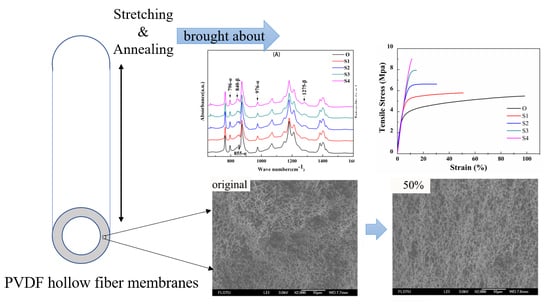

Effects of Room Temperature Stretching and Annealing on the Crystallization Behavior and Performance of Polyvinylidene Fluoride Hollow Fiber Membranes

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of the Membrane Samples

2.2. Characterization of Membrane Samples

3. Results and Discussion

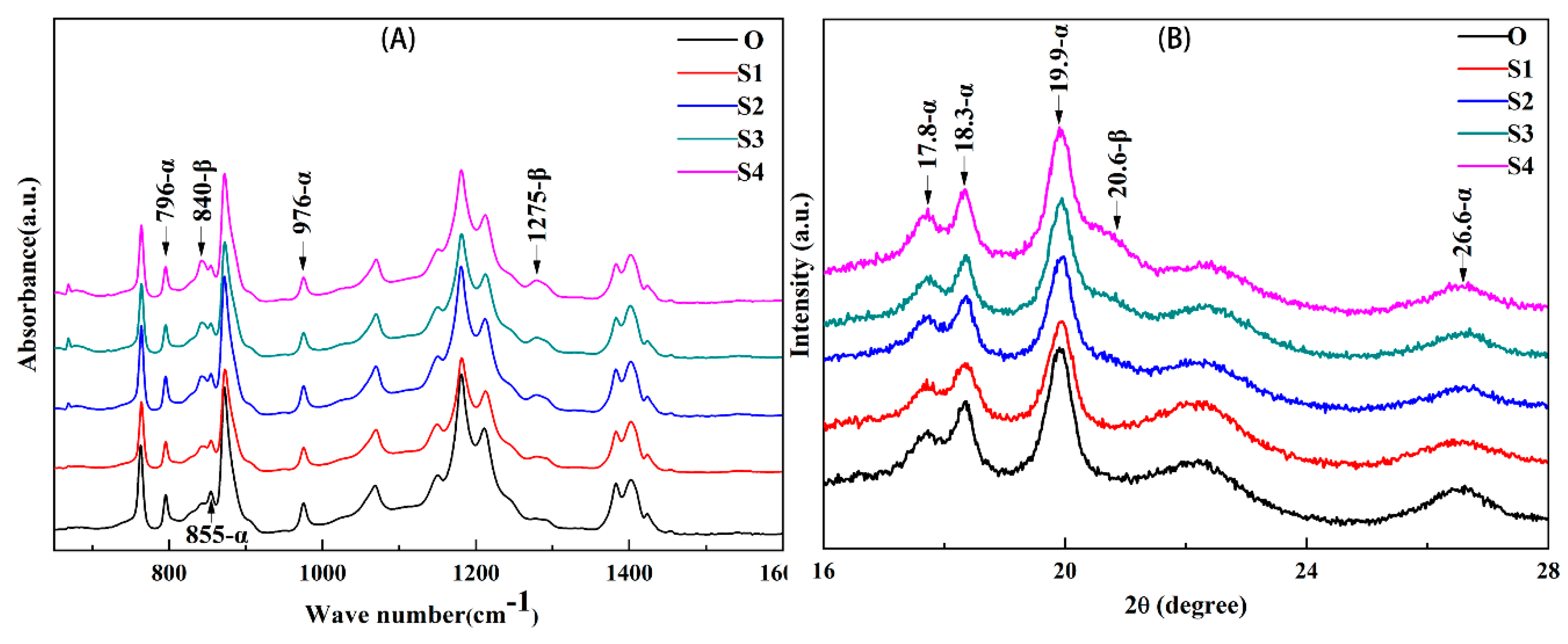

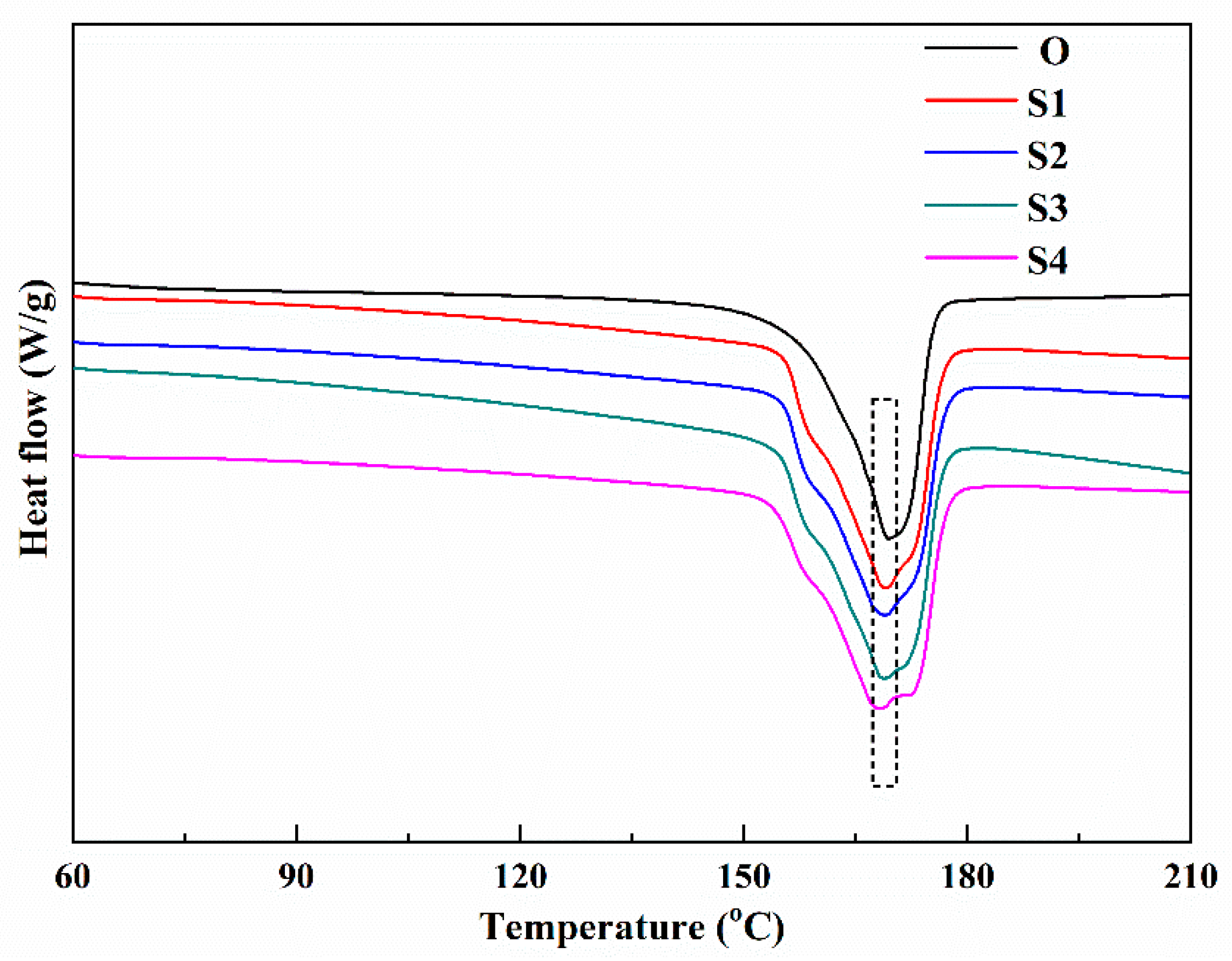

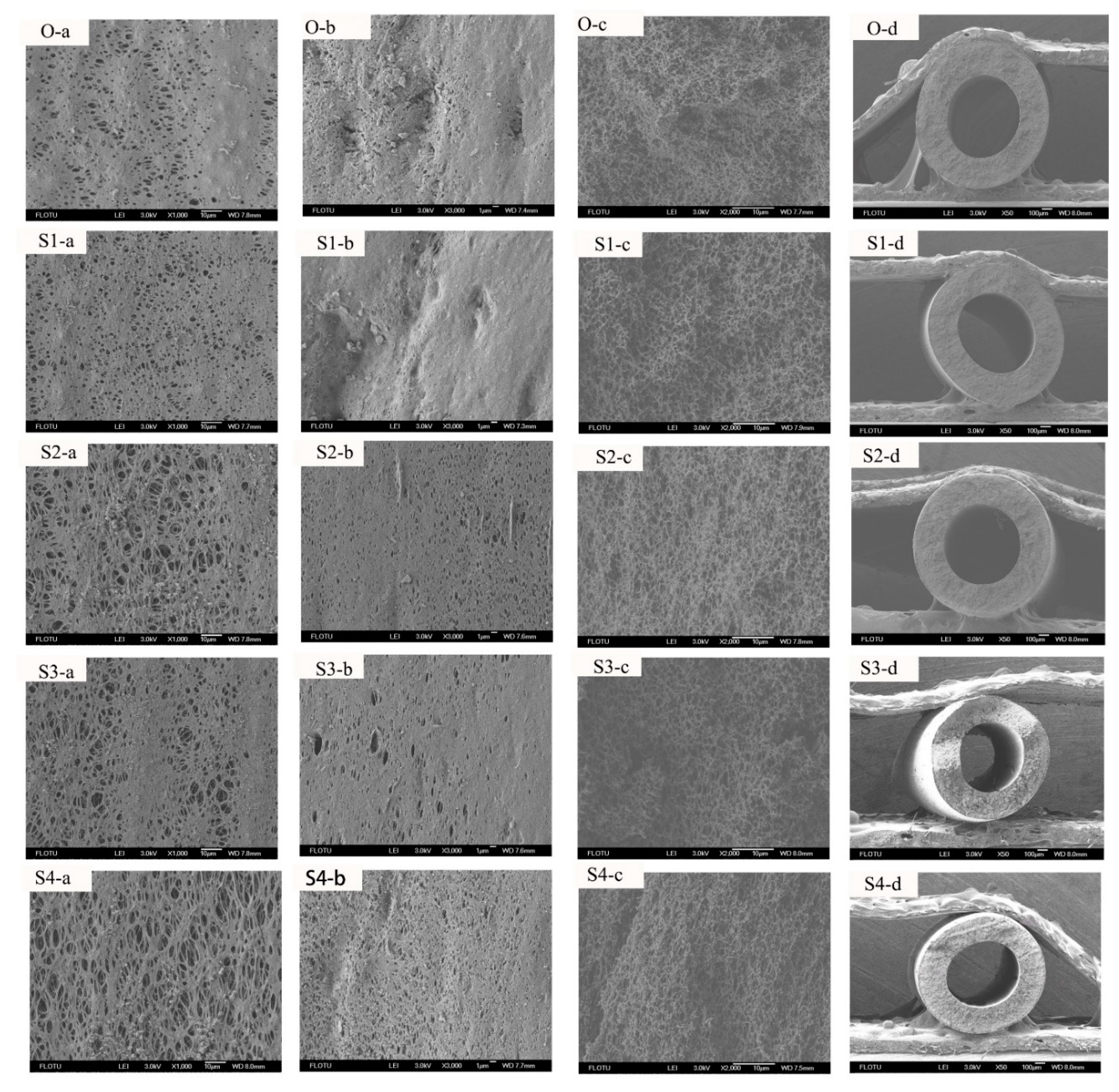

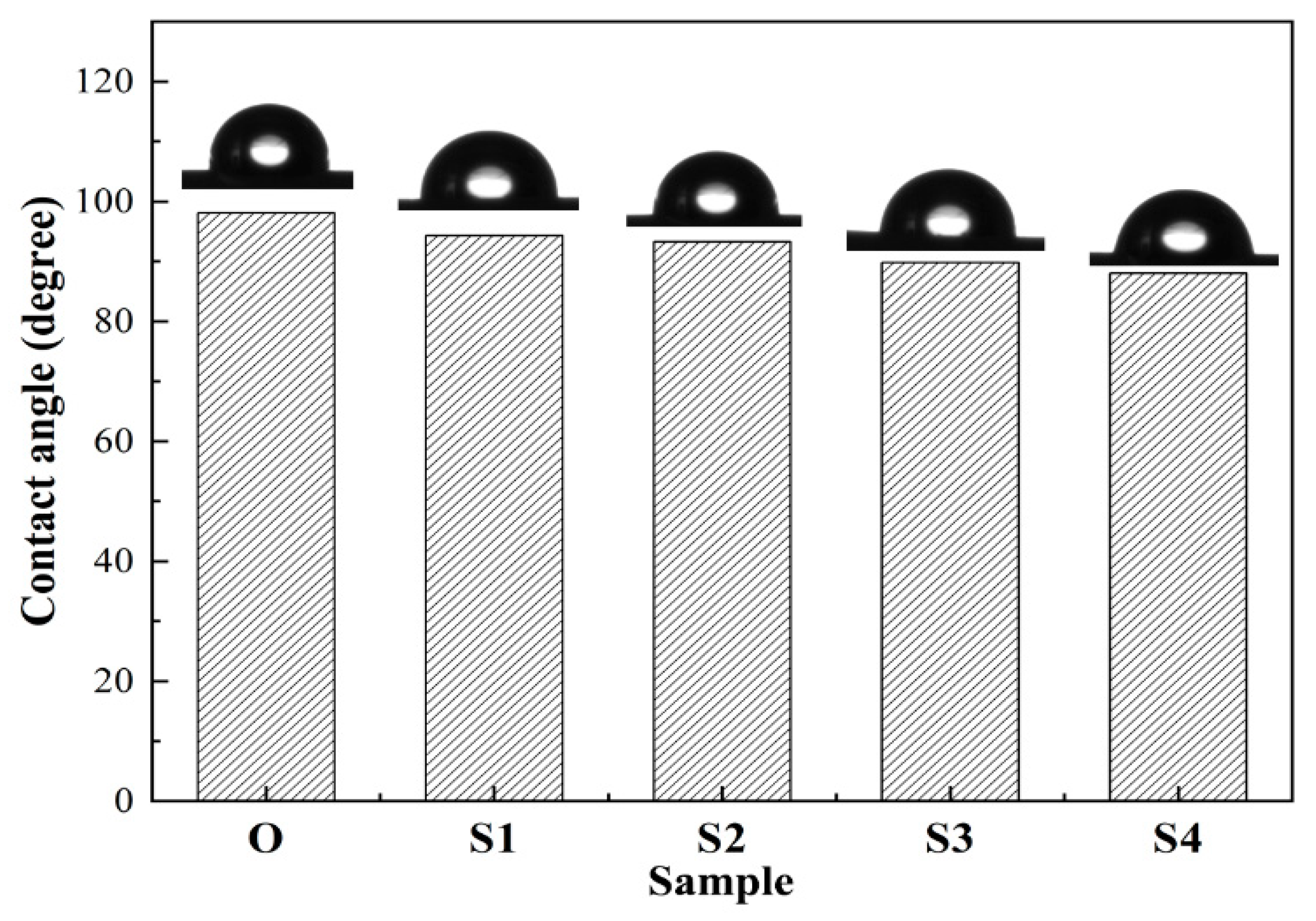

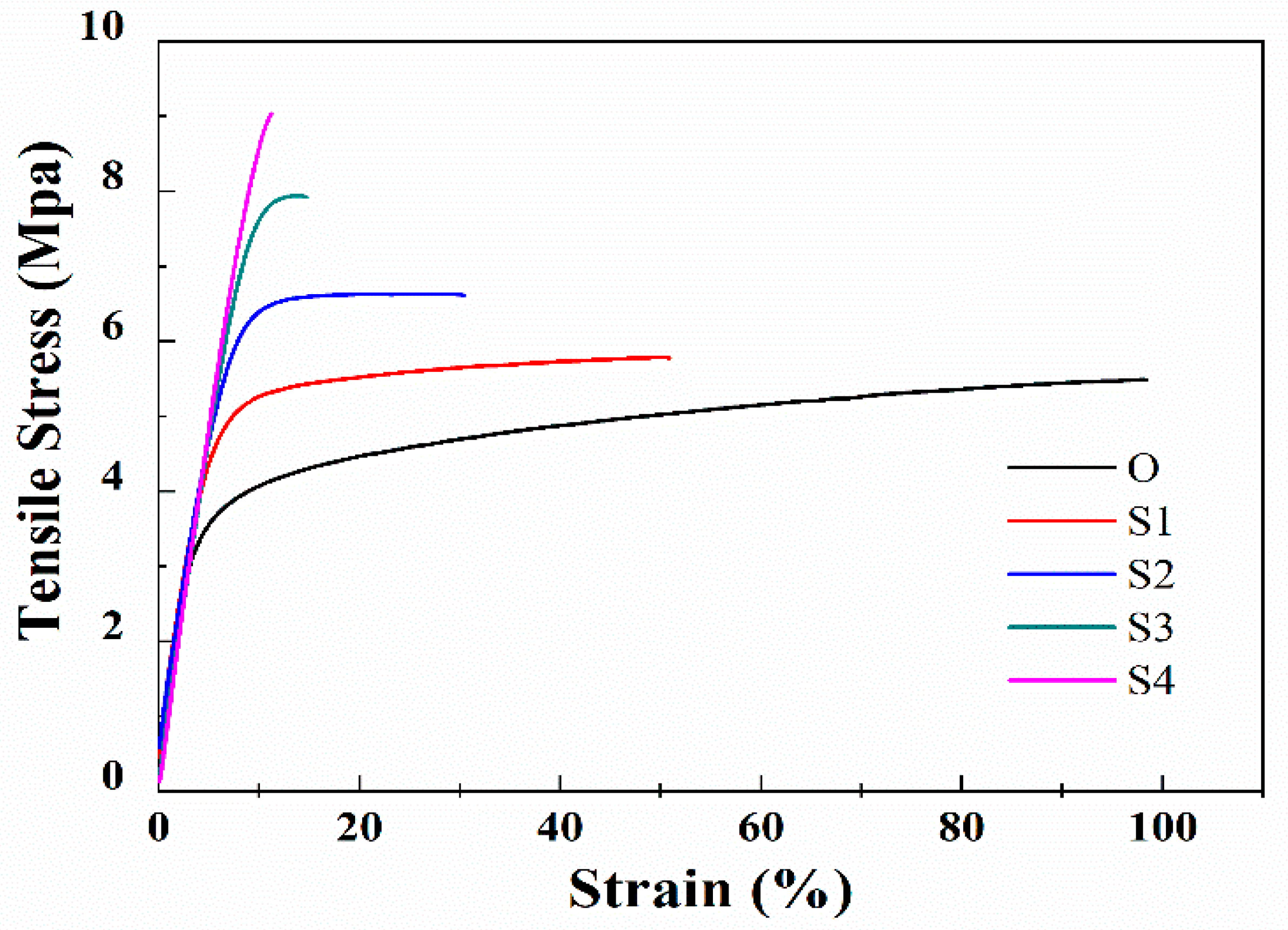

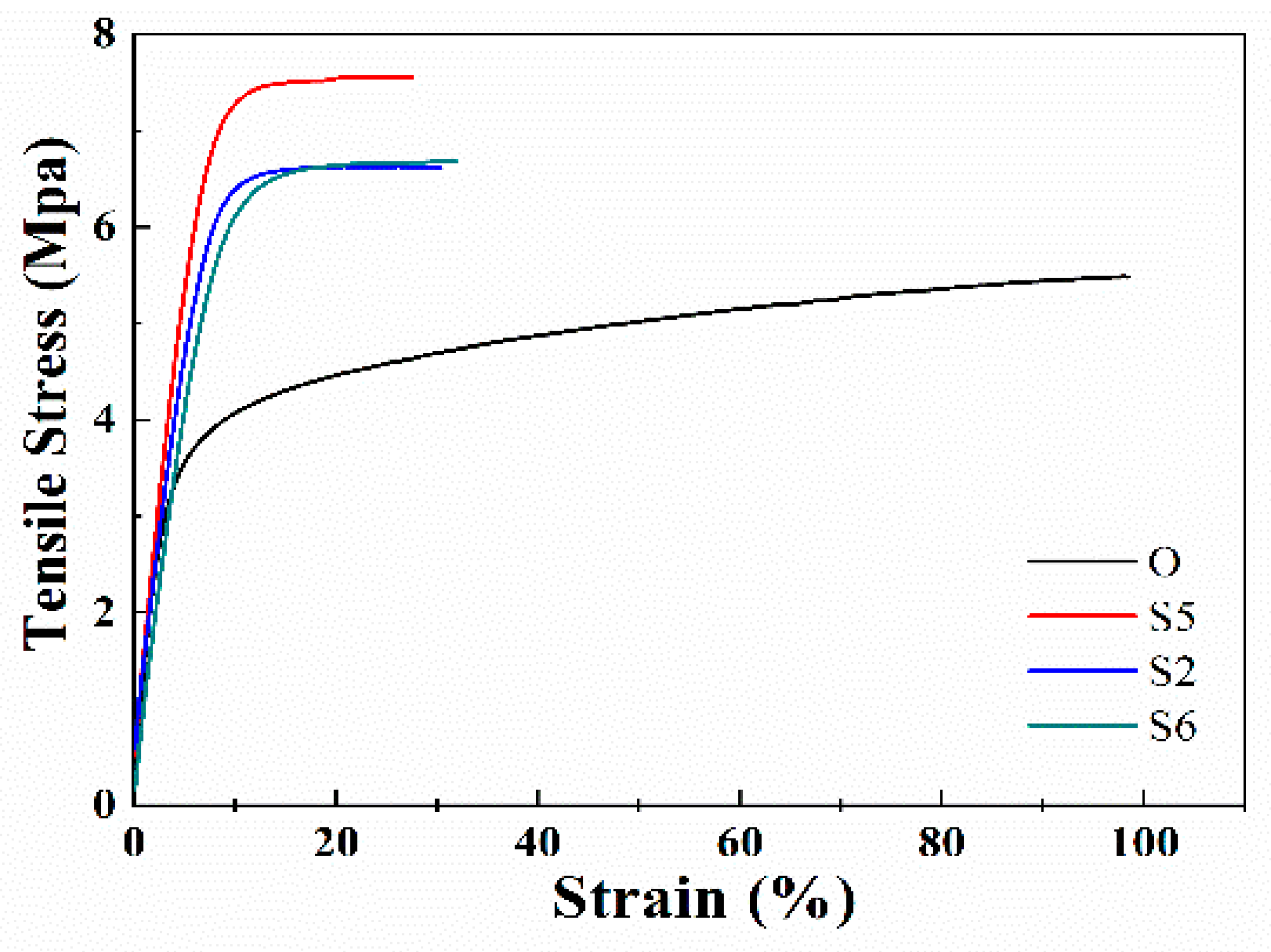

3.1. Effect of the Stretching Ratio

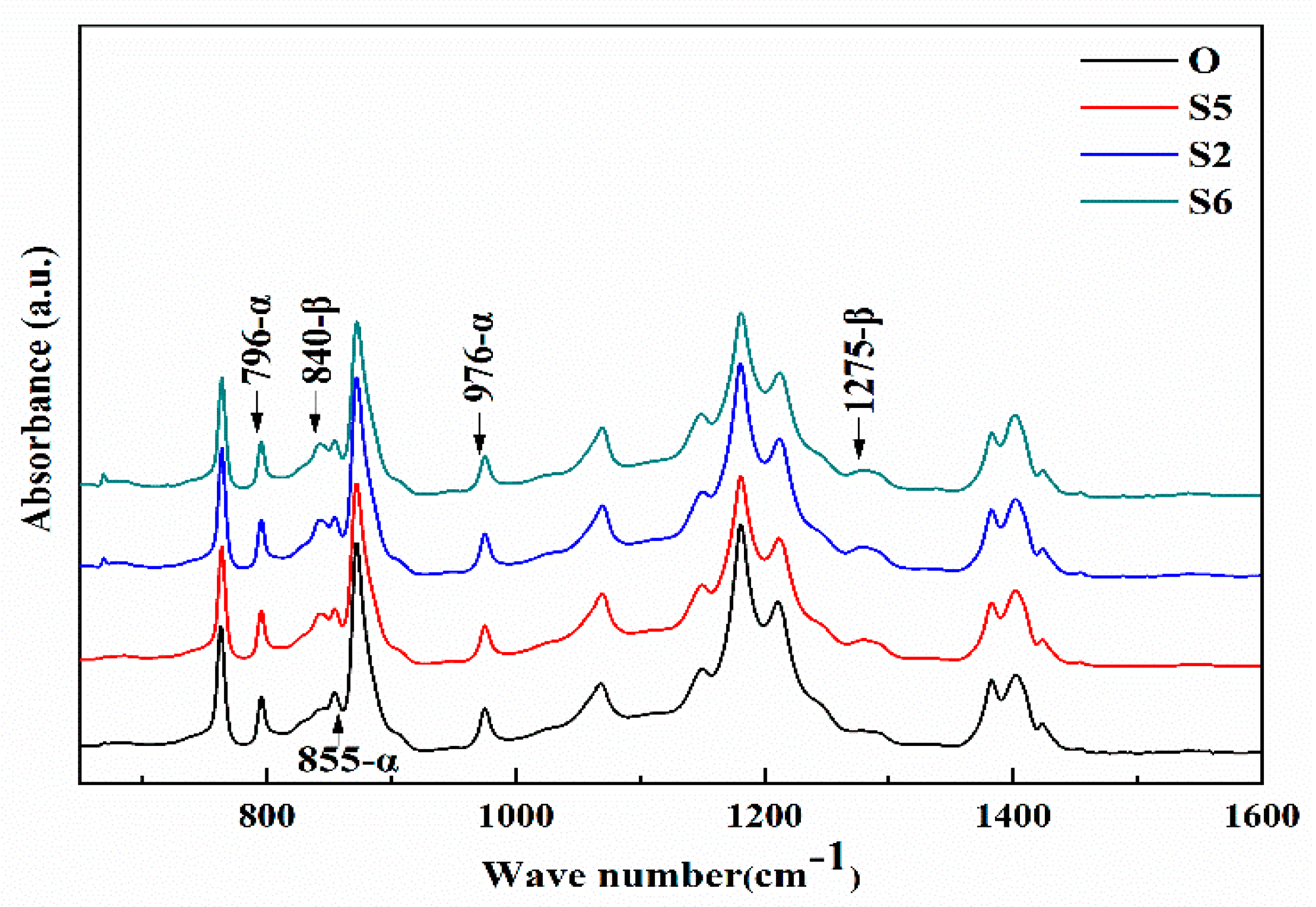

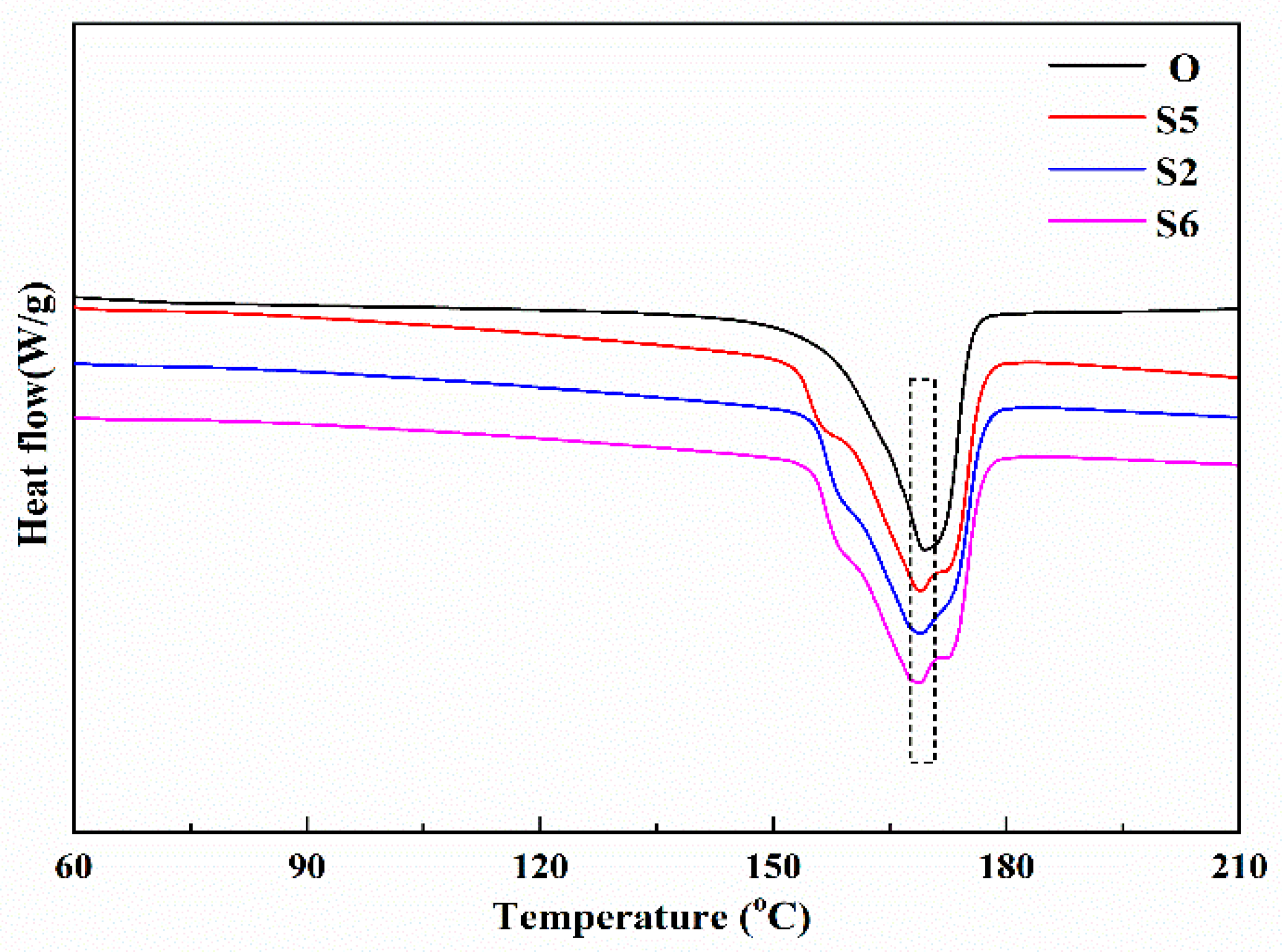

3.2. Effect of the Stretching Rate

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kim, J.F.; Kim, J.H.; Lee, Y.M.; Drioli, E. Thermally induced phase separation and electrospinning methods for emerging membrane applications: A review. AICHE J. 2016, 62, 461–490. [Google Scholar] [CrossRef]

- Liu, F.; Hashim, N.A.; Liu, Y.; Abed, M.R.M.; Li, K. Progress in the production and modification of PVDF membranes. J. Membr. Sci. 2011, 375, 1–27. [Google Scholar] [CrossRef]

- Hube, S.; Eskafi, M.; Hrafnkelsdottir, K.F.; Bjarnadottir, B.; Bjarnadottir, M.A.; Axelsdottir, S.; Wu, B. Direct membrane filtration for wastewater treatment and resource recovery: A review. Sci. Total Environ. 2019, 710, 136375. [Google Scholar] [CrossRef]

- Ruan, L.; Yao, X.; Chang, Y.; Zhou, L.; Qin, G.; Zhang, X. Properties and Applications of the β Phase Poly (vinylidene fluoride). Polymers 2018, 10, 228. [Google Scholar] [CrossRef]

- Gregorio, R. Determination of the alpha, beta, and gamma crystalline phases of poly(vinylidene fluoride) films prepared at different conditions. J. Appl. Polym. Sci. 2006, 100, 3272–3279. [Google Scholar] [CrossRef]

- Mun, J.; Park, H.M.; Koh, E.; Lee, Y.T. Enhancement of the crystallinity and surface hydrophilicity of a PVDF hollow fiber membrane on simultaneous stretching and coating method. Composites Part B: Eng. 2018, 65, 112–119. [Google Scholar] [CrossRef]

- Ma, W.; Wang, X.; Zhang, J. Crystallization kinetics of poly(vinylidene fluoride)/MMT, SiO2, CaCO3, or PTFE nanocomposite by differential scanning calorimeter. J. Therm. Anal. Calorim. 2011, 103, 319–327. [Google Scholar] [CrossRef]

- Liu, J.; Lu, X.; Wu, C. Effect of annealing conditions on crystallization behavior and mechanical properties of NIPS poly(vinylidene fluoride) hollow fiber membranes. J. Appl. Polym. Sci. 2013, 129, 1417–1425. [Google Scholar] [CrossRef]

- Ma, W.; Zhang, J.; Van der Bruggen, B.; Wang, X. Formation of an Interconnected Lamellar Structure in PVDF Membranes with Nanoparticles Addition via Solid-Liquid Thermally Induced Phase Separation. J. Appl. Polym. Sci. 2013, 127, 2715–2723. [Google Scholar] [CrossRef]

- Wang, H.; Chen, Q.; Xia, W.; Qiu, X.; Cheng, Q.; Zhu, G. Electroactive PVDF thin films fabricated via cooperative stretching process. J. Appl. Polym. Sci. 2018, 135, 46324. [Google Scholar] [CrossRef]

- Lei, C.; Hu, B.; Xu, R.; Cai, Q.; Shi, W. Influence of Room-Temperature-Stretching Technology on the Crystalline Morphology and Microstructure of PVDF Hard Elastic Film. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Hu, B.; Cai, Q.; Xu, R.; Mo, H.; Chen, C.; Zhang, F.; Lei, C. Influence of uniaxial cold stretching followed by uniaxial hot stretching conditions on crystal transformation and microstructure in extrusion cast and annealed polyvinylidene fluoride porous membranes. J. Plast. Film Sheeting 2015, 31, 269–285. [Google Scholar] [CrossRef]

- Bae, J.-H.; Chang, S.-H. A new approach to fabricate poly (vinylidene fluoride-trifluoroethylene) fibers using a torsion-stretching method and characterization of their piezoelectric properties. Composites Part B: Eng. 2016, 99, 112–120. [Google Scholar] [CrossRef]

- Tang, Y.H.; Lin, Y.K.; Zhou, B.; Wang, X.L. PVDF membranes prepared via thermally induced (liquid-liquid) phase separation and their application in municipal sewage and industry wastewater for water recycling. Desalin. Water Treat. 2016, 57, 22258–22276. [Google Scholar] [CrossRef]

- Lin, Y.; Tang, Y.; Ma, H.; Yang, J.; Tian, Y.; Ma, W.; Wang, X. Formation of a Bicontinuous Structure Membrane of Polyvinylidene Fluoride in Diphenyl Carbonate Diluent Via Thermally Induced Phase Separation. J. Appl. Polym. Sci. 2009, 114, 1523–1528. [Google Scholar] [CrossRef]

- Tang, Y.; Lin, Y.; Ma, W.; Tian, Y.; Yang, J.; Wang, X. Preparation of Microporous PVDF Membrane via Tips Method Using Binary Diluent of DPK and PG. J. Appl. Polym. Sci. 2010, 118, 3518–3523. [Google Scholar] [CrossRef]

- Jin, Y.T.; Hu, D.; Lin, Y.K.; Shi, L. Hydrophilic modification of polyvinylidene fluoride membrane by blending amphiphilic copolymer via thermally induced phase separation. Polym. Adv. Technol. 2019, 30, 110–119. [Google Scholar] [CrossRef]

- Morehouse, J.A.; Taylor, D.L.; Lloyd, D.R.; Lawler, D.F.; Freeman, B.D.; Worrel, L.S. The effect of uni-axial stretching on the roughness of microfiltration membranes. J. Membr. Sci. 2006, 280, 712–719. [Google Scholar] [CrossRef]

- Morehouse, J.A.; Worrel, L.S.; Taylor, D.L.; Lloyd, D.R.; Freeman, B.D.; Lawler, D.F. The effect of uni-axial orientation on macroporous membrane structure. J. Porous Mater. 2006, 13, 61–72. [Google Scholar] [CrossRef]

- Kim, T.H.; Jee, K.Y.; Lee, Y.T. The improvement of water flux and mechanical strength of PVDF hollow fiber membranes by stretching and annealing conditions. Macromol. Res. 2015, 23, 592–600. [Google Scholar] [CrossRef]

- Kim, J.F.; Jung, J.T.; Wang, H.H.; Lee, S.Y.; Moore, T.; Sanguineti, A.; Drioli, E.; Lee, Y.M. Microporous PVDF membranes via thermally induced phase separation (TIPS) and stretching methods. J. Membr. Sci. 2016, 509, 94–104. [Google Scholar] [CrossRef]

- Liu, T.Y.; Zhang, R.X.; Li, Q.; Van der Bruggen, B.; Wang, X.L. Fabrication of a novel dual-layer (PES/PVDF) hollow fiber ultrafiltration membrane for wastewater treatment. J. Membr. Sci. 2014, 472, 119–132. [Google Scholar] [CrossRef]

- Nakagawa, K.; Ishida, Y. Annealing effects in poly (vinylidene fluoride) as revealed by specific volume measurements, differential scanning calorimetry, and electron microscopy. J. Polym. Sci. Polym. Phys. 1973, 11, 2153–2171. [Google Scholar] [CrossRef]

- Lei, L.; Lindbråthen, A.; Hillestad, M.; Sandru, M.; Favvas, E.P.; He, X.J.I.; Research, E.C. Screening Cellulose Spinning Parameters for Fabrication of Novel Carbon Hollow Fiber Membranes for Gas Separation. Ind. Eng. Chem. Res. 2019, 58, 13330–13339. [Google Scholar] [CrossRef]

- Vijayakumar, R.P.; Khakhar, D.V.; Misra, A. Studies on alpha to beta Phase Transformations in Mechanically Deformed PVDF Films. J. Appl. Polym. Sci. 2010, 117, 3491–3497. [Google Scholar] [CrossRef]

- Al-Raheil, I.A.; Qudah, A.M. Thermal behaviour and annealing of poly (vinylidene fluoride). Polymer Int. 1996, 41, 323–326. [Google Scholar] [CrossRef]

- Ma, W.; Zhou, B.; Liu, T.; Zhang, J.; Wang, X. The supramolecular organization of PVDF lamellae formed in diphenyl ketone dilutions via thermally induced phase separation. Colloid. Polym. Sci. 2013, 291, 981–992. [Google Scholar] [CrossRef]

- Ma, W.; Wang, X.; Zhang, J. Effect of MMT, SiO2, CaCO3, and PTFE Nanoparticles on the Morphology and Crystallization of Poly(vinylidene fluoride). J. Polym. Sci., Part B: Polym. Phys. 2010, 48, 2154–2164. [Google Scholar] [CrossRef]

| Sample | Stretching Ratio + Stretching Rate | Melting Peak Point/°C | Total Crystallinity /% |

|---|---|---|---|

| O | Original membrane | 169.3 | 43.6 |

| S1 | 20% + 40 mm/min | 168.9 | 50.8 |

| S2 | 50% + 40 mm/min | 168.8 | 51.7 |

| S3 | 80% + 40 mm/min | 168.8 | 52.1 |

| S4 | 100% + 40 mm/min | 168.0 | 53.6 |

| S5 | 50% + 20 mm/min | 168.8 | 51.2 |

| S6 | 50% + 80 mm/min | 168.7 | 52.5 |

| Sample | Mean Pore Size/nm | Tensile Strength/MPa | Pure Water Flux/L·m−2·h−1·(0.1bar)−1 |

|---|---|---|---|

| O | 235.4 | 5.48 | 457.01 |

| S1 | 249.6 | 5.73 | 594.51 |

| S2 | 289.2 | 6.56 | 776.28 |

| S3 | 326.7 | 7.83 | 997.60 |

| S4 | 373.4 | 9.01 | 1000.22 |

| S5 | 268.7 | 7.47 | 796.13 |

| S6 | 283.4 | 6.32 | 771.54 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, Y.; Lin, Y.; Lin, H.; Li, C.; Zhou, B.; Wang, X. Effects of Room Temperature Stretching and Annealing on the Crystallization Behavior and Performance of Polyvinylidene Fluoride Hollow Fiber Membranes. Membranes 2020, 10, 38. https://doi.org/10.3390/membranes10030038

Tang Y, Lin Y, Lin H, Li C, Zhou B, Wang X. Effects of Room Temperature Stretching and Annealing on the Crystallization Behavior and Performance of Polyvinylidene Fluoride Hollow Fiber Membranes. Membranes. 2020; 10(3):38. https://doi.org/10.3390/membranes10030038

Chicago/Turabian StyleTang, Yuanhui, Yakai Lin, Hanhan Lin, Chunyu Li, Bo Zhou, and Xiaolin Wang. 2020. "Effects of Room Temperature Stretching and Annealing on the Crystallization Behavior and Performance of Polyvinylidene Fluoride Hollow Fiber Membranes" Membranes 10, no. 3: 38. https://doi.org/10.3390/membranes10030038

APA StyleTang, Y., Lin, Y., Lin, H., Li, C., Zhou, B., & Wang, X. (2020). Effects of Room Temperature Stretching and Annealing on the Crystallization Behavior and Performance of Polyvinylidene Fluoride Hollow Fiber Membranes. Membranes, 10(3), 38. https://doi.org/10.3390/membranes10030038