Anion-Conducting Polymer Electrolyte without Ether Linkages and with Ionic Groups Grafted on Long Side Chains: Poly(Alkylene Biphenyl Butyltrimethyl Ammonium) (ABBA)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

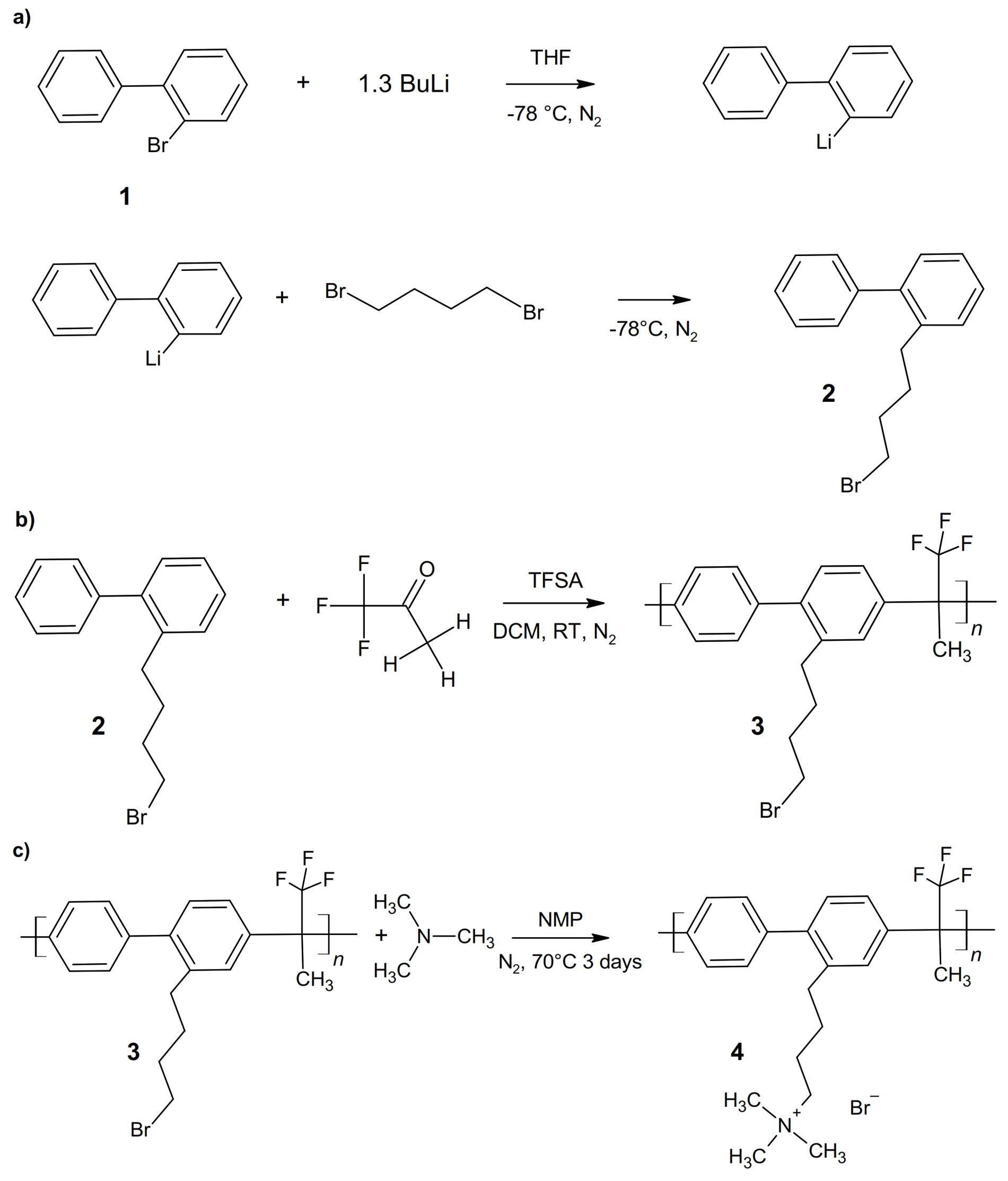

2.2. Synthesis

2.2.1. Synthesis of 2-(4-bromobutyl)biphenyl)(2)

2.2.2. Synthesis of the Precursor poly[(2-(4-bromobutyl)biphenyl-4,4′-diyltrifluoromethylmethylmethylene] (3)

2.2.3. Synthesis of the Target Polymer ABBA, namely poly[2-(N,N,N-trimetylbutane-1-aminium-4-yl)biphenyl-4,4′-diyltrifluoromethyl methylmethylene] (4)

2.2.4. Blend Membranes

PVA

PVDF

Blend Membrane Casting

2.3. Characterization Techniques

2.3.1. 1H-NMR Spectroscopy

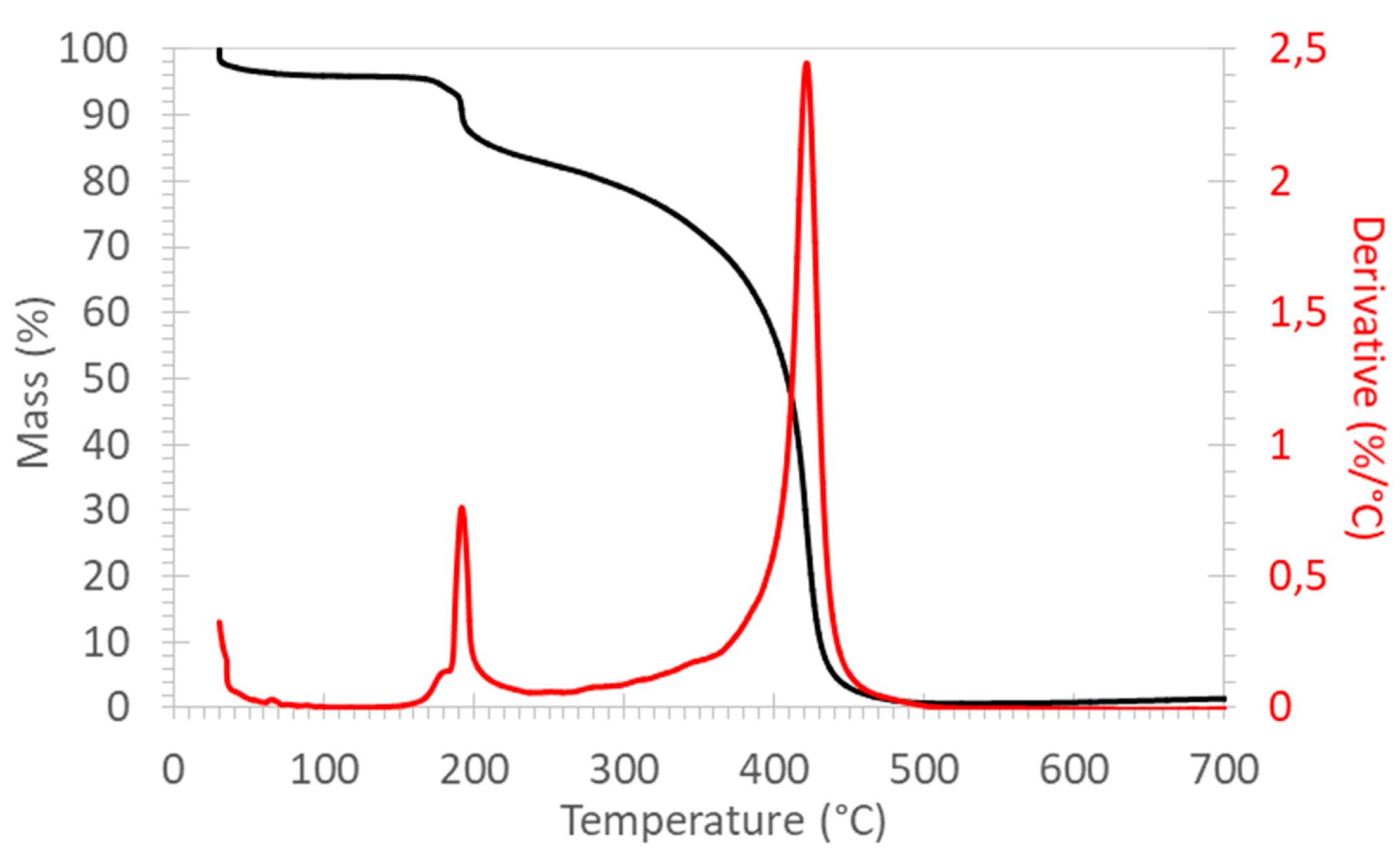

2.3.2. Thermogravimetric Analysis

2.3.3. Ion Exchange Capacity

2.3.4. Water Uptake

2.3.5. Ionic Conductivity

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Carrette, L.; Friedrich, K.A.; Stimming, U. Fuel Cells—Fundamentals and Applications. Fuel Cells 2001, 1, 5–39. [Google Scholar] [CrossRef]

- Merle, G.; Wessling, M.; Nijmeijer, K. Anion exchange membranes for alkaline fuel cells: A review. J. Membr. Sci. 2011, 377, 1–35. [Google Scholar] [CrossRef]

- Varcoe, J.R.; Atanassov, P.; Dekel, D.R.; Herring, A.M.; Hickner, M.A.; Kohl, P.A.; Kucernak, A.R.; Mustain, W.E.; Nijmeijer, K.; Scott, K.; et al. Anion-exchange membranes in electrochemical energy systems. Energy Environ. Sci. 2014, 7, 3135–3191. [Google Scholar] [CrossRef] [Green Version]

- Wang, M.; Preston, N.; Xu, N.; Wei, Y.; Liu, Y.; Qiao, J. Promoter Effects of Functional Groups of Hydroxide-Conductive Membranes on Advanced CO2 Electroreduction to Formate. ACS Appl. Mater. Interfaces 2019, 11, 6881–6889. [Google Scholar] [CrossRef] [PubMed]

- Li, N.W.; Guiver, M.D. Ion Transport by Nanochannels in Ion-Containing Aromatic Copolymers. Macromolecules 2014, 47, 2175–2198. [Google Scholar] [CrossRef] [Green Version]

- Arges, C.G.; Zhang, L. Anion Exchange Membranes’ Evolution toward High Hydroxide Ion Conductivity and Alkaline Resiliency. ACS Appl. Energy Mater. 2018, 1, 2991–3012. [Google Scholar] [CrossRef]

- Narducci, R.; Knauth, P.; Chailan, J.F.; Di Vona, M.L. How to improve Nation with tailor made annealing. RSC Adv. 2018, 8, 27268–27274. [Google Scholar] [CrossRef]

- Giancola, S.; Arciniegas, R.A.B.; Fahs, A.; Chailan, J.F.; Di Vona, M.L.; Knauth, P.; Narducci, R. Study of Annealed Aquivion (R) Ionomers with the INCA Method dagger. Membranes 2019, 9, 134. [Google Scholar] [CrossRef] [Green Version]

- Nunez, S.A.; Hickner, M.A. Quantitative H-1 NMR Analysis of Chemical Stabilities in Anion-Exchange Membranes. ACS Macro Lett. 2013, 2, 49–52. [Google Scholar] [CrossRef]

- Di Vona, M.L.; Narducci, R.; Pasquini, L.; Pelzer, K.; Knauth, P. Anion-conducting ionomers: Study of type of functionalizing amine and macromolecular cross-linking. Int. J. Hydrogen Energy 2014, 39, 14039–14049. [Google Scholar] [CrossRef]

- Sun, Z.; Pan, J.; Guo, J.; Yan, F. The Alkaline Stability of Anion Exchange Membrane for Fuel Cell Applications: The Effects of Alkaline Media. Adv. Sci. 2018, 5, 1800065. [Google Scholar] [CrossRef]

- Chen, N.; Park, J.H.; Hu, C.; Wang, H.H.; Kim, H.M.; Kang, N.Y.; Lee, Y.M. Di-piperidinium-crosslinked poly(fluorenyl-co-terphenyl piperidinium)s for high-performance alkaline exchange membrane fuel cells. J. Mater. Chem. A 2022, 10, 3678–3687. [Google Scholar] [CrossRef]

- Hu, C.; Park, J.H.; Kim, H.M.; Wang, H.H.; Bae, J.Y.; Kang, N.Y.; Chen, N.; Lee, Y.M. Elucidating the role of alkyl chain in poly(aryl piperidinium) copolymers for anion exchange membrane fuel cells. J. Membr. Sci. 2022, 647, 120341. [Google Scholar] [CrossRef]

- Pan, J.; Lu, S.; Li, Y.; Huang, A.; Zhuang, L.; Lu, J. High-Performance Alkaline Polymer Electrolyte for Fuel Cell Applications. Adv. Funct. Mater. 2010, 20, 312–319. [Google Scholar] [CrossRef]

- Li, N.W.; Leng, Y.J.; Hickner, M.A.; Wang, C.Y. Highly Stable, Anion Conductive, Comb-Shaped Copolymers for Alkaline Fuel Cells. J. Am. Chem. Soc. 2013, 135, 10124–10133. [Google Scholar] [CrossRef]

- Pandey, T.P.; Sarode, H.N.; Yang, Y.; Yang, Y.; Vezzù, K.; Noto, V.D.; Seifert, S.; Knauss, D.M.; Liberatore, M.W.; Herring, A.M. A Highly Hydroxide Conductive, Chemically Stable Anion Exchange Membrane, Poly(2,6 dimethyl 1,4 phenylene oxide)-b-Poly(vinyl benzyl trimethyl ammonium), for Electrochemical Applications. J. Electrochem. Soc. 2016, 163, H513–H520. [Google Scholar] [CrossRef]

- Thomas, O.D.; Soo, K.J.W.Y.; Peckham, T.J.; Kulkarni, M.P.; Holdcroft, S. A Stable Hydroxide-Conducting Polymer. J. Am. Chem. Soc. 2012, 134, 10753–10756. [Google Scholar] [CrossRef]

- Disabb-Miller, M.L.; Johnson, Z.D.; Hickner, M.A. Ion Motion in Anion and Proton-Conducting Triblock Copolymers. Macromolecules 2013, 46, 949–956. [Google Scholar] [CrossRef]

- Adamski, M.; Peressin, N.; Holdcroft, S. On the evolution of sulfonated polyphenylenes as proton exchange membranes for fuel cells. Mater. Adv. 2021, 2, 4966–5005. [Google Scholar] [CrossRef]

- Hren, M.; Božič, M.; Fakin, D.; Kleinschek, K.S.; Gorgieva, S. Alkaline membrane fuel cells: Anion exchange membranes and fuels. Sustain. Energy Fuels 2021, 5, 604–637. [Google Scholar] [CrossRef]

- Ul Hassan, N.; Mandal, M.; Huang, G.; Firouzjaie, H.A.; Kohl, P.A.; Mustain, W.E. Achieving High-Performance and 2000 h Stability in Anion Exchange Membrane Fuel Cells by Manipulating Ionomer Properties and Electrode Optimization. Adv. Energy Mater. 2020, 10, 2001986. [Google Scholar] [CrossRef]

- Narducci, R.; Chailan, J.F.; Fahs, A.; Pasquini, L.; Di Vona, M.L.; Knauth, P. Mechanical Properties of Anion Exchange Membranes by Combination of Tensile Stress-Strain Tests and Dynamic Mechanical Analysis. J. Polym. Sci. Part B-Polym. Phys. 2016, 54, 1180–1187. [Google Scholar] [CrossRef]

- Becerra-Arciniegas, R.A.; Narducci, R.; Ercolani, G.; Antonaroli, S.; Sgreccia, E.; Pasquini, L.; Knauth, P.; Di Vona, M.L. Alkaline stability of model anion exchange membranes based on poly (phenylene oxide) (PPO) with grafted quaternary ammonium groups: Influence of the functionalization route. Polymer 2019, 185, 121931. [Google Scholar] [CrossRef]

- Cheng, J.; He, G.; Zhang, F. A mini-review on anion exchange membranes for fuel cell applications: Stability issue and addressing strategies. Int. J. Hydrogen Energy 2015, 40, 7348–7360. [Google Scholar] [CrossRef]

- Fujimoto, C.; Kim, D.-S.; Hibbs, M.; Wrobleski, D.; Kim, Y.S. Backbone stability of quaternized polyaromatics for alkaline membrane fuel cells. J. Membr. Sci. 2012, 423–424, 438–449. [Google Scholar] [CrossRef]

- Kreuer, K.-D.; Jannasch, P. A practical method for measuring the ion exchange capacity decrease of hydroxide exchange membranes during intrinsic degradation. J. Power Sources 2018, 375, 361–366. [Google Scholar] [CrossRef]

- Li, N.; Wang, L.; Hickner, M. Cross-linked comb-shaped anion exchange membranes with high base stability. Chem. Commun. 2014, 50, 4092–4095. [Google Scholar] [CrossRef]

- Dang, H.S.; Jannasch, P. Exploring Different Cationic Alkyl Side Chain Designs for Enhanced Alkaline Stability and Hydroxide Ion Conductivity of Anion-Exchange Membranes. Macromolecules 2015, 48, 5742–5751. [Google Scholar] [CrossRef]

- Marino, M.G.; Kreuer, K.D. Alkaline Stability of Quaternary Ammonium Cations for Alkaline Fuel Cell Membranes and Ionic Liquids. Chemsuschem 2015, 8, 513–523. [Google Scholar] [CrossRef]

- Narducci, R.; Ercolani, G.; Becerra-Arciniegas, R.A.; Pasquini, L.; Knauth, P.; Di Vona, M.L. “Intrinsic” Anion Exchange Polymers through the Dissociation of Strong Basic Groups: PPO with Grafted Bicyclic Guanidines. Membranes 2019, 9, 57. [Google Scholar] [CrossRef] [Green Version]

- Bauer, B.; Strathmann, H.; Effenberger, F. anion-exchange membranes with improved alkaline stability. Desalination 1990, 79, 125–144. [Google Scholar] [CrossRef]

- Zadok, I.; Dekel, D.R.; Srebnik, S. Effect of Ammonium Cations on the Diffusivity and Structure of Hydroxide Ions in Low Hydration Media. J. Phys. Chem. C 2019, 123, 27355–27362. [Google Scholar] [CrossRef]

- Liu, L.; Li, Q.; Dai, J.; Wang, H.; Jin, B.; Bai, R. A facile strategy for the synthesis of guanidinium-functionalized polymer as alkaline anion exchange membrane with improved alkaline stability. J. Membr. Sci. 2014, 453, 52–60. [Google Scholar] [CrossRef]

- Pan, J.; Han, J.J.; Zhu, L.; Hickner, M.A. Cationic Side-Chain Attachment to Poly(Phenylene Oxide) Backbones for Chemically Stable and Conductive Anion Exchange Membranes. Chem. Mater. 2017, 29, 5321–5330. [Google Scholar] [CrossRef]

- Zhu, L.; Yu, X.; Hickner, M.A. Exploring backbone-cation alkyl spacers for multi-cation side chain anion exchange membranes. J. Power Sources 2018, 375, 433–441. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, J.; Wang, Y.; An, L.; Guiver, M.D.; Li, N. Highly stable anion exchange membranes based on quaternized polypropylene. J. Mater. Chem. A 2015, 3, 12284–12296. [Google Scholar] [CrossRef]

- Lin, C.X.; Wang, X.Q.; Hu, E.N.; Yang, Q.; Zhang, Q.G.; Zhu, A.M.; Liu, Q.L. Quaternized triblock polymer anion exchange membranes with enhanced alkaline stability. J. Membr. Sci. 2017, 541, 358–366. [Google Scholar] [CrossRef]

- Becerra-Arciniegas, R.A.; Narducci, R.; Ercolani, G.; Pasquini, L.; Knauth, P.; Di Vona, M.L. Aliphatic Anion Exchange Ionomers with Long Spacers and No Ether Links by Ziegler–Natta Polymerization: Properties and Alkaline Stability. Molecules 2022, 27, 395. [Google Scholar] [CrossRef]

- Narducci, R.; Sgreccia, E.; Di Vona, M.L.; Knauth, P. Anion Exchange Membranes with 1D, 2D and 3D Fillers: A Review. Polymers 2021, 13, 3887. [Google Scholar] [CrossRef]

- Sgreccia, E.; Narducci, R.; Knauth, P.; Di Vona, M.L. Silica Containing Composite Anion Exchange Membranes by Sol-Gel Synthesis: A Short Review. Polymers 2021, 13, 1874. [Google Scholar] [CrossRef]

- Long, H.; Kim, K.; Pivovar, B.S. Hydroxide Degradation Pathways for Substituted Trimethylammonium Cations: A DFT Study. J. Phys. Chem. C 2012, 116, 9419–9426. [Google Scholar] [CrossRef]

- Mohanty, A.D.; Bae, C. Mechanistic analysis of ammonium cation stability for alkaline exchange membrane fuel cells. J. Mater. Chem. A 2014, 2, 17314–17320. [Google Scholar] [CrossRef]

- Becerra-Arciniegas, R.A.; Narducci, R.; Ercolani, G.; Sgreccia, E.; Pasquini, L.; Di Vona, M.L.; Knauth, P. Model Long Side-Chain PPO-Based Anion Exchange Ionomers: Properties and Alkaline Stability. J. Phys. Chem. C 2020, 124, 1309–1316. [Google Scholar] [CrossRef]

- Lee, W.H.; Kim, Y.S.; Bae, C. Robust Hydroxide Ion Conducting Poly(biphenyl alkylene)s for Alkaline Fuel Cell Membranes. ACS Macro Lett. 2015, 4, 814–818. [Google Scholar] [CrossRef]

- Lee, W.-H.; Park, E.J.; Han, J.; Shin, D.W.; Kim, Y.S.; Bae, C. Poly(terphenylene) Anion Exchange Membranes: The Effect of Backbone Structure on Morphology and Membrane Property. ACS Macro Lett. 2017, 6, 566–570. [Google Scholar] [CrossRef]

- Wang, T.; Jeon, J.Y.; Han, J.; Kim, J.H.; Bae, C.; Kim, S. Poly(terphenylene) anion exchange membranes with high conductivity and low vanadium permeability for vanadium redox flow batteries (VRFBs). J. Membr. Sci. 2020, 598, 117665. [Google Scholar] [CrossRef]

- Guzmán-Gutiérrez, M.T.; Nieto, D.R.; Fomine, S.; Morales, S.L.; Zolotukhin, M.G.; Hernandez, M.C.G.; Kricheldorf, H.; Wilks, E.S. Dramatic Enhancement of Superacid-Catalyzed Polyhydroxyalkylation Reactions. Macromolecules 2011, 44, 194–202. [Google Scholar] [CrossRef]

- Diaz, A.M.; Zolotukhin, M.G.; Fomine, S.; Salcedo, R.; Manero, O.; Cedillo, G.; Velasco, V.M.; Guzman, M.T.; Fritsch, D.; Khalizov, A.F. A Novel, One-Pot Synthesis of Novel 3F, 5F, and 8F Aromatic Polymers. Macromol. Rapid Commun. 2007, 28, 183–187. [Google Scholar] [CrossRef]

- Chen, N.; Lee, Y.M. Anion exchange polyelectrolytes for membranes and ionomers. Prog. Polym. Sci. 2021, 113, 101345. [Google Scholar] [CrossRef]

- Liao, G.M.; Yang, C.C.; Hu, C.C.; Pai, Y.L.; Lue, S.J. Novel quaternized polyvinyl alcohol/quaternized chitosan nano-composite as an effective hydroxide-conducting electrolyte. J. Membr. Sci. 2015, 485, 17–29. [Google Scholar] [CrossRef]

- Wu, Y.; Li, Y.; Wang, Y.; Liu, Q.; Chen, Q.; Chen, M. Advances and prospects of PVDF based polymer electrolytes. J. Energy Chem. 2022, 64, 62–84. [Google Scholar] [CrossRef]

- Prakash, O.; Bihari, S.; Tiwari, S.; Prakash, R.; Maiti, P. Dehydrohalogenated poly(vinylidene fluoride)-based anion exchange membranes for fuel cell applications. Mater. Today Chem. 2022, 23, 100640. [Google Scholar] [CrossRef]

- Zhang, M.; Zuo, Q.; Wang, L.; Yu, S.; Mai, Y.; Zhou, Y. Poly(ionic liquid)-based polymer composites as high-performance solid-state electrolytes: Benefiting from nanophase separation and alternating polymer architecture. Chem. Commun. 2020, 56, 7929–7932. [Google Scholar] [CrossRef] [PubMed]

- Bi, S.; Sun, C.-N.; Zawodzinski, T.A., Jr.; Ren, F.; Keum, J.K.; Ahn, S.-K.; Li, D.; Chen, J. Reciprocated suppression of polymer crystallization toward improved solid polymer electrolytes: Higher ion conductivity and tunable mechanical properties. J. Polym. Sci. Part B Polym. Phys. 2015, 53, 1450–1457. [Google Scholar] [CrossRef]

- Seraji, S.M.; Guo, Q. Nanophase morphology and crystallization in poly(vinylidene fluoride)/polydimethylsiloxane-block-poly(methyl methacrylate)-block-polystyrene blends. Polym. Int. 2019, 68, 1064–1073. [Google Scholar] [CrossRef]

- Cruz, A.R.; Hernandez, M.C.G.; Guzmán-Gutiérrez, M.T.; Zolotukhin, M.G.; Fomine, S.; Morales, S.L.; Kricheldorf, H.; Wilks, E.S.; Cárdenas, J.; Salmón, M. Precision Synthesis of Narrow Polydispersity, Ultrahigh Molecular Weight Linear Aromatic Polymers by A2 + B2 Nonstoichiometric Step-Selective Polymerization. Macromolecules 2012, 45, 6774–6780. [Google Scholar] [CrossRef]

- Kurteva, V.B.; Santos, A.G.; Afonso, C.A.M. Microwave accelerated facile synthesis of fused polynuclear hydrocarbons in dry media by intramolecular Friedel–Crafts alkylation. Org. Biomol. Chem. 2004, 2, 514–523. [Google Scholar] [CrossRef]

- Williamson, K.L.; Fenstermaker, J.C. Long-range proton-fluorine coupling in a rigid system. Nuclear magnetic resonance spectra of 5-substituted difluorotetrachlorobicyclo[2.2.1]heptenes. J. Am. Chem. Soc. 1968, 90, 342–346. [Google Scholar] [CrossRef]

- Knauth, P.; Pasquini, L.; Narducci, R.; Sgreccia, E.; Becerra-Arciniegas, R.A.; Di Vona, M.L. Effective ion mobility in anion exchange ionomers: Relations with hydration, porosity, tortuosity, and percolation. J. Membr. Sci. 2021, 617, 118622. [Google Scholar] [CrossRef]

- Du, X.; Zhang, H.; Yuan, Y.; Wang, Z. Constructing micro-phase separation structure to improve the performance of anion-exchange membrane based on poly(aryl piperidinium) cross-linked membranes. J. Power Sources 2021, 487, 229429. [Google Scholar] [CrossRef]

- You, W.; Noonan, K.J.T.; Coates, G.W. Alkaline-stable anion exchange membranes: A review of synthetic approaches. Prog. Polym. Sci. 2020, 100, 101177. [Google Scholar] [CrossRef]

- Velez, A.A.I.; Reyes, E.; Diaz-Barrios, A.; Santos, F.; Fernández Romero, A.J.; Tafur, J.P. Properties of the PVA-VAVTD KOH Blend as a Gel Polymer Electrolyte for Zinc Batteries. Gels 2021, 7, 256. [Google Scholar] [CrossRef]

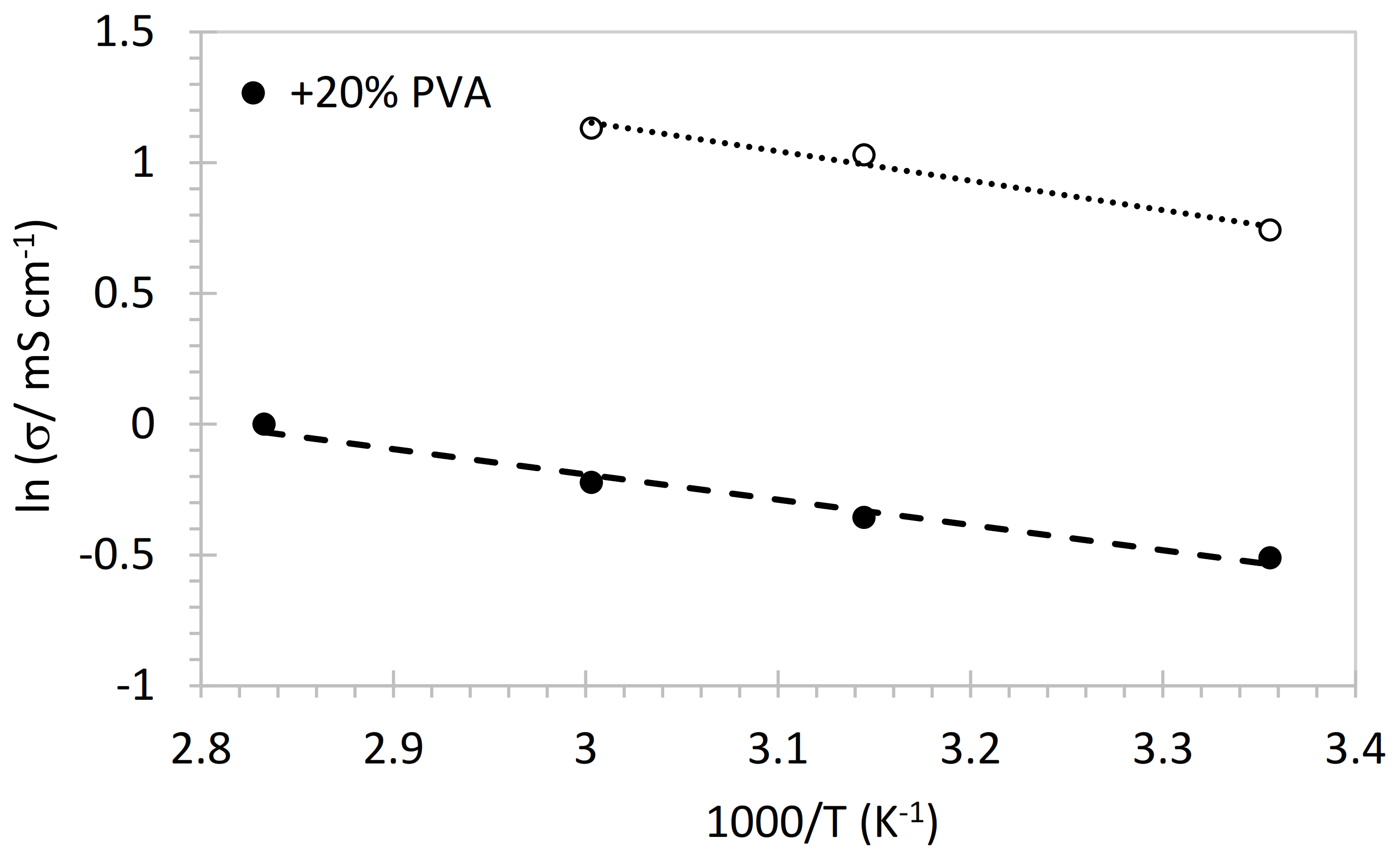

| Temperature (°C) | Conductivity (mS cm−1) | |

|---|---|---|

| +20% PVA | +30% PVDF | |

| 25 | 0.6 | 2.1 |

| 45 | 0.7 | 2.8 |

| 60 | 0.8 | 3.1 |

| 80 | 1.0 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Narducci, R.; Becerra-Arciniegas, R.A.; Pasquini, L.; Ercolani, G.; Knauth, P.; Di Vona, M.L. Anion-Conducting Polymer Electrolyte without Ether Linkages and with Ionic Groups Grafted on Long Side Chains: Poly(Alkylene Biphenyl Butyltrimethyl Ammonium) (ABBA). Membranes 2022, 12, 337. https://doi.org/10.3390/membranes12030337

Narducci R, Becerra-Arciniegas RA, Pasquini L, Ercolani G, Knauth P, Di Vona ML. Anion-Conducting Polymer Electrolyte without Ether Linkages and with Ionic Groups Grafted on Long Side Chains: Poly(Alkylene Biphenyl Butyltrimethyl Ammonium) (ABBA). Membranes. 2022; 12(3):337. https://doi.org/10.3390/membranes12030337

Chicago/Turabian StyleNarducci, Riccardo, Raul Andres Becerra-Arciniegas, Luca Pasquini, Gianfranco Ercolani, Philippe Knauth, and Maria Luisa Di Vona. 2022. "Anion-Conducting Polymer Electrolyte without Ether Linkages and with Ionic Groups Grafted on Long Side Chains: Poly(Alkylene Biphenyl Butyltrimethyl Ammonium) (ABBA)" Membranes 12, no. 3: 337. https://doi.org/10.3390/membranes12030337

APA StyleNarducci, R., Becerra-Arciniegas, R. A., Pasquini, L., Ercolani, G., Knauth, P., & Di Vona, M. L. (2022). Anion-Conducting Polymer Electrolyte without Ether Linkages and with Ionic Groups Grafted on Long Side Chains: Poly(Alkylene Biphenyl Butyltrimethyl Ammonium) (ABBA). Membranes, 12(3), 337. https://doi.org/10.3390/membranes12030337