Physics-Based Vehicle Simulation Using PD Servo

Abstract

:1. Introduction

2. Related Works

2.1. Vehicle Simulation

2.2. Ground Contact

2.3. Object Deformation

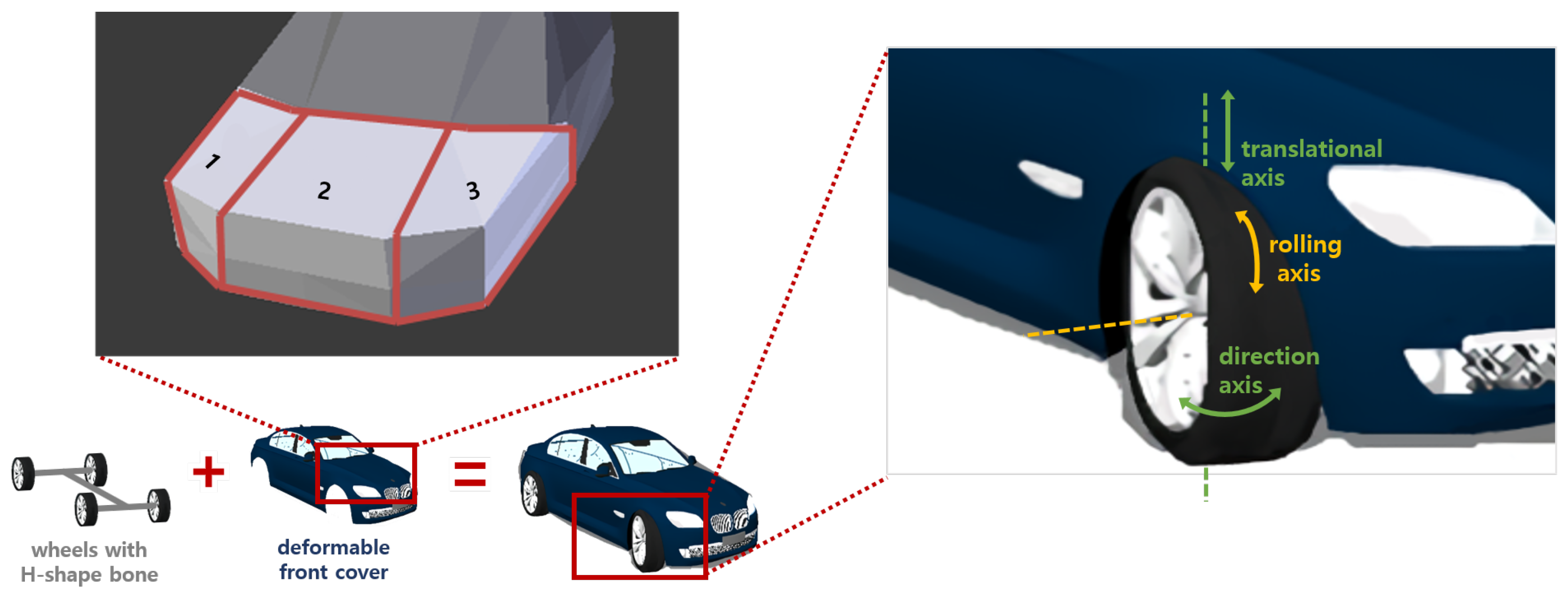

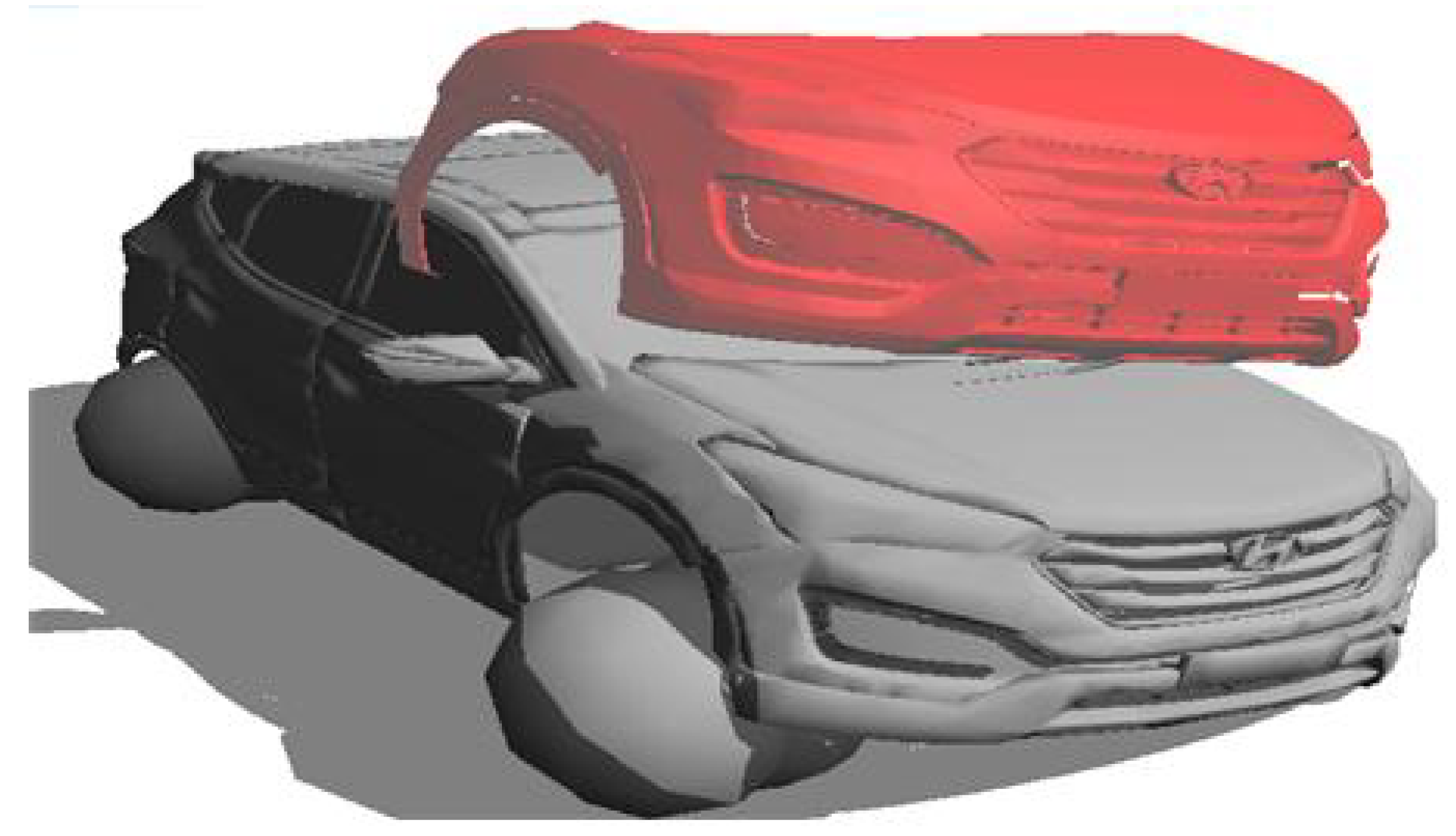

3. Vehicle Design

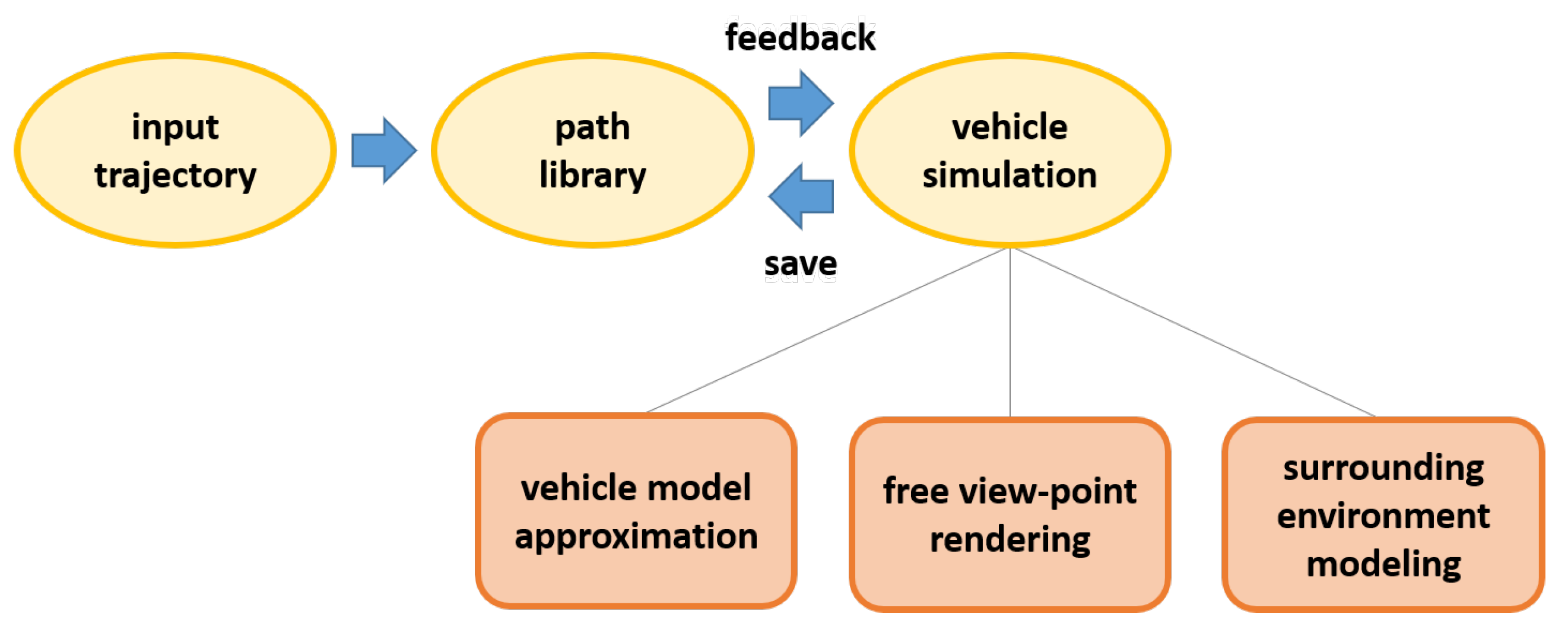

4. Vehicle Simulation

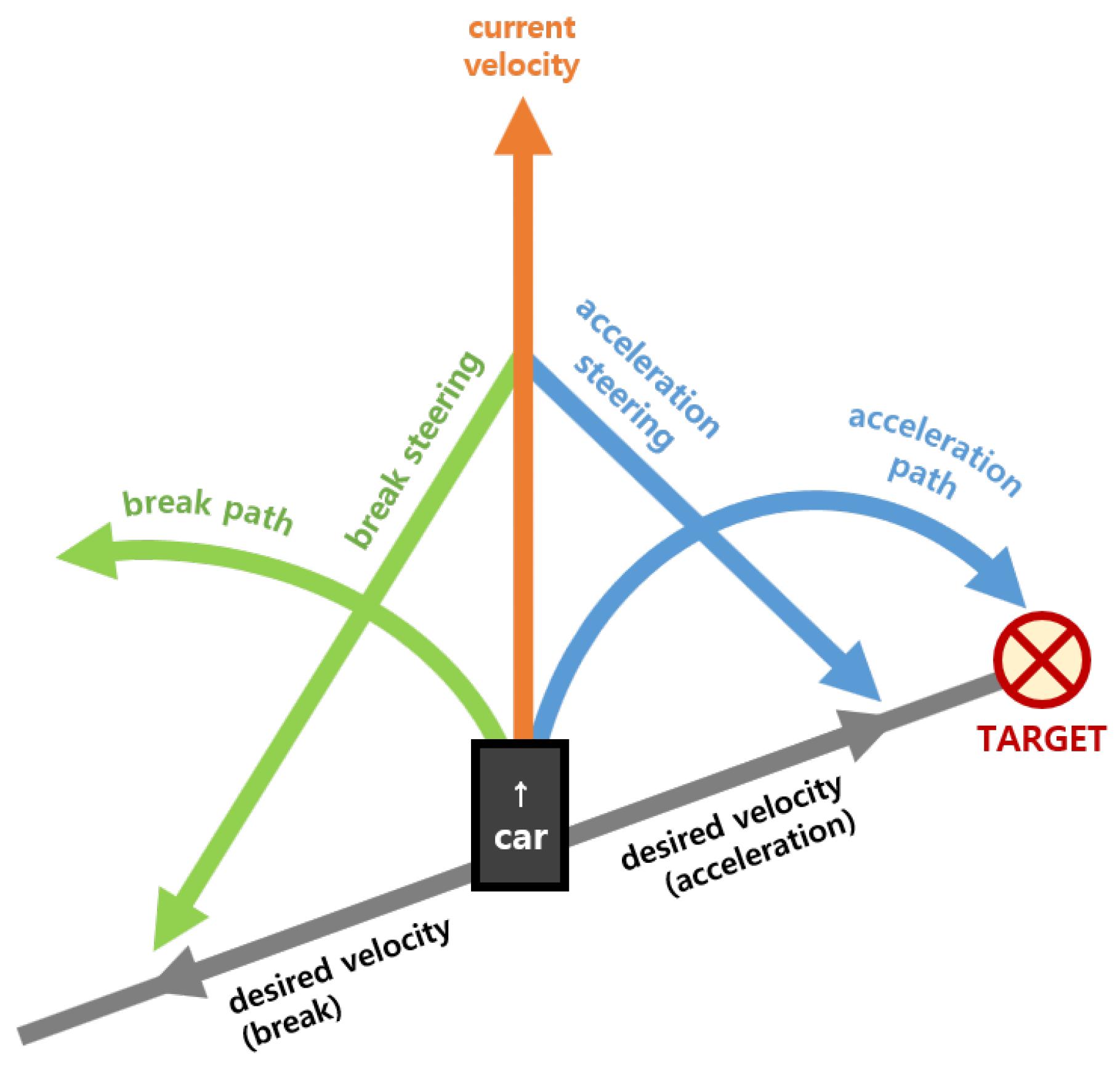

4.1. Vehicle Control

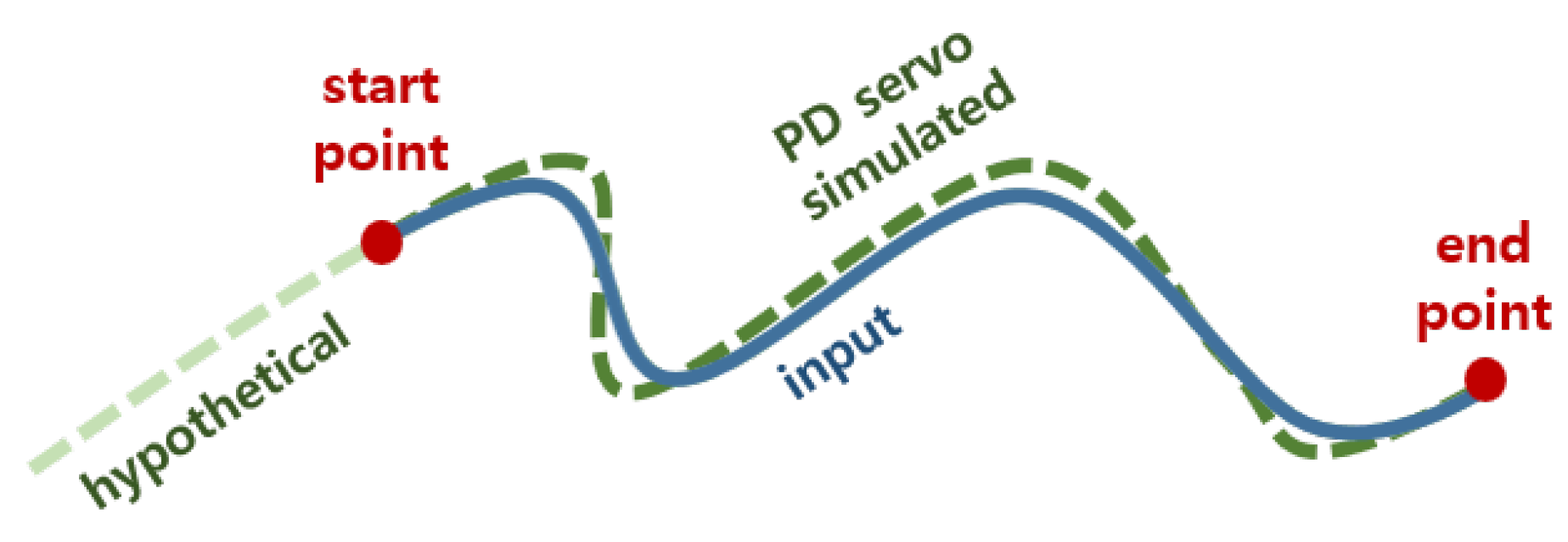

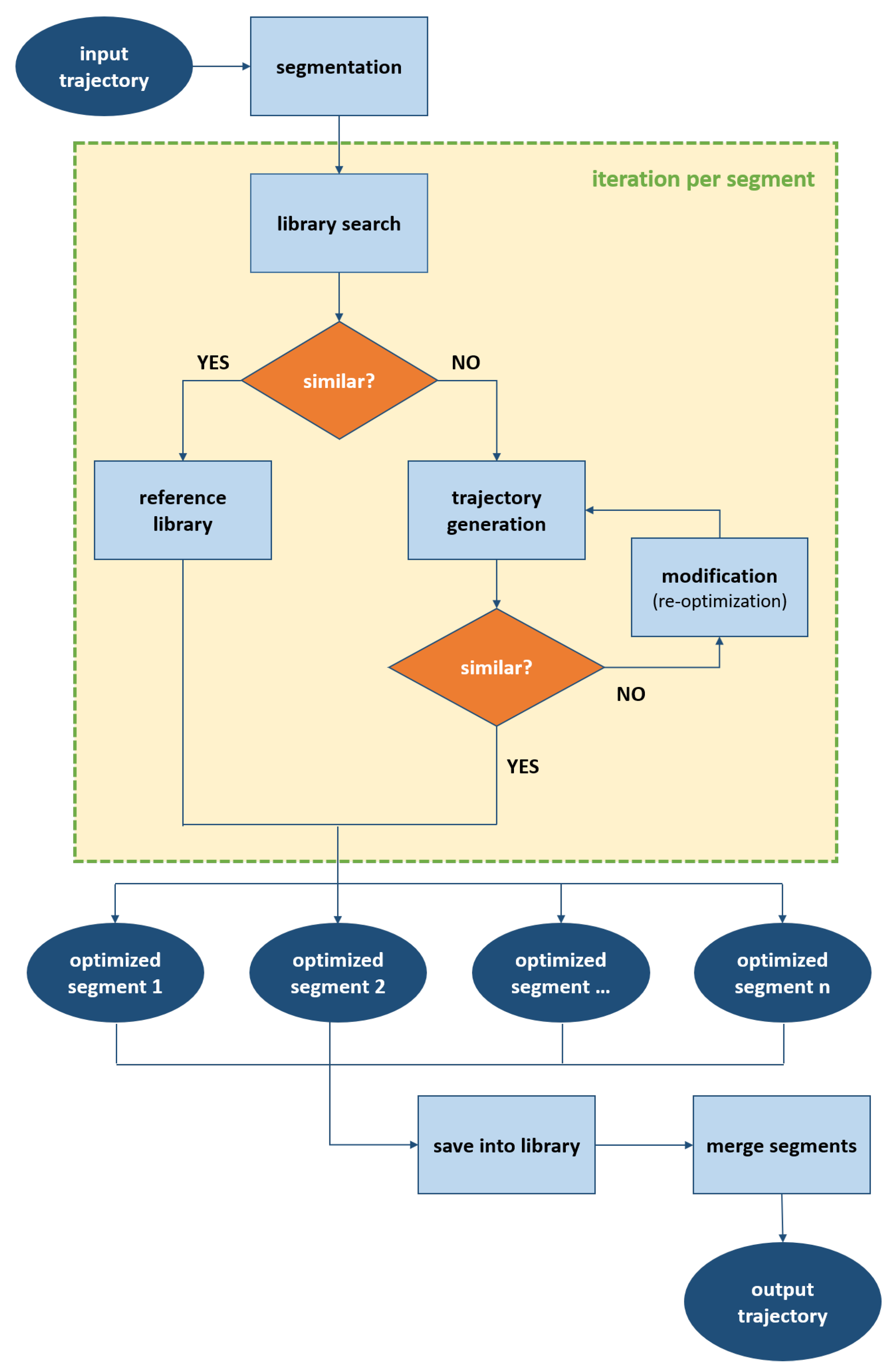

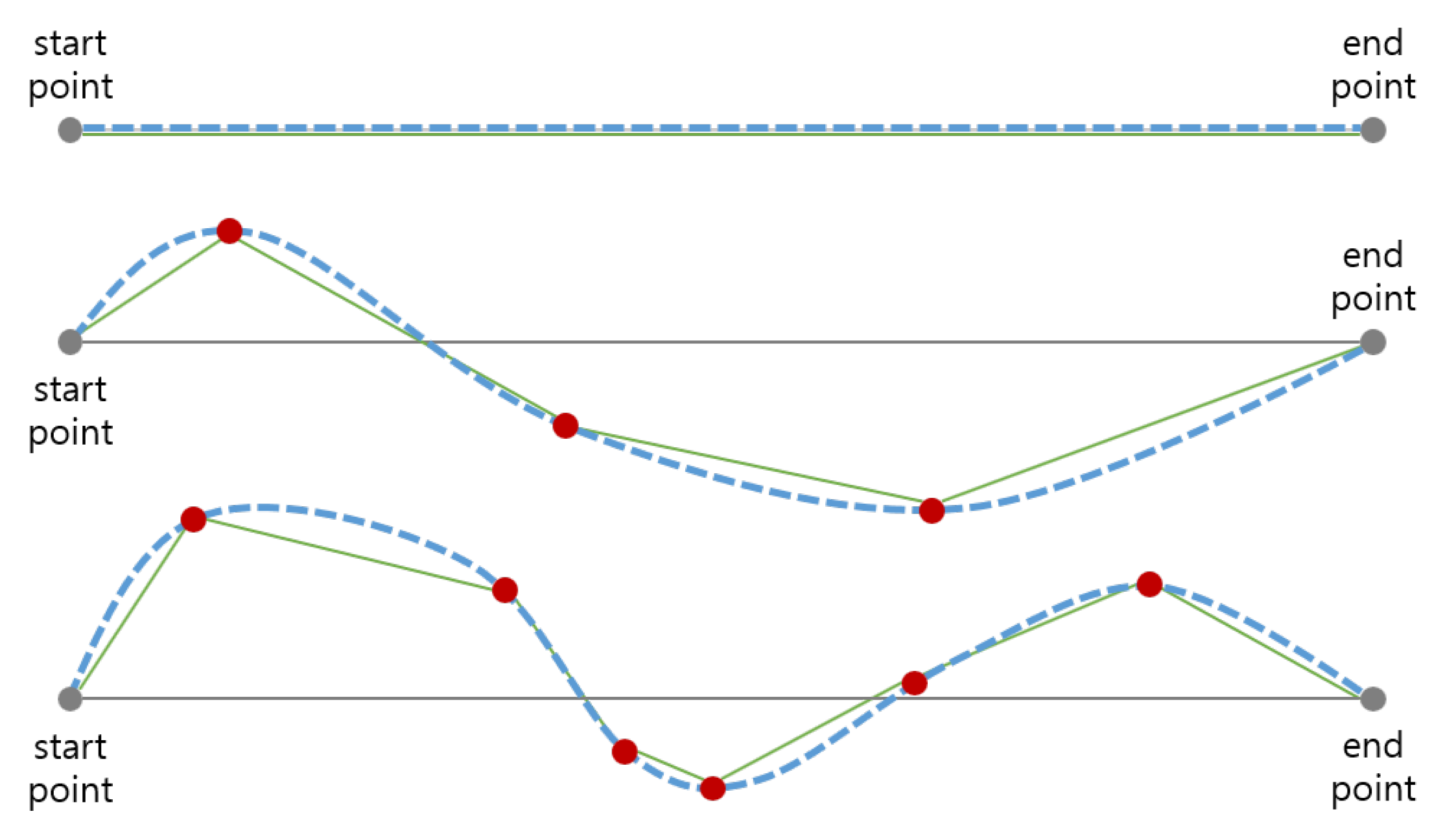

4.2. Trajectory Optimization

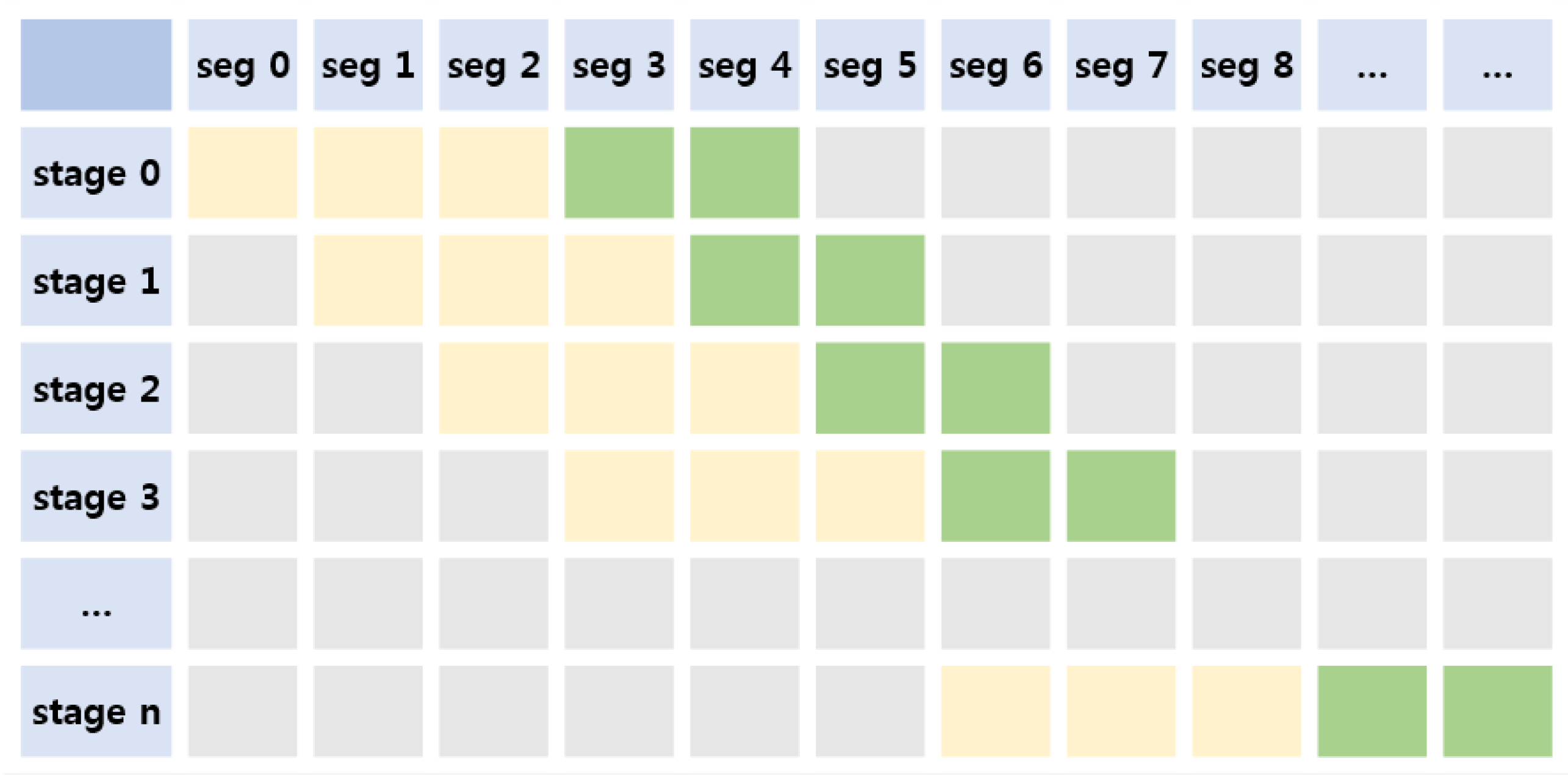

4.3. Trajectory Search

4.4. Contact with Ground Surface

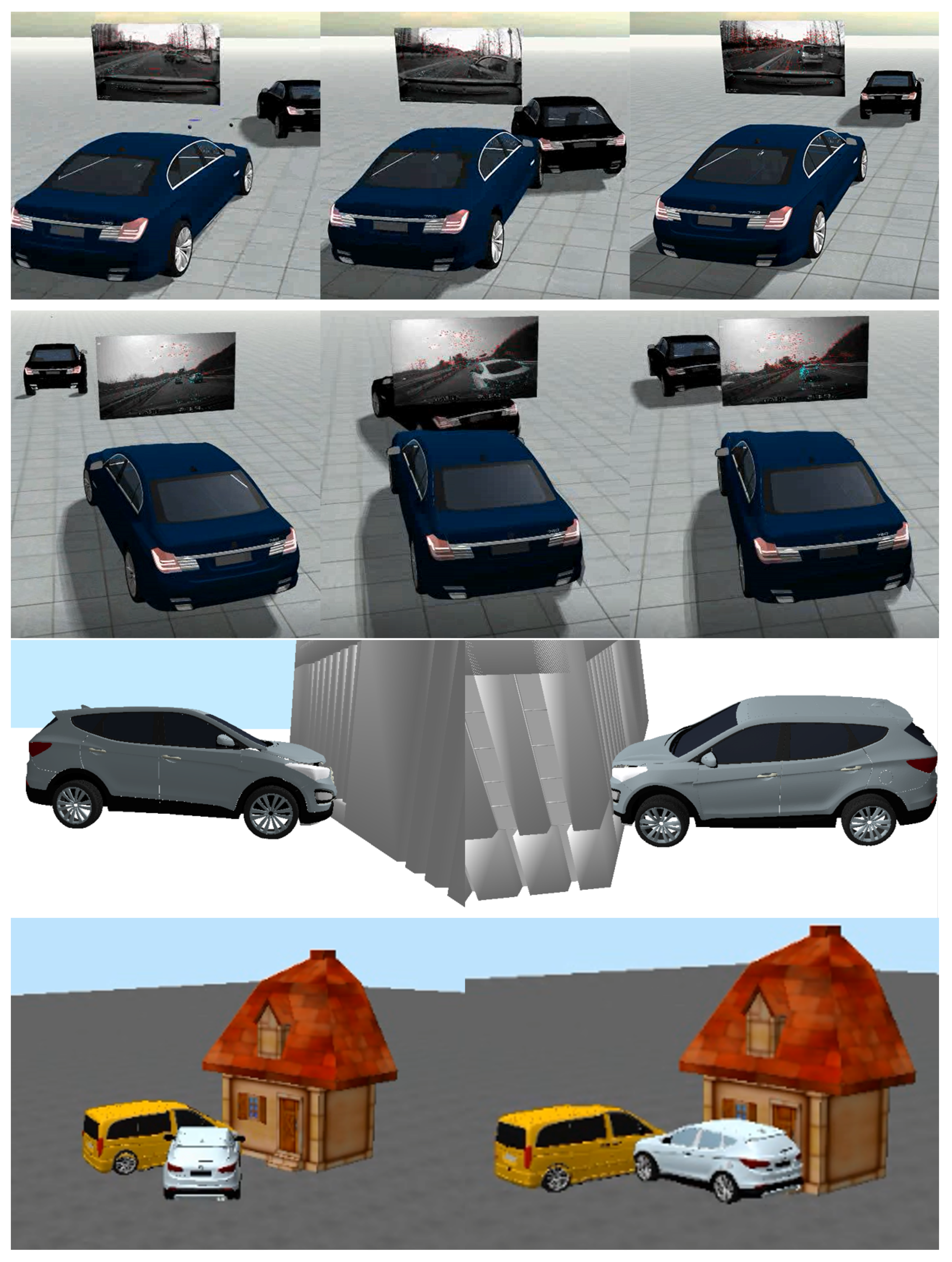

5. Vehicle Deformation

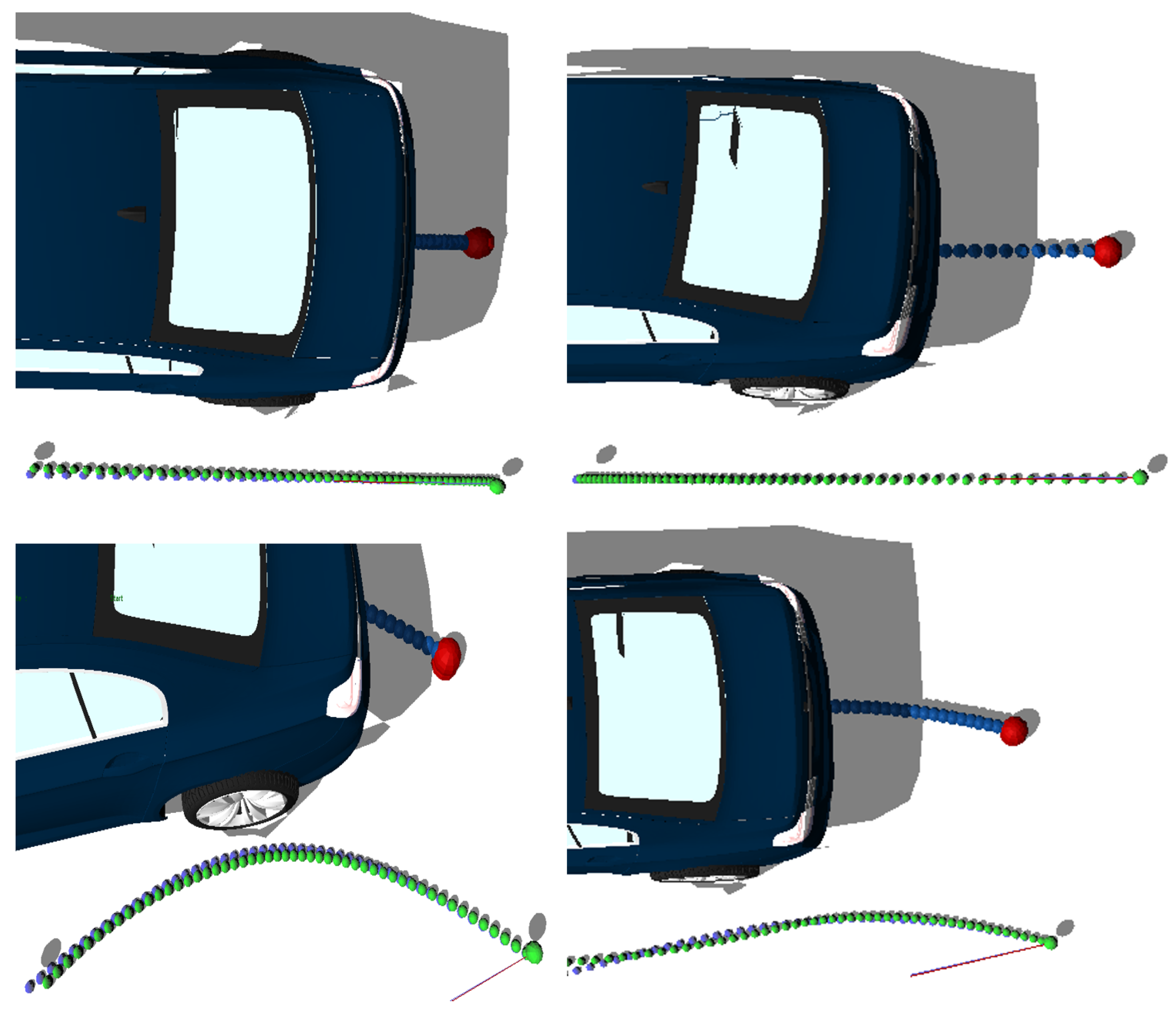

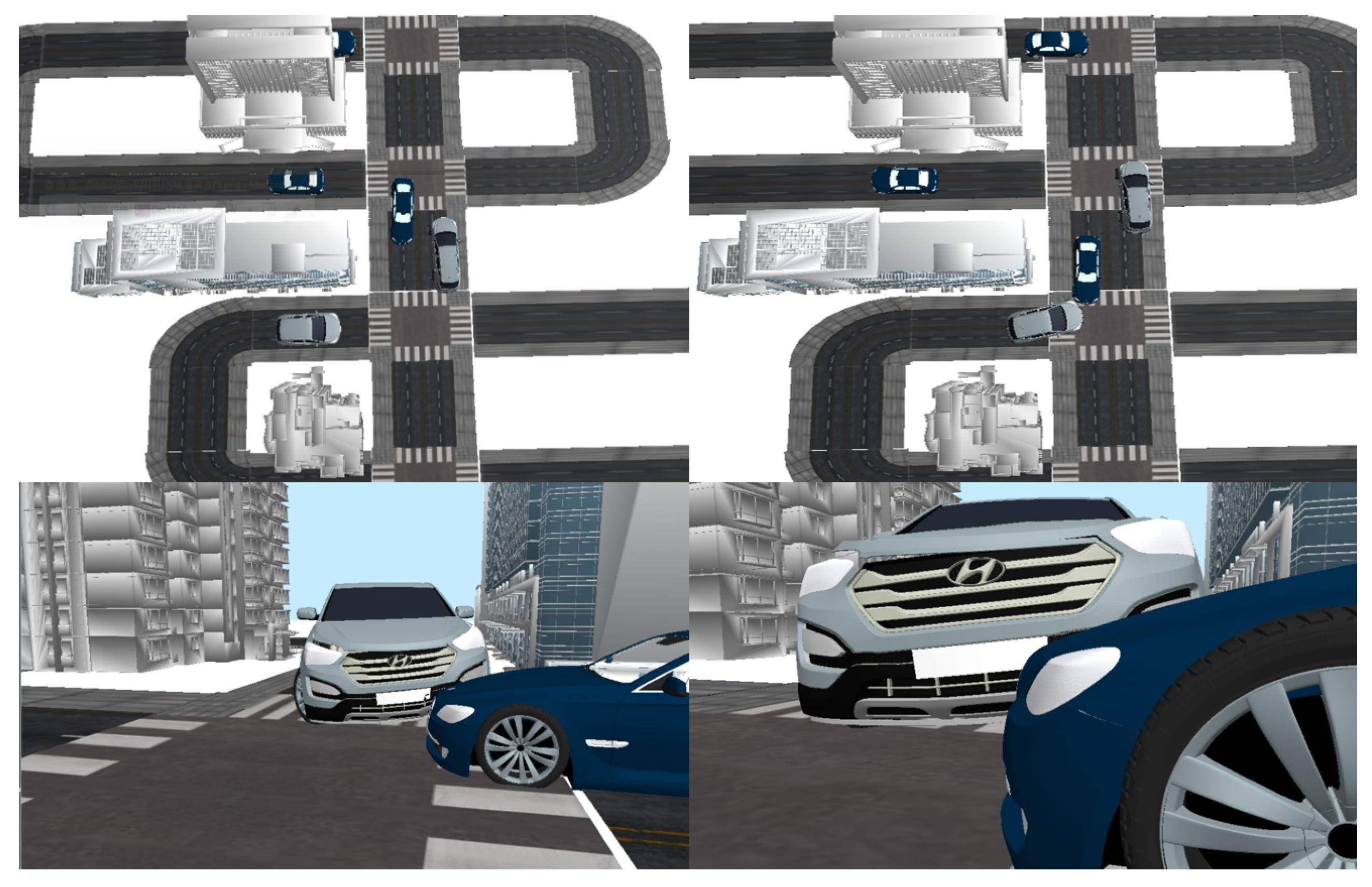

6. Experimental Results

6.1. Simulation Tool

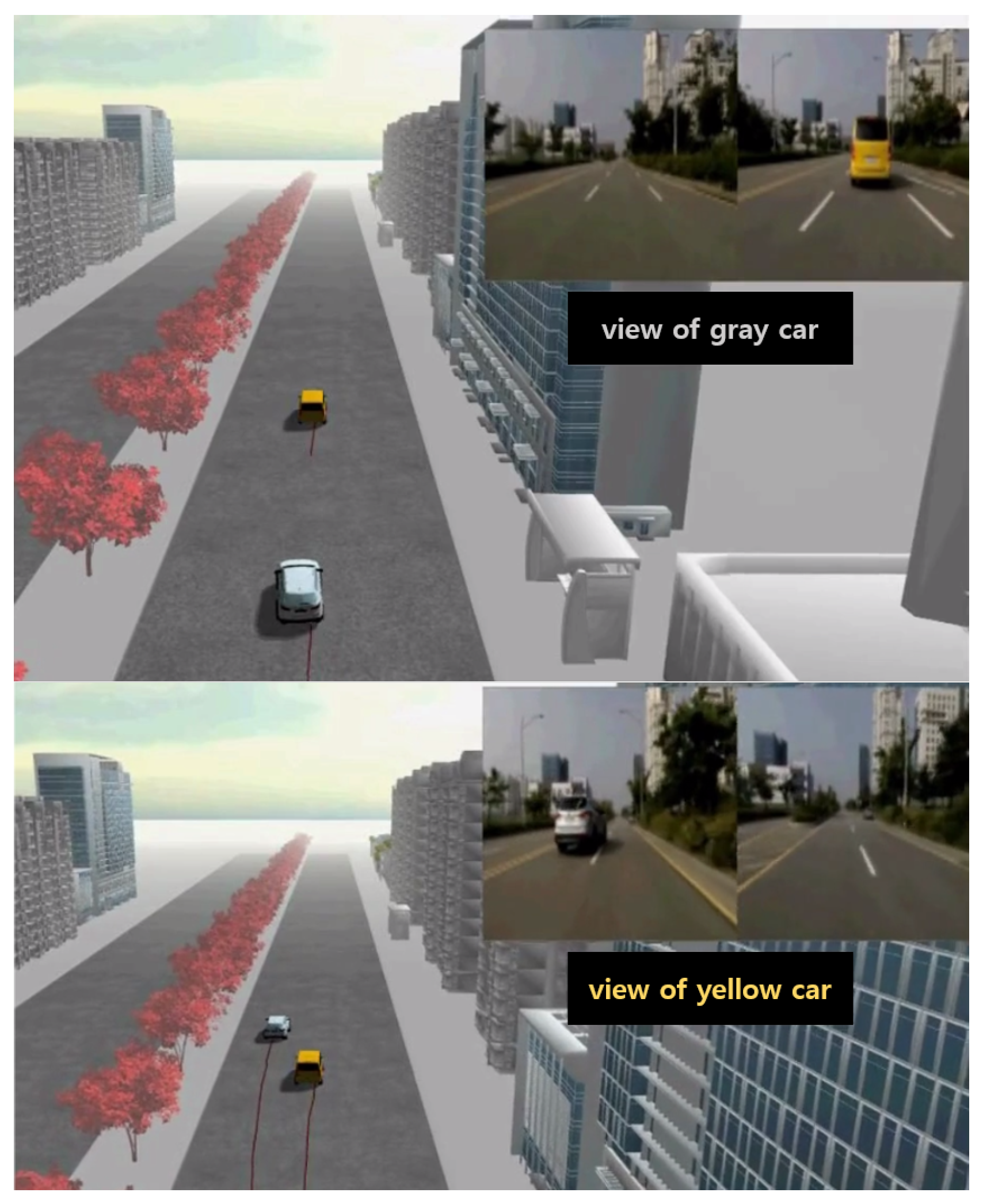

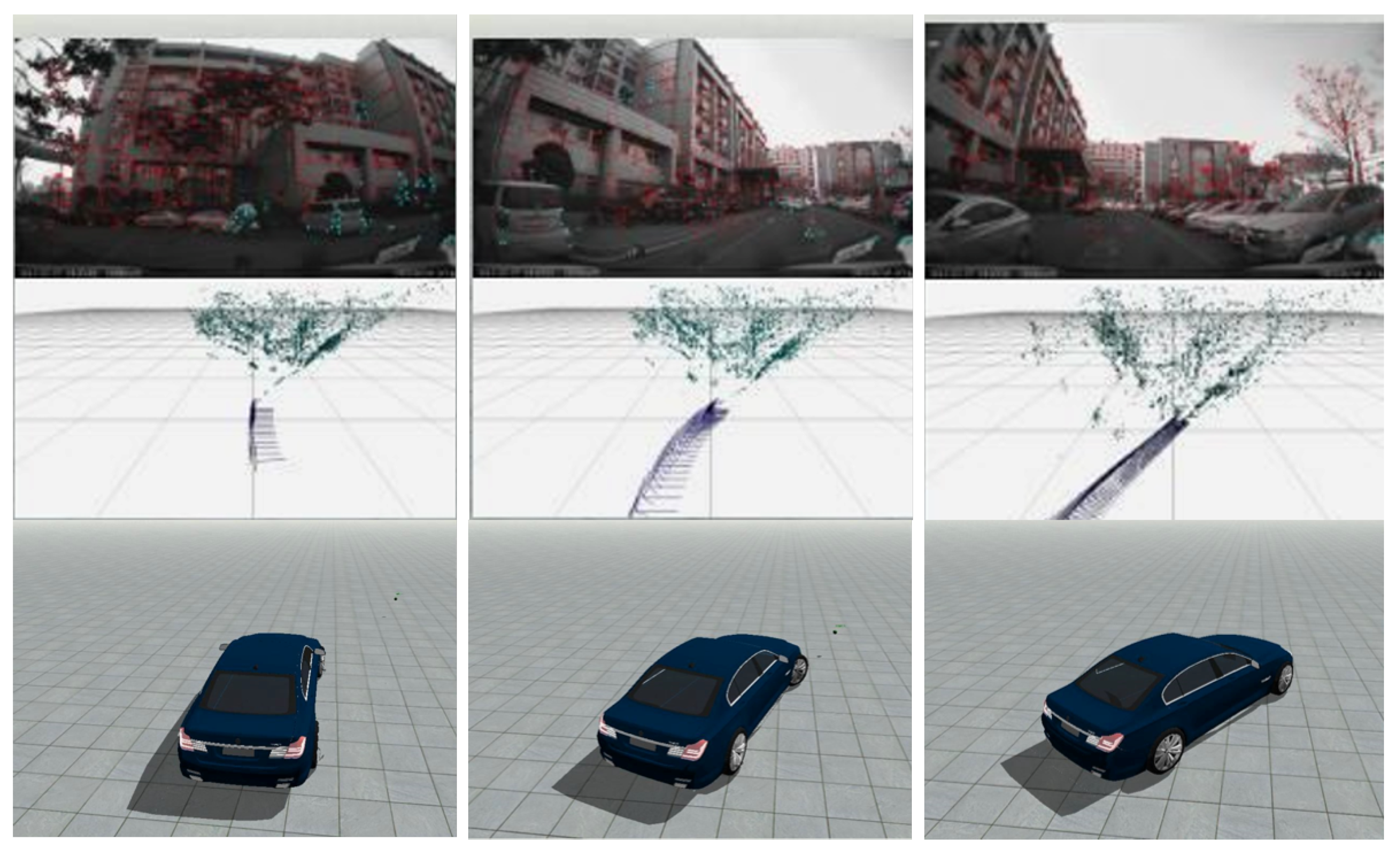

6.2. Simulation Using GPS Data

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| PD | Proportional derivative |

| LCP | Linear complementarity problem |

| LBS | Linear blend skinning |

| DQS | Dual quaternion skinning |

| GPS | Global position system |

| KLT | Kanade–Lucas–Tomasi |

| SFM | Structure from motion |

References

- Schaal, S.; Kotosaka, S.; Sternad, D. Nonlinear dynamical systems as movement primitives. In Proceedings of the IEEE International Conference on Humanoid Robotics, MIT, Cambridge, MA, USA, 7–8 September 2000; pp. 1–11. [Google Scholar]

- Schaal, S.; Peters, J.; Nakanishi, J.; Ijspeert, A. Learning movement primitives. In Robotics Research the Eleventh International Symposium; Springer: Berlin/Heidelberg, Germany, 2005; pp. 561–572. [Google Scholar]

- Kobilarov, M.; Crane, K.; Desbrun, M. Lie group integrators for animation and control of vehicles. ACM Trans. Graph. 2009, 28, 16. [Google Scholar] [CrossRef]

- Sewall, J.; Wilkie, D.; Merrell, P.; Lin, M.C. Continuum Traffic Simulation. Comput. Graph. Forum 2010, 29, 439–448. [Google Scholar] [CrossRef]

- Sewall, J.; Wilkie, D.; Lin, M.C. Interactive hybrid simulation of large-scale traffic. Acm Trans. Graph. 2011, 30, 135. [Google Scholar] [CrossRef]

- Garcia-Dorado, I.; G Aliaga, D.; V Ukkusuri, S. Designing Large-Scale Interactive Traffic Animations for Urban Modeling. Comput. Graph. Forum 2014, 33, 411–420. [Google Scholar] [CrossRef]

- Kallmann, M.; Lemoine, P.; Thalmann, D.; Cordier, F.; Magnenat-Thalmann, N.; Ruspa, C.; Quattrocolo, S. Immersive vehicle simulators for prototyping, training and ergonomics. In Proceedings of the IEEE Computer Graphics International, Tokyo, Japan, 9–11 July 2003; pp. 90–95. [Google Scholar]

- Tan, J.; Gu, Y.; Liu, C.K.; Turk, G. Learning bicycle stunts. ACM Trans. Graph. 2014, 33, 50. [Google Scholar] [CrossRef]

- Galin, E.; Peytavie, A.; Maréchal, N.; Guérin, E. Procedural Generation of Roads. Comput. Graph. Forum 2010, 29, 429–438. [Google Scholar] [CrossRef]

- Stewart, D.; Trinkle, J.C. An implicit time-stepping scheme for rigid body dynamics with coulomb friction. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA’00), San Francisco, CA, USA, 24–28 April 2000; Volume 1, pp. 162–169. [Google Scholar]

- Lötstedt, P. Numerical simulation of time-dependent contact and friction problems in rigid body mechanics. SIAM J. Sci. Stat. Comput. 1984, 5, 370–393. [Google Scholar] [CrossRef]

- Baraff, D. Coping with friction for non-penetrating rigid body simulation. ACM Siggraph Comput. Graph. 1991, 25, 31–41. [Google Scholar] [CrossRef]

- Baraff, D. Fast contact force computation for nonpenetrating rigid bodies. In Proceedings of the 21st Annual Conference on Computer Graphics and Interactive Techniques, Orlando, FL, USA, 24–29 July 1994; pp. 23–34. [Google Scholar]

- Trinkle, J.C.; Pang, J.S.; Sudarsky, S.; Lo, G. On Dynamic Multi-Rigid-Body Contact Problems with Coulomb Friction. ZAMM-J. Appl. Math. Mech. FÜR Angew. Math. Und Mech. 1997, 77, 267–279. [Google Scholar] [CrossRef]

- Erleben, K. Velocity-based shock propagation for multibody dynamics animation. ACM Trans. Graph. 2007, 26, 12. [Google Scholar] [CrossRef]

- Kaufman, D.M.; Sueda, S.; James, D.L.; Pai, D.K. Staggered projections for frictional contact in multibody systems. ACM Trans. Graph. 2008, 27, 164. [Google Scholar] [CrossRef]

- Otaduy, M.A.; Tamstorf, R.; Steinemann, D.; Gross, M. Implicit Contact Handling for Deformable Objects. Comput. Graph. Forum 2009, 28, 559–568. [Google Scholar] [CrossRef]

- Coros, S.; Martin, S.; Thomaszewski, B.; Schumacher, C.; Sumner, R.; Gross, M. Deformable objects alive! ACM Trans. Graph. 2012, 31, 69. [Google Scholar] [CrossRef]

- Barbič, J.; Popović, J. Real-time control of physically based simulations using gentle forces. ACM Trans. Graph. 2008, 27, 163. [Google Scholar] [CrossRef]

- Skouras, M.; Thomaszewski, B.; Coros, S.; Bickel, B.; Gross, M. Computational design of actuated deformable characters. ACM Trans. Graph. 2013, 32, 82. [Google Scholar] [CrossRef]

- Liu, L.; Yin, K.; Wang, B.; Guo, B. Simulation and control of skeleton-driven soft body characters. ACM Trans. Graph. 2013, 32, 215. [Google Scholar] [CrossRef]

- Tan, J.; Gu, Y.; Turk, G.; Liu, C.K. Articulated swimming creatures. ACM Trans. Graph. 2011, 30, 58. [Google Scholar] [CrossRef]

- Wang, Y.; Jacobson, A.; Barbič, J.; Kavan, L. Linear subspace design for real-time shape deformation. ACM Trans. Graph. 2015, 34, 57. [Google Scholar] [CrossRef]

- Larsson, T.; Akenine-Möller, T. Efficient collision detection for models deformed by morphing. Vis. Comput. 2003, 19, 164–174. [Google Scholar]

- Teschner, M.; Kimmerle, S.; Heidelberger, B.; Zachmann, G.; Raghupathi, L.; Fuhrmann, A.; Cani, M.P.; Faure, F.; Magnenat-Thalmann, N.; Strasser, W.; et al. Collision Detection for Deformable Objects. Comput. Graph. Forum 2005, 24, 61–81. [Google Scholar] [CrossRef]

- Kavan, L.; Žára, J. Fast Collision Detection for Skeletally Deformable Models. Comput. Graph. Forum 2005, 24, 363–372. [Google Scholar] [CrossRef]

- Kwon, T.; Hodgins, J.K. Momentum-mapped inverted pendulum models for controlling dynamic human motions. ACM Trans. Graph. 2017, 36, 10. [Google Scholar] [CrossRef]

- Yamane, K.; Nakamura, Y. A numerically robust LCP solver for simulating articulated rigid bodies in contact. In Proceedings of the Robotics: Science and Systems IV, Zurich, Switzerland, 25–28 June 2008; Volume 19, p. 20. [Google Scholar]

- Kavan, L.; Collins, S.; Žára, J.; O’Sullivan, C. Skinning with dual quaternions. In Proceedings of the 2007 Symposium on Interactive 3D Graphics and Games, Seattle, WA, USA, 30 April–2 May 2007; pp. 39–46. [Google Scholar]

- OpenHRP3. Available online: http://fkanehiro.github.io/openhrp3-doc/en/index.html (accessed on 10 June 2019).

- Bullet Collision Detection & Physics Library. Available online: https://pybullet.org/Bullet/BulletFull/index.html (accessed on 20 March 2019).

- Video for Experimental Results. Available online: https://drive.google.com/open?id=1VEkKGmnfz0a2ESw3gJinKaqwPej9QNoD (accessed on 28 October 2019).

- Tomasi, C.; Kanade, T. Detection and Tracking of Point Features; Technical Report CMU-CS-91-132; Carnegie Mellon University: Pittsburgh, PA, USA, 1991. [Google Scholar]

- Häming, K.; Peters, G. The structure-from-motion reconstruction pipeline–a survey with focus on short image sequences. Kybernetika 2010, 46, 926–937. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, D.; Jeong, J.; Ko, S.-w.; Kwon, T.; Kim, Y. Physics-Based Vehicle Simulation Using PD Servo. Appl. Sci. 2019, 9, 4949. https://doi.org/10.3390/app9224949

Kang D, Jeong J, Ko S-w, Kwon T, Kim Y. Physics-Based Vehicle Simulation Using PD Servo. Applied Sciences. 2019; 9(22):4949. https://doi.org/10.3390/app9224949

Chicago/Turabian StyleKang, Daeun, Jinuk Jeong, Seung-wook Ko, Taesoo Kwon, and Yejin Kim. 2019. "Physics-Based Vehicle Simulation Using PD Servo" Applied Sciences 9, no. 22: 4949. https://doi.org/10.3390/app9224949

APA StyleKang, D., Jeong, J., Ko, S.-w., Kwon, T., & Kim, Y. (2019). Physics-Based Vehicle Simulation Using PD Servo. Applied Sciences, 9(22), 4949. https://doi.org/10.3390/app9224949