Effect of Waste Engine Oil and Waste Cooking Oil on Performance Improvement of Aged Asphalt

Abstract

1. Introduction

2. Materials

2.1. Asphalt

2.2. Waste Engine Oil and Waste Cooking Oil

3. Experimental Sections

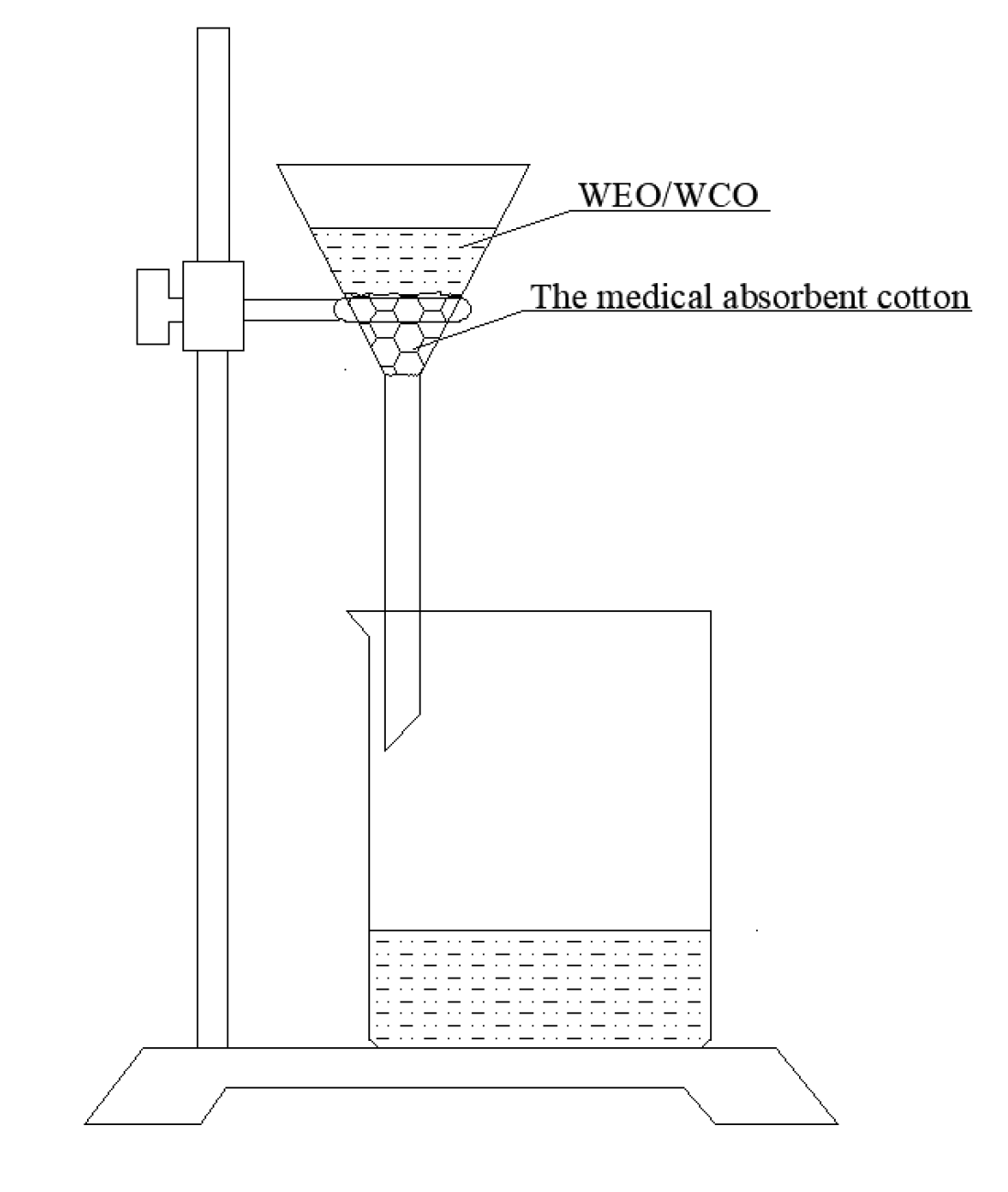

3.1. Rejuvenated Asphalts Preparation

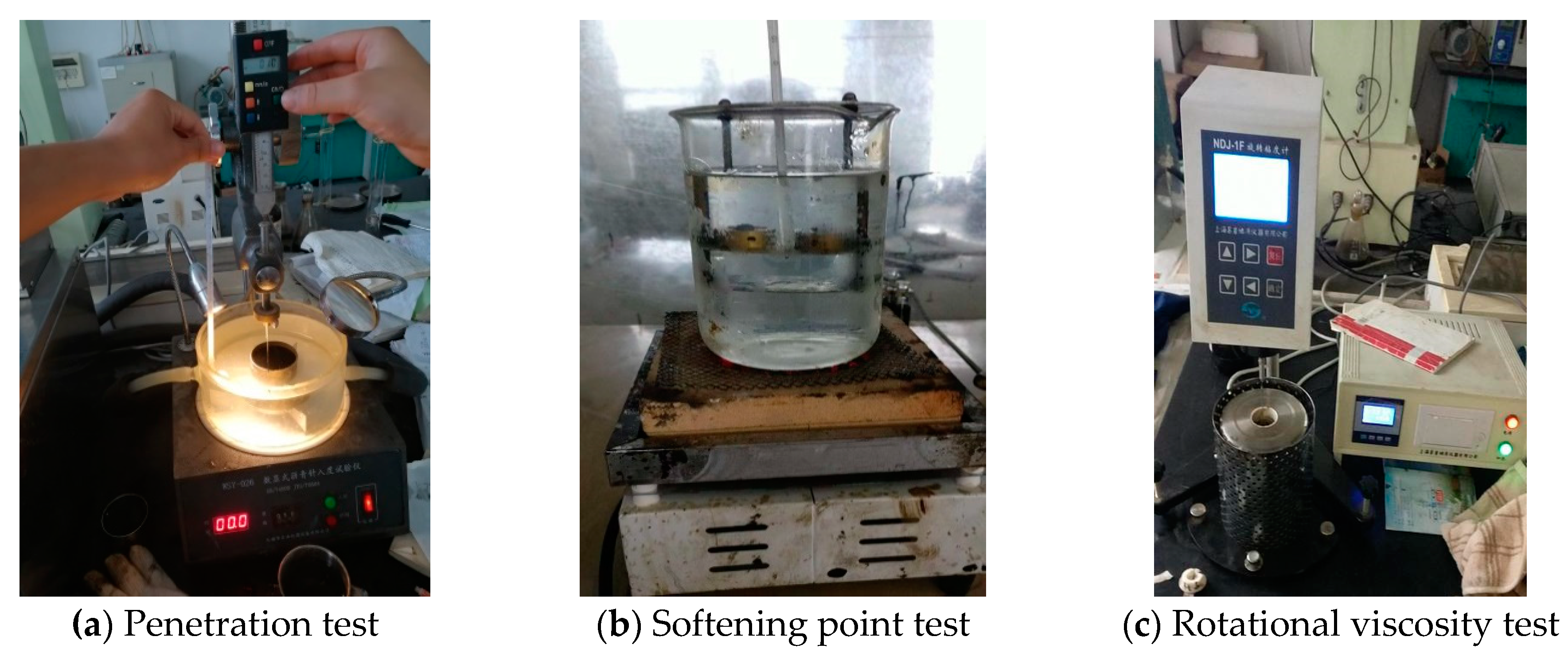

3.2. Physical Properties Tests

3.3. Chemical Properties Tests

3.4. Rheological Properties Tests

4. Results and Discussion

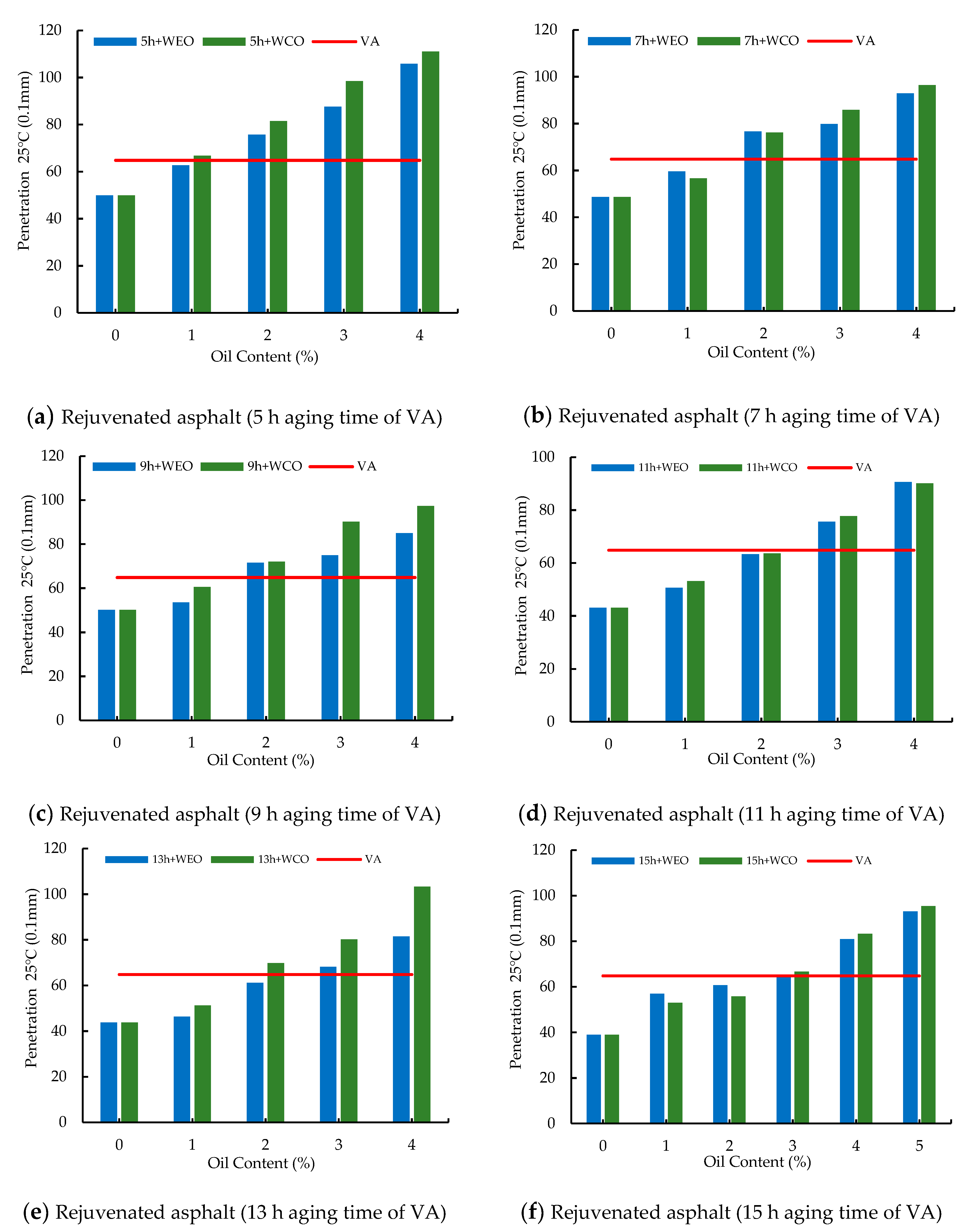

4.1. Penetration

4.2. Softening Point

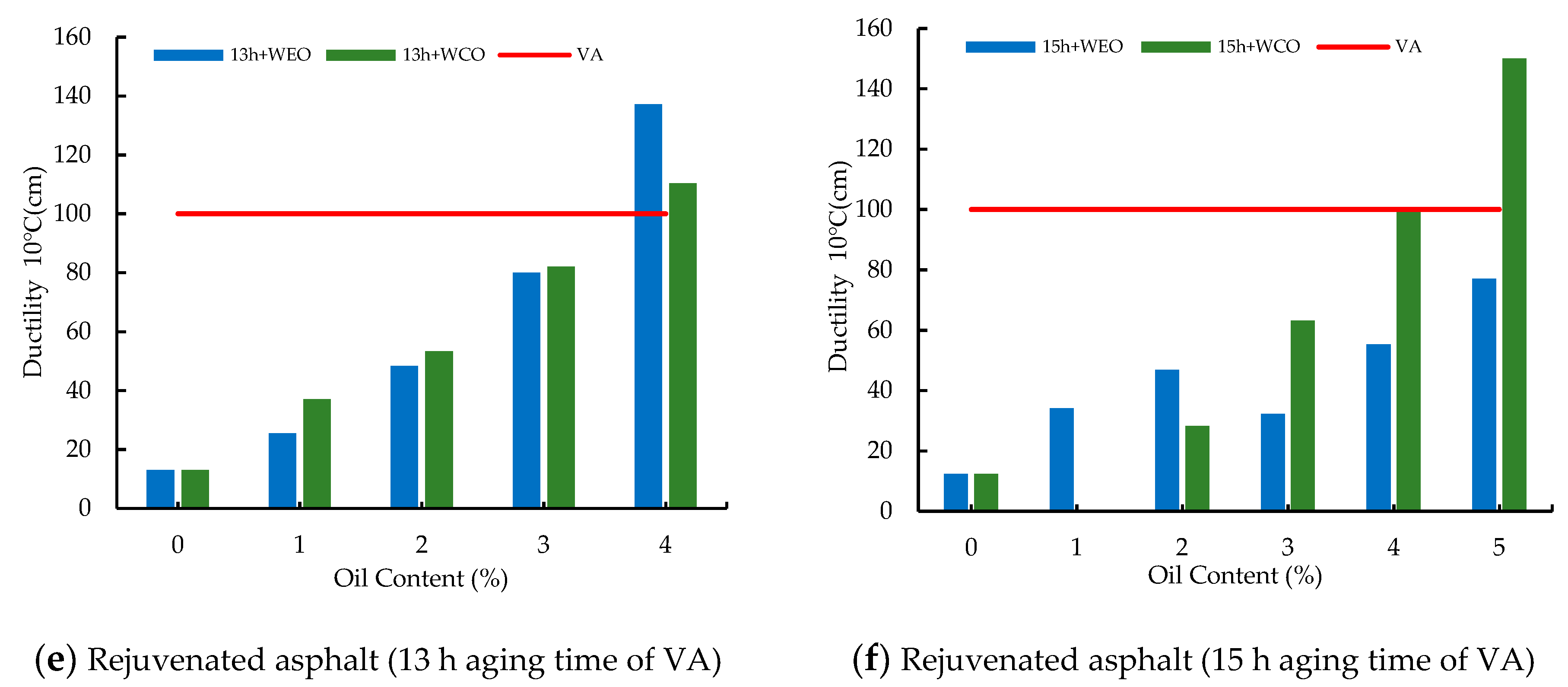

4.3. Ductility

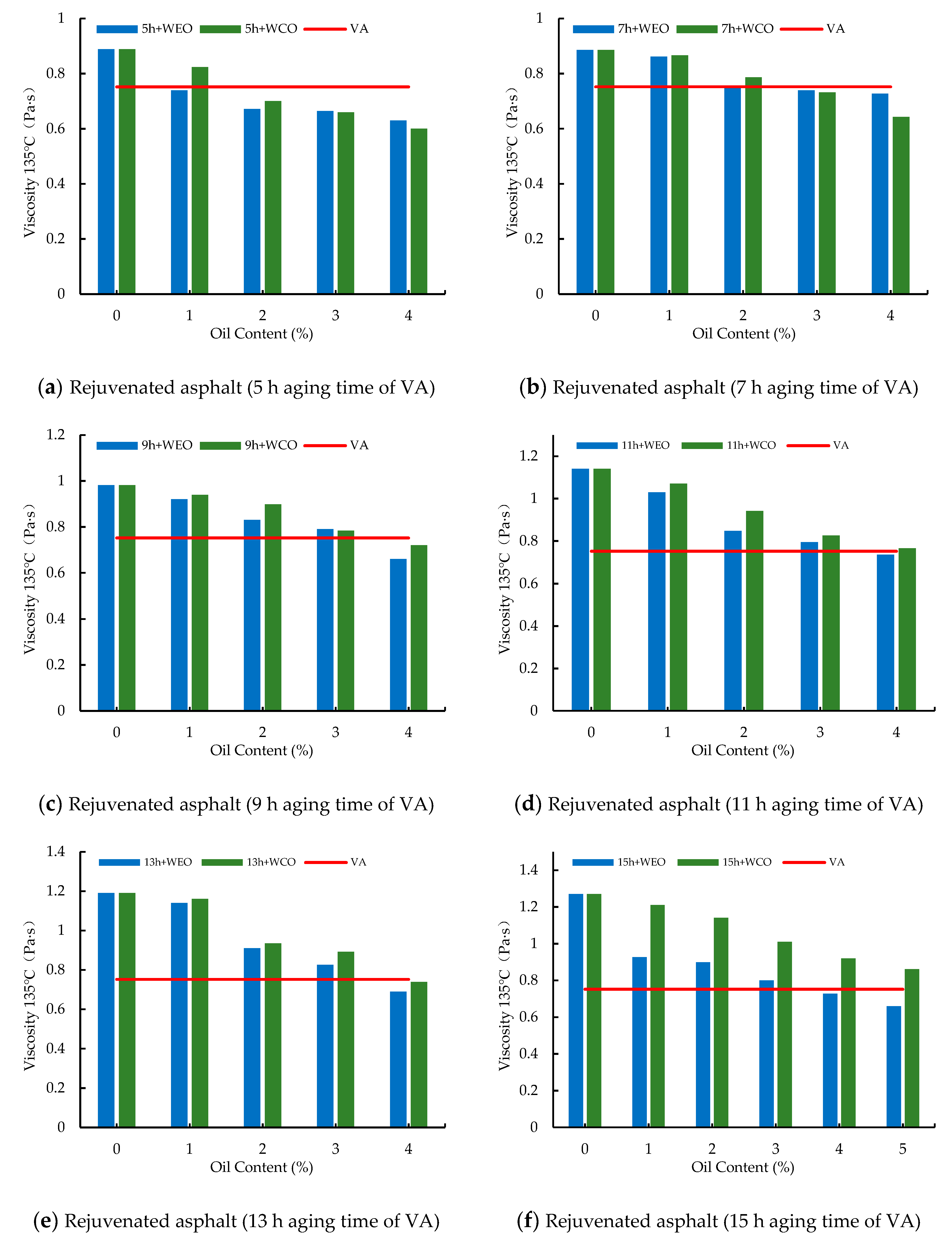

4.4. Viscosity

4.5. Chemical Properties

4.5.1. Four Components

4.5.2. Functional Groups

4.6. Rheological Properties

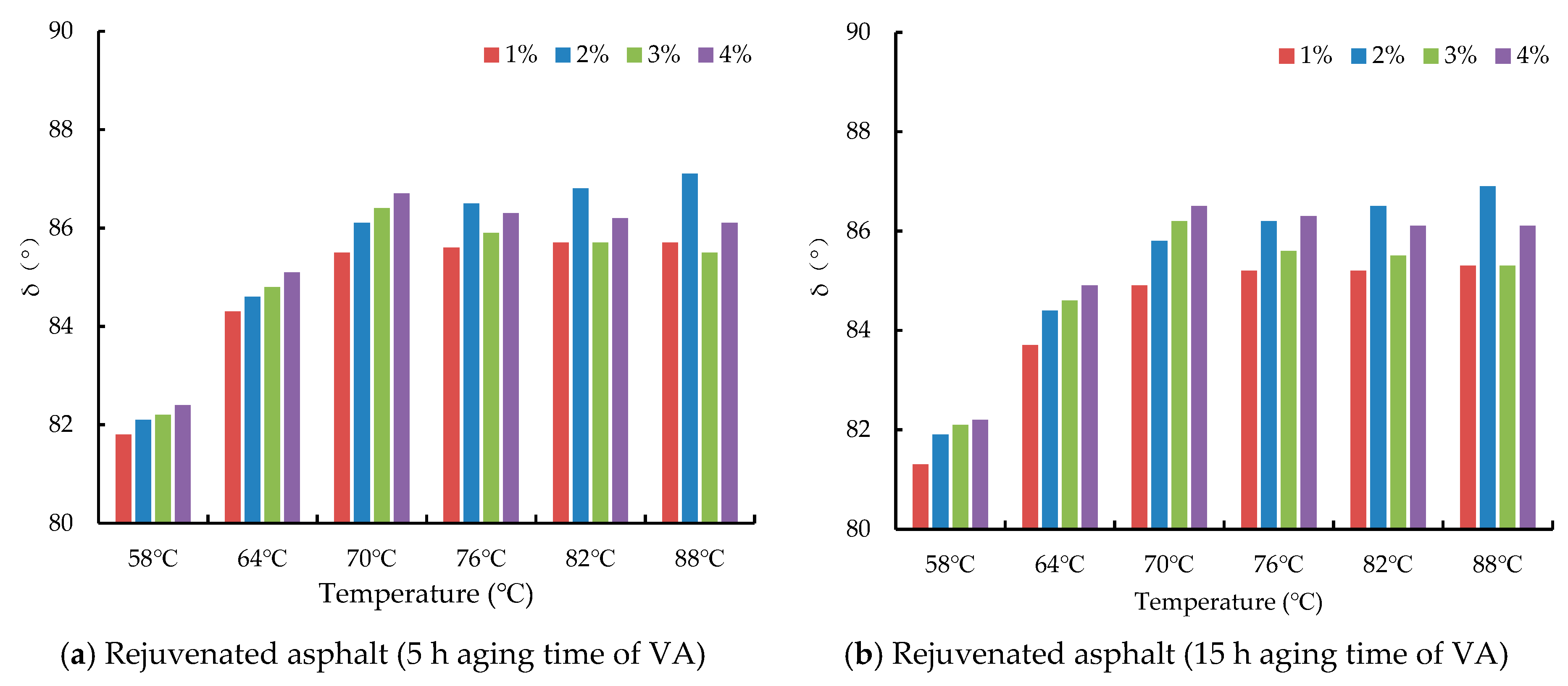

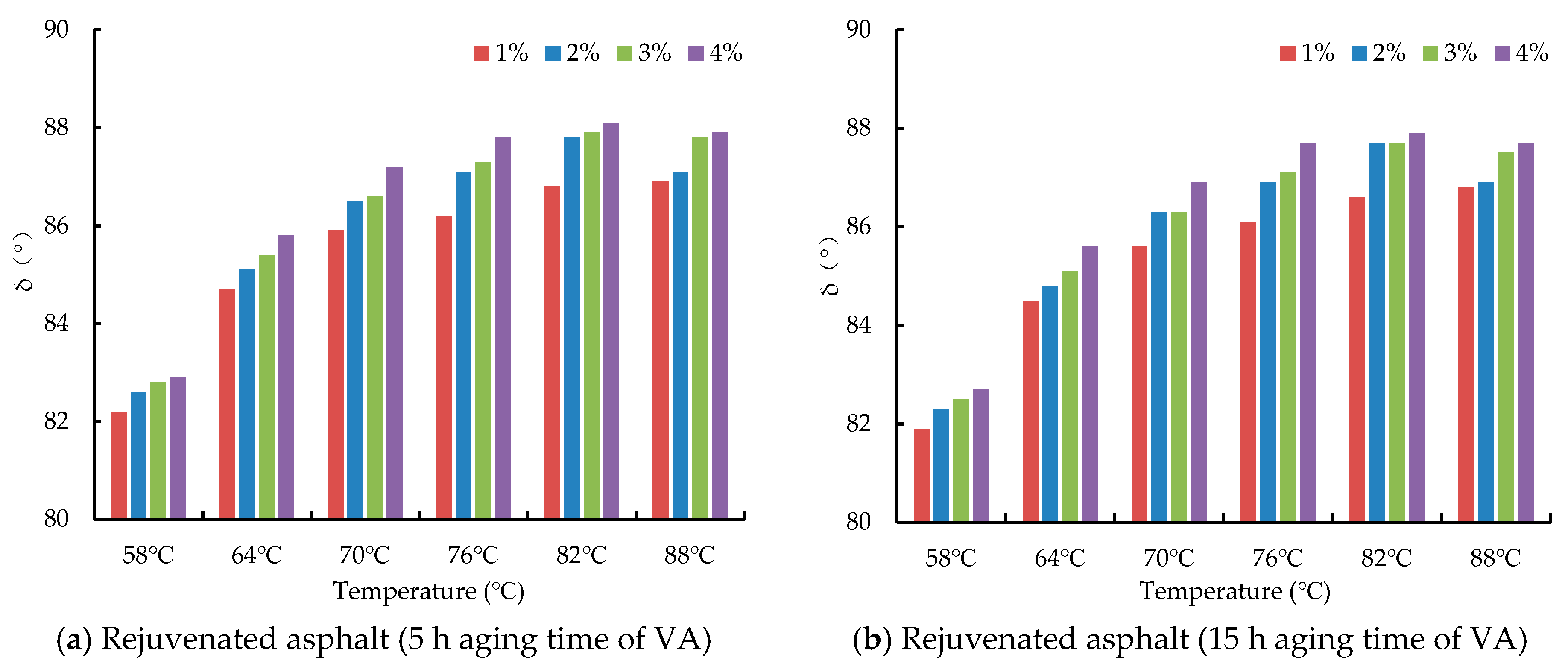

4.6.1. Phase Angle (δ)

4.6.2. Complex Modulus (G*)

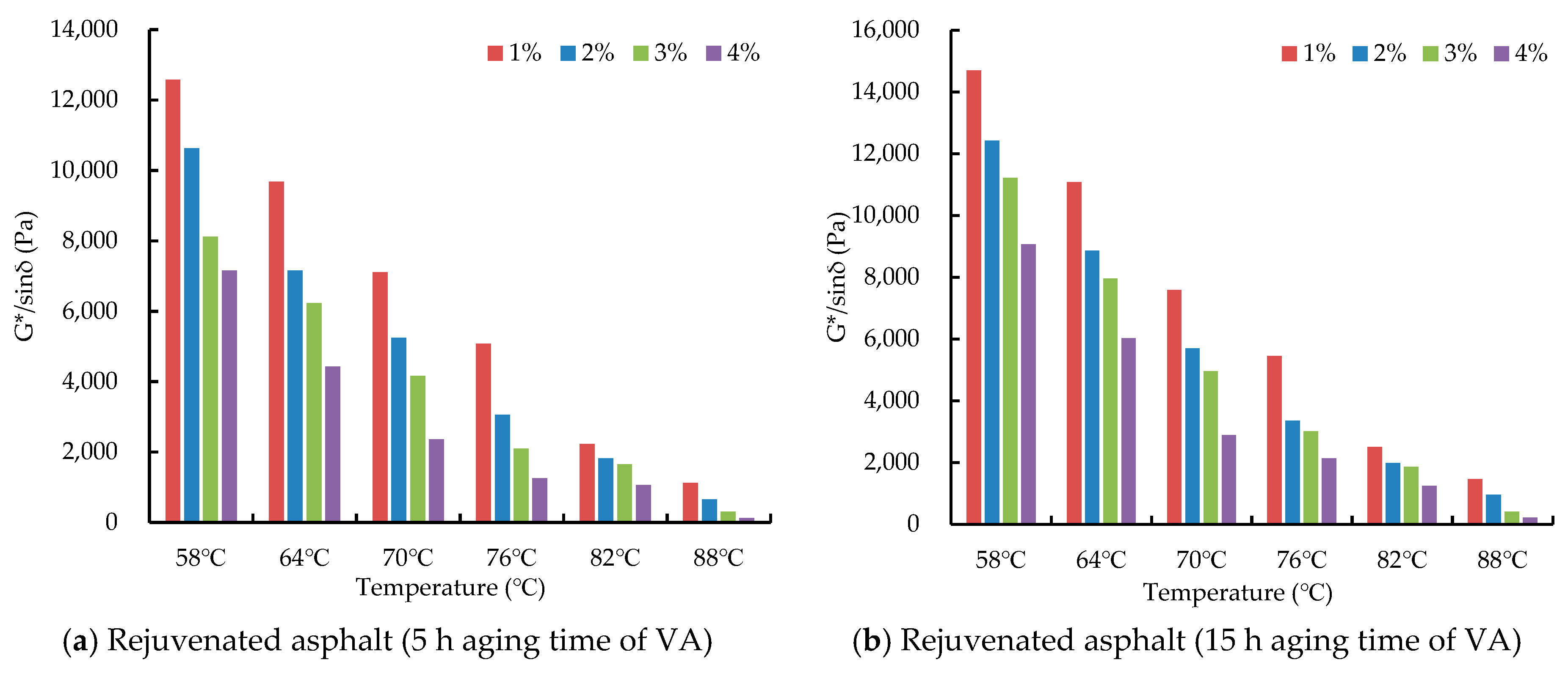

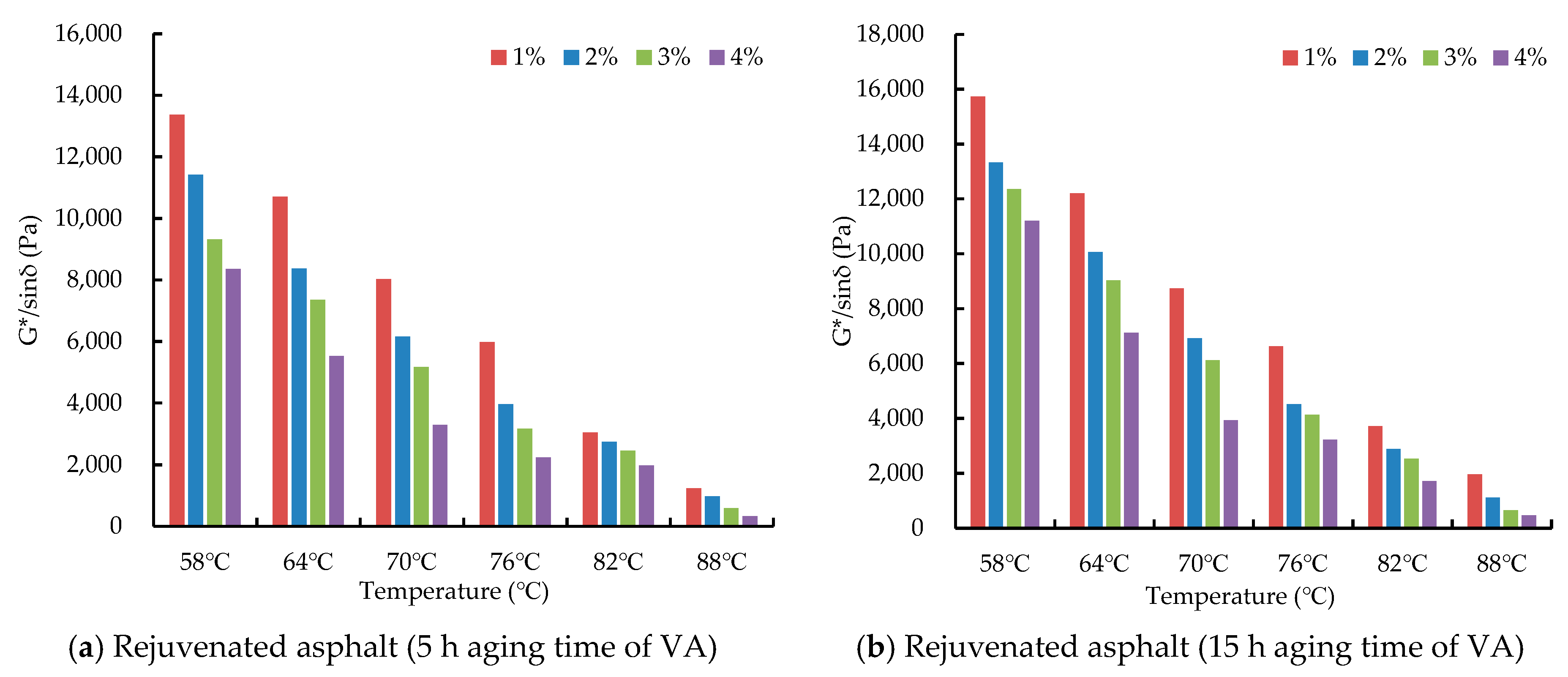

4.6.3. Rutting Resistance Factor (G*/sinδ)

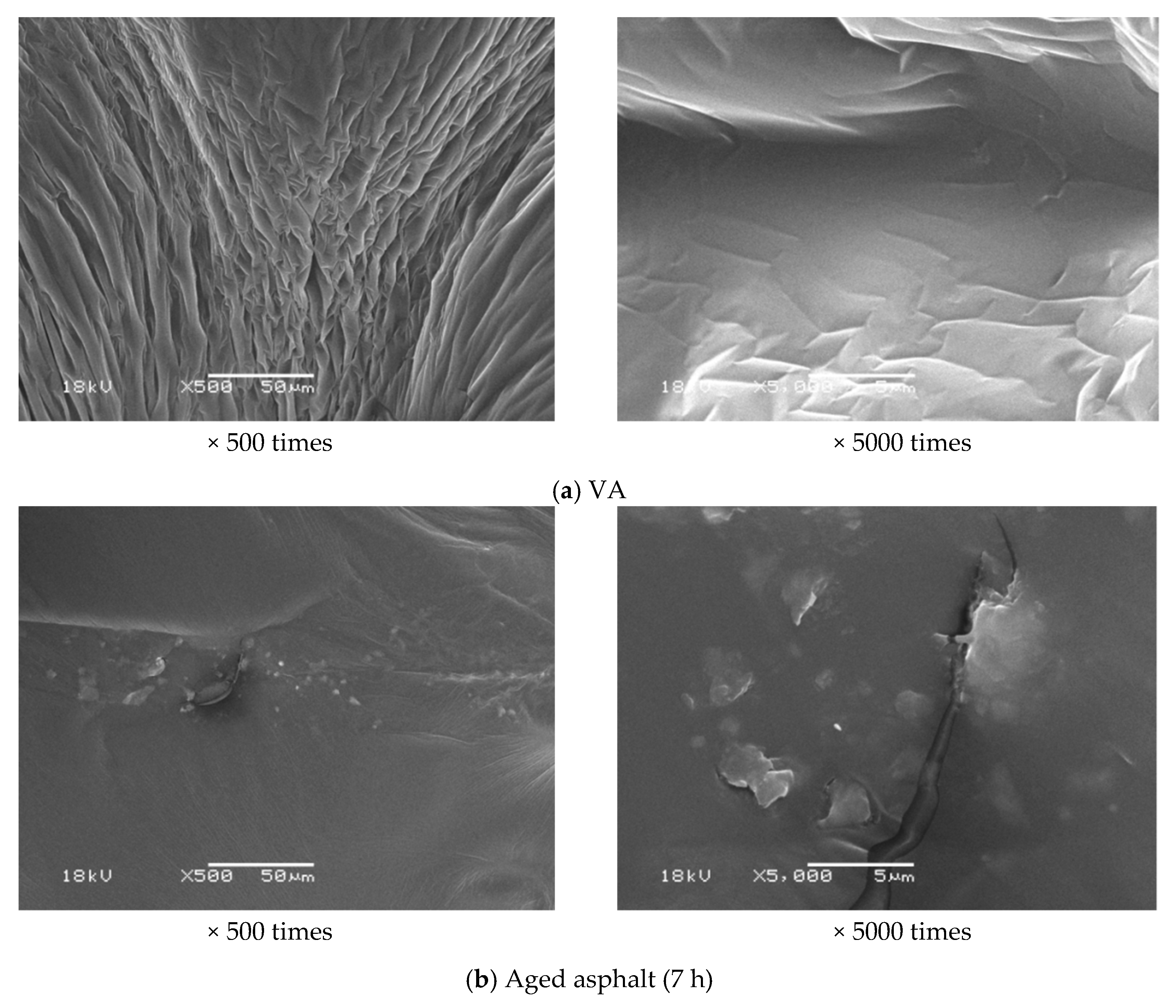

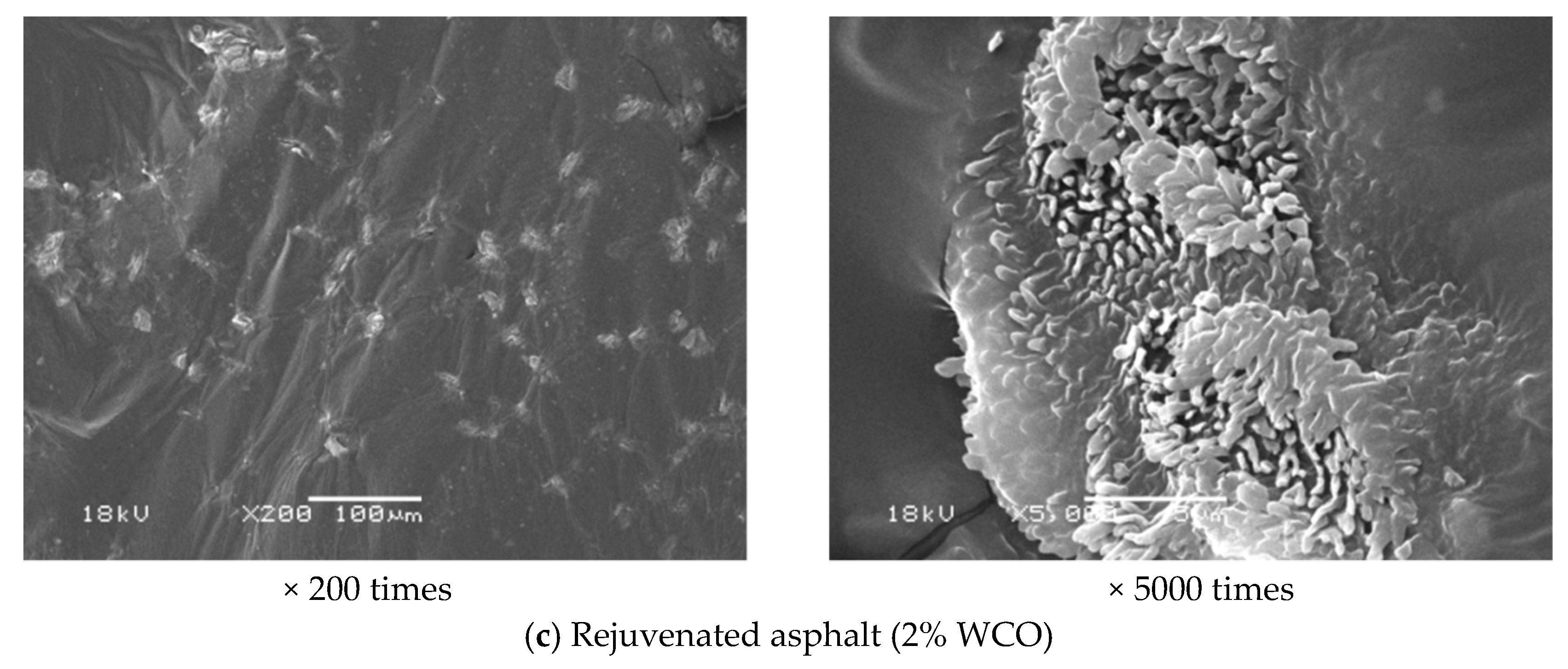

4.7. Scanning Electron Microscopy (SEM) Test

5. Conclusions

6. Future Researches

Author Contributions

Funding

Conflicts of Interest

References

- Chen, M.; Leng, B.; Wu, S.; Sang, Y. Physical, chemical and rheological properties of waste edible vegetable oil rejuvenated asphalt binders. Constr. Build. Mater. 2014, 66, 286–298. [Google Scholar] [CrossRef]

- Butt, A.A.; Mirzadeh, I.; Toller, S.; Birgisson, B. Life cycle assessment framework for asphalt pavements: Methods to calculate and allocate energy of binder and additives. Int. J. Pavement Eng. 2014, 15, 290–302. [Google Scholar] [CrossRef]

- Giani, M.I.; Dotelli, G.; Brandini, N.; Zampori, L. Comparative life cycle assessment of asphalt pavements using reclaimed asphalt, warm mix technology and cold in-place recycling. Resour. Conserv. Recycl. 2015, 104, 224–238. [Google Scholar] [CrossRef]

- Sadeeq, J.A.; Kaura, J.M.; Joshua, O.; Rabilu, A. Recycling of reclaimed asphalt pavement (rap) with rice husk ash (rha)/ordinary Portland cement (opc) blend as filler. Jordan J. Civ. Eng. 2014, 8, 2014–2473. [Google Scholar]

- Arimilli, S.; Jain, P.K.; Nagabhushana, M.N. Optimization of recycled asphalt pavement in cold emulsified mixtures by mechanistic characterization. J. Mater. Civ. Eng. 2016, 28, 04015132. [Google Scholar] [CrossRef]

- Fini, E.H.; Kalberer, E.W.; Shahbazi, A.; Basti, M. Chemical Characterization of Biobinder from Swine Manure: Sustainable Modifier for Asphalt Binder. J. Mater. Civ. Eng. 2011, 23, 1506–1513. [Google Scholar] [CrossRef]

- Tabakovi, A.; Post, W.; Cantero, D.; Copuroglu, O.; Garcia, S.J.; Schlangen, E. The reinforcement and healing of asphalt mastic mixtures by rejuvenator encapsulation in alginate compartmented fibres. Smart Mater. Struct. 2016, 25, 084003. [Google Scholar] [CrossRef]

- Su, J.F.; Schlangen, E. Synthesis and physicochemical properties of high compact microcapsules containing rejuvenator applied in asphalt. Chem. Eng. J. 2012, 198, 289–300. [Google Scholar] [CrossRef]

- Silva, H.; Oliveira, J.; Jesus, C. Are totally recycled hot mix asphalts a sustainable alternative for road paving. Resour. Conserv. Recycl. 2012, 60, 38–48. [Google Scholar] [CrossRef]

- Fernandes, S.R.M.; Silva, H.M.R.D.; Oliveira, J.R.M. Developing enhanced modified bitumens with waste engine oil products combined with polymers. Constr. Build. Mater. 2018, 160, 714–724. [Google Scholar] [CrossRef]

- Liu, S.; Meng, H.; Xu, Y. Evaluation of rheological characteristics of asphalt modified with waste engine oil (WEO). Pet. Sci. Technol. 2018, 36, 475–480. [Google Scholar] [CrossRef]

- Jia, X.; Huang, B.; Bowers, B.F.; Zhao, S. Infrared spectra and rheological properties of asphalt cement containing waste engine oil residues. J. Constr. Build. Mater. 2014, 50, 683–691. [Google Scholar] [CrossRef]

- Hesp, S.A.M.; Shurvell, H.F. X-ray fluorescence detection of waste engine oil residue in asphalt and its effect on cracking in service. Int. J. Pavement Eng. 2010, 11, 541–553. [Google Scholar] [CrossRef]

- Wan, N.A.W.A.; Jaya, R.P.; Hainin, M.R.; Bujang, M.; Ngadi, N. Chemical modification of waste cooking oil to improve the physical and rheological properties of asphalt binder. Constr. Build. Mater. 2016, 126, 218–226. [Google Scholar]

- Zaumanis, M.; Mallick, R.B.; Poulikakos, L.; Frank, R. Influence of six rejuvenators on the performance properties of Reclaimed Asphalt Pavement (RAP) binder and 100% recycled asphalt mixtures. Constr. Build. Mater. 2014, 71, 538–550. [Google Scholar] [CrossRef]

- Nayak, P.; Sahoo, U.C. Rheological, chemical and thermal investigations on an aged binder rejuvenated with two non-edible oils. Road Mater. Pavement Des. 2016, 18, 1–18. [Google Scholar] [CrossRef]

- Dong, Z.; Meizhu, C.; Shaopeng, W.; Jingxiang, L.; Serji, A. Analysis of the Relationships between Waste Cooking Oil Qualities and Rejuvenated Asphalt Properties. Materials 2017, 10, 508. [Google Scholar]

- Zargar, M.; Ahmadinia, E.; Asli, H.; Karim, M.R. Investigation of the possibility of using waste cooking oil as a rejuvenating agent for aged bitumen. J. Hazard. Mater. 2012, 233–234, 254–258. [Google Scholar] [CrossRef] [PubMed]

- Caputo, P.; Paolino, C.; Valeria, L. The efficiency of bitumen rejuvenator investigated through Powder X-ray Diffraction (PXRD) analysis and T2-NMR spectroscopy. Colloids Surf. A: Physicochem. Eng. Asp. 2019, 571, 50–54. [Google Scholar] [CrossRef]

- Yu, X.; Zaumanis, M.; Santos, S.D.; Poulikakos, L.D. Rheological, microscopic, and chemical characterization of the rejuvenating effect on asphalt binders. Fuel 2014, 135, 162–171. [Google Scholar] [CrossRef]

- Yan, Z.; Meizhu, C.; Shaopeng, W.; Siqing, L.; Jingxiang, L. Investigation on physical properties and structure of rejuvenated asphalt with different waste oils. J. Wuhan Univ. Technol. (Transp. Sci. Eng.) 2017, 41, 104–108. [Google Scholar]

- Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering (JTG E20-2011); China Communications Press: Beijing, China, 2011.

- Li, P.; Ding, Z.; Zhang, Z.; Zhang, D. Comparative evaluation of laboratory and field ageing of asphalt binder using a non-linear differential model. Road Mater. Pavement Des. 2015, 17, 1–12. [Google Scholar] [CrossRef]

- Dedene, C.D. Investigation of Using Waste Engine Oil Blended with Reclaimed Asphalt Materials to Improve Pavement Recyclability. Master’s Thesis, Michigan Technological University, Houghton, MI, USA, 2011. Available online: http://pdfs.semanticschola r.org/a9b1/0407446f36641385b5cf040 e3ed2578329aa.pdf (accessed on 10 January 2019).

- Dominguez-Rosado, E.; Pichtel, J. Chemical characterization of fresh, used and weathered motor oil via gc/ms, nmr and ftir techniques. Indiana Acad. Sci. 2003, 112, 109–116. [Google Scholar]

- Zeng, M.; Pan, H.; Zhao, Y.; Tian, W. Evaluation of asphalt binder containing castor oil-based bioasphalt using conventional tests. Constr. Build. Mater. 2016, 126, 537–543. [Google Scholar] [CrossRef]

- Li, H.; Dong, B.; Zhao, D.; Guo, P.; Zhang, J. Physical, Rheological and Stability Properties of Desulfurized Rubber Asphalt and Crumb Rubber Asphalt. Arab. J. Sci. Eng. 2019, 44, 5043–5056. [Google Scholar] [CrossRef]

- Cong, P.; Xun, P.; Xing, M.; Chen, S. Investigation of asphalt binder containing various crumb rubbers and asphalts. Constr. Build. Mater. 2013, 40, 632–641. [Google Scholar] [CrossRef]

- You, Z.; Goh, S.W.; Hao, P.; Huang, X. Laboratory evaluation on the high temperature rheological properties of rubber asphalt: A preliminary study. Rev. Can. De Génie Civ. 2012, 39, 1125–1135. [Google Scholar]

| Categories | Penetration (25 °C)/0.1 mm | Softening Point/°C | Ductility (10 °C)/cm | Viscosity (135 °C)/mPa.s |

|---|---|---|---|---|

| VA | 64.8 | 51.4 | >100 | 752 |

| Aged 5 h | 51.9 | 52.0 | 26.0 | 816 |

| Aged 7 h | 48.6 | 53.2 | 17.1 | 886 |

| Aged 9 h | 45.1 | 54.9 | 15.8 | 981 |

| Aged 11 h | 43.0 | 55.3 | 13.7 | 1140 |

| Aged 13 h | 41.2 | 55.9 | 13.0 | 1190 |

| Aged 15 h | 39.0 | 56.2 | 12.3 | 1270 |

| Categories | Flash Point/°C | Viscosity/Pa·s | Torque/% | Acid Value/mgKOH/g |

|---|---|---|---|---|

| WEO | 195 | 0.093 | 18.6 | 0.63 |

| WCO | 275 | 0.059 | 11.7 | 0.50 |

| Aging Time | 5–7 h | 7–11 h | 11–13 h | >13 h |

|---|---|---|---|---|

| penetration | 1–2% | 1–2% | 2–3% | 3–4% |

| softening point | 1–2% | 2–3% | 2–3% | 3–4% |

| ductility | 1–3% | 3–5% | 4–5% | >5% |

| viscosity | 1–3% | 3–4% | 3–4% | >4% |

| Aging Time | 5–7 h | 7–11 h | 11–13 h | >13 h |

|---|---|---|---|---|

| penetration | 1–2% | 1–2% | 2–3% | 3–4% |

| softening point | 1–2% | 1–2% | 1–2% | >2% |

| ductility | 1–3% | 1–3% | 3–4% | >4% |

| viscosity | 1–3% | 3–4% | 3–4% | 4–5% |

| Asphalt | VA | Aged Asphalt (7 h) | Rejuvenated Asphalt (3% WEO) | Rejuvenated Asphalt (2% WCO) |

|---|---|---|---|---|

| Saturates (%) | 5.68 | 4.25 | 5.93 | 6.22 |

| Aromatics (%) | 61.59 | 51.96 | 48.51 | 46.57 |

| Resins (%) | 20.01 | 26.33 | 29.19 | 31.57 |

| Asphaltenes (%) | 12.73 | 17.46 | 16.37 | 15.64 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Dong, B.; Wang, W.; Zhao, G.; Guo, P.; Ma, Q. Effect of Waste Engine Oil and Waste Cooking Oil on Performance Improvement of Aged Asphalt. Appl. Sci. 2019, 9, 1767. https://doi.org/10.3390/app9091767

Li H, Dong B, Wang W, Zhao G, Guo P, Ma Q. Effect of Waste Engine Oil and Waste Cooking Oil on Performance Improvement of Aged Asphalt. Applied Sciences. 2019; 9(9):1767. https://doi.org/10.3390/app9091767

Chicago/Turabian StyleLi, Haibin, Bo Dong, Wenjie Wang, Guijuan Zhao, Ping Guo, and Qingwei Ma. 2019. "Effect of Waste Engine Oil and Waste Cooking Oil on Performance Improvement of Aged Asphalt" Applied Sciences 9, no. 9: 1767. https://doi.org/10.3390/app9091767

APA StyleLi, H., Dong, B., Wang, W., Zhao, G., Guo, P., & Ma, Q. (2019). Effect of Waste Engine Oil and Waste Cooking Oil on Performance Improvement of Aged Asphalt. Applied Sciences, 9(9), 1767. https://doi.org/10.3390/app9091767