Tailored Chip Breaker Development for Polycrystalline Diamond Inserts: FEM-Based Design and Validation

Abstract

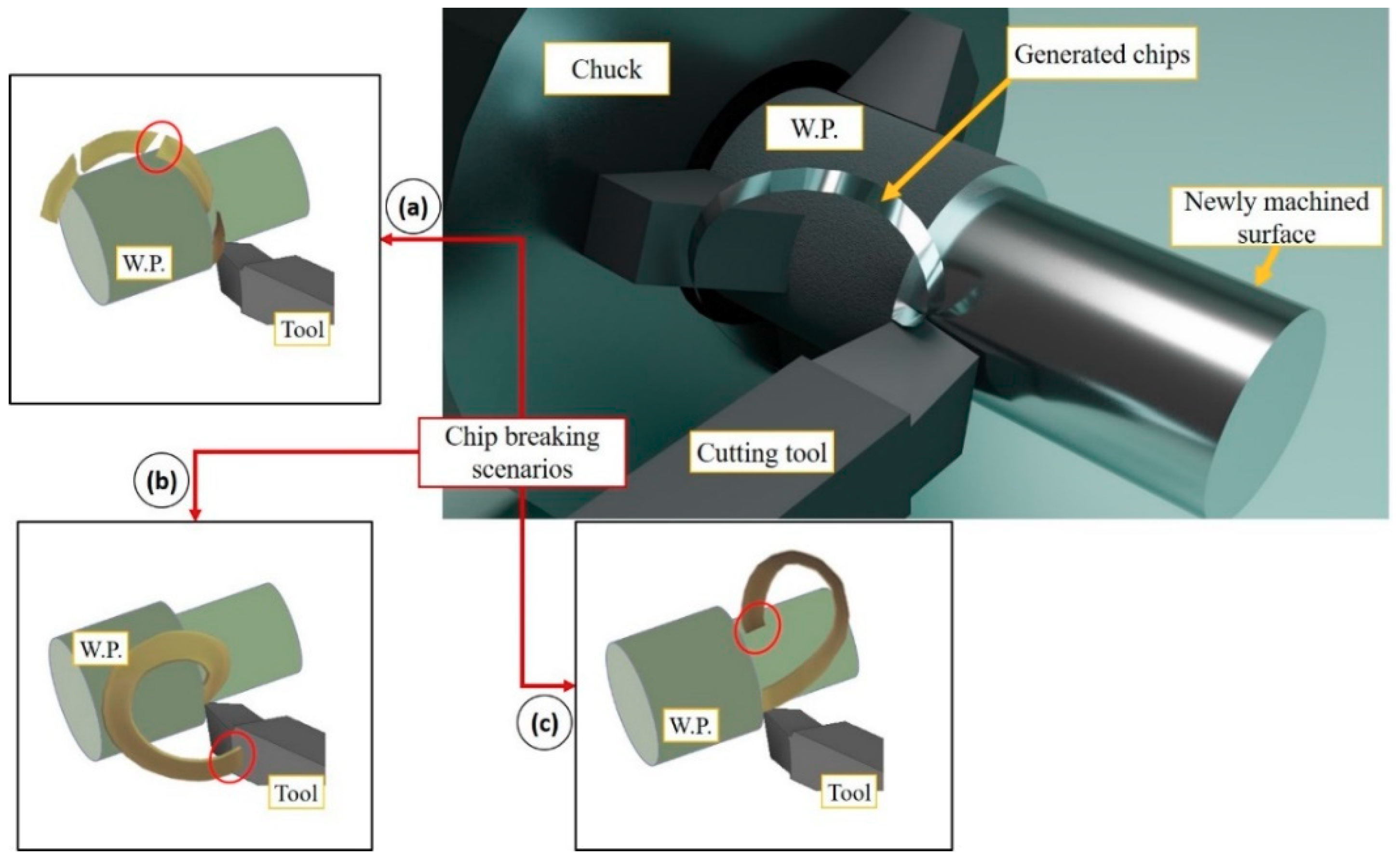

:1. Introduction

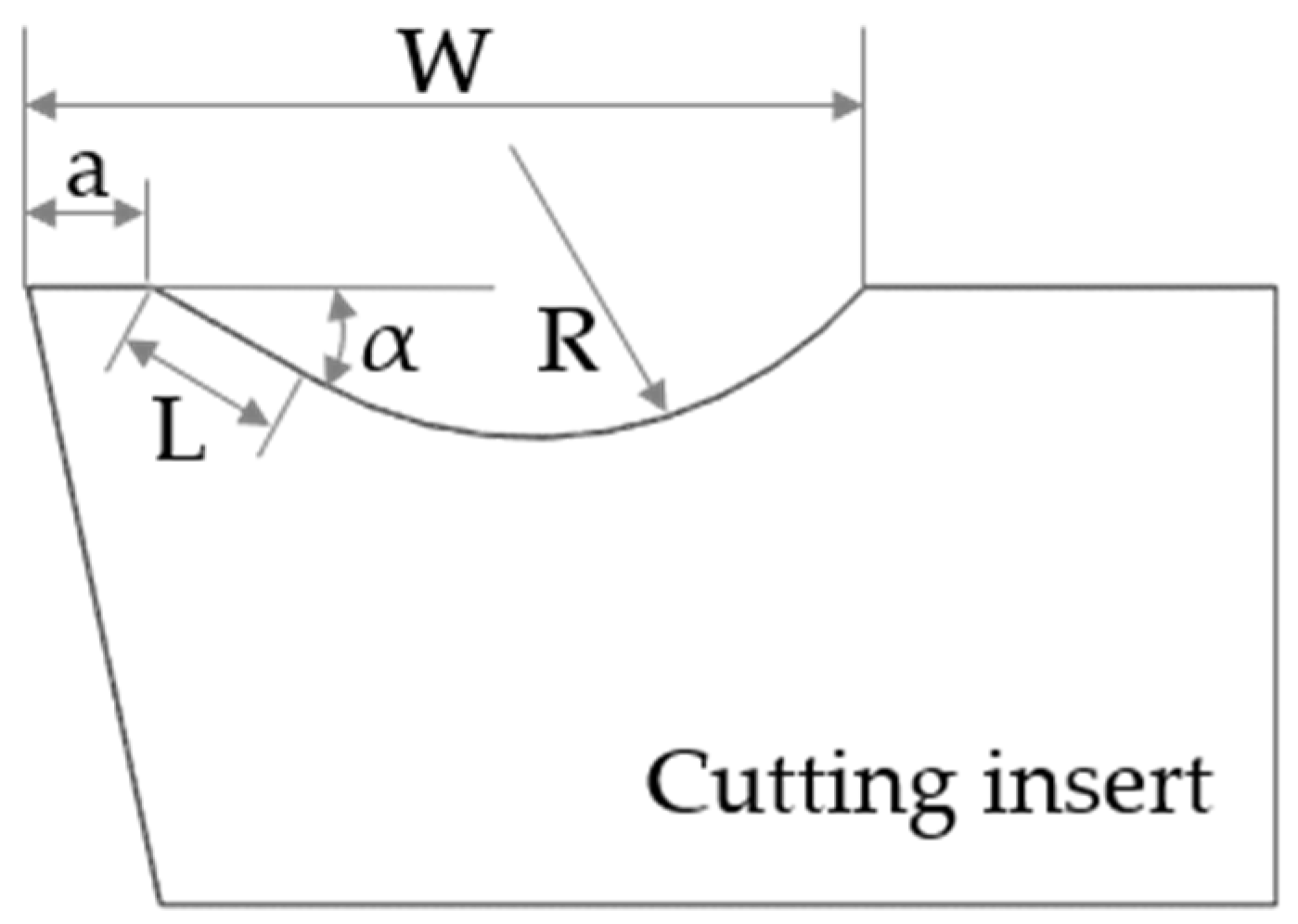

2. Chip Breaker FE Design for a PCD Turning Insert

3. Case Study

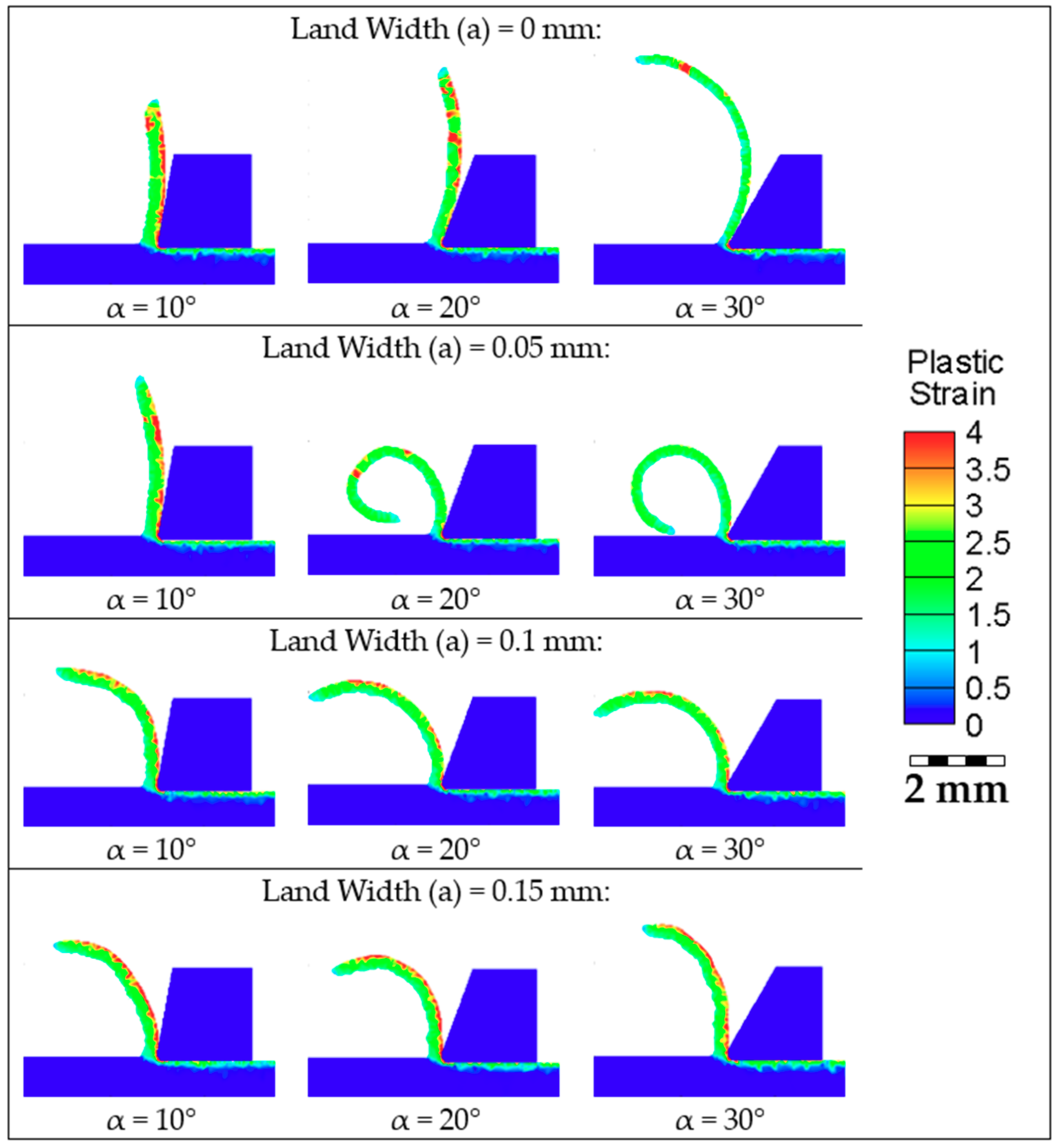

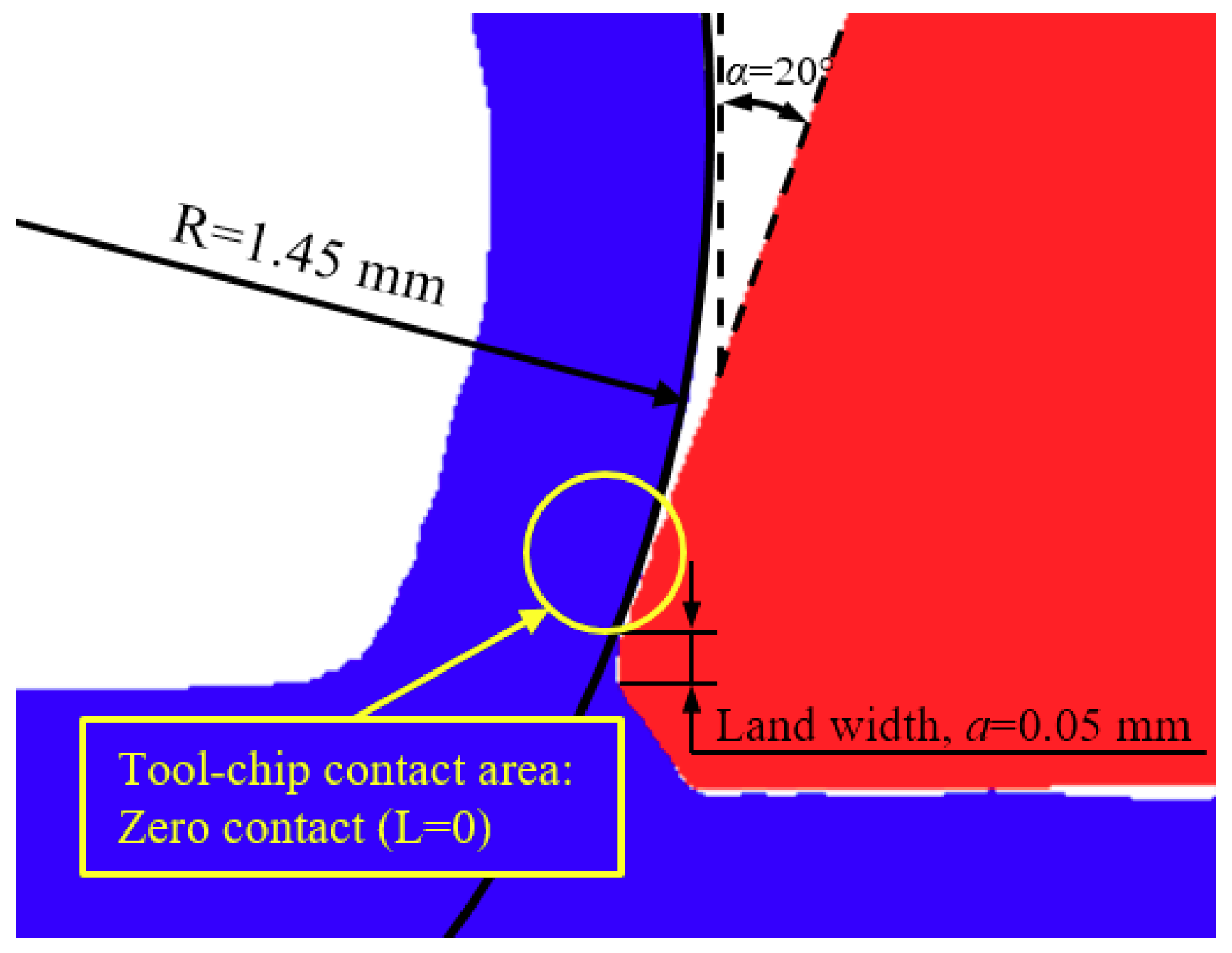

3.1. Selection of Rake Angle (α) and Land Width (a)

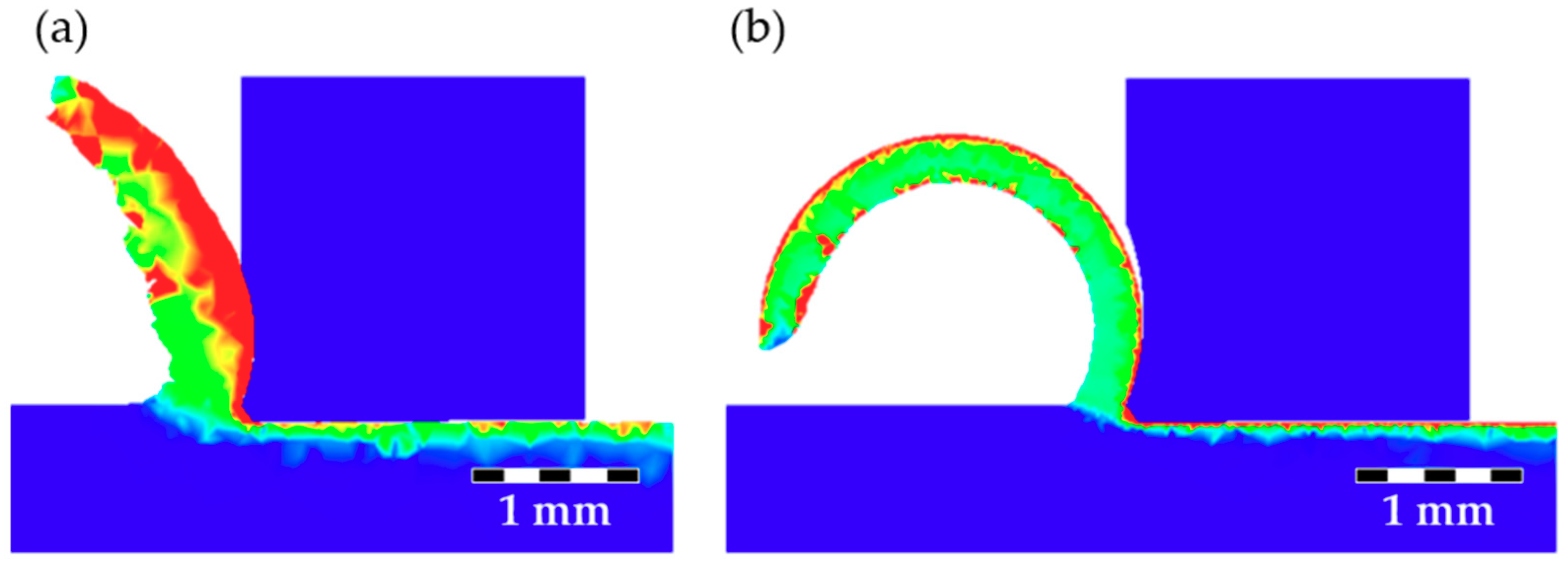

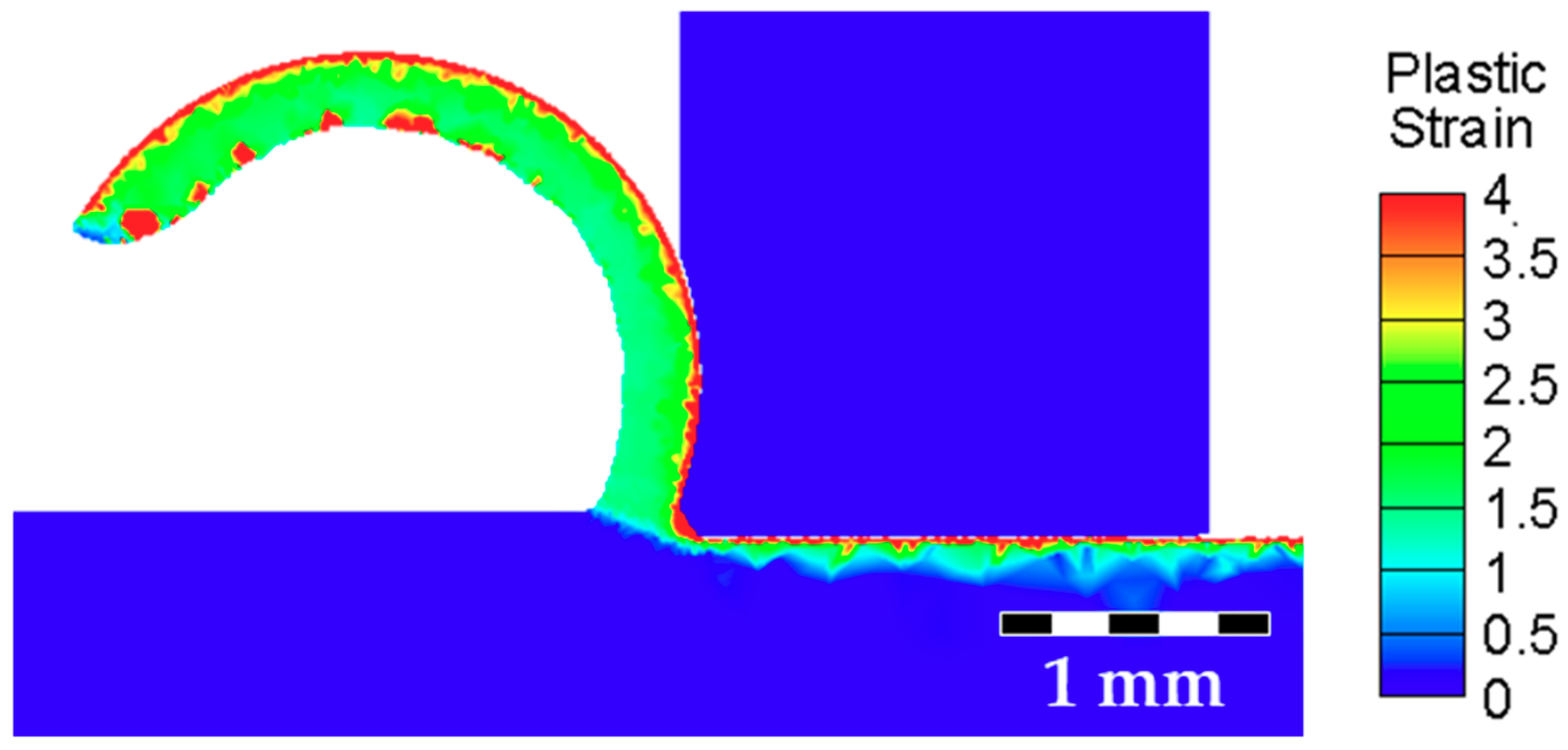

3.2. Determination of the Radius of Curvature

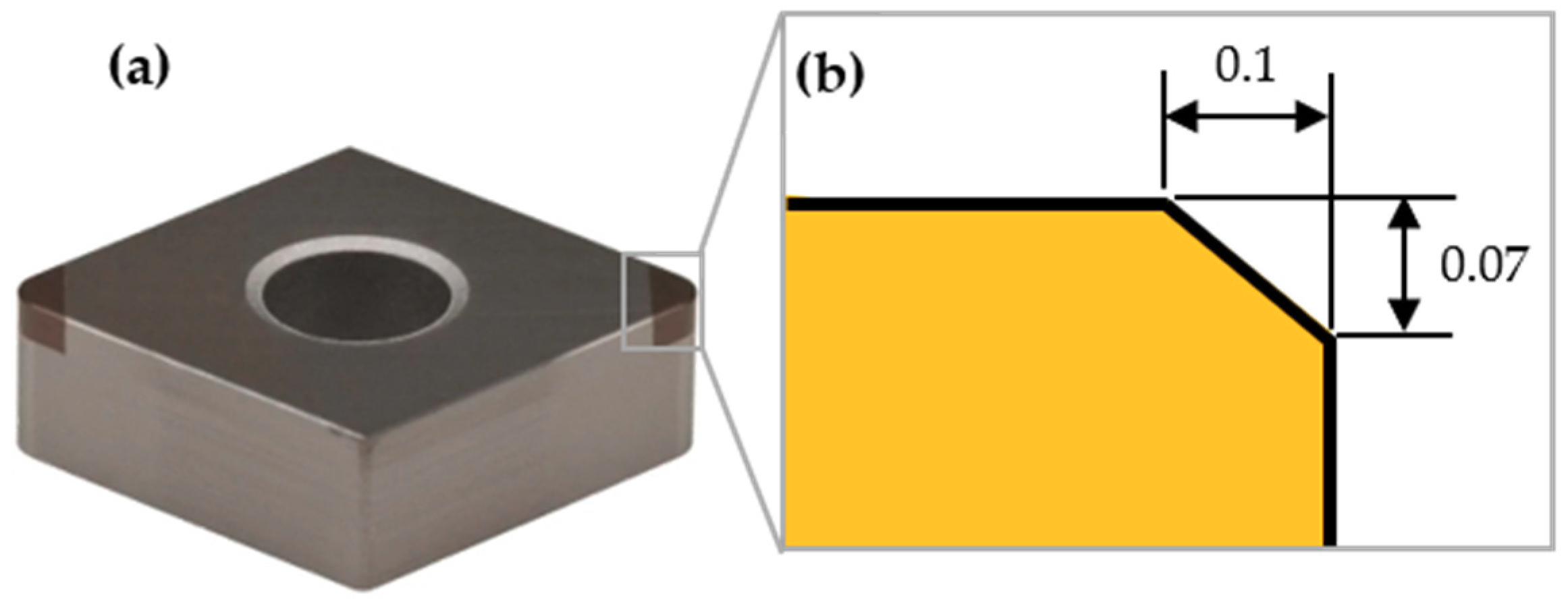

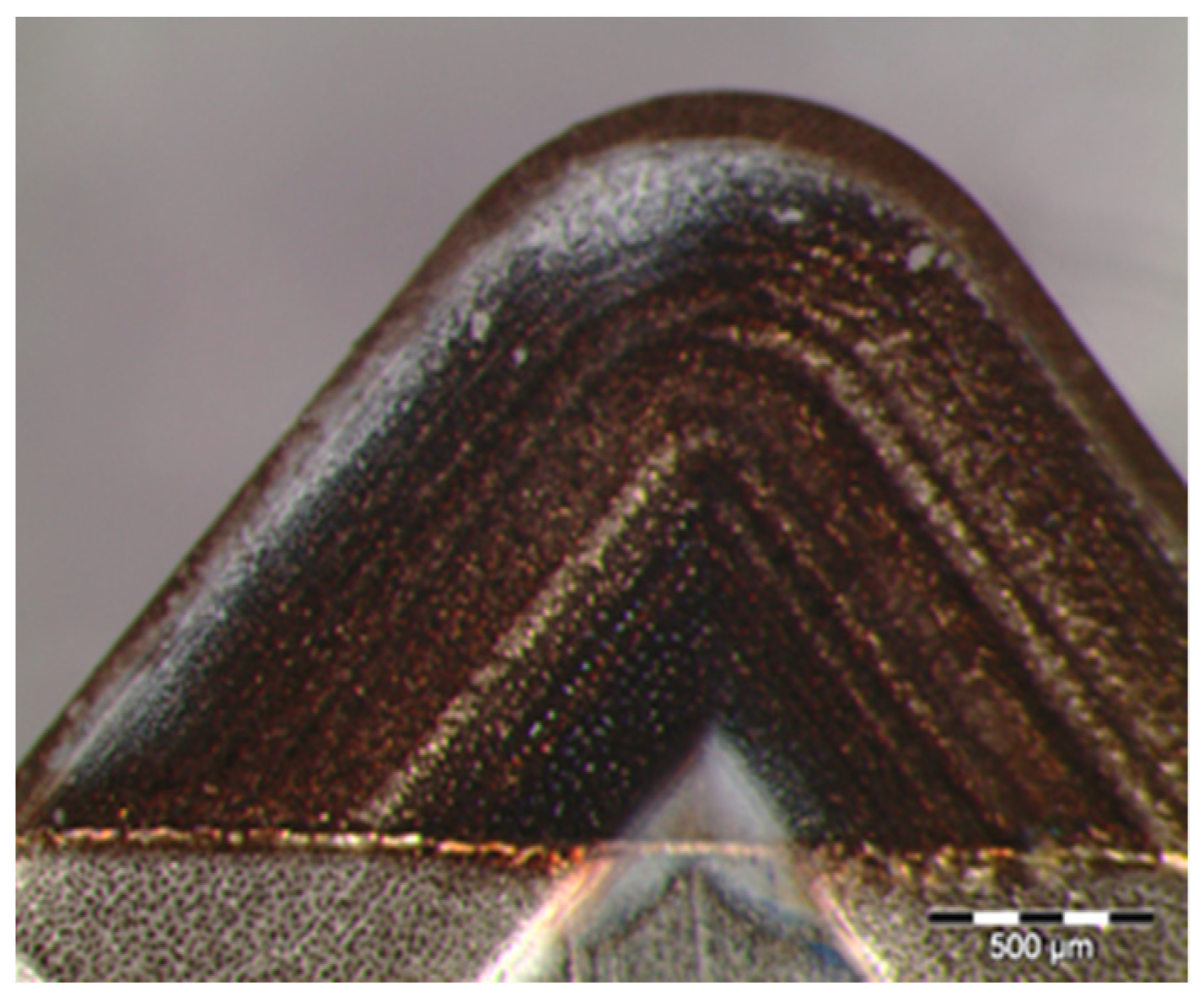

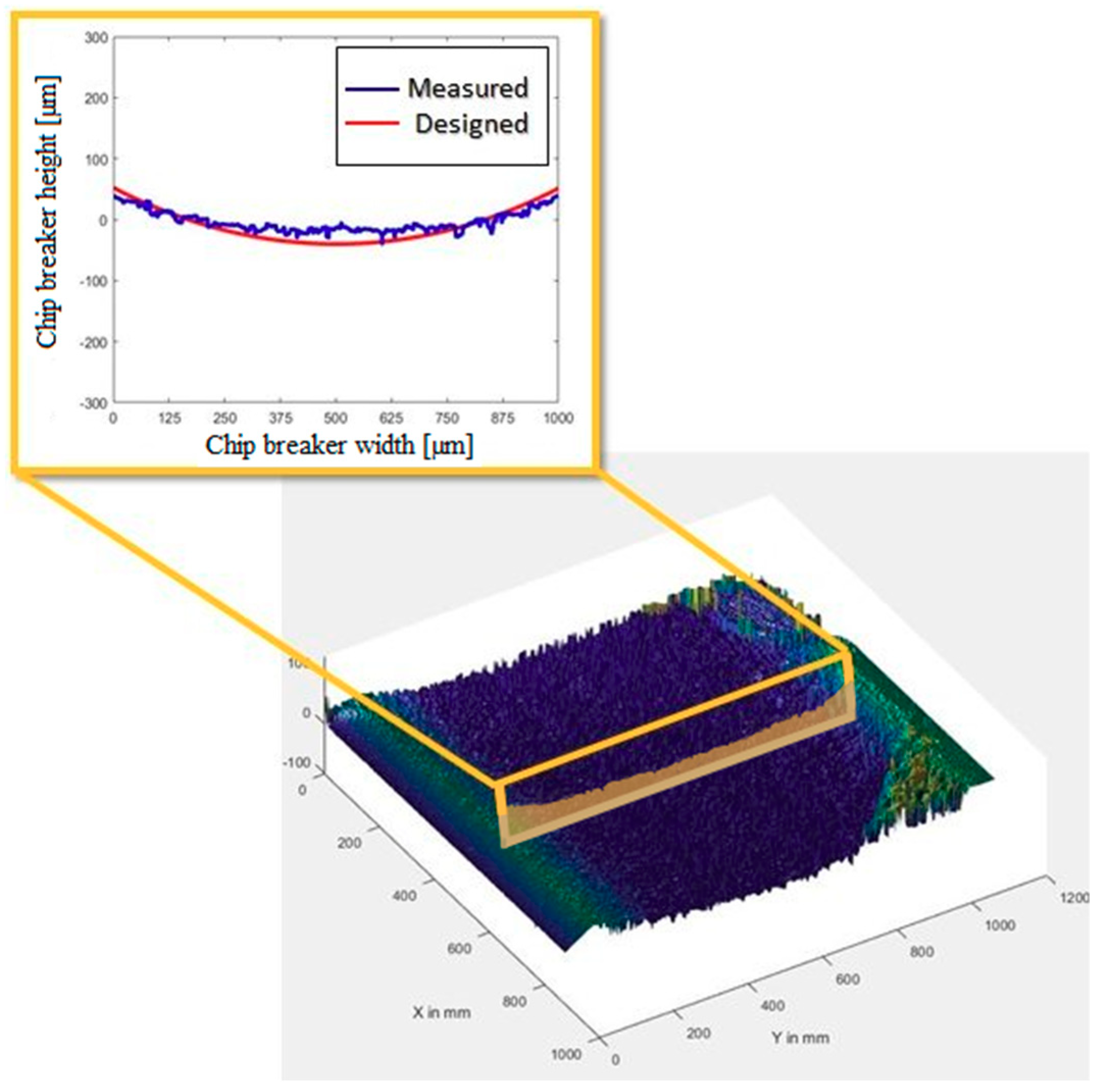

3.3. Manufacturing of the Chip Breaker

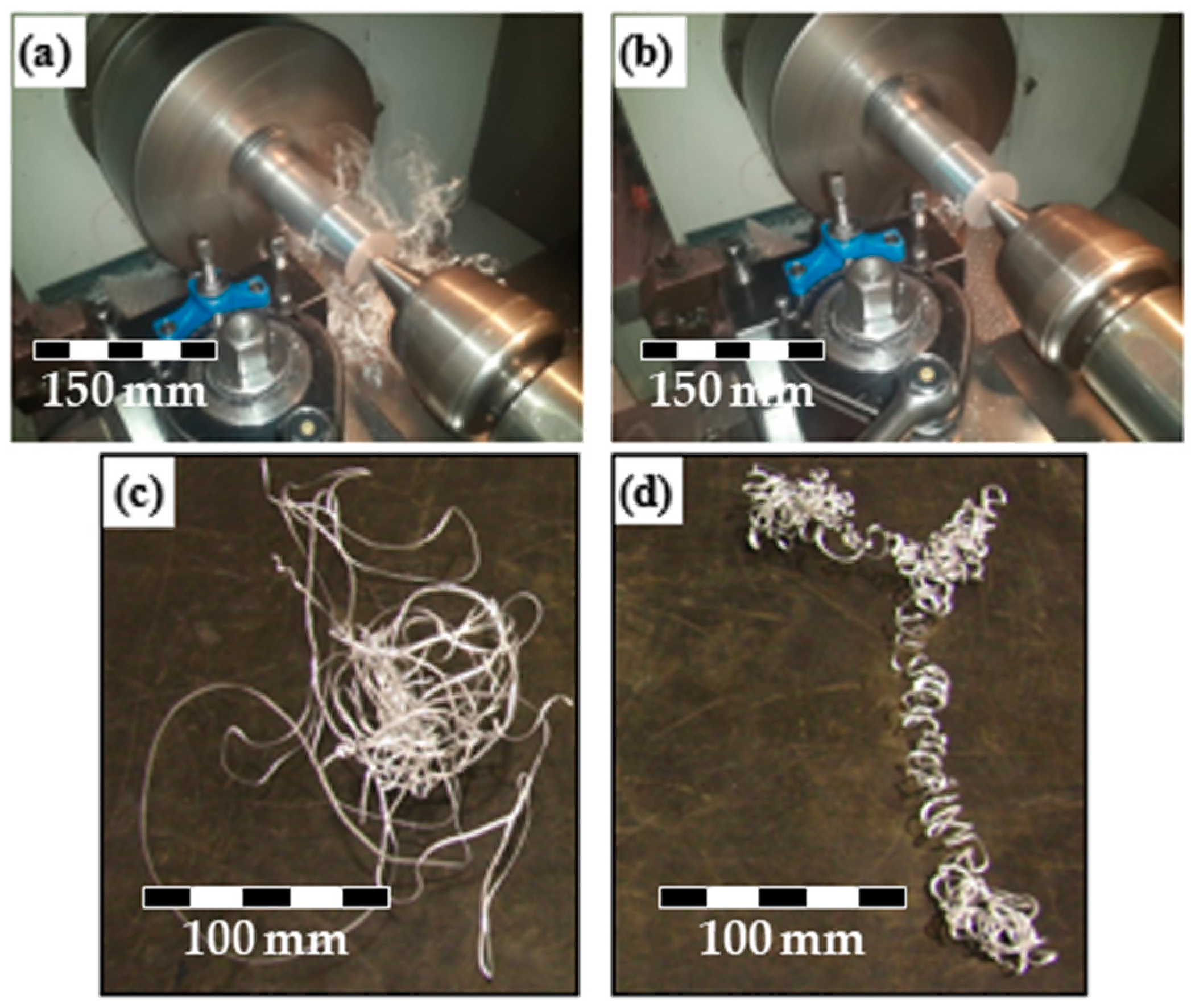

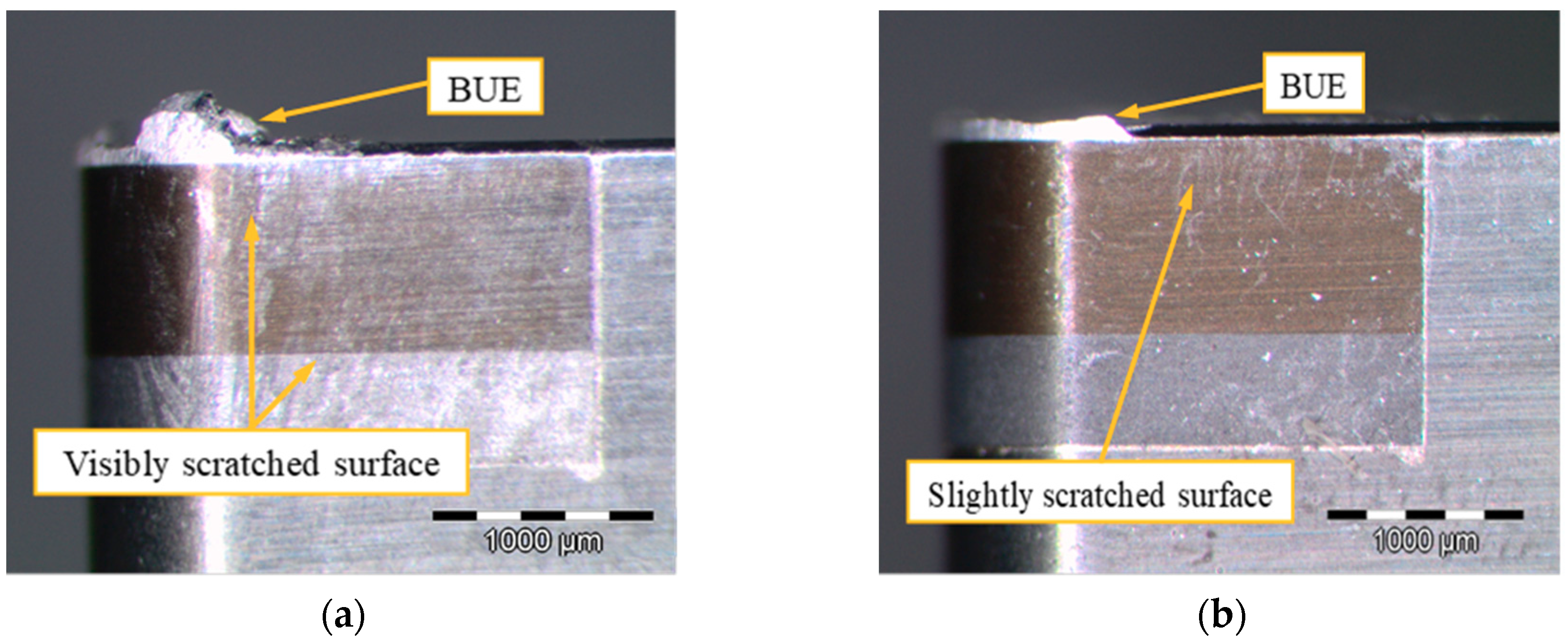

4. Experimental Turning Validation Tests

5. Conclusions

- It was confirmed that the important geometric parameters defining the shape of the chip breaker are as follows: Rake angle, α; land width, a; tool-chip contact length, L; and radius of curvature, R.

- Higher rake angles led to lower cutting forces, but that as stress in the tool edge increased, the tool became weaker.

- It was found that a rake angle of 17° produced chips associated with a relatively low cutting force, while keeping sufficient tool strength to endure machining stresses without premature failure.

- Optimum curling was found to take place with a land width being equal to half the feed rate.

- For small chip breaker radius of curvature, (e.g., 1.0 mm) the chips were prone to getting clogged, leading to a dramatic increase of cutting efforts. A 1.4 mm radius of curvature for the chip breaker gave the best solution.

- The results showed that a nano-second pulsed laser can be properly used to manufacture chip breakers.

- The insert that included the chip breaker was demonstrated to provide a curled chip formation, and reduced surface roughness significantly as well. This confirmed that the new tool-insert with a chip breaker is an effective solution, that the FE modelling is useful for the design stage, and that a nano-second laser is suitable for laser ablation.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Polvorosa, R.; Suárez, A.; López de Lacalle, L.N.; Cerrillo, I.; Wretland, A.; Veiga, F. Tool wear on nickel alloys with different coolant pressures: Comparison of Alloy 718 and Waspaloy. J. Manuf. Process. 2017, 26, 44–56. [Google Scholar] [CrossRef]

- Alagan, N.; Zeman, P.; Hoier, P.; Tomas Beno, T.; Klement, U. Investigation of micro-textured cutting tools used for face turning of alloy 718 with high-pressure cooling. J. Manuf. Process. 2019, 37, 606–616. [Google Scholar] [CrossRef]

- Suárez, A.; Veiga, F.; López de Lacalle, L.N.; Polvorosa, R.; Wretland, A. An investigation of cutting forces and tool wear in turning of Haynes 282. J. Manuf. Process. 2019, 37, 529–540. [Google Scholar] [CrossRef]

- Goiogana, M.; Elkaseer, A. Self-Flushing in EDM Drilling of Ti6Al4V Using Rotating Shaped Electrodes. Materials 2019, 12, 989. [Google Scholar] [CrossRef] [PubMed]

- Kaya, E.; Akyüz, B. Effects of cutting parameters on machinability characteristics of Ni-based superalloys: A review. Open Eng. 2017, 7, 330–342. [Google Scholar] [CrossRef]

- Fan, Y.; Wang, T.; Hao, Z.; Liu, X.; Gao, S.; Li, R. Surface residual stress in high speed cutting of superalloy Inconel718 based on multiscale simulation. J. Manuf. Process. 2018, 31, 480–493. [Google Scholar] [CrossRef]

- Behera, B.; Alemayehu, H.; Ghosh, S.; Rao, P. A comparative study of recent lubri-coolant strategies for turning of Ni-based superalloy. J. Manuf. Process. 2017, 30, 541–552. [Google Scholar] [CrossRef]

- Li, G.; Yi, S.; Sun, S.; Ding, S. Wear mechanisms and performance of abrasively ground polycrystalline diamond tools of different diamond grains in machining titanium alloy. J. Manuf. Process. 2017, 29, 320–331. [Google Scholar] [CrossRef]

- Haddad, F.; Lescalier, C.; Desaigues, J.-E.; Bomont-Arzur, A.; Bomont, O. Metallurgical Analysis of Chip Forming Process when Machining High Strength Bainitic Steels. J. Manuf. Mater. Process. 2019, 3, 10. [Google Scholar] [CrossRef]

- Yılmaz, B.; Karabulut, Ş.; Güllü, A. Performance analysis of new external chip breaker for efficient machining of Inconel 718 and optimization of the cutting parameters. J. Manuf. Process. 2018, 32, 553–563. [Google Scholar] [CrossRef]

- Słodki, B.; Zębala, W.; Struzikiewicz, G. Turning titanium alloy, grade 5 ELI, with the implementation of high pressure coolant. Materials 2019, 12, 768. [Google Scholar] [CrossRef] [PubMed]

- Elsanabary, S.; Elkaseer, A.; Abd-Rabbo, S.; AbdElsalam, M.; Abdou, S. Modelling and experimental validation of surface roughness in precision turning of dual-phase materials considering process uncertainties. Int. J. Interact. Des. Manuf. 2019, 13, 59–74. [Google Scholar] [CrossRef]

- Gao, H.; Liu, X.; Chen, Z. Cutting Performance and Wear/Damage Characteristics of PCBN Tool in Hard Milling. Appl. Sci. 2019, 9, 772. [Google Scholar] [CrossRef]

- Lotfi, M.; Akhavan Farid, A.; Soleimanimehr, H. The effect of chip breaker geometry on chip shape, bending moment, and cutting force: FE analysis and experimental study. Int. J. Adv. Manuf. Technol. 2015, 78, 917–925. [Google Scholar] [CrossRef]

- Chu, N.; Nguyen, D.; Ngo, N.; Nguyen, V.; Tran, M.; Vu, N.; Ngo, Q.; Tran, T. A New Approach to Modelling the Drilling Torque in Conventional and Ultrasonic Assisted Deep-Hole Drilling Processes. Appl. Sci. 2018, 8, 2600. [Google Scholar] [CrossRef]

- Shamoto, E.; Aoki, T.; Sencer, B.; Suzuki, N.; Hino, R.; Koide, T. Control of chip flow with guide grooves for continuous chip disposal and chip-pulling turning. CIRP Ann. 2011, 60, 125–128. [Google Scholar] [CrossRef]

- Miyake, A.; Kitakaze, A.; Katoh, S.; Muramatsu, M.; Noguchi, K.; Sannomiya, K.; Nakaya, T.; Sasahara, H. Chip control in turning with synchronization of spindle rotation and feed motion vibration. Precis. Eng. 2018, 53, 38–45. [Google Scholar] [CrossRef]

- Buchkremer, S.; Klocke, F.; Veselovac, D. 3D FEM simulation of chip breakage in metal cutting. Int. J. Adv. Manuf. Technol. 2016, 82, 645–661. [Google Scholar] [CrossRef]

- Pereira, O.; Rodríguez, A.; Fernández-Abia, A.I.; Barreiro, J.; López de Lacalle, L.N. Cryogenic and minimum quantity lubrication for an eco-efficiency turning of AISI 304. J. Clean. Prod. 2016, 139, 440–449. [Google Scholar] [CrossRef]

- Pereira, O.; Rodríguez, A.; Barreiro, J.; Fernández-Abia, A.I.; de Lacalle, L.N.L. Nozzle design for combined use of MQL and cryogenic gas in machining. Int. J. Precis. Eng. Manuf. 2017, 4, 87–95. [Google Scholar] [CrossRef]

- Kaynak, Y.; Gharibi, A. Progressive Tool Wear in Cryogenic Machining: The Effect of Liquid Nitrogen and Carbon Dioxide. J. Manuf. Mater. Process. 2018, 2, 31. [Google Scholar] [CrossRef]

- Klocke, F.; Lortz, W.; Trauth, D. Analysis of the dynamic chip formation process in turning. Int. J. Mech. Sci. 2018, 135, 313–324. [Google Scholar] [CrossRef]

- Rahimzadeh Berenji, K.; Karagüzel, U.; Özlü, E.; Budak, E. Effects of turn-milling conditions on chip formation and surface finish. CIRP Ann. 2019, 68, 113–116. [Google Scholar] [CrossRef]

- Li, B.; Zhang, S.; Zhang, Q.; Li, L. Simulated and experimental analysis on serrated chip formation for hard milling process. J. Manuf. Process. 2019, 44, 337–348. [Google Scholar] [CrossRef]

- Lotfi, M.; Farid, A.A.; Soleimanimehr, H. A new hybrid model based on the radius ratio for prediction of effective cutting limit of chip breakers. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 230, 1417–1427. [Google Scholar] [CrossRef]

- Elkaseer, A.; Lambarri, J.; Sarasua, J.A.; Cascón, I. On the development of a chip breaker in a metal-matrix polycrystalline diamond insert: Finite element based design with ns-laser ablation and machining verification. J. Micro Nano Manuf. 2017, 5, 031007. [Google Scholar] [CrossRef]

- Soares, R.B.; de Jesus, A.M.P.; Neto, R.J.L.; Rosa, P.A.R.; Machado, M.; Reis, A. Machinability of an Aluminium Cast Alloy Using PCD Tools for Turning. In Materials Design and Applications; Silva, L., Ed.; Springer: Berlin/Heidelberg, Germany, 2017; pp. 329–346. [Google Scholar]

- Diamond, L. Products, PCD and CBN Tools, Inserts with Chipbreaker. Available online: http://www.lach-diamond.com/LDI/products/pcd-and-cbn-tools/turning---drilling---milling/inserts-with-chipbreaker (accessed on 7 June 2019).

- Carbide, M. Technical Information about PCD Turning Inserts. Available online: http://www.mitsubishicarbide.net/contents/mhg/enuk/html/product/technical_information/grade/turning/pcd.html (accessed on 7 June 2019).

- Coromant, S. Chip Breaking in CNC Turning. 2016. Available online: https://www.cadem.com/single-post/cnc-turning-chip-breaking (accessed on 3 July 2019).

- Xiong, Y.; Wang, W.; Jiang, R.; Lin, K.; Shao, M. Mechanisms and FEM Simulation of Chip Formation in Orthogonal Cutting In-Situ TiB2/7050Al MMC. Materials 2018, 11, 606. [Google Scholar] [CrossRef]

- Elkaseer, A.; Abdelaziz, A.; Saber, M.; Nassef, A. FEM-Based Study of Precision Hard Turning of Stainless Steel 316L. Materials 2019, 12, 2522. [Google Scholar] [CrossRef]

- Gonzalo, O.; Quintana, I.; Etxarri, J. FEM Based Design of a Chip Breaker for the Machining with PCD Tools. Adv. Mater. Res. 2011, 223, 133–141. [Google Scholar] [CrossRef]

- Chen, D.C.; You, C.S.; Kao, S.H. Finite element analysis of chip breaker geometry in turning process. Adv. Mech. Eng. 2016, 8, 1687814016659823. [Google Scholar] [CrossRef]

- Gurbuz, H.; Kurt, A.; Seker, U. Investigation of the effects of different chip breaker forms on the cutting forces using artificial neural networks. Gazi Univ. J. Sci. 2012, 25, 803–814. [Google Scholar]

- Sreekala, P.; Visweswararao, K. A methodology for chip breaker design at low feed turning of alloy steel using finite element modelling methods. Int. J. Mech. Eng. Technol. 2012, 3, 263–273. [Google Scholar]

- Third Wave Systems. Third Wave AdvantEdge™. Available online: www.thirdwavesys.com/advantedge/ (accessed on 7 June 2019).

- Shokrani, A.; Newman, S.T. A New Cutting Tool Design for Cryogenic Machining of Ti–6Al–4V Titanium Alloy. Materials 2019, 12, 477. [Google Scholar] [CrossRef] [PubMed]

- Tsai, M.Y.; Chang, C.T.; Ho, J.K. The Machining of Hard Mold Steel by Ultrasonic Assisted End Milling. Appl. Sci. 2016, 6, 373. [Google Scholar] [CrossRef]

- Astakhov, V.P. Tribology of Metal Cutting; Elsevier: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Eberle, G.; Wegener, K. Ablation study of WC and PCD composites using 10 picosecond and 1 nanosecond pulse durations at green and infrared wavelengths. In Proceedings of the 8th International Conference on Photonic Technologies, Physics Procedia, Fürth, Germany, 8–11 September 2014; Volume 56, pp. 951–962. [Google Scholar]

- Eberle, G.; Jefimovs, K.; Wegener, K. Characterisation of Thermal Influences After Laser Processing Polycrystalline Diamond Composites Using Long to Ultra-Short Pulse Durations. Precis. Eng. 2015, 39, 16–24. [Google Scholar] [CrossRef]

| Workpiece Materials | Al 6082 |

|---|---|

| Depth of cut (Ap) | 1 mm |

| Cutting Velocity (Vc) | 100 m/min |

| Feed rate (f) | 0.1 mm/rev |

| α (°) | a (mm) | Cutting Force (N) | Temperature (°C) | Radius of Curvature of the Chip (mm) |

|---|---|---|---|---|

| 10 | 0 | 170.9 | 185.2 | 6.5 |

| 10 | 0.05 | 161.2 | 179.3 | 5 |

| 10 | 0.1 | 160.1 | 171.9 | 2 |

| 10 | 0.15 | 161.1 | 175.0 | 2.25 |

| 20 | 0 | 148.1 | 172.9 | 4.75 |

| 20 | 0.05 | 139.1 | 160.2 | 1.45 |

| 20 | 0.1 | 155.2 | 169.0 | 1.88 |

| 20 | 0.15 | 158.6 | 174.9 | 2 |

| 30 | 0 | 123.8 | 159.1 | 2.65 |

| 30 | 0.05 | 138.4 | 161.9 | 1.55 |

| 30 | 0.1 | 151.5 | 172.0 | 1.75 |

| 30 | 0.15 | 156.3 | 178.2 | 5.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cascón, I.; Sarasua, J.A.; Elkaseer, A. Tailored Chip Breaker Development for Polycrystalline Diamond Inserts: FEM-Based Design and Validation. Appl. Sci. 2019, 9, 4117. https://doi.org/10.3390/app9194117

Cascón I, Sarasua JA, Elkaseer A. Tailored Chip Breaker Development for Polycrystalline Diamond Inserts: FEM-Based Design and Validation. Applied Sciences. 2019; 9(19):4117. https://doi.org/10.3390/app9194117

Chicago/Turabian StyleCascón, Itxaso, Jon Ander Sarasua, and Ahmed Elkaseer. 2019. "Tailored Chip Breaker Development for Polycrystalline Diamond Inserts: FEM-Based Design and Validation" Applied Sciences 9, no. 19: 4117. https://doi.org/10.3390/app9194117

APA StyleCascón, I., Sarasua, J. A., & Elkaseer, A. (2019). Tailored Chip Breaker Development for Polycrystalline Diamond Inserts: FEM-Based Design and Validation. Applied Sciences, 9(19), 4117. https://doi.org/10.3390/app9194117