Influence of ZrO2 Nanoparticles on the Microstructural Development of Cement Mortars with Limestone Aggregates

Abstract

1. Introduction

2. Materials and Methods

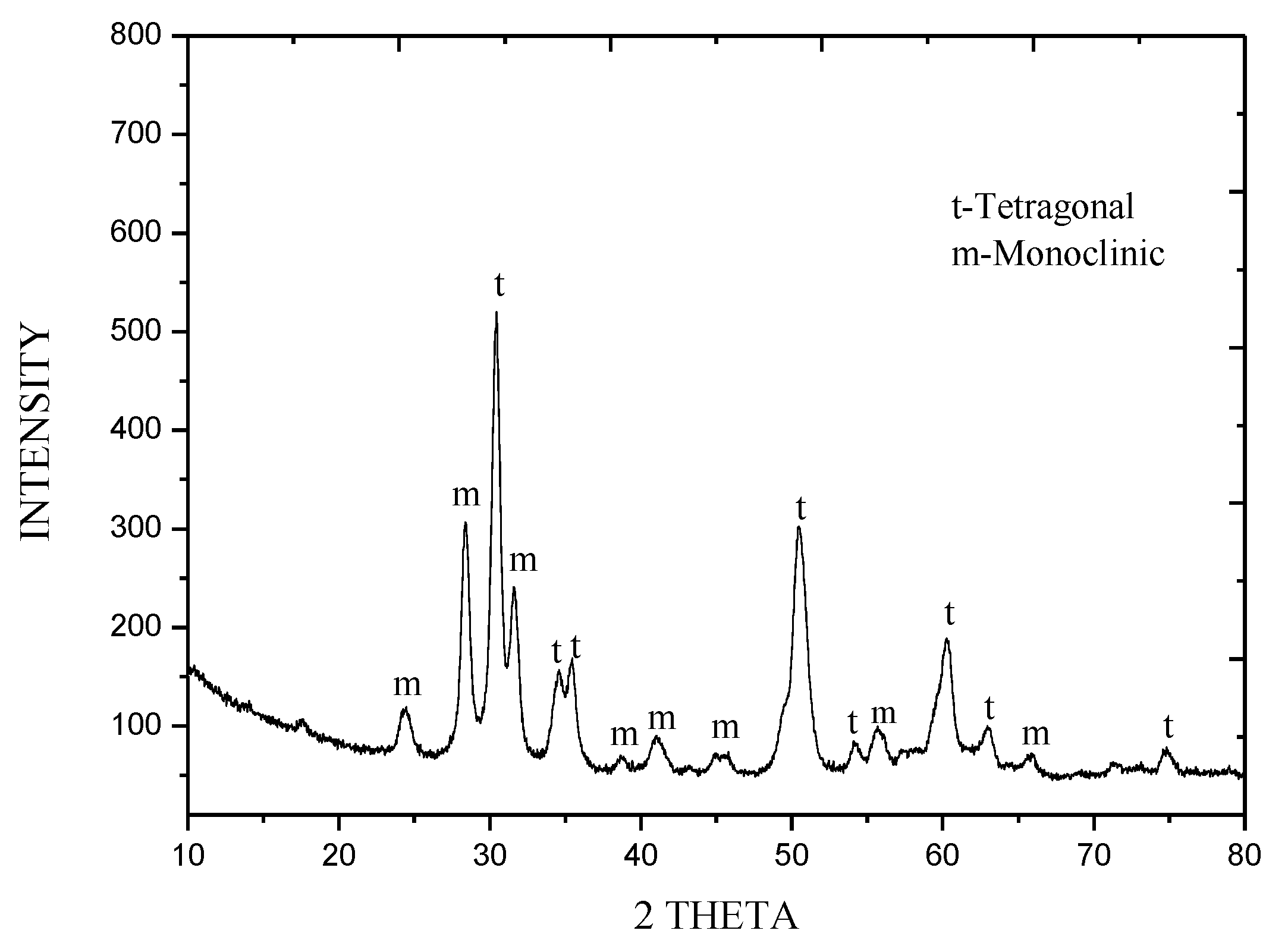

2.1. Synthesis and Characterization of ZrO2 Nanoparticles

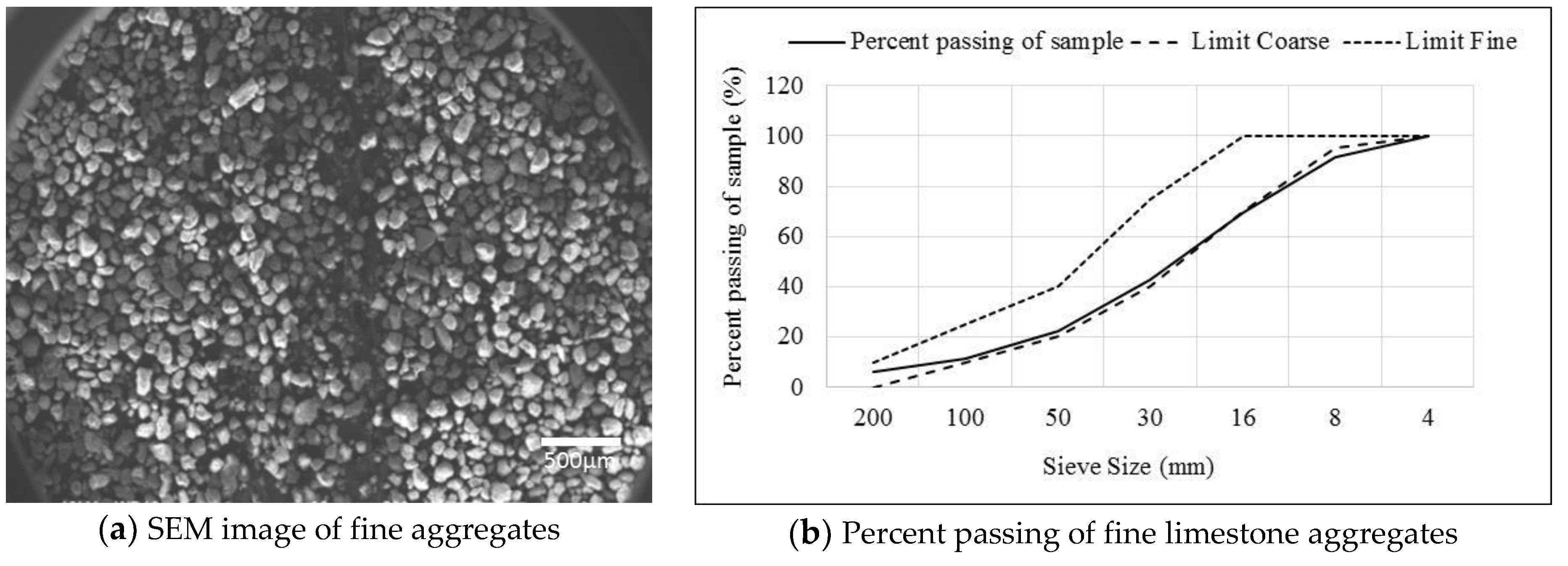

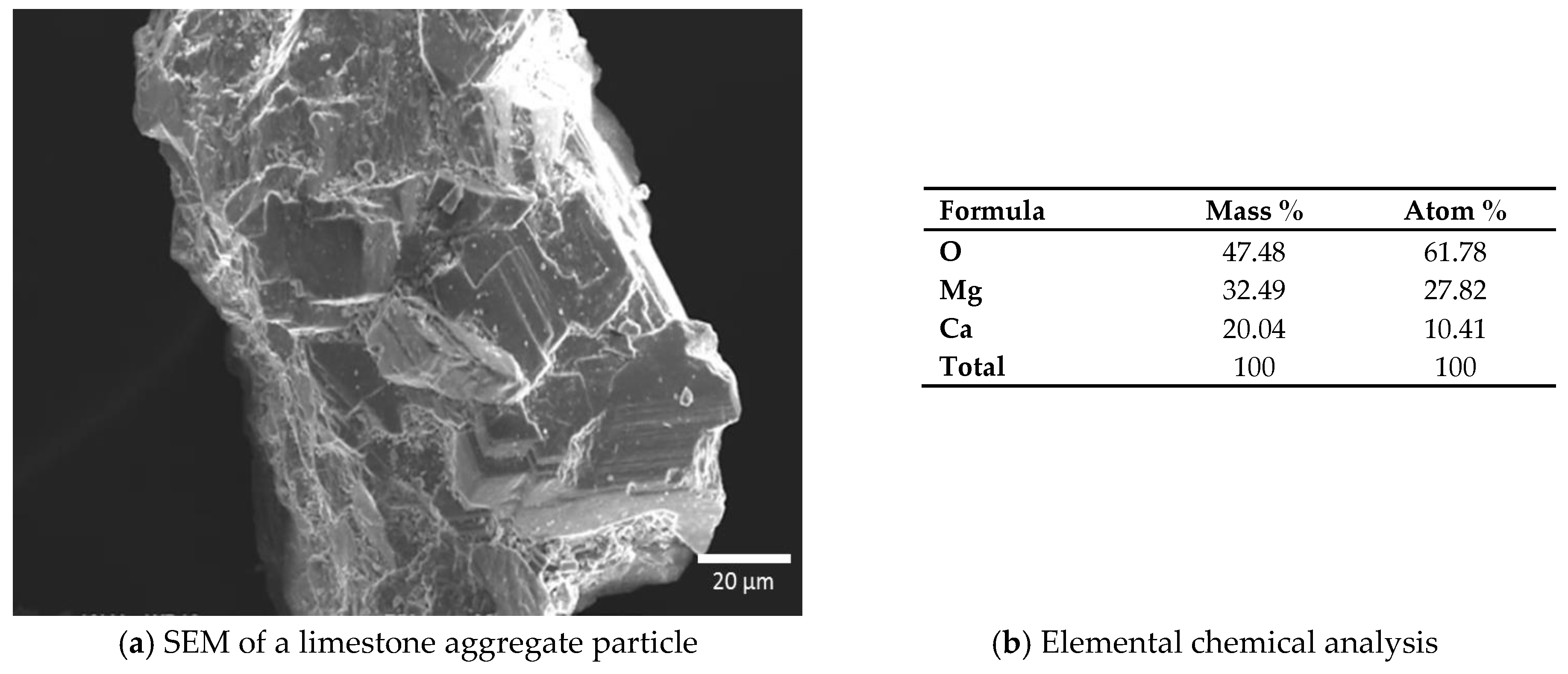

2.2. Limestone Fine Aggregate

2.3. Cementitious Composites (Mortars)

3. Results

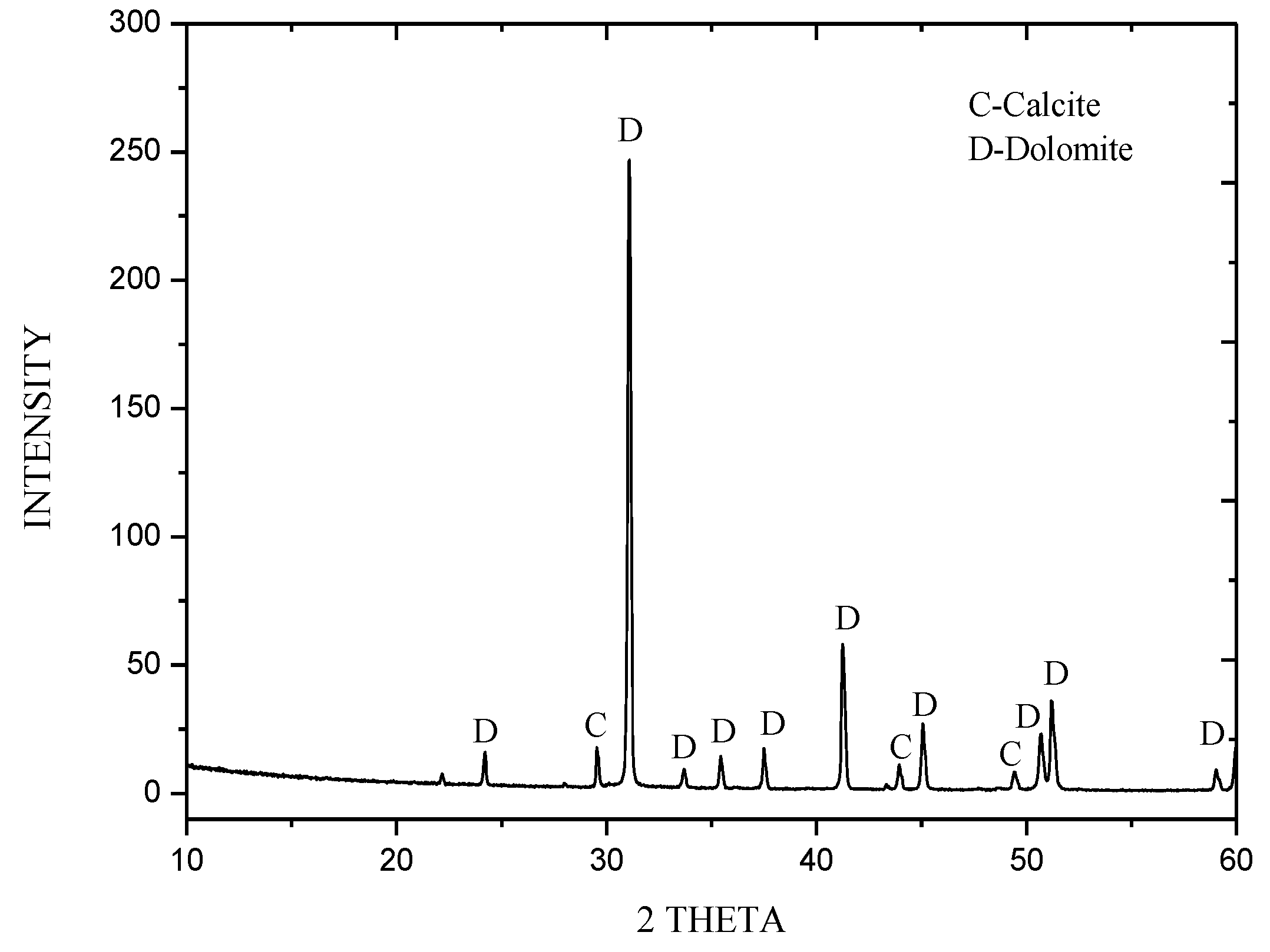

3.1. Characterization of Fine Aggregates

3.2. X-Ray Diffraction of Zirconia Nanoparticles

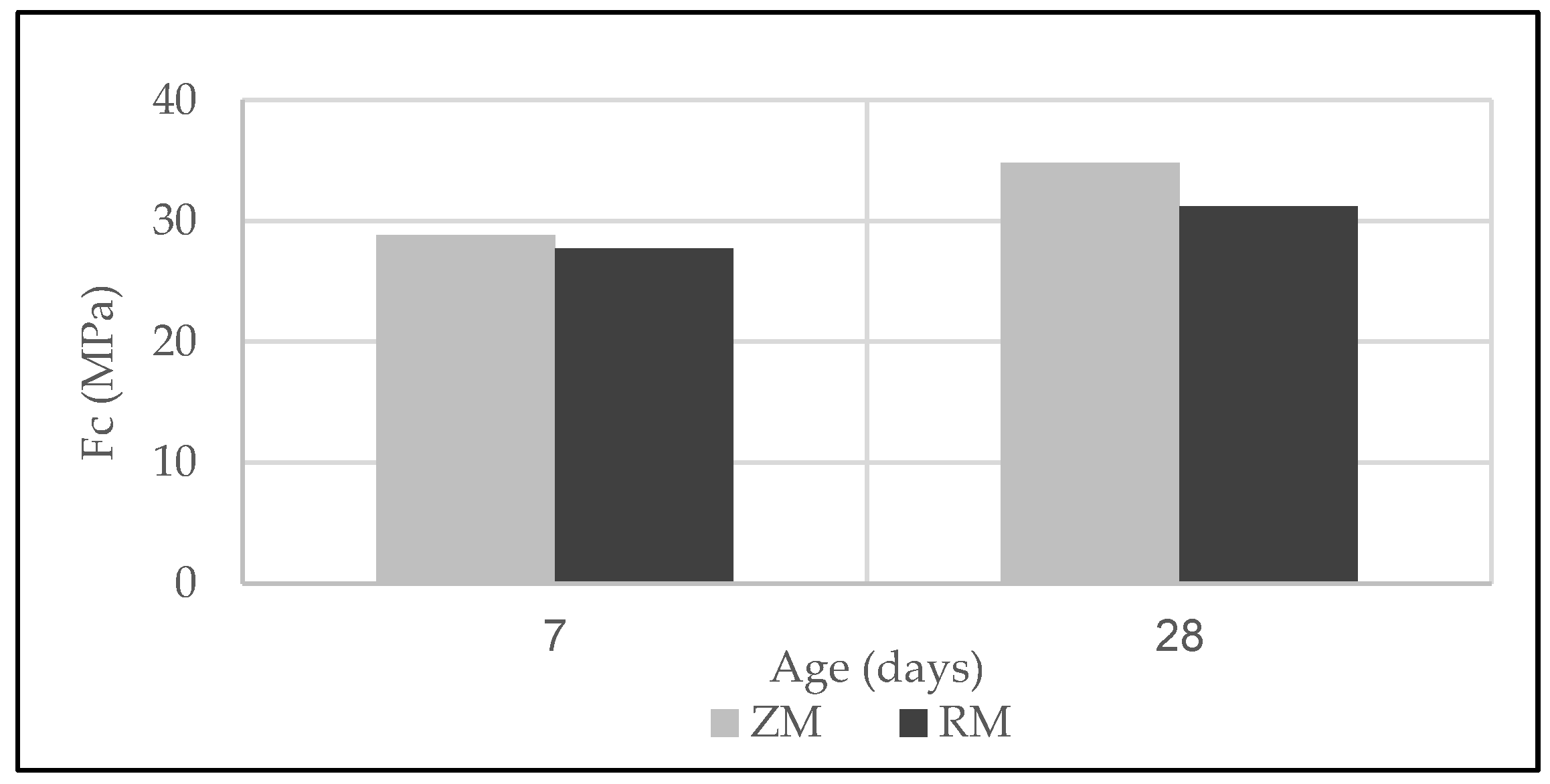

3.3. Physical–Mechanical Characterization of Cementitious Composites (Mortars)

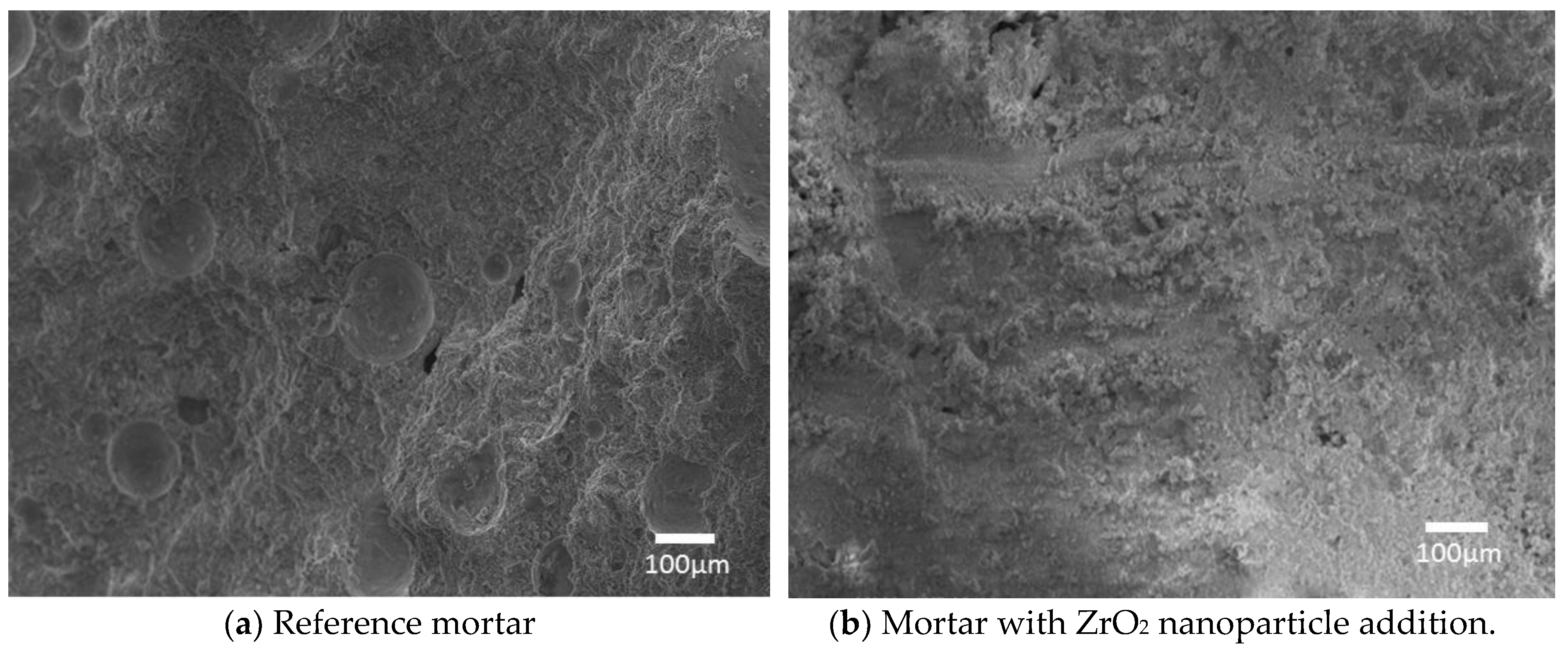

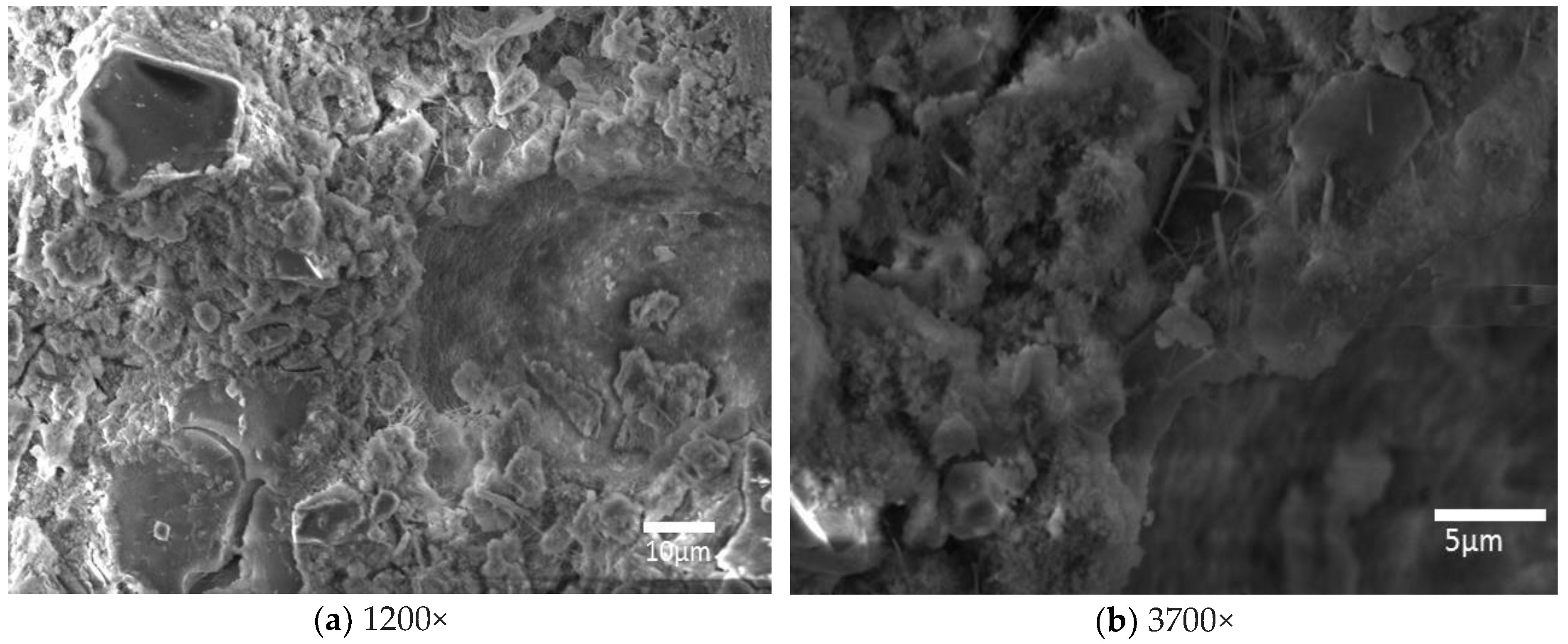

3.4. Microstructural Characterization of Cementitious Composites (Mortars)

4. Discussion

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Yaşar, E.; Erdoğan, Y.; Kılıç, A. Effect of limestone aggregate type and water–cement ratio on concrete strength. Mater. Lett. 2004, 58, 772–777. [Google Scholar] [CrossRef]

- Chan, J.L.; Solís, R.; Moreno, E.I. Influencia de los agregados pétreos en las características del concreto. Ingeniería 2003, 7, 39–46. [Google Scholar]

- Adams, M.P.; Ideker, J.H. Influence of aggregate type on conversion and strength in calcium aluminate. Cem. Concr. Res. 2017, 100, 284–296. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, L. Effect of particle shape of limestone manufactured sand and natural sand on concrete. Procedia Eng. 2017, 210, 87–92. [Google Scholar] [CrossRef]

- Chen, X.; Wu, S.; Zhou, J. Pore size distribution of cement mortar prepared with crushed limestone sand. KSCE J. Civ. Eng. 2017, 20, 762–767. [Google Scholar] [CrossRef]

- An, J.; Kim, S.S.; Nam, B.H.; Durham, S.A. Effect of aggregate mineralogy and concrete microstructure on thermal expansion and strength properties of concrete. Appl. Sci. 2017, 7, 1307. [Google Scholar] [CrossRef]

- Tasong, W.A.; Lynsdale, C.J.; Cripps, J.C. Aggregate-cement paste interface, Part I; Influence of aggregate geochemistry. Cem. Concr. Res. 1999, 29, 1019–1025. [Google Scholar] [CrossRef]

- Jebli, M.; Jamin, F.; Malachanne, E.; Garcia-Diaz, E.; El Youssoufi, M.S. Experimental characterization of mechanical properties of the cement-aggregate interface in concrete. Constr. Build. Mater. 2018, 161, 16–25. [Google Scholar] [CrossRef]

- CONCRETE: Microstructure, Properties and Materials. Available online: http://103.248.208.114:8080/dspace/bitstream/123456789/515/1/book.pdf (accessed on 6 February 2019).

- Monteiro, K.M. Concreto, estructura, propiedades y materiales, IMCYC. 1ª edición IMCYC, México D.F., México. 1998. [Google Scholar]

- Singh, N.B.; Kalra, M.; Saxena, S.K. Nanoscience of cement and concrete. Mater. Today: Proc. 2017, 4, 5478–5487. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Jalali, S. Nanotechnology: Advantages and drawbacks in the field of construction and building materials. Constr. Build. Mater. 2011, 25, 582–590. [Google Scholar] [CrossRef]

- Sanchez, F.; Sobolev, K. Nanotechnology in concrete—A review. Constr. Build. Mater. 2010, 24, 2060–2071. [Google Scholar] [CrossRef]

- Norhasri, M.S.M.; Hamidah, M.S.; Fadzil, A.M. Applications of using nano material in concrete: A review. Constr. Build. Mater. 2017, 133, 91–97. [Google Scholar] [CrossRef]

- Rashad, A.M. Effects of ZnO2, ZrO2, Cu2O3, CuO, CaCO3, SF, FA, cement and geothermal silica waste nanoparticles on properties of cementitious materials—A short guide for Civil Engineer. Constr. Build. Mater. 2013, 48, 1120–1133. [Google Scholar] [CrossRef]

- Hannink, R.H.J.; Kelly, P.M.; Muddle, B.C. Transformation toughening in zirconia-containing ceramics. J. Am. Ceram. Soc. 2000, 83, 461–487. [Google Scholar] [CrossRef]

- Nazari, A.; Shadi, R.; Shirin, R.; Shamekhi, S.F.; Khademno, A. Embedded ZrO2 nanoparticles mechanical properties monitoring in cementitious composites. J. Am. Sci. 2010, 6, 86–89. [Google Scholar]

- Negahdary, M.; Habibi-Tamijani, A.; Asadi, A.; Ayati, S. Synthesis of zirconia nanoparticles and their ameliorative roles as additives concrete structures. J. Chem. 2012, 2013. [Google Scholar] [CrossRef]

- Rafieipour, M.H.; Nazari, A.; Mohandesi, M.A.; Khalaj, G. Improvement compressive strength of cementitious composites in different curing media by incorporating ZrO2 nanoparticles. Mat. Res. 2012, 15, 177–184. [Google Scholar] [CrossRef]

- Nazari, A.; Riahi, S.; Riahi, S.; Shamekhi, S.F.; Khademno, A. An investigation on the Strength and workability of cement based concrete performance by using ZrO2 nanoparticles. J. Am. Sci. 2010, 6, 29–33. [Google Scholar]

- Yuan, H.; Shi, Y.; Xu, Z.; Lu, C.; Ni, Y.; Lan, X. Influence of nano-ZrO2 on the mechanical and thermal properties of high temperature cementitious thermal energy storage materials. Constr. Build. Mater. 2013, 48, 6–10. [Google Scholar] [CrossRef]

- Han, B.; Wang, Z.; Zeng, S.; Zhou, D.; Yu, X.; Cui, X.; Ou, J. Properties and modification mechanisms of nano-zirconia filled reactive powder concrete. Constr. Build. Mater. 2017, 141, 426–434. [Google Scholar] [CrossRef]

- Ruan, Y.; Han, B.; Yu, X.; Li, Z.; Wang, J.; Dong, S.; Ou, J. Mechanical behaviors of nano-zirconia reinforced reactive powder. Constr. Build. Mater. 2018, 162, 663–673. [Google Scholar]

- Fei, L.; Yanhuai, L.; Zhongxiao, S.; Kewei, X.; Zhi, Z.; Hong, C. Rietveld study on evolution of crystalline structure of ysz nanoparticles during co-precipitation synthesis. Rare Metal Mat. Eng. 2015, 44, 2716–2720. [Google Scholar] [CrossRef]

- Rezaei, M.S.; Alavi, M.S.; Sahebdelfar, S.; Yan, Z.; Teunissen, H.; Jacobsen, J.H.; Sehested, J. Synthesis of pure tetragonal zirconium oxide with high surface area. J. Matter Sci. 2007, 42, 1228–1237. [Google Scholar] [CrossRef]

- Viazzi, C.; Bonino, J.P.; Ansart, F.; Barnabé, A. Structural study of metastable tetragonal YSZ powders produced via a sol–gel route. J. Alloys Compd. 2008, 452, 377–383. [Google Scholar] [CrossRef]

- Monshi, A.; Foroughi, M.R.; Monshi, M.R. Modified scherrer equation to estimate more accurately nano-crystallite size using XRD. Word J. Nano Sci. Eng. 2012, 2, 154–160. [Google Scholar] [CrossRef]

- ASTM International. Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. In Annual Book of ASTM Standards; ASTM C136–06; American Society for Testing and Materials: West Conshohocken, PA, USA, 2006. [Google Scholar]

- ASTM International. Standard Specification for Aggregate for Masonry Mortar. In Annual Book of ASTM Standards; ASTM C144–11; American Society for Testing and Materials: West Conshohocken, PA, USA, 2011. [Google Scholar]

- ASTM International. Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate. In Annual Book of ASTM Standards; ASTM C128-15; American Society for Testing and Materials: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM International. Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. In Annual Book of ASTM Standards; ASTM C 642-13; American Society for Testing and Materials: West Conshohocken, PA, USA, 2013. [Google Scholar]

- ASTM International. Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). In Annual Book of ASTM Standards; ASTM C109/C109M-16a; American Society for Testing and Materials: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Jiménez, L.F.; Domínguez, J.A.; Vega-Azamar, R.E. Carbon Footprint of Recycled Aggregate Concrete. Adv. Civ. Eng. 2018, 2018, 6. [Google Scholar] [CrossRef]

- Walther, J. Essentials of Geochemistry; Jones & Bartlett Learning: Sudbury, MA, USA, 2009. [Google Scholar]

- Bullard, J.W.; Jennings, H.M.; Livingston, R.A.; Nonat, A.; Schereri, G.W.; Schweitzer, J.S.; Scrivener, K.L.; Thomas, J.J. Mechanisms of cement hydration. Cem. Concr. Res. 2011, 41, 1208–1223. [Google Scholar] [CrossRef]

- Giosuè, C.; Pierpaoli, M.; Mobili, A.; Ruello, M.L.; Tittarelli, F. Influence of binders and lightweight aggregates on the properties of cementitious mortars: From traditional requirements to indoor air quality improvement. Materials 2017, 10, 978. [Google Scholar] [CrossRef]

- Characterisation of old mortars with respect to their repair; Chapter: 2.5. Available online: https://www.researchgate.net/profile/Caspar_Groot/publication/319470227_Chapter_25_Characterisation_Porosity_of_mortars/links/59ad817faca272f8a1617e8a/Chapter-25-Characterisation-Porosity-of-mortars.pdf (accessed on 6 February 2019).

| Sample | Absorption (%) | Fineness modulus | Specific gravity |

|---|---|---|---|

| Average | 5.1 | 2.63 | 2.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trejo-Arroyo, D.L.; Acosta, K.E.; Cruz, J.C.; Valenzuela-Muñiz, A.M.; Vega-Azamar, R.E.; Jiménez, L.F. Influence of ZrO2 Nanoparticles on the Microstructural Development of Cement Mortars with Limestone Aggregates. Appl. Sci. 2019, 9, 598. https://doi.org/10.3390/app9030598

Trejo-Arroyo DL, Acosta KE, Cruz JC, Valenzuela-Muñiz AM, Vega-Azamar RE, Jiménez LF. Influence of ZrO2 Nanoparticles on the Microstructural Development of Cement Mortars with Limestone Aggregates. Applied Sciences. 2019; 9(3):598. https://doi.org/10.3390/app9030598

Chicago/Turabian StyleTrejo-Arroyo, Danna L., Karen E. Acosta, Julio C. Cruz, Ana M. Valenzuela-Muñiz, Ricardo E. Vega-Azamar, and Luis F. Jiménez. 2019. "Influence of ZrO2 Nanoparticles on the Microstructural Development of Cement Mortars with Limestone Aggregates" Applied Sciences 9, no. 3: 598. https://doi.org/10.3390/app9030598

APA StyleTrejo-Arroyo, D. L., Acosta, K. E., Cruz, J. C., Valenzuela-Muñiz, A. M., Vega-Azamar, R. E., & Jiménez, L. F. (2019). Influence of ZrO2 Nanoparticles on the Microstructural Development of Cement Mortars with Limestone Aggregates. Applied Sciences, 9(3), 598. https://doi.org/10.3390/app9030598