Abstract

In the last decades, the incorporation of copper in polymeric membranes for water treatment has received greater attention, as an innovative potential solution against biofouling formation on membranes, as well as, by its ability to improve other relevant membrane properties. Copper has attractive characteristics: excellent antimicrobial activity, high natural abundance, low cost and the existence of multiple cost-effective synthesis routes for obtaining copper-based materials with tunable characteristics, which favor their incorporation into polymeric membranes. This study presents a comprehensive analysis of the progress made in the area regarding modified membranes for water treatment when incorporating copper. The notable use of copper materials (metallic and oxide nanoparticles, salts, composites, metal-polymer complexes, coordination polymers) for modifying microfiltration (MF), ultrafiltration (UF), nanofiltration (NF), forward osmosis (FO) and reverse osmosis (RO) membranes have been identified. Antibacterial and anti-fouling effect, hydrophilicity increase, improvements of the water flux, the rejection of compounds capacity and structural membrane parameters and the reduction of concentration polarization phenomena are some outstanding properties that improved. Moreover, the study acknowledges different membrane modification approaches to incorporate copper, such as, the incorporation during the membrane synthesis process (immobilization in polymer and phase inversion) or its surface modification using physical (coating, layer by layer assembly and electrospinning) and chemical (grafting, one-pot chelating, co-deposition and mussel-inspired PDA) surface modification techniques. Thus, the advantages and limitations of these modifications and their methods with insights towards a possible industrial applicability are presented. Furthermore, when copper was incorporated into membrane matrices, the study identified relevant detrimental consequences with potential to be solved, such as formation of defects, pore block, and nanoparticles agglomeration during their fabrication. Among others, the low modification stability, the uncontrolled copper ion releasing or leaching of incorporated copper material are also identified concerns. Thus, this article offers modification strategies that allow an effective copper incorporation on these polymeric membranes and solve these hinders. The article finishes with some claims about scaling up the implementation process, including long-term performance under real conditions, feasibility of production at large scale, and assessment of environmental impact.

1. Introduction

Globalization, growing population, insufficient water sources, industrialization, and global warming have contributed to the growing demand of water resources and their scarcity, causing a global concern [1,2].

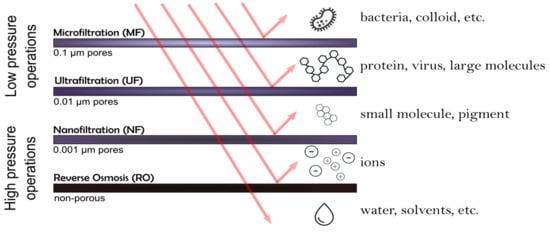

Water consumption by 2030 is expected to increase above the current level; it will be impossible to obtain it from traditional sources of freshwater [3]. Securing and allocating sufficient water resources has, thus, become one of the current major global challenges [3,4]. In this regard, scientific and technological approaches to find alternative sources to obtain fresh water have been the center of attention. The development of suitable methods to obtain freshwater, from saltwater and water reuse, has driven many researchers in the last years. In this regard, membrane-based processes are key components, dominating the field of water purification. These membrane-based processes require a pressure difference that work as a driving force. They can be grouped into four categories, according to the molecules or particles size to be separated and, therefore, according to the membrane pore size. Based on these properties, they have the ability to remove different contaminants, as shown in Figure 1. The main membranes categories are: microfiltration (MF), ultrafiltration (UF), nanofiltration (NF) and reverse osmosis (RO) [5].

Figure 1.

Schematic representation of membranes-based separation process.

The membrane performance mainly depends on the operational conditions and the material properties. In this regard, the development of novel membrane materials plays a central role in advancing the field of membrane technology [2]. In the last twenty years, novel research has focused on the development of synthetic membranes with improved properties for different applications associated with the water treatment process. For this purpose, different proposals by using organic material (polymers) or inorganic material (ceramics) were synthesized. Polymeric membranes have been widely used in comparison with ceramic membranes due to their better chemical stability, mechanical strength and the lower cost in terms of water produced [6,7]. Finally, it is easier to modify polymeric materials rather than ceramic membranes, so their application and advantages are feasibly expanded. Breakthrough effects that have been reported in the production of polymer membranes in the field of water and wastewater treatment include fouling mitigation, improvement of permeate quality and flux enhancement [8,9]. In addition, challenges to enhance long-term membrane stability, reliability, and cost efficiency have also been highlighted [10,11].

Regarding membrane fouling, it is the most critical point within membrane technologies. Although it is an inevitable obstacle in the process, it causes deterioration of the membrane performance and, consequently, higher operation and maintenance costs for cleaning and replacing [12,13,14]. Membrane fouling can be broadly categorized into three types: inorganic fouling, organic fouling and biofouling. Inorganic fouling is caused by the scale formation at the membrane surface, whereas organic fouling by the deposition of organic foulants (e.g., surfactants) on the membrane surface [10,15]. Biofouling is caused by the attachment and proliferation of microorganism communities to the membrane surface, which eventually form a biopolymer matrix or complex structure, regarded as a biofilm on the membrane surface [14].

Thus, fouling mitigation on membrane technology is necessary and must be solved with innovative and sustainable approaches. Several strategies have been studied to overcome these problems, such as: (1) optimization of the operation process; (2) use of pre-treatment of feed water; and (3) improvement of membrane properties by chemical surface modification [14,16].

In this last point, novel membranes with inherent anti-fouling capabilities for different water treatment applications, such as microfiltration, nanofiltration, ultrafiltration, forward and reverse osmosis have been reported [12,17,18,19,20]. Composite membranes as a result of the addition of different nano-materials into the polymer matrix have been an alternative that has attained much attention in antifouling membrane fabrication [14,21,22]. In general, the major factors influencing membrane fouling are associated with the physicochemical properties of membrane surface [21,23,24], such as hydrophilicity, roughness and electrostatic charge [17,25,26]. Herein, research related to these chemical surface modification has involved the introduction of hydrophilic layer mainly to favor the water permeability; the reduction of surface roughness since that biofoulants are entrapped in membranes with rougher topologies; and the improvement of charge property to favor the electrostatic repulsive force between the charged membrane surface and the foulant [14,21,27,28].

In addition, the combination with antimicrobial materials into membranes also becomes an innovative potential solution to biofouling control mainly. For example, silver (Ag), titanium dioxide (TiO2), graphene oxide (GO), iron (Fe), copper (Cu), Zinc (Zn), metal organic frameworks (MOFs), whose antibacterial properties are well known, have been incorporated into a wide variety of water filtration membranes [10,22,29,30,31,32,33,34,35,36,37].

There is particular interest in the use of copper-based materials in recent years. Copper has attractive characteristics: it has an excellent antimicrobial activity, it is one of the most toxic metals to heterotrophic bacteria in aquatic environments [29,38], and it has recently been registered by the US Environmental Protection Agency (EPA) as the first antimicrobial element [39]. Its effectiveness to inhibit the growth of pathogenic microorganisms make it an ideal candidate to be an active biocide agent. Consequently, it has been extensively used in the design of antibacterial polymeric materials for biomedical devices, food processing equipment, antifouling paints, among others [9,10,14,21,22]. In fact, it is particularly attractive due to its high natural abundance and low cost.

Another relevant feature is that multiple cost-effective synthesis routes are used to obtain copper based materials with tunable characteristics. For example, nanoparticles, composites, metal-polymer complex, and coordination polymers favor their incorporation into polymeric membranes [27,40,41,42,43].

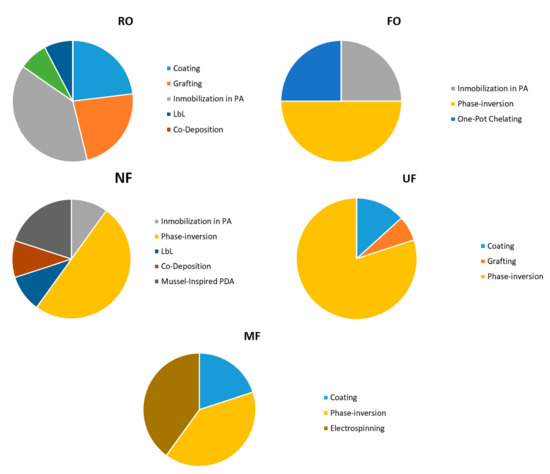

During the last 10 years, the notable use of copper-based materials for modifying MF [44,45,46,47,48], UF [28,49,50,51,52,53,54,55,56,57,58,59,60,61,62], NF [42,63,64,65,66,67,68,69,70,71], forward osmosis (FO) [72,73,74,75] and RO membranes [14,21,27,32,76,77,78,79,80] has attained much attention by the scientific community (according to the search strategy and eligibility criteria used, see Supplementary Materials, Prisma checklist, Prisma flow diagram and SRProtocol). The combination of these polymeric membranes with copper materials such as metallic and oxides nanoparticles, salts, composites, metal-polymer complex, and coordination polymers, offer a solution against biofouling formation, and, in addition, promote the improvement of other membrane properties. For these reasons, different membrane modification routes have been explored, including the incorporation of copper-based materials during the synthesis process of the membrane or the surface membrane modification using physical and chemical surface modification techniques (See Figure 2) [4,11,12,27,44,64,71,75,76,77]. Thus, the copper influence on membrane properties beyond the anti-biofouling effect, the impact of the modification, and the used method on the overall membrane properties and performance are aspects to be analyzed. Moreover, the modified membrane stability and copper leachability to operate for longer times under typical hydrodynamic conditions of a water treatment system must be also considered. These areas should be specifically addressed in order to make the industrial application of these modified membranes possible.

Figure 2.

Distribution of the different techniques used for modified membranes with copper. The diagrams are plotted using the data presented in articles [14,27,28,32,36,40,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,81,82,83,84,85,86,87].

Based on the above, this is a comprehensive review about the progress of modified membranes for water treatment by incorporating copper. Advantages and limitations on the reported modifications for each membrane type (RO, FO, NF, UF and MF) and the used methodologies are critically presented. Thus, the drawbacks in the incorporation of copper into membrane matrices are identified. Equally, strategies that might allow an effective copper incorporation on these polymeric membranes through membrane modification procedure improvements are also offered. Furthermore, perspectives about a scale up implementation considering aspects such as long-term performance under real conditions, feasibility of production at large scale, and assessment of environmental impact by the use of copper are presented. Finally, the shortfalls and future perspectives of these modified polymer membrane technology are highlighted and offer insights for further progress in the field of water treatment and desalination using these copper-modified polymeric composite membranes.

2. Overview of Copper

2.1. Properties and Toxic Mechanism

Copper is a transition metal element that can be found in different natural underground or rock deposits. This element shows excellent affinity with sulfur and is one of the most common components of sulfide ores such as pyrite, chalcopyrite, cuprite (oxides), and carbonates (malachite) [88,89]. This material has excellent properties: it is highly ductile and malleable, with high thermal and electrical conductivity. It can also be indefinitely recycled, and it can form alloys to improve mechanical properties, corrosion, and oxidation resistance, allowing extensive applications [90]. Moreover, copper has mainly been used due to its effectiveness as an antimicrobial material. Different research lines have thoroughly explored copper given its capacity to inactivate fungi [91], bacteria [92,93], viruses [94,95], parasites [96], and algae [91]. The ranking of pure metal cytotoxicity from most potent to least potent can be presented as follows: Cu > Al > Ag > V > Mn > Cr > Zr > Nb > Mo > Ti [97].

Overall, the efficacy of the microbicide effect of copper depends on several factors such as its physical form (bulk, nanoparticle, ions, etc.), its chemical state (elemental, copper oxide, etc.), concentration, wet or dry application form, temperature and humidity, and presence of buffer, among others. Copper toxicity can occur through two mechanisms: (1) direct contact killing, which depends on the proximity between the microorganism and Cu-containing surfaces, and (2) toxic effects induced by copper ions produced by copper dissolution [98,99,100].

It is known that the already mentioned parameters are clearly related to the contact killing effect of copper onto microorganisms. For example, high copper content, high temperature of application and the wet or dry condition to use it are the main factors that influence the killing of bacteria. Dry conditions have antimicrobial effectiveness in a few minutes, while wet conditions take several hours, which raises interesting questions about the contact killing mechanism [98]. Regarding the temperature of application, several works have demonstrated the effectiveness of the bacterial “contact killing” under high temperature and high humidity (37 °C-100% relative humidity) [29,93,98,101]. In addition, contact interactions strongly depend on the size of copper particles. It is well-known that nanoparticles show more serious toxicity than bulk species [99,102]. Small particles have greater interaction with biomolecules, which has a direct impact on their biocide capacity. Moreover, small copper particles increase the cellular uptake, where copper causes damage due to the interaction with intracellular molecules such as proteins and DNA [100].

Several studies revealed that the primary mechanism by which copper ions exert toxicity to bacteria is through depolarization of the cellular membrane [100,103]. This mechanism is led by the reduction of the electric potential because the Cu ions bind to the negatively charged domains in the bacteria cell membrane. The consequently depolarization causes cellular membrane rupture once the potential difference drops to zero [103]. Copper ions can affect the cell envelope of Gram-negative and Gram-positive bacteria, because they can bind to the peptidoglycans, carboxylic groups, or lipopolysaccharides of the outer membrane. The membrane depolarization of bacteria, thus the damage, depends on the bacterial morphology [104]. Alternatively, copper ions can also interact with biomolecules inside the cells, displacing metal-binding protein sites, and reducing or inactivating its activity [100].

Both mechanisms, contact killing and ion toxicity, lead to an increase in the oxidative stress of the cell membrane through the production of reactive oxygen species (ROS) [85,100,105]. Copper can impede the development of bacterial biofilm on a surface acting as a catalyst for redox reactions involving ROS. For example, redox cycling between Cu2+ and Cu1+ can generate the production of highly reactive hydroxyl radicals, which can subsequently damage all cell components of the biofilm, including lipids, proteins, DNA and other biomolecules [106]. DNA damage is a secondary effect of ROS generation by copper nanoparticles (NPs), as they can directly bind to domains in the DNA that impair their activity [107].

Likewise, copper nanoparticles and Cu ions can catalyze Fenton chemistry in vitro, generating the reactive hydroxyl radicals that participate in several reactions, oxidizing proteins, and lipids. The Fenton reaction is given by the following chemical reactions (1):

Reactions (2) and (3) demonstrate how copper ions can lead to depletion of sulfhydryls, such as in cysteines or glutathione. This causes protein damage and increases the oxidative stress in the microorganism that finally leads to cell apoptosis [100].

Copper NPs have been reported to be around fifty times less toxic than the ionic form in mammalian cells. However, to bacteria, copper NPs are more lethal than ionic forms due to the above-mentioned capacity of contact killing and rapid dissolution in comparison to the bulk. Overall, copper nanoparticles are highly toxic against a wide variety of bacteria (gram positive and gram negative) and fungus. This is possible due to their favorable surface-to-volume-ratio, generally killing cells by diverse mechanisms previously mentioned such as membrane disruptions, blocking biochemical pathways, complex formations with proteins, and DNA damages [108]. However, a different bactericidal behavior has been observed in copper metallic (Cu-NPs) with respect to copper oxide (CuO-NPs) nanoparticles, revealing the impact of the type of copper chosen for this purpose. For instance, the oxide-state of copper in CuO-NPs limits its dissolution capacity compared to Cu-NPs, due to the less soluble surface of CuO. On the contrary, elemental Cu-NPs have a rapid initial dissolution that can decrease in prolonged exposure [85,105]. Accordingly, compared to copper salts, both NPs exhibit great ROS production, even at low concentrations of dissolved copper. However, in the case of Cu-NPs, interaction of the nanoparticles with the membrane of bacteria is key to ensure ROS-induced toxicity [85,109]. When Cu-NPs are incorporated in polymeric membranes, they could diminish ROS production due to the reduced direct contact with bacteria. Authors have also found that copper salts can be completely dissolved in short periods of time, yet they cannot reach greater levels of ROS production as Cu-NPs and CuO-NPs [109]. Thus, the significant influence of copper type on their ion release capacity and the ROS production should be considered because these are key parameters in the toxicity triggered by different copper types.

Another crucial aspect for the bacteria-killing process is related to the proximity of microbes to Cu-containing surfaces. In the presence of copper ions, complete cell death should occur. However, if an inert polymer covers the copper surface, there is a reduction of copper exposure and, as consequence, a copper ion release, causing the reduction of the bacterial death [110].

Moreover, in order to obtain a significant antimicrobial effect, a minimum inhibitory concentration (MIC) and minimum bactericidal concentration (MBC) of copper in microorganisms are required. These vary depending on the type of bacteria and form of copper. For example, for E. coli, the MIC of ionic copper is estimated around 2.25 µM [111]. In the case of nanoparticles, Table 1 shows the MBC of Cu and CuO-NPs per each type of bacteria.

Table 1.

MBC of copper and copper oxide nanoparticles per bacteria. Extracted from [112].

Another consideration in the antimicrobial effect of copper is the presence of buffers or contaminants in the chemical environment. These play an essential role in copper antimicrobial activity. It was demonstrated that Tris-Cl buffer induced a 10-50-fold faster copper ion release compared to phosphate-buffered saline (PBS). Furthermore, copper ions and H2O2 present a synergistic action in E. coli killing in the presence of 4-(2-hydroxyethyl)-1-piperazine ethanesulfonate (HEPES), provoking catalysis of hydroxyls radicals release [113].

Finally, it is also important to consider that several mechanisms have been discussed related to the defense of bacteria in the presence of copper. These mechanisms are not entirely understood, because there is no evidence regarding a unique alternative to protect them from copper. As an example, in Gram-negative bacteria, such as E. coli, the CopA, an ATP-driven copper pump that expels copper (I) from the cytoplasm into the periplasmic space. There, it can become oxidized by the multi-copper oxidase CueO, which is involved in copper detoxification. This enzyme can also oxidize catechol siderophores, and the resulting pigments can capture copper. In the case of Gram-positive bacteria, only CopA-type copper transporters are present, since these kinds of bacteria do not have a periplasmic space and an outer membrane. Further research is required to understand how bacteria handle copper [103,114].

2.2. Copper-Based Materials and Relevant Features

Almost 300 different forms of Cu-based materials were registered as antimicrobial products by EPA. For example, Cu/metals/alloys and metal substrates surface-modified with Cu, composites of Cu with polymers and glass, nonmetal substrates surface-modified with Cu, and superhydrophobic surfaces containing Cu have been widely used as cheap and effective materials for sterilizing, textiles and also human tissues for centuries. Moreover, their application in different fields such as in electronics, thermal energy, catalysis, photonics, biosensors and optoelectronics have been reported [25,115].

There is evidence of a particular interest in producing copper nanoparticles. The synthesis of different metallic and metal oxide copper nanoparticles have been widely studied. Copper NPs can be obtained by several strategies that include physical and chemical methods. For physical methods, the use of sophisticated equipment and technology is necessary, which makes them a relatively complex process. In the case of chemical methodologies, several strategies can be found in the literature due to their ease of control, simplicity of operation, limited equipment requirement and high quality of particles. Chemical methodologies, such as wet chemical reduction [116], reverse micelles [117], electrochemical and sonoelectrochemical techniques [118], vapor deposition [119], laser irradiation [120], thermal decomposition [121], thiol-induced reduction and microemulsions have been reported. In all these cases, it is very important to control the morphology, particle size and shape, surface charge and physicochemical properties of the synthesized nanoparticles [116].

Thus, the characteristics and properties of copper nanoparticles can be treated and controlled during their synthesis and adapted to be added on any solid surface, such as polymeric membranes. In general, the characteristics of the nanoparticles (size and shape, among others) can be dependent on the precursor [122]. For this reason, their choice is fundamental to obtain the desired features. Thus, copper nanoparticles often entail the reduction of Cu (I) or Cu (II) sources. Copper sulfate (CuSO4), copper acetylacetonate, copper chloride (CuCl2), or copper nitrate (Cu(NO3)2) have been used as a precursor. For wet chemical techniques, commonly used reducing agents are hydrazine, sodium borohydride, ascorbic acid, glucose, and 1,2-hexadecanediol, among others [123]. Several capping agents have been employed to stabilize the nanoparticles and control particle size [26]. Moreover, these agents could condition the surface chemistry of the nanoparticle to favor a specific functionality and impact on their properties such as hydrophilicity and shape [120,121]. In addition, for Cu-NPs, the most important challenge for these kinds of studies is to synthesize a stable Cu-NPs, which can be due to rapid oxidation to Cu+2 provoked by air or the aqueous media [124]. Therefore, the methodology to obtain these kinds of nanoparticles are performed in non-aqueous media and under inert atmosphere (argon, nitrogen) [26].

The size, shape and the surface chemistry of copper nanomaterials to be incorporated in the polymer membrane could exert tremendous impact on the membrane properties [125,126]. Thus, the incorporation of copper nanomaterials and their used synthesis agents can influence on surface properties of the modified membrane. Some benefits sought are related to the increase of the hydrophilicity, the reduction of surface roughness, and the improvement of charge property to favor the foulant reject from the modified membrane surface. For instance, CuO-NPs have showed hydrophilic character, which means that these oxide nanoparticles could improve in the surface hydrophilicity and/or the water flux of the modified membrane better than hydrophobic Cu-NPs [127]. Other aspects such as the size and their shape could also influence the surface-modified membrane, having an impact in the membrane performance. For instance, a different shape changes the exposed crystal facets and hence, the atomic arrangements in each facet could also have an intense effect on its surface properties. Moreover, an increase in surface membrane roughness can be influenced by the size of the incorporated nanoparticles [14,21,22,27]. Finally, the membrane surface charge could be altered after modification attributed to the coverage of the membrane surface by positive or negative charged copper NPs [32]. Thus, the control of size, shape and the surface chemistry of copper nanomaterials to be used in membrane modification are important aspects to be considered and are mainly dependent on the synthesis method.

On the one hand, metal and metal-based compounds are commonly used to fabricate antimicrobial composite membranes involving copper. Among these metal-based compounds it is possible to mention metal-polymer complex and coordination polymers. The metal-polymer complexes can be obtained on the basis of heteroaromatic polymers, whose backbone was functionalized by units containing functional groups capable of forming coordination bonds with transition metals, particularly copper(I) or copper(II) salts [128]. In this way, the linkers anchored to polymer act as chelating arms to coordinate copper ions, promoting the metal-polymer complex formation. Thus, linkers with carboxylic, sulphur and amine groups are desirable.

On the other hand, coordination polymers contain metal ions linked with coordinated organic ligands into an infinite array. Coordination bonds must define this infinite array [129]. These compounds have attracted attention because of the different architecture that can be formed and the several physicochemical properties that can be included in a modified membrane. The development of new systems based on copper is strongly studied due to the different characteristics of copper already mentioned. Copper is a versatile type of building block that has been successfully used for the synthesis of coordination polymers in combination with different neutral ligands that can offer appreciable properties. The selection of additives to form copper-based complex materials is very important, since the overall performance of the modified membranes rely only on it. Thus, the use of copper complexing and chelating agents mainly aims at stabilizing the copper on the membrane, controlling the copper ion dissolution and improving hydrophilicity of the membrane surface.

Therefore, different copper-based materials (composites, metal-polymer complex, coordination polymers) have been synthesized to be incorporated into the membrane performance. Some examples reported are PANI-CuNPs, Chitosan-CuNPs, Cysteamine-CuNPs, CuBTTri-MOF, PEI-CuNPs, Cu-BTC-MOF, Cu2+-DOPA, DOPA-Cu2+/PEI-CuNPs, PDA-rGO-Cu, TA-Cu2+, CoFe2O4/CuO-NPs, Cu/TNTs, CuO/ZnO, Cu[DNDP]3MWCNT, Cu/Sepiolite, and Ag3PO4/ZnAlCu-NLDH. Overall, the notable use of copper materials such as metallic and oxide nanoparticles, salts, composites, metal-polymer complexes, coordination polymers for modifying MF, UF, NF, FO and RO membranes have been reported, and the analysis of the benefits and limitations of these proposals is presented in the following section.

3. Polymeric Membranes Modified by Copper Incorporation

3.1. Reverse Osmosis (RO) Membranes

Reverse osmosis desalination is the most widely used technology worldwide [14,21,22,130]. «In 2019, 21,123 desalination plants» worldwide were distributed in 170 countries, which supplied more than 100 million m3/day of fresh water to supply more than 300 million people [131]. This process implies the use of semipermeable membranes, where feed water is forced through the membrane when an external pressure force is applied, and salt ions and contaminants are rejected [132].

The most known polymer membranes have been made from polymers with aromatic polyamide groups such as thin-film composite (TFC), which dominate the RO membrane field nowadays given their great water flux and high solute rejection, but they are not completely resistant to fouling [14]. As it was mentioned above, membrane fouling is considered an inevitable obstacle affecting seawater desalination plants, causing a decrease in membrane performance [133]. As was previously mentioned, the physicochemical properties of membrane surface [21,23,127], such as hydrophilicity, roughness and electrostatic charge are the main factors influencing membrane fouling [17,108,117]. In order to enhance RO membrane properties, most research has involved the introduction of hydrophilic layer, the reduction of surface roughness, and the improvement of charge property to favor the electrostatic repulsive force between the charged membrane surface and the foulant [8,13,27,134].

Among the various proposals to modify RO membranes with anti-biofouling effect, there are a significant number of research related to copper-modified TFC membrane. In addition to the benefit of copper on the anti-biofouling effect of the membrane, given its toxicity, its impact on the surface properties of the material have also been analyzed. Different copper-based materials such as copper hydroxide nanoparticles, CuO-NPs, Cu-NPs, copper ions and copper-based MOFs have been used (Table 2). Moreover, different modification techniques to incorporate these copper materials into TFC-RO membranes have been proposed. These include a) the modification of the commercial membrane surface, through different methods such as coating, grafting and layer by layer assembly. They consider, in some cases, the use of stabilizing agents or linker agents in order to control the copper ion dissolution and the modification stability, and b) the immobilization of the modifiers fillers within polymeric matrix during the interfacial polymerization process (IPP), to modify the polyamide active layer [135]. In this review, the strategies addressed in these investigations will be widely discussed in terms of the influence of incorporated copper on the anti-biofouling effect, the surface properties, and membrane performance. In addition, the advantages and disadvantages presented by the employed modification techniques are discussed. All of these features are discussed with a view towards a possible industrial applicability.

Table 2.

Summary of TFC-RO membranes modified with different copper material.

As can be seen, the coating technique has been employed by several authors to modify TFC-RO membranes with copper-based materials. For instance, Kankanechi et al. reported the adsorption of copper hydroxide on TFC-RO commercial membranes by coat of membranes with copper hydroxide (Cu(OH)2) solution to produce anti-biofouling membrane. Hence, the anti-biofouling properties were attributed to the release of Cu2+ ion given the modified membrane. The authors demonstrated that this beneficial effect is dependent on the pH of the treated solution. Thus, the bacteria killing ratio increased when pH was increased from 6.5 to 7.5 [76]. Despite this significant improvement in the anti-biofouling effect, authors stated that the stability of this modified membrane was not adequate for long operating times due to loss of effectiveness.

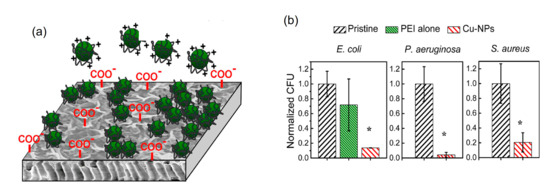

Additionally, Ben-Sasson et al. reported the functionalization of TFC-RO membranes with Cu-NPs using two ways. The first way consisted in the dip-coating of the membrane surface with a previously synthesized Cu-NPs solution. These Cu-NPs were synthesized through a wet chemical reduction employing the polycation polyethylenimine (PEI) as capping agent, which imparted positive charge to the surface of the Cu-NPs which promoted the electrostatic interaction with the negative charge of membrane surface because of its native carboxylic groups (see Figure 3a). A remarkable anti-biofouling effect was observed with 80% to 95% anti-adhesion capacity for three model bacteria strains (E. coli, P. aeruginosa, and S. aureus) attributed to the toxicity of the bound Cu-NPs (Figure 3b). With this modification, the surface properties (hydrophilicity and roughness) of the modified membrane were not affected, and they also presented flux and rejection salts similar to the pristine membrane. However, this modification had a relatively rapid dissolution rate of the Cu-NPs, with dissolution of more than 30% of the loaded copper during the first two days, which could promote an early depletion of incorporated copper [32].

Figure 3.

Results of the functionalization of TFC-RO membranes with Cu-NPs reported by Ben-Sasson et al. [32]. (a) Schematic of the electrostatic binding between the Cu-NPs (positively charged) and the carboxyl groups (negatively charged) on the active layer of the pristine membrane. (b) Biocide capacity comparison between the pristine membrane (black) and modified with the capping agent (PEI) alone (green) and Cu-NPs (red) over E. coli, P. aeruginosa (gram negative bacteria) and S. Aureus (gram positive bacteria). Asterisks (*) indicate a statistically significant difference between the functionalized and pristine membranes (p < 0.05). Adapted from [32].

The second way was the coating of membrane surface through the in situ formation of Cu-NPs using sodium borohydride as a reducing agent without the use of a capping agent. Insignificant changes in the membrane surface charge and roughness after modification were observed. However, the surface of the modified membrane was slightly less hydrophilic, with contact angles increasing from 45.46 ± 1.68° to 59.84 ± 3.13° for the pristine and in situ modified membranes, respectively. A minor increase in the membrane water permeability coefficient and slightly decrease of salt rejection were observed on modified membranes [40]. Moreover, water physicochemical parameters and hydrodynamic conditions in desalination plants might accelerate the Cu-NP dissolution on these conditions.

Furthermore, the grafting approach has also been employed to incorporate Cu-NPs in TFC-RO membranes by in situ NPs synthesis in the presence of different linking agents such as polyaniline (PANI) [77], carboxylate chitosan (CCTS) [78] and cysteamine (Cys) and GO [79]. Thus, Khajouei et al. reported the grafting of PANI on TFC-RO membrane surface by in situ aniline polymerization under acidic conditions, and subsequently in situ Cu-NPs synthesis to produce a modified PANI-CuNPs-TFC membrane. The synergistic effect between PANI and Cu-NPs allowed obtaining a more hydrophilic membrane, with positive surface charge and slightly less roughness in comparison to the pristine membrane. The hydrophilic surface of the PANI-CuNPs-TFC membrane increased the water flux ~28% and salt rejection ~1% in contrast to the unmodified membrane. Anti-biofouling properties of the PANI-CuNPs-TFC modified membrane included high inhibition zone and long-term biofouling experiments showed constant and higher permeate fluxes than those shown by the unmodified membrane [77].

The hydrophilic natural polymers, such as CCTS, have been employed to coat the RO-TFC membrane surface. After treatment with CuCl2, aqueous solutions and cross-linking agent glutaraldehyde (GA) are used to reduce the CuNPs in situ and fix them in the cross-linked coating layer [78]. In this study, authors highlighted that it is very important to find an adequate concentration of polymer coating and crosslinking agent in order to not affect the membrane performance. These membranes showed excellent antibacterial properties with antibacterial efficiency above 99% after their immersion in deionized water for 90 days. These results suggested a long-lasting antibacterial performance of membranes, which was attributed to the slow release of copper ions, since the copper ions released from Cu-NPs can be absorbed by CCTS coating via chelating effect. Besides, these modified membranes showed better hydrophilicity, lower water flux, higher salt rejection and better protein fouling resistance.

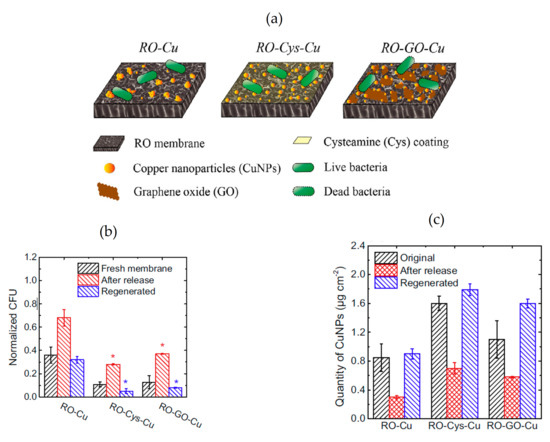

Additionally, Ma et al. conducted a comparative study in relation to the impact produced by the modification of RO-TFC membrane with Cu-NPs in two different ways. Namely, 1) the coating of membrane surface by in situ Cu-NPs reduction (RO-Cu), and 2) the grafting of RO membrane with Cys linker and Cu-NPs (RO-Cy-Cu), or GO linker and Cu-NPs (RO-GO-Cu) [79]. The study showed that the loading quantity of copper on a modified membrane surface can be improved using these linkers (see Figure 4a). This feature influences the anti-biofouling effect of membranes against E. coli bacteria that work as gram negative model bacteria, since the antibacterial and anti-adhesion effect decreased with depletion of the loading quantity of copper on membrane (RO-Cys-Cu > RO-Cu-GO > RO-Cu) (see Figure 4b). However, RO-Cys-Cu membrane was more hydrophobic while the GO linker produced more hydrophilic membrane. Authors concluded that the magnitude of the anti-biofouling effect is driven by the presence of copper in the membrane and the ability of the membrane to release these copper ions. Thus, the presence of Cys and GO linker induced a better control of the release behavior of CuNPs, promoting a gradual decrease of anti-biofouling effect until 7 days in a synthetic wastewater. Moreover, authors demonstrated the successful regeneration with Cu-NPs on the membrane surface after their depletion, evidencing the modified membranes’ potential for long-term application (Figure 4c).

Figure 4.

(a) Schematic of copper-modified RO membranes implemented by Ma et al. [79]. From left to right: Coating of membrane surface by in situ Cu-NPs reduction (RO-Cu), grafting of RO membrane with cysteamine linker and Cu-NPs (RO-Cys-Cu) and with graphene oxide linker and Cu-NPs (RO-GO-Cu); (b) Number of viable cells attached (CFU) in modified membranes compared to pristine membrane; (c) Quantity of NPs in each membrane after the release for a period of 7 days and after regeneration with Cu-NPs (note that the amount of NPs after regeneration is higher than the original amount of copper). Asterisks (*) indicate a statistically significant difference between the pristine and modified mem-branes (p < 0.05). All images and graphs are extracted from [79].

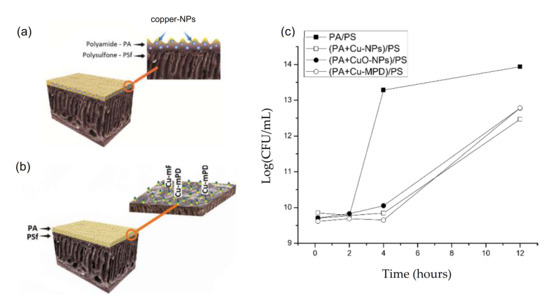

From a slightly different point of view the incorporation of CuO-NPs [14], Cu-NPs [36], Cu-meta-phenylendiamine oligomers (Cu-mPD) [27], and water-stable Cu-based MOFs [80] into some monomer (m-phenylendiamine (MPD) or trimesoyl chloride (TMC)) during IPP has been explored as a promising approach to generate TFC-RO modified membrane, which in turn enhances anti-biofouling properties.

Garcia et al. reported that the incorporation of CuO (1% wt) in MPD during IPP produced the CuO-TFC-RO modified membrane [14]. Unfavorable changes on the physicochemical properties of modified membrane surface were observed, i.e., similar contact angle, higher surface roughness and less negatively charged surface. In spite of this, the modified membrane showed anti-biofouling properties in the batch test, where E. coli acted as a model bacterium. Bactericidal effect and anti-adhesion ability were attributed to the release of copper ions from CuO-NPs, which have high ionic character, and the negative surface charge remained by the modified membrane, which underlines the anti-adhesion effect through electrostatic repulsion. An increase of water flux (~2 times respect to pristine membrane) was attributed to the hydrophilic character of CuO-NPs [14].

A similar research reported the use of Cu-NPs (0.25%) during IPP to produce a Cu-TFC-RO modified membrane (see Figure 5a) [36]. This Cu-TFC-RO modified membrane showed excellent antibacterial effect (~99%) and good anti-adhesion effect (83%) in batch tests. The anti-biofouling effect was attributed to the higher reactivity of Cu-NPs provided by the release of toxic Cu+2 ions, in addition to the generation of ROS. Cu-NPs produce ROS in the medium that damages bacterial DNA causing bacterial death [136], and the release of ions increases intracellular ROS in the bacteria, thereby inflicting its death [137]. The modification produced a detrimental effect on desalination performance with decrease of water flux (~31%) and rejection salt (~2%) with respect to the pristine membrane, which was attributed to the increase of contact angle of modified membrane surface (>33% than pristine membrane) and the agglomerate formation.

Figure 5.

(a) Schematic of CuO-NPs addition to TFC-RO membranes during IPP and (b) of a TFC-RO membrane modified by formation of copper-oligomer complex (Cu-mPD) in situ. Extracted and adapted from [24]; (c) Bactericidal capacity (quantified by CFU) of copper modified membrane by addition in IPP of Cu-NPs, CuO-NPs and Cu-MPD compared to a pristine membrane (PA/PS). Extracted from [85].

The addition of copper chloride (1 wt%) in MPD monomers during IPP allowed the formation of Cu-mPD oligomer complex in TFC-RO membrane (Figure 5b) [27]. A mechanism for formation of the oligomer within the membrane was proposed based on the interaction between the oxygen of the carbonyl group of the polyamide layer and copper ion of the Cu-mPD oligomer complex. The modified membrane showed a slight decrease in hydrophilicity and higher surface roughness. However, this modified membrane showed excellent anti-biofouling properties with bactericidal and anti-adhesion effect >99% without compromising the membrane performance, with increase of flux water (~33%) and similar rejection salts with respect to the membrane pristine.

Thus, the aforementioned studies suggest that there is a direct relationship between the type of copper material incorporated during IPP and the anti-biofouling properties of modified membranes with this approach. The bactericidal effect increases with the copper types incorporated according to the following sequences: Cu-mPD ≥ Cu-NPs >> CuO-NPs (Figure 5c). Differences in the dissolution level of copper-based NPs in membrane were noted, suggesting a dual-type effect that defined the copper toxicity into the membrane, associated to the dissolution capacity, which depends on the interactions between the copper and the polyamide (PA) layer of the membrane, and ROS production, which vary depending on the copper type [85].

Recently, Wen et al. explored the impact of the incorporation of water-stable Cu-based MOFs (CuBTTri) into the PA layer on anti-biofouling properties and desalination performance [80]. CuBTTri was incorporated in trimesoyl chloride (TMC) monomers during IPP reaction. The water flux decreased by ~70% in biofouling continuous flow test after 24 h with respect to the pristine membrane, which makes this fact dependent on MOFs dosages. This modified membrane showed a much lower Cu release rate than that in other studies using metal nanoparticles for the modification of TFC membranes (0.010 ± 0.001 µg/(cm2 day) after 3 days soaking) [87,138]. Therefore, the authors concluded that the release of Cu from the water-stable MOFs was not the dominant factor contributing to the antibacterial behavior in the long-term. Thus, the anti-biofouling test and the anti-biofouling behavior were attributed to the direct contact of bacteria with MOFs, which might cause the oxidation of functional groups of the bacteria, e.g., thiols [139,140], causing damage to the bacterial cells.

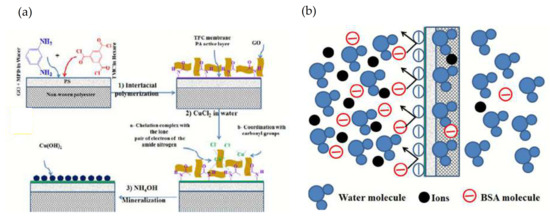

The combination of two approaches (IPP and coating) has also been used to modify a TFC-RO membrane with enhanced anti-fouling properties [141]. Thus, the incorporation of GO during IPP and after the coating of this membrane with CuCl2 produced a TFC-Cu-GO membrane. An additional treatment of this membrane with ammonium hydroxide produced the membrane mineralization (M-TFC) by generation of Cu(OH)2 on the membrane surface (see Figure 6a). The mineralized membrane with optimum concentrations of copper showed higher pure water permeability and solute water flux compared to the pristine TFC membrane with an excellent salt rejection. Moreover, the antifouling tests using bovine serum albumin (BSA) as an organic fouling showed that TFC-Cu-GO and M-TFC membranes had an excellent antifouling property. This is due to the fact that copper hydroxide increases the hydrophilicity and the negative charge density of the membrane surface. The membrane hydrophilicity increased the water molecules onto the membrane surface and hence lowered the adhesion property between the foulant molecules and the membrane surface. In addition, the electrostatic repulsion between the membrane surface and foulant molecules increased due to the increasing negative surface charge density (see Figure 6b).

Figure 6.

(a) Schematic representation of the IPP and mineralization of TFC-RO membrane with formation of Cu(OH)2 surface modification; (b) Mechanism of electrostatic repulsion between BSA and membrane surface. Extracted and adapted from [141].

Finally, other approaches to modify commercial TFC-RO membranes have been scarcely reported. For example, the physical vapor deposition (PVD) approach has been reported to coat polyamide membranes with CuO-NPs employing metal-gas plasma, under optimal conditions of time plasma treatment, and current research obtained membranes with bactericidal activity to E. coli of 99%. Nevertheless, the materials were not tested under real operating conditions [86]. In addition, spray- and spin-assisted layer-by-layer self-assembly (SSLbL) method was reported to incorporate Cu-NPs in polyamide layers of RO-TFC commercial membranes [87]. Layer by layer (LbL) assembly was achieved by electrostatic interaction. The first layer was produced by interaction between the negative charge of polyamide layer and Cu-NPs stabilized with PEI (PEI-CuNPs), and subsequent layers were formed between poly(acrylic) acid (PAA) and PEI-CuNPs [87]. The spray and spin technique allowed to obtain uniform bilayer PEI-CuNPs/PAA on RO-TFC membrane in short times, increasing the number of bilayers that increased the copper load on the membrane. The modified membrane showed similar negative surface charge, slight increase in roughness and decrease in the surface hydrophilicity, which was attributed to the Cu-NPs loading. A ten-bilayer coating of the membrane resulted in only 13.3% reduction in the water permeation flux. Regarding anti-biofouling properties, the PEI-CuNPs/PAA modified membrane showed high antibacterial activity in the range of 94.3% to nearly 100%. Continued biofouling test showed 43% reduction of permeate flux for the PEI-CuNPs/PAA modified membrane, which was very close to the control LB solution without bacteria, showing 38% reduction of the permeate flux.

In summary, different copper-based materials (copper hydroxide, copper ions, copper oxide and copper metal nanoparticles and copper-based MOFs) have been used to modify TFC-RO membranes, mainly to promote the anti-biofouling effect. Although the mechanism of toxicity can be dependent on the type of copper incorporated, an impact on the effectiveness of this effect and the performance of the membrane is undoubtedly dependent on the method of modification. Different approach techniques such as coating, grafting, layer by layer assembly and interfacial polymerization processes have promoted excellent anti-biofouling effects. However, disadvantages such as the stability of modification, loss of effectiveness over time, limitations in long-lasting operating times are associated with the method. Coating/dip-coating is the most practical approach technique, but low stability of modified membrane limits its application during long operating times due to the loss of effectiveness by early depletion of incorporated copper. A strategy could be the incorporation of copper nanoparticles stabilized by stabilizing agents with nitrogenous functional groups in order to control the capacity of copper ion dissolution from the nanoparticle. In contrast, the grafting approach has allowed to obtain modified membranes with long-lasting antibacterial performance due to the slow release of copper ions given the chelating effect of different linker agents on copper ions. Nevertheless, membrane flux should be affected, and an adequate concentration of linker agent is required. In this context, systematic grafting studies with linkers that have high capacity to chelate copper ions and that can improve the water flux without blocking the porous should be addressed. Linkers such as branched polymers and graphene oxide with amine and sulfur functional groups are promising targets in order to achieve the aforementioned conditions. Finally, the immobilization of copper materials within a polymer matrix through their incorporation during interfacial polymerization process is another strategy. This promising approach allows to modify the membrane from the manufacturing process itself, which would enable tuning the properties of the new filter. However, several synthesis parameters should be optimized in order to avoid surface defects on the PA layer and the copper nanoparticles agglomeration, which impacts the membrane performance. Hence, this approach has great potential to produce copper modified TFC-RO membranes with tunable properties, but it might also require a long time to achieve its industrial implementation.

3.2. Forward Osmosis (FO) Membranes

Forward osmosis is an emerging technology primarily studied for water desalination with the advantage of offering an alternative way to purify saline sources using low-cost energy. Compared with RO technologies, the market relevance and science impact of FO is relatively small, but in the past few years there has been an increment in the amount of studies for this alternative membrane technology. This trend shows the efforts of the scientific community to diversify the conventional methods of purification of saline water sources using low impact methods in environmental, energy and economic terms [142].

Technically, the operation of FO is based on a dense hydrophilic semipermeable membrane that separates two sources with different concentrations called feed solution (FS) and draw solution (DS). The osmotic pressure gradient between them is the driving force process [143]. As well as RO, FO membranes consist of an active layer, which in theory possesses a high-water permeability, a low reverse solute permeation, and a support layer with high water mass transfer and high resistance to concentration polarization phenomena. However, these basic qualities should be accompanied by good antifouling properties, chemical resistance, and mechanical stability. Of course, finding materials with all these properties could be challenging. For this reason, some active layer materials used in RO or NF technologies have been implemented in FO studies, especially in desalination studies, that include multivalent saline feed treatments, waste-water treatments with large organic molecules and ionic contaminants.

Among the typical RO active layer materials, the current research about FO materials points at cellulosic derivatives, polyamides and polyelectrolytes [143,144]. However, there are some limitations in relation to an overall low flux, principally due to unfavorable material characteristics, such as thick sponge-like substrates and compact supports. These largely block the water mass transfer and cause a high internal concentration polarization (ICP) inside the support. The ICP is an important challenge for the performance of FO processes, and is influenced by some membrane sublayer characteristics including porosity, tortuosity, and thickness. The structural parameters (S, thickness and X, tortuosity/porosity) are a strong indicative value in order to quantify the structural contribution of the FO membrane in the ICP effect [143,145]. In this sense, the modification of FO membranes has been mainly directed to the increase of water mass transfer, structural membrane parameters and avoiding the ICP phenomena. Studies conducted on the modification of membranes with copper materials have thus aimed at the already mentioned benefits and have also targeted antibacterial properties (Table 3). The main studies on copper modified FO membranes are related to the introduction of Cu-based MOFs as load removable filler to prepare MOFs-based polymeric substrates through a phase inversion method, or the modification of the active layer by this kind of particles using in situ polymerization techniques. Hence, the approaches of these studies will be described in relation to the effectiveness of the copper modification regarding the properties achieved in terms of water mass transfer, antifouling effects and ICP resistance.

Table 3.

Summary of FO membranes modified with different copper-containing compounds.

For instance, Lee et al. [72] explored the use of metal organic frameworks: copper based Cu-BTC MOF (HKUST-1 or copper benzene-1,3,5-tricarboxylate) were used as a removable filler for preparing MOFs-based porous membranes by phase inversion method using a polymeric dope solution of polyacrylonitrile (PAN). The resulting substrate seemed to have an improved water mass transfer and ICP controller support for the active layer synthesized later by LbL conventional technique, leading to the final FO membranes. In the case of the copper MOF, the overall membrane bulk porosity (porosity 85%) and the hydrophilicity (contact angle 44° to 29°), compared to the original PAN, increases, resulting in a reduced structural parameter from 360 µm to 190 µm, high water flux (>130 L m2 h) and a decrease of the material tortuosity, mediated through the macropore formation in the support.

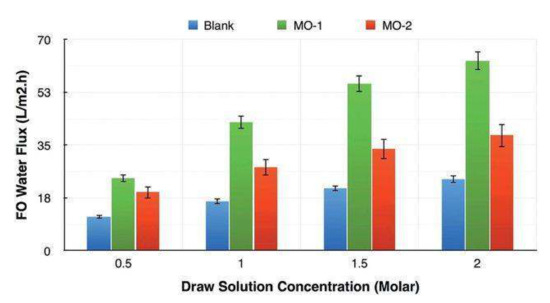

On another note, Zirehpour et al. [73] studied the effect of the addition of the same Cu-BTC MOF to improve the performance of cellulosic based FO membranes with the aim of increasing the overall porosity, pore interconnectivity and membrane hydrophilicity. These FO modified membranes were prepared by phase inversion via the immersion precipitation method using a dope solution of cellulose acetate/triacetate (CA/CTA) mix loaded with a casting MOF solution. The results show a significant reduction in the structural parameter of the modified polymeric matrix from 579 µm in the original CA/CTA matrix to 136 µm in the cellulosic MOF based membrane. The water permeability increased by 72% and the water flux was enhanced about 180% with respect to the polymeric unmodified matrix (see Figure 7). The overall porosity increased in form less than 70% to almost 90% followed by an increase in the hydrophilicity, all compared with the unmodified cellulose matrix. These combined effects enhanced the mass transfer of water and seem to control the effect of ICP in the membrane during the osmotically driven process.

Figure 7.

FO water flux of the membranes in atomic layer deposition (ALDS) mode and using different DS concentrations (T ¼ 25 C, feed ¼ DI water), error bars represent standard deviation over runs. Extracted from [73].

One more similar report from Dai et al. [74] used the Cu-BTC synthesized as layered 2D particles to modify the PA active layer of a TFC-FO membrane using interfacial polymerization method. In this case, the reported TFC-FO exhibited an increment of 50% in the water flux with respect to the unmodified membrane in membranes, loaded with 0.12% of Cu-BTS layered particles. The membrane showed an important increase in hydrophilicity and a decrease in the structural parameter, from 402 µm to 366 µm. The authors highlighted the theoretical potential of antifouling and antibacterial effect without any directed test but provided by the micrographic presence verification of these Cu-layered particles in the obtained surface.

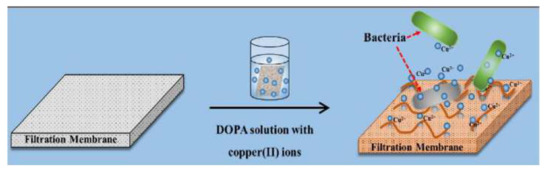

Only one recent study reported by Liu et al. [75] involved the modification of the active layer of an FO polyamide membrane with a copper-dopamine complex using the one-pot chelating Mussel-inspired method. The aim of this work was to generate a cost-effective method for mitigating the effect of biofouling on various surfaces, including the FO membranes. The oxygenation during the reaction stage showed an accelerated DOPA polymerization with high incorporation of copper cations in the active layer (see Figure 8). The membranes showed good antibacterial properties against S. aureus. Despite the antibacterial success, the membranes exhibited a comparative decrease of water flux of 28%, attributed to a blocked surface effect, with no reported structural parameters.

Figure 8.

Schematic of the one-pot chelating copper ions modification on FO membrane. Copper ion release and interactions between bacteria and the copper-containing surface results add biocide properties. Extracted from [75].

In summary, modification of FO membranes by copper incorporation has been directed mainly to the increase of water mass transfer, structural membrane parameters and avoiding the ICP phenomena. For this purpose, MOF-based polymeric substrates can be obtained using different strategies. For example, the phase inversion method or the modification of the active layer by this kind of particles using in situ polymerization techniques. Despite the good results regarding the structural parameters and the water mass transfer using proper amounts of particles load, a high loading percentage could lead to severe particle agglomeration in the membrane support/active layer, and subsequently may have an adverse effect on the membrane properties and performance. The best results in all studies were given with exceptionally low copper MOF particle loads. However, the high solubility in water of these particles can lead to serious losses of the properties acquired in short times, due to the low concentrations. This might affect the levels of porosity and tortuosity due to dissolution phenomena during the FO, and consequently the geometrical dependent S parameter. Conversely, copper-dopamine complex by one-pot chelating Mussel-inspired method is another alternative route for the modification of the active layer of an FO polyamide membrane. Given the simplicity of this approach, this technique could be important in further investigations for treating biofouling problems but should be adjusted to acceptable parameters for a performance on osmotically driven processes.

3.3. Nanofiltration (NF) Membranes

The implementation of nanofiltration processes started three decades ago with a promising membrane-based separation method directed to give a solution to the problem in different areas, such as drinking water, wastewater treatment, partial desalination, chemical separation, and other industries. In fact, the NF process provides an intermediate approach between UF and RO processes, rejecting particles of about 1 nm, which corresponds to a minimal molecular weight cut-off (MWCO) of 300 Da (including oligomers, polyvalent ions, and similar species), pressure operation between 3–20 bar, pore size range between 0.5–2 nm and permeabilities around 1.5–30 L/(h m2 bar−1).

The challenges of all pressure driven technologies in NF are strongly linked with membrane fouling/biofouling, insufficient separation, generation of concentrates, membranes short lifespan, low chemical resistance and deficient rejection for particular compounds [146]. Regarding the separation, it is well known that NF membranes typically had low rejection of monovalent ions, high rejection of divalent species and higher fluxes at low pressure than RO techniques. This specificity allows the NF technologies to be used in applications that require specific separations in wastewater treatment and fine-chemistry areas especially, such as within the pharmaceutical and biotechnology fields, where the removal or concentration of a determined compound is required. The mentioned technical development allows the NF to be used in multiple specific applications in diverse industries, with well-established membrane, modular and processing development [147].

Conversely, there are still several active trending investigation lines especially environmental applications, membrane fabrication/modification, fouling, desalination, dye wastewater treatment and process modeling [147,148,149]. Regarding the water treatment area, the wastewater treatment (WWT) is undoubtedly the most common probed application of NF with around 18% of the studies in the past decade, combined with water-related investigation in fouling, desalination and membrane design topics [17,148,149]. While studies in WWT are generally concerned with the removal of specific molecules or ions, studies in desalination generally focus on pre-treatment or partial desalting. Membrane design topics include the development of advanced techniques for membrane preparation using different strategies such as blending, interfacial polymerization, layer by layer, grafting, nanoparticle incorporation or beam irradiation, and reporting enhancement of properties such as antifouling, antibiofouling, hardness removal, dye removal and dissolved salts removal [150].

In this connection, the antimicrobial activity is an appreciated enhancement due to costly biofouling problems in NF. An excellent alternative is the use of copper-based modifications that, in the case of NF technologies, had a limited but promissory number of related studies. Thus, the research reported to date combining nanofiltration and the use of copper as a modifier is divided in WWT composite membranes and pretreatment desalination composite membranes, prepared usually by blending/phase inversion techniques combined with a pool of complex advanced methodologies illustrated in Table 4. Some of them objectively stated the bactericidal enhancements of copper-based modifications, while others were directed to the improvements of hydrophilic properties and surface/pore characteristics. In these regards, the studies will be analyzed based on the preparation strategies and success of modifications regarding the rejection of species, water flux, hydrophilicity, membrane fouling effect and antibacterial activity. These, depending on the case, can be applied for two main applications: wastewater treatment and desalination.

Table 4.

Summary of NF membranes modified with copper-containing compounds.

First, the studies including copper-containing membrane preparation and design for WWT are dominated by the PAN matrix alongside with one research output with a CA based membrane. In the latter case, Asapu et al. [63] developed a low-biofouling membrane mediated by de CA functionalization with glycidyl methacrylate (GMA) combined with iminodiacetic acid (IDA) as chelating agent for copper divalent ion fixing. The methodology involves a homopolymerization and a phase inversion stage followed by an immobilized metal affinity (IMA) based chemistry reactions. The authors propose the development of a simple method using readily available and cost-effective materials such as cellulose-based polymers, thus fixing an antibacterial agent only by coordination interactions. The antibiofouling properties show a biocidal effect against P. fluorescence, manifested in the reduction of biofilm area formation and a lower flux rate decline compared with unmodified membranes, after organic foulant filtration essays (BSA, Lipase). These results suggest an increase in lifespan and antibiofouling/antifouling properties for the new membranes. However, the rejection rates on salts and organic contaminants are not reported to hinder the objective analysis of the NF membrane efficiency. In addition, the cooper leached from the membranes seems to be low, confirming the stability of the modification.

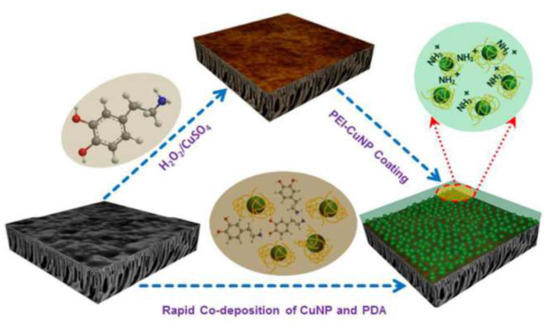

The PAN-based studies show similar behaviors despite the big differences among modifications. For example, Zhu et al. [64] developed two modification strategies using two step deposition and co-deposition employing Mussel-inspired polydopamine (PDA) chemistry for the immobilization of polyethyleneimine-functionalized copper nanoparticles (PEI-CuNPs) on a PAN-UF template, generating a loose NF membrane (see Figure 9). The treatment reduced the pore size of the membrane by bridging the pore cavities. The results of the modification showed an enhancement of hydrophilicity, homogeneous particle distribution and low roughness. Regarding the operational parameters, the modified membranes show low salt rejection in both divalent and monovalent salts, and superior rejection against different textile dyes (0.6–2 kDa), offering the possibility to be used as dye concentrator in textile WWT. The antibacterial activity was extremely high against E. coli, with 93.7% of inhibition.

Figure 9.

Schematic diagram of the surface modifications of the HPAN membrane via two-step deposition and co-deposition using PDA and CuNPs. Extracted from [64].

Another similar work, by Zhu et al. [42], describes the nanocomposite membrane preparation of an NF material using reduced graphene oxide-copper (rGOC) nanocomposites to bridge the pore cavities of a PAN hydrolyzed membrane by a Mussel-inspired PDA modification. The obtained membranes had high water permeability, hydrophilicity, and strong antibacterial performance (97% against E. coli). In addition, the salt rejection was low for divalent and monovalent salt and the rejection against dyes was remarkably high (99.4%), confirming a potential use as a fractionator of textile dyes in WWT.

Finally, another similar research by Chakrabarty et al. [65] used a simple tannic acid-cupric acetate complex (TA-Cu2+) functionalization to coat porous PAN hydrolyzed UF membranes through surficial co-deposition with gallol (1,2,3-trihydroxyphenyl) and catechol (1,2-dihydroxyphenyl) bio-polyphenols via polymerization. The structural analysis confirms the formation of a thin layer with good hydrophilicity properties and high pure water flux. Once again, the rejection of divalent and monovalent ions is low, while the filtration percentage of textile dyes and polymer molecules is remarkably high (99% 0.6 kDa), showing a membrane with potential use in desalting of organic solutes or WWT in contrast with the use of small organic molecules. Although those works are particularly directed towards the treatment of dyes or organic molecules, a low rejection on divalent salt has been observed. There is a detrimental influence given the modifications on the reduction of the pore size of the original UF membranes to the NF range, either due to inhomogeneities in the surface modification or low functionalization rates

Second, four reports on desalination applications for copper-modified NF membranes contain sulfonated polymers that work as the main starting point: polysulfone (PSf) and polyethersulfone (PES). The remaining two studies are related to the modification of alternative NF matrixes as PAN and PEI. In almost all these cases, the preparation of the membrane and its final structure behave as typical developments in reverse osmosis: a porous supporting polymer base covered by a dense active thin layer.

For instance, Isloor et al. [66] describe the membrane surface modification of a PSf/polyisobutylene-alt-maleic anhydride (PSf-PIAM) matrix through direct PVD of elemental copper. The resulting coating is reported to be highly homogeneous for its application in desalination and antibiofouling purposes. The pure water flux is about 36 with a monovalent salt rejection of 96% (3500 ppm NaCl), proving its desalination capacity. The antimicrobial effect was probed against B. cereus through qualitative inhibition halo formation. The less overall flux decline of the membrane suggests a successful antibiofouling property even with the slight increment of the hydrophobicity of the phase inversion in the obtained membrane. In this case, the main concern with respect to this methodology is the release of metallic copper exposed to oxidation-reduction processes in an aggressive saline environment, which can lead to a rapid leaching of the deposited layer by physical methods, and a final short membrane lifespan.

On the other side, Misdan et al. [67] made a simple chemical modification loading different concentration of copper benzene-1,3,5-tricarboxylate (CuBTC) nanoparticles on a PSf matrix by blending, followed by and interfacial polymerization to form a poly (piperazineamide) (poly-PIP) selective layer. The modification of the substrate support altered the thin layer properties, increasing the hydrophilicity and promoting layer densification. The results show a clear enhancement of the rejection performance especially for divalent ions (97% MgSO4) and organic foulants (99.9% BSA). Despite the good performance results, no leaching study is observed to verify the stability of a highly soluble species such as copper MOF, since its presence in the support membrane (permeate side) could generate the release of copper ions in the desalted water.

In the same line, another study related to PSf-(poly-PIP) based matrixes is described by Tajuddin et al. [68]. This modification consists in thin film composites fabrication by incorporation of copper-aluminum layered double hydroxide nanofillers (Cu-Al LDH), directly in the interfacial polymerization step. After the incorporation of layer double hydroxide (LDH)-type nanostructures, the morphology of the membrane surface was smoothened and its nodular characteristics decreased, also its hydrophilicity increased. Regarding the desalination performance, the results show an outstanding divalent ion rejection (MgSO4 95.4%, Na2SO4 96.8%, MgCl2 95.6%) and partial desalination performance against monovalent ions (NaCl 60.6%). In addition, the pure water flux was increased by a significant amount (15%), and the enhancement of antifouling properties was probed against an organic foulant (cetyltrimethylammonium bromide, CTAB). However, despite the good structural and morphological characterization exposed, there is an absence of necessary characterizations to verify the stability of the LDH nano-filler compounds, which are chemically sensitive to dissolution in aqueous medium. This phenomenon could generate the presence of copper and aluminum ions in the resulting permeate, and/or defects in the integrity of the active layer of the NF membrane, compromising the effectiveness of the modification.

In another study, Zareei et al. [69] prepared a composited PES-based membrane loaded with CoFe2O4/CuO nanoparticles using blending followed by phase inversion technique. The resulting matrix exhibited higher hydrophilicity and low roughness. The performance parameters, such as pure water flux and salt rejection, showed a remarkable increase (95% Na2SO4, 72% NaCl); the rejection of heavy metal proved to be successful with more than 85% rejection of Cu2+, Ni2+and Pb2+. In this case, the asymmetrical membrane exhibited high void formation and bigger channeling in the polymer matrix with the NPs load. Surprisingly, these pore irregularities do not show adverse effects on the membrane performance, on the contrary, the desalination properties were critically enhanced. An antibiofouling study should be necessary to take advantage of the high concentration of loaded copper. Nevertheless, again, it is necessary to address quantitative studies of copper lixiviation stability to avoid Cu ion liberation on the wrong side of the filtration process.

Alternatively, Sumisha et al. [70] used PEI for the fabrication of NF membranes functionalized with TiO2 nanotubes and hydrogen trititanate (H2Ti3O7) nanotubes (TNT), by means of simple dispersion and phase inversion methods. One of the modifications includes the functionalization with TNT-based nanotubes, previously charged with copper salts via ion exchange doping treatments (Cu-TNT). The resulting mixed matrix membrane showed a macro-void pattern morphology. An enhancement in hydrophilicity was reached directly related with Cu-TNT functionalization. The salt rejection against divalent ions was acceptable in terms of softening process (80% K2SO4-45% CaCl2), but in general lines is lower than the conventional NF membranes. The monovalent ion rejection is surprisingly high regarding the macro-void morphology (75–65% NaCl), but only at lower salt concentrations (500–2000 ppm). The performance in pure water flux reached the maximum in the comparative study with the addition of Cu-TNT, also with good fouling properties against protein absorption. Nonetheless, despite the novelty of the modification, mainly by the use of alternative components, the rejection and recovery rates are not adequate for desalination, even against divalent ions. For instance, the water softening and brackish water treatments could be a feasible application.

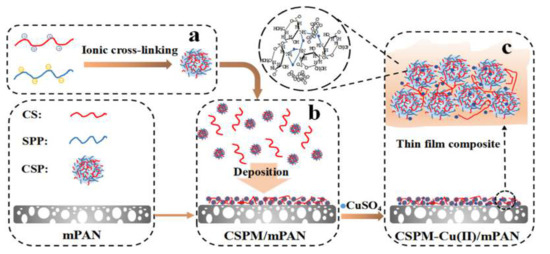

Finally, Zhao et al. [71] describe the deposition of an active chitosan (CS)/polyphosphate (SPP) active layer onto a hydrolyzed PAN support by means of ionic crosslinking and LbL deposition, followed by a functionalization with copper divalent ions (see Figure 10). The resulting PAN-CS-SSP-Cu thin film composite membrane showed better hydrophilicity and higher pure water flux combined with a notable increase in salt and organic molecule rejection. In addition to this, the modified NF membrane exhibited a total antibacterial effect against E. coli. The main risk for this membrane is the long-term stability due to Cu(II) leaching and CS high rate degradation. However, the described method is an interesting approach for incorporating another more stable polyelectrolyte in high performance substrates.

Figure 10.

Diagrammatic sketch of membrane fabrication process of CSPM-Cu(II)/mPAN: (a) formation of CSPs, (b) deposition of CSP suspension onto mPAN to form CSPM/mPAN, (c) Cu(II) chelation of CSPM/mPAN to form CSPM-Cu(II)/mPAN. Extracted from [71].

In summary, copper modified NF membranes for WWT and pretreatment desalination have been prepared mainly by blending/phase inversion techniques combined with a pool of complex advanced methodologies. The anti-bactericidal effect and the improvements of hydrophilic properties and surface/pore characteristics have been the main focus of the modification. Regarding WWT, the studies are dominated by the PAN matrix alongside with one research output with a CA based membrane. Although those works are particularly directed towards the treatment of textile dyes or oligomeric organic molecules, the general divalent salt rejection is surprisingly low. These results suggest that modifications may have some problems in reducing the size of the original UF membranes to the NF range, either due to inhomogeneities in the surface modification or low functionalization rates. Regarding the desalination applications, copper-modified NF membranes based on sulfonated polymers such as PSf, PES and PAN modification, have enhanced the rejection performance. Moreover, water flux and salt rejection showed a remarkable increase, however, salt rejection is still lower than RO. Considering some factors such as low pressures and high fluxes, the modified NF approaches could be an excellent pretreatment complement in the water desalination fight against fouling/biofouling.

3.4. Ultrafiltration (UF) Membranes

Ultrafiltration is a membrane filtration process similar to reverse osmosis, using hydrostatic pressure to force water through a semipermeable membrane, with several operational advantages, such as low operating pressures, environmental operating temperature and low operating cost. Ultrafiltration membranes generally have pore sizes between 1 and 100 nm (Figure 1), making them an attractive option for the separation and removal of particles, bacteria and viruses from different water sources. Thus, this technology is used in a wide range of applications, such as RO pretreatment, production of drinking water and wastewater treatment.

UF membranes are typically made of polymeric materials such as PES, poly (vinylidene fluoride) (PVDF), PEI, PAN, PSf, among others. In this regard, PES can distinguish it from others considering its suitable chemical properties, thermal stability, and appropriate resistance to the oxidation process. However, its inherent hydrophobic property often causes significant membrane fouling due to the adsorption of nonpolar solutes, hydrophobic particles and bacteria, affecting widespread applications of membrane processes. Therefore, various efforts have focused on preventing fouling, biofouling, and increasing membrane flux properties in this type membranes [151,152,153,154,155]. Some research has been carried out on the surface modification of UF membranes through the introduction of hydrophilic polymers and inorganic particles. To date, various modification methods, including chemical grafting [156], surface coating [157] and blending-crosslinking [158], have been employed to improve the hydrophilicity and the antifouling properties of these membranes.

In this context, modifications of UF membranes through the incorporation of copper-based materials, mainly as nanoparticles, have been carried out in order to improve these properties. A comparative summary of the modifications studied by the different authors is shown in Table 5. In the analysis the following is considered: the different base polymers used in the production of modified UF membrane (PES, PVDF, PEI, PAN, PSf, among others), the different copper- based materials proposed for the modification and their impact in the properties mentioned before.

Table 5.

A comparative summary of the UF membranes modified with Cu.