Novel Approach to Manufacture an AUV Propeller by Additive Manufacturing and Error Analysis

Abstract

1. Introduction

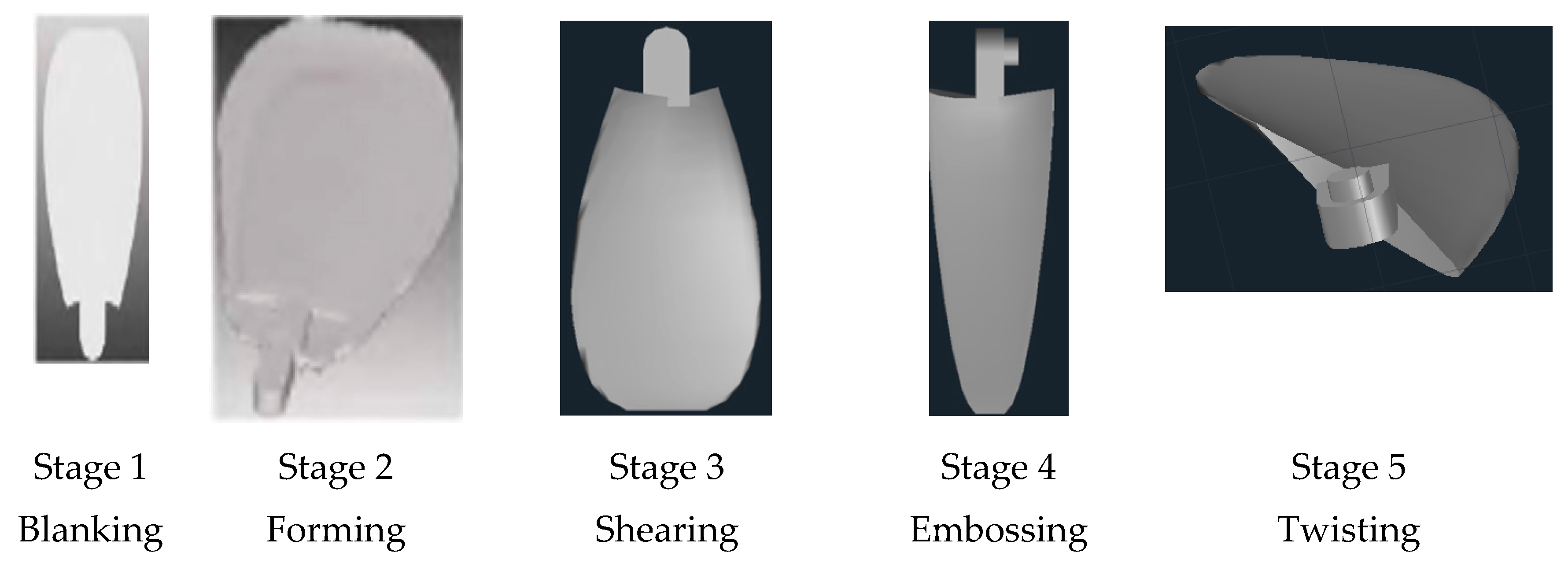

2. Materials and Methods

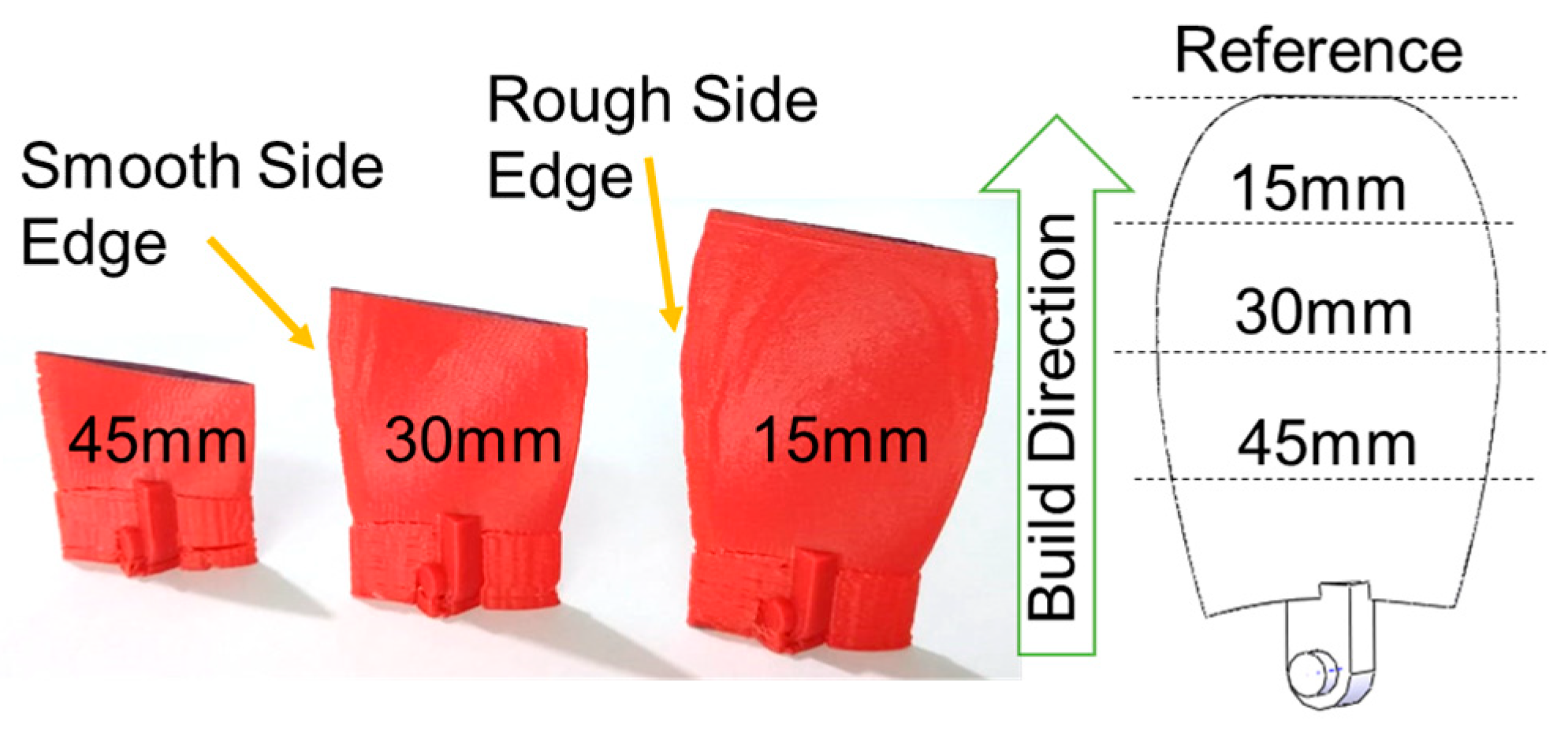

2.1. Procedure for 3D Printing by FDM

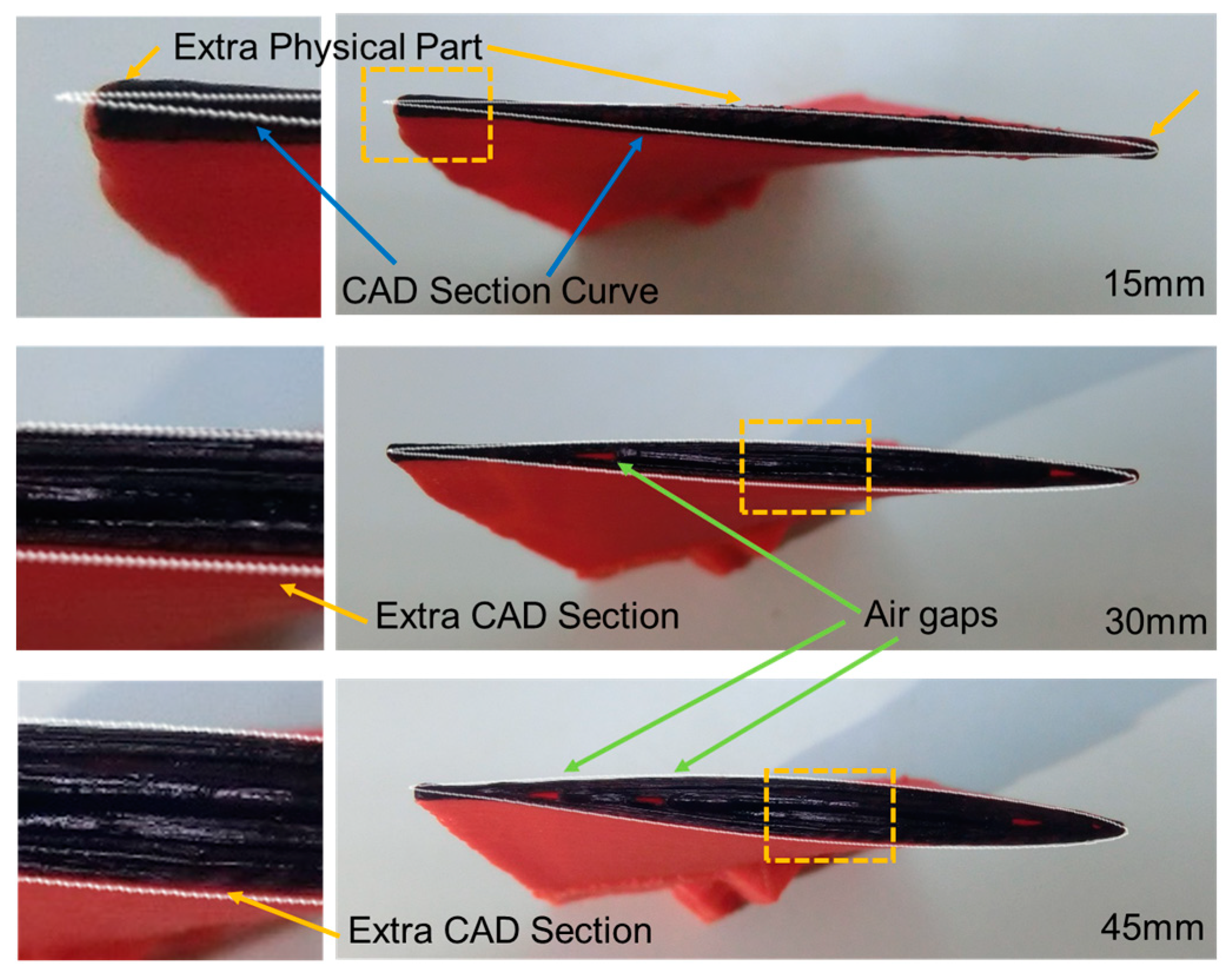

2.2. Profile Comparison and Error Measurement

3. Results and Discussion

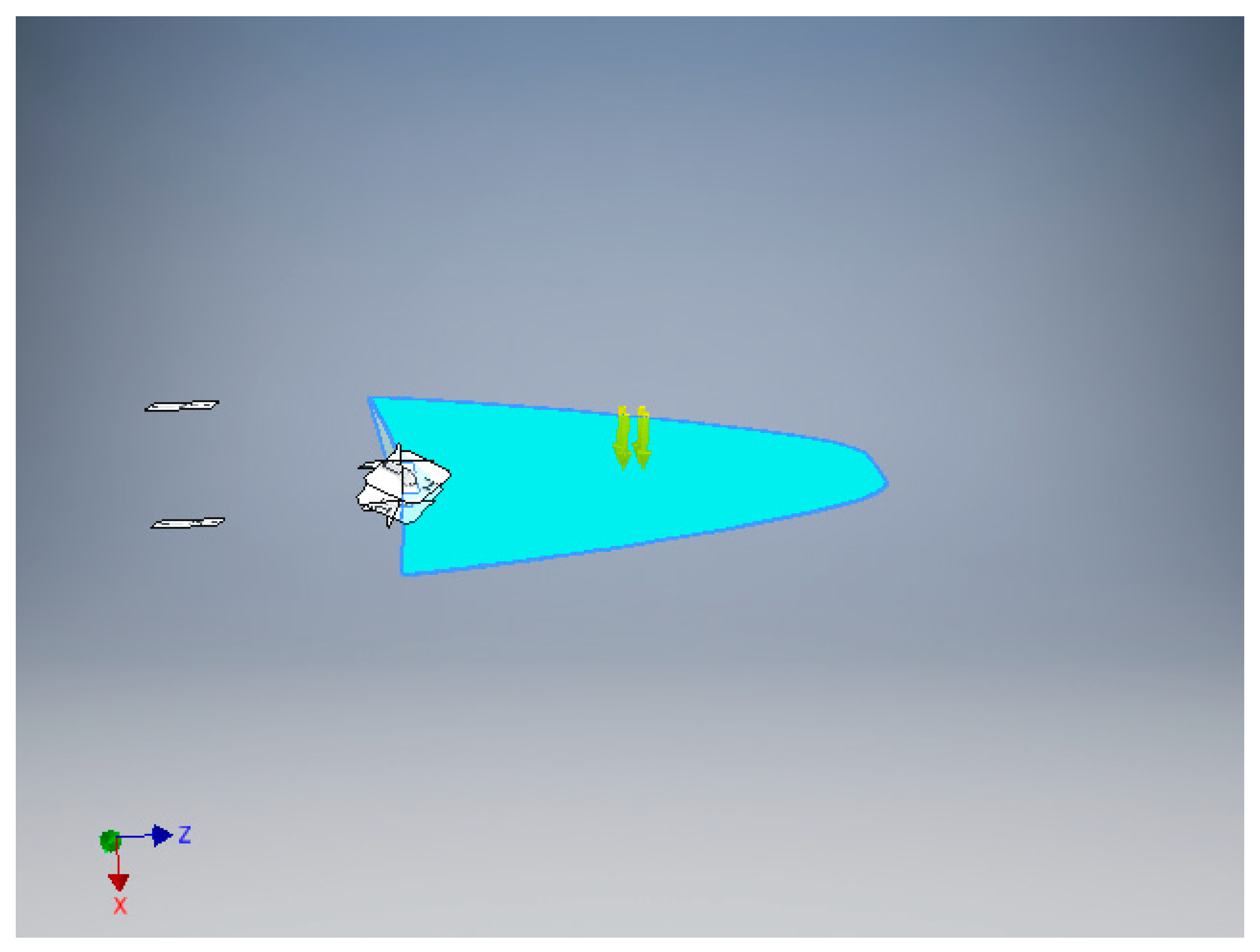

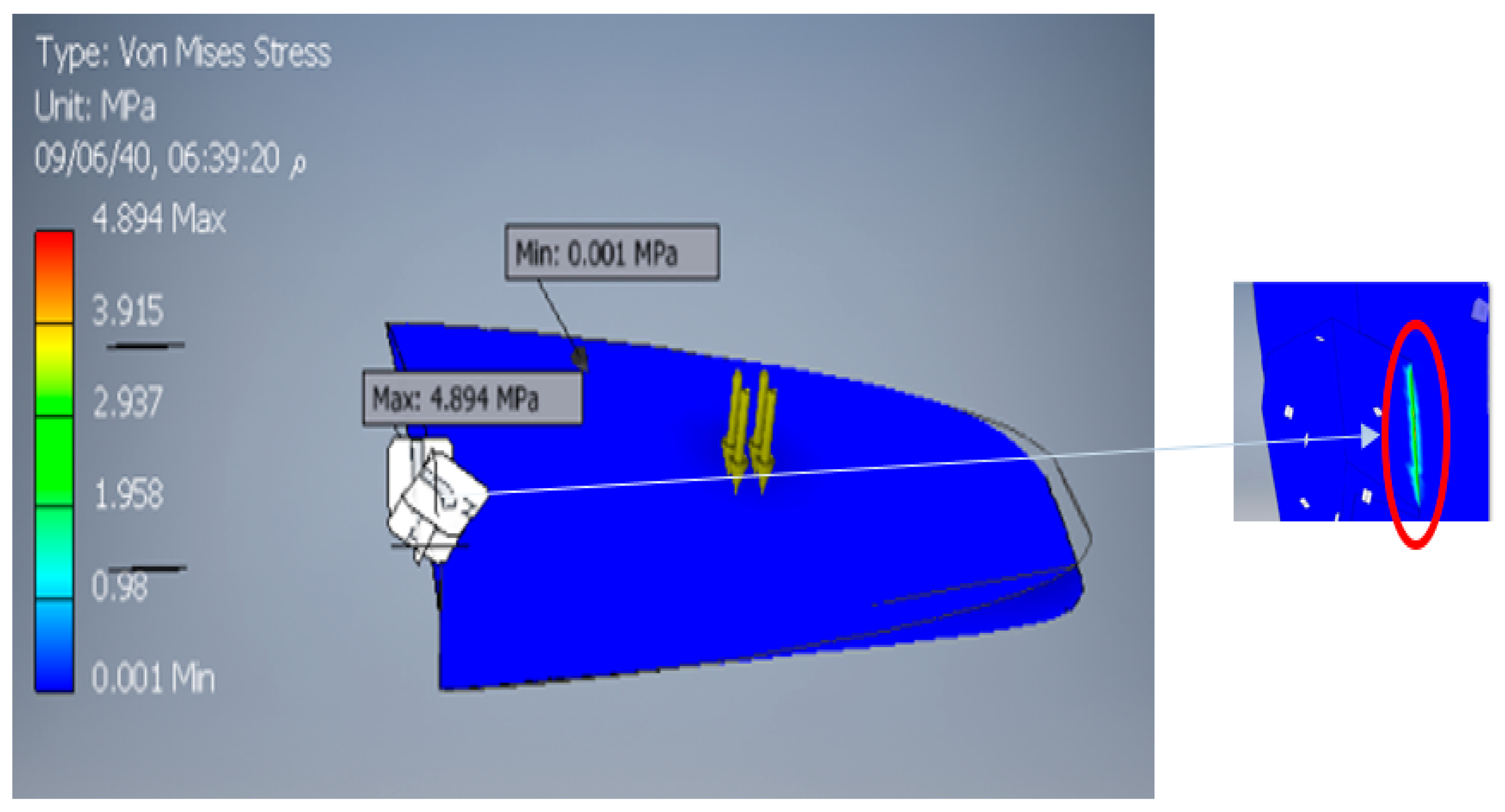

3.1. FEM Analysis

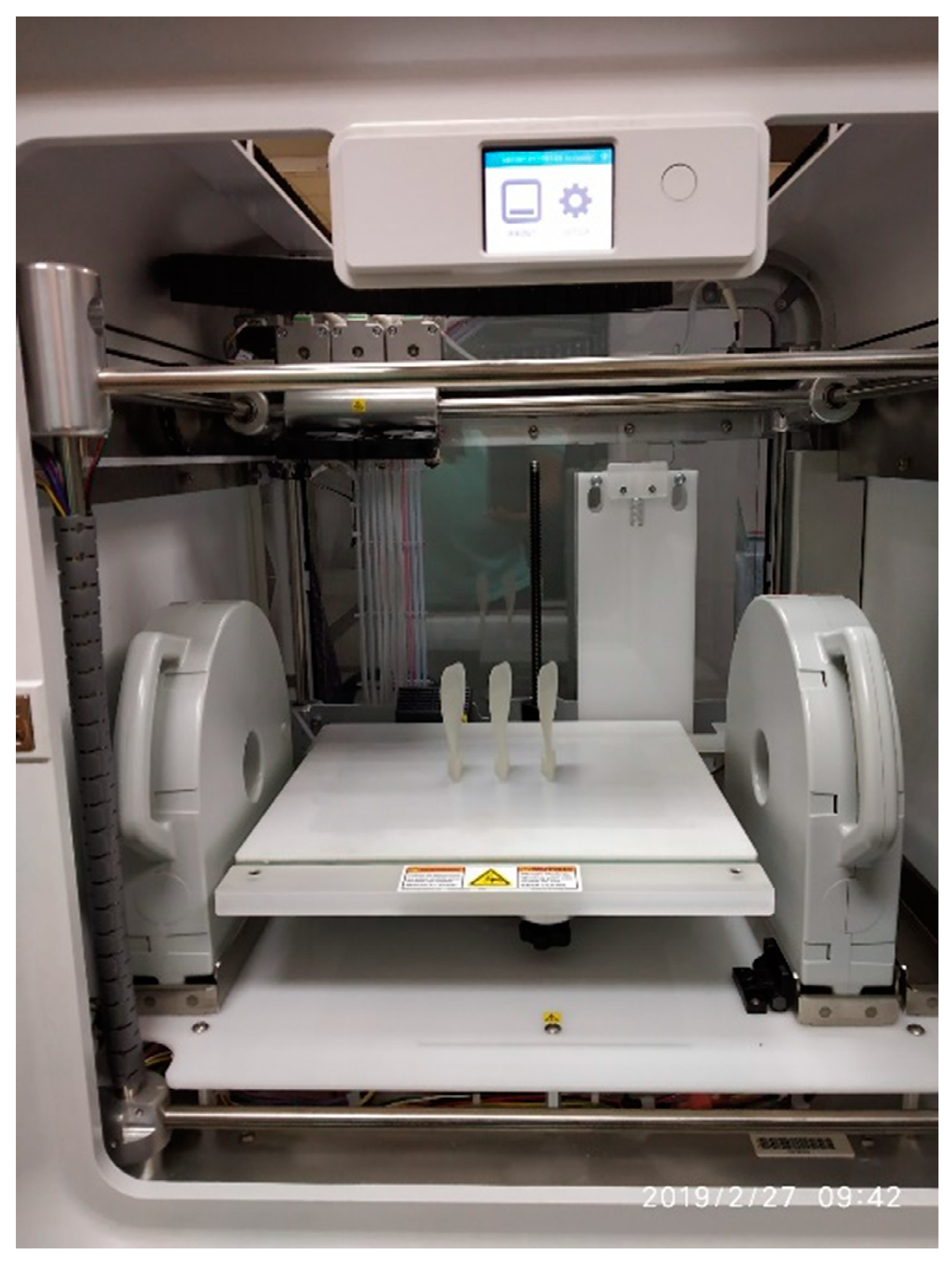

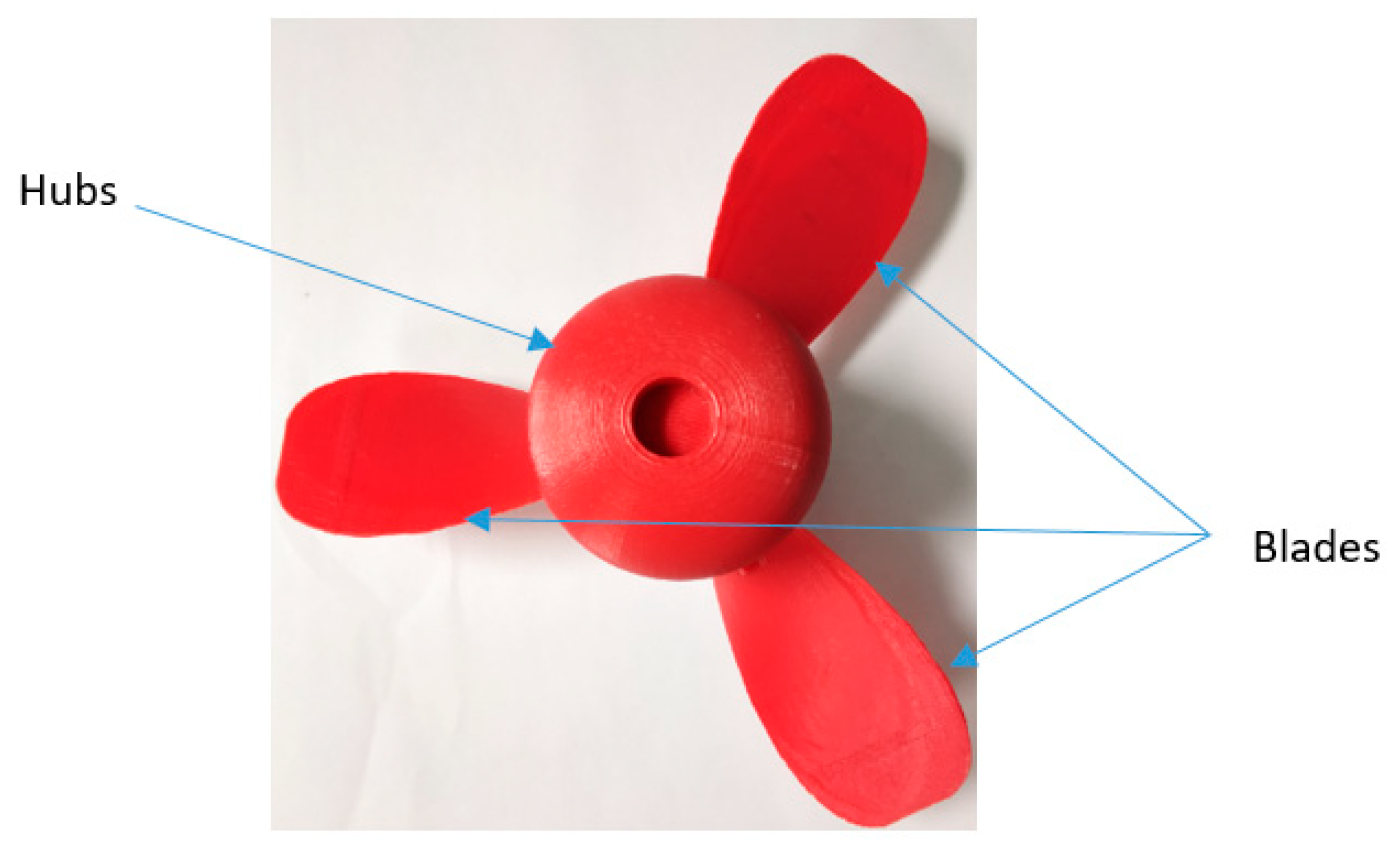

3.2. 3D Printing by FDM

3.3. Error Measurement

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhangwei, C.; Ziyong, L.; Chengbo, L.; Changshi, L.; Yuelong, F.; Changyong, L.; Yang, L.; Pei, W.; Yi, H. 3D printing of ceramics: A review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar]

- Ahangar, P.; Cooke, M.E.; Weber, M.H.; Rosenzweig, D.H. Current biomedical applications of 3D printing and additive manufacturing. Appl. Sci. 2019, 9, 1713. [Google Scholar] [CrossRef]

- Brunello, G.; Sivolella, S.; Meneghello, R.; Ferroni, L.; Gardin, C.; Piattelli, A.; Zavan, B.; Bressan, E. Powder-based 3D printing for bone tissue engineering. Biotechnol. Adv. 2016, 34, 740–753. [Google Scholar] [CrossRef] [PubMed]

- Martijn, T.B.M.; Tate, D.; Wang, S.; Campanile, F.; Chen, Y. Application of robust design techniques for 3D printing on textiles. Adv. Int. Syst. Comput. 2020, 975, 153–165. [Google Scholar]

- Jeong, H.Y.; An, S.C.; Seo, I.C.; Kim, N.; Jun, Y.C. 3D printing of plant tissue for innovative food manufacturing: Encapsulation of alive plant cells into pectin based bio-ink. J. Food Eng. 2019, 263, 454–464. [Google Scholar]

- Hu, B.; Duan, X.; Xing, Z.; Chen, R.; Shan, B. Improved design of fused deposition modeling equipment for 3D printing of high-performance PEEK parts. Mech. Mater. 2019, 137, 103139. [Google Scholar] [CrossRef]

- Ivanov, E.; Kotsilkova, R.; Xia, H.; Chen, Y.; Donato, R.K.; Donato, K.; Godoy, A.P.; Di Maio, R.; Silvestre, C.; Cimmino, S.; et al. PLA/Graphene/MWCNT composites with improved electrical and thermal properties suitable for FDM 3D printing applications. Appl. Sci. 2019, 9, 1209. [Google Scholar] [CrossRef]

- Gültekin, H.E.; Tort, S.; Acartürk, F. An Effective Technology for the Development of Immediate Release Solid Dosage Forms Containing Low-Dose Drug: Fused Deposition Modeling 3D Printing. Pharm. Res. 2019, 36, 128. [Google Scholar] [CrossRef]

- Saleem, H.; Batalha, G.F.; van Tyne, C.J.; Yilbas, B. Comprehensive Materials Processing; Elsevier: Amsterdam, The Netherlands, 2014; pp. 69–91. [Google Scholar]

- Melchels, F.P.W.; Bertoldi, K.; Gabbrielli, R.; Velders, A.H.; Feijen, J.; Grijpma, D.W. Mathematically defined tissue engineering scaffold architectures prepared by stereolithography. Biomaterials 2010, 31, 6909–6916. [Google Scholar] [CrossRef]

- Sano, Y.; Matsuzaki, R.; Ueda, M.; Todoroki, A.; Hirano, Y. 3D printing of discontinuous and continuous fibre composites using stereolithography. Addit. Manuf. 2018, 24, 521–552. [Google Scholar] [CrossRef]

- Park, H.K.; Shin, M.; Kim, B.; Park, J.W.; Lee, H. A visible light-curable yet visible wavelength-transparent resin for stereolithography 3D printing. NPG Asia Mater. 2018, 10, 82–89. [Google Scholar] [CrossRef]

- Yan, C.; Hao, L.; Hussein, A.; Young, P.; Huang, J.; Zhu, W. Microstructure and mechanical properties of aluminium alloy cellular lattice structures manufactured by direct metal laser sintering. Mater. Sci. Eng. A 2015, 628, 238–246. [Google Scholar] [CrossRef]

- Lahtinen, E.; Precker, R.L.M.; Lahtinen, M.; Hey-Hawkins, E.; Haukka, M. Selective Laser Sintering of Metal-Organic Frameworks: Production of Highly Porous Filters by 3D Printing onto a Polymeric Matrix. ChemPlusChem 2019, 84, 222–225. [Google Scholar] [CrossRef]

- Khan, S.Z.; Masood, S.H.; Cottam, R. Mechanical properties of a novel plymetal manufactured by laser-assisted direct metal deposition. Int. J. Adv. Manuf. Technol. 2017, 91, 1839–1849. [Google Scholar] [CrossRef]

- Nouri, H.; Guessasma, S.; Belhabib, S. Structural imperfections in additive manufacturing perceived from the X-ray micro-tomography perspective. J. Mater. Process. Technol. 2016, 234, 113–124. [Google Scholar] [CrossRef]

- Sood, A.K.; Ohdar, R.K.; Mahapatra, S.S. Improving dimensional accuracy of Fused Deposition Modelling processed part using grey Taguchi method. Mater. Des. 2009, 30, 4243–4252. [Google Scholar] [CrossRef]

- Wang, J.; Xie, H.; Weng, Z.; Senthil, T.; Wu, L. A novel approach to improve mechanical properties of parts fabricated by fused deposition modeling. Mater. Des. 2016, 105, 152–159. [Google Scholar] [CrossRef]

- Jill Manapat, Z.; Qiyi, C.; Piaoran Ye, C.; Rigoberto, A. 3D Printing of Polymer Nanocomposites via Stereolithography. Macromol. Mater. Eng. 2017, 302, 1600553. [Google Scholar] [CrossRef]

- Eshraghi, S.; Das, S. Mechanical and microstructural properties of polycaprolactone scaffolds with one-dimensional, two-dimensional, and threedimensional orthogonally oriented porous architectures produced by selective laser sintering. Acta Biomater. 2010, 6, 467–476. [Google Scholar] [CrossRef]

- Vaezi, M.; Seitz, H.; Yang, S. A review on 3D microadditive manufacturing technologies. Int. J. Adv. Manuf. Technol. 2013, 67, 1721–1754. [Google Scholar] [CrossRef]

- Khaleed, H.M.T.; Samad, Z.; Mujeebu, M.A.; Abdullah, A.B. Flash-less Cold Forging of AUV Propeller Blade: Work-piece Optimization and Thermal Analysis. Arab. J. Sci. Eng. 2013, 38, 2509–2519. [Google Scholar] [CrossRef]

- Tan, D.K.; Maniruzzaman, M.; Nokhodchi, A. Advanced pharmaceutical applications of hot-melt extrusion coupled with fused deposition modelling (FDM) 3D printing for personalised drug delivery. Pharmaceuticals 2018, 10, 203. [Google Scholar] [CrossRef] [PubMed]

- Haidiezul, A.H.M.; Aiman, A.F.; Bakar, B. Surface Finish Effects Using Coating Method on 3D Printing (FDM) Parts. Mater. Sci. Eng. 2018, 318, 012065. [Google Scholar] [CrossRef]

| Name | ABS Plastic | |

|---|---|---|

| General | Mass Density | 1.06 g/cm3 |

| Yield Strength | 20 MPa | |

| Ultimate Tensile Strength | 29.6 MPa | |

| Flexural Strength | 75 MPa | |

| Stress | Young’s Modulus | 2.24 GPa |

| Poisson’s Ratio | 0.38 ul | |

| Shear Modulus | 0.811594 GPa | |

| Part Name(s) | Blade1 | |

| Section Number | Section Type | Cross-Sectional Area | Area Variation | Perimeter | Perimeter Variation |

|---|---|---|---|---|---|

| mm2 | % | mm | % | ||

| 15 | CAD | 47.83 | −35.51% | 84.56 | −0.34% |

| Physical | 64.81 | 84.85 | |||

| 30 | CAD | 83.28 | 6.04% | 91.66 | 0.76% |

| Physical | 78.25 | 90.96 | |||

| 45 | CAD | 112.78 | 6.72% | 88.44 | 1.59% |

| Physical | 105.20 | 87.03 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khaleed, H.M.T.; Badruddin, I.A.; Saquib, A.N.; Addas, M.F.; Kamangar, S.; Yunus Khan, T.M. Novel Approach to Manufacture an AUV Propeller by Additive Manufacturing and Error Analysis. Appl. Sci. 2019, 9, 4413. https://doi.org/10.3390/app9204413

Khaleed HMT, Badruddin IA, Saquib AN, Addas MF, Kamangar S, Yunus Khan TM. Novel Approach to Manufacture an AUV Propeller by Additive Manufacturing and Error Analysis. Applied Sciences. 2019; 9(20):4413. https://doi.org/10.3390/app9204413

Chicago/Turabian StyleKhaleed, H. M. T., Irfan Anjum Badruddin, A. N. Saquib, M. F. Addas, Sarfaraz Kamangar, and T. M. Yunus Khan. 2019. "Novel Approach to Manufacture an AUV Propeller by Additive Manufacturing and Error Analysis" Applied Sciences 9, no. 20: 4413. https://doi.org/10.3390/app9204413

APA StyleKhaleed, H. M. T., Badruddin, I. A., Saquib, A. N., Addas, M. F., Kamangar, S., & Yunus Khan, T. M. (2019). Novel Approach to Manufacture an AUV Propeller by Additive Manufacturing and Error Analysis. Applied Sciences, 9(20), 4413. https://doi.org/10.3390/app9204413