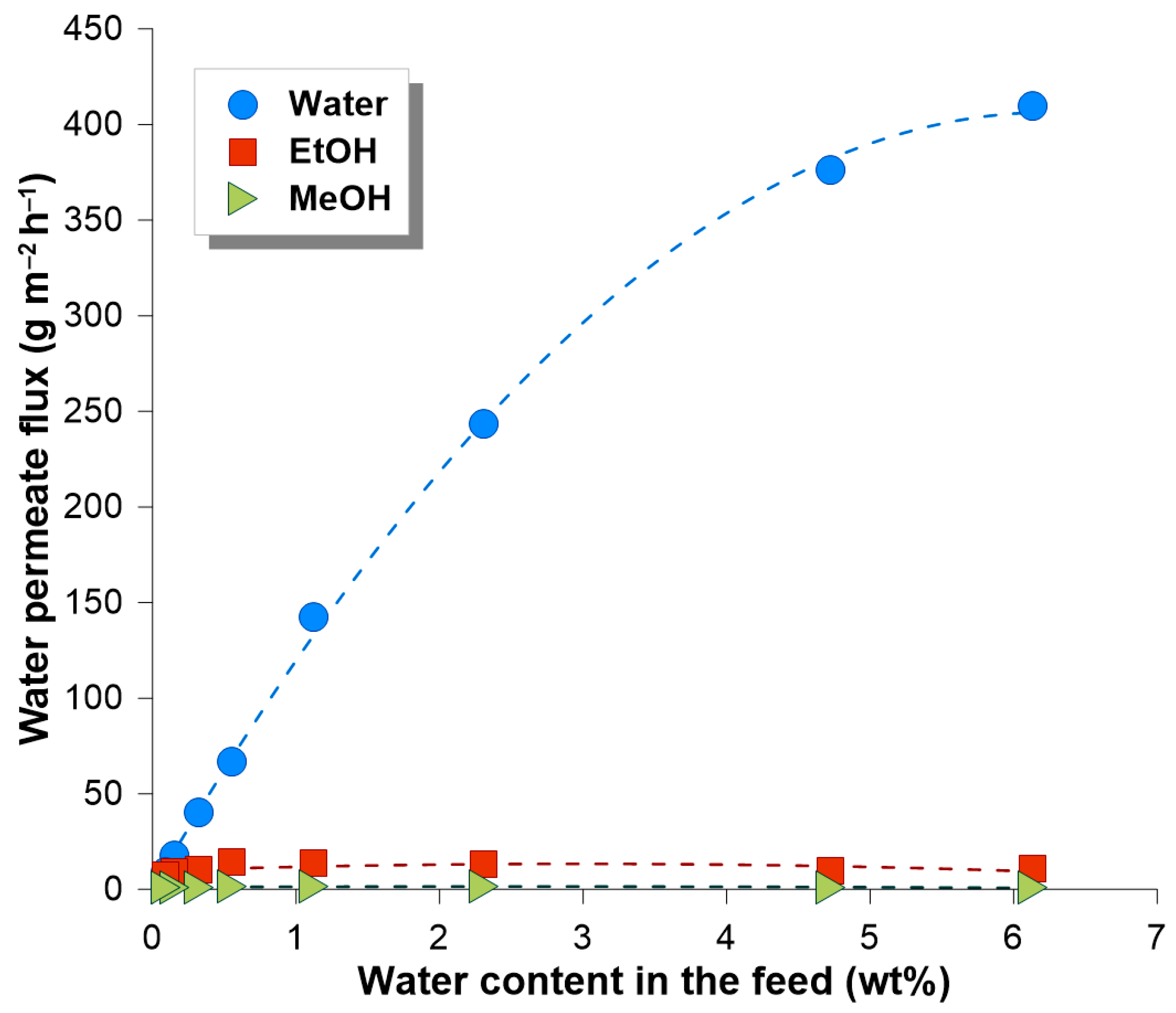

- Ethanol and methanol as polar components permeated also through the membrane; however, the cumulative content of both alcohols in the permeate was lower than 10 wt%.

- The ECO-001 unit equipped with hydrophilic PERVAPTM membranes is an ideal approach to test various organic solvents for dehydration applications. Nowadays, pervaporation can be used as the simple and efficient method for ethanol dehydration either as the separated method or coupled with an existing dehydration system (i.e., entrainer distillation or molecular sieves units).

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| AD | Azeotropic distillation |

| Co-SiO2 | Cobalt doped silica |

| DPSU | Distillation-Pervaporation in a Single Unit |

| DWC | Dividing-wall columns |

| EtOH | Ethanol |

| E-DWC | Extractive dividing-wall column |

| ExD | Extractive distillation |

| GO | Graphene oxide |

| MSA | Mass separating agents |

| MSC | Molecular-sieving carbon |

| PSI | Pervaporation Separation Index |

| PV | Pervaporation |

| PVA | Poly (vinyl alcohol) |

| SGPV | Sweeping gas pervaporation |

| SQP | Sequential quadratic programming |

| TPV | Thermopervaporation |

| VPV | Vacuum pervaporation |

References

- Castro-Munoz, R.; Buera-Gonzalez, J.; de la Iglesia, O.; Galiano, F.; Fila, V.; Malankowska, M.; Rubio, C.; Figoli, A.; Tellez, C.; Coronas, J. Towards the dehydration of ethanol using pervaporation cross-linked poly (vinyl alcohol)/graphene oxide membranes. J. Membr. Sci. 2019, 582, 423–434. [Google Scholar] [CrossRef]

- Berthele, H.; Sella, O.; Lavarde, M.; Mielcarek, C.; Pense-Lheritier, A.M.; Pirnay, S. Determination of the influence of factors (ethanol, pH and a W) on the preservation of cosmetics using experimental design. Int. J. Cosmet. Sci. 2014, 36, 54–61. [Google Scholar] [CrossRef] [PubMed]

- Meyers, C.; Kass, R.; Goldenberg, D.; Milici, J.; Alam, S.; Robison, R. Ethanol and isopropanol inactivation of human coronavirus on hard surfaces. J. Hosp. Infect. 2021, 107, 45–49. [Google Scholar] [CrossRef] [PubMed]

- Bueno, M.; Gallego, R.; Chourio, A.M.; Ibáñez, E.; Herrero, M.; Saldaña, M.D.A. Green ultra-high pressure extraction of bioactive compounds from Haematococcus pluvialis and Porphyridium cruentum microalgae. Innov. Food Sci. Emerg. Technol. 2020, 66, 102532. [Google Scholar] [CrossRef]

- Kujawska, A.; Kujawski, J.; Bryjak, M.; Kujawski, W. ABE fermentation products recovery methods—A review. Renew. Sust. Energ. Rev. 2015, 48, 648–661. [Google Scholar] [CrossRef]

- Baeyens, J.; Kang, Q.; Appels, L.; Dewil, R.; Lv, Y.Q.; Tan, T.W. Challenges and opportunities in improving the production of bio-ethanol. Prog. Energy Combust. Sci. 2015, 47, 60–88. [Google Scholar] [CrossRef]

- Seo, D.J.; Takenaka, A.; Fujita, H.; Mochidzuki, K.; Sakoda, A. Practical considerations for a simple ethanol concentration from a fermentation broth via a single adsorptive process using molecular-sieving carbon. Renew. Energy 2018, 118, 257–264. [Google Scholar] [CrossRef]

- Chen, W.C.; Sheng, C.T.; Liu, Y.C.; Chen, W.J.; Huang, W.L.; Chang, S.H.; Chang, W.C. Optimizing the efficiency of anhydrous ethanol purification via regenerable molecular sieve. Appl. Energy 2014, 135, 483–489. [Google Scholar] [CrossRef]

- Guo, M.; Song, W. Buhain, Bioenergy and biofuels: History, status, and perspective. Renew. Sust. Energ. Rev. 2015, 42, 712–725. [Google Scholar] [CrossRef]

- Lopes, M.L.; Paulillo, S.C.D.L.; Godoy, A.; Cherubin, R.A.; Lorenzi, M.S.; Giometti, F.H.C.; Bernardino, C.D.; Neto, H.B.D.A.; Amorim, H.V.D. Ethanol production in Brazil: A bridge between science and industry. Braz. J. Microbiol. 2016, 47, 64–76. [Google Scholar] [CrossRef]

- Kiss, A.A.; Ignat, R.M. Innovative single step bioethanol dehydration in an extractive dividing-wall column. Sep. Purif. Technol. 2012, 98, 290–297. [Google Scholar] [CrossRef]

- EN 15376:2014; Automotive Fuels—Ethanol as a Blending Component for Petrol—Requirements and Test Methods. European Committee for Standardization: Brussels, Belgium, 2014.

- ASTM D4806-21a; Standard Specification for Denatured Fuel Ethanol for Blending with Gasolines for Use as Automotive Spark-Ignition Engine Fuel. ASTM International: West Conshohocken, PA, USA, 2021.

- Kiss, A.A.; Suszwalak, D. Enhanced bioethanol dehydration by extractive and azeotropic distillation in dividing-wall columns. Sep. Purif. Technol. 2012, 86, 70–78. [Google Scholar] [CrossRef]

- Battisti, R.; Urruth, N.S.; Machado, R.A.F.; Marangoni, C. Optimization of Pressure-Swing Distillation for i C-5-Methanol Azeotropic Mixture Purification. Process Integr. Optim. Sustain. 2020, 4, 255–263. [Google Scholar] [CrossRef]

- Ma, S.T.; Shang, X.Y.; Li, L.M.; Song, Y.F.; Pan, Q.; Sun, L.Y. Energy-saving thermally coupled ternary extractive distillation process using ionic liquids as entrainer for separating ethyl acetate-ethanol-water ternary mixture. Sep. Purif. Technol. 2019, 226, 337–349. [Google Scholar] [CrossRef]

- Saini, S.; Chandel, A.; Sharma, K. Past practices and current trends in recovery and purification of first generation ethanol: A learning curve for lignocellulosic ethanol. J. Clean. Prod. 2020, 268, 122357. [Google Scholar] [CrossRef]

- Confalonieri, G.; Quartieri, S.; Vezzalini, G.; Tabacchi, G.; Fois, E.; Daou, T.J.; Arletti, R. Differential penetration of ethanol and water in Si-chabazite: High pressure dehydration of azeotrope solution. Microporous Mesoporous Mater. 2019, 284, 161–169. [Google Scholar] [CrossRef]

- Zhu, Z.Y.; Yu, M.X.; Zhang, W.X.; Liu, Y.G.; Cui, P.Z.; Yang, J.W.; Wang, Y.L.; Gao, J. Exploration of the effects of pressure on the controllability of extractive distillation for separating pressure-sensitive azeotropes. Sep. Purif. Technol. 2019, 227, 18. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Z.J.; Xu, X.; Gao, J.; Xu, D.M.; Zhang, L.Z.; Wang, Y.L. Entrainers selection and vapour-liquid equilibrium measurements for separating azeotropic mixtures (ethanol plus n-hexane/cyclohexane) by extractive distillation. J. Chem. Thermodyn. 2020, 144, 106070. [Google Scholar] [CrossRef]

- Quijada-Maldonado, E.; Meindersma, G.W.; de Haan, A.B. Ionic liquid effects on mass transfer efficiency in extractive distillation of water–ethanol mixtures. Comput. Chem. Eng. 2014, 71, 210–219. [Google Scholar] [CrossRef]

- Pan, Q.; Shang, X.Y.; Li, J.; Ma, S.T.; Li, L.M.; Sun, L. Energy-efficient separation process and control scheme for extractive distillation of ethanol-water using deep eutectic solvent. Sep. Purif. Technol. 2019, 219, 113–126. [Google Scholar] [CrossRef]

- Li, J.; Li, R.C.; Zhou, H.; Yang, X.; Ma, Z.H.; Sun, L.Y.; Zhang, N. Energy-Saving Ionic Liquid-Based Extractive Distillation Configurations for Separating Ternary Azeotropic System of Tetrahydrofuran/Ethanol/Water. Ind. Eng. Chem. Res. 2019, 58, 16858–16868. [Google Scholar] [CrossRef]

- Kunnakorn, D.; Rirksomboon, T.; Siemanond, K.; Aungkavattana, P.; Kuanchertchoo, N.; Chuntanalerg, P.; Hemra, K.; Kulprathipanja, S.; James, R.B.; Wongkasemjit, S. Techno-economic comparison of energy usage between azeotropic distillation and hybrid system for water–ethanol separation. Renew. Energ. 2013, 51, 310–316. [Google Scholar] [CrossRef]

- Tomaszewska, M.; Bialonczyk, L. The investigation of ethanol separation by the membrane distillation process. Pol. J. Environ. Stud. 2011, 13, 66–69. [Google Scholar] [CrossRef]

- Mahdi, T.; Ahmad, A.; Mahmoud Nasef, M.; Ripin, A. State-of-the-Art Technologies for Separation of Azeotropic Mixtures. Sep. Purif. Rev. 2015, 44, 308–330. [Google Scholar] [CrossRef]

- Zhu, Z.; Xu, D.; Liu, X.; Zhang, Z.; Wang, Y. Separation of acetonitrile/methanol/benzene ternary azeotrope via triple column pressure-swing distillation. Sep. Purif. Technol. 2016, 169, 66–77. [Google Scholar] [CrossRef]

- Vane, L.M. Review of pervaporation and vapor permeation process factors affecting the removal of water from industrial solvents. J. Chem. Technol. Biotechnol. 2020, 95, 495–512. [Google Scholar] [CrossRef] [PubMed]

- Cai, W.B.; Cheng, X.; Chen, X.H.; Li, J.D.; Pei, J.Q. Poly(vinyl alcohol)-Modified Membranes by Ti3C2Tx for Ethanol Dehydration via Pervaporation. ACS Omega 2020, 5, 6277–6287. [Google Scholar] [CrossRef] [PubMed]

- Neto, A.P.A.; Neto, G.W.F.; Neves, T.G.; Ramos, W.B.; Brito, K.D.; Brito, R.P. Changing product specification in extractive distillation process using intelligent control system. Neural Comput. Appl. 2020, 32, 13255–13266. [Google Scholar] [CrossRef]

- Rouquerol, F. Adsorption by Powders and Porous Solids: Principles, Methodology and Applications; Academic Press: Oxford, UK, 2014. [Google Scholar]

- Simo, M.; Sivashanmugam, S.; Brown, C.J.; Hlavacek, V. Adsorption/Desorption of Water and Ethanol on 3A Zeolite in Near-Adiabatic Fixed Bed. Ind. Eng. Chem. Res. 2009, 48, 9247–9260. [Google Scholar] [CrossRef]

- Nagy, E. (Ed.) 11—Pervaporation. In Basic Equations of the Mass Transport through a Membrane Layer; Elsevier: Oxford, UK, 2012; pp. 267–291. [Google Scholar]

- Wijmans, J.G.; Baker, R.W. The solution-diffusion model—A review. J. Membr. Sci. 1995, 107, 1–21. [Google Scholar] [CrossRef]

- Crespo, J.G. 1—Fundamentals of pervaporation. In Pervaporation, Vapour Permeation and Membrane Distillation; Basile, A., Khayet, A.F., Eds.; Woodhead Publishing: Oxford, UK, 2015; pp. 3–17. [Google Scholar]

- Kujawski, W. Application of pervaporation and vapor permeation in environmental protection. Pol. J. Environ. Stud. 2000, 9, 13–26. [Google Scholar]

- Shao, P.; Huang, R.Y.M. Polymeric membrane pervaporation. J. Membr. Sci. 2007, 287, 162–179. [Google Scholar] [CrossRef]

- Kujawska, A.; Knozowska, K.; Kujawa, J.; Kujawski, W. Influence of downstream pressure on pervaporation properties of PDMS and POMS based membranes. Sep. Purif. Technol. 2016, 159, 68–80. [Google Scholar] [CrossRef]

- Baker, R. Membrane Technology and Applications, 3rd ed.; John Wiley & Sons Ltd.: Chichester, UK, 2012. [Google Scholar]

- Vallieres, C.; Favre, E. Vacuum versus sweeping gas operation for binary mixtures separation by dense membrane processes. J. Membr. Sci. 2004, 244, 17–23. [Google Scholar] [CrossRef]

- Kujawski, W.; Krajewski, S.R. Sweeping gas pervaporation with hollow-fiber ion-exchange membranes. Desalination 2004, 162, 129–135. [Google Scholar] [CrossRef]

- Kujawska, A.; Kujawski, J.; Bryjak, M.; Kujawski, W. Removal of volatile organic compounds from aqueous solutions applying thermally driven membrane processes. 1. Thermopervaporation. Chem. Eng. Process.-Process Intensif. 2015, 94, 62–71. [Google Scholar] [CrossRef]

- Borisov, I.L.; Volkov, V.V. Thermopervaporation concept for biobutanol recovery: The effect of process parameters. Sep. Purif. Technol. 2015, 146, 33–41. [Google Scholar] [CrossRef]

- Conde-Mejía, C.; Jiménez-Gutiérrez, A. Analysis of ethanol dehydration using membrane separation processes. Open Life Sci. 2020, 15, 122–132. [Google Scholar] [CrossRef]

- Kujawski, J.K.; Kujawski, W.M.; Sondej, H.; Jarzynka, K.; Kujawska, A.; Bryjak, M.; Rynkowska, E.; Knozowska, K.; Kujawa, J. Dewatering of 2,2,3,3-tetrafluoropropan-1-ol by hydrophilic pervaporation with poly(vinyl alcohol) based Pervap™ membranes. Sep. Purif. Technol. 2017, 174, 520–528. [Google Scholar] [CrossRef]

- Knozowska, K.; Kujawska, A.; Li, G.; Kujawa, J.; Bryjak, M.; Kujawski, W.; Lipnizki, F.; Ahrné, L.; Petrinić, I.; Kujawski, J.K. Membrane assisted processing of acetone, butanol, and ethanol (ABE) aqueous streams. Chem. Eng. Process.-Process Intensif. 2021, 166, 108462. [Google Scholar] [CrossRef]

- Wang, J.H.; Tsuru, T. Cobalt-doped silica membranes for pervaporation dehydration of ethanol/water solutions. J. Membr. Sci. 2011, 369, 13–19. [Google Scholar] [CrossRef]

- Novita, F.J.; Lee, H.Y.; Lee, M. Energy-efficient and ecologically friendly hybrid extractive distillation using a pervaporation system for azeotropic feed compositions in alcohol dehydration process. J. Taiwan Inst. Chem. Eng. 2018, 91, 251–265. [Google Scholar] [CrossRef]

- Kang, Q.; Huybrechts, J.; Van der Bruggen, B.; Baeyens, J.; Tan, T.W.; Dewil, R. Hydrophilic membranes to replace molecular sieves in dewatering the bio-ethanol/water azeotropic mixture. Sep. Purif. Technol. 2014, 136, 144–149. [Google Scholar] [CrossRef]

- León, J.A.; Schuur, B.; Fontalvo, J. Hybrid distillation-pervaporation in a single unit: Experimental proof of concept in a batch operation. Sep. Purif. Technol. 2020, 252, 117464. [Google Scholar] [CrossRef]

| Feed Composition [wt%] | ||||

|---|---|---|---|---|

| Component | Run I | Run II | Run III | Run IV |

| Water | 6.97 | 5.87 | 7.56 | 8.46 |

| Methanol | 6.81 | 6.86 | 2.40 | 2.29 |

| Ethanol | 82.45 | 84.63 | 89.64 | 88.83 |

| Higher alcohols (C3–C5) | 1.35 | 0.86 | 0.224 | 0.184 |

| Acetaldehyde | 0.020 | 0.027 | 0.005 | 0.004 |

| Cyclohexane | 2.40 | 1.76 | 0.17 | 0.23 |

| Run ID | Amount of the Feed [kg] | Feed Circulation Rate [kg/h] | Feed Temperature [°C] |

|---|---|---|---|

| I | 140 | 5–80 | 70–77 |

| II | 77 | 80 | 77 |

| III | 82 | 80 | 82 |

| IV | 87 | 80 | 92 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kujawska, A.; Kujawski, W.; Capała, W.; Kiełkowska, U.; Plesnar, M.; Kujawa, J. Influence of Process Parameters on the Efficiency of Pervaporation Pilot ECO-001 Plant for Raw Ethanol Dehydration. Membranes 2024, 14, 90. https://doi.org/10.3390/membranes14040090

Kujawska A, Kujawski W, Capała W, Kiełkowska U, Plesnar M, Kujawa J. Influence of Process Parameters on the Efficiency of Pervaporation Pilot ECO-001 Plant for Raw Ethanol Dehydration. Membranes. 2024; 14(4):90. https://doi.org/10.3390/membranes14040090

Chicago/Turabian StyleKujawska, Anna, Wojciech Kujawski, Wiesław Capała, Urszula Kiełkowska, Marek Plesnar, and Joanna Kujawa. 2024. "Influence of Process Parameters on the Efficiency of Pervaporation Pilot ECO-001 Plant for Raw Ethanol Dehydration" Membranes 14, no. 4: 90. https://doi.org/10.3390/membranes14040090

APA StyleKujawska, A., Kujawski, W., Capała, W., Kiełkowska, U., Plesnar, M., & Kujawa, J. (2024). Influence of Process Parameters on the Efficiency of Pervaporation Pilot ECO-001 Plant for Raw Ethanol Dehydration. Membranes, 14(4), 90. https://doi.org/10.3390/membranes14040090