Fabrication, Optimization, and Performance of a TiO2 Coated Bentonite Membrane for Produced Water Treatment: Effect of Grafting Time

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of TiO2 Sol

2.3. Deposition of TiO2 Nanoparticle on Bentonite Membrane

2.4. Membrane Characterization

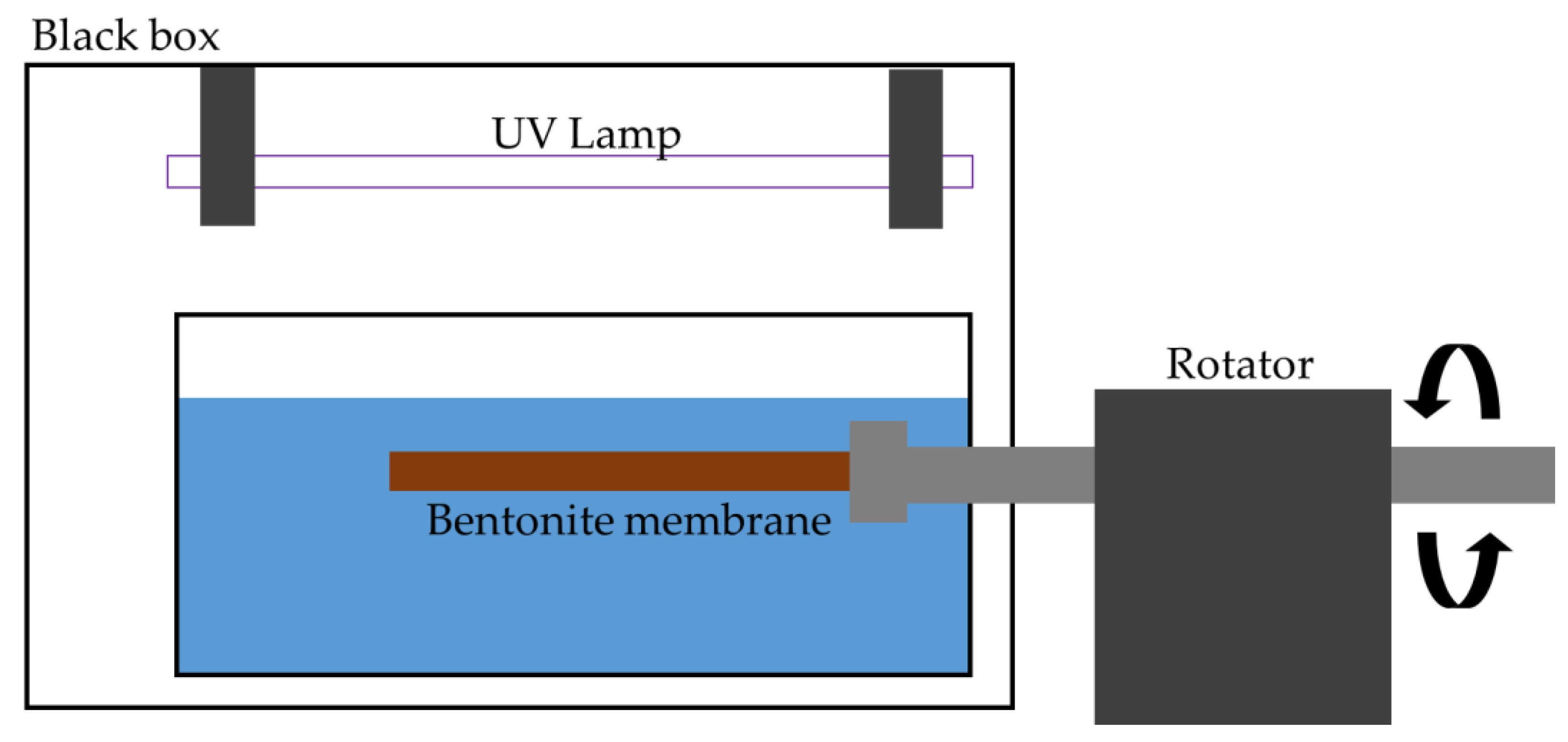

2.5. Water Flux Permeation and Oil Rejection Performance

3. Results and Discussion

3.1. Characterization of Pristine Bentonite and Coated Bentonite Membranes

3.1.1. FTIR Analysis

3.1.2. Surface and Cross-Sectional Morphology Analysis

3.1.3. Wettability Analysis

3.2. Performance Tests of Pristine Bentonite Membrane and TiO2 Coated Bentonite Membranes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ahmad, N.A.; Goh, P.S.; Yogarathinam, L.T.; Zulhairun, A.K.; Ismail, A.F. Current advances in membrane technologies for produced water desalination. Desalination 2020, 493, 114643. [Google Scholar] [CrossRef]

- Al-Ghouti, M.A.; Al-Kaabi, M.A.; Ashfaq, M.Y.; Da’na, D.A. Produced water characteristics, treatment and reuse: A review. J. Water Process Eng. 2019, 28, 222–239. [Google Scholar] [CrossRef]

- Rahman, A.; Agrawal, S.; Nawaz, T.; Pan, S.; Selvaratnam, T. A review of algae-based produced water treatment for biomass and biofuel production. Water 2020, 12, 2351. [Google Scholar] [CrossRef]

- Rosell-Melé, A.; Moraleda-Cibrián, N.; Cartró-Sabaté, M.; Colomer-Ventura, F.; Mayor, P.; Orta-Martínez, M. Oil pollution in soils and sediments from the Northern Peruvian Amazon. Sci. Total Environ. 2018, 610–611, 1010–1019. [Google Scholar] [CrossRef] [PubMed]

- Ossai, I.C.; Ahmed, A.; Hassan, A.; Hamid, F.S. Remediation of soil and water contaminated with petroleum hydrocarbon: A review. Environ. Technol. Innov. 2020, 17, 100526. [Google Scholar] [CrossRef]

- Nasiri, M.; Jafari, I.; Parniankhoy, B. Oil and gas produced water management: A review of treatment technologies, challenges, and opportunities. Chem. Eng. Commun. 2017, 204, 990–1005. [Google Scholar] [CrossRef]

- Nasiri, M.; Jafari, I. Produced water from oil-gas plants: A short review on challenges and opportunities. Period. Polytech. Chem. Eng. 2017, 61, 73–81. [Google Scholar] [CrossRef] [Green Version]

- Kusworo, T.D.; Aryanti, N.; Utomo, D.P. Oilfield produced water treatment to clean water using integrated activated carbon-bentonite adsorbent and double stages membrane process. Chem. Eng. J. 2018, 347, 462–471. [Google Scholar] [CrossRef]

- Ishak, K.E.H.K.; Ayoub, M.A. Predicting the efficiency of the oil removal from surfactant and polymer produced water by using liquid–liquid hydrocyclone: Comparison of prediction abilities between response surface methodology and adaptive neuro-fuzzy inference system. IEEE Access 2019, 7, 179605–179619. [Google Scholar] [CrossRef]

- Sosa-Fernandez, P.; Post, J.; Leermakers, F.; Rijnaarts, H.; Bruning, H. Removal of divalent ions from viscous polymer-flooding produced water and seawater via electrodialysis. J. Membr. Sci. 2019, 589, 117251. [Google Scholar] [CrossRef]

- Zhang, Z.; Du, X.; Carlson, K.H.; Robbins, C.A.; Tong, T. Effective treatment of shale oil and gas produced water by membrane distillation coupled with precipitative softening and walnut shell filtration. Desalination 2019, 454, 82–90. [Google Scholar] [CrossRef]

- Fard, A.K.; Mckay, G.; Chamoun, R.; Rhadfi, T.; Preud’Homme, H.; Atieh, M.A. Barium removal from synthetic natural and produced water using MXene as two dimensional (2-D) nanosheet adsorbent. Chem. Eng. J. 2017, 317, 331–342. [Google Scholar] [CrossRef]

- Hedar, Y. Pollution impact and alternative treatment for produced water. In Proceedings of the E3S Web of Conferences, EDP Sciences, Semarang, Indonesia, 15−16 August 2017; p. 03004. [Google Scholar]

- Rawlins, C.H.; Sadeghi, F. Experimental study on oil removal in nutshell filters for produced-water treatment. SPE Prod. Oper. 2018, 33, 145–153. [Google Scholar]

- Khalifa, O.; Banat, F.; Srinivasakannan, C.; Radjenovic, J.; Hasan, S.W. Performance tests and removal mechanisms of aerated electrocoagulation in the treatment of oily wastewater. J. Water Process Eng. 2020, 36, 101290. [Google Scholar] [CrossRef]

- Jiménez, S.; Micó, M.M.; Arnaldos, M.; Ferrero, E.; Malfeito, J.J.; Medina, F.; Contreras, S. Integrated processes for produced water polishing: Enhanced flotation/sedimentation combined with advanced oxidation processes. Chemosphere 2017, 168, 309–317. [Google Scholar] [CrossRef] [PubMed]

- Bagheri, M.; Roshandel, R.; Shayegan, J. Optimal selection of an integrated produced water treatment system in the upstream of oil industry. Process Saf. Environ. Prot. 2018, 117, 67–81. [Google Scholar] [CrossRef]

- Shamaei, L.; Khorshidi, B.; Perdicakis, B.; Sadrzadeh, M. Treatment of oil sands produced water using combined electrocoagulation and chemical coagulation techniques. Sci. Total Environ. 2018, 645, 560–572. [Google Scholar] [CrossRef]

- Al Hawli, B.; Benamor, A.; Hawari, A.A. A hybrid electro-coagulation/forward osmosis system for treatment of produced water. Chem. Eng. Process. Process Intensif. 2019, 143, 107621. [Google Scholar] [CrossRef]

- Santos, A.S.; Oliveira, L.F.S.; Marques, A.M.; Silva, D.C.; Mansur, C.R. Evaluation of the efficiency of polyethylenimine as flocculants in the removal of oil present in produced water. Colloids Surf. A Physicochem. Eng. Asp. 2018, 558, 200–210. [Google Scholar] [CrossRef]

- Jain, P.; Sharma, M.; Dureja, P.; Sarma, P.M.; Lal, B. Bioelectrochemical approaches for removal of sulfate, hydrocarbon and salinity from produced water. Chemosphere 2017, 166, 96–108. [Google Scholar] [CrossRef]

- Lusinier, N.; Seyssiecq, I.; Sambusiti, C.; Jacob, M.; Lesage, N.; Roche, N. A comparative study of conventional activated sludge and fixed bed hybrid biological reactor for oilfield produced water treatment: Influence of hydraulic retention time. Chem. Eng. J. 2021, 420, 127611. [Google Scholar] [CrossRef]

- Chang, H.; Li, T.; Liu, B.; Vidic, R.D.; Elimelech, M.; Crittenden, J.C. Potential and implemented membrane-based technologies for the treatment and reuse of flowback and produced water from shale gas and oil plays: A review. Desalination 2019, 455, 34–57. [Google Scholar] [CrossRef]

- Zoubeik, M.; Ismail, M.; Salama, A.; Henni, A. New developments in membrane technologies used in the treatment of produced water: A review. Arab. J. Sci. Eng. 2018, 43, 2093–2118. [Google Scholar] [CrossRef]

- Jepsen, K.L.; Bram, M.V.; Pedersen, S.; Yang, Z. Membrane fouling for produced water treatment: A review study from a process control perspective. Water 2018, 10, 847. [Google Scholar] [CrossRef] [Green Version]

- Atallah, C.; Tremblay, A.Y.; Mortazavi, S. Silane surface modified ceramic membranes for the treatment and recycling of SAGD produced water. J. Pet. Sci. Eng. 2017, 157, 349–358. [Google Scholar] [CrossRef]

- Weschenfelder, S.E.; Fonseca, M.J.C.; Costa, B.R.S.; Borges, C.P. Influence of the use of surfactants in the treatment of produced water by ceramic membranes. J. Water Process Eng. 2019, 32, 100955. [Google Scholar] [CrossRef]

- Kayvani Fard, A.; McKay, G.; Buekenhoudt, A.; Al Sulaiti, H.; Motmans, F.; Khraisheh, M.; Atieh, M. Inorganic membranes: Preparation and application for water treatment and desalination. Materials 2018, 11, 74. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aziz, M.H.A.; Othman, M.H.D.; Hashim, N.A.; Rahman, M.A.; Jaafar, J.; Hubadillah, S.K.; Tai, Z.S. Pretreated aluminium dross waste as a source of inexpensive alumina-spinel composite ceramic hollow fibre membrane for pretreatment of oily saline produced water. Ceram. Int. 2019, 45, 2069–2078. [Google Scholar] [CrossRef]

- Usman, J.; Othman, M.H.; Ismail, A.F.; Rahman, M.A.; Jaafar, J.; Raji, Y.O.; El Badawy, T.H.; Gbadamosi, A.O.; Kurniawan, T.A. Impact of organosilanes modified superhydrophobic-superoleophilic kaolin ceramic membrane on efficiency of oil recovery from produced water. J. Chem. Technol. Biotechnol. 2020, 95, 3300–3315. [Google Scholar] [CrossRef]

- Twibi, M.F.; Othman, M.H.D.; Hubadillah, S.K.; Alftessi, S.A.; Kurniawan, T.A.; Ismail, A.F.; Rahman, M.A.; Jaafar, J.; Raji, Y.O. Development of high strength, porous mullite ceramic hollow fiber membrane for treatment of oily wastewater. Ceram. Int. 2021, 47, 15367–15382. [Google Scholar] [CrossRef]

- Hu, X.; Yu, Y.; Zhou, J.; Wang, Y.; Liang, J.; Zhang, X.; Chang, Q.; Song, L. The improved oil/water separation performance of graphene oxide modified Al2O3 microfiltration membrane. J. Membr. Sci. 2015, 476, 200–204. [Google Scholar] [CrossRef]

- Raji, Y.O.; Othman, M.H.D.; Nordin, N.A.H.S.M.; Kurniawan, T.A.; Ismail, A.F.; Rahman, M.A.; Jaafar, J.; Adam, M.R.B.; Alftessi, S.A.; El-badawy, T.; et al. Wettability improvement of ceramic membrane by intercalating nano-Al2O3 for oil and water separation. Surf. Interfaces 2021, 25, 101178. [Google Scholar] [CrossRef]

- Li, Y.-X.; Cao, Y.; Wang, M.; Xu, Z.-L.; Zhang, H.-Z.; Liu, X.-W.; Li, Z. Novel high-flux polyamide/TiO2 composite nanofiltration membranes on ceramic hollow fibre substrates. J. Membr. Sci. 2018, 565, 322–330. [Google Scholar] [CrossRef]

- Abd Aziz, M.H.; Dzarfan Othman, M.H.; Alias, N.H.; Nakayama, T.; Shingaya, Y.; Hashim, N.A.; Kurniawan, T.A.; Matsuura, T.; Rahman, M.A.; Jaafar, J. Enhanced omniphobicity of mullite hollow fiber membrane with organosilane-functionalized TiO2 micro-flowers and nanorods layer deposition for desalination using direct contact membrane distillation. J. Membr. Sci. 2020, 607, 118137. [Google Scholar] [CrossRef]

- Magnone, E.; Kim, M.K.; Lee, H.J.; Park, J.H. Facile synthesis of TiO2-supported Al2O3 ceramic hollow fiber substrates with extremely high photocatalytic activity and reusability. Ceram. Int. 2021, 47, 7764–7775. [Google Scholar] [CrossRef]

- Raji, Y.O.; Othman, M.H.D.; Md Nordin, N.A.H.; Ismail, A.; Rahman, M.A.; Jaafar, J.; Usman, J.; Momah, S.C. Preparation and Characterization of Bentonite-Based Ceramic Hollow Fiber Membrane. J. Membr. Sci. Res. 2021, 7, 95–101. [Google Scholar]

- Jamalludin, M.R.; Hubadillah, S.K.; Harun, Z.; Othman, M.H.D.; Yunos, M.Z.; Ismail, A.F.; Salleh, W.N.W. Facile fabrication of superhydrophobic and superoleophilic green ceramic hollow fiber membrane derived from waste sugarcane bagasse ash for oil/water separation. Arab. J. Chem. 2020, 13, 3558–3570. [Google Scholar] [CrossRef]

- Guo, H.; Zhao, S.; Wu, X.; Qi, H. Fabrication and characterization of TiO2/ZrO2 ceramic membranes for nanofiltration. Microporous Mesoporous Mater. 2018, 260, 125–131. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, H.; Fan, X.; Lv, F.; Chen, S.; Quan, X. Fabrication of TiO2 nanofiber membranes by a simple dip-coating technique for water treatment. Surf. Coat. Technol. 2016, 298, 45–52. [Google Scholar] [CrossRef]

- Ahmad, R.; Lee, C.S.; Kim, J.H.; Kim, J. Partially coated TiO2 on Al2O3 membrane for high water flux and photodegradation by novel filtration strategy in photocatalytic membrane reactors. Chem. Eng. Res. Des. 2020, 163, 138–148. [Google Scholar] [CrossRef]

- Li, X.; Chen, Y.; Hu, X.; Zhang, Y.; Hu, L. Desalination of dye solution utilizing PVA/PVDF hollow fiber composite membrane modified with TiO2 nanoparticles. J. Membr. Sci. 2014, 471, 118–129. [Google Scholar] [CrossRef]

- Yong, J.; Chen, F.; Yang, Q.; Farooq, U.; Hou, X. Photoinduced switchable underwater superoleophobicity–superoleophilicity on laser modified titanium surfaces. J. Mater. Chem. A 2015, 3, 10703–10709. [Google Scholar] [CrossRef]

- Zhan, H.; Peng, N.; Lei, X.; Huang, Y.; Li, D.; Tao, R.; Chang, C. UV-induced self-cleanable TiO2/nanocellulose membrane for selective separation of oil/water emulsion. Carbohydr. Polym. 2018, 201, 464–470. [Google Scholar] [CrossRef] [PubMed]

- Sun, T.; Liu, Y.; Shen, L.; Xu, Y.; Li, R.; Huang, L.; Lin, H. Magnetic field assisted arrangement of photocatalytic TiO2 particles on membrane surface to enhance membrane antifouling performance for water treatment. J. Colloid Interface Sci. 2020, 570, 273–285. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Ren, Y.; Zhao, P.; Wang, J.; Liu, J.; Zhang, Y. Graphitic carbon nitride (g-C3N4) nanosheets functionalized composite membrane with self-cleaning and antibacterial performance. J. Hazard. Mater. 2019, 365, 606–614. [Google Scholar] [CrossRef] [PubMed]

- Li, N.; Chen, G.; Zhao, J.; Yan, B.; Cheng, Z.; Meng, L.; Chen, V. Self-cleaning PDA/ZIF-67@PP membrane for dye wastewater remediation with peroxymonosulfate and visible light activation. J. Membr. Sci. 2019, 591, 117341. [Google Scholar] [CrossRef]

- Chen, X.; Huang, G.; An, C.; Feng, R.; Yao, Y.; Zhao, S.; Huang, C.; Wu, Y. Plasma-induced poly(acrylic acid)-TiO2 coated polyvinylidene fluoride membrane for produced water treatment: Synchrotron X-Ray, optimization, and insight studies. J. Clean. Prod. 2019, 227, 772–783. [Google Scholar] [CrossRef]

- Li, C.; Sun, W.; Lu, Z.; Ao, X.; Yang, C.; Li, S. Systematic evaluation of TiO2-GO-modified ceramic membranes for water treatment: Retention properties and fouling mechanisms. Chem. Eng. J. 2019, 378, 122138. [Google Scholar] [CrossRef]

- Marzouk, S.S.; Naddeo, V.; Banat, F.; Hasan, S.W. Preparation of TiO2/SiO2 ceramic membranes via dip coating for the treatment of produced water. Chemosphere 2021, 273, 129684. [Google Scholar] [CrossRef]

- Shah, A.H.; Rather, M.A. Effect of calcination temperature on the crystallite size, particle size and zeta potential of TiO2 nanoparticles synthesized via polyol-mediated method. Mater. Today Proc. 2021, 44, 482–488. [Google Scholar] [CrossRef]

| Membrane | Grafting Time (min) | Grafting Cycle (times) | Calcination Temperature (°C) |

|---|---|---|---|

| Pristine Ben | 0 | 3 | 400 |

| Ti-Ben 30 | 30 | 3 | 400 |

| Ti-Ben 60 | 60 | 3 | 400 |

| Ti-Ben 90 | 90 | 3 | 400 |

| Membrane | Average Pore Size (µm) | Porosity (%) | Coating Thickness (µm) |

|---|---|---|---|

| Pristine Ben | 1.75 | 62 | - |

| Ti-Ben 30 | 0.92 | 61 | 10 |

| Ti-Ben 60 | 0.89 | 58 | 12 |

| Ti-Ben 90 | 0.63 | 45 | 23 |

| Parameter | Value | Unit |

|---|---|---|

| Size of oil droplets | 1.0 | µm |

| pH | 6 | - |

| Zeta potential | −5 to −6 | mV |

| Time (min) | Rejection of Oil (%) |

|---|---|

| 60 | 98 |

| 120 | 98 |

| 180 | 98.5 |

| 240 | 98.5 |

| 300 | 99 |

| 360 | 99 |

| Properties | Before Filtration | In First 3 h | At the End of Filtration |

|---|---|---|---|

| OCA | 147° | 147° | 130° |

| Zeta potential | −33 mV | −33 mV | −30 mV |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohamad Esham, M.I.; Ahmad, A.L.; Othman, M.H.D. Fabrication, Optimization, and Performance of a TiO2 Coated Bentonite Membrane for Produced Water Treatment: Effect of Grafting Time. Membranes 2021, 11, 739. https://doi.org/10.3390/membranes11100739

Mohamad Esham MI, Ahmad AL, Othman MHD. Fabrication, Optimization, and Performance of a TiO2 Coated Bentonite Membrane for Produced Water Treatment: Effect of Grafting Time. Membranes. 2021; 11(10):739. https://doi.org/10.3390/membranes11100739

Chicago/Turabian StyleMohamad Esham, Mohamad Izrin, Abdul Latif Ahmad, and Mohd Hafiz Dzarfan Othman. 2021. "Fabrication, Optimization, and Performance of a TiO2 Coated Bentonite Membrane for Produced Water Treatment: Effect of Grafting Time" Membranes 11, no. 10: 739. https://doi.org/10.3390/membranes11100739

APA StyleMohamad Esham, M. I., Ahmad, A. L., & Othman, M. H. D. (2021). Fabrication, Optimization, and Performance of a TiO2 Coated Bentonite Membrane for Produced Water Treatment: Effect of Grafting Time. Membranes, 11(10), 739. https://doi.org/10.3390/membranes11100739