Hybrid Micro-Grids Exploiting Renewables Sources, Battery Energy Storages, and Bi-Directional Converters

Abstract

Featured Application

Abstract

1. Introduction

2. Renewable Energy Source Trends for Micro-Grids

2.1. Renewable Energy and Micro-Grids

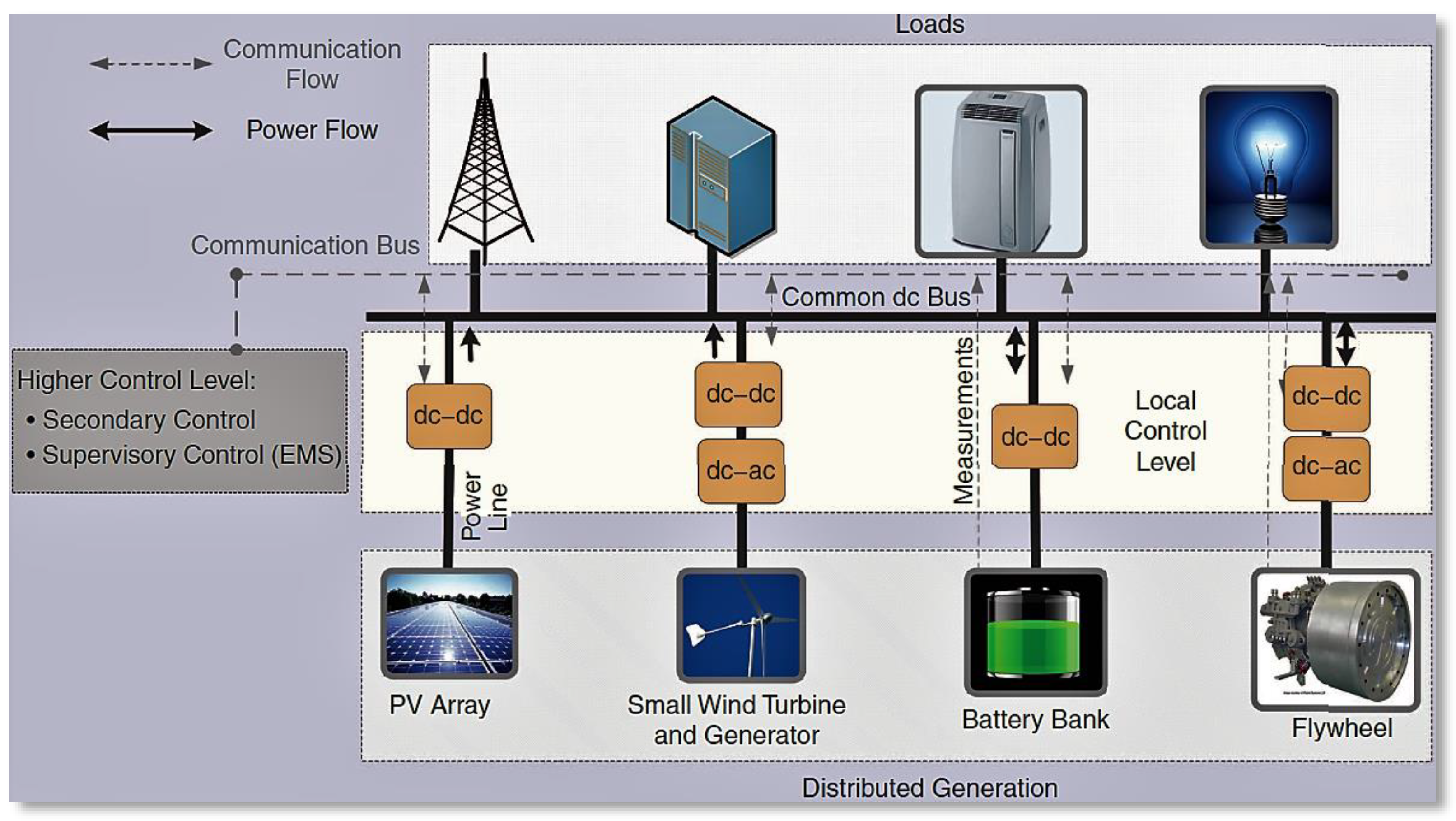

2.2. Power Electronic Converters Used in Micro-Grids

2.3. Control Strategies Used in Hybrid Micro-Grids

- local decentralized control of individual distributed resources;

- regional control of manageable subsets of resources, at micro-grid or VPP (Virtual Power Plant) level; and

- central control of all the system resources, previously aggregated at the second hierarchy level.

2.4. Integration of RES into Hybrid Micro-Grid Systems

3. The Role of Energy Storage in Micro-Grids

3.1. Energy Storage System Technologies for Micro-Grids

3.2. Non Lithium Battery Technologies for Micro-Grids

3.3. Advanced Battery Management Systems

3.4. Battery Charging Process

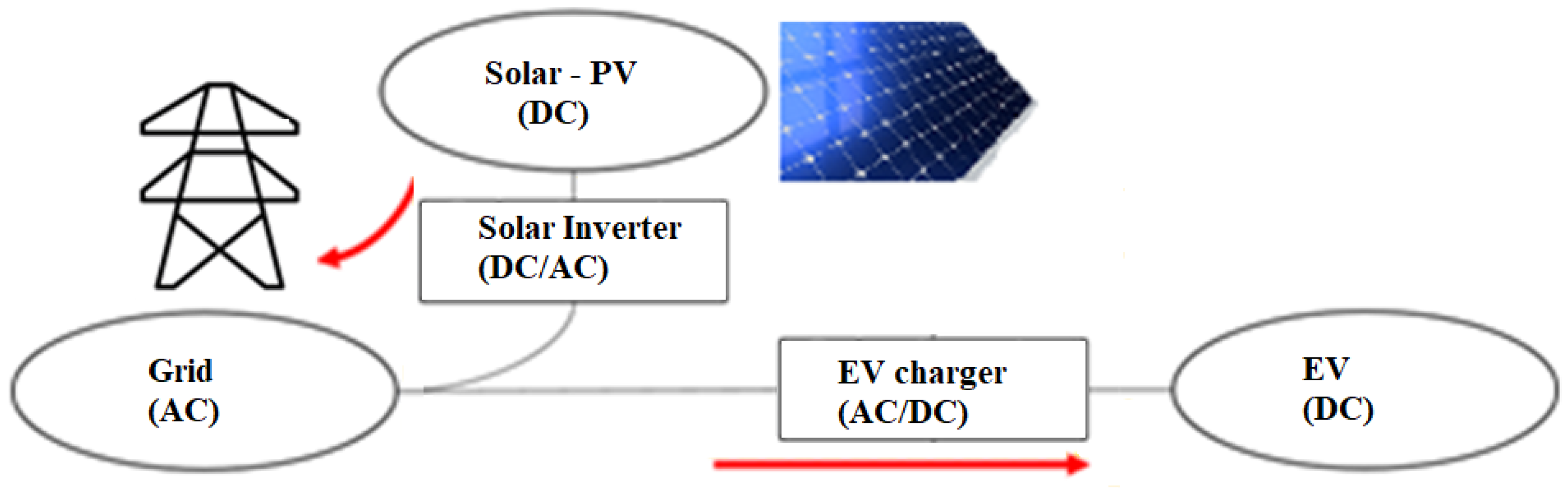

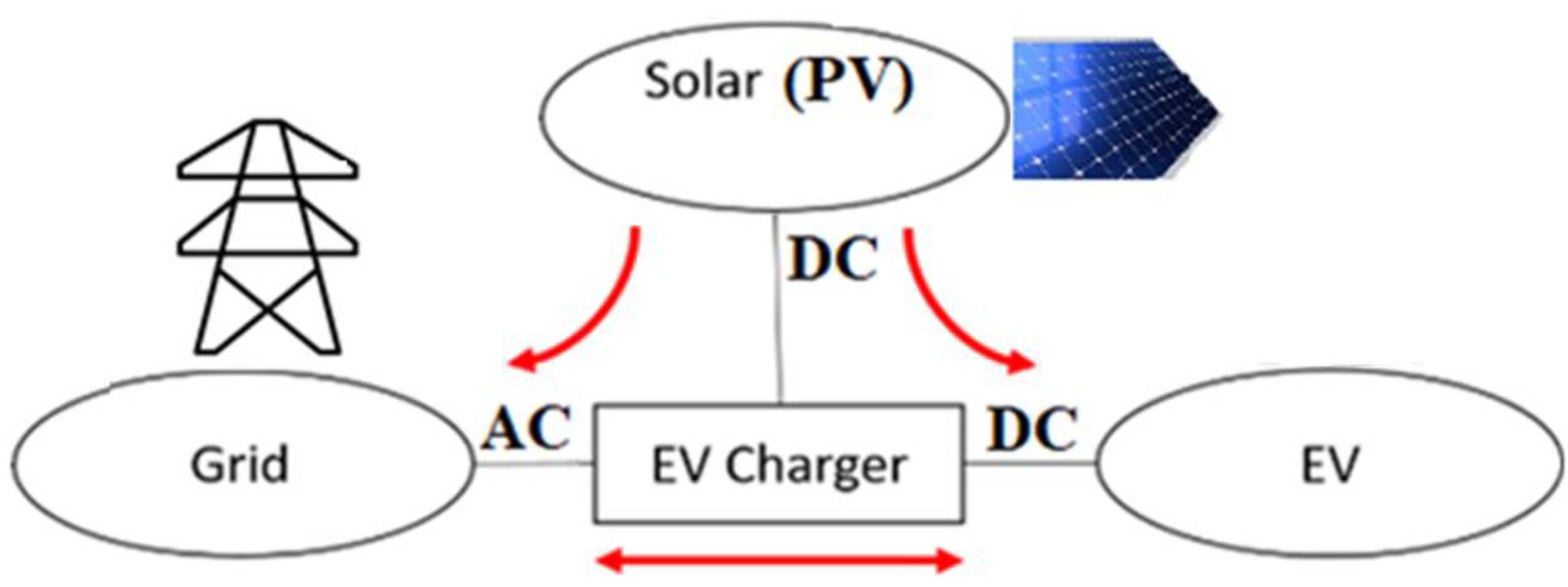

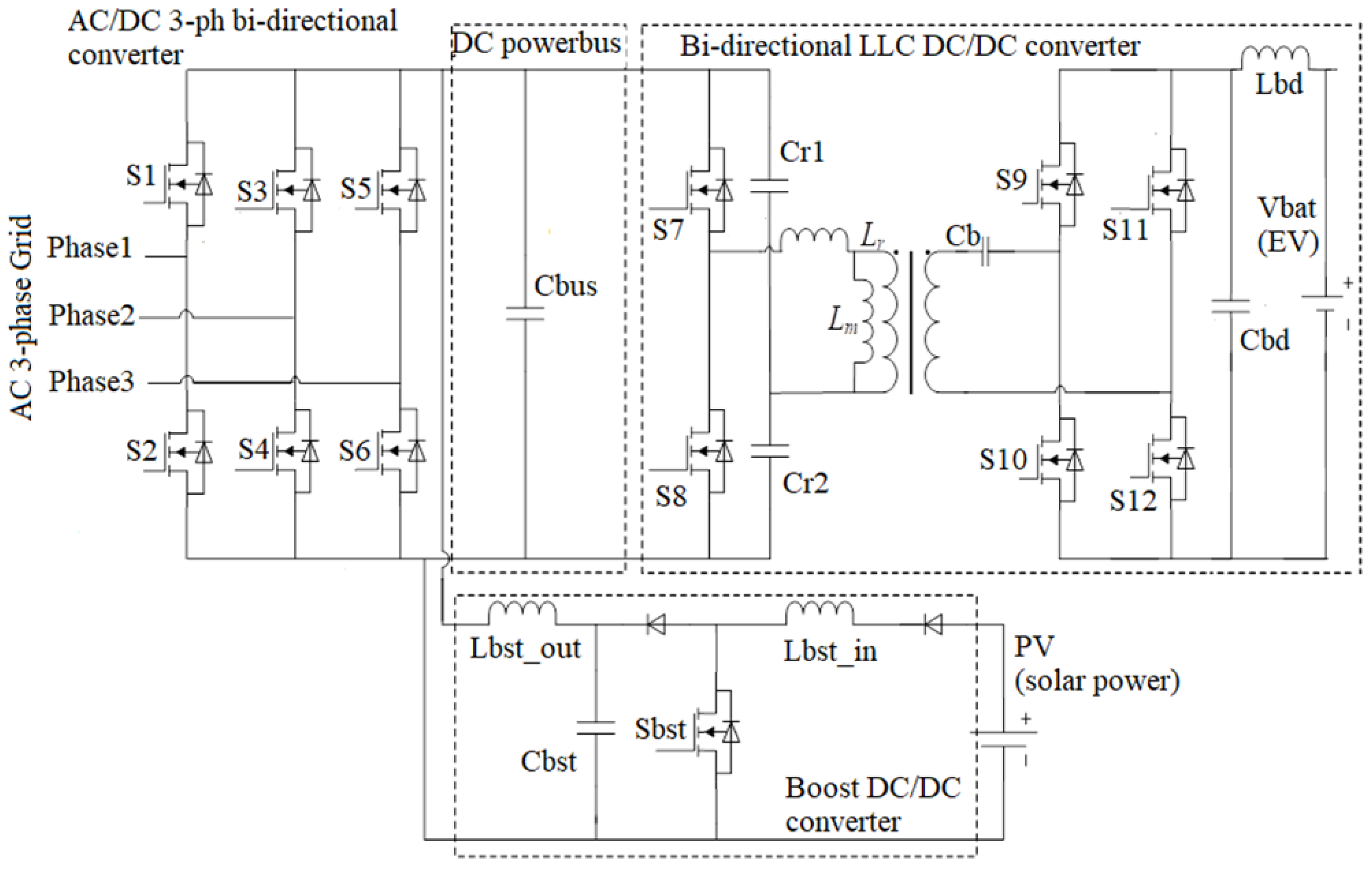

4. Innovative Micro-Grid with Bi-Directional Flows for RES and EV Charging

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mihet-Popa, L.; Saponara, S. Toward Green Vehicles Digitalization for the Next Generation of Connected and Electrified Transport Systems. Energies 2018, 11, 3124. [Google Scholar] [CrossRef]

- Available online: https://new.abb.com/power-converters-inverters/solar/photovoltaic-energy-storage/react-2 (accessed on 16 November 2019).

- Wang, X.; Jiang, C.; Lei, B.; Teng, H.; Bai, H.K.; Kirtley, J.L. Power-loss analysis and efficiency maximization of a silicon-carbide MOSFET-based three-phase 10-kW bidirectional EV charger using variable-DC-bus control. IEEE J. Emerg. Sel. Top. Power Electron. 2016, 4, 880–892. [Google Scholar] [CrossRef]

- Jain, P.; Jain, T. Impacts of G2V and V2G power on electricity demand profile. In Proceedings of the 2014 IEEE International Electric Vehicle Conference (IEVC), Florence, Italy, 17–19 December 2014. [Google Scholar]

- Wall, S.; Ruan, R.; Wang, C.; Xie, J. Evaluation of three-phase solar inverters using SiC devices. In Proceedings of the IEEE EPE’16 ECCE Europe, Karlsruhe, Germany, 5–9 September 2016. [Google Scholar]

- Olivares, D.E.; Mehrizi-Sani, A.; Etemadi, A.H.; Cañizares, C.A.; Iravani, R.; Kazerani, M.; Hajimiragha, A.H.; Gomis-Bellmunt, O.; Saeedifard, M.; Palma-Behnke, R.; et al. Trends in Micro-grid Control. IEEE Trans. Smart Grid 2014, 5, 1905–1919. [Google Scholar] [CrossRef]

- Hirsch, A.; Parag, Y.; Guerrero, J. Micro-grids: A review of technologies, key drivers, and outstanding issues. Renew. Sustain. Energy Rev. 2018, 90, 402–411. [Google Scholar] [CrossRef]

- Sánchez-Miralles, M.M.F.; Rivier, A.M. A literature review of micro-grids: A functional layer based classification. Renew. Sustain. Energy 2016, 62, 1133–1153. [Google Scholar]

- Vadi, S.; Padmanaban, S.; Bayindir, R.; Blaabjerg, F.; Mihet-Popa, L. A Review on Optimization and Control Methods Used to Provide Transient Stability in Micro-grids. Energies 2019, 12, 3582. [Google Scholar] [CrossRef]

- Ganesan, S.; Padmanaban, S.; Varadarajan, R.; Subramaniam, U.; Mihet-Popa, L. Study and Analysis of an Intelligent Micro-grid Energy Management Solution with Distributed Energy Sources. Energies 2017, 10, 1419. [Google Scholar] [CrossRef]

- Ton, D.; Reilly, J. Micro-grid Controller Initiatives. IEEE Power Energy Mag. 2017, 15, 24–31. [Google Scholar] [CrossRef]

- Xavier Saury, F.; Tomlinson, C. Hybrid Micro-Grids: The Time Is Now; CATERPILLAR-LEXE0904; Peoria, IL, USA, 2016; Available online: https://www.cat.com/en_US/by-industry/electric-power-generation/Articles/White-papers/white-paper-hybrid-microgrids-the-time-is-now.html (accessed on 28 September 2019).

- Xiao, Y.; Ren, C.; Han, X.; Wang, P. A generalized and mode-adaptive approach to the power flow analysis of the isolated hybrid AC/DC micro-grids. Energies 2019, 12, 2253. [Google Scholar] [CrossRef]

- Han, Y.; Li, H.; Shen, P.; Coelho, E.A.A.; Guerrero, J.M. Review of active and reactive power sharing strategies in hierarchical controlled micro-grids. IEEE Trans. Power Electron. 2017, 32, 2427–2451. [Google Scholar] [CrossRef]

- Unamunon, E.; Barrena, J.A. Hybrid AC/DC microgrids-Part II: Review and classification of control strategies. Renew. Sustain. Energy Rev. 2012, 52, 1123–1134. [Google Scholar] [CrossRef]

- Mani Venkata, S.S.; Shahidehpour, M. Microgrid Controllers: The Brain, Heart, & Soul of Microgrid Automation. IEEE Power Energy Mag. 2017, 15, 16–22. [Google Scholar]

- Colak, I.; Kabalci, E.; Fulli, G.; Lazarou, S. A survey on the contributions of power electronics to smart grid systems. Renew. Sustain. Energy Rev. 2015, 47, 562–579. [Google Scholar] [CrossRef]

- Mohammed, A.; Refaat, S.S.; Bayhan, S.; Abu-Rub, H. AC Microgrid Control and Management Strategies-Evaluation and review. IEEE Power Electron. Mag. 2019, 6, 18–31. [Google Scholar] [CrossRef]

- Shen, X.; Tan, D.; Shuai, Z.; Luo, A. Control techniques for bidirectional interlinking converters in Hybrid Microgrids. IEEE Power Electron. Mag. 2019, 6, 39–47. [Google Scholar] [CrossRef]

- Bhalla, A. Electromagnetic interference mitigation in wide-bandgap power conversion. IEEE Power Electron. Mag. 2019, 6, 32–35. [Google Scholar] [CrossRef]

- Adan, A.O.; Tanaka, D.; Burgyan, L.; Kakizaki, Y. The current status and trends of 1200-V commercial silicon-carbide MOSFETs. IEEE Power Electron. Mag. 2019, 6, 36–47. [Google Scholar] [CrossRef]

- Bindra, A. Wide-bandgap power devices: Adoption gathers momentum. IEEE Power Electron. Mag. 2018, 22–27. [Google Scholar] [CrossRef]

- Mookken, J. SiC MOSFETs enable high frequency in high power conversion systems. Bodo’s Power Syst. 2016, 28–32. Available online: https://www.richardsonrfpd.com/docs/rfpd/SiC_MOSFET_Article.pdf (accessed on 16 November 2019).

- International Energy Agency-IEA. Renewables 2018. Market Analysis and Forecast from 2018 to 2023, October 2018; ISBN 978-92-64-36998-6. Available online: https://www.iea.org/renewables2018/ (accessed on 16 November 2019).

- International Energy Agency-IEA. Renewables 2019. Market Analysis and Forecast from 2019 to 2024, October 2019; ISBN 978-92-64-30684-4. Available online: https://www.iea.org/renewables2019/ (accessed on 16 November 2019).

- Shivarama Krishna, K.; Sathish Kumar, K. A review on hybrid renewable energy systems. Renew. Sustain. Energy Rev. 2015, 52, 907–916. [Google Scholar] [CrossRef]

- Rocabert, J.; Luna, A.; Blaabjerg, F.; Rodríguez, P. Control of power converters in AC microgrids. IEEE Trans. Power Electron. 2012, 27, 4734–4749. [Google Scholar] [CrossRef]

- Zang, M.; Li, Y.; Peng, Y.; Li, W.; Liu, F. A control architecture to coordinate DG inverters a series-LC-filter hybrid active filter for power quality improvement in Micro-Grid. In Proceedings of the 2017 IEEE International Conference on Environment and Electrical Engineering and 2017 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I & CPS Europe), Milan, Italy, 13 July 2017. [Google Scholar]

- Cirrincione, M.; Pucci, M.; Vitale, G. A single-phase DG generation unit with shunt active power filter capability by adaptive neural filtering. IEEE Trans. Ind. Electron. 2008, 5, 2093–2110. [Google Scholar] [CrossRef]

- Yu, Y.; Guerrero, J.M.; Sun, L.; Li, H. Modeling and stability analysis of CCIs- and VCIs- Based Hybrid Microgrids operating in Grid-Connected Modes. In Proceedings of the 2018 International Conference on Smart Energy Systems and Technologies (SEST), Sevilla, Spain, 10–12 September 2018. [Google Scholar]

- Luo, F.; Loo, K.H.; Lai, Y.M. A Hybrid AC/DC Microgrid Control Scheme with Voltage-Source Inverter-Controlled Interlinking Converters. In Proceedings of the 18th European Conference on Power Electronics and Applications, EPE 2016 ECCE Europe, Karlsruhe, Germany, 5–9 September 2016. [Google Scholar]

- Peyghami, S.; Mokhtari, H.; Blaabjerg, F. Autonomous operation of a Hybrid AC/DC Microgrid with multiple interlinking converters. IEEE Trans. Smart Grid 2018, 19, 6480–6488. [Google Scholar] [CrossRef]

- Liu, Q.; Caldognetto, T.; Buso, S. Flexible control of interlinking converters for DC Microgrids coupled to smart AC power systems. IEEE Trans. Ind. Electron. 2019, 66, 3477–3485. [Google Scholar] [CrossRef]

- Guerrero, J.M.; Loh, P.C.; Lee, T.L.; Chandorkar, M. Advanced control architectures for intelligent microgrids—Part II: Power quality, energy storage, and AC/DC microgrids. IEEE Trans. Ind. Electron. 2013, 60, 1263–1270. [Google Scholar] [CrossRef]

- Sadeghkhani, I.; Golshan, M.E.H.; Mehrizi-Sani, A.; Guerrero, J. Low voltage ride-through of a droop-based three-phase four-wire grid-connected microgrid. IET Gener. Transm. Distrib. 2018, 12, 1906–1914. [Google Scholar] [CrossRef]

- Mihaylov, M.; Razo-Zapata, I.; Rădulescu, R.; Nowé, A. Boosting the Renewable Energy Economy with NRGcoin. In Proceedings of the 4th International Conference on ICT for Sustainability (ICT4S), Amsterdam, The Netherlands, 29 August–1 September 2016. [Google Scholar]

- Beaudin, M.; Zareipour, H.; Schellenberg, A.; Rosehart, W. Energy Storage for Mitigating the Variability of Renewable Electricity Sources. Energy Storage Smart Grids 2010, 14, 302–314. [Google Scholar]

- Zhao, T.; Ding, Z. Cooperative Optimal Control of Battery Energy Storage System under Wind Uncertainties in a Micro-grid. IEEE Trans. Power Syst. 2018, 33, 2292–2300. [Google Scholar] [CrossRef]

- Xie, H.; Teng, X.; Xu, Y.; Wang, Y. Optimal Energy Storage Sizing for Networked Micro-grids Considering Reliability and Resilience. IEEE Access 2019, 7, 86336–86348. [Google Scholar] [CrossRef]

- Khodabakhsh, R.; Sirouspour, S. Optimal Control of Energy Storage in a Micro-grid by Minimizing Conditional Value-at-Risk. IEEE Trans. Sustain. Energy 2016, 7, 1264–1273. [Google Scholar] [CrossRef]

- Ju, C.; Wang, P.; Goel, L.; Xu, Y. A Two-Layer Energy Management System for Micro-grids With Hybrid Energy Storage Considering Degradation Costs. IEEE Trans. Smart Grid 2018, 9, 6047–6057. [Google Scholar] [CrossRef]

- Qi, X.; Bai, Y.; Luo, H.; Zhang, Y.; Zhou, G.; Wei, Z. Novel Distributed Optimal Control of Battery Energy Storage System in an Islanded Microgrid with Fast Frequency Recovery. Energies 2018, 11, 1955. [Google Scholar] [CrossRef]

- García Vera, Y.E.; Dufo-López, R.; Bernal-Agustín, J.L. Energy Management in Microgrids with Renewable Energy Sources: A Literature Review. Appl. Sci. 2019, 9, 3854. [Google Scholar] [CrossRef]

- Ross, M.; Abbey, C.; Bouffard, F.; Joós, G. Micro-grid Economic Dispatch with Energy Storage Systems. IEEE Trans. Smart Grid 2018, 9, 3039–3047. [Google Scholar] [CrossRef]

- Faisal, M.; Hannan, M.A.; Ker, P.J.; Hussain, A.; Mansor, M.B.; Blaabjerg, F. Review of Energy Storage System Technologies in Micro-grid Applications: Issues and Challenges. IEEE Access 2018, 6, 35143–35164. [Google Scholar] [CrossRef]

- Nadeem, F.; Hussain, S.S.; Tiwari, P.K.; Goswami, A.K.; Ustun, T.S. Comparative Review of Energy Storage Systems, Their Roles, and Impacts on Future Power Systems. IEEE Access 2019, 7, 4555–4585. [Google Scholar] [CrossRef]

- Rahimi-Eichi, H.; Ojha, U.; Baronti, F.; Chow, M.-Y. Battery Management System: An Overview of Its Application in the Smart Grid and Electric Vehicles. IEEE Ind. Electron. Mag. 2013, 7, 4–16. [Google Scholar] [CrossRef]

- Brandl, M.; Gall, H.; Wenger, M.; Lorentz, V.; Giegerich, M.; Baronti, F.; Fantechi, G.; Fanucci, L.; Roncella, R.; Saletti, R.; et al. Batteries and battery management systems for electric vehicles. In Proceedings of the 2012 Design, Automation & Test. in Europe Conference & Exhibition (DATE), Dresden, Germany, 12–16 March 2012. [Google Scholar]

- Analog Device 12 Channel Multicell Battery Monitor with Addressable Interface. Available online: https://www.analog.com/media/en/technical-documentation/data-sheets/680412fc.pdf (accessed on 16 November 2019).

- Maxim Integrated MAX14920 High-Accuracy 12-/16-Cell Measurement Analog Front Ends. Available online: https://datasheets.maximintegrated.com/en/ds/MAX14920-MAX14921.pdf (accessed on 16 November 2019).

- Texas Instruments bq76PL455A 16-Cell Industrial Integrated Battery Monitor with Passive Cell Balancing. Available online: http://www.ti.com/lit/ds/symlink/bq76pl455a.pdf (accessed on 16 November 2019).

- Lahiri, A.; Shah, N.; Dales, C. Building a safer, denser lithium-ion battery. IEEE Spectr. 2018, 55, 34–39. [Google Scholar] [CrossRef]

- Omariba, Z.B.; Zhang, L.; Sun, D. Review of Battery Cell Balancing Methodologies for Optimizing Battery Pack Performance in Electric Vehicles. IEEE Access 2019, 7, 129335–129352. [Google Scholar] [CrossRef]

- Ci, S.; Lin, N.; Wu, D. Reconfigurable Battery Techniques and Systems: A Survey. IEEE Access 2016, 4, 1175–1189. [Google Scholar] [CrossRef]

- Lin, N.; Ci, S.; Wu, D.; Guo, H. An Optimization Framework for Dynamically Reconfigurable Battery Systems. IEEE Trans. Energy Convers. 2018, 33, 1669–1676. [Google Scholar] [CrossRef]

- Baronti, F.; Fantechi, G.; Roncella, R.; Saletti, R. Design of a module switch for battery pack reconfiguration in high-power applications. In Proceedings of the 2012 IEEE International Symposium on Industrial Electronics (ISIE), Hangzhou, China, 28–31 May 2012; pp. 1330–1335. [Google Scholar] [CrossRef]

- Morello, R.; Baronti, F.; Tian, X.; Chau, T.; Di Rienzo, R.; Roncella, R.; Saletti, R. Hardware-in-the-loop simulation of FPGA-based state estimators for electric vehicle batteries. In Proceedings of the IEEE International Symposium on Industrial Electronics, Santa Clara, CA, USA, 8–10 June 2016. [Google Scholar] [CrossRef]

- Sudworth, J.L. Zebra batteries. J. Power Sources 1994, 51, 105–114. [Google Scholar] [CrossRef]

- Moseley, P.T.; Rand, D.A. Chapter 15-High-Temperature Sodium Batteries for Energy Storage. In Electrochemical Energy Storage for Renewable Sources and Grid Balancing, 1st ed.; Moseley, P.T., Garche, J., Eds.; Elsevier: London, UK, 2015; pp. 253–268. ISBN 978-044-462-616-5. [Google Scholar]

- Li, G.; Lu, X.; Kim, J.Y.; Lemmon, J.P.; Sprenkle, V.L. Improved cycling behavior of ZEBRA battery operated at intermediate temperature of 175 °C. J. Power Sources 2014, 249, 414–417. [Google Scholar] [CrossRef]

- Lawder, M.T.; Suthar, B.; Northrop, P.W.; De, S.; Hoff, C.M.; Leitermann, O.; Subramanian, V.R. Battery Energy Storage System (BESS) and Battery Management System (BMS) for Grid-Scale Applications. Proc. IEEE 2014, 102, 1014–1030. [Google Scholar] [CrossRef]

- Kim, H.; Shin, K.G. DESA: Dependable, Efficient, Scalable Architecture for Management of Large-Scale Batteries. IEEE Trans. Ind. Inform. 2012, 8, 406–417. [Google Scholar] [CrossRef]

- Steinhorst, S.; Lukasiewycz, M.; Narayanaswamy, S.; Kauer, M.; Chakraborty, S. Smart Cells for Embedded Battery Management. In Proceedings of the 2014 IEEE International Conference on Cyber-Physical Systems, Networks, and Applications, Hong Kong, China, 25–26 August 2014. [Google Scholar]

- Baronti, F.; Fantechi, G.; Roncella, R.; Saletti, R. Intelligent cell gauge for a hierarchical battery management system. In Proceedings of the 2012 IEEE Transportation Electrification Conference and Expo (ITEC), Dearborn, MI, USA, 18–20 June 2012; pp. 1–5. [Google Scholar] [CrossRef]

- Di Rienzo, R.; Baronti, F.; Vellucci, F.; Cignini, F.; Ortenzi, F.; Pede, G.; Saletti, R. Experimental analysis of an electric minibus with small battery and fast charge policy. In Proceedings of the 2016 International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles and International Transportation Electrification Conference, ESARS-ITEC, Toulouse, France, 2–4 November 2016. [Google Scholar] [CrossRef]

- Rivera-Barrera, J.P.; Muñoz-Galeano, N.; Sarmiento-Maldonado, H.O. SoC Estimation for Lithium-ion Batteries: Review and Future Challenges. Electronics 2017, 6, 102. [Google Scholar] [CrossRef]

- Xiong, R.; Cao, J.; Yu, Q.; He, H.; Sun, F. Critical Review on the Battery State of Charge Estimation Methods for Electric Vehicles. IEEE Access 2018, 6, 1832–1843. [Google Scholar] [CrossRef]

- Berecibar, M.; Gandiaga, I.; Villarreal, I.; Omar, N.; Van Mierlo, J.; Van den Bossche, P. Critical review of state of health estimation methods of Li-ion batteries for real applications. Renew. Sustain. Energy Rev. 2016, 56, 572–587. [Google Scholar] [CrossRef]

- Ungurean, L.; Cârstoiu, G.; Micea, M.V.; Groza, V. Battery state of health estimation: A structured review of models, methods and commercial devices. Int. J. Energy Res. 2017, 41, 151–181. [Google Scholar] [CrossRef]

- Lin, Q.; Wang, J.; Xiong, R.; Shen, W.; He, H. Towards a smarter battery management system: A critical review on optimal charging methods of lithium ion batteries. Energy 2019, 183, 220–234. [Google Scholar] [CrossRef]

- Hillers, A.; Christen, D.; Biela, J. Design of a Highly Efficient Bidirectional Isolated LLC Resonant Converter. In Proceedings of the 2012 15th International Power Electronics and Motion Control Conference (EPE/PEMC), Novi Sad, Serbia, 4–6 September 2012. [Google Scholar]

- Gadelrab, R.; Yang, Y.; Li, B.; Lee, F.C.; Li, Q. High-Frequency High-Density Bidirectional EV Charger. In Proceedings of the IEEE Transportation Electrification Conference and Expo (ITEC) 2018, Long Beach, CA, USA, 13–15 June 2018. [Google Scholar]

- Li, B.; Li, Q.; Lee, F.C. A Novel PCB Winding Transformer with Controllable Leakage Integration for a 6.6 kW 500 kHz High Efficiency High Density Bi-Directional On-Board Charger. In Proceedings of the 2017 IEEE Applied Power Electronics Conference and Exposition (APEC), Tampa, FL, USA, 26–30 March 2017; pp. 2917–2924. [Google Scholar]

- Li, B.; Li, Q.; Lee, F.C.; Liu, Z.; Yang, Y. A High-Efficiency High-Density Wide-Bandgap Device-Based Bidirectional On-Board Charger. IEEE J. Emerg. Sel. Top. Power Electron. 2018, 6, 1627–1636. [Google Scholar] [CrossRef]

- Ejuri, J. How to Compare the Figure of Merit (FOM) of MOSFETs. In Infineon Application Note; 2003; Available online: http://cdn14.21dianyuan.com (accessed on 2 October 2019).

- Saponara, S.; Fanucci, L.; Bernardo, F.; Falciani, A. Predictive diagnosis of high-power transformer faults by networking vibration measuring nodes with integrated signal processing. IEEE Trans. Instrum. Meas. 2016, 65, 1749–1760. [Google Scholar] [CrossRef]

- Saponara, S.; Bacchillone, T. Network architecture, security issues, and hardware implementation of a home area network for smart grid. J. Comput. Netw. Commun. 2012, 2012, 534512. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saponara, S.; Saletti, R.; Mihet-Popa, L. Hybrid Micro-Grids Exploiting Renewables Sources, Battery Energy Storages, and Bi-Directional Converters. Appl. Sci. 2019, 9, 4973. https://doi.org/10.3390/app9224973

Saponara S, Saletti R, Mihet-Popa L. Hybrid Micro-Grids Exploiting Renewables Sources, Battery Energy Storages, and Bi-Directional Converters. Applied Sciences. 2019; 9(22):4973. https://doi.org/10.3390/app9224973

Chicago/Turabian StyleSaponara, Sergio, Roberto Saletti, and Lucian Mihet-Popa. 2019. "Hybrid Micro-Grids Exploiting Renewables Sources, Battery Energy Storages, and Bi-Directional Converters" Applied Sciences 9, no. 22: 4973. https://doi.org/10.3390/app9224973

APA StyleSaponara, S., Saletti, R., & Mihet-Popa, L. (2019). Hybrid Micro-Grids Exploiting Renewables Sources, Battery Energy Storages, and Bi-Directional Converters. Applied Sciences, 9(22), 4973. https://doi.org/10.3390/app9224973