Abstract

The overall objectives of this study were to determine the most appropriate additive for improving the physical properties and the medium- and high-temperature performances (mechanical performance) of asphalt binders. Three different types of modified binders were prepared: crumb rubber modifier (CRM), polypropylene (PP), and tafpack super (TPS), which had concentrations of 2%, 3%, 3.5%, and 4% by weight of asphalt binder, for each modifier. Their physical and rheological properties were evaluated by applying various tests such as ductility, rotational viscosity, toughness, and tenacity, as well as the dynamic shear rheometer (DSR) test. As a result, the physical properties of the modified bitumen binders were compared, as were the medium- and high-temperature performances (mechanical performance), which had temperatures of 58, 64, 70, 76, 82, and 88 °C, respectively. This was how the most appropriate modifier was determined. The results demonstrated that the asphalt binder properties significantly improved by utilizing CRM followed by PP and TPS modifiers. The increase in the rutting parameter (G*/sin(δ)) after asphalt modification indicated its excellent performance at both medium- and high-temperatures. Lastly, the CRM was determined as the most preferred additive because of its positive effect on the physical properties and enhancement of the medium- and high-temperature performance (mechanical performance).

1. Introduction

Asphalt is a smooth material consisting of more than a thousand chemical types and has vital significance for the transportation infrastructure [1]. Asphalt is used extensively as a binding in flexible pavement construction worldwide due to its excellent viscoelastic properties and superior service performance [2,3]. Due to asphalt’s temperature sensitivity, it changes in climatic conditions, reducing the quality of asphalt pavement, which causes different distresses, such as rutting at high temperatures and cracking at low temperatures [4]. When asphalt pavement is exposed to heavy traffic loads, its quality is considerably reduced [5]. The suitable modification of the asphalt binder must be perfect for promoting safe, reliable, and environment-friendly flexible pavement materials [6]. The physical properties and medium- and high-temperature performances (mechanical performance) can be enhanced by using asphalt modifiers [7,8]. Among various bitumen modifiers, crumb rubber modifier (CRM), tafpack super (TPS), and polypropylene (PP) have attracted enormous attention in the field of asphalt pavements [9,10].

Al-Hadidy et al. investigated the influence of accelerated ageing on the engineering properties of modified asphalt mixtures with polypropylene (PP). They concluded that the addition of polypropylene to asphalt concrete mixes enhanced its resistance to permanent deformation, fatigue, cracking, and ageing [11].

Khabaz and Khare conducted their experimental tests and simulations using styrene-butadiene rubber (SBR) and molecular dynamics (MD), respectively, to verify glass transmission and molecular mobility in modified asphalt. Their results pointed out that the volumetric features of the SBR modified asphalt were found to be insensitive to the presence of SBR additives. Further, the addition of SBR increased the aggregation of the asphaltene molecules. Likewise, the addition of SBR led to a decrease in the mobility of the asphalt particles constituent. The proposed outcomes show the potential for polymeric modifiers as enhancements to the dynamic mechanical features of asphalt, but not its volumetric properties [1].

The laboratory tests and the volume-temperature behavior of the asphalt systems in the simulation exhibited the same glass transition phenomenon. The glass transition temperature, room temperature density, and coefficient of volume thermal expansion of the virgin asphalt systems agreed with the experimental data when calculating the effect of the high cooling rate used in the simulation [1,12].

Ting et al. conducted a study on shear resistance properties of TPS and styrene-butadiene-styrene (SBS) modified bitumen binders and mixtures by measuring the laboratory creep data over a broad domain of the constant shear stresses and examining the permanent deformation of the porous asphalt mixtures for fixed compressive stress. They conducted a comparison between the shear strain rate and shear creep modulus of the TPS and SBS modified asphalt binders that concluded in a similar trend [9].

Bouraima et al. utilized different modifiers such as TPS, high-viscosity additive (HVA), road-science technology (RST), and SBS additives, summarizing that the conventional binders did not meet the requirements of a 60 °C dynamic viscosity with TPS and HVA modifiers. Besides, the SBS modified asphalt binder has better viscosity. Their results concluded that the SBS modifier is a suitable choice [10].

Barco et al. compared the performance of the crumb rubber modifier and the SBS modifier binders. The results showed that the crumb rubber modifier (CRM) contents have to be higher than that of the SBS to obtain the same performance. Additionally, the crumb rubber modifier (CRM) binders are more stable than the SBS modified asphalt in terms of modifier concentration. Furthermore, the CRM binders exhibited less water susceptibility and similar thermal and ageing susceptibility to SBS [13].

The crumb rubber types are different; their sources are extensive and their components are various, so their modified influence on the asphalt binders will not be the same [13]. CRM was utilized in the modification of asphalt binders to improve its rutting resistance properties by increasing the stiffness and ductility of the asphalt at high service temperatures [14,15]. It was also used to extend the fatigue life of asphalt through the thickening of asphalt film and accordingly decrease the asphalt ageing rate [16]. Moreover, the application of the crumb rubber modifier as an additive reduces the stiffness of the asphalt binder at low service temperatures, which are convenient for its low service temperature performance [17,18]. Because of these advantages, there is considerable attention regarding the utilization of tire rubber for modified asphalt binders, which could potentially enhance flexible pavement [18].

Using TPS to modify asphalt has broad applications. In recent years, it has been shown to improve the rutting resistance to permanent deformations [19]. TPS commonly holds the thermoplastics elastomer as an essential component, which is hard to melt in a bitumen binder. However, when combining the polymer implementation with asphalt, it is possible for a plasticizer to become soluble in the virgin bitumen, wherein it modifies it to the high viscous bitumen for a higher quality [9,19].

The polypropylene (PP) is interacted with virgin asphalt and enhance the asphalt performance characteristics, which are transported by changing the rheological properties of the modified asphalt. When the PP is introduced to the bitumen binder, the flow decreases with an increase in the modified binder concentration, which reflects the increase in the viscosity of the modified binder [3].

The objectives of this study were for the laboratory experiments to evaluate the physical properties and mechanical performance of the modified asphalt binders using CRM, TPS, and PP modifiers. Secondly, the comparison was conducted between the results to determine the most appropriate additive for enhancing the medium- and high-temperature performance and physical properties of the bitumen binders. To achieve these goals various tests such as ductility, rotational viscosity, toughness, and tenacity tests as well as a rheological test such as the dynamic shear rheometer (DSR) test were applied on the modified asphalt binders using CRM, PP, and TPS modifiers.

2. Materials and Methods

2.1. Materials

The modifiers used in this study were CRM, PP, and TPS. Their percentage concentrations were 2%, 3%, 3.5%, and 4%, respectively, by weight of the asphalt binder for each modifier. The virgin asphalt, CRM, PP, and TPS modifiers were obtained from Jiangsu Tiannuo Advanced Material Technology Co., Ltd./China.

2.1.1. Asphalt

The neat asphalt used in this study was an asphalt with a 60/70 penetration grade. Its physical properties are illustrated in Table 1.

Table 1.

Physical properties of the base asphalt.

2.1.2. Crumb Rubber Modifier

The tire rubber powder size used in this study was passed through a No. 80 sieve and retained on sieve No. 90. To guarantee the uniformity of the CRM maintained throughout the study, only one batch of crumb rubber used. The physical properties of a used crumb rubber modifier illustrated in Table 2.

Table 2.

Components and properties of crumb rubber modifier (CRM).

2.1.3. Tafpack Super

TPS is a bitumen modifier and takes the form of a pellet with a 2–3 mm diameter that makes it possible to modify the neat asphalt into a high viscosity. TPS holds the thermoplastics elastomer as an essential component and is commonly difficult to melt in a bitumen binder. However, when combining the polymer implementation with asphalt, it is possible for a plasticizer to become soluble in the virgin bitumen, wherein it modifies it to the high viscous bitumen for a higher quality [9]. The basic physical features of TPS modifier are illustrated in Table 3.

Table 3.

Physical properties of tafpack super (TPS).

2.1.4. Polypropylene

PP was used in the form of granules (pellets) and melted in the asphalt binder by heating and mixing with a high shear and propeller mixtures. The properties of the used polypropylene were illustrated in Table 4.

Table 4.

Physical properties of polypropylene (PP).

2.2. Methods

2.2.1. Sample Preparation

In this study, all modified asphalt samples were prepared using both the mechanical and high-shear mixers. Before the modification process, 1000 g of neat asphalt was heated to 175 °C and the viscosity of the original bitumen (135 °C) was checked; it was about 0.411 Pa. s [20]. The various mass concentrations of CRM, PP, and TPS had percentages of 2, 3, 3.5, and 4%, respectively, by weight of the asphalt binder. These were added progressively to the neat asphalt binder for 1 h. The mixing speed was 1600 rpm and was conducted with a propeller mixer. Then, the prepared bitumen was transferred to a high-speed mixer at a rate of 2500 RPM and with a constant temperature of 185 ± 5 °C for a duration of 2 h [13,21].

To prepare the sample for the ductility test, the modified asphalt was heated to 163 ± 5 °C while mixing and then poured in the mold assembly and placed on a brass plate. To prevent the material under test from sticking the surface of the plate and interior surfaces of the sides of the mold were coated by a mixture of equal parts of glycerin and dextrin. The plate assembly along with the sample was kept in a water bath for about 30–40 min. The temperature of the water bath was 25 °C for half an hour. The sample and mold assembly were removed from the water bath and the specimen was trimmed by levelling its surface using a hot knife. The mold assembly was kept in a water bath for 85 to 95 min according to American Society for Testing and Materials (ASTM D113) [9].

In the rotational viscosity test sample preparation, the modified asphalt was heated with continued stirring until a consistent binder temperature of 190 °C was achieved. Further, 10 g was then poured into the container. The actual test temperature was 135 °C and recorded with the corresponding viscosity measurement (ASTM D2170).

When preparing the DSR test sample, 0.6 g of the specimen was sandwiched between two plates with a diameter of 25 mm with a 1 mm gap.

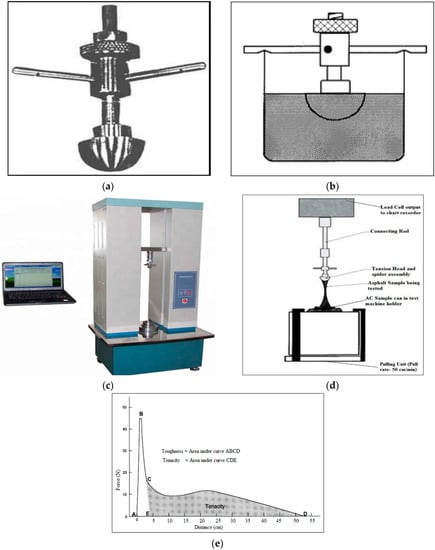

To conduct the toughness and tenacity test, the test specimens were heated to 150 °C for 90 min. Then, 90 mL was poured into the container with nominal inside dimensions of 55 mm in diameter and 35 mm in depth. Next, the mixture was carefully lowered into the tension head using the knurled screws until immersed in the sample to a depth of exactly 11 mm in the center of the specimen. The container and head were cooled at an ambient laboratory temperature for 60 min, then placed in a water bath that was maintained at 25 °C. After 60 min, the specimen was removed from the water bath and immediately placed in the testing machine in which all charts, gears, and other parts were prepared and calibrated [4]. Figure 1 illustrates the toughness and tenacity experimental setup and test instruments.

Figure 1.

Apparatus for the toughness and tenacity test: (a) Tension head and spider; (b) proper position of tension head in asphalt sample; (c) testing machine; (d) asphalt sample under pulling force; and (e) chart for calculating toughness and tenacity.

2.2.2. Testing Procedures

To evaluate and compare the changes in the physical and rheological properties of CRM-, PP-, and TPS-modified asphalt samples with the corresponding parameters of the unmodified asphalt binders to determine the most appropriate additive, the conventional ductility, rotational viscosity (RV), and the dynamic shear rheometer (DSR) tests were performed following the ASTM specifications. At least three samples were measured for each type of modified bitumen; the average was considered the result.

A Brookfield rotational viscometer apparatus was used to measure the binder viscosity at high temperatures ranging from 60–200 °C. The test was also conducted to determine the flow features of modified asphalt and assess workability parameters [22]. This test procedure is used to measure the rotational viscosity of the modified asphalt binders at an elevated temperature of 135 °C. The viscometer spindle and rotor were inserted in the hot binder sample near the edge of the can but were no more profound than the immersion depth mark on the shaft without plugging the vent hole. The rotor was allowed to acclimate to the temperature of the binder for approximately 1 min. The torque on the moving spindle in a sample of heated modified asphalt binder was used to measure the relative resistance to rotation. The torque and speed were used to determine viscosity in centipoises.

The ductility test was applied to measure the tensile characteristics of the modified and unmodified asphalt materials. The ductility was measured by the distance in centimeters to which the standard specimen elongated before breaking. This occurs when a sample of the materials is pulled at a specified speed and temperature. After the sample preparation, the sides of the mold were removed and the clips were carefully hooked onto the testing machine without causing any initial strain. The pointer was adjusted to zero. The testing machine was then operated and the clips were pulled horizontally at a speed of 50 mm per minute. While the test is being done, the specimen both above and below by at least 25 mm was covered with water in the tank of the testing machine, where the temperature was maintained at 25 °C continuously within ±0.5 °C [9].

This method describes the process for determining the toughness and tenacity of modified asphalt binders by using several apparatuses such as container-metal, which is cylindrical in shape, has a flat bottom, and a nominal capacity of 90 mL and nominal inside dimensions of 55 mm in diameter, 35 mm in depth. Tension Head-polished metal has a hemispherical shape like a spider. The testing machine capable of the uniform movement of 50 cm/min had a minimum load capacity of 0.5 kN, sensitive to 0.005 kN. Moreover, a computer was used to automatically measure the three separate areas under the stress-strain curve to determine toughness, tenacity, and cohesiveness. The testing machine was operated to pull the tension head vertically at a speed of 50 cm/minute for the distance of 75 cm. The extension continued until the asphalt column broke, the curve reached zero force, it stabilized at a constant force close to zero, or until the machine’s extension limit was reached [23].

A DSR test was performed to determine an asphalt binder’s resistance to permanent deformation (rutting) at medium- and high-temperatures by measuring the rutting parameter (G*/sin(δ)), phase angle (δ), and complex shear modulus (G*) of the modified and unmodified asphalt binders. The temperature corresponding to the minimum amount of G*/sin(δ) is known as the failure temperature and is predominantly used to determine the performance grade (PG) of asphalt [24]. The rutting parameter (G*/sin(δ)), phase angle (δ), and complex shear modulus (G*) for the modified and unmodified binders were measured at temperatures of 58, 64, 70, 76, 82, and 88 °C, respectively, and had a constant loading frequency of 10 rad/s (1.59 Hz).

3. Results and Discussion

3.1. Ductility

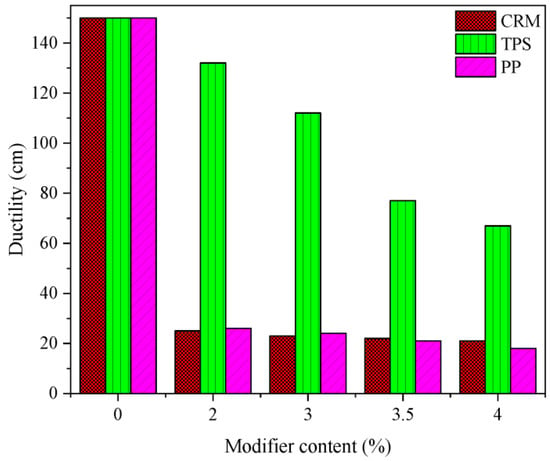

The ductility test was conducted at 25 °C to investigate the tensile characteristics of the modified and unmodified asphalt binders. The results are illustrated in Figure 2 and demonstrate that the ductility of the base asphalt appears to decrease as the modifier content increases dramatically. The ductility value of base asphalt was 150 cm, which was further reduced to 21 cm by the addition of 4% CRM, 18 cm by the addition of 4% PP, and 67 cm by the addition of 4% TPS. The percentage decrease in ductility of the base asphalt value concerning CRM, PP, and TPS were 86%, 88%, and 55%, respectively. These significant reductions in ductility indicate a great loss in the flexibility of the base asphalt occurred by the addition of CRM, PP, and TPS modifiers with a concentration of 2–4% by the weight of each asphalt binder’s modifier. It is observed from the results that the TPS modifier has a high ductility, which means it is more flexible. It is important to note that TPS behaves differently from both CRM and PP, as all concentrations of TPS hold thermoplastics’ elastomer as an essential component, which are commonly hard to melt in bitumen binder. Nevertheless, it was possible for a plasticizer to soluble in virgin asphalt and modified to highly viscous bitumen of a high-quality.

Figure 2.

Effect of modifier content on ductility.

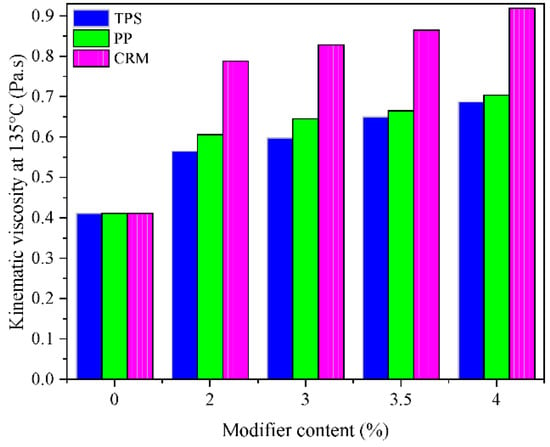

3.2. Kinematic Viscosity

The RV test results showed that the asphalt binder viscosity increases almost linearly with the increasing of CRM, PP, and TPS contents. Figure 3 explains that the viscosity values acquired from the CRM-modified asphalt binders were higher than those values obtained from the unmodified asphalt binder, TPS- and PP-modified bitumen binders of 124%, 34%, and 31%, respectively, and with a concentration 4% of each modifier. The influence of CRM, PP, and TPS modifiers on the asphalt binder viscosity demonstrated that the addition of these modifiers led to an increase in the kinematic viscosity of the asphalt binder. Our results demonstrated that the kinematic viscosity increased from 0.411 Pa. s (base asphalt) to 0.919, 0.703, and 0.687 Pa. s by adding 4% of the CRM, PP, and TPS modifiers, respectively. Further, our results noted that the increment in viscosity with the addition of 4% CRM is more than two times the base asphalt value. These results indicate that CRM, PP, and TPS are extremely useful when trying to improve the viscosity property of an asphalt binder. A higher viscosity is required to improve the rutting resistance and fatigue/reflection cracking resistance in flexible pavement. When comparing between the viscosity results of the modifiers, CRM has a higher viscosity property than those of both PP- and TPS-modified binders. Hence, CRM is the best modifier to improve the viscosity property of asphalt binders, followed by PP and TPS. As a result, CRM is the most appropriate additive for enhancing the rutting resistance and fatigue/reflection cracking resistance in flexible pavement, followed by PP and TPS modifiers.

Figure 3.

Effect of modifier content on viscosity.

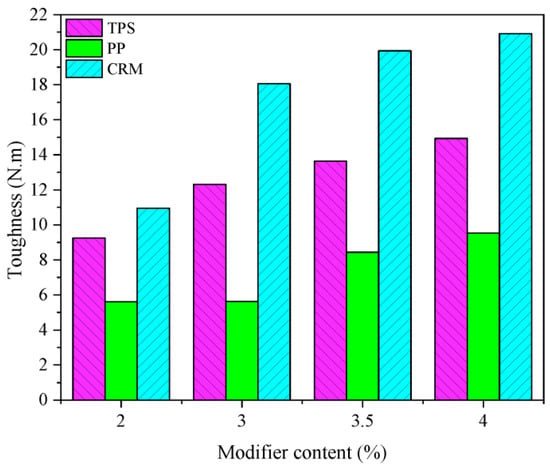

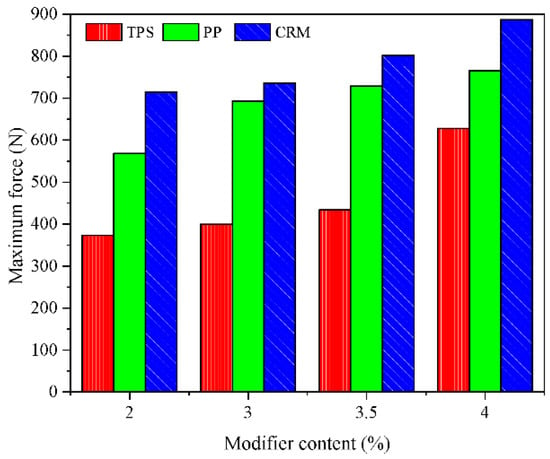

3.3. Toughness and Tenacity

The effect of CRM, PP, and TPS contents on toughness and the maximum force of asphalt binders are illustrated in Figure 4 and Figure 5, respectively. Figure 4 shows that toughness is increased linearly with an increase in modifier content. CRM has the highest toughness, followed by the TPS and PP modifiers. Thus, the capability of the CRM-modified binders to resist the permanent deformation is better than the TPS- and PP-modified binders. Moreover, our results indicate that CRM has a higher dissipated energy during the fracturing process. Thus, the higher the dissipated energy in the fracture, the better the asphalt mixture quality is. Concretely, CRM is the best modifier for enhancing the mechanical performance than both the TPS and PP modifiers.

Figure 4.

Effect of modifier content on toughness.

Figure 5.

Effect of modifier content on max force.

Figure 5 shows how the maximum force was increased linearly with the rise of CRM, PP, and TPS concentrations. It is observed that the addition of CRM yielded a better maximum force than PP and TPS modifiers. Hence, it can be deduced that CRM has a more significant force during the fracturing process. Tenacity has been considered as an essential factor for performance evaluation of modified asphalt. Therefore, Table 5 illustrates the tenacity of the modifiers. Therein, it is observed that CRM has small values in the tenacity property and is thus the best one in the performance evaluation, followed by PP and TPS.

Table 5.

Tenacity values of the modifiers.

3.4. Dynamic Shear Rheometer

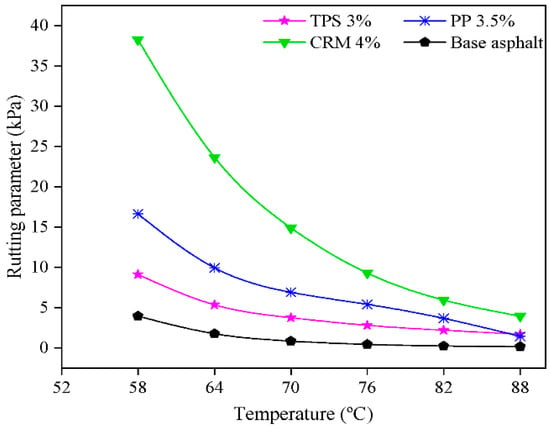

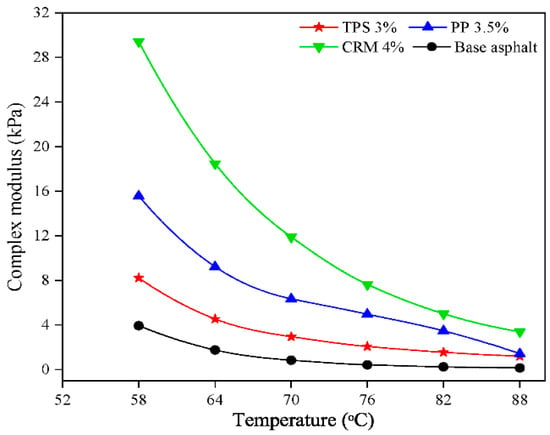

3.4.1. Rutting Parameter and Complex Shear Modulus

Figure 6 and Figure 7 show the obtained results of the DSR experiment. The figures display the rutting parameter (G*/sin(δ)) and complex shear modulus (G*), respectively. To understand the behavior of each modifier, the optimum content for each modifier was selected (e.g., TPS 3%, PP 3.5%, and CRM 4%). These concentrations represented the ideal percentages to improve the rutting resistance property as well as the medium- and high-temperature properties of the modified bituminous binders. Figure 6 shows that the G*/sin(δ) decreased when the temperature increased. Furthermore, the values obtained from the CRM-modified binder was higher than those of the PP- and TPS-modified binders. The increase in G*/sin(δ) increased the exact grade temperature of the asphalt binder. Thus, the PG-temperature grade of the modified asphalt roe significantly when CRM content increased, ranging from PG58-xx to PG88-xx for the binders with modifier concentrations ranged from 2% to 4%. The PG grade achieved by the PP-modified binder ranged from PG80-xx at 4% PP. Yet the PG grade obtained by the TPS-modified binder was not significant and ranged from PG73-xx for all concentrations.

Figure 6.

G*/sin(δ); temperature curves of modified and unmodified asphalt binders.

Figure 7.

G*; temperature curves of modified and unmodified asphalt binders.

According to G*/sin(δ) values, the CRM-modified asphalt binders have a higher resistance to permanent deformations (rutting) than their PP and TPS counterparts. Thus, CRM is the most appropriate additive for enhancing medium and high-temperature performance properties (i.e., mechanical performance).

It can be noted that the addition of CRM, PP, and TPS increased the G*. With respect to the base asphalt, the increase in the complex shear modulus (G*) in each modified binder indicated the degree of change in the structures and compositions of bitumen, which allowed for the modifiers to influence the mechanical properties of the modified bitumen. The G* values decreased with the temperature increased as illustrated in Figure 7. The results demonstrated that the G* value increased when TPS concentration increased by 3% and then decreased. Meanwhile, the G* increased when PP concentration increased by 3.5% and then reduced. Therefore, the 3% and 3.5% represent the ideal percentages of the TPS and PP modifiers to enhance the medium- and high-temperature performance. The G* value increased with CRM concentration and increased for all CRM contents from 2 to 4%. Note that Figure 6 and Figure 7 are plotted from these ideal percentages.

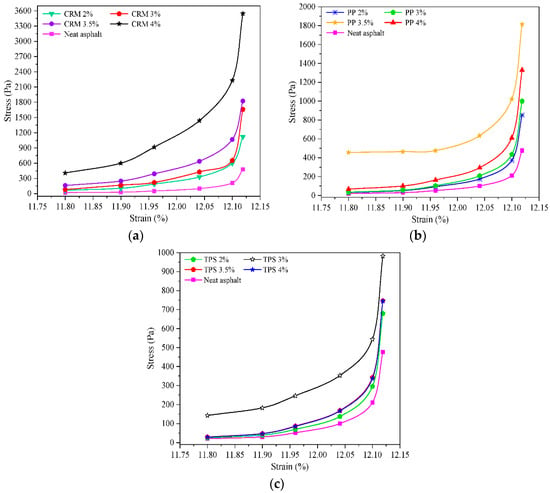

3.4.2. Strain Sweep Test

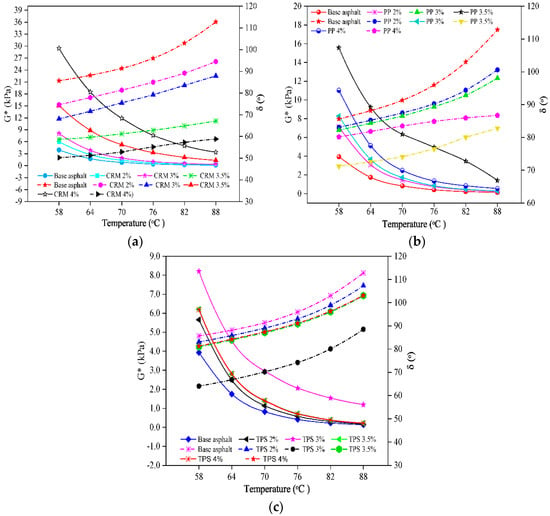

The DSR test stress-strain control mode at medium- and high temperatures ranging from 58 to 88 °C were conducted on the modified and unmodified bitumen binders. The stress-strain relationship curves of unmodified and modified bitumen at medium- and high-temperatures is illustrated in Figure 8a–c. The results show that the CRM has a more extensive linear viscoelasticity areas than PP- and TPS-modified binders.

Figure 8.

The stress-strain relationship at medium- and high-temperatures: (a) CRM; (b) PP; and (c) TPS.

Figure 8a–c shows that the stress-strain relationship of the modified bitumen binders demonstrates a significant difference. The relationship increased with the addition of CRM, PP, and TPS modifiers. Therefore, the dosage of the additive has vital importance in medium- and high-temperature properties.

The elevated-temperature features (stress) were increased when CRM content increased for all concentrations. However, in the case of PP and TPS, the properties increased at 2%, 3%, and 3.5%, respectively, in the PP contents, and then decreased considerably at 4% PP. Then, the properties increased at concentrations 2% and 3% of TPS; then, the stress significantly reduced at 3.5% and 4% of TPS contents (Figure 8b,c). Thus, the 3.5% of PP and 3% of TPS concentrations are considered as ideal percentages for PP and TPS, respectively.

The rutting resistance features of the bitumen were remarkably enhanced by adding 2 to 4% CRM, 2 to 3.5% of PP, and 2 to 3% of TPS modifiers. The medium- and high-temperature characteristics obtained from the ideal percentages were substantially higher in the 4% of CRM modified bitumen than the 3.5% of PP and 3% of TPS modified bitumen binders. At temperatures above 76 °C, the 3.5% of CRM- and 3.5% of PP-modified binders are close to each other and showed a very slight variation. The medium- and high-temperature properties of the 2% of PP-, 3.5%, and 4% of TPS-modified asphalt are also close to each other and displayed only minor differences at temperatures less than 76 °C.

The complex shear modulus (G*) and the phase angle (δ) serve as a function of temperature for modified and unmodified bitumen binders at medium- and high-temperatures (Figure 9a–c). The complex shear modulus and phase angle temperature relationship further demonstrate that CRM has more extensive linear viscoelasticity areas. Figure 9a–c show the complex shear modulus and phase angle temperature relationship that is obtained by the same behaviors as the stress-strain relationship. It is observed that when the G* values increased, the δ magnitudes decreased with increasing concentrations of CRM, PP, and TPS modifiers. This increase in G* increases the asphalt’s resistance to permanent deformation. Meanwhile, a decrease in δ improves the elastic response of the binder and mixture flexibility. Overall, the results of all the modified binders prove that CRM-modified binders have the highest rutting resistance. Therefore, CRM is the most preferable for enhancing medium and high-temperature performance.

Figure 9.

G* (left) and δ (right) serving as a function of temperature for modified binders: (a) CRM; (b) PP; and (c) TPS.

4. Conclusions

From the outcomes of this study, the following conclusions can be drawn:

With the addition of 4% CRM, the increase in viscosity is more than two times the viscosity of the neat asphalt, and about 31% and 34% more than the addition of 4% of PP and TPS, respectively. Thus, to enhance the viscosity in an asphalt binder, use CRM, as it is the preferred additive for improving rutting resistance and fatigue/reflection cracking resistance in flexible pavement, followed by PP and TPS modifiers.

The results showed that significant reduction in ductility occurred by the addition of CRM, PP, and TPS modifiers. Moreover, TPS-modified asphalt binder was found to have a high ductility and thus TPS is more flexible. Further, it concluded that TPS behaves differently from both CRM and PP for all concentrations.

The results of the toughness and tenacity test concluded that the maximum force increased linearly with the increase of CRM, PP, and TPS concentrations. The consequences indicated that the maximum strength obtained from the addition of CRM is better than those derived from PP and TPS modifiers. The significant dissipated energy during the fracturing process was achieved by adding CRM. Outcomes also showed that CRM has a small value of tenacity. Thus, CRM is the most appropriate modifier for enhancing the mechanical properties of the asphalt binder behavior.

The DSR test results showed that the G*/sin(δ) and G* values increased with the modifier content and decreased when the temperature increased. The values obtained from the CRM-modified bitumen binders were higher than those of the PP- and TPS-modified binders. Thus, CRM-modified asphalt binders were the most preferable for enhancing the medium and high-temperature performance and permanent deformations.

The DSR stress-strain relationship results indicate that the medium- and high-temperature features (stress) increased when CRM content increased. However, in the case of PP and TPS, the properties increased at 2% and 3.5% of PP and the stress decreased considerably at 4% of PP. Further, the properties increased at concentrations of 2% and 3% TPS and the stress reduced substantially at 3.5% and 4% TPS. Because the CRM-modified binder has a wide linear viscoelasticity area, CRM is the most appropriate modifier to enhance medium- and high-temperature performances.

Note that this study investigated only medium- and high-temperature effects. In future studies, the authors will investigate the low-temperature properties of asphalt binders modified by CRM, PP, and TPS, as well as the effect of these modifiers on the physical properties and the low-temperature performance (mechanical performance) of the modified asphalt binders, in order to prove which additive is preferable when enhancing bitumen binders.

Author Contributions

I.B.E. conceptualized the paper, designed experiments, manufactured the specimens, and performed and analyzed the experimental investigations. H.X. oversight the research and contributed to the review and construction of the manuscript.

Funding

This research received no external funding but, the author would like to thank the Jiangsu Tiannuo Advanced Material Technology Co., Ltd./China, for patronizing this research study.

Conflicts of Interest

The authors have no conflict of interest to report.

Abbreviations

| CRM | crumb rubber modifier |

| DSR | dynamic shear rheometer |

| G* | complex shear modulus |

| G*/sin(δ) | rutting parameter |

| HVA | high-viscosity additive |

| MD | molecular dynamics |

| PG | performance grade |

| PP | polypropylene |

| RST | road-science-technology |

| RV | rotational viscometer |

| SBR | styrene–butadiene rubber |

| SBS | styrene–butadiene–styrene |

| TPS | tafpack super |

References

- Khabaz, F.; Khare, R. Glass Transition and Molecular Mobility in Styrene–Butadiene Rubber Modified Asphalt. J. Phys. Chem. B. 2015, 119, 14261–14269. [Google Scholar] [CrossRef] [PubMed]

- Siddig, E.A.; Cheng, C.P.; Ming, L.Y. Effects of Ethylene Vinyl Acetate and Nanoclay Additions on High-Temperature Performance of Asphalt Binders. Constr. Build. Mater. 2018, 169, 276–282. [Google Scholar] [CrossRef]

- Habib, N.Z.; Kamaruddin, I.; Napiah, M.; Tan, I.M. Effect of Mixing Process on Polypropylene Modified Bituminous Concrete Mix Properties. J. Civ. Environ. Eng. 2011, 5, 477–482. [Google Scholar]

- Lin, J.D.; Chen, S.H.; Liu, P.; Wang, J.N. Modified Toughness Used to Evaluate the Effect of Polymer Modified Asphalt on Sma. J. Chin. Inst. Eng. 2004, 27, 8. [Google Scholar] [CrossRef]

- Galooyak, S.S.; Dabir, B.; Nazarbeygi, A.E.; Moeinic, A. Rheological Properties and Storage Stability of Bitumen/Sbs/Montmorillonite Composites. Constr. Build. Mater. 2010, 24, 300–307. [Google Scholar] [CrossRef]

- Li, R.; Xiao, F.; Amirkhanian, S.; You, Z.; Huang, J. Developments of Nano Materials and Technologies on Asphalt Materials–a Review. Constr. Build. Mater. 2017, 143, 633–648. [Google Scholar] [CrossRef]

- Dong, R.; Zhao, M.; Tang, N. Characterization of Crumb Tire Rubber Lightly Pyrolyzed in Waste Cooking Oil and the Properties of Its Modified Bitumen. Constr. Build. Mater. 2019, 195, 10–18. [Google Scholar] [CrossRef]

- Cui, S.; Blackman, B.R.; Kinloch, A.J.; Taylor, A.C. Durability of Asphalt Mixtures: Effect of Aggregate Type and Adhesion Promoters. Int. J. Adhes. Adhes. 2014, 54, 100–111. [Google Scholar] [CrossRef]

- Cao, T.; Wu, S.; Liu, C.; Zhang, T. Shear Resistance Properties of Tps Modified Bitumen Binders and Asphalt Mixtures. J. Cent. South Univ. Technol. 2008, 15, 434–437. [Google Scholar] [CrossRef]

- Bouraima, M.B.; Zhang, X.; Zhou, S.; Qiu, Y. Impact of Viscosity Modifier on Asphalt Properties Used for Bus Rapid Transit Lane in Chengdu. J. Modern Transp. 2017, 25, 185–193. [Google Scholar] [CrossRef][Green Version]

- Yi-Qiu, T.; Ai, A. World Cup 2010 Traffic Simulation Long-Term Aging of Polypropylene Asphalt Paving Mixtures. In Proceedings of the 2007 26th Southern African Transport Conference (SATC), Pretoria, South Africa, 9–12 July 2007; pp. 761–767. [Google Scholar]

- Khabaz, F.; Khare, R. Molecular Simulations of Asphalt Rheology: Application of Time–Temperature Superposition Principle. J. Rheol. 2018, 62, 941–954. [Google Scholar] [CrossRef]

- Barco-Carrión, A.J.; García-Travé, G.; Moreno-Navarro, F.; Martínez-Montes, G.; Rubio-Gámez, M.C. Comparison of the Effect of Recycled Crumb Rubber and Polymer Concentration on the Performance of Binders for Asphalt Mixtures. Mater. Constr. 2016, 66, 090. [Google Scholar]

- Bahia, H.U.; Davies, R. Effect of Crumb Rubber Modifiers (CRM) on Performance Related Properties of Asphalt Binders. Asph. Paving Technol. 1994, 63, 414. [Google Scholar]

- Zumrawi, M. Effect of Crumb Rubber Modifiers (CRM) on Characteristics of Asphalt Binders in Sudan. Int. J. Mater. Sci. Appl. 2017, 6, 1–6. [Google Scholar]

- Bulei, C.; Todor, M.P.; Heput, T.; Kiss, I. Directions for Material Recovery of Used Tires and Their Use in the Production of New Products Intended for the Industry of Civil Construction and Pavements. In Proceedings of the 2017 1st International Conference on Applied Sciences (ICAS), Hunedoara, Romania, 10–12 May 2017. [Google Scholar]

- Billiter, T.C.; Chun, J.S.; Davison, R.R.; Glover, C.J.; Bullin, J.A. Investigation of the Curing Variables of Asphalt-Rubber Binder. Liq. Fuels Technol. 1997, 15, 445–469. [Google Scholar] [CrossRef]

- Airey, G.D. Rheological Properties of Styrene Butadiene Styrene Polymer Modified Road Bitumens. Fuel 2003, 82, 1709–1719. [Google Scholar] [CrossRef]

- Liu, Q.; Wu, S.; Liu, C.; Wang, J. Investigation of Rheological Properties of TPS Modified Bitumen. J. Cent. South Univ. Technol. 2010, 15, 118–121. [Google Scholar] [CrossRef]

- Polacco, G.; Stastna, J.; Biondi, D.; Zanzotto, L. Relation between Polymer Architecture and Nonlinear Viscoelastic Behavior of Modified Asphalts. Curr. Opin. Colloid Interface Sci. 2006, 11, 230–245. [Google Scholar] [CrossRef]

- Merighi, J.V.; Fortes, R.M. The Study of Permanent Deformation Using the Static Creep Test. In Proceedings of the 3rd Eurasphalt and Eurobitume Congress, Vienna, Austria, 12–14 May 2004; Volume 2, pp. 12–14. [Google Scholar]

- Hossain, Z.; Zaman, M.; Saha, M.C.; Hawa, T. Evaluation of Viscosity and Rutting Properties of Nanoclay-Modified Asphalt Binders. In Proceedings of the Geo-Congress 2014, Geo-characterization and Modeling for Sustainability, Atlanta, Georgia, 23–26 February 2014. [Google Scholar]

- Noguera, A.H.; Miró, R. Asphalt Toughness Effect on Bituminous Mixture Fatigue Behavior. Rev. Ing. Constr. 2011, 26, 224–239. [Google Scholar] [CrossRef]

- Ke, Z.; Mingzhi, S.; Ronghua, C. Performance Evaluation of High-Elastic/Salt-Storage Asphalt Mixture Modified with Mafilon and Rubber Particles. Constr. Build. Mater. 2018, 193, 153–161. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).