Low-Temperature Plasma Nitriding of Mini-/Micro-Tools and Parts by Table-Top System

Abstract

:Featured Application

Abstract

1. Introduction

2. Experimental Procedure

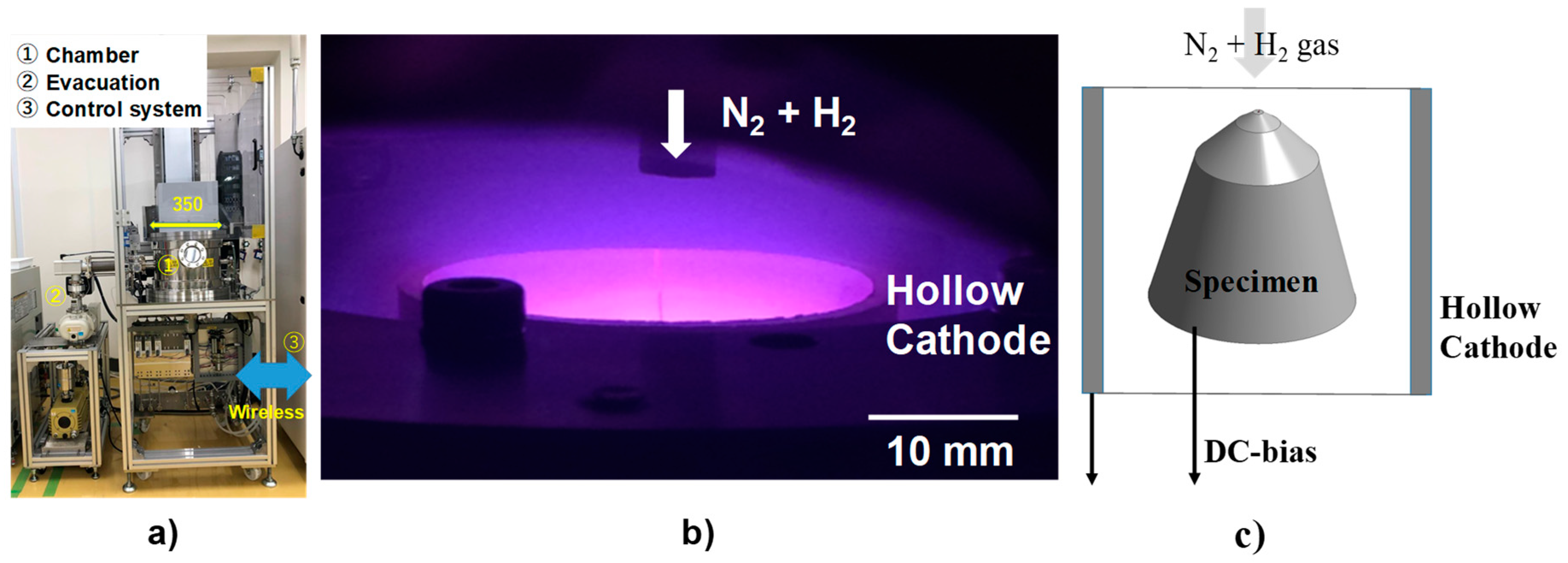

2.1. Down-Sized Plasma Nitriding System

2.2. Nitriding Conditions

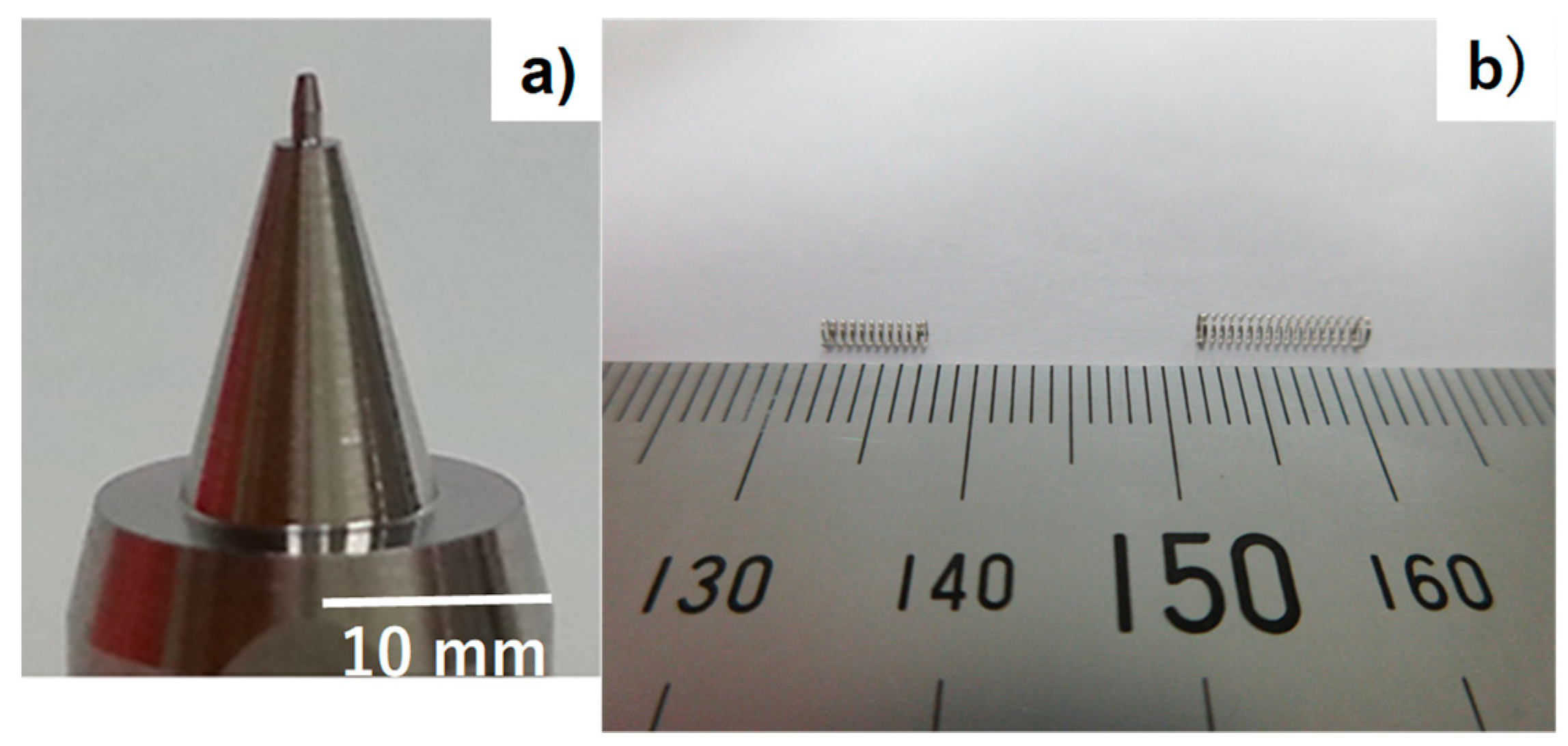

2.3. Specimens

2.4. Observation and Measurement

3. Results

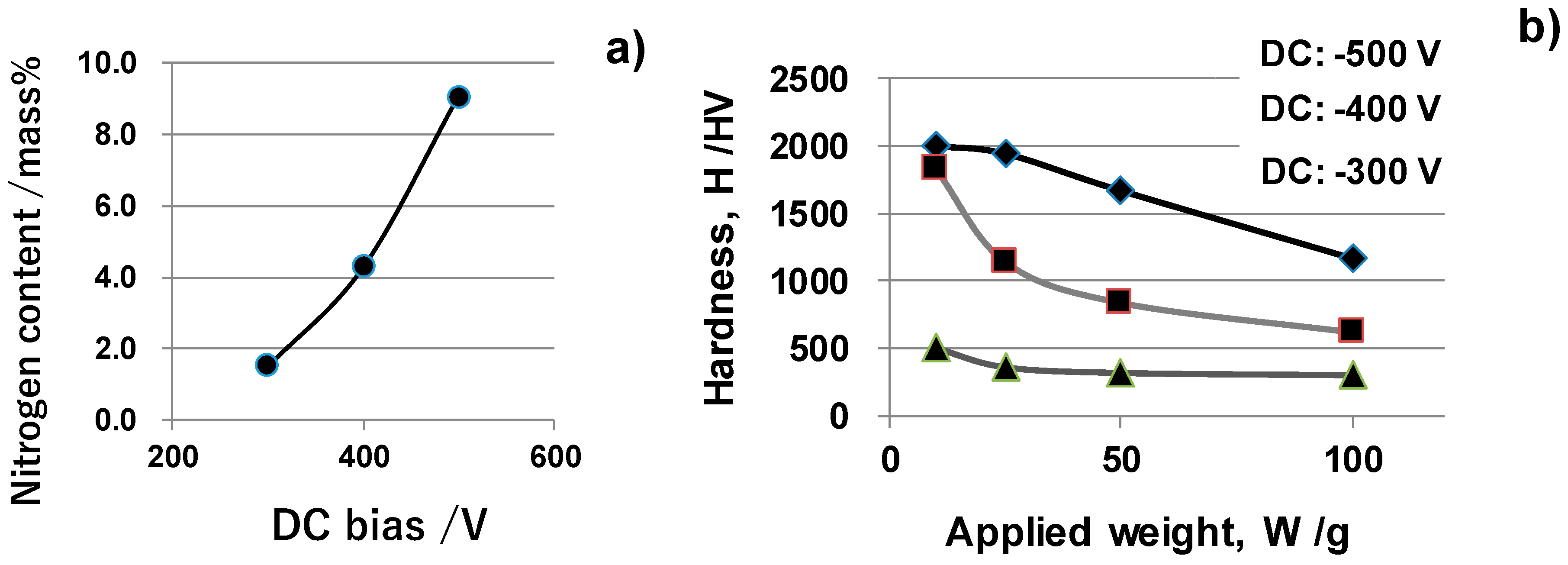

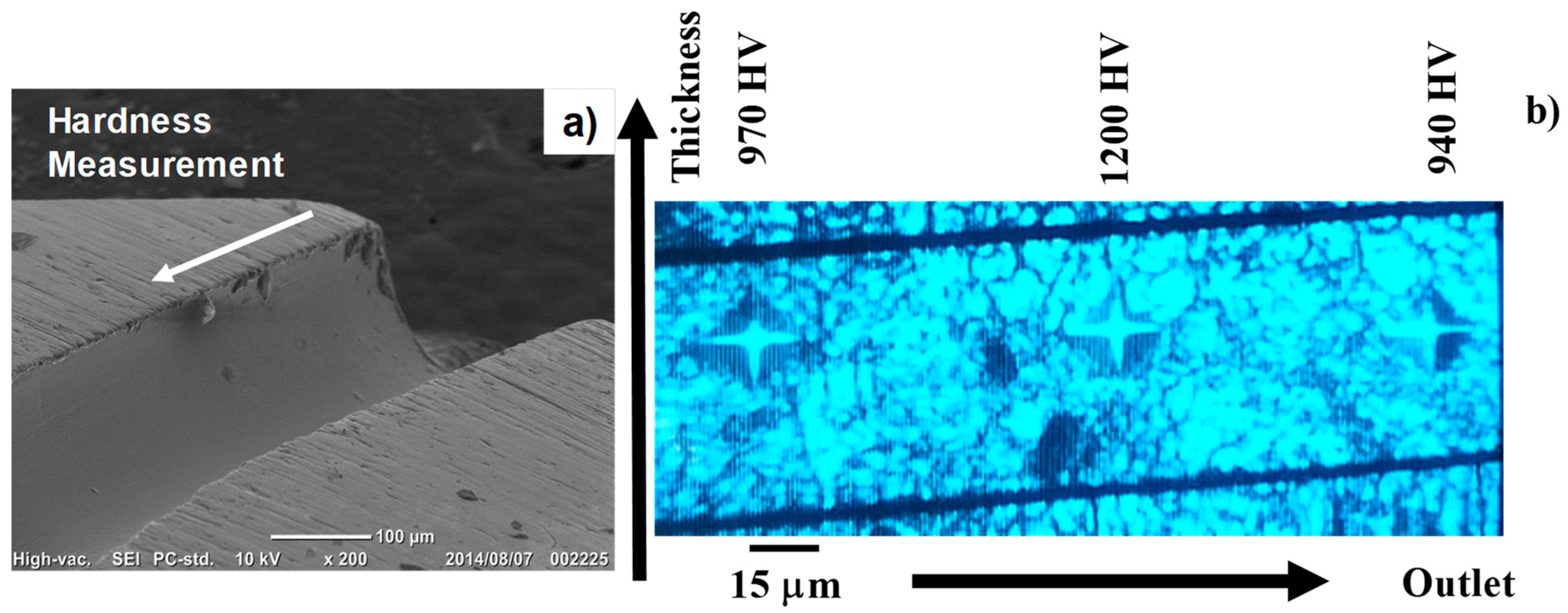

3.1. Nitriding Behavior of AISI316 Substrates

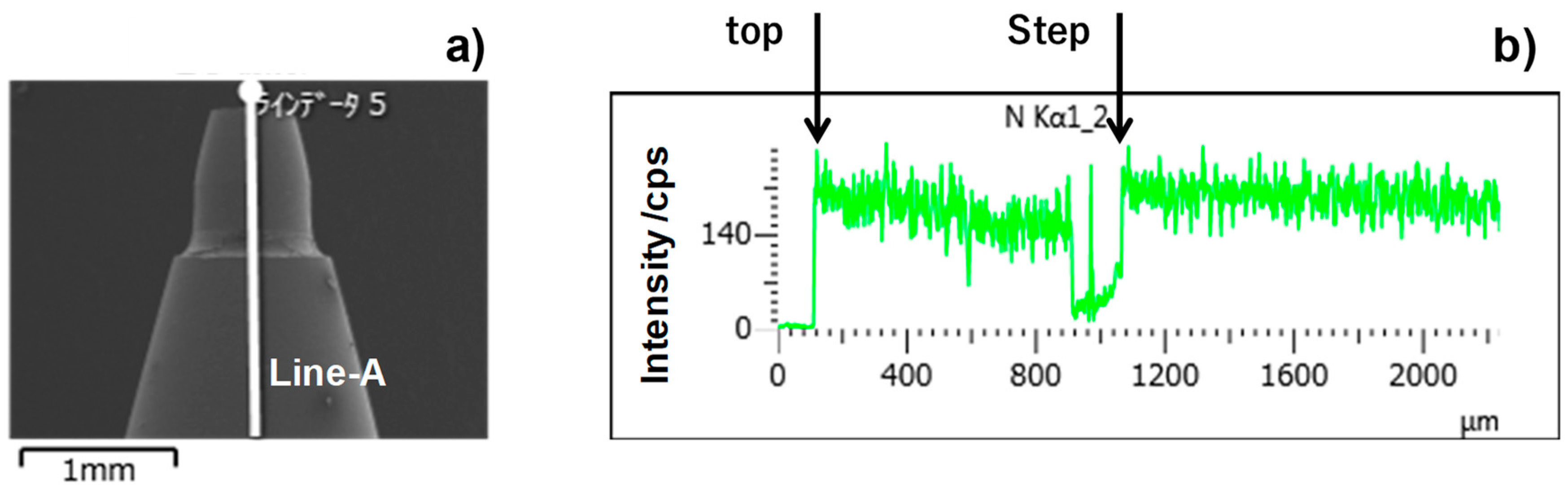

3.2. Nitriding of a Single Micro-Nozzle

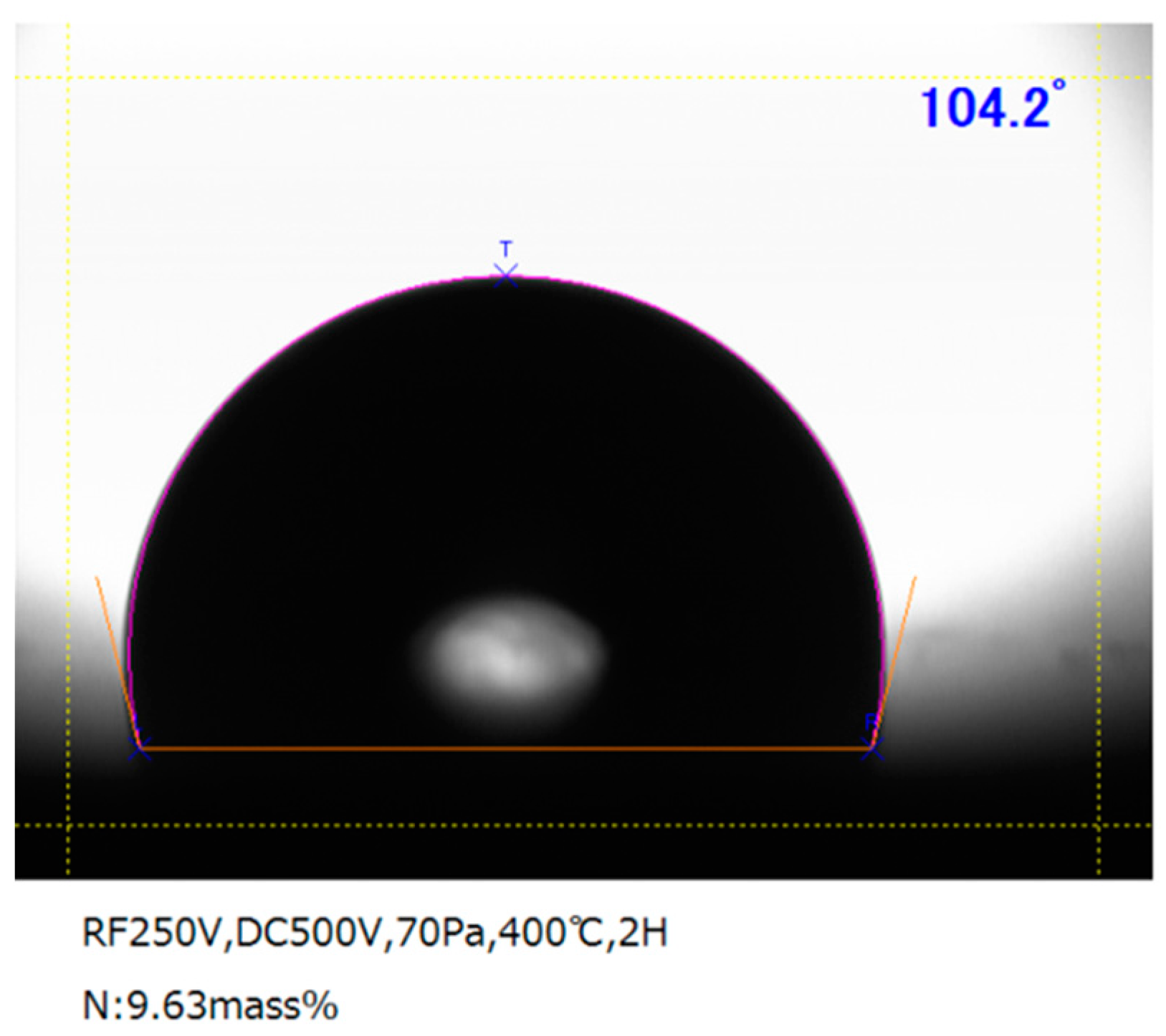

3.3. Wettability Control by Plasma Nitriding

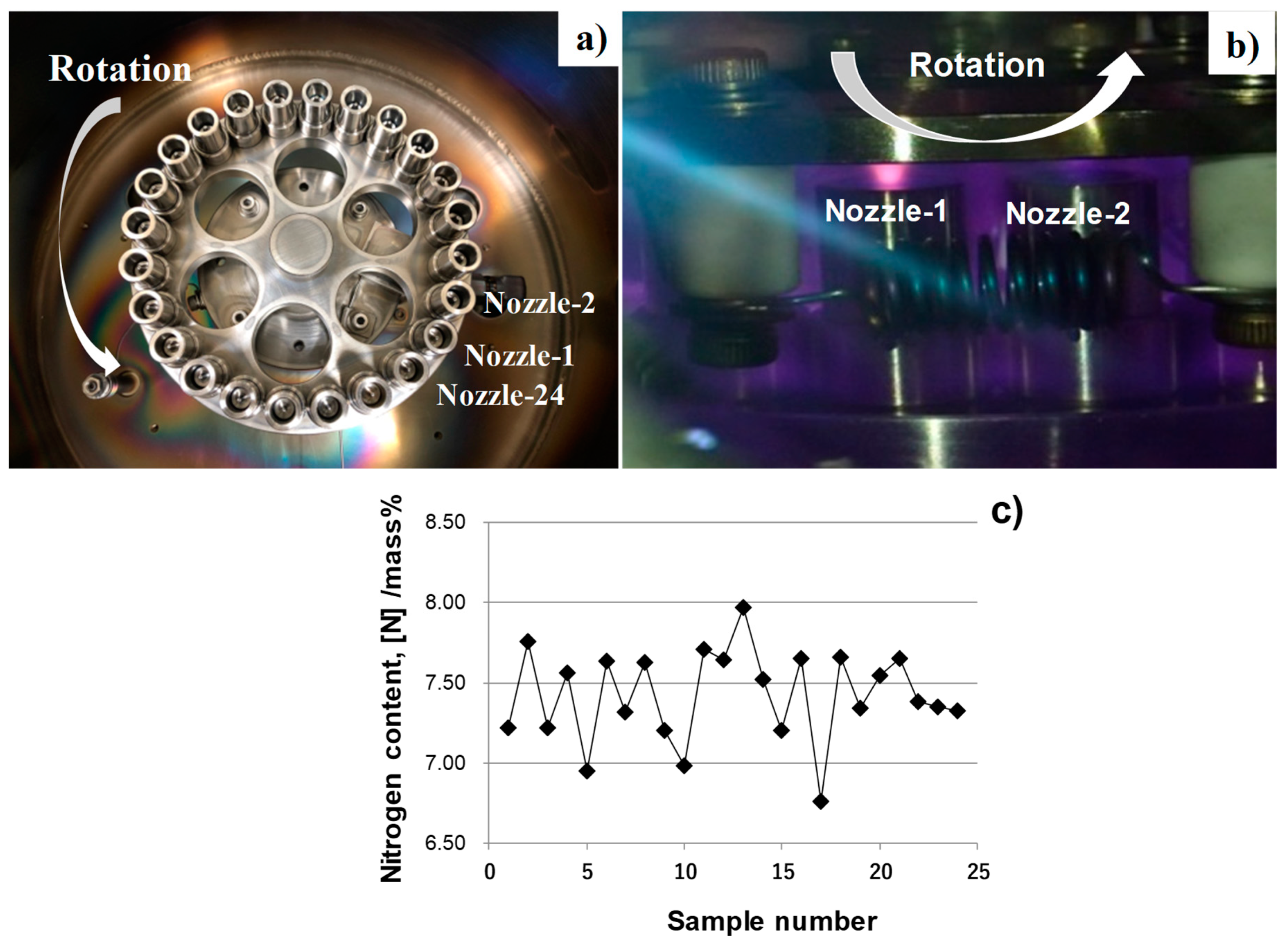

3.4. Simultaneous Nitriding of Micro-Nozzles

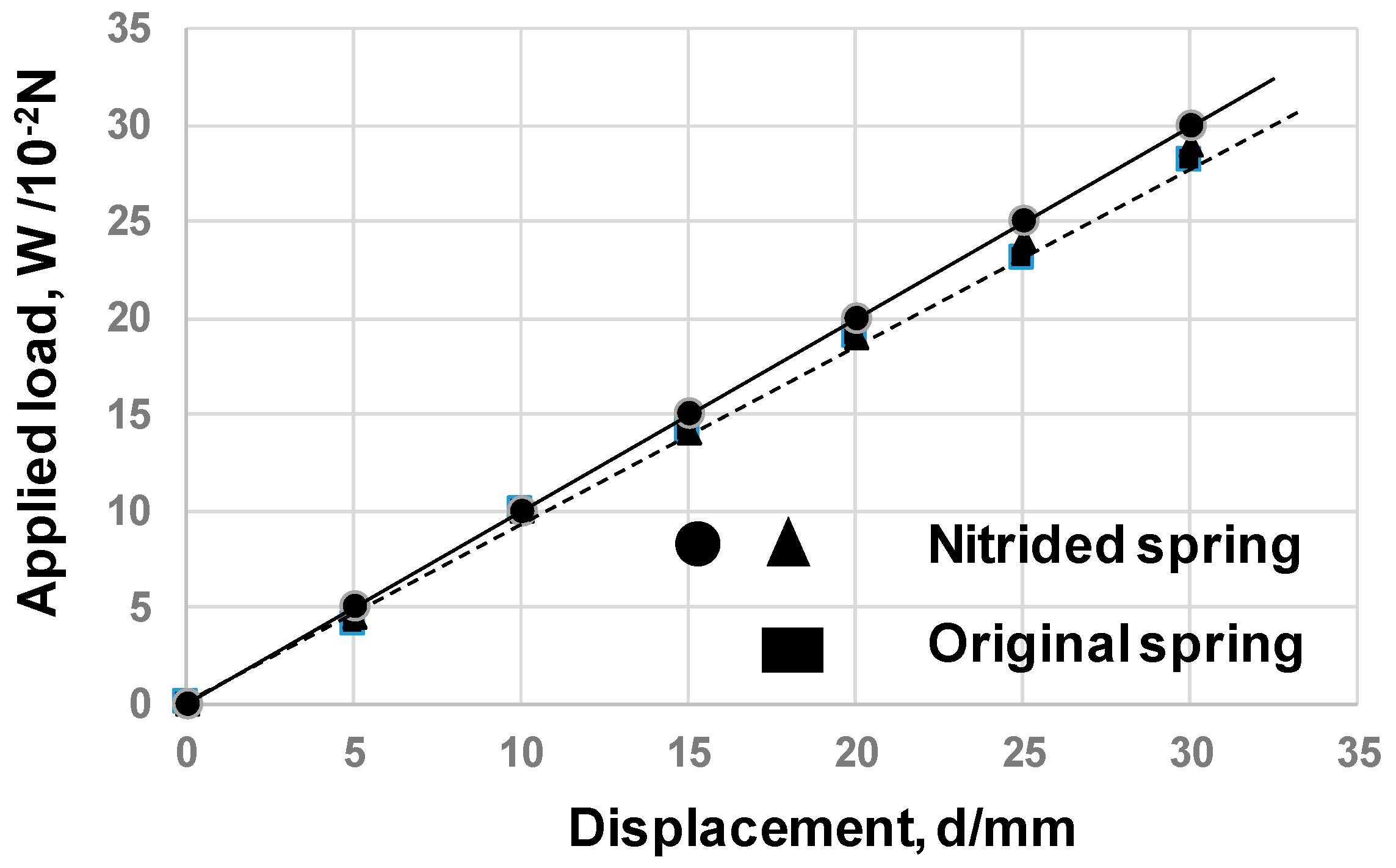

3.5. Simultaneous Nitriding of Micro-Springs

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ku, I.S.Y.; Reddyhoff, T.; Holmes, A.S.; Spikes, H.A. Wear of silicon surfaces in MEMS. Wear 2011, 271, 1050–1058. [Google Scholar] [CrossRef]

- Kamenik, R.; Pilc, J.; Varga, D.; Martincek, J.; Sadilek, M. Identification of tool wear intensity during miniature machining of austenitic steels and titanium. Proc. Eng. 2017, 192, 410–415. [Google Scholar] [CrossRef]

- Erdemir, C.D. Tribology of diamond-like carbon films: Recent progress and future prospects. J. Phys. 2006, 39, 311–327. [Google Scholar] [CrossRef]

- Tamagaki, H.; Haga, J.; Ito, H.; Umeda, A. A MF-AC plasma enhanced CVD technology for high rate deposition of DLC. In Proceedings of the 57th Society of Vacuum Coaters (SVC) Annual Technical Conference, Chicago, IL, USA, 3–8 May 2014; pp. 215–220. [Google Scholar]

- Dong, H. S-phase surface engineering of Fe-Cr, Co-Cr and Ni-Cr alloys. Int. Mater. Rev. 2011, 55, 65–98. [Google Scholar] [CrossRef]

- Farghali, A.; Aizawa, T. Phase transformation induced by high nitrogen content solid solution in the martensitic stainless steels. Mater. Trans. 2017, 58, 697–700. [Google Scholar] [CrossRef]

- Lu, S.; Zhao, X.; Wang, S.; Li, J.; Wei, W.; Hu, J. Performance enhancement by plasma nitriding at low gas pressure for 304 austenitic stainless steel. Vacuum 2017, 145, 334–339. [Google Scholar] [CrossRef]

- Farghali, A.; Aizawa, T. Nitrogen super-saturation process in the AISI420 martensitic stainless steels by low temperature plasma nitriding. ISIJ Int. 2018, 58, 401–407. [Google Scholar] [CrossRef]

- Aizawa, T. Low Temperature Plasma Nitriding of Austenitic Stainless Steels. In Stainless Steels and Alloys; IntechOpen: London, UK, 2019; Chapter 3; pp. 31–50. [Google Scholar]

- Ferreira, L.M.; Brunatto, S.F.; Cardoso, R.P. Martensitic stainless steels low-temperature nitriding dependence on substrate composition. Mater. Res. 2015, 18, 622–627. [Google Scholar] [CrossRef]

- Aizawa, T.; Yoshihara, S.-I. Microtexturing into AISI420 dies for fine piercing of micropatterns into metallic sheets. J. JSTP 2019, 60, 53–57. [Google Scholar] [CrossRef]

- Aizawa, T.; Wasa, K. Plasma nitriding of inner surfaces in the mini- and micro-nozzles for joining. In Proceedings of the 11th International Conference on Multi-Material Micro Manufacture and 10th International Workshop on Microfactories (4M/IWMF2016), Kgs. Lyngby, Denmark, 13–15 September 2016; pp. 145–148. [Google Scholar]

- Aizawa, T.; Wasa, K. Low temperature plasma nitriding of inner surfaces in the stainless steel mini-/micro-pipes and nozzles for industries. Micromachines 2017, 8, 157. [Google Scholar] [CrossRef]

- Aizawa, T.; Sugita, Y. Distributed plasma nitriding systems for surface treatment of miniature functional products. In Proceedings of the 9th 4M/ICOMM, Milan, Italy, 31 March–2 April 2015; pp. 449–453. [Google Scholar]

- Aizawa, T.; Morita, H.; Wasa, K. Low temperature plasma nitriding of mini-/micro-tools and parts. In Proceedings of the 2nd WCMNM, Portoroz, Slovenia, 18–20 September 2018; pp. 207–210. [Google Scholar]

- Smith, R.L.; Sandland, G.E. An accurate method of determining the hardness of metals with particular reference to those of a high degree of hardness. Proc. Inst. Mech. Eng. 1992, 102, 623–641. [Google Scholar] [CrossRef]

- Donovan, R.P.; Yamamoto, T.; Periasamy, R. Particle deposition, adhesion and removal. MRS 1993, 315, 3–15. [Google Scholar] [CrossRef]

- Schoenbach, K.H. High-pressure hollow cathode discharges. Plasma Sources Sci. Technol. 1997, 6, 468–477. [Google Scholar] [CrossRef]

| Item | Parameters |

|---|---|

| RF-Voltage | 250 V |

| DC-bias | −300 V, −400 V, −500 V |

| Pressure | 70 Pa |

| Temperature | 673 K |

| Duration | 7.2 ks |

| Item | Microspring-1 | Microspring-2 |

|---|---|---|

| Wire diameter (d) | 0.2 | 0.15 |

| Coil diameter (D) | 1.7 | 1.5 |

| Length (L) | 5.7 | 9.5 |

| Number of turns (N) | 10 | 16 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aizawa, T.; Morita, H.; Wasa, K. Low-Temperature Plasma Nitriding of Mini-/Micro-Tools and Parts by Table-Top System. Appl. Sci. 2019, 9, 1667. https://doi.org/10.3390/app9081667

Aizawa T, Morita H, Wasa K. Low-Temperature Plasma Nitriding of Mini-/Micro-Tools and Parts by Table-Top System. Applied Sciences. 2019; 9(8):1667. https://doi.org/10.3390/app9081667

Chicago/Turabian StyleAizawa, Tatsuhiko, Hiroshi Morita, and Kenji Wasa. 2019. "Low-Temperature Plasma Nitriding of Mini-/Micro-Tools and Parts by Table-Top System" Applied Sciences 9, no. 8: 1667. https://doi.org/10.3390/app9081667

APA StyleAizawa, T., Morita, H., & Wasa, K. (2019). Low-Temperature Plasma Nitriding of Mini-/Micro-Tools and Parts by Table-Top System. Applied Sciences, 9(8), 1667. https://doi.org/10.3390/app9081667