Modeling the Response of Magnetorheological Fluid Dampers under Seismic Conditions

Abstract

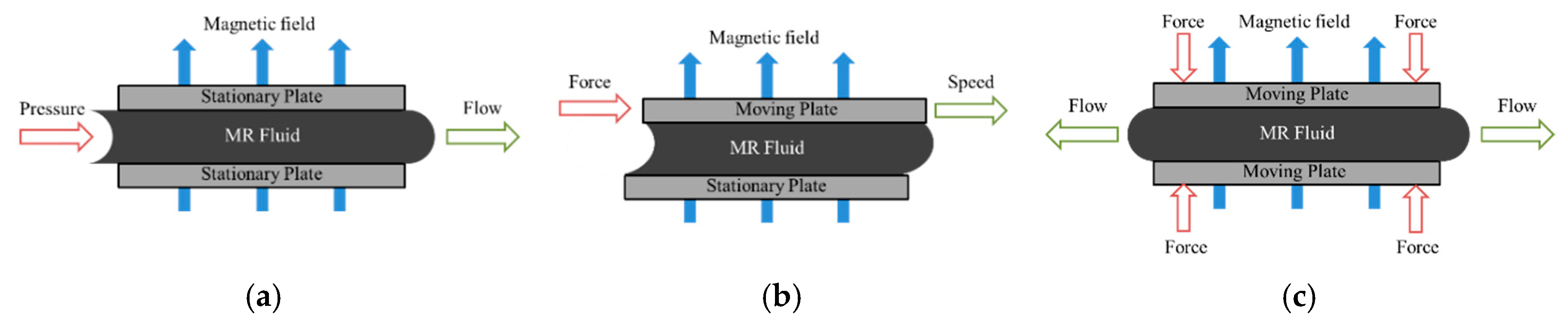

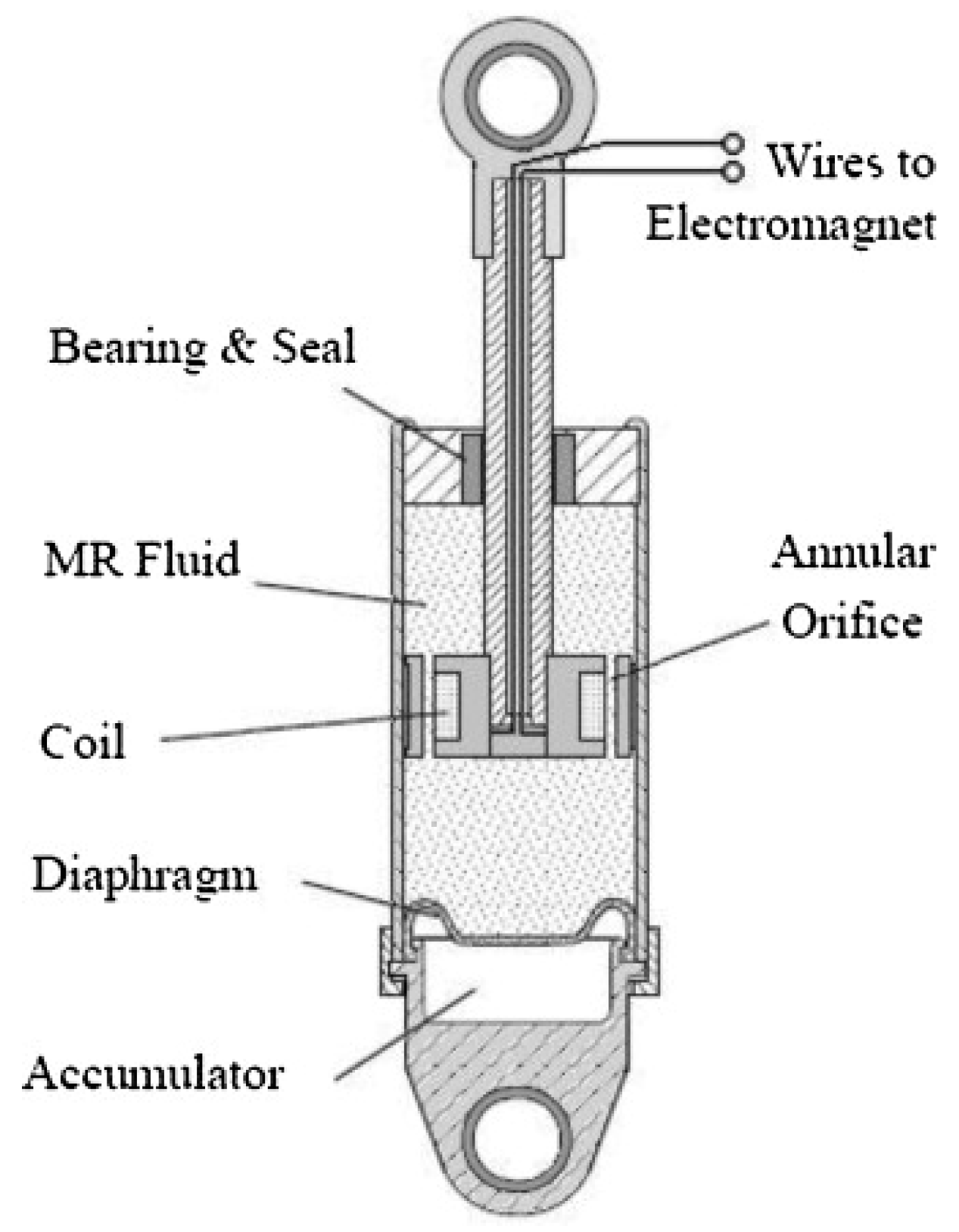

1. Introduction

2. Mathematical Model

2.1. Computational Fluid Dynamics

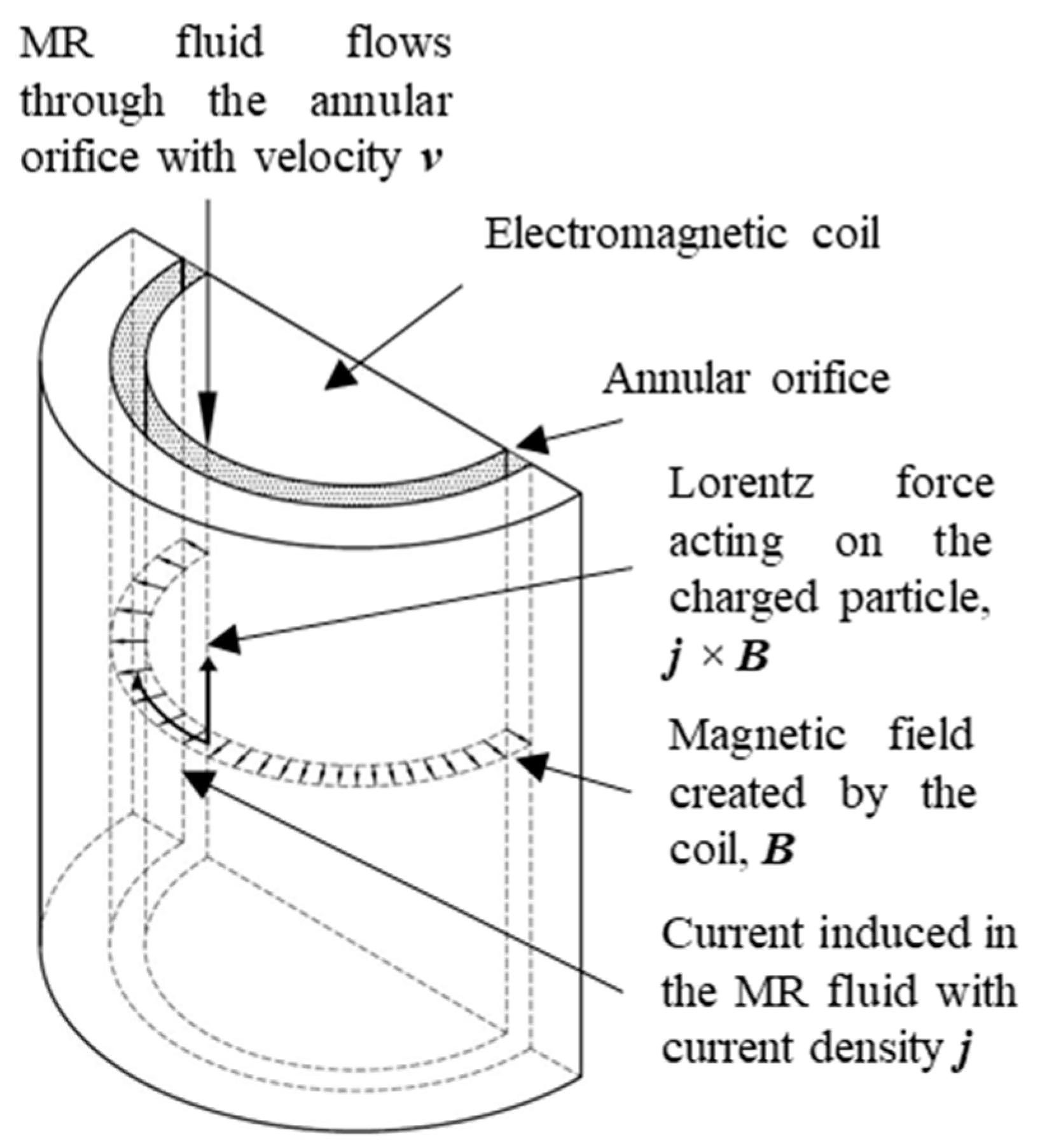

2.2. Magneto-Hydrodynamic Model

3. Numerical Model

3.1. Material Properties

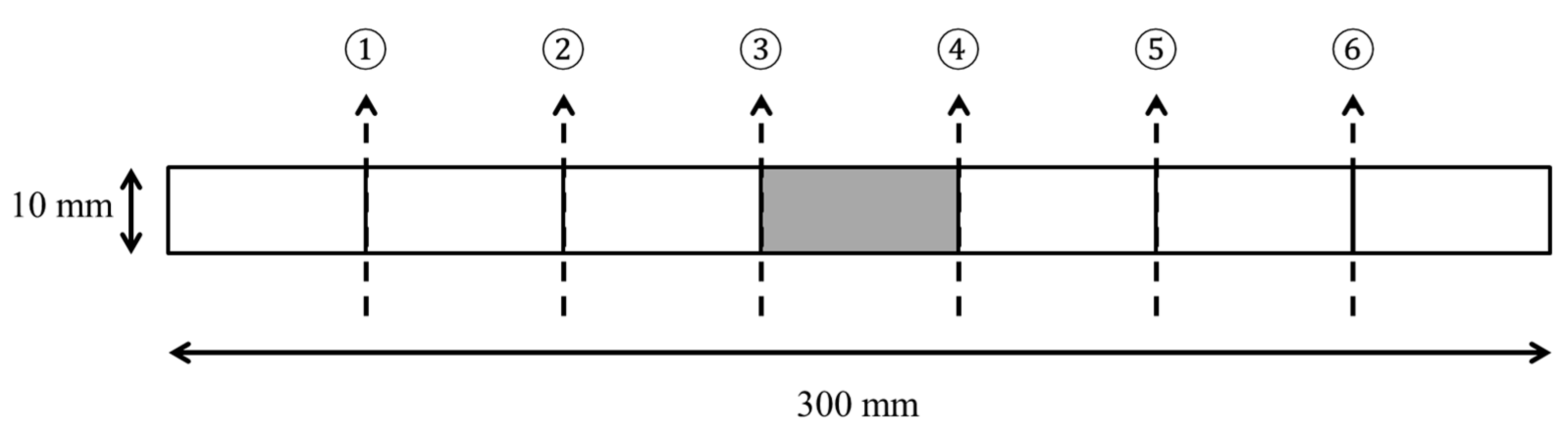

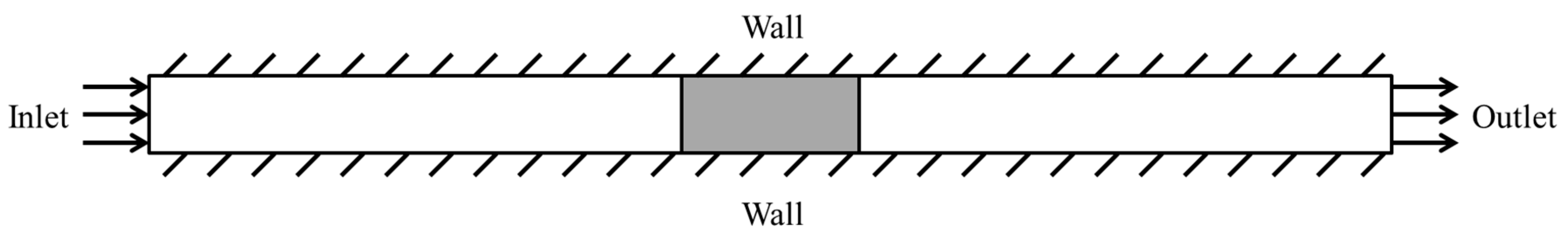

3.2. Computational Domain

3.3. Mesh

3.4. Numerical Scheme

3.5. Boundary Conditions

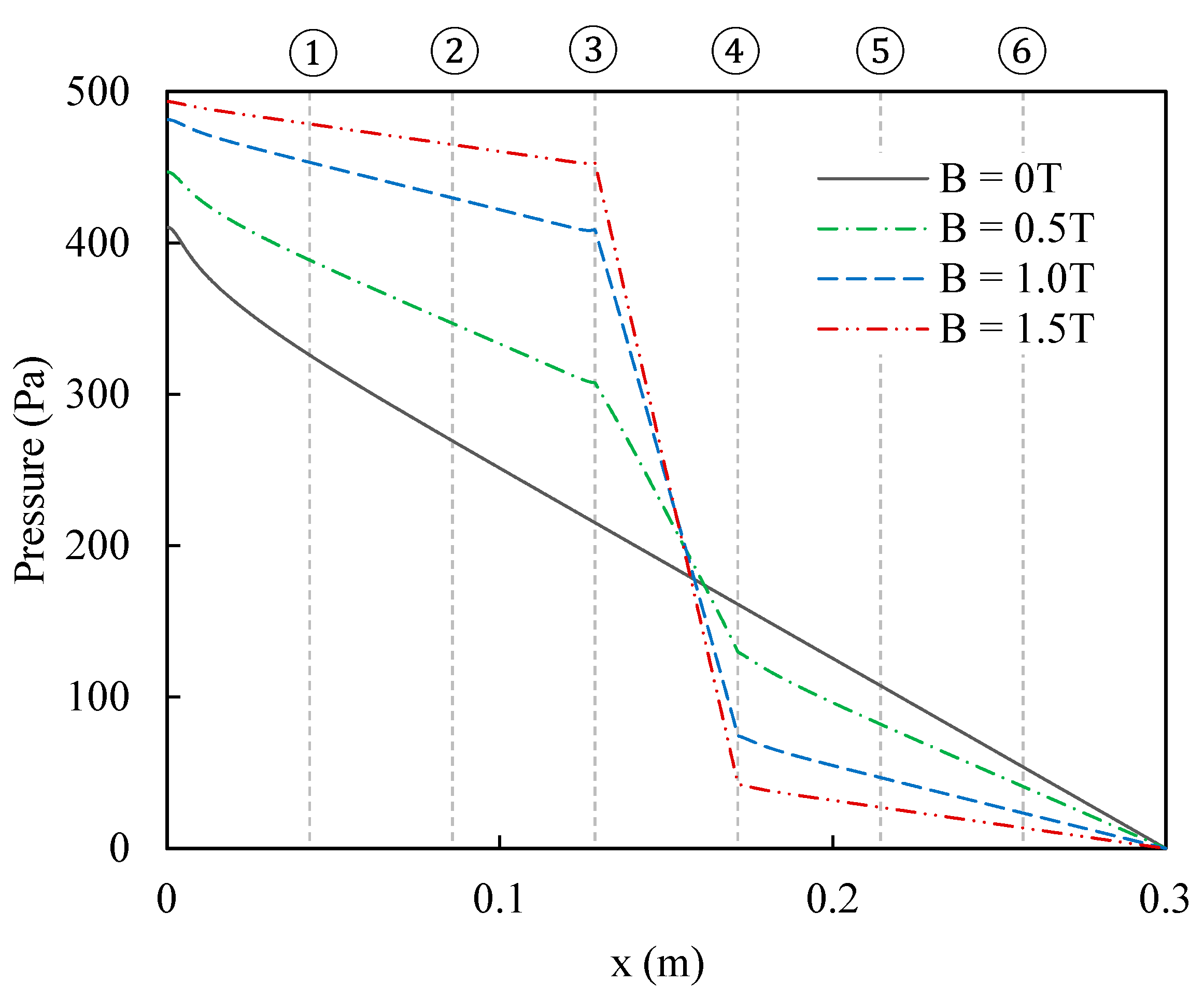

4. Results and Discussion

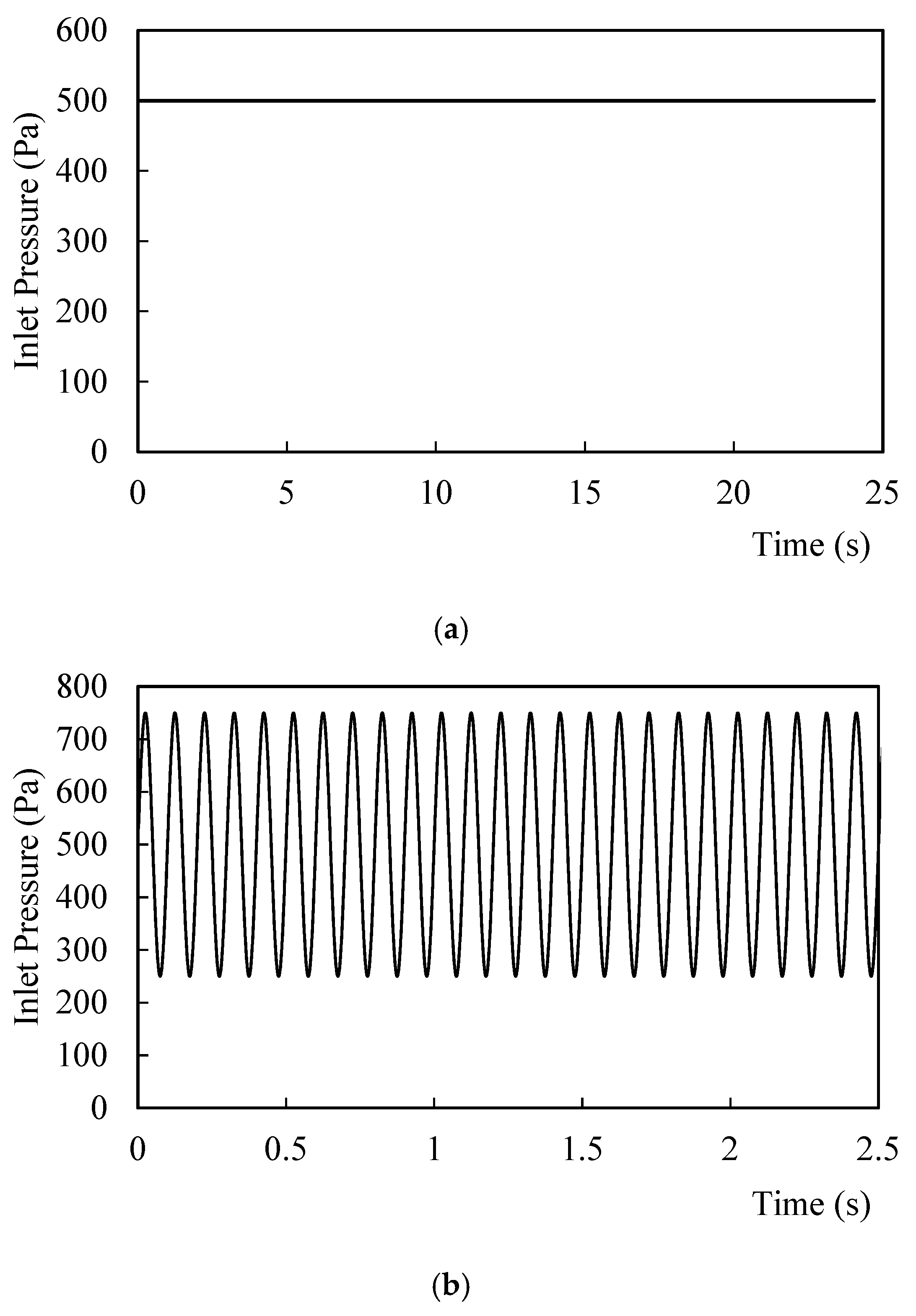

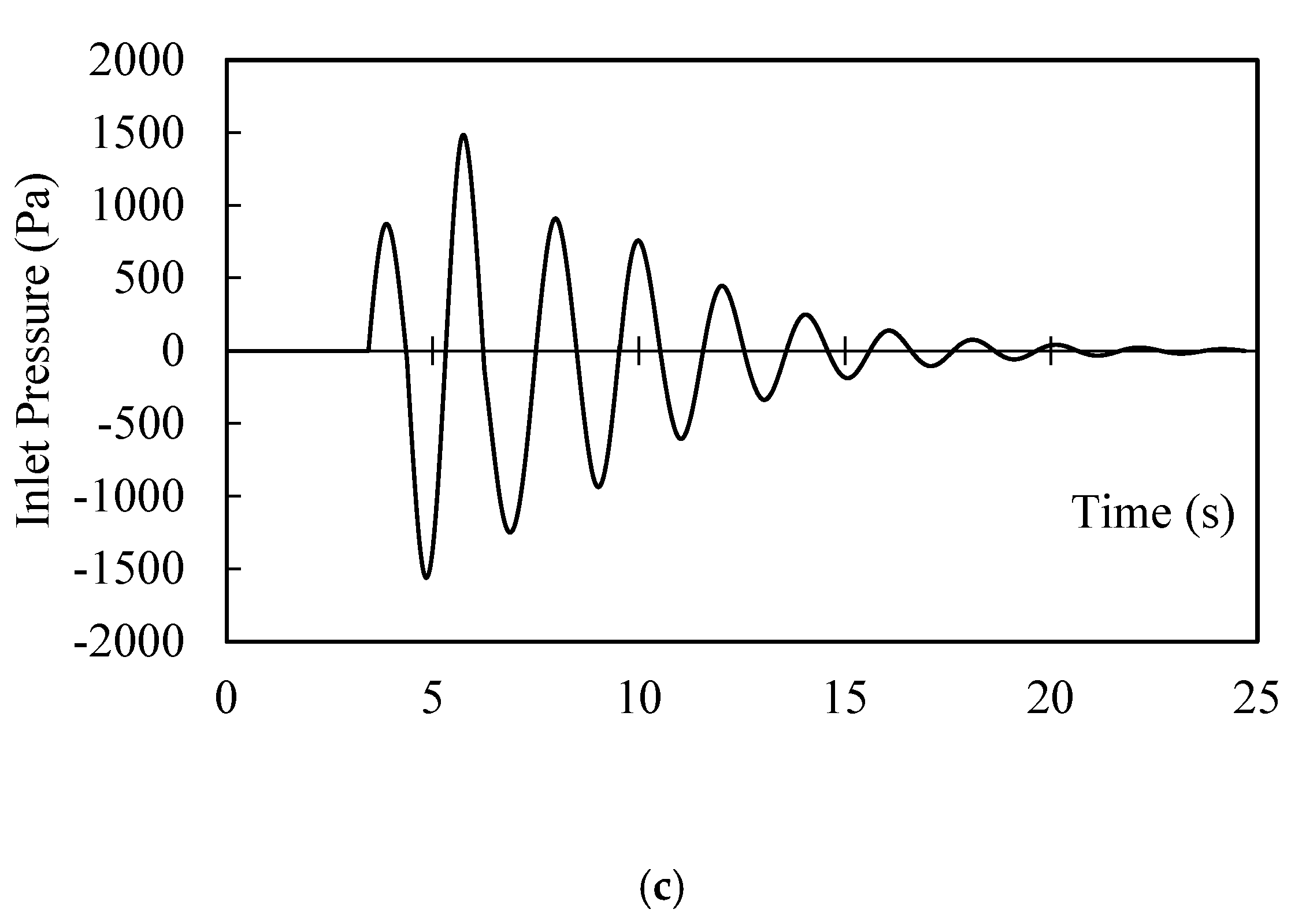

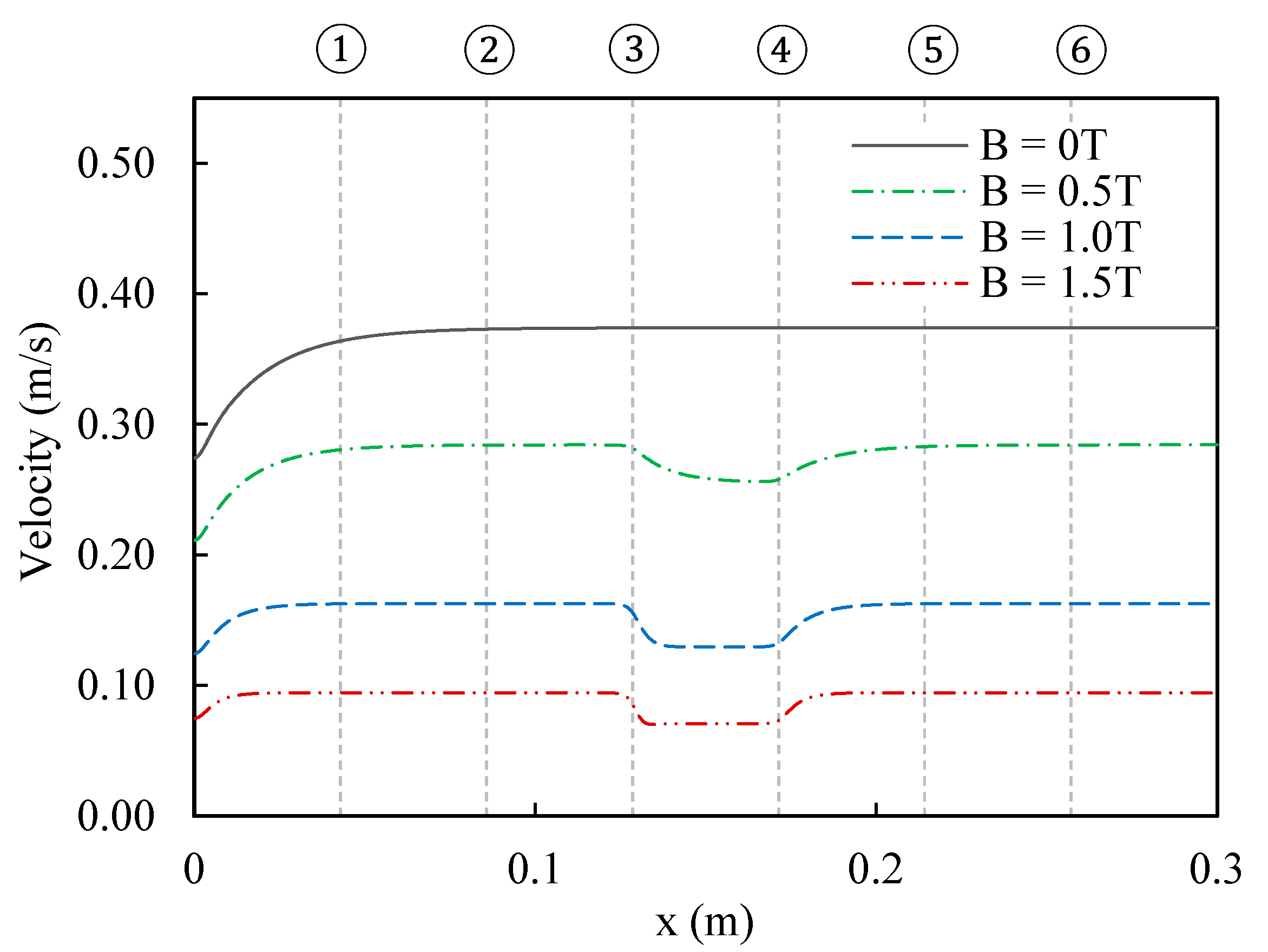

4.1. Constant Pressure

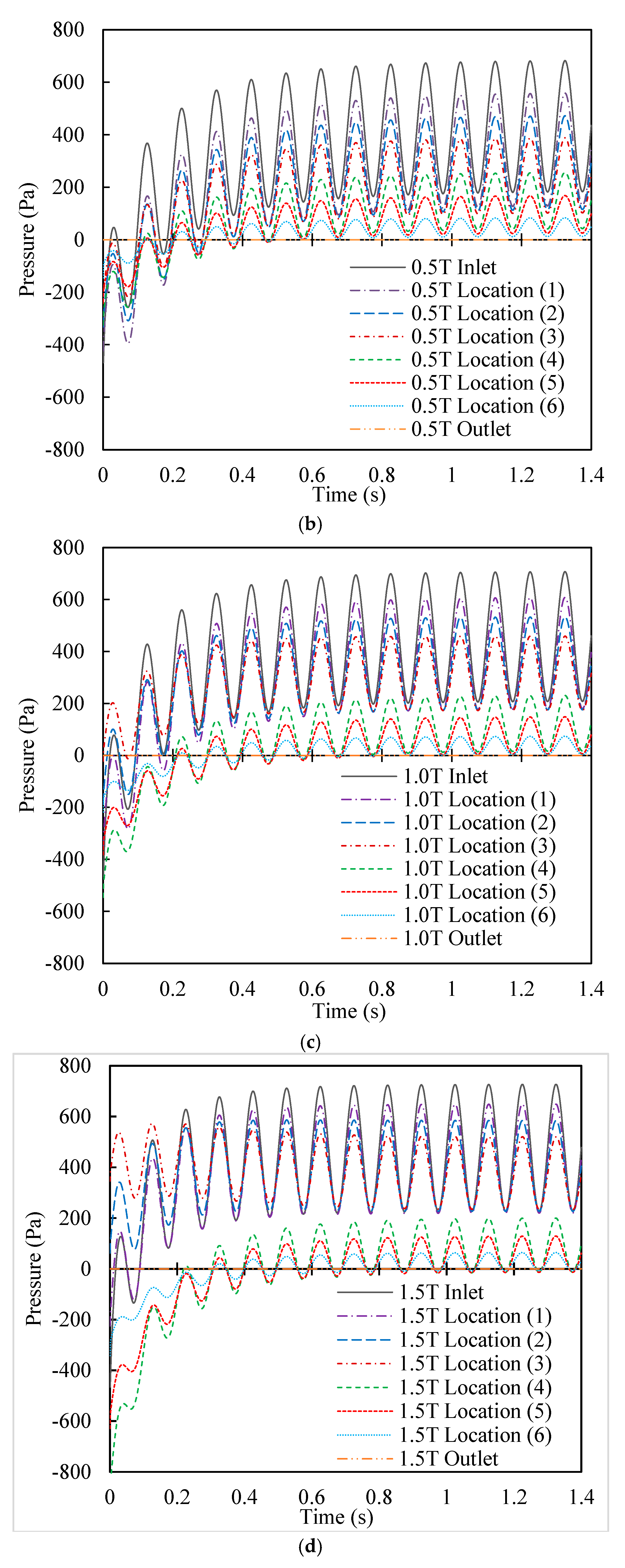

4.2. Sinusoidal Pressure Profile

4.3. Seismic Response

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Munoz, B.C. Magnetorheological Fluid. Google Patents 5,683,615, 4 November 1997. [Google Scholar]

- Li, D.D.; Yeoh, G.H.; Timchenko, V.; Lam, H.F. Numerical Modeling of Magnetic Nanoparticle and Carrier Fluid Interactions Under Static and Double-Shear Flows. IEEE Trans. Nanotechnol. 2017, 16, 798–805. [Google Scholar] [CrossRef]

- Wang, D.H.; Liao, W.H. Magnetorheological fluid dampers: A review of parametric modelling. Smart Mater. Struct. 2011, 20, 023001. [Google Scholar] [CrossRef]

- Rabinow, J. The Magnetic Fluid Clutch. Trans. Am. Inst. Electr. Eng. 1948, 67, 1308–1315. [Google Scholar] [CrossRef]

- Vicente, D.J.; Klingenberg, D.J.; Hidalgo-Alvarez, R. Magnetorheological fluids: A review. Soft Matter 2011, 7, 3701–3710. [Google Scholar] [CrossRef]

- Bell, R.C.; Miller, E.D.; Karli, J.O.; Vavreck, A.N.; Zimmerman, D.T. Influence of particle shape on the properties of magnetorheological fluids. Int. J. Mod. Phys. B 2007, 21, 5018–5025. [Google Scholar] [CrossRef]

- Lemaire, E.; Meunier, A.; Bossis, G.; Liu, J.; Felt, D.; Bashtovoi, P.; Matoussevitch, N. Influence of the particle size on the rheology of magnetorheological fluids. J. Rheol. 1995, 39, 1011–1020. [Google Scholar] [CrossRef]

- Sarkar, C.; Hirani, H. Effect of Particle Size on Shear Stress of Magnetorheological Fluids. Smart Sci. 2015, 3, 2015. [Google Scholar] [CrossRef]

- Olabi, A.G.; Grunwald, A. Design and application of magneto-rheological fluid. Mater. Des. 2007, 28, 2658–2664. [Google Scholar] [CrossRef]

- Carlson, J.D.; Chrzan, M.J. Magnetorheological Fluid Dampers. U.S. Patent 5,277,281, 11 January 1994. [Google Scholar]

- Crivellaro, C.; Alves, S.J. Phenomenological Model of a Magnetorheological Damper. J. Eng. Mech. 1997, 123, 230–238. [Google Scholar]

- Dyke, S.J.; Spencer, B.F., Jr.; Sain, M.K.; Carlson, J.D. Modeling and Control of Magnetorheological Dampers for Seismic Response Reduction. Smart Mater. Struct. 1996, 5, 565–575. [Google Scholar] [CrossRef]

- Bica, I.; Liu, Y.D.; Choi, H.J. Physical characteristics of magnetorheological suspensions and their applications. J. Ind. Eng. Chem. 2013, 19, 394–406. [Google Scholar] [CrossRef]

- Lai, C.Y.; Liao, W.H. Vibration Control of a Suspension System via a Magnetorheological Fluid Damper. J. Vib. Control 2002, 8, 527–547. [Google Scholar] [CrossRef]

- Lam, A.H.-F.; Liao, W.-H. Semi-active Control of Automotive Suspension Systems with Magneto-rheological Dampers. Int. J. Veh. Des. 2003, 33, 50–74. [Google Scholar] [CrossRef]

- Tu, F.; Yang, Q.; He, C.; Wang, L. Experimental Study and Design on Automobile Suspension Made of Magneto-Rheological Damper. Energy Procedia 2012, 16, 417–425. [Google Scholar] [CrossRef]

- Choi, S.-B.; Lee, H.-S.; Park, Y.-P. H8 Control Performance of a Full-Vehicle Suspension Featuring Magnetorheological Dampers. Veh. Syst. Dyn. 2002, 38, 341–360. [Google Scholar] [CrossRef]

- Gordaninejad, F.; Kelso, S.P. Fail-Safe Magneto-Rheological Fluid Dampers for Off-Highway, High-Payload Vehicles. J. Intell. Mater. Syst. Struct. 2000, 11, 395–406. [Google Scholar] [CrossRef]

- Zong, L.H.; Gong, X.L.; Xuan, S.H.; Guo, C.Y. Semi-active H∞ control of high-speed railway vehicle suspension with magnetorheological dampers. Veh. Syst. Dyn. 2013, 51, 600–626. [Google Scholar] [CrossRef]

- Liao, W.H.; Wang, D.H. Semiactive Vibration Control of Train Suspension Systems via Magnetorheological Dampers. J. Intell. Mater. Syst. Struct. 2003, 14, 161–172. [Google Scholar] [CrossRef]

- Kwak, M.K.; Lee, J.H.; Yang, D.H.; You, W.H. Hardware-in-the-loop Simulation Experiment for Semi-active Vibration Control of Lateral Vibrations of Railway Vehicle by Magneto-rheological Fluid Damper. Veh. Syst. Dyn. 2014, 52, 891–908. [Google Scholar] [CrossRef]

- Wang, D.H.; Liao, W.H. Semi-active Suspension Systems for Railway Vehicles Using Magnetorheological Dampers. Part I: System Integration and Modelling. Veh. Syst. Dyn. 2009, 47, 1305–1325. [Google Scholar] [CrossRef]

- Wang, D.H.; Liao, W.H. Semi-active Suspension Systems for Railway Vehicles Using Magnetorheological Dampers. Part II: Simulation and Analysis. Veh. Syst. Dyn. 2009, 47, 1439–1471. [Google Scholar] [CrossRef]

- Liu, W.; Shi, W.; Ya, H. Semi-Active Vibration Control of Landing Gear Using Magneto-Rhelological Dampers. SAE Int. J. Aerosp. 2011, 4, 958–964. [Google Scholar] [CrossRef]

- Bandaru, S.; Maiti, D.K. Lateral stability of a typical nose landing gear using torsional magneto-rheological (MR) damper. In Proceedings of the 2008 Annual IEEE India Conference, Kanpur, India, 11–13 December 2008. [Google Scholar]

- Sateesh, B.; Maiti, D.K. Non-linear analysis of a typical nose landing gear model with torsional free play. Proc. Ins. Mech. Eng. Part G J. Aerosp. Eng. 2009, 223, 627–641. [Google Scholar] [CrossRef]

- Zhu, S.X.; Chen, C.J. Study on Variable Universe Fuzzy PID Control for Landing Gear Based on MRF (Magneto-Rheological Fluid) Damper. Appl. Mech. Mater. 2012, 233, 66–71. [Google Scholar] [CrossRef]

- Cornejo, C.; Alvarez-Icaza, L. Vibration control of a building with magneto-rheological-dampers based on interconnection and damping assignment. In Proceedings of the 45th IEEE Conference on Decision and Control, San Diego, CA, USA, 13–15 December 2006. [Google Scholar]

- Dyke, S.J.; Spencer, B.F., Jr.; Sain, M.K.; Carlson, J.D. Seismic Response Reduction Using Magnetorheological Dampers. IFAC Proc. Vol. 1996, 29, 5530–5535. [Google Scholar] [CrossRef]

- Ding, Y.; Zhang, L.; Zhu, H.T.; Li, Z.X. A new magnetorheological damper for seismic control. Smart Mater. Struct. 2013, 22, 115003. [Google Scholar] [CrossRef]

- Kim, K.; Jeon, D. Vibration Suppression in an MR Fluid Damper Suspension System. J. Intell. Mater. Syst. Struct. 1999, 10, 779–786. [Google Scholar] [CrossRef]

- Kataria, N.P.; Jangid, R.S. Optimum Semi-active Hybrid System for Seismic Control of the Horizontally Curved Bridge with Magnetorheological Damper. Bridge Structures-Assessment. Des. Constr. 2014, 10, 145–160. [Google Scholar]

- Kumar, P.; Jangid, R.; Reddy, G. Response of piping system with semi-active magnetorheological damper under tri-directional seismic excitation. Int. J. Appl. Sci. Eng. 2012, 10, 99. [Google Scholar]

- Housner, G.W.; Bergman, L.A.; Caughey, T.K.; Chassiakos, A.G.; Claus, R.O.; Masri, S.F.; Skelton, R.E.; Soong, T.T.; Spencer, B.F.; Yao, J.T. Structural Control: Past, Present, and Future. J. Eng. Mech. 1997, 123, 897–971. [Google Scholar] [CrossRef]

- Spencer, B.F., Jr.; Nagarajaiah, S. State of the Art of Structural. J. Struct. Eng. 2003, 129, 845–856. [Google Scholar] [CrossRef]

- Jung, H.J.; Spencer, B.F., Jr.; Ni, Y.Q.; Lee, I.W. State-of-the-Art of Semiactive Control Systems Using MR Fluid Dampers in Civil Engineering Applications. Struct. Eng. Mech. 2004, 17, 493–526. [Google Scholar] [CrossRef]

- Li, D.D.; Yeoh, G.H.; Timchenko, V.; Lam, H.F. Numerical modelling of magnetic nanoparticle and carrier fluid interactions. In Proceedings of the 2016 IEEE Nanotechnology Materials and Devices Conference (NMDC), Toulouse, France, 9–12 October 2016; pp. 1–3. [Google Scholar]

- Li, D.D.; Gu, X.; Timchenko, V.; Chan, Q.N.; Yuen, A.C.; Yeoh, G.H. Study of Morphology and Optical Properties of Gold Nanoparticle Aggregates under Different pH Conditions. Langmuir 2018, 34, 10340–10352. [Google Scholar] [CrossRef] [PubMed]

- Li, D.D. A Computational Study of Particulate Colloidal Systems, in School of Mechanical and Manufacturing Engineering; The University of New South Wales: Kensington, Australia, 2018. [Google Scholar]

- Bai, X.-X.; Wereley, N.M.; Hu, W. Maximizing semi-active vibration isolation utilizing a magnetorheological damper with an inner bypass configuration. J. Appl. Phys. 2015, 117, 17C711. [Google Scholar] [CrossRef]

- Rahman, M.; Ong, Z.C.; Chong, W.T.; Julai, S.; Ahamed, R. Experimental investigation of nonlinear characteristics of a smart fluid damper. AIP Conf. Proc. 2018, 1958, 020031. [Google Scholar]

- Lim, S.H.; Prusty, B.G.; Lee, A.; Yeoh, G.H. Experimental development and control of magnetorheological damper towards smart energy absorption of composite structures. In Proceedings of the Fourth International Conference on Smart Materials and Nanotechnology in Engineering, Gold Coast, Australia, 10–12 July 2013. [Google Scholar]

- Einstein, A. Eine neue Bestimmung der Moleküldimensionen. Ann. Phys. 1906, 324, 289–306. [Google Scholar] [CrossRef]

- Vand, V. Viscosity of Solutions and Suspensions. I. Theory. J. Phys. Colloid Chem. 1948, 52, 277–299. [Google Scholar] [CrossRef] [PubMed]

- Davidson, P.A. A Qualitative Overview of MHD. In Introduction to Magnetohydrodynamics; Davidson, P.A., Ed.; Cambridge University Press: Cambridge, UK, 2016; pp. 3–26. [Google Scholar]

- Bharti, S.D.; Dumne, S.M.; Shrimali, M.K. Seismic response analysis of adjacent buildings connected with MR dampers. Eng. Struct. 2010, 32, 2122–2133. [Google Scholar] [CrossRef]

- Gavin, H.; Hoagg, J.; Dobossy, M. Optimal design of MR dampers. In Proceedings of the US-Japan Workshop on Smart Structures for Improved Seismic Performance in Urban Regions; Duke University: Durham, NC, USA, 2001; pp. 225–236. [Google Scholar]

- Nguyen, Q.-H.; Choi, S.-B. Optimal design of MR shock absorber and application to vehicle suspension. Smart Mater. Struct. 2009, 18, 035012. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, D.D.; Keogh, D.F.; Huang, K.; Chan, Q.N.; Yuen, A.C.Y.; Menictas, C.; Timchenko, V.; Yeoh, G.H. Modeling the Response of Magnetorheological Fluid Dampers under Seismic Conditions. Appl. Sci. 2019, 9, 4189. https://doi.org/10.3390/app9194189

Li DD, Keogh DF, Huang K, Chan QN, Yuen ACY, Menictas C, Timchenko V, Yeoh GH. Modeling the Response of Magnetorheological Fluid Dampers under Seismic Conditions. Applied Sciences. 2019; 9(19):4189. https://doi.org/10.3390/app9194189

Chicago/Turabian StyleLi, Darson Dezheng, Declan Finn Keogh, Kevin Huang, Qing Nian Chan, Anthony Chun Yin Yuen, Chris Menictas, Victoria Timchenko, and Guan Heng Yeoh. 2019. "Modeling the Response of Magnetorheological Fluid Dampers under Seismic Conditions" Applied Sciences 9, no. 19: 4189. https://doi.org/10.3390/app9194189

APA StyleLi, D. D., Keogh, D. F., Huang, K., Chan, Q. N., Yuen, A. C. Y., Menictas, C., Timchenko, V., & Yeoh, G. H. (2019). Modeling the Response of Magnetorheological Fluid Dampers under Seismic Conditions. Applied Sciences, 9(19), 4189. https://doi.org/10.3390/app9194189