Synthesis of Trimetallic Nanoparticle (NiCoPd)-Supported Carbon Nanofibers as a Catalyst for NaBH4 Hydrolysis

Abstract

:1. Introduction

2. Experimental

2.1. Materials

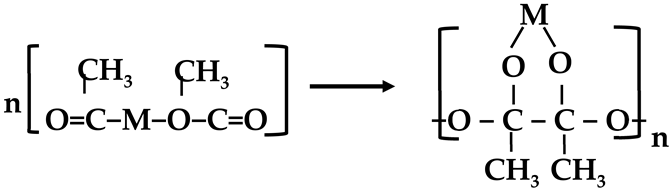

2.2. Preparation of the NiCoPd tri-NPs@CNFs Catalyst

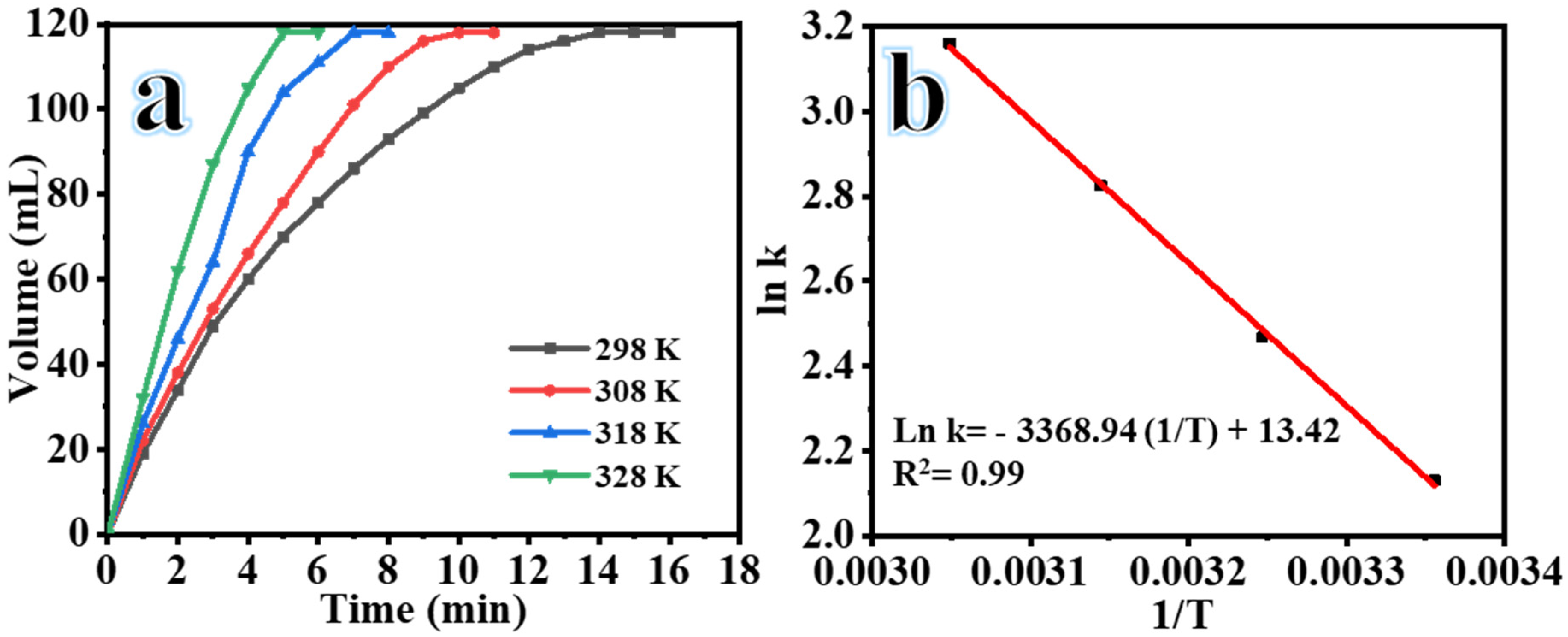

2.3. Characterization

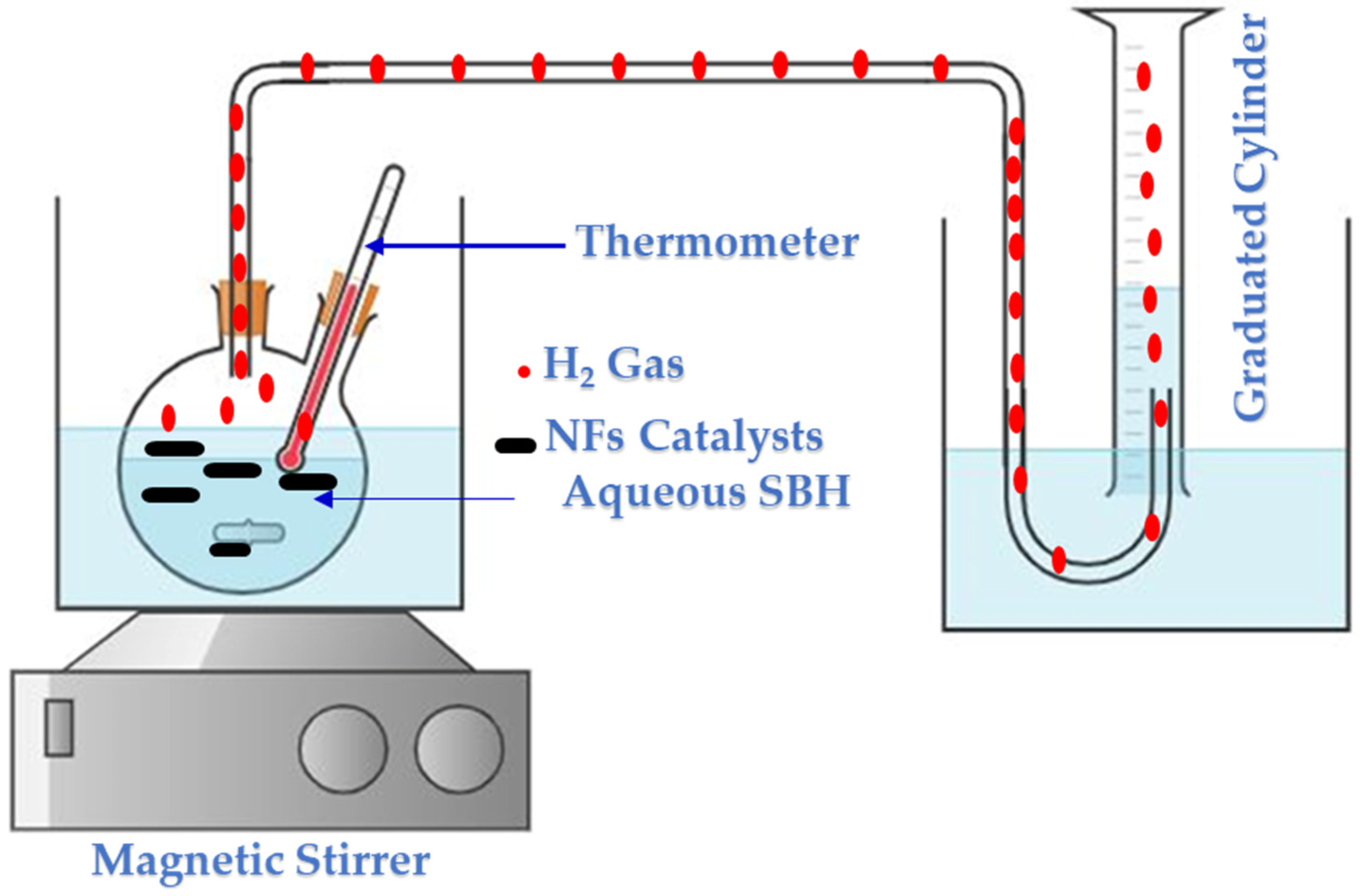

2.4. Hydrolysis of SBH Using the NiCoPd tri-NPs@CNFs Catalyst

3. Results and Discussion

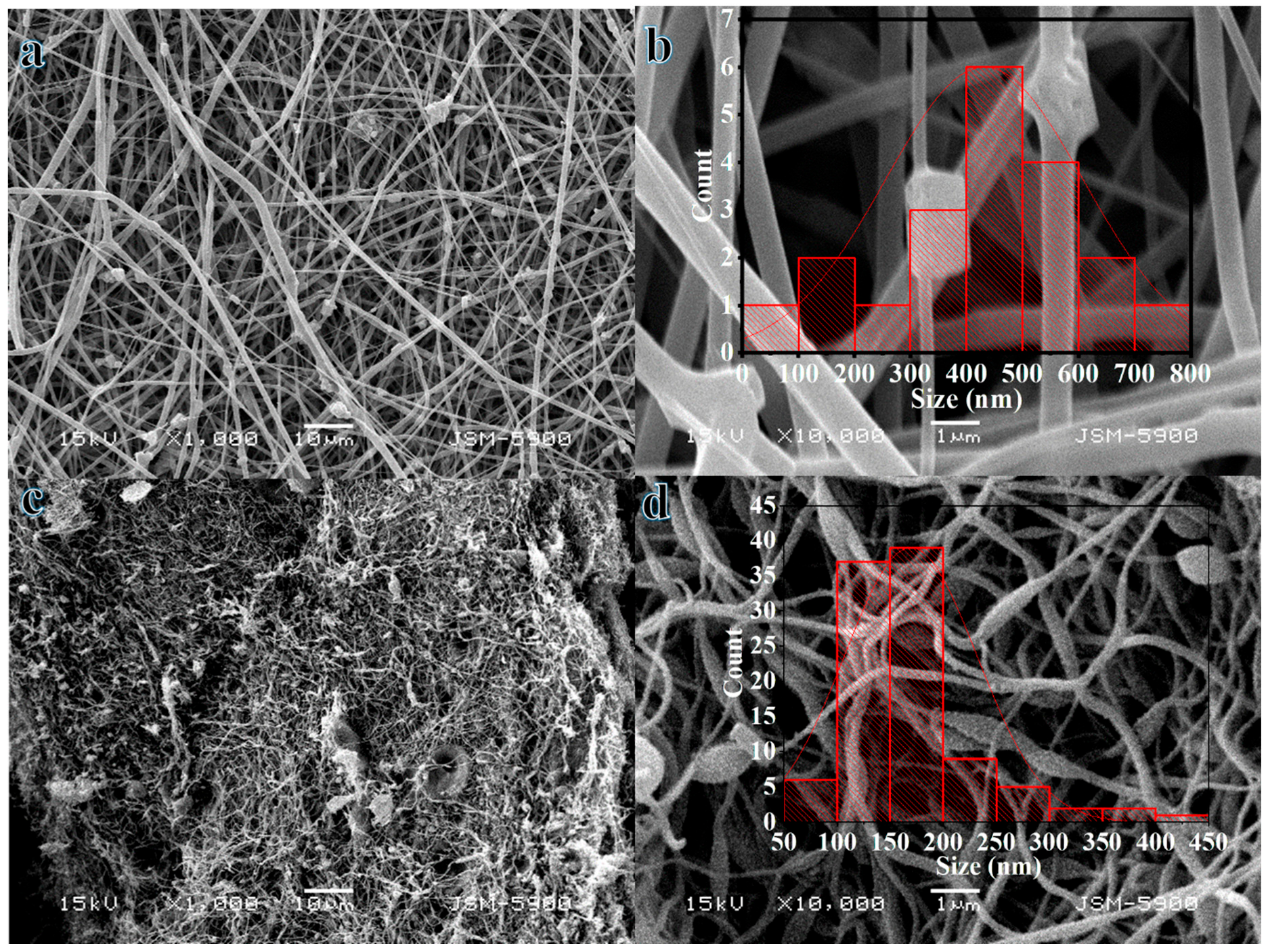

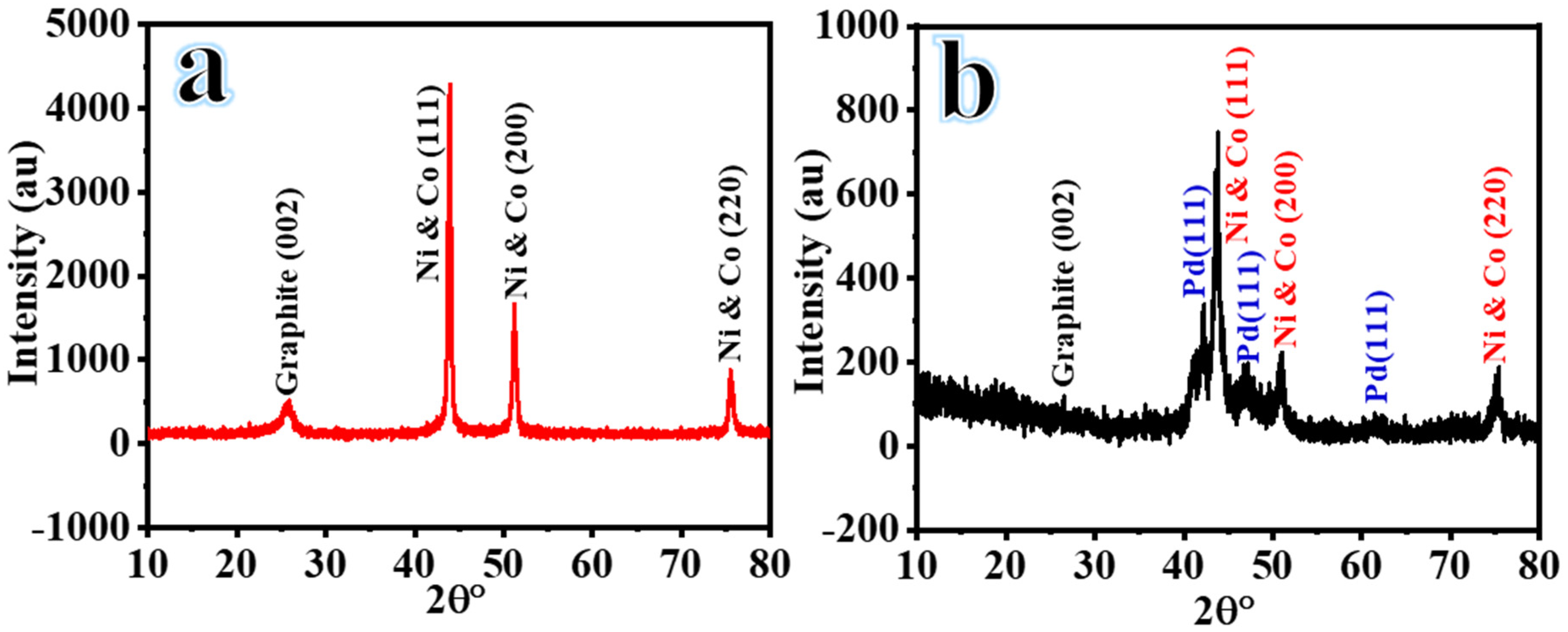

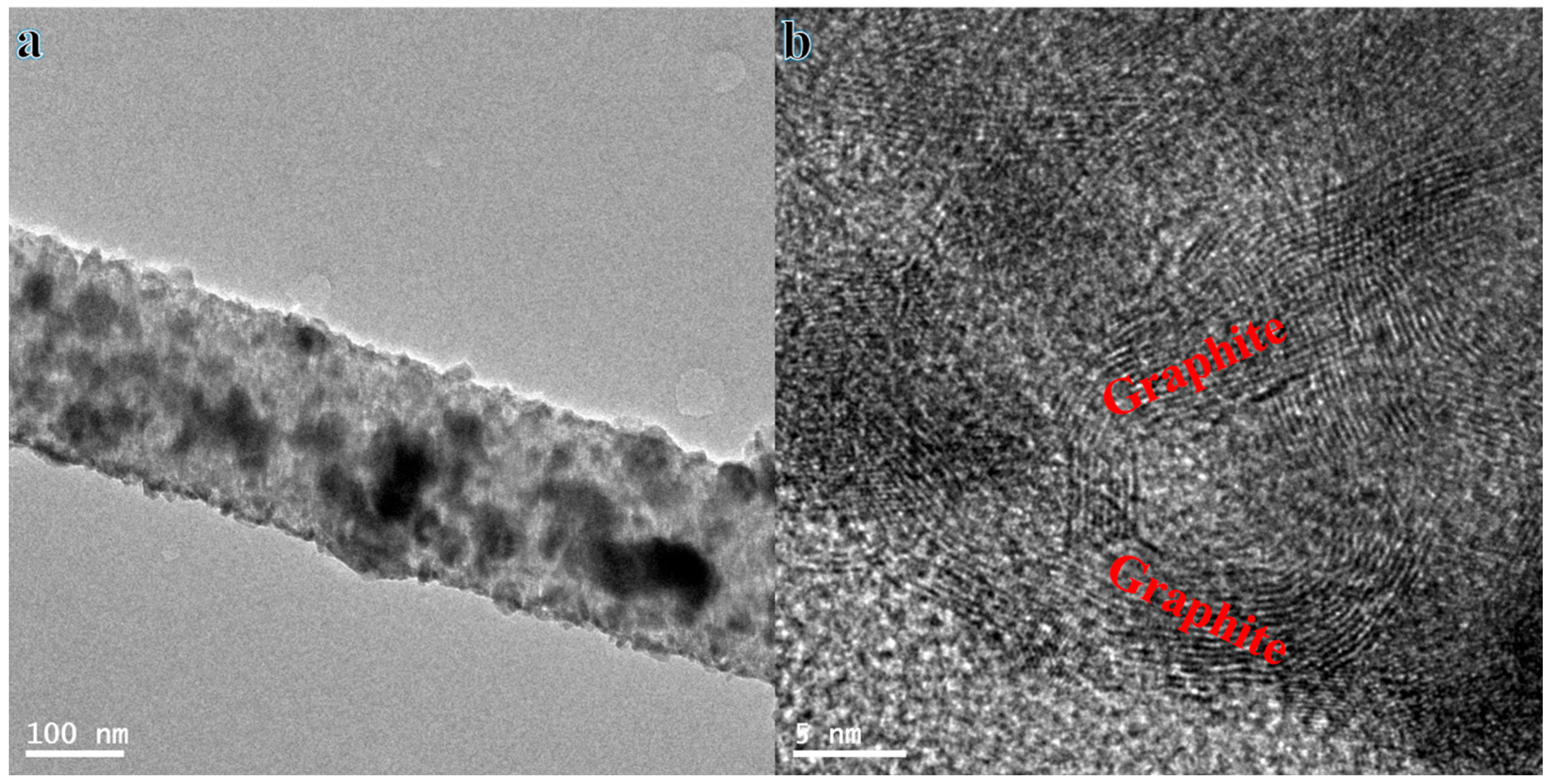

3.1. Characterization of Pd-NiCo@CNFs

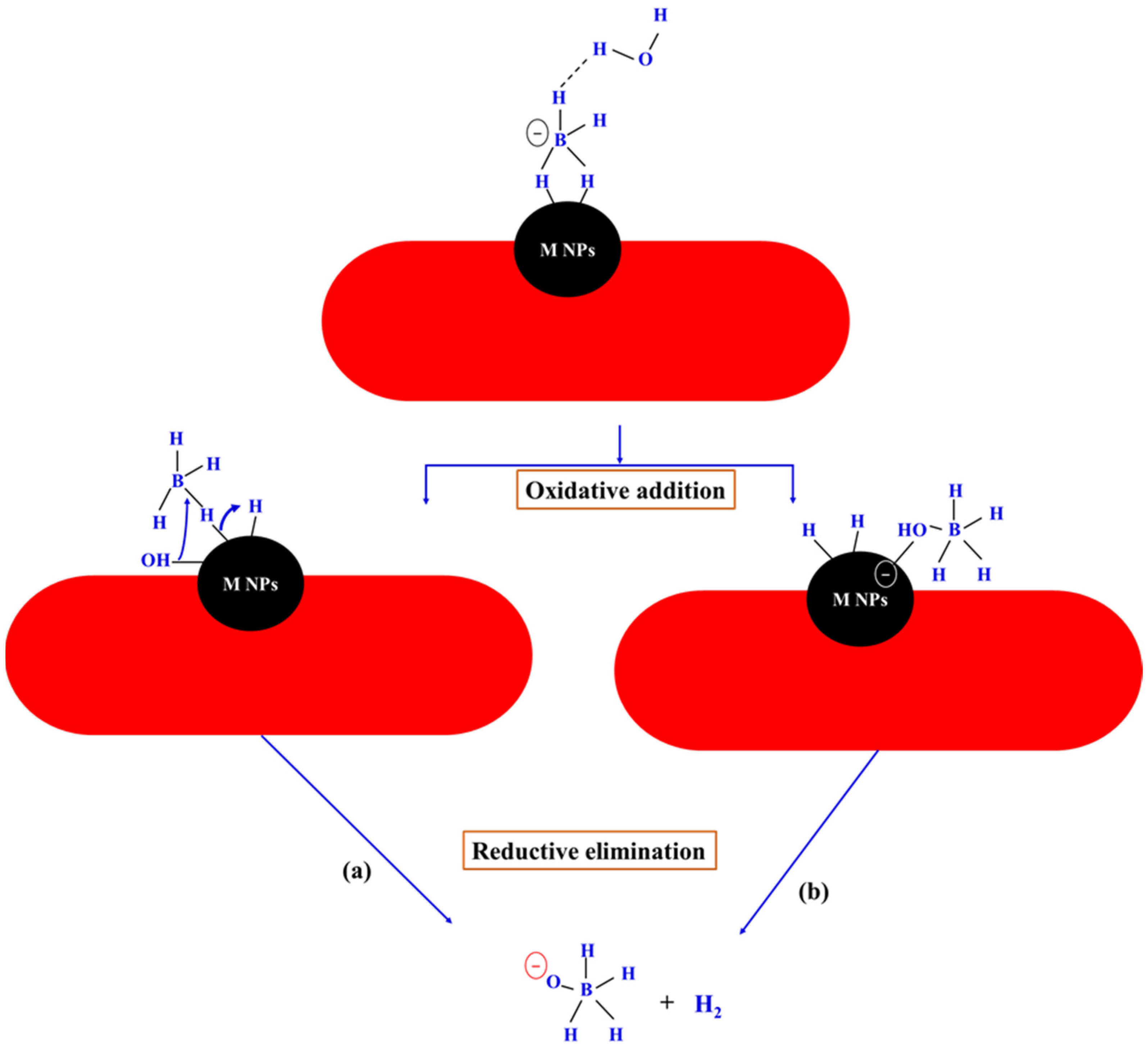

3.2. Catalytic Hydrolysis of SBH

4. Influences of Catalyst Dose

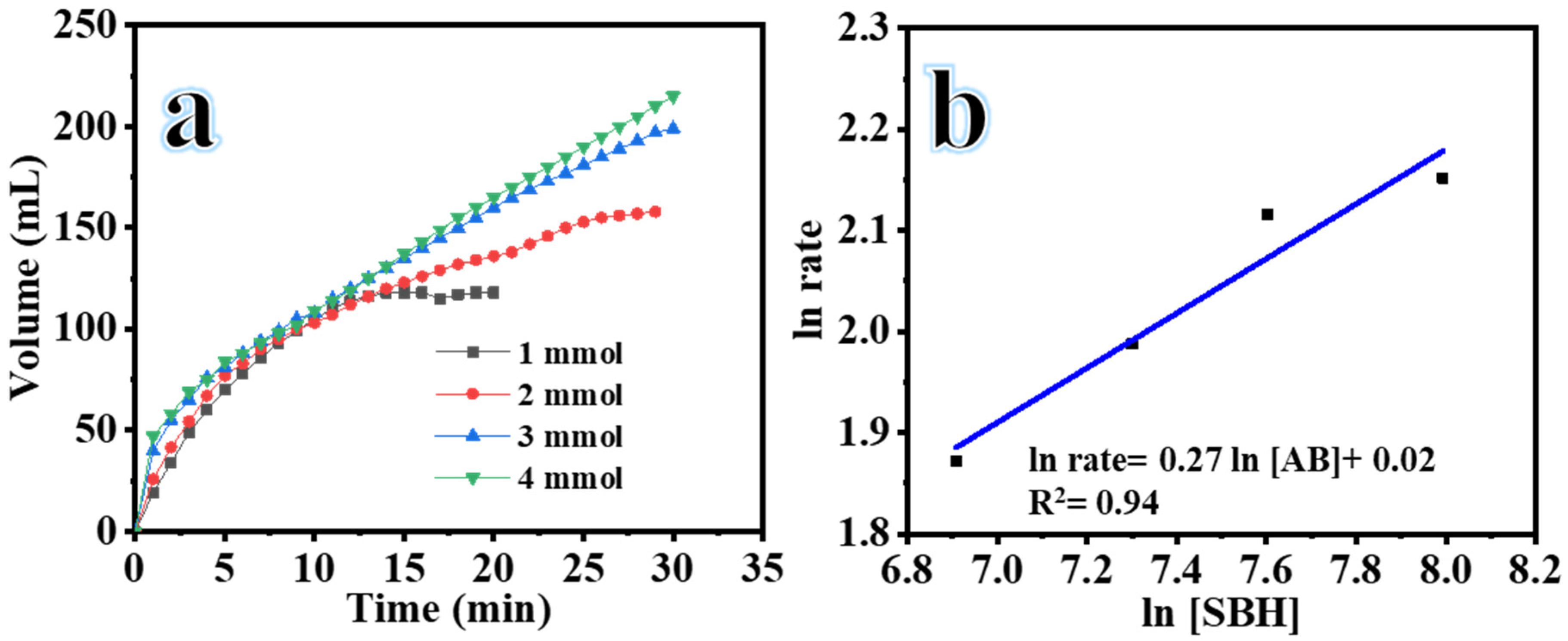

5. Influences of SBH Concentration

6. Influences of Reaction Temperature

7. Recyclability Studies of Ni0.3Co0.5Pd0.2 tri-NPs@CNFs Catalyst towards SBH Hydrolysis

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Barbir, F. Transition to renewable energy systems with hydrogen as an energy carrier. Energy 2009, 34, 308–312. [Google Scholar] [CrossRef]

- Jiao, C.; Huang, Z.; Wang, X.; Zhang, H.; Lu, L.; Zhang, S. Synthesis of Ni/Au/Co trimetallic nanoparticles and their catalytic activity for hydrogen generation from alkaline sodium borohydride aqueous solution. RSC Adv. 2015, 5, 34364–34371. [Google Scholar] [CrossRef]

- Cipriani, G.; Di Dio, V.; Genduso, F.; La Cascia, D.; Liga, R.; Miceli, R.; Galluzzo, G.R. Perspective on hydrogen energy carrier and its automotive applications. Int. J. Hydrogen Energy 2014, 39, 8482–8494. [Google Scholar] [CrossRef]

- Hamaed, A.; Hoang, T.K.A.; Moula, G.; Aroca, R.; Trudeau, M.L.; Antonelli, D.M. Hydride-induced amplification of performance and binding enthalpies in chromium hydrazide gels for Kubas-type hydrogen storage. J. Am. Chem. Soc. 2011, 133, 15434–15443. [Google Scholar] [CrossRef] [PubMed]

- Ou, T.; Barbucci, A.; Carpanese, P.; Congiu, S.; Panizza, M. Thermodynamic and kinetic studies of NaBH4 regeneration by NaBO2–Mg–H2 ternary system at isothermal condition. Int. J. Hydrogen Energy 2014, 39, 11094–11102. [Google Scholar] [CrossRef]

- Wee, J.-H.; Lee, K.-Y.; Kim, S.H. Sodium borohydride as the hydrogen supplier for proton exchange membrane fuel cell systems. Fuel Process. Technol. 2006, 87, 811–819. [Google Scholar] [CrossRef]

- Al-Enizi, A.M.; Nafady, A.; El-Halwany, M.M.; Brooks, R.M.; Abutaleb, A.; Yousef, A. Electrospun carbon nanofiber-encapsulated NiS nanoparticles as an efficient catalyst for hydrogen production from hydrolysis of sodium borohydride. Int. J. Hydrogen Energy 2019, 44, 21716–21725. [Google Scholar] [CrossRef]

- Tong, Y.; Lu, X.; Sun, W.; Nie, G.; Yang, L.; Wang, C. Electrospun polyacrylonitrile nanofibers supported Ag/Pd nanoparticles for hydrogen generation from the hydrolysis of ammonia borane. J. Power Sources 2014, 261, 221–226. [Google Scholar] [CrossRef]

- Lucarelli, C.; Albonetti, S.; Vaccari, A.; Resini, C.; Taillades, G.; Roziere, J.; Liew, K.-E.; Ohnesorge, A.; Wolff, C.; Gabellini, I. On-board H2 generation by catalytic dehydrogenation of hydrocarbon mixtures or fuels. Catal. Today 2011, 175, 504–508. [Google Scholar] [CrossRef]

- Crisafulli, C.; Scirè, S.; Salanitri, M.; Zito, R.; Calamia, S. Hydrogen production through NaBH4 hydrolysis over supported Ru catalysts: An insight on the effect of the support and the ruthenium precursor. Int. J. Hydrogen Energy 2011, 36, 3817–3826. [Google Scholar] [CrossRef]

- Gunnarsson, F.; Granlund, M.Z.; Englund, M.; Dawody, J.; Pettersson, L.J.; Härelind, H. Combining HC-SCR over Ag/Al2O3 and hydrogen generation over Rh/CeO2-ZrO2 using biofuels: An integrated system approach for real applications. Appl. Catal. B Environ. 2015, 162, 583–592. [Google Scholar] [CrossRef]

- Liu, Z.; Guo, B.; Chan, S.H.; Tang, E.H.; Hong, L. Pt and Ru dispersed on LiCoO2 for hydrogen generation from sodium borohydride solutions. J. Power Sources 2008, 176, 306–311. [Google Scholar] [CrossRef]

- Shih, Y.-J.; Su, C.-C.; Huang, Y.-H.; Lu, M.-C. SiO2-supported ferromagnetic catalysts for hydrogen generation from alkaline NaBH4 (sodium borohydride) solution. Energy 2013, 54, 263–270. [Google Scholar] [CrossRef]

- Dinc, M.; Metin, Ö.; Özkar, S. Water soluble polymer stabilized iron (0) nanoclusters: A cost-effective and magnetically recoverable catalyst in hydrogen generation from the hydrolysis of sodium borohydride and ammonia borane. Catal. Today 2012, 183, 10–16. [Google Scholar] [CrossRef]

- Lee, J.; Shin, H.; Choi, K.S.; Lee, J.; Choi, J.-Y.; Yu, H.K. Carbon layer supported nickel catalyst for sodium borohydride (NaBH4) dehydrogenation. Int. J. Hydrogen Energy 2019, 44, 2943–2950. [Google Scholar] [CrossRef]

- Zhu, J.; Li, R.; Niu, W.; Wu, Y.; Gou, X. Fast hydrogen generation from NaBH4 hydrolysis catalyzed by carbon aerogels supported cobalt nanoparticles. Int. J. Hydrogen Energy 2013, 38, 10864–10870. [Google Scholar] [CrossRef]

- Ai, L.; Gao, X.; Jiang, J. In situ synthesis of cobalt stabilized on macroscopic biopolymer hydrogel as economical and recyclable catalyst for hydrogen generation from sodium borohydride hydrolysis. J. Power Sources 2014, 257, 213–220. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, Y.; Peng, X.; Jing, C.; Hu, W.; Tian, S.; Tian, J. In situ synthesis of cobalt-based tri-metallic nanosheets as highly efficient catalysts for sodium borohydride hydrolysis. Int. J. Hydrogen Energy 2016, 41, 219–226. [Google Scholar] [CrossRef]

- Patil, K.N.; Prasad, D.; Manoorkar, V.K.; Nabgan, W.; Nagaraja, B.M.; Jadhav, A.H. Engineered nano-foam of tri-metallic (FeCuCo) oxide catalyst for enhanced hydrogen generation via NaBH4 hydrolysis. Chemosphere 2021, 281, 130988. [Google Scholar] [CrossRef]

- Wang, X.; Sun, S.; Huang, Z.; Zhang, H.; Zhang, S. Preparation and catalytic activity of PVP-protected Au/Ni bimetallic nanoparticles for hydrogen generation from hydrolysis of basic NaBH4 solution. Int. J. Hydrogen Energy 2014, 39, 905–916. [Google Scholar] [CrossRef]

- Khan, Z.; Al-Thabaiti, S.A.; Rafiquee, M.Z.A. Cu-based tri-metallic nanoparticles with noble metals (Ag, Pd, and Ir) and their catalytic activities for hydrogen generation. Int. J. Hydrogen Energy 2021, 46, 39754–39767. [Google Scholar] [CrossRef]

- Al-Msrhad, T.M.H.; Devrim, Y.; Uzundurukan, A.; Budak, Y. Investigation of hydrogen production from sodium borohydride by carbon nano tube-graphene supported PdRu bimetallic catalyst for PEM fuel cell application. Int. J. Energy Res. 2022, 46, 4156–4173. [Google Scholar] [CrossRef]

- Hansu, T.A. A novel and active ruthenium based supported multiwalled carbon nanotube tungsten nanoalloy catalyst for sodium borohydride hydrolysis. Int. J. Hydrogen Energy 2023, 48, 6788–6797. [Google Scholar] [CrossRef]

- Ivanenko, I.; Ruda, A. Cobalt, nitrogen-doped carbons as catalysts for sodium borohydride hydrolysis: Role of surface chemistry. J. Mater. Sci. 2022, 57, 1994–2011. [Google Scholar] [CrossRef]

- Saka, C. Phosphorus decorated g-C3N4-TiO2 particles as efficient metal-free catalysts for hydrogen release by NaBH4 methanolysis. Fuel 2022, 322, 124196. [Google Scholar] [CrossRef]

- Luo, X.; Sun, L.; Xu, F.; Cao, Z.; Zeng, J.; Bu, Y.; Zhang, C.; Xia, Y.; Zou, Y.; Zhang, K. Metal boride-decorated CoNi layered double hydroxides supported on muti-walled carbon nanotubes as efficient hydrolysis catalysts for sodium borohydride. J. Alloys Compd. 2023, 930, 167339. [Google Scholar] [CrossRef]

- Zhang, H.; Wei, Q.; Wu, G.; Qiu, S.; Zou, Y.; Xia, Y.; Xu, F.; Sun, L.; Chu, H. Zn-MOF-74-derived graphene nanosheets supporting CoB alloys for promoting hydrolytic dehydrogenation of sodium borohydride. J. Alloys Compd. 2023, 930, 167486. [Google Scholar] [CrossRef]

- Al-Enizi, A.M.; Yousef, A.; Shaikh, S.F.; Pandit, B.; El-Halwany, M.M. Electrospun Nickel Nanoparticles@ Poly (vinylidene fluoride-hexafluoropropylene) Nanofibers as Effective and Reusable Catalyst for H2 Generation from Sodium Borohydride. Arab. J. Chem. 2022, 15, 104207. [Google Scholar] [CrossRef]

- Al-Enizi, A.M.; Brooks, R.M.; Ahmad, M.; El-Halwany, M.; El-Newehy, M.H.; Yousef, A. In-situ synthesis of amorphous co nanoparticles supported onto TiO2 nanofibers as a catalyst for hydrogen generation from the hydrolysis of ammonia borane. J. Nanosci. Nanotechnol. 2018, 18, 4714–4719. [Google Scholar] [CrossRef]

- Yousef, A.; Brooks, R.M.; El-Halwany, M.; Obaid, M.; El-Newehy, M.H.; Al-Deyab, S.S.; Barakat, N.A. A novel and chemical stable Co–B nanoflakes-like structure supported over titanium dioxide nanofibers used as catalyst for hydrogen generation from ammonia borane complex. Int. J. Hydrogen Energy 2016, 41, 285–293. [Google Scholar] [CrossRef]

- Wang, H.; Zou, W.; Liu, C.; Sun, Y.; Xu, Y.; Sun, W.; Wang, Y. β-Ketoenamine-Linked Covalent Organic Framework with Co Intercalation: Improved Lithium-Storage Properties and Mechanism for High-Performance Lithium-Organic Batteries. Batter. Supercaps 2023, 6, e202200434. [Google Scholar] [CrossRef]

- Lu, Y.; Wu, D.; Qin, Y.; Xie, Y.; Ling, Y.; Ye, H.; Zhang, Y. Facile construction of BiOBr/CoAl-LDH heterojunctions with suppressed Z-axis growth for efficient photoreduction of CO2. Sep. Purif. Technol. 2022, 302, 122090. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Y.; Guo, C.; Wang, Y. Molybdenum carbide-based photocatalysts: Synthesis, functionalization, and applications. Langmuir 2022, 38, 12739–12756. [Google Scholar] [CrossRef] [PubMed]

- Yousef, A.; Barakat, N.A.; El-Newehy, M.; Kim, H.Y. Chemically stable electrospun NiCu nanorods@ carbon nanofibers for highly efficient dehydrogenation of ammonia borane. Int. J. Hydrogen Energy 2012, 37, 17715–17723. [Google Scholar] [CrossRef]

- Yousef, A.; El-Halwany, M.M.; Barakat, N.A.M.; Kim, H.Y. One pot synthesis of Cu-doped TiO2 carbon nanofibers for dehydrogenation of ammonia borane. Ceram. Int. 2015, 41, 6137–6140. [Google Scholar] [CrossRef]

- Abbas, M.; Hameed, R.A.; Al-Enizi, A.M.; Thamer, B.M.; Yousef, A.; El-Newehy, M.H. Decorated carbon nanofibers with mixed nickel− manganese carbides for methanol electro-oxidation in alkaline solution. Int. J. Hydrogen Energy 2021, 46, 6494–6512. [Google Scholar] [CrossRef]

- Al-Enizi, A.M.; Brooks, R.M.; Abutaleb, A.; El-Halwany, M.; El-Newehy, M.H.; Yousef, A.J. Electrospun carbon nanofibers containing Co-TiC nanoparticles-like superficial protrusions as a catalyst for H2 gas production from ammonia borane complex. Nano-Struct. Nano-Objects 2017, 43, 15735–15742. [Google Scholar] [CrossRef]

- Yousef, A.; Barakat, N.A.; Amna, T.; Unnithan, A.R.; Al-Deyab, S.S.; Kim, H.Y. Influence of CdO-doping on the photoluminescence properties of ZnO nanofibers: Effective visible light photocatalyst for waste water treatment. J. Lumin. 2012, 132, 1668–1677. [Google Scholar] [CrossRef]

- Barakat, N.A.M.; Khalil, K.A.; Mahmoud, I.H.; Kanjwal, M.A.; Sheikh, F.A.; Kim, H.Y. CoNi bimetallic nanofibers by electrospinning: Nickel-based soft magnetic material with improved magnetic properties. J. Phys. Chem. C 2010, 114, 15589–15593. [Google Scholar] [CrossRef]

- Abutaleb, A.; Zouli, N.; El-Halwany, M.; Ubaidullah, M.; Yousef, A. Graphitic nanofibers supported NiMn bimetallic nanoalloys as catalysts for H2 generation from ammonia borane. Int. J. Hydrogen Energy 2021, 46, 35248–35260. [Google Scholar] [CrossRef]

- Barakat, N.A.M. Catalytic and photo hydrolysis of ammonia borane complex using Pd-doped Co nanofibers. Appl. Catal. A: Gen. 2013, 451, 21–27. [Google Scholar] [CrossRef]

- Liu, B.H.; Li, Z.P. A review: Hydrogen generation from borohydride hydrolysis reaction. J. Power Sources 2009, 187, 527–534. [Google Scholar] [CrossRef]

- Yao, Q.; Ding, Y.; Lu, Z.-H. Noble-metal-free nanocatalysts for hydrogen generation from boron-and nitrogen-based hydrides. Inorg. Chem. Front. 2020, 7, 3837–3874. [Google Scholar] [CrossRef]

- Huff, C.; Long, J.M.; Heyman, A.; Abdel-Fattah, T.M. Palladium nanoparticle multiwalled carbon nanotube composite as catalyst for hydrogen production by the hydrolysis of sodium borohydride. ACS Appl. Energy Mater. 2018, 1, 4635–4640. [Google Scholar] [CrossRef]

- Al-shaikh, H.; Lasri, J.; Knight, J.G.; Al-Goul, S.T. Palladium mesoporous nanoparticles Pd NPs@[KIT-6] and Pd NPs@[KIT-6]-PEG-imid as efficient heterogeneous catalysts for H2 production from NaBH4 hydrolysis. Fuel 2022, 325, 124962. [Google Scholar] [CrossRef]

- Prasad, D.; Patil, K.N.; Sandhya, N.; Chaitra, C.R.; Bhanushali, J.T.; Samal, A.K.; Keri, R.S.; Jadhav, A.H.; Nagaraja, B.M. Highly efficient hydrogen production by hydrolysis of NaBH4 using eminently competent recyclable Fe2O3 decorated oxidized MWCNTs robust catalyst. Appl. Surf. Sci. 2019, 489, 538–551. [Google Scholar] [CrossRef]

- Prasad, D.; Patil, K.N.; Chaitra, C.R.; Sandhya, N.; Bhanushali, J.T.; Gosavi, S.W.; Jadhav, A.H.; Nagaraja, B.M. Sulfonic acid functionalized PVA/PVDF composite hollow microcapsules: Highly phenomenal & recyclable catalysts for sustainable hydrogen production. Appl. Surf. Sci. 2019, 488, 714–727. [Google Scholar]

- Patil, K.N.; Prasad, D.; Bhanushali, J.T.; Kim, H.; Atar, A.B.; Nagaraja, B.M.; Jadhav, A.H. Sustainable hydrogen generation by catalytic hydrolysis of NaBH 4 using tailored nanostructured urchin-like CuCo2O4 spinel catalyst. Catal. Lett. 2020, 150, 586–604. [Google Scholar] [CrossRef]

- Wu, Y.; Tiri, R.N.E.; Bekmezci, M.; Altuner, E.E.; Aygun, A.; Mei, C.; Yuan, Y.; Xia, C.; Dragoi, E.-N.; Sen, F. Synthesis of novel activated carbon-supported trimetallic Pt–Ru–Ni nanoparticles using wood chips as efficient catalysts for the hydrogen generation from NaBH4 and enhanced photodegradation on methylene blue. Int. J. Hydrogen Energy 2022, 48, 21055–21065. [Google Scholar] [CrossRef]

- Ozay, O.; Aktas, N.; Inger, E.; Sahiner, N. Hydrogel assisted nickel nanoparticle synthesis and their use in hydrogen production from sodium boron hydride. Int. J. Hydrogen Energy 2011, 36, 1998–2006. [Google Scholar] [CrossRef]

- Walter, J.C.; Zurawski, A.; Montgomery, D.; Thornburg, M.; Revankar, S. Sodium borohydride hydrolysis kinetics comparison for nickel, cobalt, and ruthenium boride catalysts. J. Power Sources 2008, 179, 335–339. [Google Scholar] [CrossRef]

- Sagbas, S.; Sahiner, N. A novel p (AAm-co-VPA) hydrogel for the Co and Ni nanoparticle preparation and their use in hydrogel generation from NaBH4. Fuel Process. Technol. 2012, 104, 31–36. [Google Scholar] [CrossRef]

- Du, X.; Liu, C.; Du, C.; Cai, P.; Cheng, G.; Luo, W. Nitrogen-doped graphene hydrogel-supported NiPt-CeO x nanocomposites and their superior catalysis for hydrogen generation from hydrazine at room temperature. Nano Res. 2017, 10, 2856–2865. [Google Scholar] [CrossRef]

- Song, X.; Yang, P.; Wang, J.; Zhao, X.; Zhou, Y.; Li, Y.; Yang, L. NiFePd/UiO-66 nanocomposites as highly efficient catalysts to accelerate hydrogen evolution from hydrous hydrazine. Inorg. Chem. Front. 2019, 6, 2727–2735. [Google Scholar] [CrossRef]

- Sen, B.; Demirkan, B.; Şavk, A.; Gülbay, S.K.; Sen, F. Trimetallic PdRuNi nanocomposites decorated on graphene oxide: A superior catalyst for the hydrogen evolution reaction. Int. J. Hydrogen Energy 2018, 43, 17984–17992. [Google Scholar] [CrossRef]

- Wen, M.; Sun, Y.; Li, X.; Wu, Q.; Wu, Q.; Wang, C. Ru-capped/FeCo nanoflowers with high catalytic efficiency towards hydrolytic dehydrogenation. J. Power Sources 2013, 243, 299–305. [Google Scholar] [CrossRef]

- Bhanushali, J.T.; Prasad, D.; Patil, K.N.; Babu, G.V.R.; Kainthla, I.; Rao, K.S.R.; Jadhav, A.H.; Nagaraja, B.M. The selectively regulated vapour phase dehydrogenation of 1, 4-butanediol to γ-butyrolactone employing a copper-based ceria catalyst. New J. Chem. 2019, 43, 11968–11983. [Google Scholar] [CrossRef]

- Prasad, D.; Patil, K.N.; Chaudhari, N.K.; Kim, H.; Nagaraja, B.M.; Jadhav, A.H. Paving way for sustainable earth-abundant metal based catalysts for chemical fixation of CO2 into epoxides for cyclic carbonate formation. Catal. Rev. 2022, 64, 356–443. [Google Scholar] [CrossRef]

- Patil, K.N.; Prasad, D.; Bhanushali, J.T.; Kakade, B.; Jadhav, A.H.; Nagaraja, B.M. Chemoselective hydrogenation of cinnamaldehyde over a tailored oxygen-vacancy-rich Pd@ ZrO 2 catalyst. New J. Chem. 2021, 45, 5659–5681. [Google Scholar] [CrossRef]

- Balčiūnaitė, A.; Sukackienė, Z.; Antanavičiūtė, K.; Vaičiūnienė, J.; Naujokaitis, A.; Tamašauskaitė-Tamašiūnaitė, L.; Norkus, E. Investigation of hydrogen generation from sodium borohydride using different cobalt catalysts. Int. J. Hydrogen Energy 2021, 46, 1989–1996. [Google Scholar] [CrossRef]

- Groven, L.J.; Pfeil, T.L.; Pourpoint, T.L. Solution combustion synthesized cobalt oxide catalyst precursor for NaBH4 hydrolysis. Int. J. Hydrogen Energy 2013, 38, 6377–6380. [Google Scholar] [CrossRef]

- Baydaroglu, F.O.; Özdemir, E.; Gürek, A.G. Polypyrrole supported Co–W–B nanoparticles as an efficient catalyst for improved hydrogen generation from hydrolysis of sodium borohydride. Int. J. Hydrogen Energy 2022, 47, 9643–9652. [Google Scholar] [CrossRef]

- Doherty, S.; Knight, J.G.; Alharbi, H.Y.; Paterson, R.; Wills, C.; Dixon, C.; Šiller, L.; Chamberlain, T.W.; Griffiths, A.; Collins, S.M. Efficient hydrolytic hydrogen evolution from sodium borohydride catalyzed by polymer immobilized ionic liquid-stabilized platinum nanoparticles. ChemCatChem 2022, 14, e202101752. [Google Scholar] [CrossRef]

- Kahri, H.; Flaud, V.; Touati, R.; Miele, P.; Demirci, U.B. Reaction intermediate/product-induced segregation in cobalt–copper as the catalyst for hydrogen generation from the hydrolysis of sodium borohydride. RSC Adv. 2016, 6, 102498–102503. [Google Scholar] [CrossRef]

- Rakap, M.; Özkar, S. Intrazeolite cobalt (0) nanoclusters as low-cost and reusable catalyst for hydrogen generation from the hydrolysis of sodium borohydride. Appl. Catal. B Environ. 2009, 91, 21–29. [Google Scholar] [CrossRef]

| Catalyst | Volume (mL) | Time (min) | Yield (%) | Rate (mL H2/min) | Rate (mol H2/h. mol Metal) |

|---|---|---|---|---|---|

| Ni0.5Co0.5 | 103 | 31 | 86 | 3.30 | 468 |

| Ni0.7Co0.1Pd0.2 | 107 | 31 | 89 | 3.45 | 486 |

| Ni0.5Co0.3Pd0.2 | 115 | 31 | 95.8 | 3.70 | 522 |

| Ni0.3Co0.5Pd0.2 | 118 | 14 | 100 | 8.42 | 1188 |

| Ni0.1Co0.7Pd0.2 | 118 | 21 | 100 | 5.60 | 792 |

| Catalyst Loading (g) | Volume (mL) | Time (min) | Yield (%) | Rate (mL H2/min) |

|---|---|---|---|---|

| 0.05 | 118 | 14 | 100 | 8.42 |

| 0.1 | 118 | 11 | 100 | 10.7 |

| 0.15 | 118 | 8 | 100 | 14.75 |

| 0.2 | 118 | 6 | 100 | 19.67 |

| Catalyst | Ea (KJ/mol) | Ref. |

|---|---|---|

| (Ni5Pt5)1-(CeOx)0.3/NGH | 38.66 | [53] |

| Ni0.25Fe0.25Pd0.5/UiO-66 | 43.5 | [54] |

| Ni45Au45Co10 | 18.8 | [2] |

| PdRuNi@GO | 55.47 | [55] |

| AC@Pt-Ru-Ni | 24.29 | [49] |

| Cu0.04Co0.864Ni0.096 | 40 | [18] |

| Ru-capped/FeCo | 42.9 | [56] |

| Ni0.3Co0.5Pd0.2 | 16.30 | This study |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abutaleb, A.; Maafa, I.M.; Zouli, N.; Yousef, A.; El-Halwany, M.M. Synthesis of Trimetallic Nanoparticle (NiCoPd)-Supported Carbon Nanofibers as a Catalyst for NaBH4 Hydrolysis. Membranes 2023, 13, 783. https://doi.org/10.3390/membranes13090783

Abutaleb A, Maafa IM, Zouli N, Yousef A, El-Halwany MM. Synthesis of Trimetallic Nanoparticle (NiCoPd)-Supported Carbon Nanofibers as a Catalyst for NaBH4 Hydrolysis. Membranes. 2023; 13(9):783. https://doi.org/10.3390/membranes13090783

Chicago/Turabian StyleAbutaleb, Ahmed, Ibrahim M. Maafa, Nasser Zouli, Ayman Yousef, and M. M. El-Halwany. 2023. "Synthesis of Trimetallic Nanoparticle (NiCoPd)-Supported Carbon Nanofibers as a Catalyst for NaBH4 Hydrolysis" Membranes 13, no. 9: 783. https://doi.org/10.3390/membranes13090783

APA StyleAbutaleb, A., Maafa, I. M., Zouli, N., Yousef, A., & El-Halwany, M. M. (2023). Synthesis of Trimetallic Nanoparticle (NiCoPd)-Supported Carbon Nanofibers as a Catalyst for NaBH4 Hydrolysis. Membranes, 13(9), 783. https://doi.org/10.3390/membranes13090783