Modeling of the Accidentality Phenomenon in the Construction Industry

Abstract

:1. Introduction

- A decreasing number of people that are injured in occupational accidents,

- Lower material losses related to, among others, the suspension of production, the necessity of replacing an injured employee with another employee, the repair or replacement of damaged equipment, and sometimes the rebuilding of an entire destroyed workstation,

- Lower social losses related to costs that are incurred by society, such as the costs of treatment or the costs of compensations paid by insurance companies [3].

2. Literature Review

3. Assumptions for the Creation of the Model

- 1.

- Occupational accidents in the construction industry occur in different places and at different times, and each accident follows a specific individual scenario.

- 2.

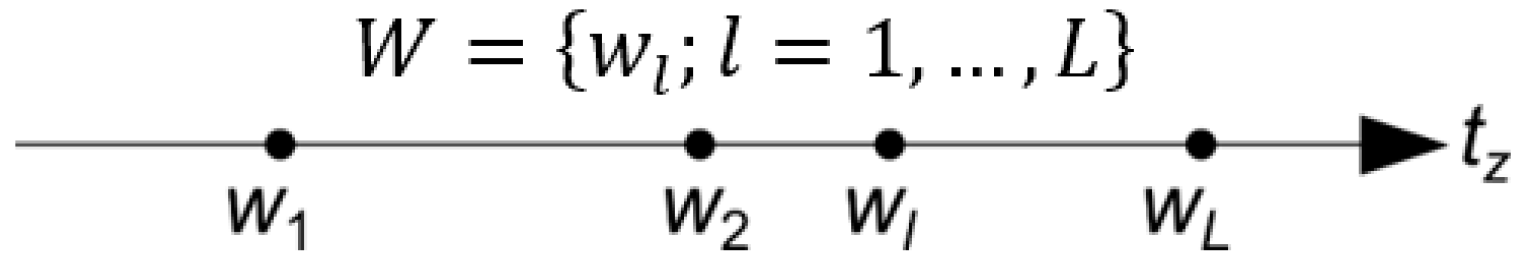

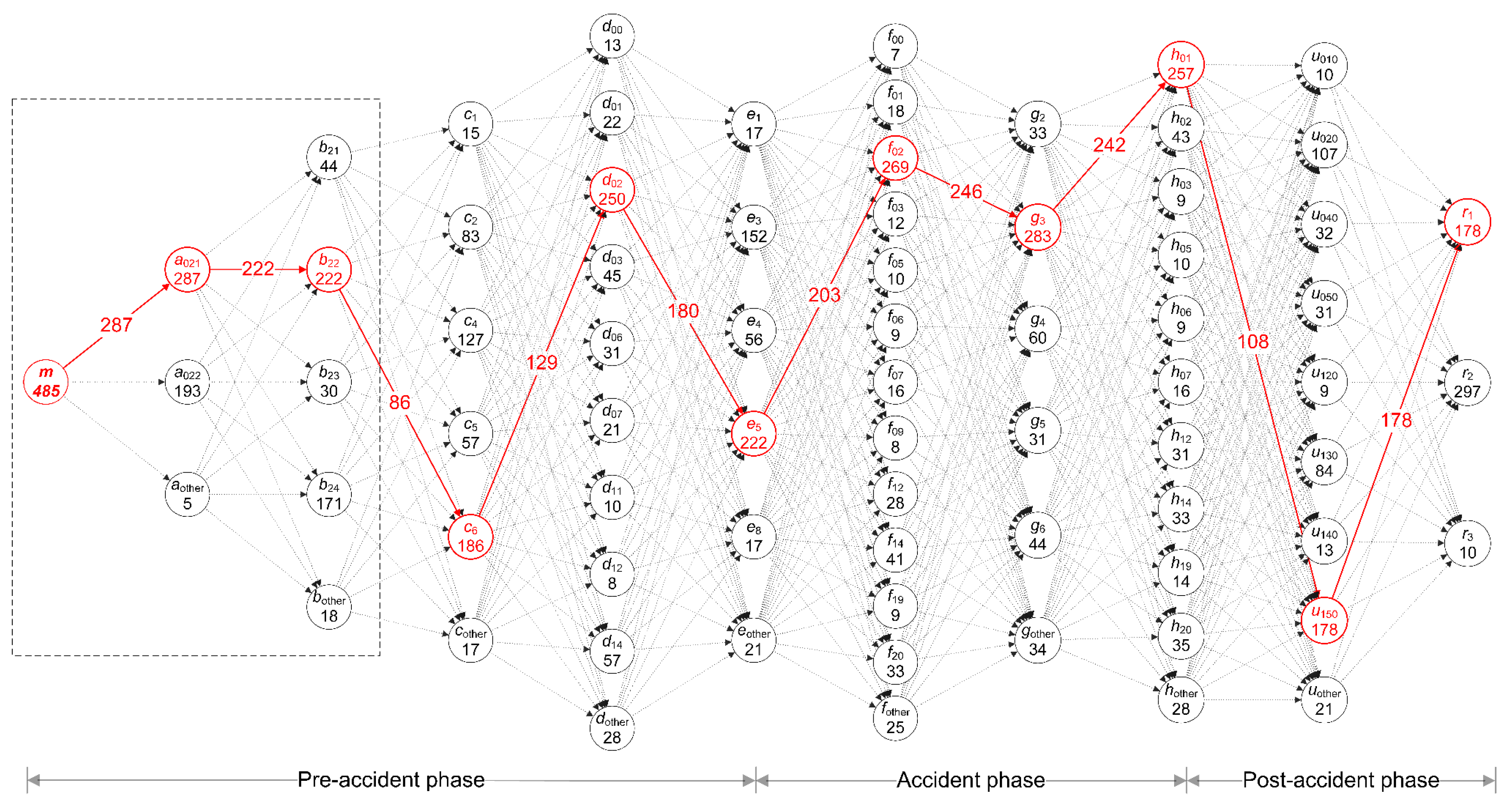

- Accidents ordered in accordance with the passage of time form an infinite sequence, which can be analyzed as the discrete resultant process presented in Figure 1, where:

- —a set of all identified accident scenarios,

- —a single accident event that follows a specific individual scenario. The following accident scenarios are identified by an index placed next to a small letter ,

- —a set of all occupational accidents, where: .

- 3.

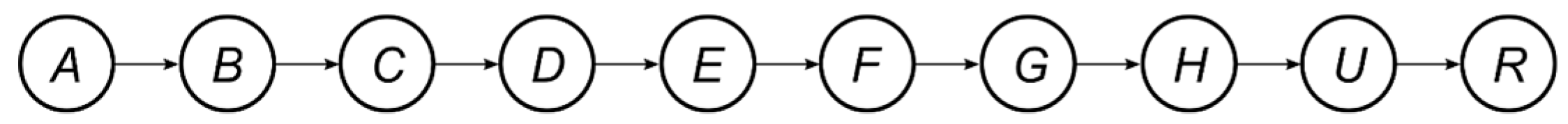

- Every occupational accident can be presented in the form of the sequence of successive events that illustrate the circumstances of an accident and its course, which is shown in Figure 2. In this sequence, the following event is a consequence of the occurrence of the preceding event.

- 4.

- Every single accident takes place through a specific intermediate event, from node to node , and is accompanied by specific circumstances that lead to the occurrence of the final event, which is a result of an accident with different degrees of severity, e.g., death, severe body injuries, light accident.

- 5.

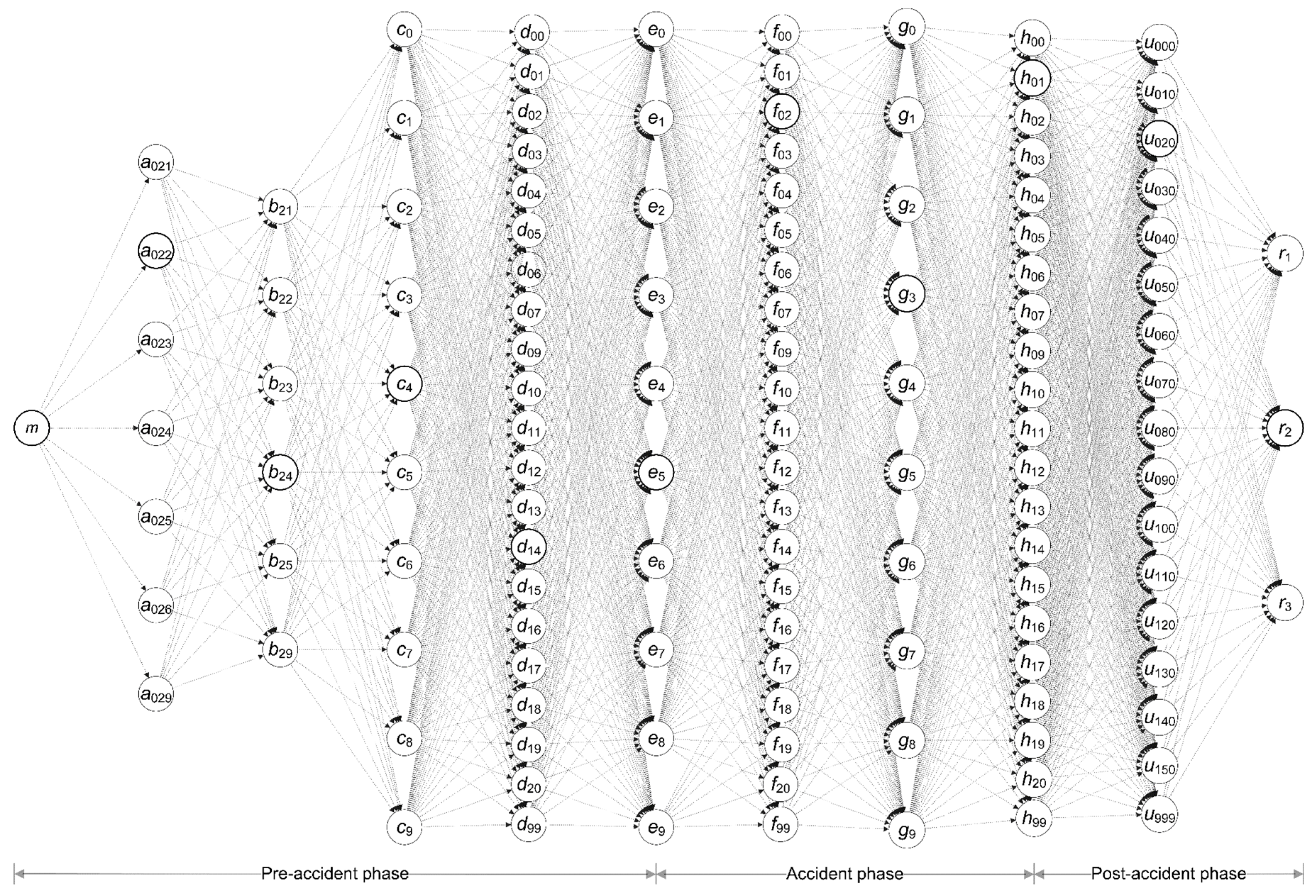

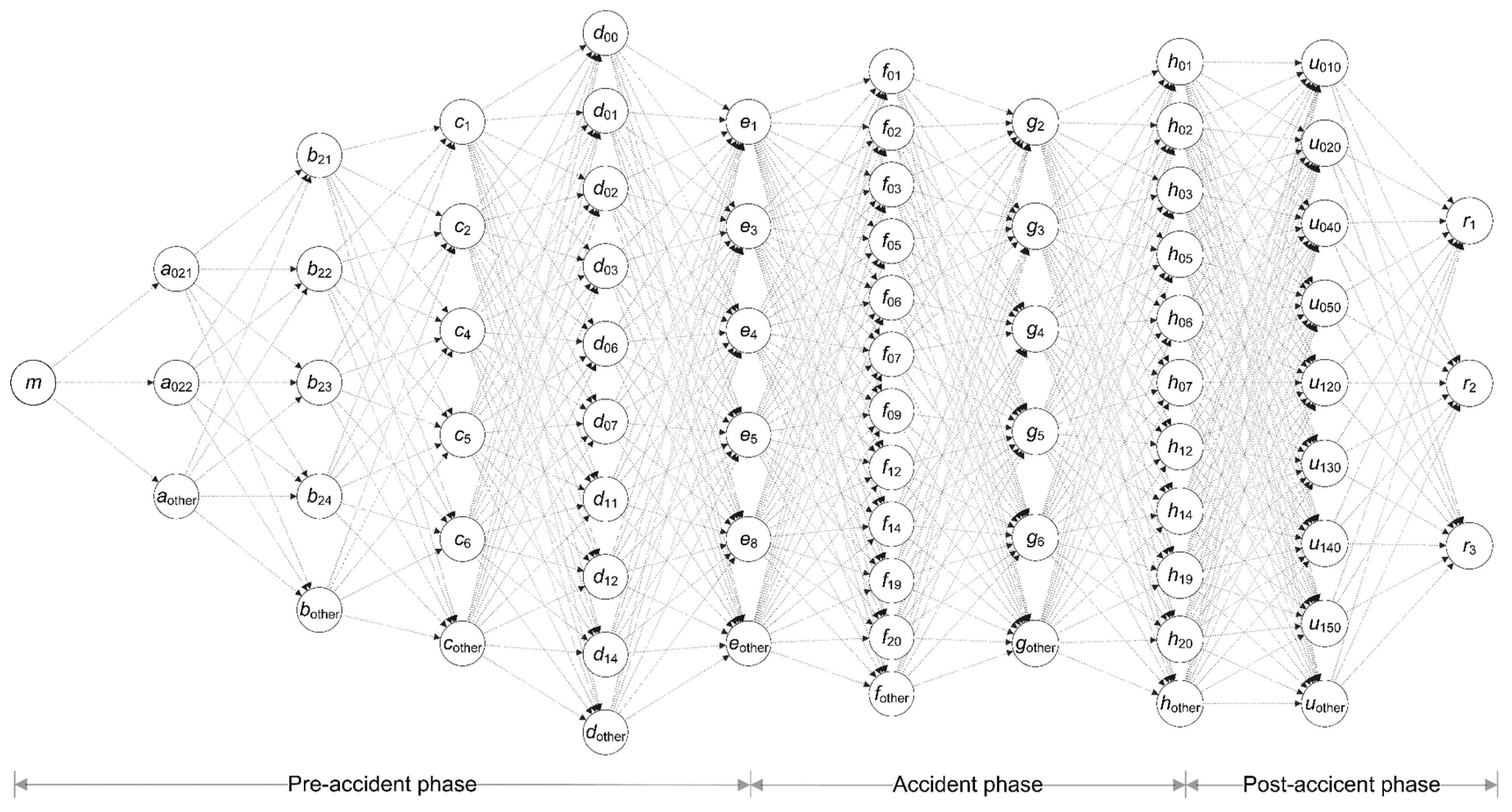

- Each node in the model shown in Figure 2, depending on the location of work, activities, machines, and used devices, can have many different meanings. This is due to the fact that the construction industry is characterized by large diversity and a high variability of implementation conditions. Individual detailed cases concerning different situations and circumstances are identified by an index placed next to a small letter that denotes a node. The numbers that are used to describe the indexes are identical to the indexes proposed by the Central Statistical Office of the European Union and those used in statistical accident cards [2,34]. From the set of all the detailed cases proposed by ESAW, cases that are definitely not found in the construction industry were eliminated. For this purpose, a method of experts was used. The experts were inspectors from the National Labor Inspectorate who examine occupational accidents in the Polish construction industry. Table 1 presents the main groups of nodes in the model, which is shown in Figure 2, as well as their individual components.

4. A Model of a Complex Accident Process in the Construction Industry

- quantitative analysis of the node activation in the graph,

- analysis of the relations between neighboring nodes in the graph.

4.1. Quantitative Analysis of the Node Activation in the Graph

4.2. Analysis of the Relations Between Neighboring Nodes

4.3. The Probability of the Occurrence of Accident Scenarios

5. Case Study

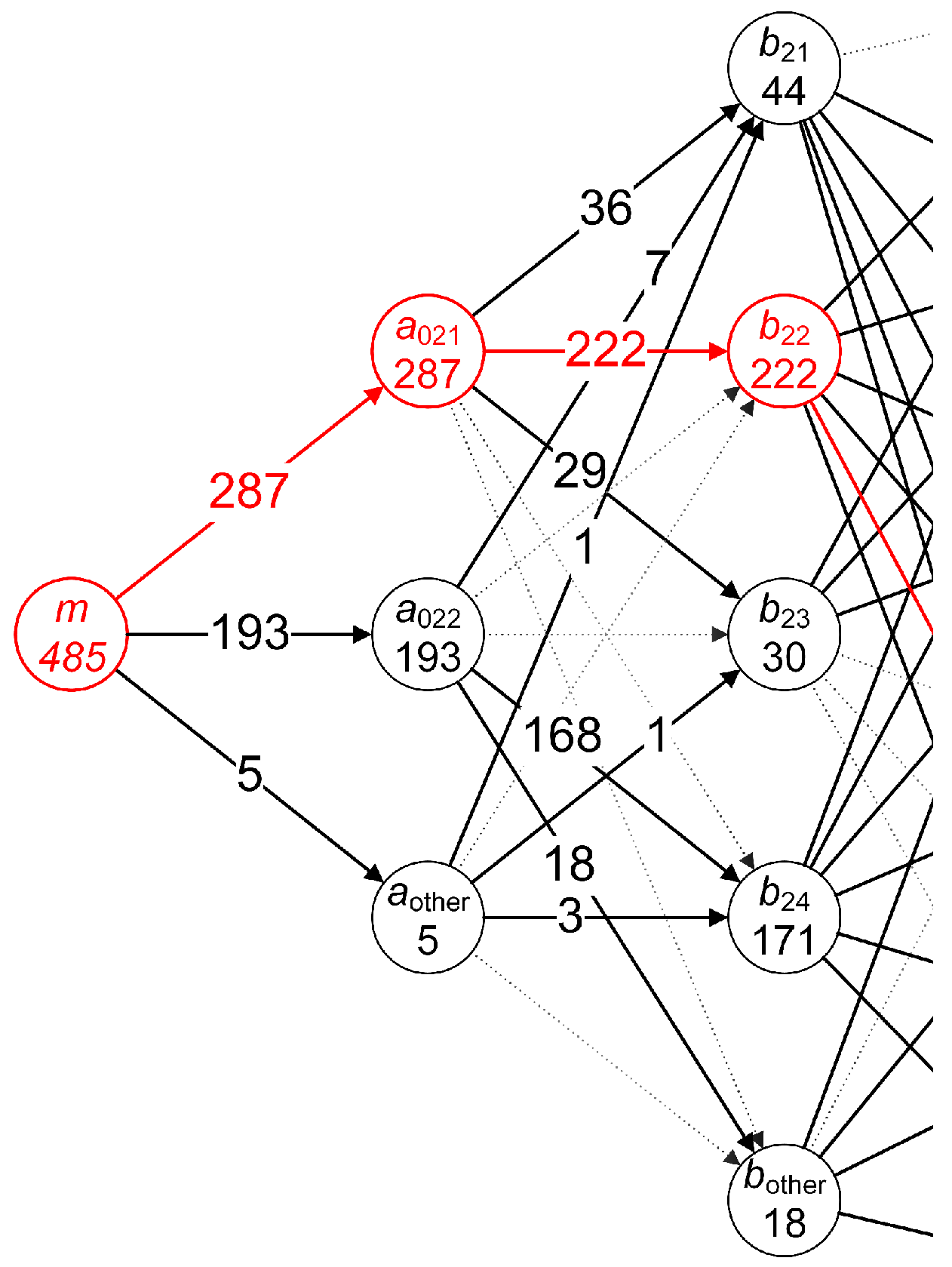

- In the set of 485 analyzed cases, the highest probability value was obtained by relation , which connects the source of an accident with the place where the accident occurred—which in this case was the construction site of new buildings. The probability of such a relationship was equal to 59.2%;

- The probability that a victim at the time of an accident was working while constructing a new facility is equal to 45.8% and applies to relationship ;

- The probability that an employee was moving around a construction site at the time of the accident was equal to 17.7% and applies to relationship ;

- The probability that an injured person was moving on surfaces or building constructions located above ground level at the time of the accident was equal to 26.6% and applies to relationship ;

- The probability of slipping, stumbling, or falling of an employee when moving around surfaces that are located above ground level was equal to 37.1% and applies to relationship ;

- The probability that the material agent, which is associated with the slipping, tripping, or falling of an injured person, were surfaces of objects and structures located above ground level was equal to 41.9% and applies to relationship ;

- The probability that a collision or hitting a stationary object would occur as a result of slipping, tripping, or falling of an injured person, who was on surfaces or building structures located above ground level was equal to 50.7% and applies to relationship ;

- The probability that the object with which the impact will occur, or which a victim hits, are structures and their elements located at ground level was equal to 49.9% and applies to relationship ;

- The probability that a victim suffers injuries due to falling from a height as a result of a collision or hitting structures and their elements located at ground level was equal to 22.3% and applies to relationship ;

- The probability that the result of an injury will be the death of an injured person amounted to 36.7% and applies to relationship .

6. Conclusions and Limitations

- The developed model of a complex accident process in the form of a directed graph and its computer application, which is combined with the IT Database (CKD) that contains information on occupational accidents, enabled a selected sequence of accidents to be analyzed as a discrete dynamic process. Accidents that create a sequence of events occur at discrete time periods and at various workstations in terms of their location, construction, and technical equipment.

- Conducted research and analysis with the use of the model enabled individual accident scenarios in the examined set of accidents to be identified, and the probability of their occurrence and the critical path that indicates the most accident-causing operations to be determined.

- The most common event in the set of analyzed accidents, which is a deviation from the normal state and the cause of an accident, was the slipping, stumbling, or falling of an injured person () on surfaces of constructions located above ground level (). As a result of such an event, a fall to a lower level took place (). Most often, such an event resulted in a severe body injury () or death of an employee ().

- The prepared model of the development of an accident situation, due to its construction based on the methodology of collecting statistical data on occupational accidents in European Union countries, is a tool, which after its previous adaptation, can be used to analyze the accidentality phenomenon in various European Union countries and various sections of the national economy.

- The proposed model is of great importance for construction practice. On the basis of a large set of data on accidents contained in the IT Database (CKD), it is possible to study the impact of technologies used in the construction industry, the types of carried out construction works, and the applied equipment and methods of work organization on the accident rate.

- The proposed model for the development of an accident situation in the construction industry can be the basis for conducting similar research in other areas of construction activity. This is important for comparison purposes. The results of comparative studies can be the basis for determining the most dangerous construction areas.

- Knowledge of the circumstances of accidents will allow labor law regulations to be properly formulated or modified, as well as preventive activities and training in the field of occupational safety to be targeted. This will certainly reduce the number of accidents. The obtained test results form the basis for determining the most dangerous types of construction works and situations in the construction industry. The identification of such situations is the basis for formulating new, or modifying existing, labor law provisions, e.g., regarding the imposition of fines on enterprises in which significant safety deficiencies were found.

- The results obtained on the basis of the conducted research may be a justification for the directions of preventive actions carried out in order to reduce the number of occupational accidents in the construction industry. This will significantly contribute to an increase of the level of occupational safety in the Polish construction industry.

- The presented model of the development of an accident situation is focused on the circumstances that lead to accidents. The model cannot be used to analyze the causes of accidents. This issue is currently the subject of research and analysis.

Author Contributions

Funding

Conflicts of Interest

References

- Hoła, B. Qualitative and Quantitative Modelling of Accident Situation in Building Industry; Scientific Works of the Institute of Building Engineering at the Wrocław University of Technology: Wrocław, Poland, 2008; Volume 89. [Google Scholar]

- European Statistics on Accident at Work ESAW. Summary Methodology; Eurostat Methodologies & Working Papers: Luxembourg, 2013. [Google Scholar]

- Hoła, A.; Hoła, B.; Sawicki, M.; Szóstak, M. Analysis of selected factors that generate the costs of accidents at work using the Polish construction industry as an example. MATEC Web. Conf. 2016, 86, 07005. [Google Scholar] [CrossRef]

- Okoye, P.U. Occupational Health and Safety Risk Levels of Building Construction Trades in Nigeria. Australas. J. Constr. Econ. Build. 2018, 18, 92–109. [Google Scholar] [CrossRef]

- Sanchez, F.A.S.; Pelaez, G.I.C.; Alis, J.C. Occupational safety and health in construction: A review of applications and trends. Ind. Health 2017, 55, 210–218. [Google Scholar] [CrossRef]

- Hui Liy, C.; Ibrahim, S.H.; Affandi, R.; Rosli, N.A.; Mohd Nawi, M.N. Causes of fall hazards in construction site management. Int. Rev. Manag. Mark. 2016, 6, 257–263. [Google Scholar]

- López Arquillos, A.; Rubio Romero, J.C.; Gibb, A. Analysis of construction accidents in Spain, 2003–2008. J. Saf. Res. 2012, 43, 381–388. [Google Scholar] [CrossRef]

- Leung, M.; Chan, I.Y.S.; Yu, J. Preventing construction worker injury incidents through the management of personal stress and organizational stressors. Accid. Anal. Prev. 2012, 48, 156–166. [Google Scholar] [CrossRef] [PubMed]

- Irumba, R. Spatial analysis of construction accidents in Kampala, Uganda. Saf. Sci. 2014, 64, 109–120. [Google Scholar] [CrossRef]

- Samuel, O.; Adul Hamid, R.; Saidin Misnan, M. Analysis of Fatal Building Construction Accidents: Cases and Causes. J. Multidiscip. Eng. Sci. Technol. 2017, 4, 8030–8040. [Google Scholar]

- Hoque, I.; Ahmed, S.; Sobuz, H.R. Identification of Factors Influencing Accidents on Construction Sites. J. Syst. Manag. Sci. 2017, 7, 1–16. [Google Scholar]

- Chi, S.; Han, S. Analyses of systems theory for construction accident prevention with specific reference to OSHA accident reports. Int. J. Proj. Manag. 2013, 31, 1027–1041. [Google Scholar] [CrossRef]

- Drozd, W.; Kowalik, M. A study on the state of knowledge of managers of construction sites in the field of occupational safety. MATEC Web Conf. 2019, 262, 07001. [Google Scholar] [CrossRef]

- Di Bona, G.; Silvestri, A.; Forcina, A.; Petrillo, A. Total efficient risk priority number (TERPN): A new method for risk assessment. J. Risk Res. 2018, 21, 1384–1408. [Google Scholar] [CrossRef]

- Haslam, R.A.; Hide, S.A.; Gibb, A.G.F.; Gyi, D.E.; Pavitt, T.; Atkinson, S.; Duff, A.R. Contributing factors in construction accidents. Appl. Ergon. 2005, 36, 401–415. [Google Scholar] [CrossRef]

- Lin, Y.-H.; Chen, C.-Y.; Wang, W.; Wang, T.-W. Fatal occupational falls in the Taiwan construction industry. J. Chin. Inst. Ind. Eng. 2011, 28, 586–596. [Google Scholar] [CrossRef]

- Islam, M.S.; Razwanul, I.; Mahmud, M.T. Safety Practices and Causes of Fatality in Building Construction Projects: A Case Study for Bangladesh. Jordan J. Civ. Eng. 2017, 11, 267–278. [Google Scholar]

- Camino López, M.A.; Ritzel, D.O.; Fontaneda, I.; González Alcantara, O.J. Construction industry accidents in Spain. J. Saf. Res. 2008, 39, 497–507. [Google Scholar] [CrossRef] [PubMed]

- Bellamy, L.J.; Ale, B.J.M.; Whiston, J.Y.; Mud, M.L.; Baksteen, H.; Hale, A.R.; Papazoglou, I.A.; Bloemhoff, A.; Damen, M.; Oh, J.I.H. The software tool storybuilder and the analysis of the horrible stories of occupational accidents. Saf. Sci. 2008, 46, 186–197. [Google Scholar] [CrossRef]

- Mitropoulos, P.; Abdelhamid, T.S.; Howell, G.A. Systems Model of Construction Accident Causation. J. Constr. Eng. Manag. 2005, 131, 816–825. [Google Scholar] [CrossRef]

- Heinrich, H.W. Industrial Accidents Prevention; Mc Graw Hill Book Company, Inc.: New York, NY, USA, 1959. [Google Scholar]

- Bird, F.E. Management Guide to Loss Control, Atlanta, Institute Press; InternatioSafety Academy: Houston, TX, USA, 1974. [Google Scholar]

- Benner, L. Accident Theory and Accident Investigation; Proceedings of the Society of Air Safety Investigators Annual Seminar: Ottawa, ON, Canada, 1975. [Google Scholar]

- Manu, P.A.; Ankrah, N.A.; Proverbs, D.G.; Suresh, S. Investigating the multi-causal and complex nature of the accident causal influence of construction project features. Accid. Anal. Prev. 2012, 48, 126–133. [Google Scholar] [CrossRef]

- Haddon, W. Energy Damage and the Ten Countermeasure Strategies. Hum. Factors J. Hum. Factors Ergon. Soc. 1973, 15, 355–366. [Google Scholar] [CrossRef]

- Chua, D.K.H.; Goh, Y.M. Incident Causation Model for Improving Feedback of Safety Knowledge. J. Constr. Eng. Manag. 2004, 130, 542–551. [Google Scholar] [CrossRef]

- Behm, M.; Schneller, A. Application of the Loughborough Construction Accident Causation model: A framework for organizational learning. Constr. Manag. Econ. 2013, 31, 580–595. [Google Scholar] [CrossRef]

- Reason, J. Human Error; Cambridge University Press: New York, NY, USA, 1990; ISBN 9781139062367. [Google Scholar]

- Shao, B.; Hu, Z.; Liu, Q.; Chen, S.; He, W. Fatal accident patterns of building construction activities in China. Saf. Sci. 2019, 111, 253–263. [Google Scholar] [CrossRef]

- Mistikoglu, G.; Gerek, I.H.; Erdis, E.; Mumtaz Usmen, P.E.; Cakan, H.; Kazan, E.E. Decision tree analysis of construction fall accidents involving roofers. Expert Syst. Appl. 2015, 42, 2256–2263. [Google Scholar] [CrossRef]

- Kjellen, U.; Larsson, T.J. Investigating accidents and reducing risks—A dynamic approach. J. Occup. Accid. 1981, 3, 129–140. [Google Scholar] [CrossRef]

- Kjellén, U. The deviation concept in occupational accident control-II. Data collection and assessment of significance. Accid. Anal. Prev. 1984, 16, 307–323. [Google Scholar] [CrossRef]

- Abdelhamid, T.S.; Everett, J.G. Identifying Root Causes of Construction Accidents. J. Constr. Eng. Manag. 2000, 126, 52–60. [Google Scholar] [CrossRef]

- Minister of Labour and Social Policy Order of 8 November 2010 Amending the Order Concerning the Statistical Accident-at-Work Card (Law Gazette, No. 218, it. 1440, No 240, it. 1612). Available online: http://prawo.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20102181440 (accessed on 1 March 2019).

- Kordecki, W. Theory of Probability and Mathematical Statistics. Definitions, Theorems, Formulas; Printing House GiS: Wrocław, Poland, 2010. [Google Scholar]

- Hebda, A. A Method of Engineering and Economical Assessment of Components and Occupational Risk Disutility in Coal Mines; The AGH University of Science and Technology Press: Krakow, Poland, 2005. [Google Scholar]

- Hoła, B.; Szóstak, M. A Computer Knowledge Database of accidents at work in the construction industry. IOP Conf. Ser. Mater. Sci. Eng. 2017, 251. [Google Scholar] [CrossRef]

| The location of an occupational accident (working environment) | ||||

| —construction site—building being constructed | —construction site—building being demolished, repaired, maintained | |||

| —opencast quarry, opencast mine, excavation, trench | —construction site—underground | |||

| —construction site—in a high-pressure environment | ||||

| —construction site—on/over water | ||||

| —other unnamed or unknown places in this group | ||||

| The work process | ||||

| —excavation | —new construction building | |||

| —new construction—civil engineering, infrastructures, roads, bridges, dams | —remodeling, repairing, extending, building maintenance—all types of constructions | |||

| —demolition—all types of construction | ||||

| —other unnamed or unknown works in this group | ||||

| The action performed by the victim at the time of the accident | ||||

| —no information | —operating machines | |||

| —working with hand-held tools | —driving/being on board a means of transport or handling equipment | |||

| —handling of objects | ||||

| —carrying by hand | —movement | |||

| —presence | —other physical activities not listed in this group | |||

| The material agent related to the operation performed by the victim at the time of an accident | ||||

| —no material agent or no information | —buildings, structures, surface—at ground level | |||

| —buildings, structures surfaces—above ground level | ||||

| —buildings, structures surfaces—below ground level | ||||

| —systems for the supply and distribution of materials, pipe networks | ||||

| —motors, systems for energy transmission and storage | ||||

| —hand tools, not powered | —hand-held or hand-guided tools, mechanical | |||

| —machines and equipment—portable or mobile | ||||

| —machines and equipment—fixed | ||||

| —conveying, transport and storage systems | —land vehicles | |||

| —other transport vehicles | ||||

| —materials, objects, products, machine or vehicle components, debris, dust | —chemical, explosive, radioactive, biological substances | |||

| —safety devices and equipment | —office equipment: personal equipment, sports equipment, weapons | |||

| —living organisms and human-beings | ||||

| —bulk waste | —physical phenomena and natural elements | |||

| —other material agents not listed in this group | ||||

| The event being a deviation from the normal state | ||||

| —no information | —deviation due to electrical problems, explosion, fire | |||

| —deviation by overflow, overturn, leak, flow, vaporization, emission | ||||

| —breakage, bursting, splitting, slipping, fall, collapse of material agent | ||||

| —loss of control (total or partial) of machine, means of transport or handling equipment, hand-held tool, object | ||||

| —slipping, stumbling and falling—fall of persons | ||||

| —body movement without any physical stress (generally leading to an external injury) | —body movement under or with physical stress (generally leading to an internal injury) | |||

| —shock, fright, violence, aggression, threat, presence | —other deviations not listed in this group | |||

| The material agent associated with a deviation from the normal state. Classification of material agents as in nodeD | ||||

| The event causing an injury | ||||

| —no information | —contact with electrical voltage, temperature, hazardous substances | |||

| drowned, buried, enveloped | ||||

| —horizontal or vertical impact with or against a stationary object (the victim is in motion) | —struck by object in motion, collision with | |||

| —contact with sharp, pointed, rough, coarse material agent | ||||

| —trapped, crushed, etc. | —physical or mental stress | |||

| —bite, kick, etc. (human) | —other events not listed in this group | |||

| The material agent that is the source of an injury associated with an event that causes the injury. Classification of material agents as in nodeD | ||||

| The type of injury | ||||

| —type of injury unknown or unspecified | —wounds and superficial injuries | |||

| —bone fractures | ||||

| —dislocations, sprains and strains | —traumatic amputations (loss of body parts) | |||

| —concussion and internal injuries | ||||

| —burns, scalds and frostbites | —poisonings and infections | |||

| —drowning and asphyxiation | —effects of sounds, vibrations and pressure | |||

| —effects of temperature extremes, light and radiation | —shocks (acute reaction to stress, traumatic shock) | |||

| —multiple injuries | —unspecified injuries as a result of falling from height | |||

| —unspecified injury as a result of backfilling with ground | ||||

| —unspecified injuries leading to death | ||||

| —other specified injuries not included under other headings | ||||

| The severity of injury | ||||

| —fatal accident | —severe body injuries | |||

| —minor body injuries | ||||

| Node | Code | Number | Node | Code | Number |

|---|---|---|---|---|---|

| Location of accident A | 287 | Event that causes injury G | 33 | ||

| 193 | 283 | ||||

| 5 | 60 | ||||

| Work process B | 44 | 31 | |||

| 222 | 44 | ||||

| 30 | 34 | ||||

| 171 | Material agent that is the source of an injury, which is associated with the event causing the injury H | 257 | |||

| 18 | 43 | ||||

| Material agent related to the operation performed by the victim at the time of the accident C | 15 | 9 | |||

| 83 | 10 | ||||

| 127 | 9 | ||||

| 57 | 16 | ||||

| 186 | 31 | ||||

| 17 | 33 | ||||

| Material agent related to the operation performed by the victim at the time of the accident D | 13 | 14 | |||

| 22 | 35 | ||||

| 250 | 28 | ||||

| 45 | Type of injury U | 10 | |||

| 31 | 107 | ||||

| 21 | 32 | ||||

| 10 | 31 | ||||

| 8 | 9 | ||||

| 57 | 84 | ||||

| 28 | 13 | ||||

| Event that is a deviation from the normal state E | 17 | 178 | |||

| 152 | 21 | ||||

| 56 | Severity of injury R | 178 | |||

| 222 | 297 | ||||

| 17 | 10 | ||||

| 21 | |||||

| Material agent related to a deviation from the normal state F | 7 | ||||

| 18 | |||||

| 269 | |||||

| 12 | |||||

| 10 | |||||

| 9 | |||||

| 16 | |||||

| 8 | |||||

| 28 | |||||

| 41 | |||||

| 9 | |||||

| 33 | |||||

| 25 |

| Work process | ||||||||

| ∑ | ||||||||

| Place of accident A | 36 | 222 | 29 | 0 | 0 | 0 | 287 | |

| 7 | 0 | 0 | 168 | 18 | 0 | 193 | ||

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | ||

| 1 | 0 | 0 | 3 | 0 | 0 | 4 | ||

| 0 | 0 | 1 | 0 | 0 | 0 | 1 | ||

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | ||

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | ||

| ∑ | 44 | 222 | 30 | 171 | 18 | 0 | 485 | |

| Type of Relation | Number of Relationship Activations [-] | Probability of the Occurrence of Relation [%] |

|---|---|---|

| 287 | 59,2 | |

| 222 | 45,8 | |

| 86 | 17,7 | |

| 129 | 26,6 | |

| 180 | 37,1 | |

| 203 | 41,9 | |

| 246 | 50,7 | |

| 242 | 49,9 | |

| 108 | 22,3 | |

| 178 | 36,7 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hoła, B.; Szóstak, M. Modeling of the Accidentality Phenomenon in the Construction Industry. Appl. Sci. 2019, 9, 1878. https://doi.org/10.3390/app9091878

Hoła B, Szóstak M. Modeling of the Accidentality Phenomenon in the Construction Industry. Applied Sciences. 2019; 9(9):1878. https://doi.org/10.3390/app9091878

Chicago/Turabian StyleHoła, Bożena, and Mariusz Szóstak. 2019. "Modeling of the Accidentality Phenomenon in the Construction Industry" Applied Sciences 9, no. 9: 1878. https://doi.org/10.3390/app9091878

APA StyleHoła, B., & Szóstak, M. (2019). Modeling of the Accidentality Phenomenon in the Construction Industry. Applied Sciences, 9(9), 1878. https://doi.org/10.3390/app9091878