Recent Developments and Perspectives of Recycled Poly(ethylene terephthalate)-Based Membranes: A Review

Abstract

1. Introduction

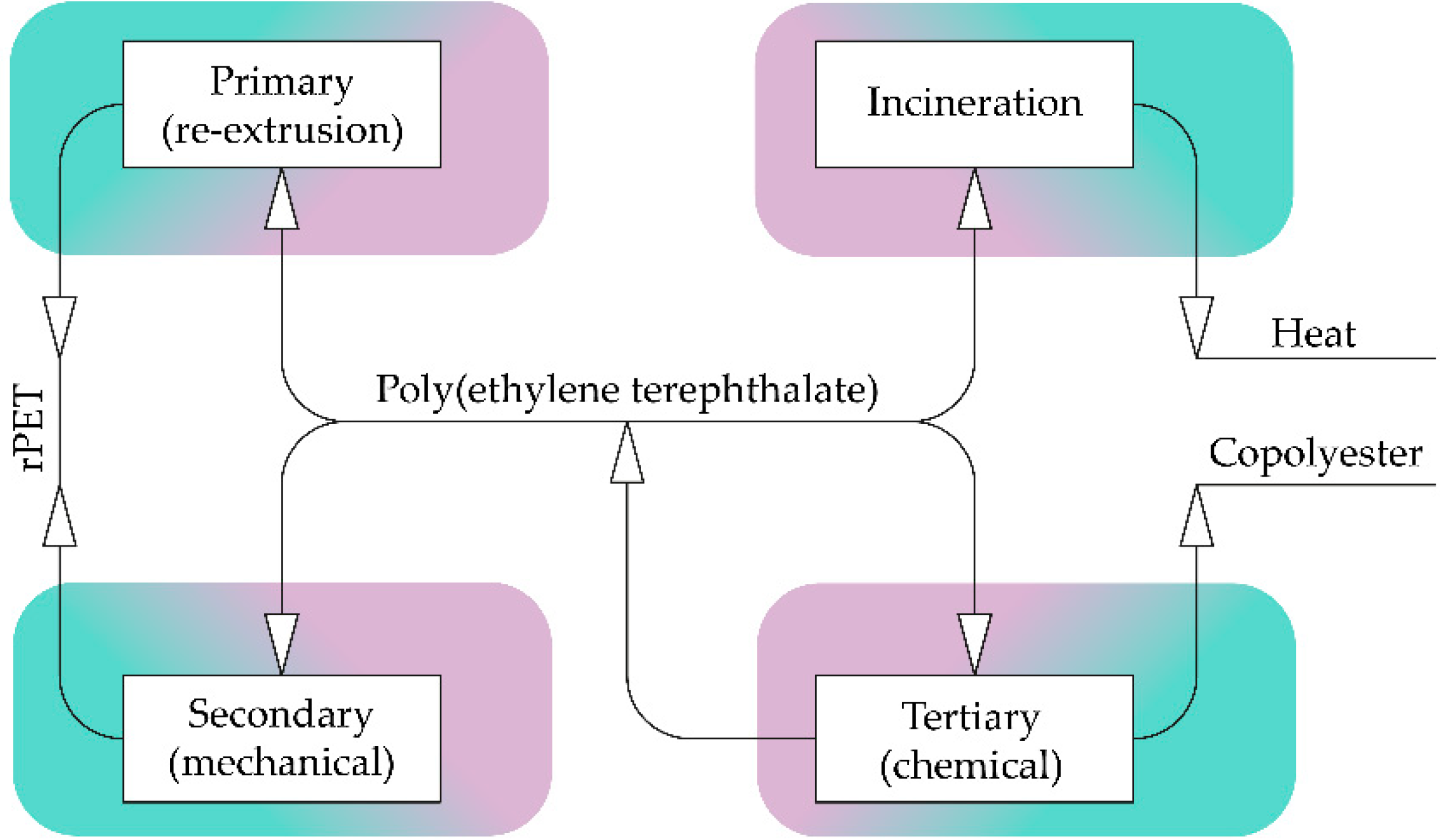

2. Poly(ethylene terephthalate) Recycling Methods

2.1. Chemical Recycling Methods

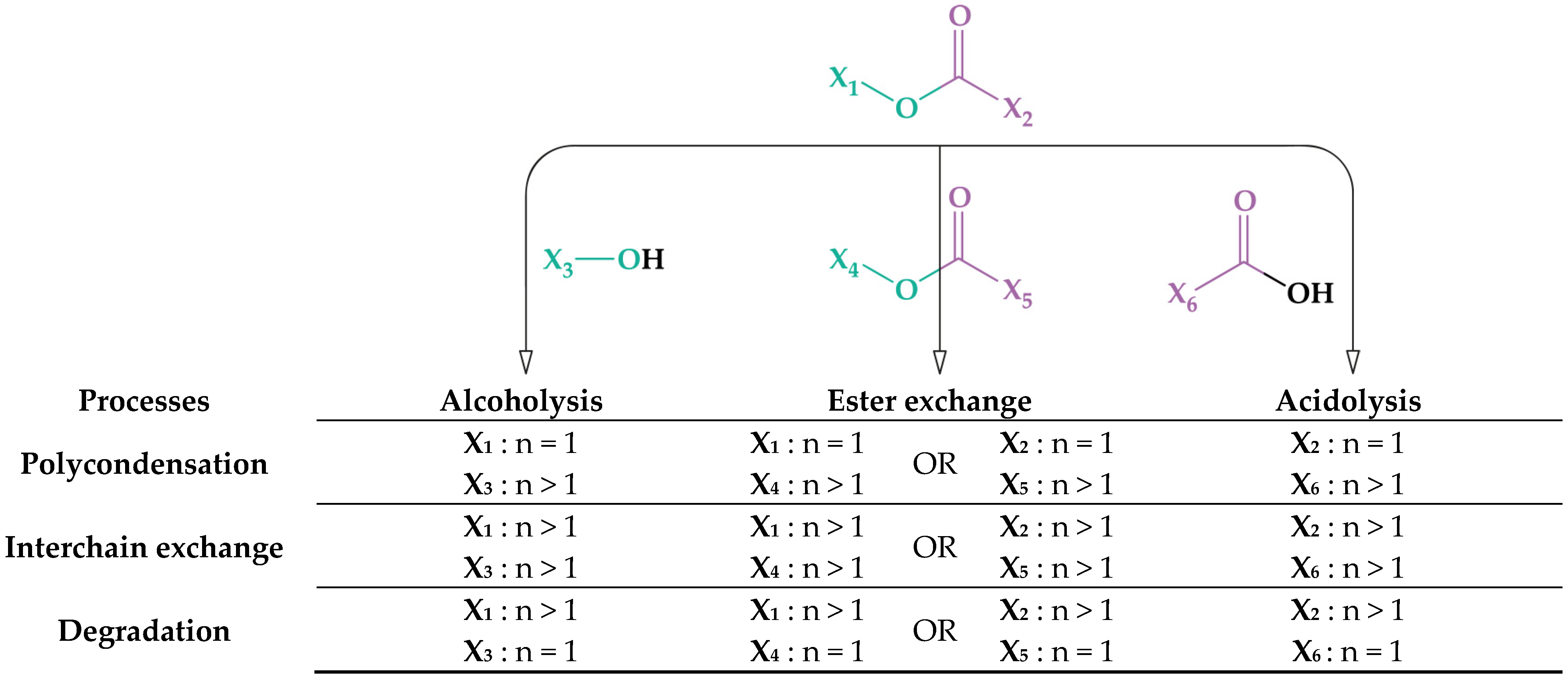

2.2. Poly(ethylene terephthalate) Preparation Methods

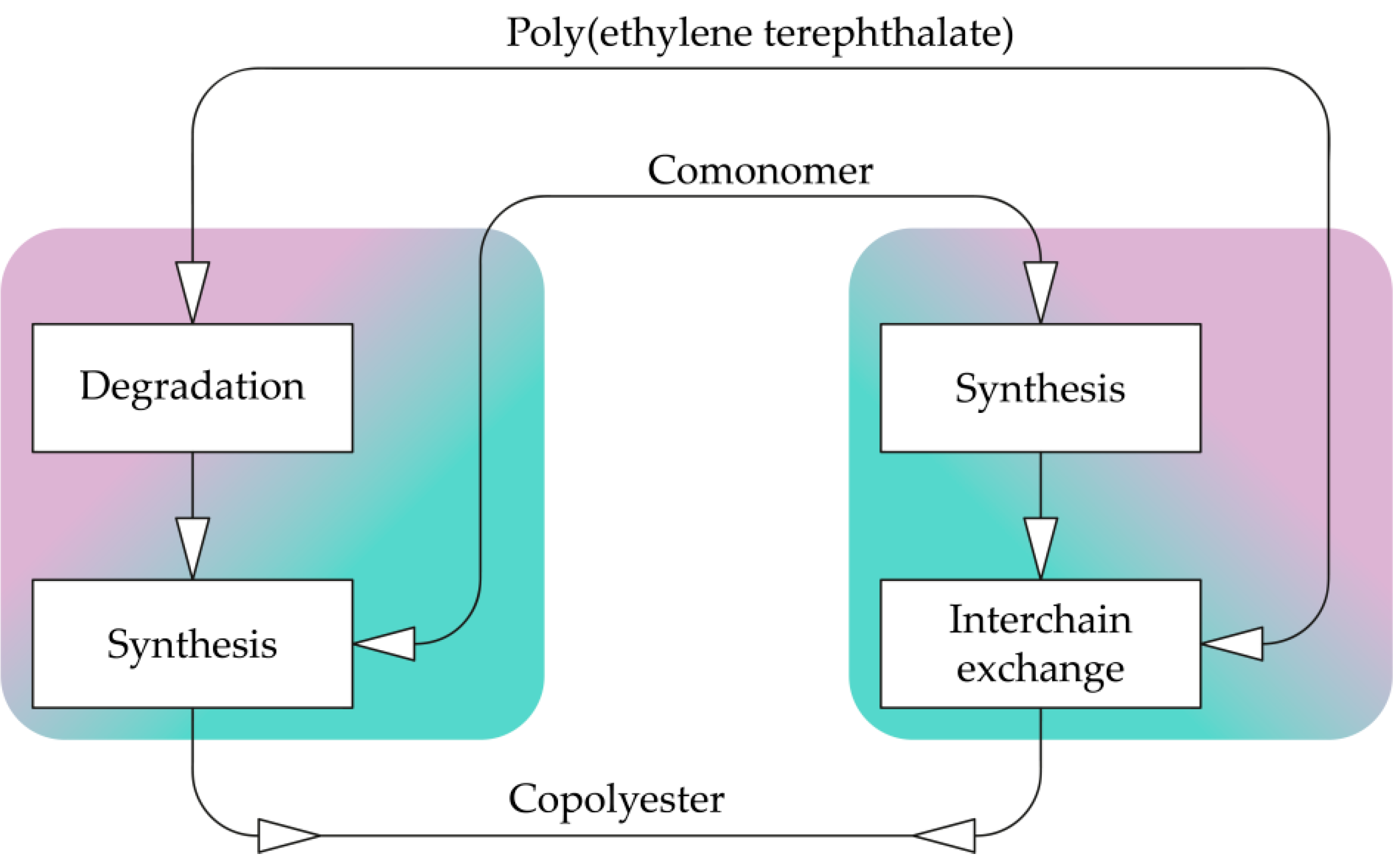

2.3. Copolyester Preparation Methods

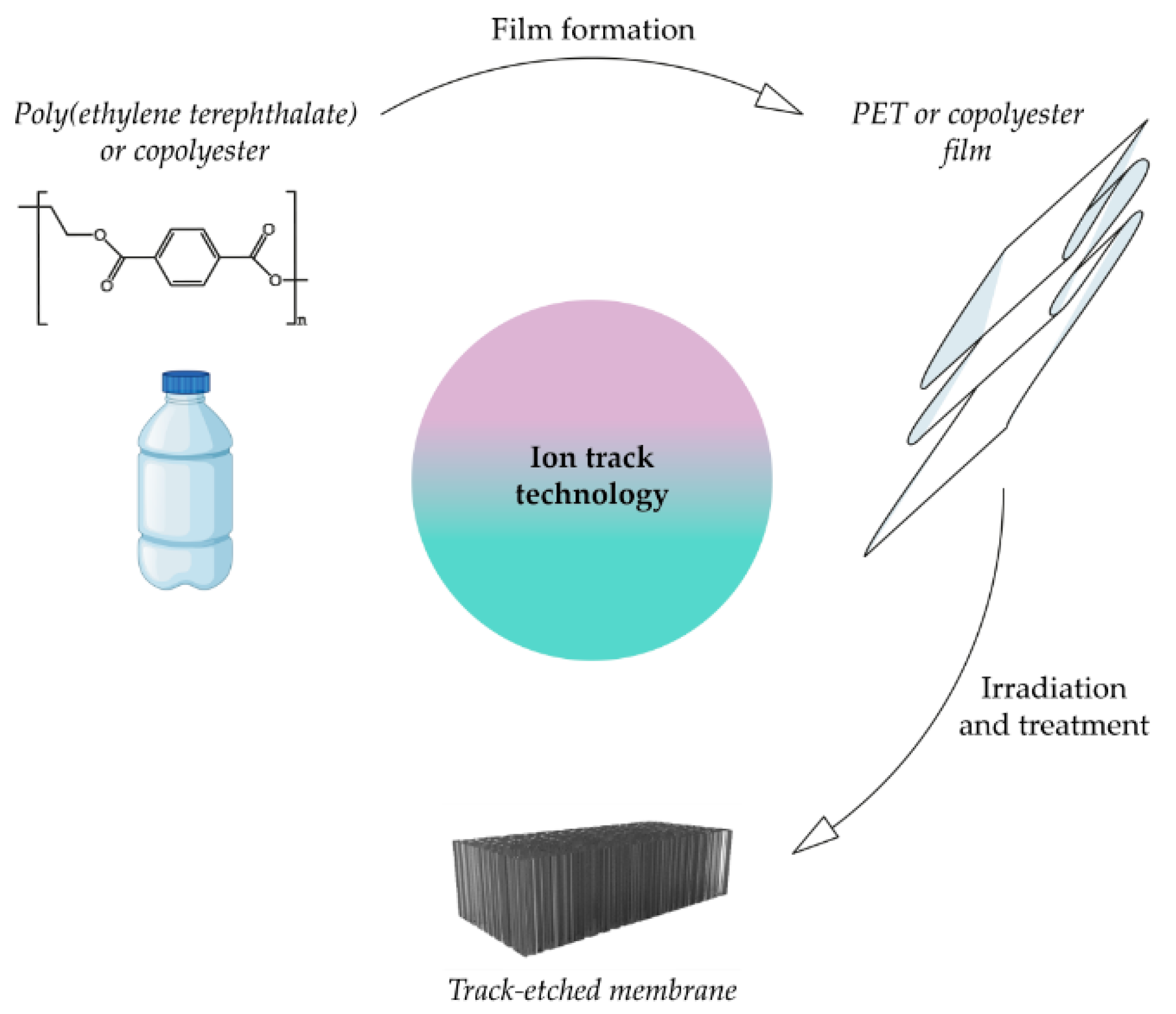

3. Membrane Preparation Methods

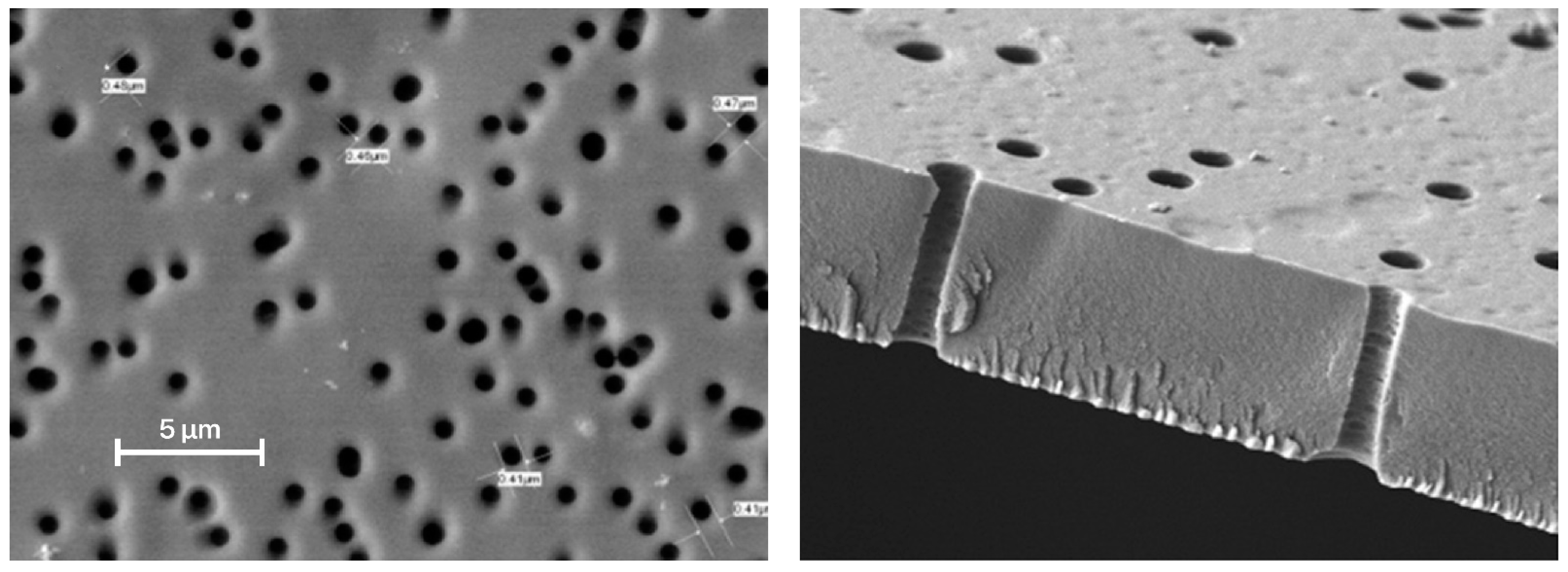

3.1. Ion Tracking Technology

3.1.1. PET-Based Track Membranes

3.1.2. Copolyester-Based Track Membranes

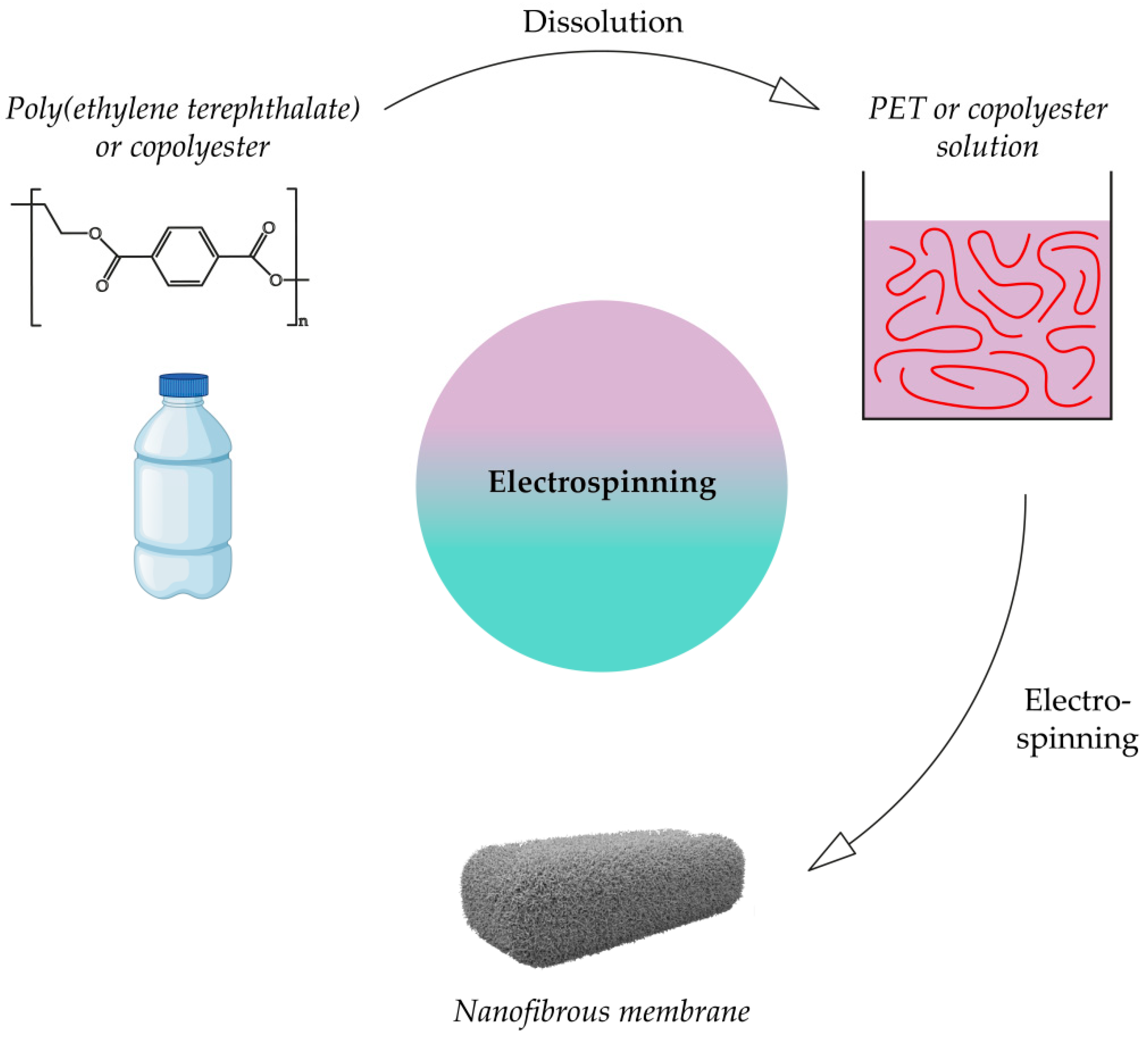

3.2. Electrospinning

| Solvent | Ratio, Weight | References |

|---|---|---|

| Trifluoroacetic acid | — | [139,140] |

| Trifluoroacetic acid, dichloromethane | 7:3 | [140,141,142,143] |

| 1,1,1,3,3,3-Hexafluoro-2-propanol, dichloromethane | 2:8 | [144,145] |

3.2.1. PET-Based Nanofibrous Membranes

3.2.2. Copolyester-Based Nanofibrous Membranes

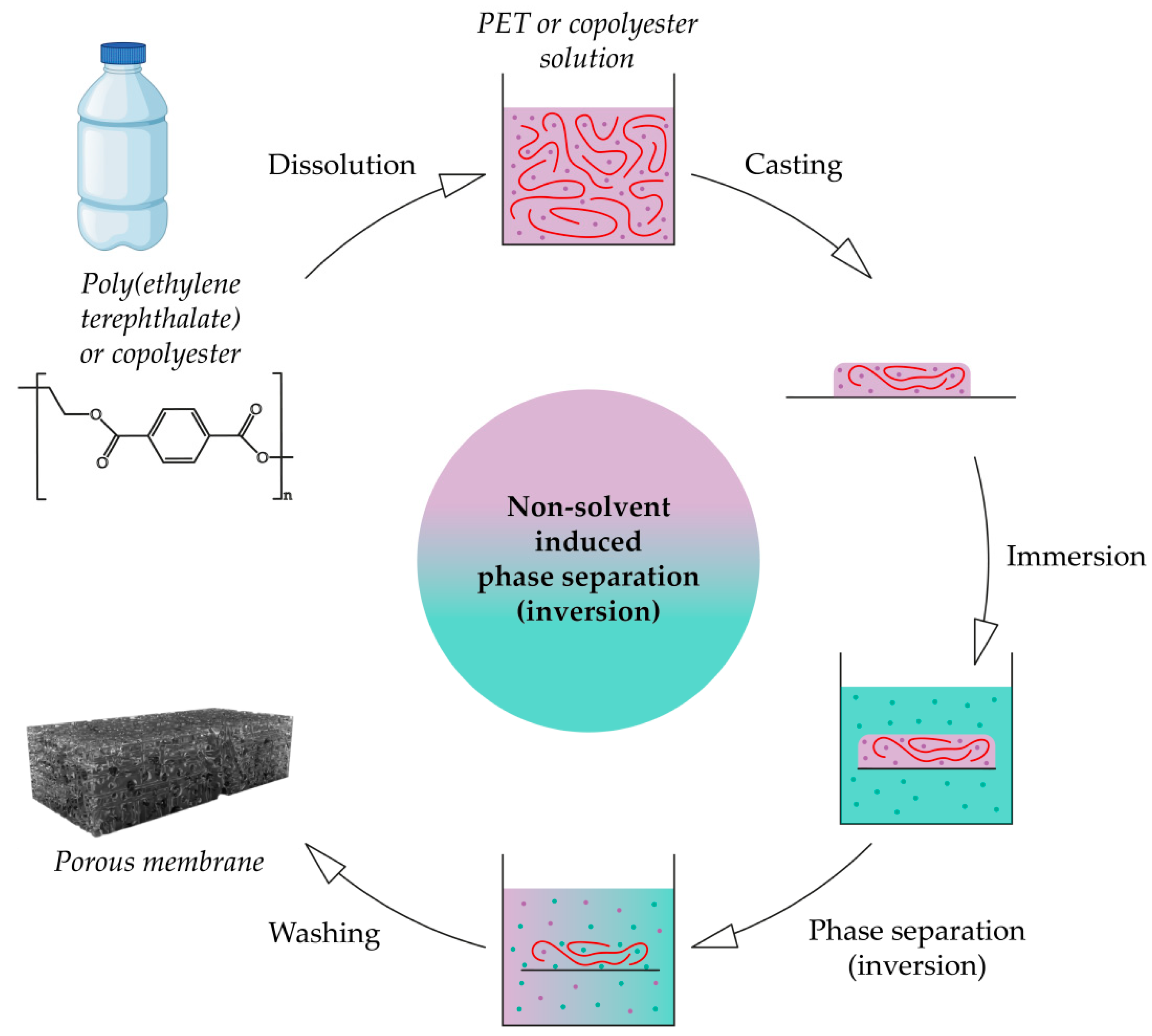

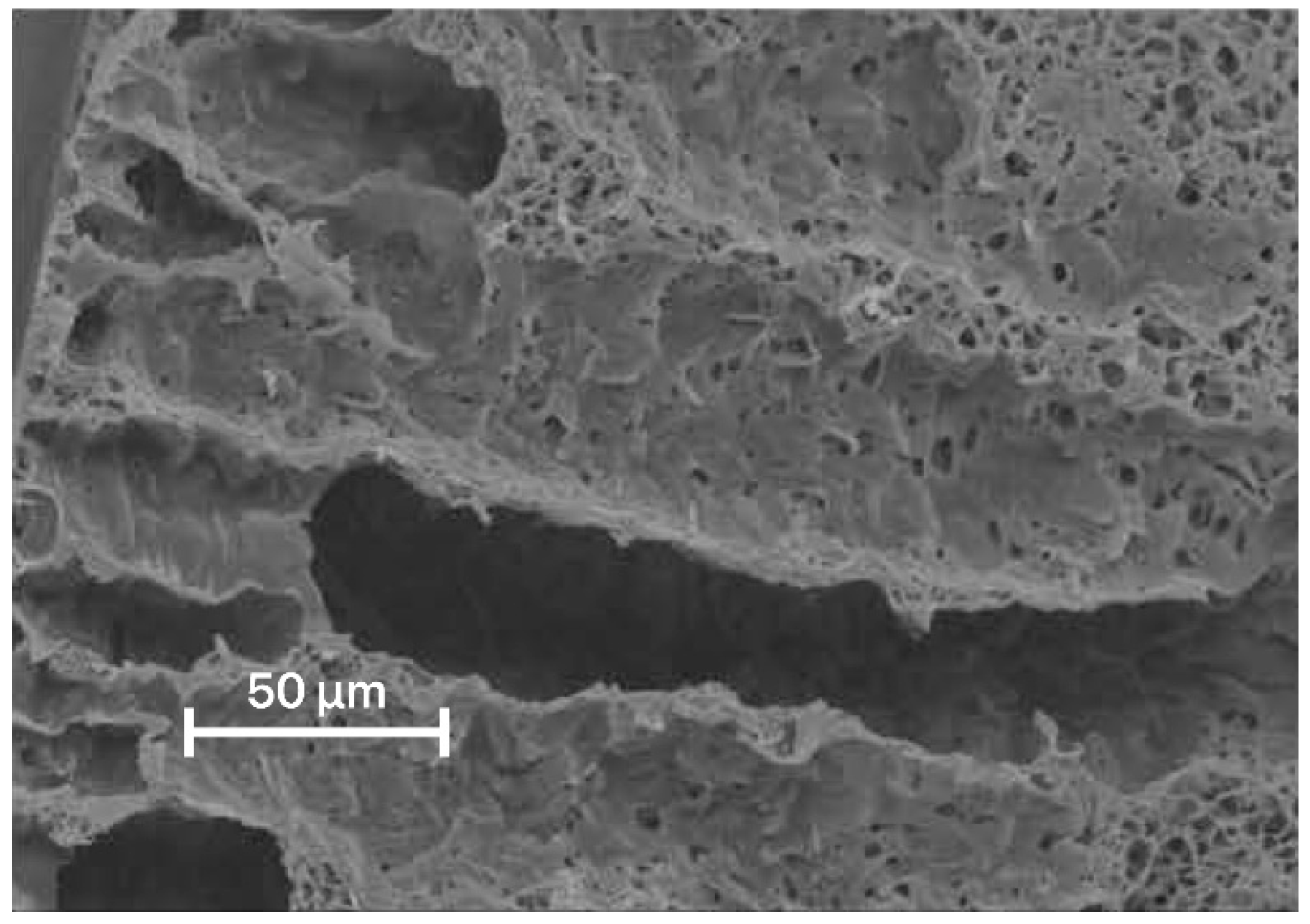

3.3. Phase Inversion or Separation

3.3.1. PET-Based Porous Membranes

3.3.2. Copolyester-Based Porous Membranes

3.4. Other Methods

4. Conclusions and Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Watt, E.; Picard, M.; Maldonado, B.; Abdelwahab, M.A.; Mielewski, D.F.; Drzal, L.T.; Misra, M.; Mohanty, A.K. Ocean Plastics: Environmental Implications and Potential Routes for Mitigation—A Perspective. RSC Adv. 2021, 11, 21447–21462. [Google Scholar] [CrossRef] [PubMed]

- Benyathiar, P.; Kumar, P.; Carpenter, G.; Brace, J.; Mishra, D.K. Polyethylene Terephthalate (PET) Bottle-to-Bottle Recycling for the Beverage Industry: A Review. Polymers 2022, 14, 2366. [Google Scholar] [CrossRef] [PubMed]

- Juanga-Labayen, J.P.; Labayen, I.V.; Yuan, Q. A Review on Textile Recycling Practices and Challenges. Textiles 2022, 2, 174–188. [Google Scholar] [CrossRef]

- Kirshanov, K.; Toms, R.; Melnikov, P.; Gervald, A. Investigation of Polyester Tire Cord Glycolysis Accompanied by Rubber Crumb Devulcanization. Polymers 2022, 14, 684. [Google Scholar] [CrossRef]

- Kirshanov, K.A.; Toms, R.V.; Gerval’d, A.Y. Prospects of Polyester Tire Cord Waste Utilization. Kauchuk I Rezina 2022, 81, 148–154. [Google Scholar]

- Bogusz, P.; Miedzińska, D.; Wieczorek, M. Experimental Investigation of the Tensile Behavior of Selected Tire Cords Using Novel Testing Equipment. Materials 2022, 15, 4163. [Google Scholar] [CrossRef]

- Kirshanov, K.A.; Gervald, A.Y.U.; Toms, R.V.; Balashov, M.S. Natural Latex Deproteinization Issues. Kauchuk I Rezina 2020, 79, 310–316. [Google Scholar] [CrossRef]

- Kirshanov, K.A.; Gervald, A.Y. Elastomeric Compositions in Wound Dressings. Kauchuk I Rezina 2021, 80, 150–154. [Google Scholar] [CrossRef]

- Burrows, S.D.; Ribeiro, F.; O’Brien, S.; Okoffo, E.; Toapanta, T.; Charlton, N.; Kaserzon, S.; Lin, C.-Y.; Tang, C.; Rauert, C.; et al. The Message on the Bottle: Rethinking Plastic Labelling to Better Encourage Sustainable Use. Environ. Sci. Policy 2022, 132, 109–118. [Google Scholar] [CrossRef]

- Kirshanov, K.A.; Gervald, A.Y.U.; Toms, R.V.; Lobanov, A.N. Obtaining Phthalate Substituted Post-Consumer Polyethylene Terephthalate and Its Isothermal Crystallization. Fine Chem. Technol. 2022, 17, 164–171. [Google Scholar] [CrossRef]

- Hou, D.; Xin, J.; Lu, X.; Guo, X.; Dong, H.; Ren, B.; Zhang, S. Conversion of Bis(2-Hydroxyethylene Terephthalate) into 1,4-Cyclohexanedimethanol by Selective Hydrogenation Using RuPtSn/Al2O3. RSC Adv. 2016, 6, 48737–48744. [Google Scholar] [CrossRef]

- Kirshanov, K.A.; Toms, R.V.; Gervald, A.Y. Study of Methods for Obtaining Unsaturated Polyester Resins Based on Recycled Polyethylene Terephthalate. Plast. Massy 2022, 1, 46–47. [Google Scholar] [CrossRef]

- Kirshanov, K.; Toms, R.; Melnikov, P.; Gervald, A. Unsaturated Polyester Resin Nanocomposites Based on Post-Consumer Polyethylene Terephthalate. Polymers 2022, 14, 1602. [Google Scholar] [CrossRef] [PubMed]

- Bórquez-Mendivil, A.; Hurtado-Macías, A.; Leal-Pérez, J.E.; Flores-Valenzuela, J.; Vargas-Ortíz, R.Á.; Cabrera-Covarrubias, F.G.; Almaral-Sánchez, J.L. Hybrid Coatings of SiO2–Recycled PET Unsaturated Polyester Resin by Sol-Gel Process. Polymers 2022, 14, 3280. [Google Scholar] [CrossRef] [PubMed]

- Li, M.-J.; Huang, Y.-H.; Ju, A.-Q.; Yu, T.-S.; Ge, M.-Q. Synthesis and Characterization of Azo Dyestuff Based on Bis(2-Hydroxyethyl) Terephthalate Derived from Depolymerized Waste Poly(Ethylene Terephthalate) Fibers. Chin. Chem. Lett. 2014, 25, 1550–1554. [Google Scholar] [CrossRef]

- Kamrani, H.; Nosrati, A. Fabrication of Nanofiber Filtration Membranes Using Polyethylene Terephthalate (PET): A Review. J. Membr. Sci. Technol 2018, 8, 1000183. [Google Scholar] [CrossRef]

- Al-Shaeli, M.; Al-Juboori, R.A.; al Aani, S.; Ladewig, B.P.; Hilal, N. Natural and Recycled Materials for Sustainable Membrane Modification: Recent Trends and Prospects. Sci. Total Environ. 2022, 838, 156014. [Google Scholar] [CrossRef]

- Yeszhanov, A.B.; Korolkov, I.V.; Dosmagambetova, S.S.; Zdorovets, M.V.; Güven, O. Recent Progress in the Membrane Distillation and Impact of Track-Etched Membranes. Polymers 2021, 13, 2520. [Google Scholar] [CrossRef]

- Al-Sabagh, A.M.; Yehia, F.Z.; Eshaq, G.H.; Rabie, A.M.; ElMetwally, A.E. Greener Routes for Recycling of Polyethylene Terephthalate. Egypt. J. Pet. 2016, 25, 53–64. [Google Scholar] [CrossRef]

- Damayanti; Wu, H.-S. Strategic Possibility Routes of Recycled PET. Polymers 2021, 13, 1475. [Google Scholar] [CrossRef]

- Suhaimi, N.A.S.; Muhamad, F.; Abd Razak, N.A.; Zeimaran, E. Recycling of Polyethylene Terephthalate Wastes: A Review of Technologies, Routes, and Applications. Polym. Eng. Sci. 2022, 62, 2355–2375. [Google Scholar] [CrossRef]

- Geyer, B.; Lorenz, G.; Kandelbauer, A. Recycling of Poly(Ethylene Terephthalate)—A Review Focusing on Chemical Methods. Express Polym. Lett. 2016, 10, 559–586. [Google Scholar] [CrossRef]

- Nikles, D.E.; Farahat, M.S. New Motivation for the Depolymerization Products Derived from Poly(Ethylene Terephthalate) (PET) Waste: A Review. Macromol. Mater. Eng. 2005, 290, 13–30. [Google Scholar] [CrossRef]

- Raheem, A.B.; Noor, Z.Z.; Hassan, A.; Abd Hamid, M.K.; Samsudin, S.A.; Sabeen, A.H. Current Developments in Chemical Recycling of Post-Consumer Polyethylene Terephthalate Wastes for New Materials Production: A Review. J. Clean. Prod. 2019, 225, 1052–1064. [Google Scholar] [CrossRef]

- Ghosal, K.; Nayak, C. Recent Advances in Chemical Recycling of Polyethylene Terephthalate Waste into Value Added Products for Sustainable Coating Solutions—Hope vs. Hype. Mater. Adv. 2022, 3, 1974–1992. [Google Scholar] [CrossRef]

- Aguado, A.; Martínez, L.; Becerra, L.; Arieta-araunabeña, M.; Arnaiz, S.; Asueta, A.; Robertson, I. Chemical Depolymerisation of PET Complex Waste: Hydrolysis vs. Glycolysis. J. Mater. Cycles Waste Manag. 2014, 16, 201–210. [Google Scholar] [CrossRef]

- Raheem, A.B.; Hassan, A.B.; Noor, Z.Z.; Samsudin, S.B.; Hamid, M.A.; Bello, A.; Oladokun, O.; Sabee, A.H.; Shamiri, A. Process Simulation of Bis (2- Hydroxyethyl) Terephthalate and Its Recovery Using Two–Stage Evaporation Systems. Chem. Eng. Trans. 2018, 63, 655–660. [Google Scholar]

- Lu, J.; Li, M.; Li, Y.; Li, X.; Gao, Q.; Ge, M. Synthesis and Sizing Performances of Water-Soluble Polyester Based on Bis(2-Hydroxyethyl) Terephthalate Derived from Depolymerized Waste Poly(Ethylene Terephthalate) Fabrics. Text. Res. J. 2019, 89, 572–579. [Google Scholar] [CrossRef]

- Liu, B.; Lu, X.; Ju, Z.; Sun, P.; Xin, J.; Yao, X.; Zhou, Q.; Zhang, S. Ultrafast Homogeneous Glycolysis of Waste Polyethylene Terephthalate via a Dissolution-Degradation Strategy. Ind. Eng. Chem. Res. 2018, 57, 16239–16245. [Google Scholar] [CrossRef]

- Stoski, A.; Viante, M.F.; Nunes, C.S.; Muniz, E.C.; Felsner, M.L.; Almeida, C.A.P. Oligomer Production through Glycolysis of Poly(Ethylene Terephthalate): Effects of Temperature and Water Content on Reaction Extent. Polym. Int. 2016, 65, 1024–1030. [Google Scholar] [CrossRef]

- Hoang, C.N.; Pham, C.T.; Dang, T.M.; Hoang, D.; Lee, P.-C.; Kang, S.-J.; Kim, J. Novel Oligo-Ester-Ether-Diol Prepared by Waste Poly(Ethylene Terephthalate) Glycolysis and Its Use in Preparing Thermally Stable and Flame Retardant Polyurethane Foam. Polymers 2019, 11, 236. [Google Scholar] [CrossRef] [PubMed]

- Fuentes, C.A.; Gallegos, M.V.; García, J.R.; Sambeth, J.; Peluso, M.A. Catalytic Glycolysis of Poly(Ethylene Terephthalate) Using Zinc and Cobalt Oxides Recycled from Spent Batteries. Waste Biomass Valorization 2020, 11, 4991–5001. [Google Scholar] [CrossRef]

- Chen, F.; Zhou, Q.; Bu, R.; Yang, F.; Li, W. Kinetics of Poly(Ethylene Terephthalate) Fiber Glycolysis in Ethylene Glycol. Fibers Polym. 2015, 16, 1213–1219. [Google Scholar] [CrossRef]

- Scé, F.; Cano, I.; Martin, C.; Beobide, G.; Castillo, Ó.; de Pedro, I. Comparing Conventional and Microwave-Assisted Heating in PET Degradation Mediated by Imidazolium-Based Halometallate Complexes. New J. Chem. 2019, 43, 3476–3485. [Google Scholar] [CrossRef]

- Esquer, R.; García, J.J. Metal-Catalysed Poly(Ethylene) Terephthalate and Polyurethane Degradations by Glycolysis. J. Organomet. Chem. 2019, 902, 120972. [Google Scholar] [CrossRef]

- Fang, P.; Liu, B.; Xu, J.; Zhou, Q.; Zhang, S.; Ma, J.; Lu, X. High-Efficiency Glycolysis of Poly(Ethylene Terephthalate) by Sandwich-Structure Polyoxometalate Catalyst with Two Active Sites. Polym. Degrad. Stab. 2018, 156, 22–31. [Google Scholar] [CrossRef]

- Li, M.; Li, Y.; Lu, J.; Li, X.; Lu, Y. Decolorization and Reusing of PET Depolymerization Waste Liquid by Electrochemical Method with Magnetic Nanoelectrodes. Environ. Sci. Pollut. Res. 2018, 25, 34531–34539. [Google Scholar] [CrossRef]

- Nabid, M.R.; Bide, Y.; Jafari, M. Boron Nitride Nanosheets Decorated with Fe3O4 Nanoparticles as a Magnetic Bifunctional Catalyst for Post-Consumer PET Wastes Recycling. Polym. Degrad. Stab. 2019, 169, 108962. [Google Scholar] [CrossRef]

- Alzuhairi, M. Bubble Column and CFD Simulation for Chemical Recycling of Polyethylene Terephthalate. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2018; p. 030041. [Google Scholar]

- Cano, I.; Martin, C.; Fernandes, J.A.; Lodge, R.W.; Dupont, J.; Casado-Carmona, F.A.; Lucena, R.; Cardenas, S.; Sans, V.; de Pedro, I. Paramagnetic Ionic Liquid-Coated SiO2@Fe3O4 Nanoparticles—The next Generation of Magnetically Recoverable Nanocatalysts Applied in the Glycolysis of PET. Appl. Catal. B 2020, 260, 118110. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, M.; Zhao, R.; Liu, F.; Ge, X.; Yu, S. Heterogeneous CaO(SrO, BaO)/MCF as Highly Active and Recyclable Catalysts for the Glycolysis of Poly(Ethylene Terephthalate). Res. Chem. Intermed. 2018, 44, 7711–7729. [Google Scholar] [CrossRef]

- Park, G.; Bartolome, L.; Lee, K.G.; Lee, S.J.; Kim, D.H.; Park, T.J. One-Step Sonochemical Synthesis of a Graphene Oxide–Manganese Oxide Nanocomposite for Catalytic Glycolysis of Poly(Ethylene Terephthalate). Nanoscale 2012, 4, 3879. [Google Scholar] [CrossRef] [PubMed]

- Guo, Z.; Lindqvist, K.; de la Motte, H. An Efficient Recycling Process of Glycolysis of PET in the Presence of a Sustainable Nanocatalyst. J. Appl. Polym. Sci. 2018, 135, 46285. [Google Scholar] [CrossRef]

- Veregue, F.R.; Pereira da Silva, C.T.; Moisés, M.P.; Meneguin, J.G.; Guilherme, M.R.; Arroyo, P.A.; Favaro, S.L.; Radovanovic, E.; Girotto, E.M.; Rinaldi, A.W. Ultrasmall Cobalt Nanoparticles as a Catalyst for PET Glycolysis: A Green Protocol for Pure Hydroxyethyl Terephthalate Precipitation without Water. ACS Sustain. Chem. Eng. 2018, 6, 12017–12024. [Google Scholar] [CrossRef]

- Lima, G.R.; Monteiro, W.F.; Ligabue, R.; Santana, R.M.C. Titanate Nanotubes as New Nanostrutured Catalyst for Depolymerization of PET by Glycolysis Reaction. Mater. Res. 2017, 20, 588–595. [Google Scholar] [CrossRef]

- Lima, G.R.; Monteiro, W.F.; Toledo, B.O.; Ligabue, R.A.; Santana, R.M.C. Titanate Nanotubes Modified with Zinc and Its Application in Post-Consumer PET Depolymerization. Macromol. Symp. 2019, 383, 1800008. [Google Scholar] [CrossRef]

- Al-Sabagh, A.M.; Yehia, F.Z.; Harding, D.R.K.; Eshaq, G.H.; ElMetwally, A.E. Fe3O4-Boosted MWCNT as an Efficient Sustainable Catalyst for PET Glycolysis. Green Chem. 2016, 18, 3997–4003. [Google Scholar] [CrossRef]

- Al-Sabagh, A.M.; Yehia, F.Z.; Eshaq, G.H.; ElMetwally, A.E. Ionic Liquid-Coordinated Ferrous Acetate Complex Immobilized on Bentonite as a Novel Separable Catalyst for PET Glycolysis. Ind. Eng. Chem. Res. 2015, 54, 12474–12481. [Google Scholar] [CrossRef]

- Sert, E.; Yılmaz, E.; Atalay, F.S. Chemical Recycling of Polyethlylene Terephthalate by Glycolysis Using Deep Eutectic Solvents. J. Polym. Environ. 2019, 27, 2956–2962. [Google Scholar] [CrossRef]

- Liu, B.; Fu, W.; Lu, X.; Zhou, Q.; Zhang, S. Lewis Acid–Base Synergistic Catalysis for Polyethylene Terephthalate Degradation by 1,3-Dimethylurea/Zn(OAc)2 Deep Eutectic Solvent. ACS Sustain. Chem. Eng. 2019, 7, 3292–3300. [Google Scholar] [CrossRef]

- Yunita, I.; Putisompon, S.; Chumkaeo, P.; Poonsawat, T.; Somsook, E. Effective Catalysts Derived from Waste Ostrich Eggshells for Glycolysis of Post-Consumer PET Bottles. Chem. Pap. 2019, 73, 1547–1560. [Google Scholar] [CrossRef]

- Wang, Q.; Yao, X.; Tang, S.; Lu, X.; Zhang, X.; Zhang, S. Urea as an Efficient and Reusable Catalyst for the Glycolysis of Poly(Ethylene Terephthalate) Wastes and the Role of Hydrogen Bond in This Process. Green Chem. 2012, 14, 2559. [Google Scholar] [CrossRef]

- De Castro, A.M.; Carniel, A. A Novel Process for Poly(Ethylene Terephthalate) Depolymerization via Enzyme-Catalyzed Glycolysis. Biochem. Eng. J. 2017, 124, 64–68. [Google Scholar] [CrossRef]

- Jamdar, V.; Kathalewar, M.; Jagtap, R.N.; Dubey, K.A.; Sabnis, A. Effect of γ-Irradiation on Glycolysis of PET Waste and Preparation of Ecofriendly Coatings Using Bio-Based and Recycled Materials. Polym. Eng. Sci. 2015, 55, 2653–2660. [Google Scholar] [CrossRef]

- Kirshanov, K.A.; Gerval’d, A.Y.; Toms, R.V. Obtaining Oligoesters by Directed Glycolytic Destruction of Polyethylene Terephthalate Waste. Plast. Massy 2020, 1, 51–53. [Google Scholar] [CrossRef]

- Kirshanov, K.A.; Toms, R.V. Study of Polyethylene Terephthalate Glycolysis with a Mixture of Bis(2-Hydroxyethyl) Terephthalate and Its Oligomers. Plast. Massy 2021, 1, 50–52. [Google Scholar] [CrossRef]

- El Mejjatti, A.; Harit, T.; Riahi, A.; Khiari, R.; Bouabdallah, I.; Malek, F. Chemical Recycling of Poly(Ethylene Terephthalate). Application to the Synthesis of Multiblock Copolyesters. Express Polym. Lett. 2014, 8, 544–553. [Google Scholar] [CrossRef]

- Nagahata, R.; Sugiyama, J.; Velmathi, S.; Nakao, Y.; Goto, M.; Takeuchi, K. Synthesis of Poly(Ethylene Terephthalate-Co-Isophthalate) by Copolymerization of Ethylene Isophthalate Cyclic Dimer and Bis(2-Hydroxyethyl) Terephthalate. Polym. J. 2004, 36, 483–488. [Google Scholar] [CrossRef][Green Version]

- Sun, L.; Zhang, Y.; Wang, J.; Liu, F.; Jia, Z.; Liu, X.; Zhu, J. 2,5-Furandicarboxylic Acid as a Sustainable Alternative to Isophthalic Acid for Synthesis of Amorphous Poly(Ethylene Terephthalate) Copolyester with Enhanced Performance. J. Appl. Polym. Sci. 2019, 136, 47186. [Google Scholar] [CrossRef]

- Gan, Z.; Qu, S.; Li, S.; Tan, T.; Yang, J. Facile Synthesis of PET-Based Poly(Ether Ester)s with Striking Physical and Mechanical Properties. React. Funct. Polym. 2021, 164, 104936. [Google Scholar] [CrossRef]

- Shirali, H.; Rafizadeh, M.; Taromi, F.A. Synthesis and Characterization of Amorphous and Impermeable Poly(Ethylene-Co-1,4-Cyclohexylenedimethylene Terephthalate)/Organoclay Nanocomposite via in Situ Polymerization. J. Compos. Mater. 2014, 48, 301–315. [Google Scholar] [CrossRef]

- Kim, J.H.; Lee, S.Y.; Park, J.H.; Lyoo, W.S.; Noh, S.K. Kinetics of Polycondensation and Copolycondensation of Bis(3-Hydroxypropyl Terephthalate) and Bis(2-Hydroxyethyl Terephthalate). J. Appl. Polym. Sci. 2000, 77, 693–698. [Google Scholar] [CrossRef]

- Lewis, C.L.; Spruiell, J.E. Crystallization of 2-Methyl-1,3-Propanediol Substituted Poly(Ethylene Terephthalate). I. Thermal Behavior and Isothermal Crystallization. J. Appl. Polym. Sci. 2006, 100, 2592–2603. [Google Scholar] [CrossRef]

- Tsai, Y.; Fan, C.-H.; Wu, J.-H. Synthesis, Microstructures and Properties of Amorphous Poly(Ethylene Terephthalate-Co- Tricyclodecanedimethylene Terephthalate). J. Polym. Res. 2016, 23, 42. [Google Scholar] [CrossRef]

- Heidarzadeh, N.; Rafizadeh, M.; Taromi, F.A.; del Valle, L.J.; Franco, L.; Puiggalí, J. Biodegradability and Biocompatibility of Copoly(Butylene Sebacate-Co-Terephthalate)s. Polym. Degrad. Stab. 2017, 135, 18–30. [Google Scholar] [CrossRef]

- Collins, S.; Peace, S.K.; Richards, R.W.; MacDonald, W.A.; Mills, P.; King, S.M. Transesterification in Poly(Ethylene Terephthalate). Molecular Weight and End Group Effects. Macromolecules 2000, 33, 2981–2988. [Google Scholar] [CrossRef]

- Yeszhanov, A.B.; Korolkov, I.V.; Gorin, Y.G.; Dosmagambetova, S.S.; Zdorovets, M.V. Membrane Distillation of Pesticide Solutions Using Hydrophobic Track-Etched Membranes. Chem. Pap. 2020, 74, 3445–3453. [Google Scholar] [CrossRef]

- Kozhina, E.; Kulesh, E.; Bedin, S.; Doludenko, I.; Piryazev, A.; Korolkov, I.; Kozlovskiy, A.; Zdorovets, M.; Rogachev, A.; Shumskaya, A. One-Dimensional Magneto-Optical Nanostructures: Template Synthesis, Structure, Properties, and Application in Spectroscopy Based on Plasmon Resonance. IEEE Magn. Lett. 2022, 13, 6101905. [Google Scholar] [CrossRef]

- Kovalets, N.P.; Panov, D.V.; Filippova, Y.U.A.; Razumovskaya, I.V. Point Agglomeration of Nickel and Iron Nanowires Synthesized in the Pores of Track Membranes. Bull. Russ. Acad. Sci. Phys. 2021, 85, 1400–1403. [Google Scholar] [CrossRef]

- Doludenko, I.M.; Volchkov, I.S.; Turenko, B.A.; Koshelev, I.O.; Podkur, P.L.; Zagorskiy, D.L.; Kanevskii, V.M. Electrical Properties Arrays of Intersecting of Nanowires Obtained in the Pores of Track Membranes. Mater. Chem. Phys. 2022, 287, 126285. [Google Scholar] [CrossRef]

- Doludenko, I.M. Aspects of Pore Filling in Synthesis of FeNi Alloy Nanowires Using Track-Etched Membranes. Inorg. Mater. Appl. Res. 2022, 13, 531–535. [Google Scholar] [CrossRef]

- Lee, P.L.J.; Thangavel, V.; Guery, C.; Trautmann, C.; Toimil-Molares, M.E.; Morcrette, M. Etched Ion-Track Membranes as Tailored Separators in Li–S Batteries. Nanotechnology 2021, 32, 365401. [Google Scholar] [CrossRef] [PubMed]

- Temnov, D.; Rossouw, A.; Vinogradov, I.; Shabanova, N.; Mamonova, T.; Lizunov, N.; Perold, W.; Nechaev, A. Thermo-Activation Spectroscopy of Track-Etched Membranes Based on Polyethylene Terephthalate Films Irradiated by Swift Xe Ions. Radiat. Phys. Chem. 2022, 191, 109868. [Google Scholar] [CrossRef]

- Sokhoreva, V.V.; Kanaev, V.G.; Kashkarov, E.B.; Kulyukina, E.S.; Kuznetsov, S.I. Formation of a Track Template during PETP Irradiation with High-Energy Helium Ions for the Template Synthesis of Regular Microstructures. J. Surf. Investig. X-ray Synchrotron Neutron Tech. 2018, 12, 598–602. [Google Scholar] [CrossRef]

- Apel, P.Y.U.; Blonskaya, I.V.; Ivanov, O.M.; Kristavchuk, O.V.; Lizunov, N.E.; Nechaev, A.N.; Orelovich, O.L.; Polezhaeva, O.A.; Dmitriev, S.N. Creation of Ion-Selective Membranes from Polyethylene Terephthalate Films Irradiated with Heavy Ions: Critical Parameters of the Process. Membr. Membr. Technol. 2020, 2, 98–108. [Google Scholar] [CrossRef]

- Negi, S. Photo Driven Ion Transport and Pumping through Synthetic Nanochannels. Mater. Today Commun. 2021, 26, 102127. [Google Scholar] [CrossRef]

- Apel, P.Y.; Blonskaya, I.V.; Ivanov, O.M.; Kristavchuk, O.V.; Nechaev, A.N.; Olejniczak, K.; Orelovich, O.L.; Polezhaeva, O.A.; Dmitriev, S.N. Do the Soft-Etched and UV-Track Membranes Actually Have Uniform Cylindrical Subnanometer Channels? Radiat. Phys. Chem. 2022, 198, 110266. [Google Scholar] [CrossRef]

- Zhao, J.; Du, G.; Yao, H.; Guo, J.; Mao, G.; Liu, W.; Wu, R.; Shen, C.; Mou, H.; Zhao, C.; et al. Fabrication of Double Conical PET Nanochannel for Molecular Detection. Vacuum 2022, 202, 111198. [Google Scholar] [CrossRef]

- Wang, P.; Wang, X.; Ling, Y.; Wang, M.; Ding, S.; She, W.; Wang, Z.; Wang, Y.; Liu, F. Ultrafast Selective Ionic Transport through Heat-Treated Polyethylene Terephthalate Track Membranes with Sub-Nanometer Pores. Radiat. Meas. 2018, 119, 80–84. [Google Scholar] [CrossRef]

- Korolkov, I.V.; Yeszhanov, A.B.; Gorin, Y.G.; Zdorovets, M.V.; Khlebnikov, N.A.; Serkov, K.V. Hydrophobization of PET Track-Etched Membranes for Direct Contact Membrane Distillation. Mater. Res. Express 2018, 5, 065317. [Google Scholar] [CrossRef]

- Korolkov, I.V.; Narmukhamedova, A.R.; Melnikova, G.B.; Muslimova, I.B.; Yeszhanov, A.B.; Zhatkanbayeva, Z.K.; Chizhik, S.A.; Zdorovets, M.V. Preparation of Hydrophobic PET Track-Etched Membranes for Separation of Oil–Water Emulsion. Membranes 2021, 11, 637. [Google Scholar] [CrossRef]

- Korolkov, I.V.; Gorin, Y.G.; Yeszhanov, A.B.; Kozlovskiy, A.L.; Zdorovets, M.V. Preparation of PET Track-Etched Membranes for Membrane Distillation by Photo-Induced Graft Polymerization. Mater. Chem. Phys. 2018, 205, 55–63. [Google Scholar] [CrossRef]

- Shumskaya, A.; Kaniukov, E.; Yakimchuk, D.; Plisko, T.; Burts, K.; Bildyukevich, A.; Nikolaevich, L.; Kozlovskiy, A.; Zdorovets, M. Modified Ion-Track Membranes for Separation of Biological Objects. Mater. Res. Express 2019, 6, 0850h3. [Google Scholar] [CrossRef]

- Korolkov, I.V.; Mashentseva, A.A.; Güven, O.; Gorin, Y.G.; Zdorovets, M.V. Protein Fouling of Modified Microporous PET Track-Etched Membranes. Radiat. Phys. Chem. 2018, 151, 141–148. [Google Scholar] [CrossRef]

- Mashentseva, A.A. Effect of the Oxidative Modification and Activation of Templates Based on Poly(Ethylene Terephthalate) Track-Etched Membranes on the Electroless Deposition of Copper and the Catalytic Properties of Composite Membranes. Pet. Chem. 2019, 59, 1337–1344. [Google Scholar] [CrossRef]

- Vo, T.S.; Vo, T.T.B.C. Surface Characterization of Polyimide and Polyethylene Terephthalate Membranes toward Plasma and UV Treatments. Prog. Nat. Sci. Mater. Int. 2022, 32, 314–327. [Google Scholar] [CrossRef]

- Filippova, E.O.; Karpov, D.A.; Pichugin, V.F.; Ulbricht, M. The Investigation of the Influence of Low-Temperature Plasma and Steam Sterilization on the Properties of Track Membranes Made of Polyethylene Terephthalate. Inorg. Mater. Appl. Res. 2020, 11, 1116–1123. [Google Scholar] [CrossRef]

- Korolkov, I.V.; Yeszhanov, A.B.; Shakayeva, A.K.; Shlimas, D.I.; Zhumazhanova, A.; Zdorovets, M.V. Photo-Induced Graft (Co)Polymerization of Glycidyl Methacrylate and Acrylonitrile on PET Ion-Track Membranes for Electrochemical Detection of Uranyl Ions. Colloids Surf. A Physicochem. Eng. Asp. 2022, 648, 129086. [Google Scholar] [CrossRef]

- Zdorovets, M.V.; Korolkov, I.V.; Yeszhanov, A.B.; Gorin, Y.G. Functionalization of PET Track-Etched Membranes by UV-Induced Graft (Co)Polymerization for Detection of Heavy Metal Ions in Water. Polymers 2019, 11, 1876. [Google Scholar] [CrossRef]

- Nguyen, T.; Jung, S.H.; Lee, M.S.; Park, T.-E.; Ahn, S.; Kang, J.H. Robust Chemical Bonding of PMMA Microfluidic Devices to Porous PETE Membranes for Reliable Cytotoxicity Testing of Drugs. Lab. Chip. 2019, 19, 3706–3713. [Google Scholar] [CrossRef]

- Parmanbek, N.; Sütekin, D.S.; Barsbay, M.; Mashentseva, A.A.; Zheltov, D.A.; Aimanova, N.A.; Jakupova, Z.Y.; Zdorovets, M.V. Hybrid PET Track-Etched Membranes Grafted by Well-Defined Poly(2-(Dimethylamino)Ethyl Methacrylate) Brushes and Loaded with Silver Nanoparticles for the Removal of As(III). Polymers 2022, 14, 4026. [Google Scholar] [CrossRef]

- Shang, Y.; Zhang, Y.; Li, P.; Lai, J.; Kong, X.-Y.; Liu, W.; Xiao, K.; Xie, G.; Tian, Y.; Wen, L.; et al. DNAzyme Tunable Lead (ii) Gating Based on Ion-Track Etched Conical Nanochannels. Chem. Commun. 2015, 51, 5979–5981. [Google Scholar] [CrossRef] [PubMed]

- Muench, F. Direct Surface Functionalization with Metal and Metal Oxide Nanostructures. In Reference Module in Materials Science and Materials Engineering; Hashmi, S., Ed.; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Muench, F. Electroless Plating of Metal Nanomaterials. ChemElectroChem 2021, 8, 2993–3012. [Google Scholar] [CrossRef]

- Do Nascimento, K.T.O.; Ratkovski, G.P.; Pedro, G.D.C.; Gorza, F.D.S.; da Silva, R.J.; de Melo, C.P. Intrinsically Conductive Polymers Hybrid Bilayer Films for the Fluorescence Molecular Diagnosis of the Zika Virus. Colloids Surf. B Biointerfaces 2021, 208, 112120. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.-L.; Hua, Y.; Pan, Z.-Q.; Qian, J.-H.; Yu, X.-Y.; Bao, N.; Huo, X.-L.; Wu, Z.-Q.; Xia, X.-H. PNP Nanofluidic Transistor with Actively Tunable Current Response and Ionic Signal Amplification. Nano Lett. 2022, 22, 3678–3684. [Google Scholar] [CrossRef] [PubMed]

- Wiedenhöft, L.; Elleithy, M.M.A.; Ulbricht, M.; Schacher, F.H. Polyelectrolyte Functionalisation of Track Etched Membranes: Towards Charge-Tuneable Adsorber Materials. Membranes 2021, 11, 509. [Google Scholar] [CrossRef]

- Korolkov, I.V.; Zhumanazar, N.; Gorin, Y.G.; Yeszhanov, A.B.; Zdorovets, M.V. Enhancement of Electrochemical Detection of Pb2+ by Sensor Based on Track-Etched Membranes Modified with Interpolyelectrolyte Complexes. J. Mater. Sci. Mater. Electron. 2020, 31, 20368–20377. [Google Scholar] [CrossRef]

- Rossouw, A.; Olejniczak, A.; Olejniczak, K.; Gorberg, B.; Vinogradov, I.; Kristavchuk, O.; Nechaev, A.; Petrik, L.; Perold, W.; Dmitriev, S. Ti and TiO2 Magnetron Sputtering in Roll-to-Roll Fabrication of Hybrid Membranes. Surf. Interfaces 2022, 31, 101975. [Google Scholar] [CrossRef]

- Rossouw, A.; Kristavchuk, O.; Olejniczak, A.; Bode-Aluko, C.; Gorberg, B.; Nechaev, A.; Petrik, L.; Perold, W.; Apel, P. Modification of Polyethylene Terephthalate Track Etched Membranes by Planar Magnetron Sputtered Ti/TiO2 Thin Films. Thin Solid Films 2021, 725, 138641. [Google Scholar] [CrossRef]

- Pereao, O.; Uche, C.; Bublikov, P.S.; Bode-Aluko, C.; Rossouw, A.; Vinogradov, I.I.; Nechaev, A.N.; Opeolu, B.; Petrik, L. Chitosan/PEO Nanofibers Electrospun on Metallized Track-Etched Membranes: Fabrication and Characterization. Mater. Today Chem. 2021, 20, 100416. [Google Scholar] [CrossRef]

- Kutuzau, M.; Shumskaya, A.; Kaniukov, E.; Alisienok, O.; Shidlouskaya, V.; Melnikova, G.; Shemukhin, A.; Nazarov, A.; Kozlovskiy, A.; Zdorovets, M. Photocatalytically Active Filtration Systems Based on Modified with Titanium Dioxide PET-Membranes. Nucl. Instrum. Methods Phys. Res. B 2019, 460, 212–215. [Google Scholar] [CrossRef]

- Altynbaeva, L.S.H.; Barsbay, M.; Aimanova, N.A.; Jakupova, Z.Y.; Nurpeisova, D.T.; Zdorovets, M.V.; Mashentseva, A.A. A Novel Cu2O/ZnO@PET Composite Membrane for the Photocatalytic Degradation of Carbendazim. Nanomaterials 2022, 12, 1724. [Google Scholar] [CrossRef] [PubMed]

- Khashij, M.; Salmani, M.H.; Dalvand, A.; Fallahzadeh, H.; Haghirosadat, F.; Mokhtari, M. Fabrication of ZnO/y-FeOOH Nanoparticles Embedded on the Polyethylene Terephthalate Membrane: Evaluation of Antifouling Behavior and COD Removal. Environ. Sci. Pollut. Res. 2022, 29, 67014–67025. [Google Scholar] [CrossRef] [PubMed]

- Korolkov, I.V.; Mashentseva, A.A.; Güven, O.; Gorin, Y.G.; Kozlovskiy, A.L.; Zdorovets, M.V.; Zhidkov, I.S.; Cholach, S.O. Electron/Gamma Radiation-Induced Synthesis and Catalytic Activity of Gold Nanoparticles Supported on Track-Etched Poly(Ethylene Terephthalate) Membranes. Mater. Chem. Phys. 2018, 217, 31–39. [Google Scholar] [CrossRef]

- Ndilowe, G.M.; Bode-Aluko, C.A.; Chimponda, D.; Kristavchuk, O.; Kochnev, I.; Nechaev, A.; Petrik, L. Fabrication of Silver-Coated PET Track-Etched Membrane as SERS Platform for Detection of Acetaminophen. Colloid Polym. Sci. 2021, 299, 1729–1741. [Google Scholar] [CrossRef]

- Ashtiani, S.; Khoshnamvand, M.; Shaliutina-Kolešová, A.; Bouša, D.; Sofer, Z.; Friess, K. Co0·5Ni0·5FeCrO4 Spinel Nanoparticles Decorated with UiO-66-Based Metal-Organic Frameworks Grafted onto GO and O-SWCNT for Gas Adsorption and Water Purification. Chemosphere 2020, 255, 126966. [Google Scholar] [CrossRef]

- Ashtiani, S.; Sofer, Z.; Průša, F.; Friess, K. Molecular-Level Fabrication of Highly Selective Composite ZIF-8-CNT-PDMS Membranes for Effective CO2/N2, CO2/H2 and Olefin/Paraffin Separations. Sep. Purif. Technol. 2021, 274, 119003. [Google Scholar] [CrossRef]

- Usman, M.; Ali, M.; Al-Maythalony, B.A.; Ghanem, A.S.; Saadi, O.W.; Ali, M.; Jafar Mazumder, M.A.; Abdel-Azeim, S.; Habib, M.A.; Yamani, Z.H.; et al. Highly Efficient Permeation and Separation of Gases with Metal–Organic Frameworks Confined in Polymeric Nanochannels. ACS Appl. Mater. Interfaces 2020, 12, 49992–50001. [Google Scholar] [CrossRef]

- Awasthi, K.; Choudhury, S.; Komber, H.; Simon, F.; Formanek, P.; Sharma, A.; Stamm, M. Functionalization of Track-Etched Poly (Ethylene Terephthalate) Membranes as a Selective Filter for Hydrogen Purification. Int. J. Hydrogen Energy 2014, 39, 9356–9365. [Google Scholar] [CrossRef]

- Kamakshi, K.R.; Saraswat, V.K.; Kumar, M.; Awasthi, K. Palladium Nanoparticle Binding in Functionalized Track Etched PET Membrane for Hydrogen Gas Separation. Int. J. Hydrogen Energy 2017, 42, 16186–16194. [Google Scholar] [CrossRef]

- Kozhina, E.P.; Bedin, S.A.; Nechaeva, N.L.; Podoynitsyn, S.N.; Tarakanov, V.P.; Andreev, S.N.; Grigoriev, Y.V.; Naumov, A.V. Ag-Nanowire Bundles with Gap Hot Spots Synthesized in Track-Etched Membranes as Effective SERS-Substrates. Appl. Sci. 2021, 11, 1375. [Google Scholar] [CrossRef]

- Korolkov, I.V.; Shumskaya, A.; Kozlovskiy, A.L.; Kaliyekperov, M.E.; Lissovskaya, L.I.; Zdorovets, M.V. Magnetic-Plasmonic Ni Nanotubes Covered with Gold for Improvement of SERS Analysis. J. Alloys Compd. 2022, 901, 163661. [Google Scholar] [CrossRef]

- Shumskaya, A.; Kozhina, E.; Bedin, S.; Andreev, S.; Kulesh, E.; Rogachev, A.; Yarmolenko, M.; Korolkov, I.; Kozlovskiy, A.; Zdorovets, M.; et al. Detection of Polynitro Compounds at Low Concentrations by SERS Using Ni@Au Nanotubes. Chemosensors 2022, 10, 306. [Google Scholar] [CrossRef]

- Mashentseva, A.; Borgekov, D.; Kislitsin, S.; Zdorovets, M.; Migunova, A. Comparative Catalytic Activity of PET Track-Etched Membranes with Embedded Silver and Gold Nanotubes. Nucl. Instrum. Methods Phys. Res. B 2015, 365, 70–74. [Google Scholar] [CrossRef]

- Mashentseva, A.; Borgekov, D.; Zdorovets, M.; Russakova, A. Synthesis, Structure, and Catalytic Activity of Au/Poly(Ethylene Terephthalate) Composites. Acta Phys. Pol. A 2014, 125, 1263–1267. [Google Scholar] [CrossRef]

- Mashentseva, A.A.; Korolkov, I.V.; Yeszhanov, A.B.; Zdorovets, M.V.; Russakova, A.V. The Application of Composite Ion Track Membranes with Embedded Gold Nanotubes in the Reaction of Aminomethylation of Acetophenone. Mater. Res. Express 2019, 6, 115022. [Google Scholar] [CrossRef]

- Mashentseva, A.A.; Barsbay, M.; Aimanova, N.A.; Zdorovets, M.V. Application of Silver-Loaded Composite Track-Etched Membranes for Photocatalytic Decomposition of Methylene Blue under Visible Light. Membranes 2021, 11, 60. [Google Scholar] [CrossRef]

- Mashentseva, A.A.; Zdorovets, M.V. Composites Based on Polyethylene Terephthalate Track-Etched Membranes and Silver as Hydrogen Peroxide Decomposition Catalysts. Pet. Chem. 2017, 57, 954–960. [Google Scholar] [CrossRef]

- Muench, F.; Rauber, M.; Stegmann, C.; Lauterbach, S.; Kunz, U.; Kleebe, H.-J.; Ensinger, W. Ligand-Optimized Electroless Synthesis of Silver Nanotubes and Their Activity in the Reduction of 4-Nitrophenol. Nanotechnology 2011, 22, 415602. [Google Scholar] [CrossRef]

- Borgekov, D.; Mashentseva, A.; Kislitsin, S.; Kozlovskiy, A.; Russakova, A.; Zdorovets, M. Temperature Dependent Catalytic Activity of Ag/PET Ion-Track Membranes Composites. Acta Phys. Pol. A 2015, 128, 871–875. [Google Scholar] [CrossRef]

- Mashentseva, A.A.; Barsbay, M.; Zdorovets, M.V.; Zheltov, D.A.; Güven, O. Cu/CuO Composite Track-Etched Membranes for Catalytic Decomposition of Nitrophenols and Removal of As(III). Nanomaterials 2020, 10, 1552. [Google Scholar] [CrossRef]

- Mashentseva, A.A.; Zdorovets, M.V. Catalytic Activity of Composite Track-Etched Membranes Based on Copper Nanotubes in Flow and Static Modes. Pet. Chem. 2019, 59, 552–557. [Google Scholar] [CrossRef]

- Mashentseva, A.A.; Kozlovskiy, A.L.; Zdorovets, M.V. Influence of Deposition Temperature on the Structure and Catalytic Properties of the Copper Nanotubes Composite Membranes. Mater. Res. Express 2018, 5, 065041. [Google Scholar] [CrossRef]

- Russakova, A.V.; Altynbaeva, L.S.; Barsbay, M.; Zheltov, D.A.; Zdorovets, M.V.; Mashentseva, A.A. Kinetic and Isotherm Study of As(III) Removal from Aqueous Solution by PET Track-Etched Membranes Loaded with Copper Microtubes. Membranes 2021, 11, 116. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Ning, W.; Peng, Q.; Yang, M.; Lei, D.; Guo, S.; Liu, P.; Jiang, K.; He, X.; Li, Y. Superbroad-Band Actively Tunable Acoustic Metamaterials Driven from Poly (Ethylene Terephthalate)/Carbon Nanotube Nanocomposite Membranes. Nano Res. 2021, 14, 100–107. [Google Scholar] [CrossRef]

- Kaniukov, E.; Shumskaya, A.; Yakimchuk, D.; Kozlovskiy, A.; Korolkov, I.; Ibragimova, M.; Zdorovets, M.; Kadyrzhanov, K.; Rusakov, V.; Fadeev, M.; et al. FeNi Nanotubes: Perspective Tool for Targeted Delivery. Appl. Nanosci. 2019, 9, 835–844. [Google Scholar] [CrossRef]

- Kozlovskiy, A.; Zdorovets, M.; Kadyrzhanov, K.; Korolkov, I.; Rusakov, V.; Nikolaevich, L.; Fesenko, O.; Budnyk, O.; Yakimchuk, D.; Shumskaya, A.; et al. FeCo Nanotubes: Possible Tool for Targeted Delivery of Drugs and Proteins. Appl. Nanosci. 2019, 9, 1091–1099. [Google Scholar] [CrossRef]

- Kozlovskiy, A.L.; Zdorovets, M.V.; Shumskaya, A.E.; Kadyrzhanov, K.K. Study of the Applicability of FE Nanotubes as an Anode Material of Lithium-ion Batteries. Prog. Electromagn. Res. M 2019, 82, 157–166. [Google Scholar] [CrossRef]

- Starosta, W.; Wawszczak, D.; Sartowska, B.; Buczkowski, M. Investigations of Heavy Ion Tracks in Polyethylene Naphthalate Films. Radiat. Meas. 1999, 31, 149–152. [Google Scholar] [CrossRef]

- Molokanova, L.G.; Kochnev, Y.U.K.; Nechaev, A.N.; Chukova, S.N.; Apel, P.Y.U. Effect of Ultraviolet Radiation on Polyethylene Naphthalate Films Irradiated with High-Energy Heavy Ions. High Energy Chem. 2017, 51, 182–188. [Google Scholar] [CrossRef]

- Ivanova, N.M.; Filippova, E.O.; Tverdokhlebov, S.I.; Levkovich, N.V.; Apel, P.Y.U. Preparation, Structure, and Properties of Track-Etched Membranes Based on Polylactic Acid. Membr. Membr. Technol. 2021, 3, 282–290. [Google Scholar] [CrossRef]

- Kang, H.J.; Youm, J.S.; Kim, J.H. Characteristics of PET-PEN Copolymer as a Material for Flexible Substrate. Polym. Korea 2011, 35, 599–604. [Google Scholar] [CrossRef]

- Krentsel’, L.B.; Makarova, V.V.; Kudryavtsev, Y.A.V.; Govorun, E.N.; Litmanovich, A.D.; Markova, G.D.; Vasnev, V.A.; Kulichikhin, V.G. Interchain Exchange and Interdiffusion in Blends of Poly(Ethylene Terephthalate) and Poly(Ethylene Naphthalate). Polym. Sci. Ser. A 2009, 51, 1241–1248. [Google Scholar] [CrossRef]

- Gunes, K.; Isayev, A.I.; Li, X.; Wesdemiotis, C. Fast in Situ Copolymerization of PET/PEN Blends by Ultrasonically-Aided Extrusion. Polymer 2010, 51, 1071–1081. [Google Scholar] [CrossRef]

- Buasri, A.; Ongmali, D.; Sriboonpeng, P.; Prompanut, S.; Loryuenyong, V. Synthesis of PET-PLA Copolymer from Recycle Plastic Bottle and Study of Its Applications in the Electrochromic Devices with Graphene Conductive Ink. Mater. Today Proc. 2018, 5, 11060–11067. [Google Scholar] [CrossRef]

- Flores, I.; Etxeberria, A.; Irusta, L.; Calafel, I.; Vega, J.F.; Martínez-Salazar, J.; Sardon, H.; Müller, A.J. PET-PLA Partially Degradable Random Copolymers Prepared by Organocatalysis: Effect of Poly( Lactic Acid) Incorporation on Crystallization and Morphology. ACS Sustain. Chem. Eng. 2019, 7, 8647–8659. [Google Scholar] [CrossRef]

- Yasin, S.; Bakr, Z.H.; Ali, G.A.M.; Saeed, I. Recycling Nanofibers from Polyethylene Terephthalate Waste Using Electrospinning Technique. In Waste Recycling Technologies for Nanomaterials Manufacturing; Springer: Cham, Switzerland, 2021; pp. 805–821. [Google Scholar]

- Xu, G.-R.; An, X.-C.; Das, R.; Xu, K.; Xing, Y.-L.; Hu, Y.-X. Application of Electrospun Nanofibrous Amphiphobic Membrane Using Low-Cost Poly (Ethylene Terephthalate) for Robust Membrane Distillation. J. Water Process Eng. 2020, 36, 101351. [Google Scholar] [CrossRef]

- Topuz, F.; Oldal, D.G.; Szekely, G. Valorization of Polyethylene Terephthalate (PET) Plastic Wastes as Nanofibrous Membranes for Oil Removal: Sustainable Solution for Plastic Waste and Oil Pollution. Ind. Eng. Chem. Res. 2022, 61, 9077–9086. [Google Scholar] [CrossRef]

- Doan, H.N.; Phong Vo, P.; Hayashi, K.; Kinashi, K.; Sakai, W.; Tsutsumi, N. Recycled PET as a PDMS-Functionalized Electrospun Fibrous Membrane for Oil-Water Separation. J. Environ. Chem. Eng. 2020, 8, 103921. [Google Scholar] [CrossRef]

- Strain, I.N.; Wu, Q.; Pourrahimi, A.M.; Hedenqvist, M.S.; Olsson, R.T.; Andersson, R.L. Electrospinning of Recycled PET to Generate Tough Mesomorphic Fibre Membranes for Smoke Filtration. J. Mater. Chem. A Mater. 2015, 3, 1632–1640. [Google Scholar] [CrossRef]

- Bonfim, D.P.F.; Cruz, F.G.S.; Bretas, R.E.S.; Guerra, V.G.; Aguiar, M.L. A Sustainable Recycling Alternative: Electrospun PET-Membranes for Air Nanofiltration. Polymers 2021, 13, 1166. [Google Scholar] [CrossRef]

- Opálková Šišková, A.; Frajová, J.; Nosko, M. Recycling of Poly(Ethylene Terephthalate) by Electrospinning to Enhanced the Filtration Efficiency. Mater. Lett. 2020, 278, 128426. [Google Scholar] [CrossRef]

- Opálková Šišková, A.; Mosnáčková, K.; Hrůza, J.; Frajová, J.; Opálek, A.; Bučková, M.; Kozics, K.; Peer, P.; Eckstein Andicsová, A. Electrospun Poly(Ethylene Terephthalate)/Silk Fibroin Composite for Filtration Application. Polymers 2021, 13, 2499. [Google Scholar] [CrossRef]

- Song, J.; Zhao, Q.; Meng, C.; Meng, J.; Chen, Z.; Li, J. Hierarchical Porous Recycled PET Nanofibers for High-Efficiency Aerosols and Virus Capturing. ACS Appl. Mater. Interfaces 2021, 13, 49380–49389. [Google Scholar] [CrossRef]

- Wu, H.; Zhao, H.; Lin, Y.; Liu, X.; Yao, H.; Yu, L.; Wang, H.; Wang, X. Fabrication of Polysulfone Membrane with Sponge-like Structure by Using Different Non-Woven Fabrics. Sep. Purif. Technol. 2022, 297, 121553. [Google Scholar] [CrossRef]

- Tas, M.; Musa, U.G.; Ahmed, I.; Xu, F.; Smartt, C.; Hou, X. Functionalised SiO2 Modified Icephobic Nanocomposite Electrospun Membranes for Outdoor Electromagnetic Shielding Applications. Polymer 2022, 240, 124499. [Google Scholar] [CrossRef]

- Liu, R.; Qu, M.; Qiu, X.; Wang, H.; Fan, M.; Zhang, A.; Chen, Q.; Bin, Y. Poly (Ethylene Terephthalate) Nonwoven Fabrics-based Membranes Modified by Electrospinning of Thermoplastic Polyurethane, Nano SiO 2 and Ag Particles as Medical Packing Materials. Packag. Technol. Sci. 2022, 35, 557–567. [Google Scholar] [CrossRef]

- Grumezescu, A.M.; Stoica, A.E.; Dima-Bălcescu, M.-Ș.; Chircov, C.; Gharbia, S.; Baltă, C.; Roșu, M.; Herman, H.; Holban, A.M.; Ficai, A.; et al. Electrospun Polyethylene Terephthalate Nanofibers Loaded with Silver Nanoparticles: Novel Approach in Anti-Infective Therapy. J. Clin. Med. 2019, 8, 1039. [Google Scholar] [CrossRef]

- De Oliveira Santos, R.P.; Ramos, L.A.; Frollini, E. Bio-Based Electrospun Mats Composed of Aligned and Nonaligned Fibers from Cellulose Nanocrystals, Castor Oil, and Recycled PET. Int. J. Biol. Macromol. 2020, 163, 878–887. [Google Scholar] [CrossRef]

- Essa, W.K.; Yasin, S.A.; Abdullah, A.H.; Thalji, M.R.; Saeed, I.A.; Assiri, M.A.; Chong, K.F.; Ali, G.A.M. Taguchi L25 (54) Approach for Methylene Blue Removal by Polyethylene Terephthalate Nanofiber-Multi-Walled Carbon Nanotube Composite. Water 2022, 14, 1242. [Google Scholar] [CrossRef]

- Gün Gök, Z.; İnal, M.; Bozkaya, O.; Yiğitoğlu, M.; Vargel, İ. Production of 2-hydroxyethyl Methacrylate-g-poly(Ethylene Terephthalate) Nanofibers by Electrospinning and Evaluation of the Properties of the Obtained Nanofibers. J. Appl. Polym. Sci. 2020, 137, 49257. [Google Scholar] [CrossRef]

- Wu, C.-S.; Wu, D.-Y.; Wang, S.-S. Characterization and Functionality of Nanocomposite Mats Containing Polyester, Seashell, and Silica Aerogel Using an Electrospinning Fabrication Approach. Polym. Bull. 2022. [Google Scholar] [CrossRef]

- Danti, S.; Anand, S.; Azimi, B.; Milazzo, M.; Fusco, A.; Ricci, C.; Zavagna, L.; Linari, S.; Donnarumma, G.; Lazzeri, A.; et al. Chitin Nanofibril Application in Tympanic Membrane Scaffolds to Modulate Inflammatory and Immune Response. Pharmaceutics 2021, 13, 1440. [Google Scholar] [CrossRef] [PubMed]

- Cho, C.-J.; Chang, Y.-S.; Lin, Y.-Z.; Jiang, D.-H.; Chen, W.-H.; Lin, W.-Y.; Chen, C.-W.; Rwei, S.-P.; Kuo, C.-C. Green Electrospun Nanofiber Membranes Filter Prepared from Novel Biomass Thermoplastic Copolyester: Morphologies and Filtration Properties. J. Taiwan Inst. Chem. Eng. 2020, 106, 206–214. [Google Scholar] [CrossRef]

- Baig, U.; Waheed, A. Fabrication of Polypyrrole-Graphitic Carbon Nitride Nanocomposite Containing Hyper-Cross-Linked Polyamide Photoresponsive Membrane with Self-Cleaning Properties for Water Decontamination and Desalination Applications. J. Water Process Eng. 2022, 47, 102721. [Google Scholar] [CrossRef]

- Lu, D.; Babaniamansour, P.; Williams, A.; Opfar, K.; Nurick, P.; Escobar, I.C. Fabrication and Evaporation Time Investigation of Water Treatment Membranes Using Green Solvents and Recycled Polyethylene Terephthalate. J. Appl. Polym. Sci. 2022, 139, e52823. [Google Scholar] [CrossRef]

- Cadore, Í.R.; Ambrosi, A.; Cardozo, N.S.M.; Tessaro, I.C. Poly(Ethylene Terephthalate) Phase Inversion Membranes: Thermodynamics and Effects of a Poor Solvent on the Membrane Characteristics. Polym. Eng. Sci. 2022, 62, 1847–1858. [Google Scholar] [CrossRef]

- Cadore, Í.R.; Ambrosi, A.; Cardozo, N.S.M.; Tessaro, I.C. Phase Separation Behavior of Poly(Ethylene Terephthalate)/(Trifluoroacetic Acid/Dichloromethane)/Water System for Wet Phase Inversion Membrane Preparation. J. Appl. Polym. Sc.i 2019, 136, 47263. [Google Scholar] [CrossRef]

- Kiani, S.; Mousavi, S.M.; Bidaki, A. Preparation of Polyethylene Terephthalate/Xanthan Nanofiltration Membranes Using Recycled Bottles for Removal of Diltiazem from Aqueous Solution. J. Clean. Prod. 2021, 314, 128082. [Google Scholar] [CrossRef]

- Pulido, B.A.; Habboub, O.S.; Aristizabal, S.L.; Szekely, G.; Nunes, S.P. Recycled Poly(Ethylene Terephthalate) for High Temperature Solvent Resistant Membranes. ACS Appl. Polym. Mater. 2019, 1, 2379–2387. [Google Scholar] [CrossRef]

- Park, S.-H.; Alammar, A.; Fulop, Z.; Pulido, B.A.; Nunes, S.P.; Szekely, G. Hydrophobic Thin Film Composite Nanofiltration Membranes Derived Solely from Sustainable Sources. Green Chem. 2021, 23, 1175–1184. [Google Scholar] [CrossRef]

- Park, S.-H.; Yang, C.; Ayaril, N.; Szekely, G. Solvent-Resistant Thin-Film Composite Membranes from Biomass-Derived Building Blocks: Chitosan and 2,5-Furandicarboxaldehyde. ACS Sustain. Chem. Eng. 2022, 10, 998–1007. [Google Scholar] [CrossRef]

- Kusumocahyo, S.P.; Ambani, S.K.; Kusumadewi, S.; Sutanto, H.; Widiputri, D.I.; Kartawiria, I.S. Utilization of Used Polyethylene Terephthalate (PET) Bottles for the Development of Ultrafiltration Membrane. J. Environ. Chem. Eng. 2020, 8, 104381. [Google Scholar] [CrossRef]

- Kusumocahyo, S.P.; Ambani, S.K.; Marceline, S. Improved Permeate Flux and Rejection of Ultrafiltration Membranes Prepared from Polyethylene Terephthalate (PET) Bottle Waste. Sustain. Environ. Res. 2021, 31, 19. [Google Scholar] [CrossRef]

- Ashtiani, S.; Khoshnamvand, M.; Číhal, P.; Dendisová, M.; Randová, A.; Bouša, D.; Shaliutina-Kolešová, A.; Sofer, Z.; Friess, K. Fabrication of a PVDF Membrane with Tailored Morphology and Properties via Exploring and Computing Its Ternary Phase Diagram for Wastewater Treatment and Gas Separation Applications. RSC Adv. 2020, 10, 40373–40383. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Lu, X.; Zhao, L. Preparation of Polyvinylidene Fluoride (PVDF) Hollow Fiber Hemodialysis Membranes. Membranes 2014, 4, 81–95. [Google Scholar] [CrossRef]

- Kesting, R.E. Microporous Polyester Membranes and Polymer Assisted Phase Inversion Process for Their Manufacture. U.S. Patent 3,957,651, 18 May 1976. [Google Scholar]

- Gronwald, O.; Weber, M.; Muhlbach, K. Process for Producing Microporous Polyester Membranes for Electronic. Applications. Patent No. PCT/EP2015/062538, 17 December 2015. [Google Scholar]

- Realpe, Á.; Romero, K.A.; Acevedo, M.T. Síntesis de Membranas de Intercambio Protónico a Partir de Mezcla de Poliéster Insaturado y Látex Natural, Para Su Uso En Celdas de Combustible. Inf. Tecnol. 2015, 26, 55–62. [Google Scholar] [CrossRef][Green Version]

- Wu, L.; Sancaktar, E. Effect of PET Support Membrane Thickness on Water Permeation Behavior of Thermally Responsive PNIPAM-g-PET Membranes. J. Memb. Sci. 2020, 610, 118304. [Google Scholar] [CrossRef]

- Voss, H.; Therre, J.; Kaltenborn, N.; Richter, H.; Voigt, I. Process for Producing Carbon Membranes. U.S. Patent No. US8608828, 5 April 2012. [Google Scholar]

- Efimov, M.N.; Vasilev, A.A.; Muratov, D.G.; Dzidziguri, E.L.; Sheverdiyev, K.A.; Karpacheva, G.P. Conversion of Polyethylene Terephthalate Waste in the Presence of Cobalt Compound into Highly-Porous Metal-Carbon Nanocomposite (c-PET-Co). Compos. Commun. 2022, 33, 101200. [Google Scholar] [CrossRef]

| Disadvantage | Primary and Secondary Recycling | Incineration | Tertiary (Chemical) Recycling |

|---|---|---|---|

| Deterioration of polymer properties | + | + | - |

| Moisture sensitivity | + | - | - |

| Negative effect of additives on properties | + | - | +/- 1 |

| Low process rate | - | - | + |

| The need to regenerate liquid components | - | - | + |

| Toxicity of the components | - | + | + |

| Method | Agents | References |

|---|---|---|

| Grafting | Polyvinyl alcohol, glutaraldehyde (binding agent), hydrochloric acid (catalyst) | [83] |

| Acrylic acid, N-vinylimidazole | [84] | |

| Oxidation | Hydrogen peroxide | [84,85] |

| UV treatment | [86] | |

| Plasma treatment | [86,87] | |

| Steam treatment | [87] 1 |

| Coating Type | Substances | Properties | Applications | References |

|---|---|---|---|---|

| Polyelectrolyte | Polyaniline | Electrical conductivity and other electrophysical properties | Detection of the charged molecules | [95,96] |

| Polypyrrole | [95] | |||

| Poly(2-acrylamido glycolic acid) | [97] | |||

| Poly(N-acetyl dehydroalanine) | [97] | |||

| Methacrylic acid/poly(allylamine) | Heavy ions detection | [98] | ||

| Nanoparticles | Titanium | Electrical conductivity, chemical and thermal stability | Production of the sensitive electrodes | [99,100,101] |

| Titanium dioxide | Catalytic activity | Preparation of the catalysts | [99,100,102] | |

| Cuprous oxide | [103] | |||

| Zinc oxide | [103,104] | |||

| Gold | [105] | |||

| Silver | Detection of acetaminophen in water | [106] | ||

| Co0·5 Ni0·5 FeCrO4 | Magnetic properties | Gas adsorption or separation, water purification | [107] | |

| Adsorption properties | ||||

| Metal–organic framework | [108,109] | |||

| Pd | Hydrogen purification | [110,111] | ||

| Tubes and wires | Ag nanowires | SERS analysis | [112] | |

| Nickel/gold microtubes | [113,114] | |||

| Gold microtubes | [113,114] | |||

| Catalytic activity | Preparation of the catalysts | [115,116,117] | ||

| Silver microtubes | [118,119,120,121] | |||

| Copper microtubes | [122,123,124] | |||

| Adsorption properties | Removal of the arsenic compounds | [125] | ||

| Carbon nanotubes | Gas adsorption or separation, water purification | [107,108] | ||

| Lightweight, electrical conductivity, low specific heat | Production of acoustic membranes, production of batteries, protection against electromagnetic interference | [126] | ||

| Fe/Ni nanotubes | Targeted delivery of drugs and proteins | [127] | ||

| Fe/Co nanotubes | [128] | |||

| Fe nanotubes | Preparation of lithium-ion batteries | [129] |

| Component Type | Substances | References |

|---|---|---|

| Solvent | Trifluoroacetic acid, dichloromethane | [159,160] |

| Trifluoroacetic acid | [161,162] | |

| 1,1,1,3,3,3-Hexafluoro-2-propanol | [162] | |

| Phenol, 100 °C | [165,166] | |

| m-Cresol, 100 °C | [165] | |

| Dimethyl sulfoxide, 100 °C | [165] | |

| Non-solvent | Water | [160,161,162] |

| Methanol | [161,162] | |

| Ethanol | [162,165,166] | |

| n-Propanol | [165] | |

| n-Butanol | [165] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kirshanov, K.; Toms, R.; Aliev, G.; Naumova, A.; Melnikov, P.; Gervald, A. Recent Developments and Perspectives of Recycled Poly(ethylene terephthalate)-Based Membranes: A Review. Membranes 2022, 12, 1105. https://doi.org/10.3390/membranes12111105

Kirshanov K, Toms R, Aliev G, Naumova A, Melnikov P, Gervald A. Recent Developments and Perspectives of Recycled Poly(ethylene terephthalate)-Based Membranes: A Review. Membranes. 2022; 12(11):1105. https://doi.org/10.3390/membranes12111105

Chicago/Turabian StyleKirshanov, Kirill, Roman Toms, Gadir Aliev, Alina Naumova, Pavel Melnikov, and Alexander Gervald. 2022. "Recent Developments and Perspectives of Recycled Poly(ethylene terephthalate)-Based Membranes: A Review" Membranes 12, no. 11: 1105. https://doi.org/10.3390/membranes12111105

APA StyleKirshanov, K., Toms, R., Aliev, G., Naumova, A., Melnikov, P., & Gervald, A. (2022). Recent Developments and Perspectives of Recycled Poly(ethylene terephthalate)-Based Membranes: A Review. Membranes, 12(11), 1105. https://doi.org/10.3390/membranes12111105