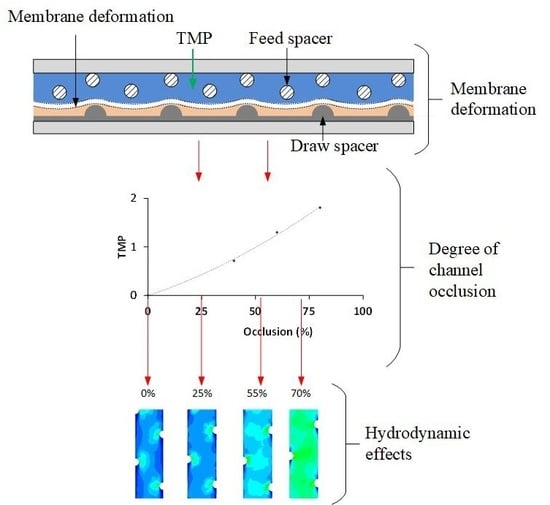

Impact of FO Operating Pressure and Membrane Tensile Strength on Draw-Channel Geometry and Resulting Hydrodynamics

Abstract

1. Introduction

2. Materials and Methods

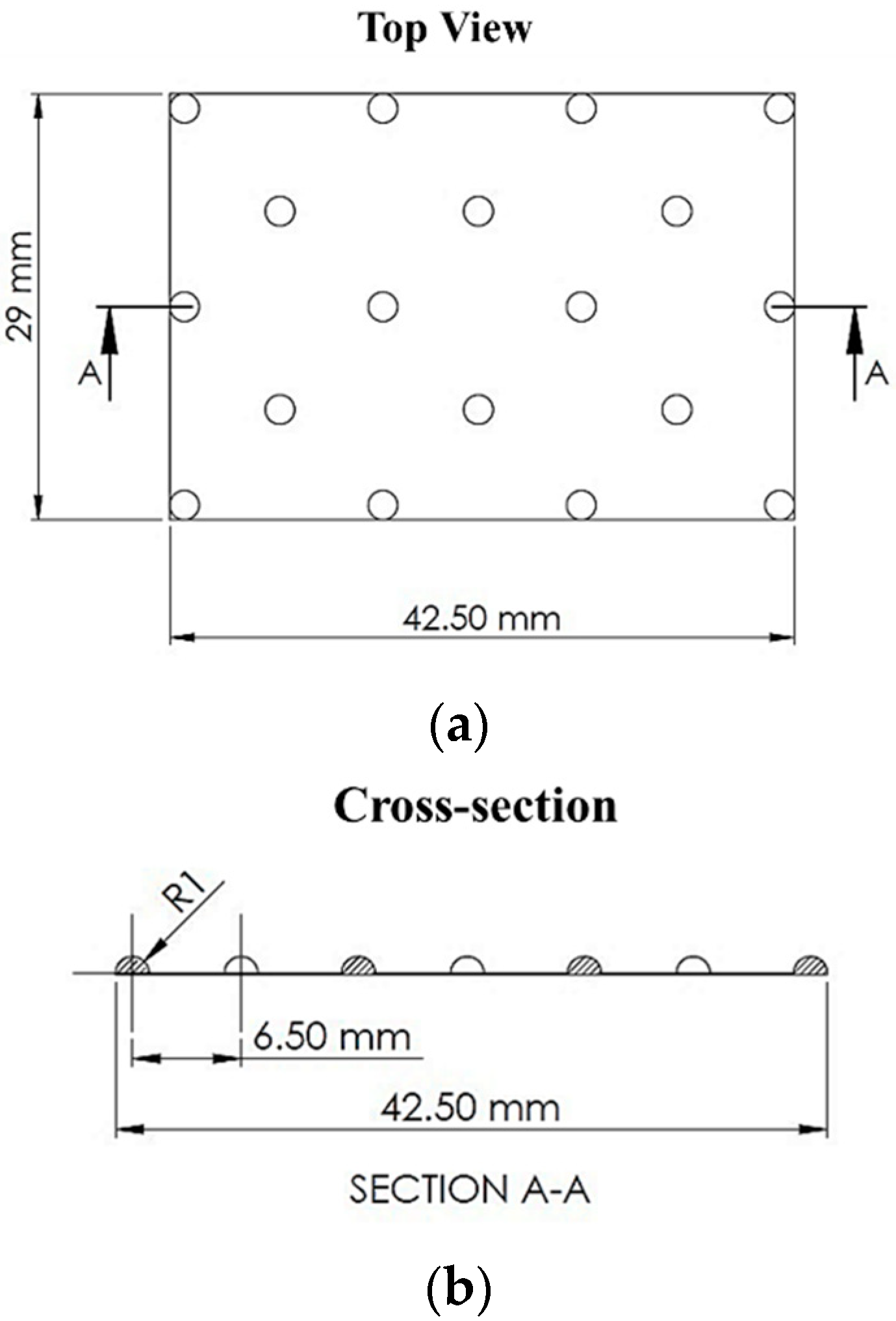

2.1. CFD Modelling of Membrane Processes

2.2. Application of Tensile Membrane Characterisation into ANSYS Model

2.3. Wall Shear Rate

2.4. Reynolds Number Analysis

2.5. Experimental Setup

3. Results and Discussion

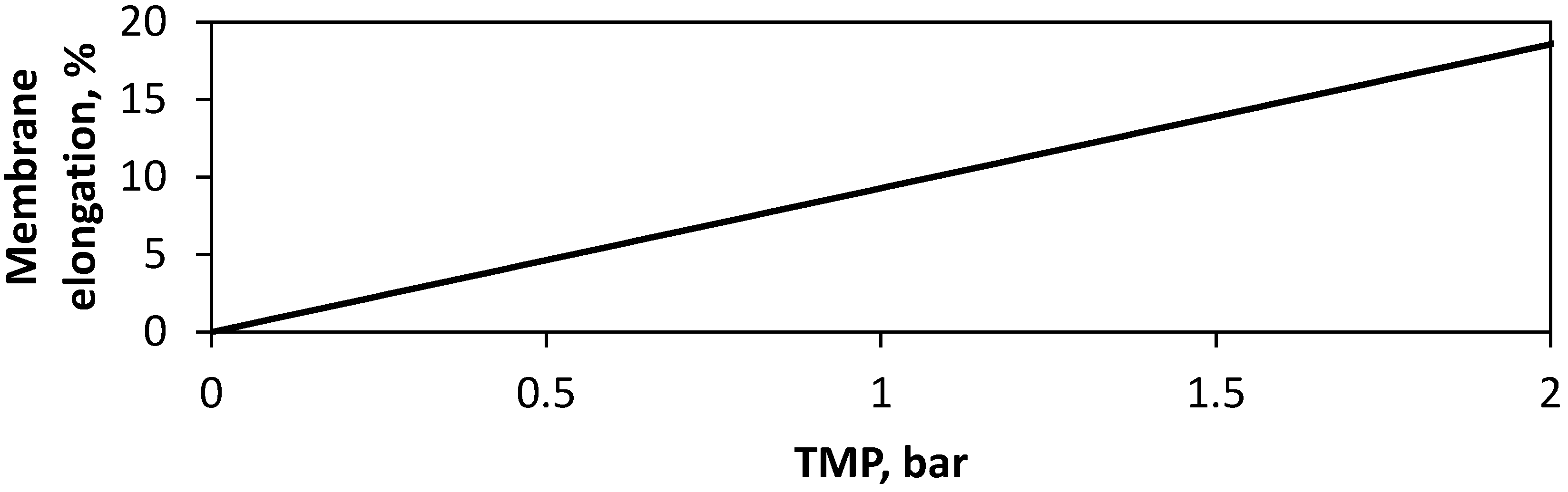

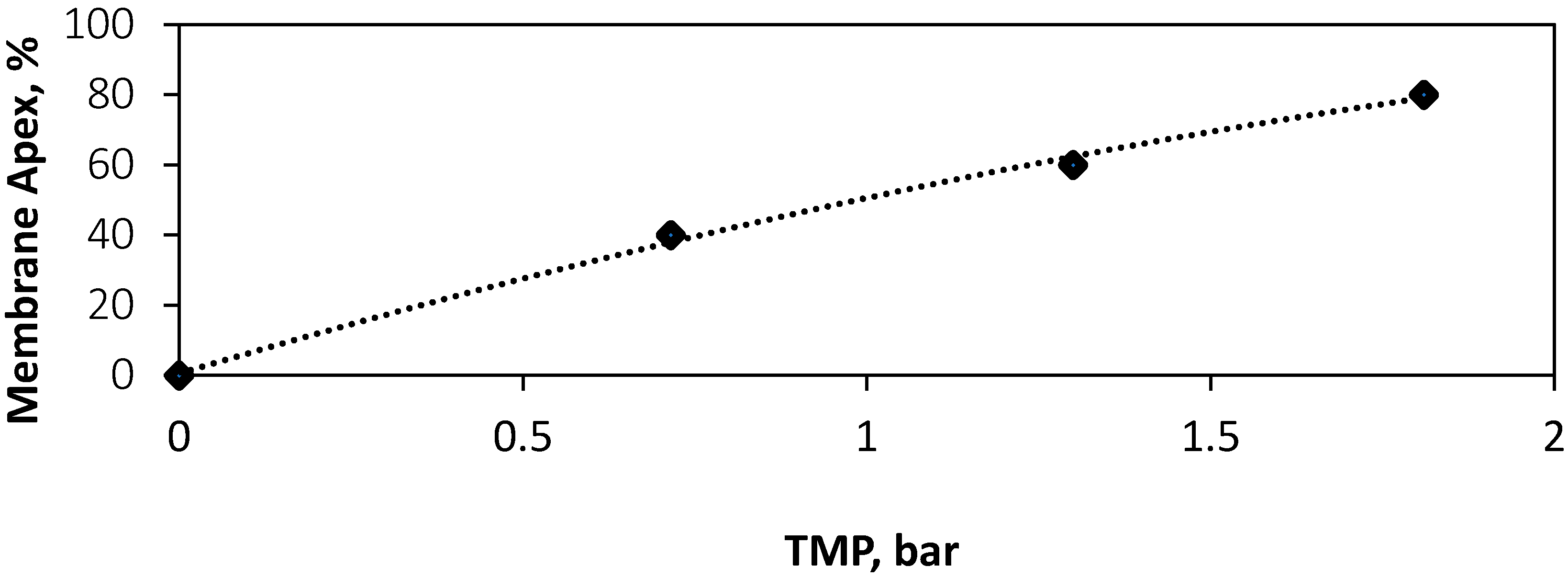

3.1. Tensile Strength of Membrane and Structural Implications

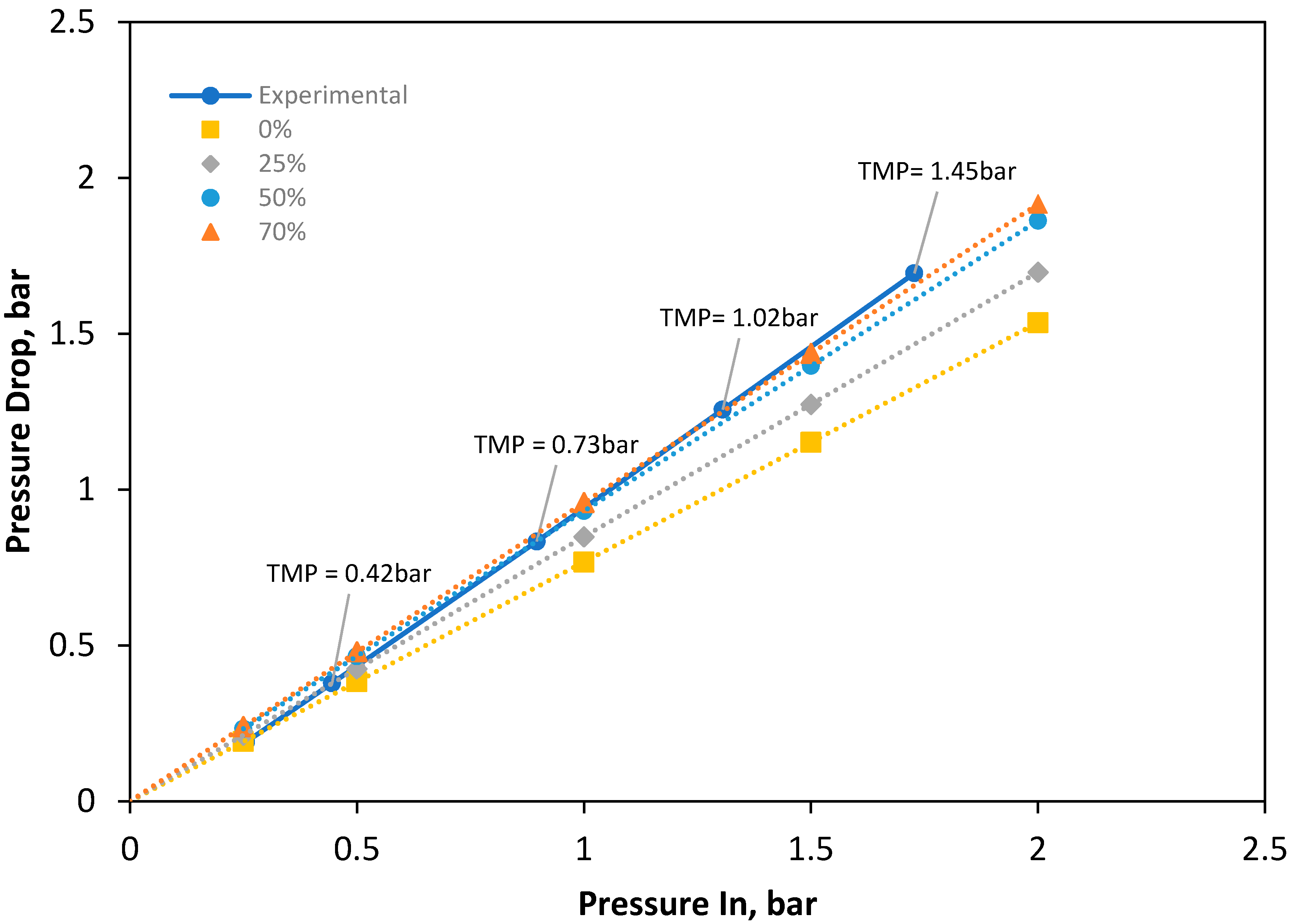

3.2. Pressure Drop Analysis

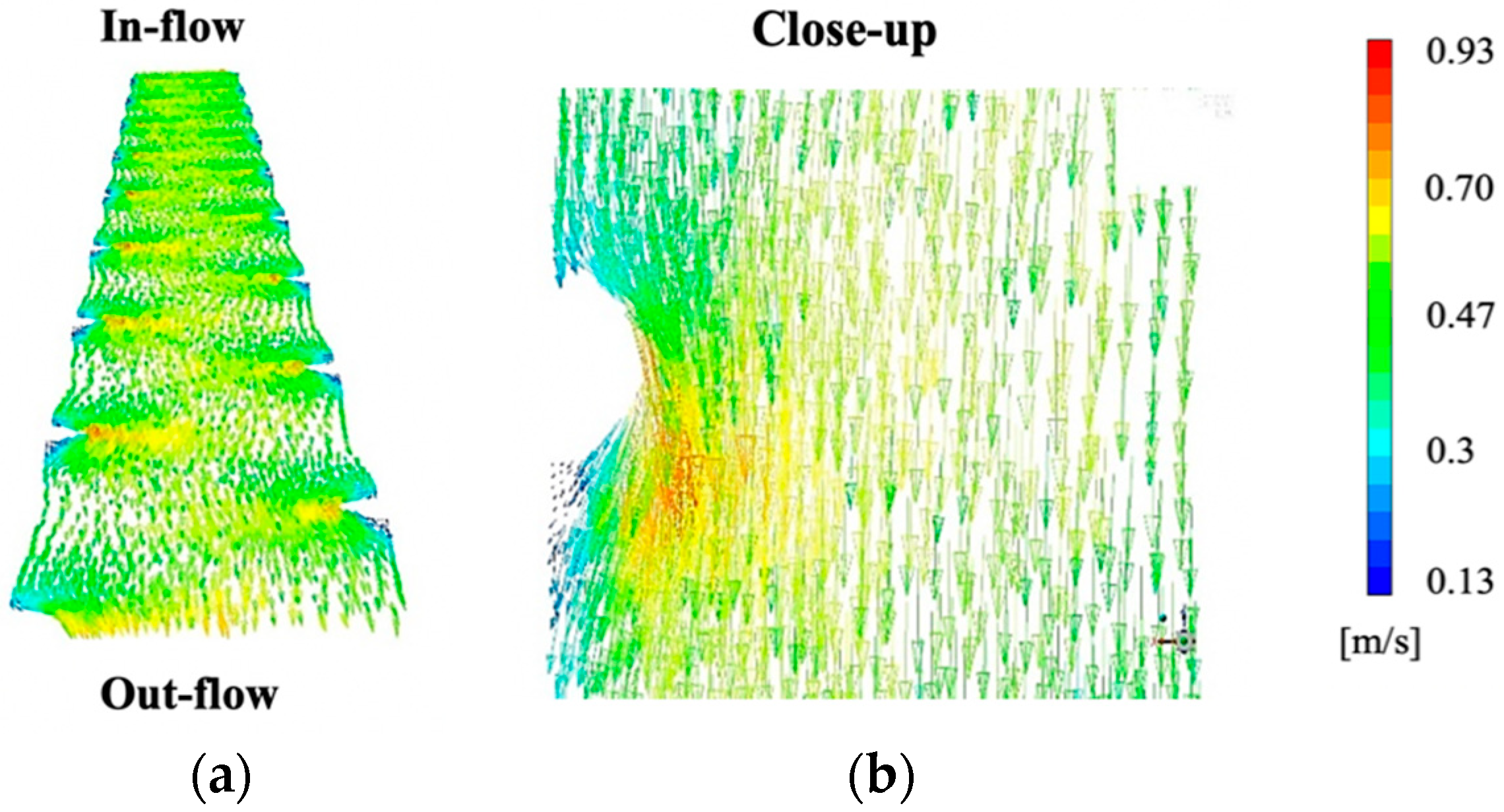

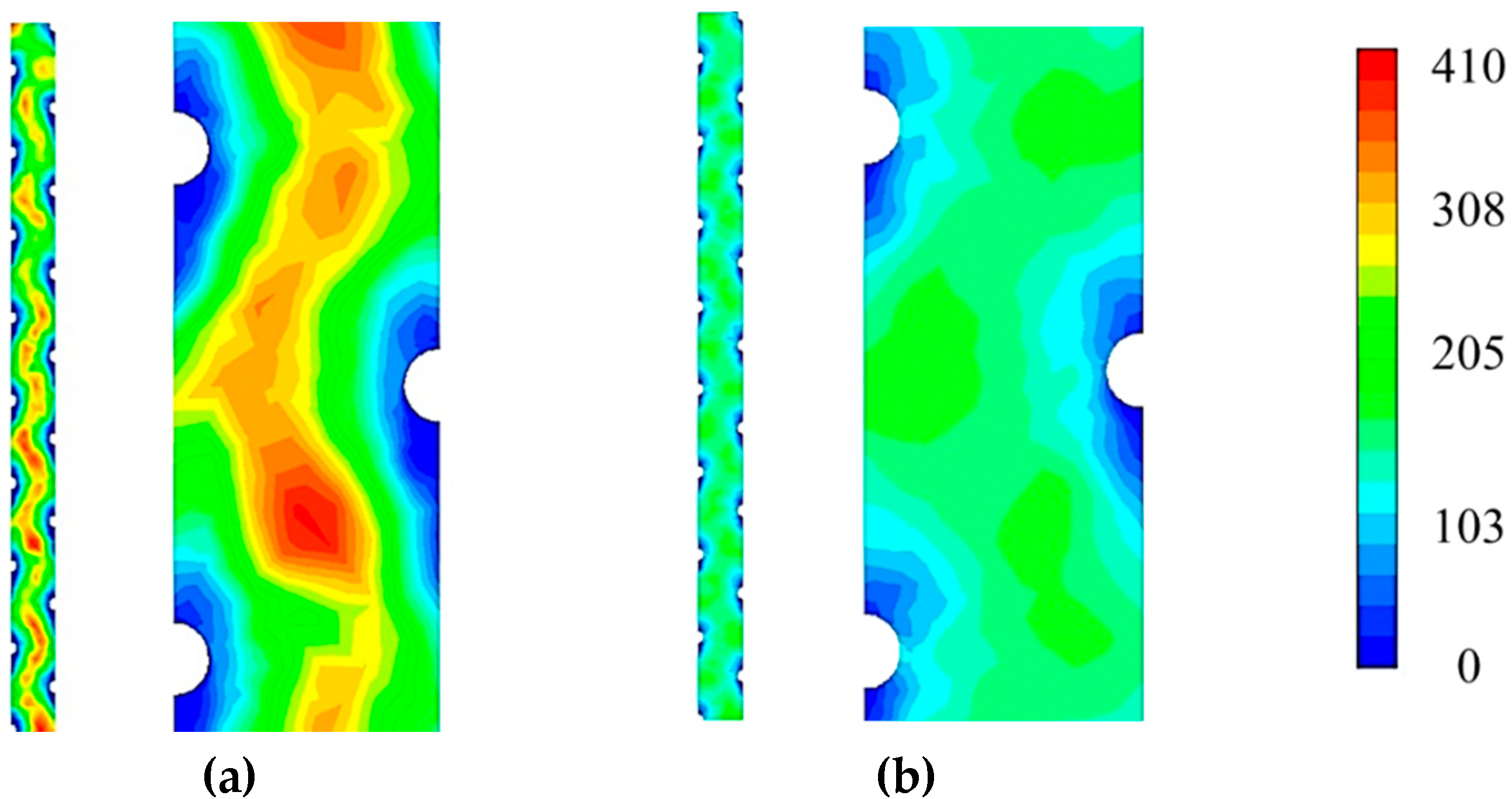

3.3. Velocity Profile Analysis to Determine Spacer Effects on Fluid Flow

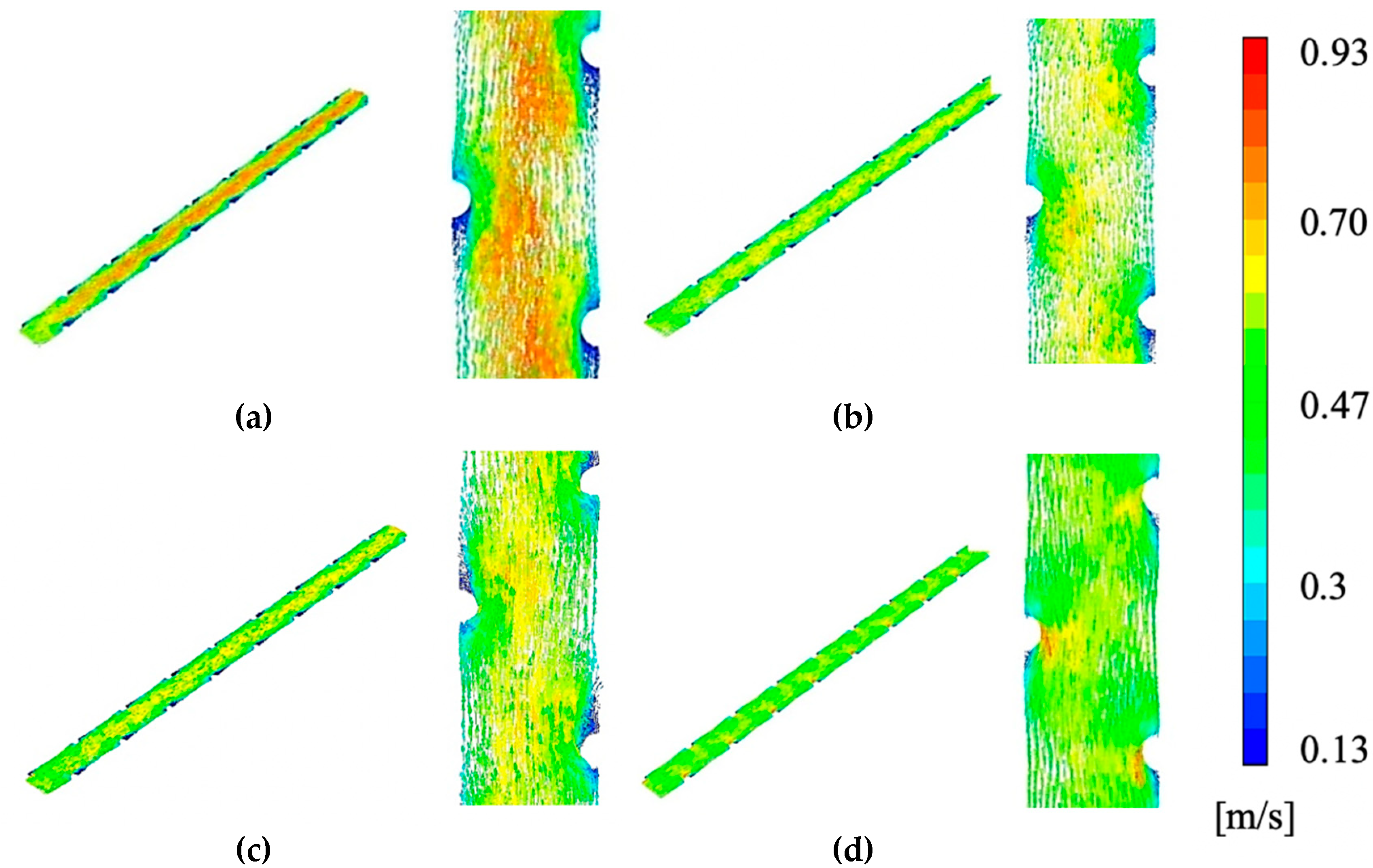

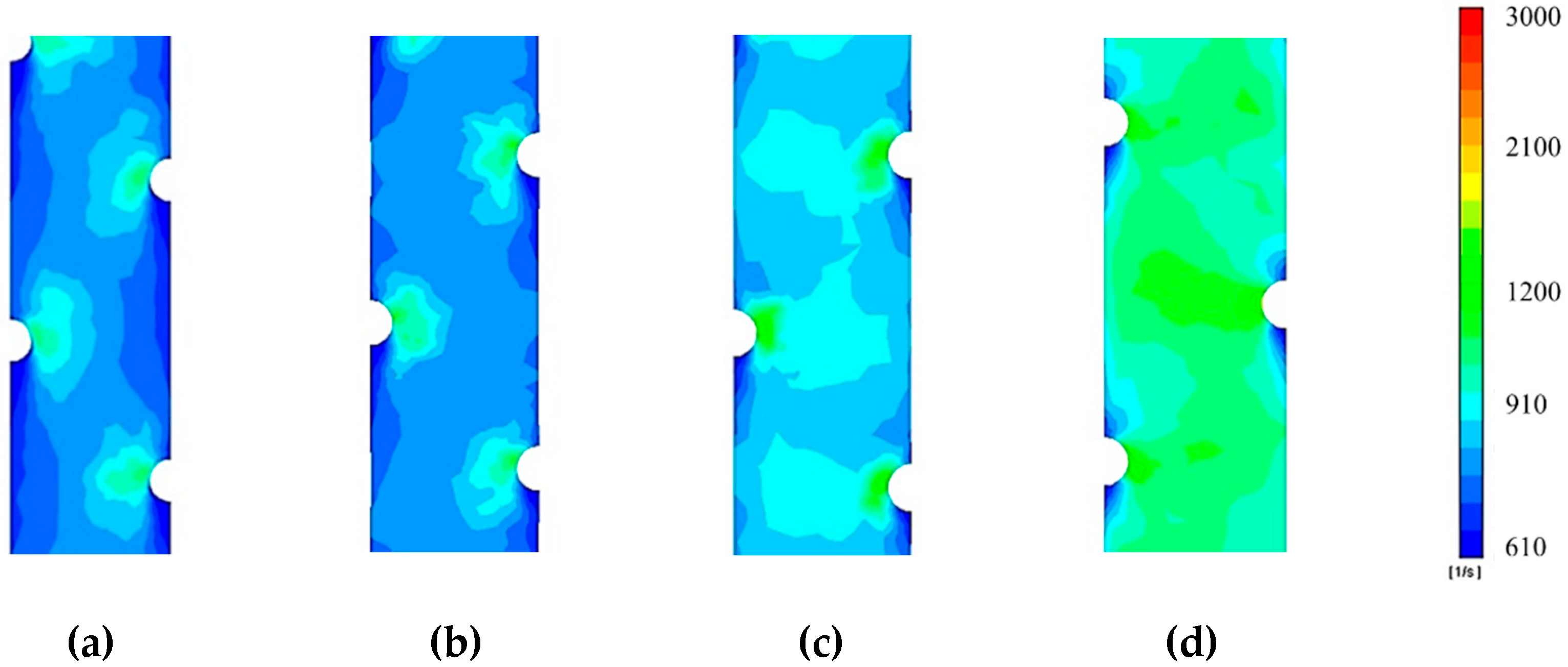

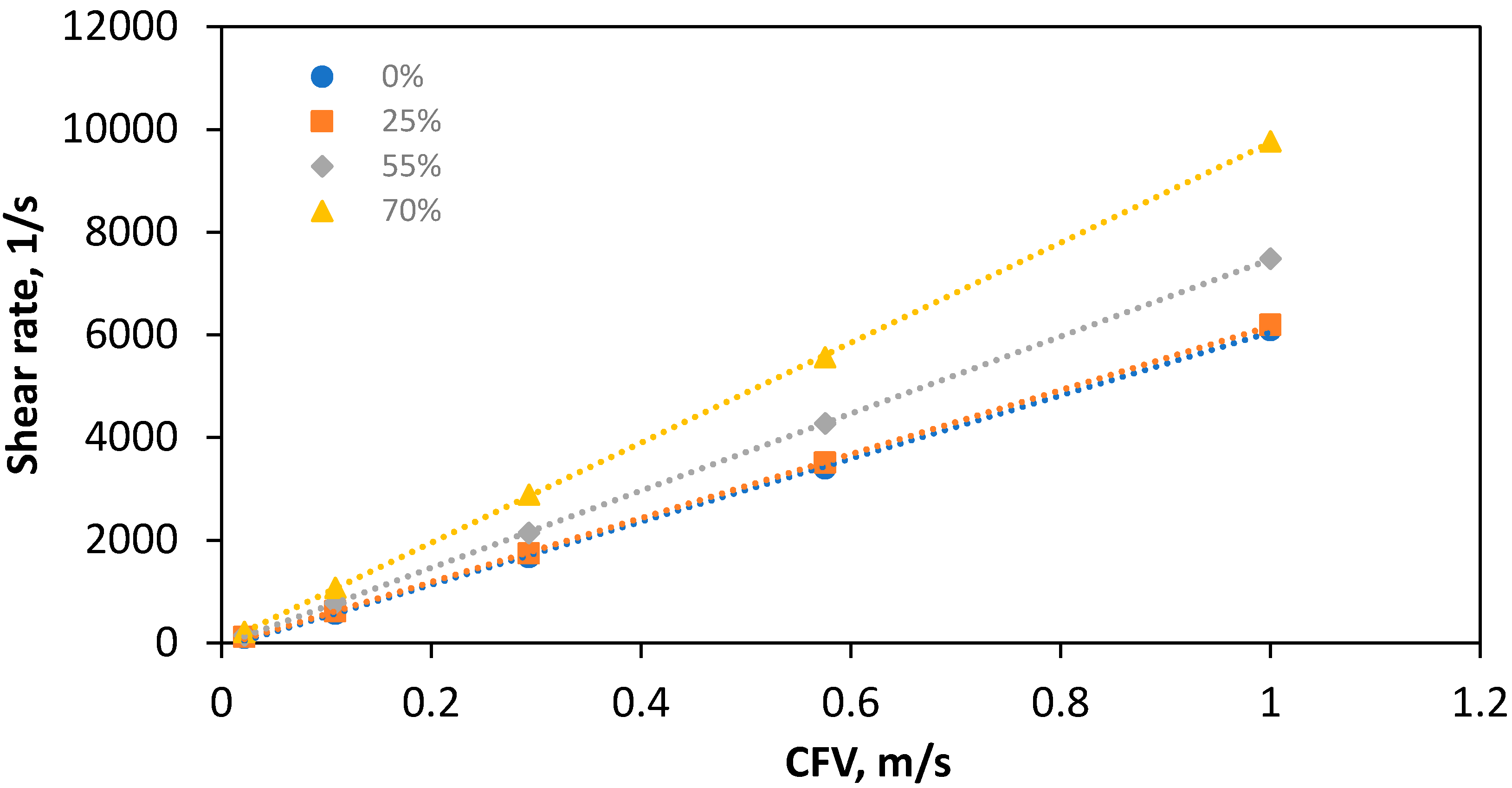

3.4. Assessment of Channel Occlusion on Shear Rate

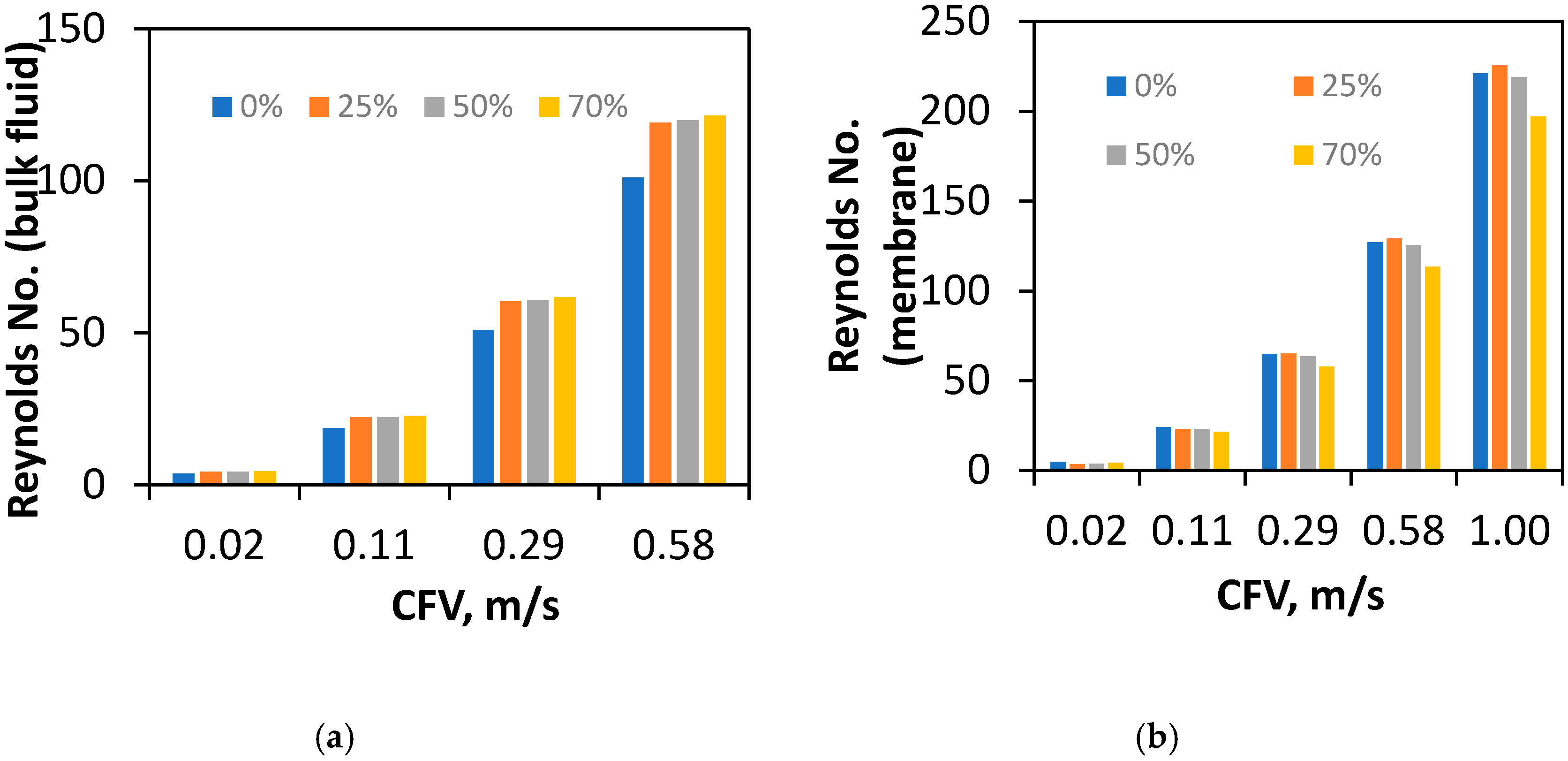

3.5. Reynolds Number

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Akther, N.; Sodiq, A.; Giwa, A.; Daer, S.; Arafat, H.A.; Hasan, S.W. Recent advancements in forward osmosis desalination: A review. Chem. Eng. J. 2015, 281, 502–522. [Google Scholar] [CrossRef]

- Boo, C.; Elimelech, M.; Hong, S. Fouling control in a forward osmosis process integrating seawater desalination and wastewater reclamation. J. Membr. Sci. 2013, 444, 148–156. [Google Scholar] [CrossRef]

- Cheng, Z.L.; Li, X.; Chung, T.-S. The forward osmosis-pressure retarded osmosis (FO-PRO) hybrid system: A new process to mitigate membrane fouling for sustainable osmotic power generation. J. Membr. Sci. 2018, 559, 63–74. [Google Scholar] [CrossRef]

- Law, J.Y.; Mohammad, A. Employing forward osmosis technology through hybrid system configurations for the production of potable/pure water: A review. J. Teknol. 2017, 79, 125–135. [Google Scholar] [CrossRef][Green Version]

- Chekli, L.; Phuntsho, S.; Kim, J.E.; Kim, J.; Choi, J.Y.; Choi, J.-S.; Kim, S.; Kim, J.H.; Hong, S.; Sohn, J.; et al. A comprehensive review of hybrid forward osmosis systems: Performance, applications and future prospects. J. Membr. Sci. 2016, 497, 430–449. [Google Scholar] [CrossRef]

- Lutchmiah, K.; Verliefde, A.R.D.; Roest, K.; Rietveld, L.C.; Cornelissen, E.R. Forward osmosis for application in wastewater treatment: A review. Water Res. 2014, 58, 179–197. [Google Scholar] [CrossRef]

- Petrotos, K.B.; Lazarides, H.N. Osmotic concentration of liquid foods. J. Food Eng. 2001, 49, 201–206. [Google Scholar] [CrossRef]

- Goh, P.S.; Ismail, A.F.; Ng, B.C.; Abdullah, M.S. Recent Progresses of Forward Osmosis Membranes Formulation and Design for Wastewater Treatment. Water 2019, 11, 2043. [Google Scholar] [CrossRef]

- Suwaileh, W.; Pathak, N.; Shon, H.; Hilal, N. Forward osmosis membranes and processes: A comprehensive review of research trends and future outlook. Desalination 2020, 485, 114455. [Google Scholar] [CrossRef]

- Lian, B.; Blandin, G.; Leslie, G.; Le-Clech, P. Impact of module design in forward osmosis and pressure assisted osmosis: An experimental and numerical study. Desalination 2018, 426, 108–117. [Google Scholar] [CrossRef]

- Hancock, N.T.; Cath, T.Y. Solute Coupled Diffusion in Osmotically Driven Membrane Processes. Environ. Sci. Technol. 2009, 43, 6769–6775. [Google Scholar] [CrossRef] [PubMed]

- Touati, K. Pressure Retarded Osmosis: Renewable Energy Generation and Recovery; Academic Press: San Diego, CA, USA, 2017. [Google Scholar]

- Song, X.; Liu, Z.; Sun, D.D. Nano Gives the Answer: Breaking the Bottleneck of Internal Concentration Polarization with a Nanofiber Composite Forward Osmosis Membrane for a High Water Production Rate. Adv. Mater. 2011, 23, 3256–3260. [Google Scholar] [CrossRef] [PubMed]

- McCutcheon, J.R.; Elimelech, M. Influence of concentrative and dilutive internal concentration polarization on flux behavior in forward osmosis. J. Membr. Sci. 2006, 284, 237–247. [Google Scholar] [CrossRef]

- Suh, C.; Lee, S. Modeling reverse draw solute flux in forward osmosis with external concentration polarization in both sides of the draw and feed solution. J. Membr. Sci. 2013, 427, 365–374. [Google Scholar] [CrossRef]

- Gulied, M.; Al Nouss, A.; Khraisheh, M.; AlMomani, F. Modeling and simulation of fertilizer drawn forward osmosis process using Aspen Plus-MATLAB model. Sci. Total Environ. 2020, 700, 134461. [Google Scholar] [CrossRef]

- Hidayat, M.A.; Kook, S.; Kim, I.S. Draw channel contraction of an 8040 spiral-wound forward osmosis membrane element in pressure-assisted forward osmosis (PAFO). Desalin. Water Treat. 2018, 109, 17–27. [Google Scholar] [CrossRef]

- Kim, J.; Blandin, G.; Phuntsho, S.; Verliefde, A.; Le-Clech, P.; Shon, H. Practical considerations for operability of an 8″ spiral wound forward osmosis module: Hydrodynamics, fouling behaviour and cleaning strategy. Desalination 2017, 404, 249–258. [Google Scholar] [CrossRef]

- Blandin, G.; Verliefde, A.R.D.; Tang, C.Y.; Childress, A.E.; Le-Clech, P. Validation of assisted forward osmosis (AFO) process: Impact of hydraulic pressure. J. Membr. Sci. 2013, 447, 1–11. [Google Scholar] [CrossRef]

- Lee, C.; Jang, J.; Tin, N.T.; Kim, S.; Tang, C.Y.; Kim, I.S. Effect of spacer configuration on the characteristics of FO membranes: Alteration of permeation characteristics by membrane deformation and concentration polarization. Environ. Sci. Technol. 2020. [Google Scholar] [CrossRef]

- Johnson, J.; Busch, M. Engineering aspects of reverse osmosis module design. Desalin. Water Treat. 2010, 15, 236–248. [Google Scholar] [CrossRef]

- Kleffner, C.; Braun, G.; Antonyuk, S. Influence of Membrane Intrusion on Permeate-Sided Pressure Drop During High-Pressure Reverse Osmosis. Chem. Ing. Tech. 2019, 91, 443–454. [Google Scholar] [CrossRef]

- Blandin, G.; Verliefde, A.R.D.; Comas, J.; Rodriguez-Roda, I.; Le-Clech, P. Efficiently Combining Water Reuse and Desalination through Forward Osmosis-Reverse Osmosis (FO-RO) Hybrids: A Critical Review. Membranes 2016, 6, 37. [Google Scholar] [CrossRef] [PubMed]

- Blandin, G.; Verliefde, A.R.D.; Tang, C.Y.; Le-Clech, P. Opportunities to reach economic sustainability in forward osmosis–reverse osmosis hybrids for seawater desalination. Desalination 2015, 363, 26–36. [Google Scholar] [CrossRef]

- Zaspalis, V.T.; Burggraaf, A.J. Inorganic Membrane Reactors to Enhance the Productivity of Chemical Processes. In Inorganic Membranes Synthesis, Characteristics and Applications; Springer: Dordrecht, The Netherlands, 1991; pp. 177–207. [Google Scholar]

- Wang, Y.; Ou, R.; Ge, Q.; Wang, H.; Xu, T. Preparation of polyethersulfone/carbon nanotube substrate for high-performance forward osmosis membrane. Desalination 2013, 330, 70–78. [Google Scholar] [CrossRef]

- Maarten Biesheuvel, P.; Verweij, H. Design of ceramic membrane supports: Permeability, tensile strength and stress. J. Membr. Sci. 1999, 156, 141–152. [Google Scholar] [CrossRef]

- Blandin, G.; Vervoort, H.; D’Haese, A.; Schoutteten, K.; Bussche, J.V.; Vanhaecke, L.; Myat, D.T.; Le-Clech, P.; Verliefde, A.R.D. Impact of hydraulic pressure on membrane deformation and trace organic contaminants rejection in pressure assisted osmosis (PAO). Process Saf. Environ. Prot. 2016, 102, 316–327. [Google Scholar] [CrossRef]

- Zhang, X.; Tian, J.; Ren, Z.; Shi, W.; Zhang, Z.; Xu, Y.; Gao, S.; Cui, F. High performance thin-film composite (TFC) forward osmosis (FO) membrane fabricated on novel hydrophilic disulfonated poly(arylene ether sulfone) multiblock copolymer/polysulfone substrate. J. Membr. Sci. 2016, 520, 529–539. [Google Scholar] [CrossRef]

- Lee, C.; Kook, S.; Choi, C.; Nguyen, T.; Kim, I. Effects of Membrane Envelope Geometry on Hydrodynamics Inside Draw Channel of Forward Osmosis Spiral Wound Membrane Element. Desalin. Water Treat. 2018, 112, 282–291. [Google Scholar] [CrossRef]

- Majeed, T.; Phuntsho, S.; Sahebi, S.; Kim, J.; Yoon, J.; Kim, K.; Shon, H. Influence of the process parameters on hollow fiber-forward osmosis membrane performances. Desalin. Water Treat. 2015, 54, 817–828. [Google Scholar] [CrossRef]

- Puguan, J.M.C.; Kim, H.-S.; Lee, K.-J.; Kim, H. Low internal concentration polarization in forward osmosis membranes with hydrophilic crosslinked PVA nanofibers as porous support layer. Desalination 2014, 336, 24–31. [Google Scholar] [CrossRef]

- Ren, J.; O’Grady, B.; deJesus, G.; McCutcheon, J.R. Sulfonated polysulfone supported high performance thin film composite membranes for forward osmosis. Polymer 2016, 103, 486–497. [Google Scholar] [CrossRef]

- Sabir, A.; Islam, A.; Shafiq, M.; Shafeeq, A.; Butt, M.T.Z.; Ahmad, N.M.; Sanaullah, K.; Jamil, T. Novel polymer matrix composite membrane doped with fumed silica particles for reverse osmosis desalination. Desalination 2015, 368, 159–170. [Google Scholar] [CrossRef]

- Park, S.-H.; Kwon, S.J.; Shin, M.G.; Park, M.S.; Lee, J.S.; Park, C.H.; Park, H.; Lee, J.-H. Polyethylene-supported high performance reverse osmosis membranes with enhanced mechanical and chemical durability. Desalination 2018, 436, 28–38. [Google Scholar] [CrossRef]

- Böhm, L.; Drews, A.; Prieske, H.; Bérubé, P.R.; Kraume, M. The importance of fluid dynamics for MBR fouling mitigation. Bioresour. Technol. 2012, 122, 50–61. [Google Scholar] [CrossRef]

- Bian, R.; Yamamoto, K.; Watanabe, Y. The effect of shear rate on controlling the concentration polarization and membrane fouling. Desalination 2000, 131, 225–236. [Google Scholar] [CrossRef]

- Yang, M.; Yu, D.; Liu, M.; Zheng, L.; Zheng, X.; Wei, Y.; Wang, F.; Fan, Y. Optimization of MBR hydrodynamics for cake layer fouling control through CFD simulation and RSM design. Bioresour. Technol. 2017, 227, 102–111. [Google Scholar] [CrossRef]

- Springer, F.; Ghidossi, R.; Carretier, E.; Veyret, D.; Dhaler, D.; Moulin, P. Study of the Effect of Geometry on Wall Shear Stress and Permeate Flux for Ceramic Membranes: CFD and Experimental Approaches. Eng. Appl. Comput. Fluid Mech. 2010, 4, 17–28. [Google Scholar] [CrossRef]

- Alshwairekh, A.M.; Alghafis, A.A.; Alwatban, A.M.; Alqsair, U.F.; Oztekin, A. The effects of membrane and channel corrugations in forward osmosis membrane modules—Numerical analyses. Desalination 2019, 460, 41–55. [Google Scholar] [CrossRef]

- Carter, J.W.; Hoyland, G.; Hasting, A.P.M. Concentration polarisation in reverse osmosis flow systems under laminar conditions. Effect of surface roughness and fouling. Chem. Eng. Sci. 1974, 29, 1651–1658. [Google Scholar] [CrossRef]

- Schwinge, J.; Wiley, D.E.; Fletcher, D.F. A CFD study of unsteady flow in narrow spacer-filled channels for spiral-wound membrane modules. Desalination 2002, 146, 195–201. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Charlton, A.J.; Lian, B.; Blandin, G.; Leslie, G.; Le-Clech, P. Impact of FO Operating Pressure and Membrane Tensile Strength on Draw-Channel Geometry and Resulting Hydrodynamics. Membranes 2020, 10, 111. https://doi.org/10.3390/membranes10050111

Charlton AJ, Lian B, Blandin G, Leslie G, Le-Clech P. Impact of FO Operating Pressure and Membrane Tensile Strength on Draw-Channel Geometry and Resulting Hydrodynamics. Membranes. 2020; 10(5):111. https://doi.org/10.3390/membranes10050111

Chicago/Turabian StyleCharlton, Alexander J., Boyue Lian, Gaetan Blandin, Greg Leslie, and Pierre Le-Clech. 2020. "Impact of FO Operating Pressure and Membrane Tensile Strength on Draw-Channel Geometry and Resulting Hydrodynamics" Membranes 10, no. 5: 111. https://doi.org/10.3390/membranes10050111

APA StyleCharlton, A. J., Lian, B., Blandin, G., Leslie, G., & Le-Clech, P. (2020). Impact of FO Operating Pressure and Membrane Tensile Strength on Draw-Channel Geometry and Resulting Hydrodynamics. Membranes, 10(5), 111. https://doi.org/10.3390/membranes10050111