RCS and Aero Surfaces Control Allocation Research on RLV’s Re-Entry Phase

Abstract

1. Introduction

2. Mathematical Model

2.1. Nonlinear Model of RCS and AS

2.2. Dynamic Model of RLV

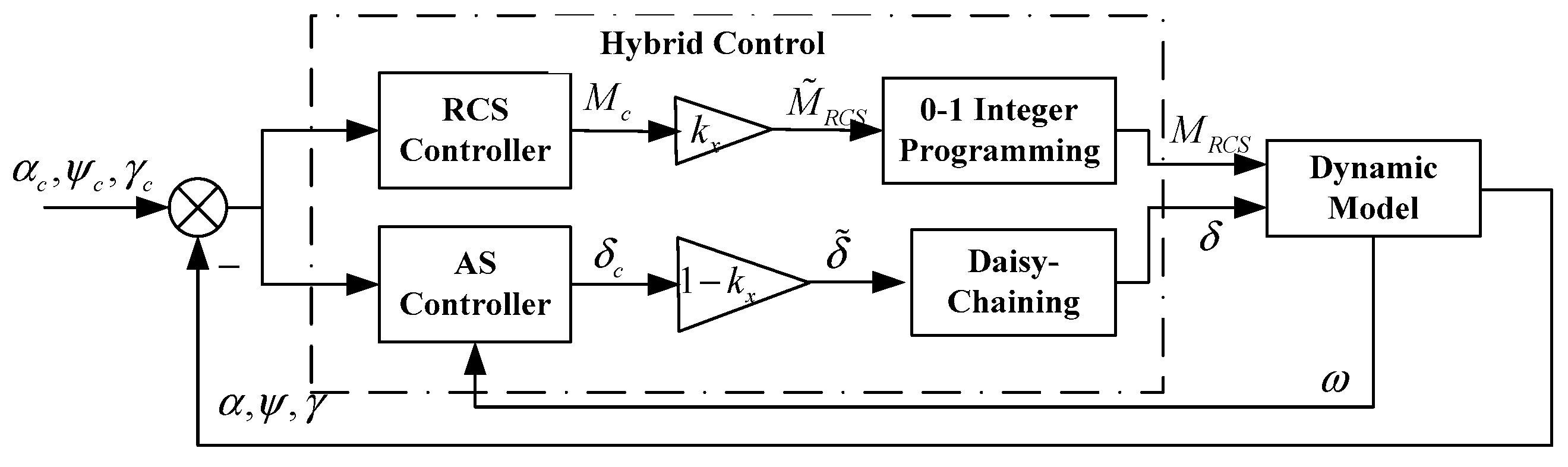

3. Control Allocation Scheme Design

3.1. Proportional Allocation

3.2. Daisy-Chaining Allocation

3.3. Multi-Object-Based Optimal Allocation

3.4. Stability Analysis

4. Simulation Results

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Anoop, P.R.; Laila, B.M.; Ashima, C.R. Robust adaptive backstepping control of RLV’s in descent phase using continuous switching functions. In Proceedings of the 2015 International Conference on Control Communication & Computing India (ICCC), Trivandrum, India, 19–21 November 2015; pp. 131–136. [Google Scholar]

- Jia, J.; Qin, Y.; Xu, J. Re-entry attitude two-loop SMC control and rudders-nozzles blending selection allocation of RLV. Aerosp. Shanghai 2009, 26, 27–30, 34. [Google Scholar]

- Hu, Q.; Niu, G.; Wang, C. Spacecraft attitude fault-tolerant control based on iterative learning observer and control allocation. Aerosp. Sci. Technol. 2018, 75, 245–253. [Google Scholar] [CrossRef]

- Qiao, J.; Liu, Z.; Li, W. Anti-disturbance attitude control of combined spacecraft with enhanced control allocation scheme. Chin. J. Aeronaut. 2018, 31, 1741–1751. [Google Scholar] [CrossRef]

- Li, Q. Performance Analysis and Autopilot Design for a Missile with Blended Lateral Thrust and Aerodynamic Force. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2014. [Google Scholar]

- Kim, S.; Cho, D.; Kim, H.J. Force and moment blending control for agile dual missiles. In Proceedings of the 2013 American Control Conference, Washington, DC, USA, 17–19 June 2013; pp. 5574–5580. [Google Scholar]

- Xing, L.; Zhang, K.; Chen, W.; Yin, X. Optimal control and output feedback considerations for missile with blended aero-fin and lateral impulsive thrust. Chin. J. Aeronaut. 2010, 23, 401–408. [Google Scholar]

- Buffington, J.M.; Enns, D.F.; Teel, A.R. Control allocation and zero dynamics. J. Guid. Control Dyn. 1998, 21, 458–464. [Google Scholar] [CrossRef]

- Mukherjee, B.K.; Giri, D.K.; Sinha, M. Lorentz-Force-Based Fuzzy Proportional-Integral-Derivative Attitude Control for Earth-Pointing Satellites. J. Spacecr. Rocket. 2017, 54, 1153–1160. [Google Scholar] [CrossRef]

- Shao, X.; Ren, Z.; Wang, R. New control allocation algorithm for three dimension problem based on genetic algorithm. In Proceedings of the 33rd Chinese Control Conference, Nanjing, China, 28–30 July 2014; pp. 3766–3770. [Google Scholar]

- Cheng, J.; Wang, L.; Jiang, Q.; Cao, Z.; Xiong, Y. Cuckoo search algorithm with dynamic feedback information. J. Future Gener. Comput. Syst. 2018, 89, 317–334. [Google Scholar] [CrossRef]

- Anoop, P.R.; Laila, B.M. Robustness study for longitudinal and lateral dynamics of RLV with adaptive backstepping controller. Int. J. Eng. Tech. Res. 2015, 4, 157–161. [Google Scholar] [CrossRef]

- Johansen, T.A.; Fossen, T.I. Control allocation—A survey. Automatica 2013, 49, 1087–1103. [Google Scholar] [CrossRef]

- Krovel, T.D. Optimal Tuning of PWPF Modulator for Attitude Control. Ph.D. Thesis, Norway Norwegian University of Science and Technology, Trondheim, Norway, 2005. [Google Scholar]

- Zamani, I.; Sadati, N.; Zarif, M. On the stability issues for fuzzy large-scale systems. Fuzzy Sets Syst. 2011, 174, 31–49. [Google Scholar] [CrossRef]

- Liu, C.; Tang, S.; Xu, Z. Research on hybrid control for reusable launch vehicle. Comput. Simul. 2013, 30, 76–80. [Google Scholar]

- Mu, R.; Zhang, X. Control allocation design of reaction control system for reusable launch vehicle. Abstr. Appl. Anal. 2014, 2014, 541627. [Google Scholar] [CrossRef]

- Caiti, A.; Corato, F.D.; Fenucci, D.; Grechi, S.; Novi, M.; Pacini, F.; Paoli, G. The project V-fides: A new generation AUV for deep underwater exploration, operation and monitoring. In Proceedings of the 2014 Oceans-St. John’s, St. John’s, NL, Canada, 14–19 September 2014; pp. 1–7. [Google Scholar]

- Cheng, X.; Xin, R.; Wu, L.; Guo, Z. RCS and Aerodynamic Parameters Identification of The Reentry Spacecraft from Chang’E Flight Test. In Proceedings of the 21st AIAA International Space Planes and Hypersonics Technologies Conference, Xiamen, China, 6–9 March 2017. [Google Scholar]

- He, C.; Wang, X.; Chang, Y.; Zhang, Z. Research on Dynamic Allocation Strategy for Multi-Effectors Compound Control. Navig. Position. Timing 2018, 5, 54–59. [Google Scholar]

| Index | Simulation Comparison |

|---|---|

| control error (or allocation error) 1 | case 3 < case 2 < case 1 |

| switching smoothness | case 3 is the best, then is case 1, and case 2 is the worst |

| RCS fuel consumption | case 3 < case 1 < case 2 |

| deflection angles’ smoothness of AS | case 1 is the best, then is case 3, and case 2 is the worst |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mu, R.; Zhang, X.; Wu, P.; Chen, J. RCS and Aero Surfaces Control Allocation Research on RLV’s Re-Entry Phase. Appl. Sci. 2019, 9, 1617. https://doi.org/10.3390/app9081617

Mu R, Zhang X, Wu P, Chen J. RCS and Aero Surfaces Control Allocation Research on RLV’s Re-Entry Phase. Applied Sciences. 2019; 9(8):1617. https://doi.org/10.3390/app9081617

Chicago/Turabian StyleMu, Rongjun, Xin Zhang, Peng Wu, and Jiaye Chen. 2019. "RCS and Aero Surfaces Control Allocation Research on RLV’s Re-Entry Phase" Applied Sciences 9, no. 8: 1617. https://doi.org/10.3390/app9081617

APA StyleMu, R., Zhang, X., Wu, P., & Chen, J. (2019). RCS and Aero Surfaces Control Allocation Research on RLV’s Re-Entry Phase. Applied Sciences, 9(8), 1617. https://doi.org/10.3390/app9081617