Mechanical Properties and Crack Classification of Basalt Fiber RPC Based on Acoustic Emission Parameters

Abstract

1. Introduction

2. Acoustic Emission Method

3. Experimental Details

3.1. Materials

3.2. Mixture Proportions and Sample Preparation

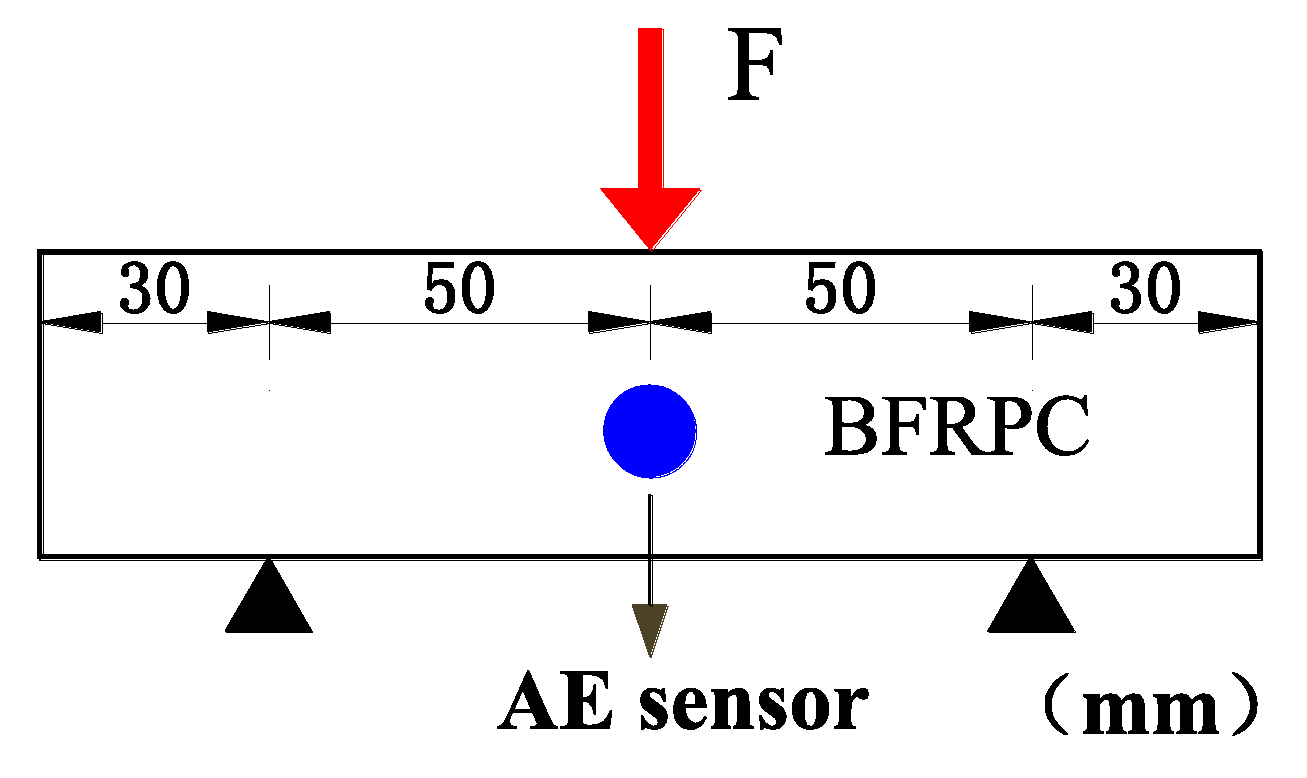

3.3. Testing

4. Discussion

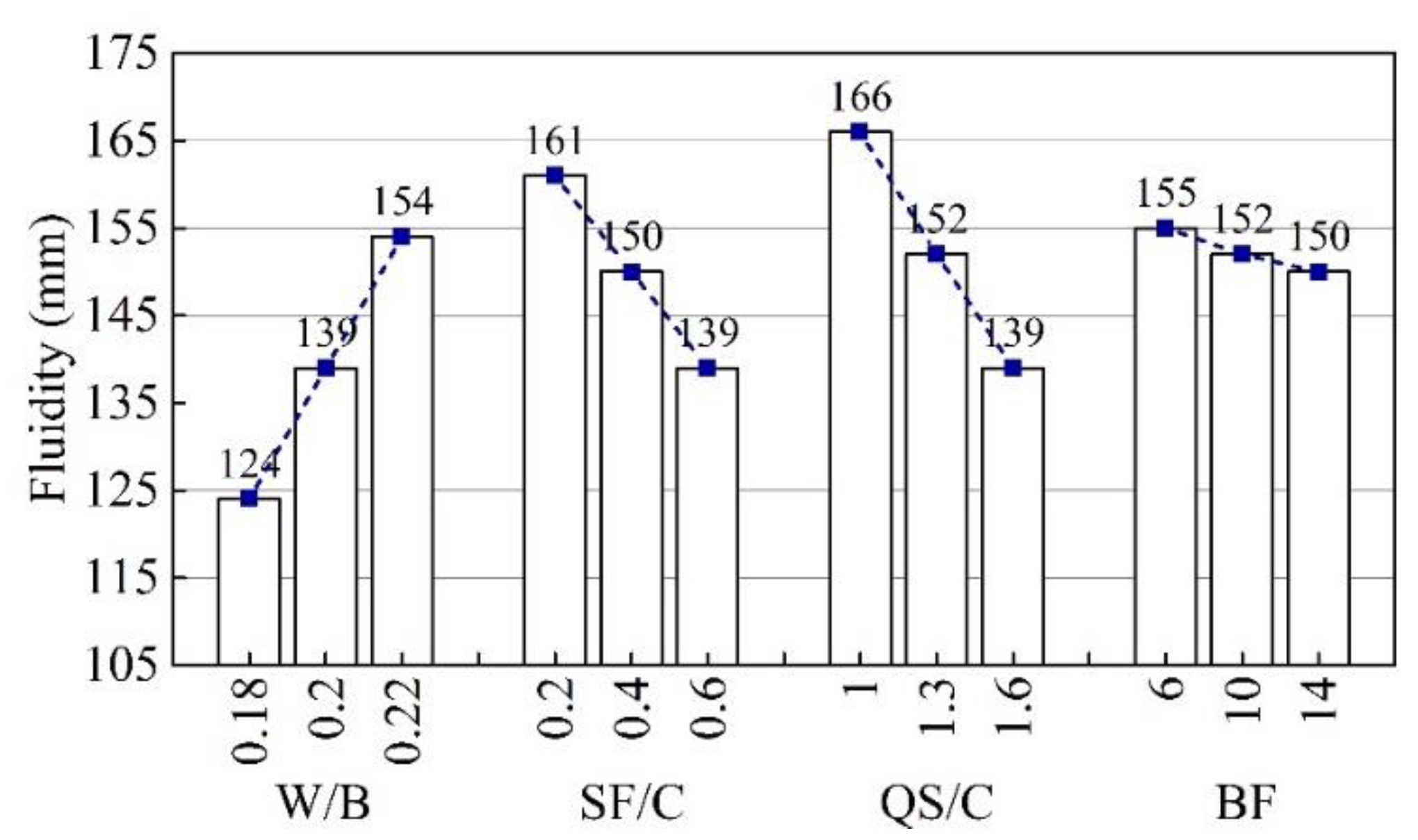

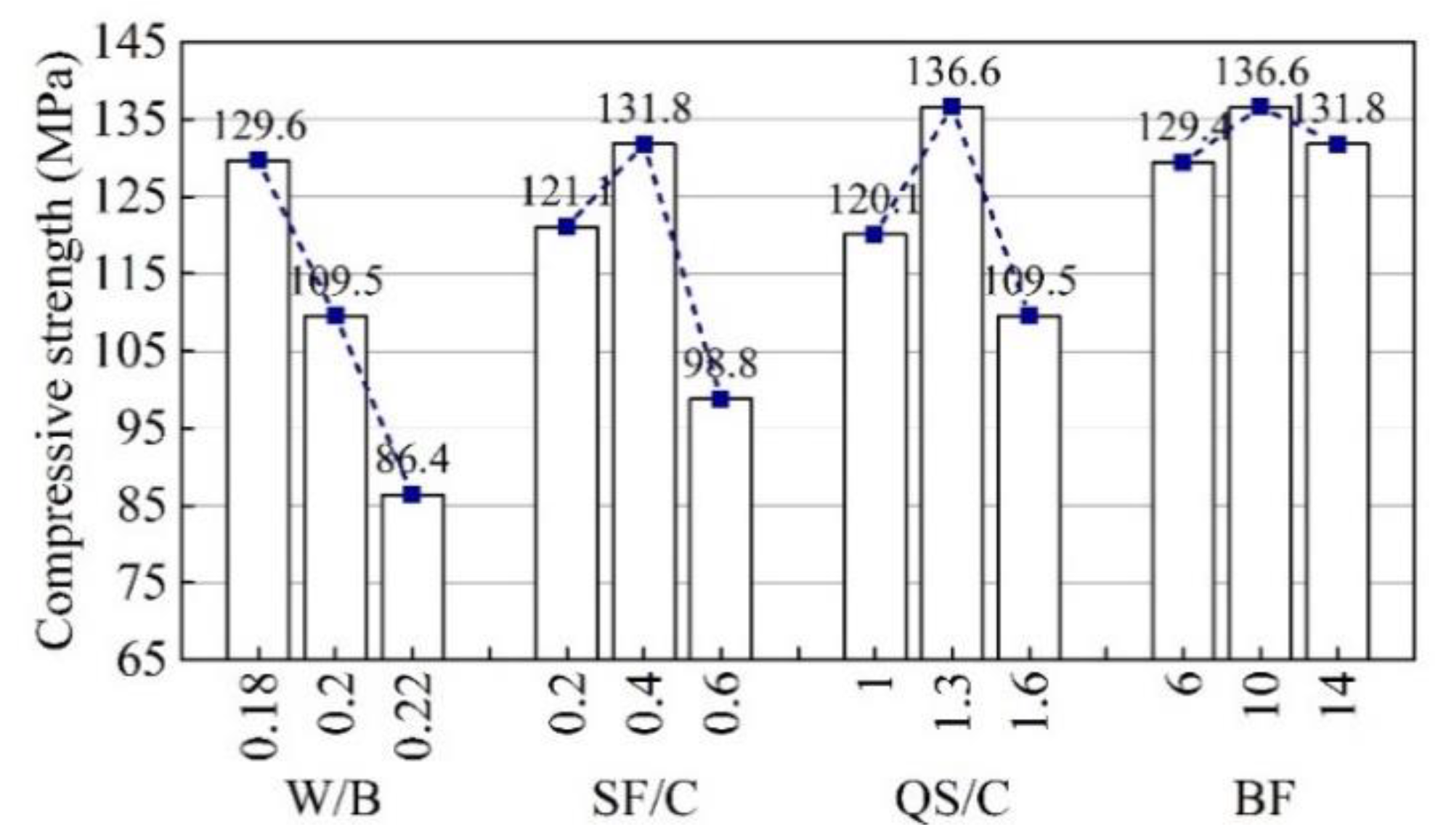

4.1. Workability and Mechanical Properties

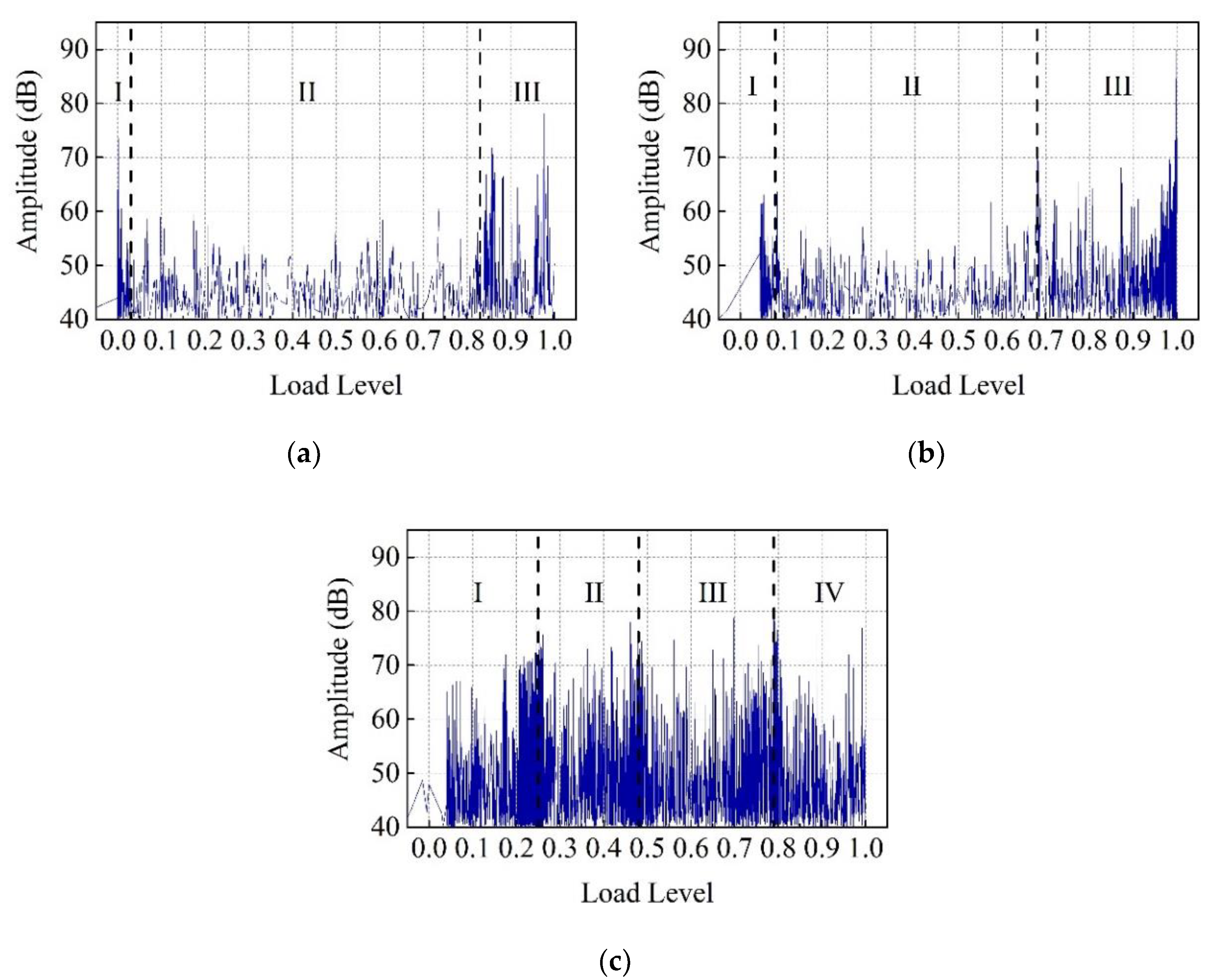

4.2. Acoustic Emission Results

4.2.1. Total AE Hits

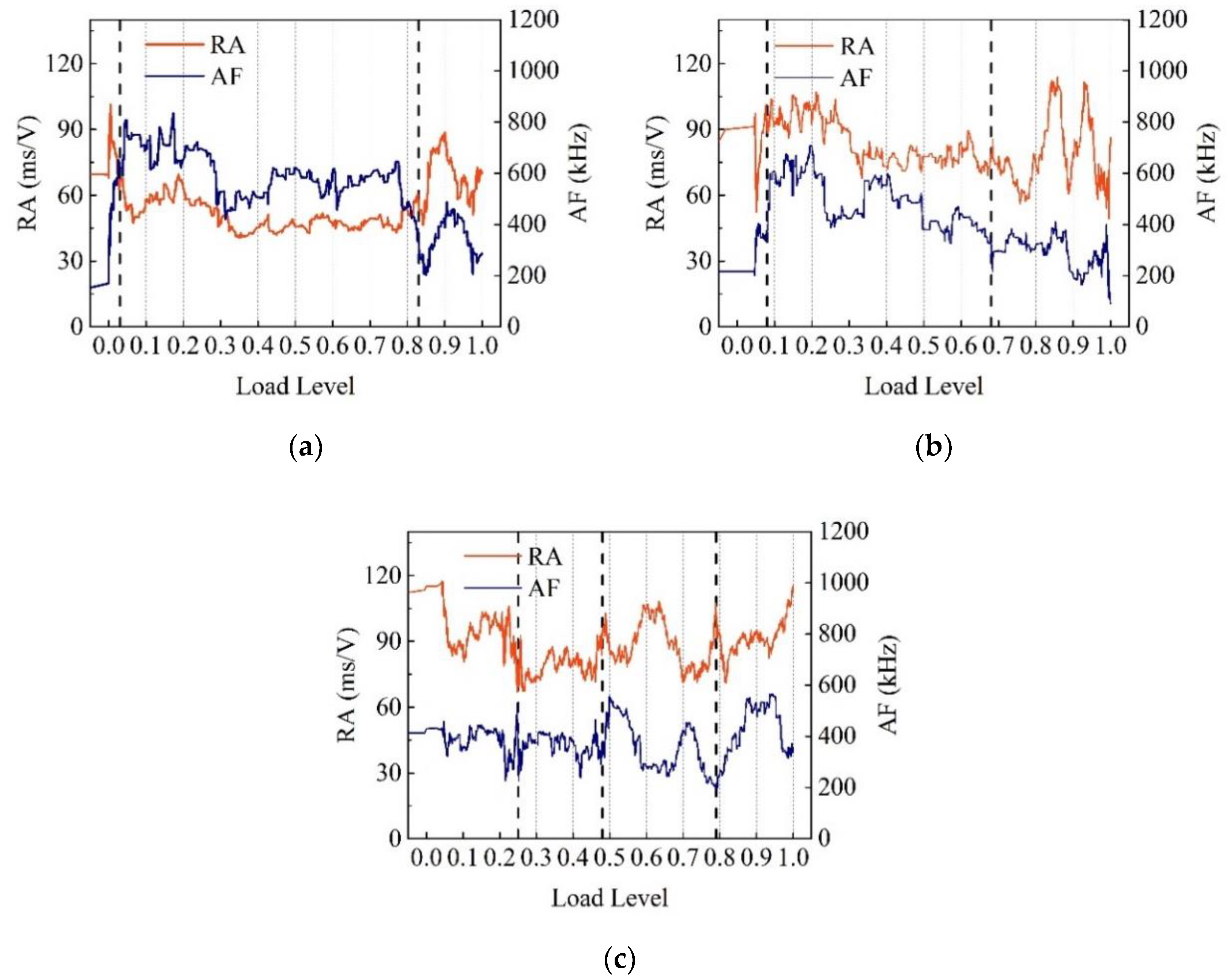

4.2.2. Investigation of Fracture Mode

5. Conclusions

- The addition of basalt fibers improved significantly the flexural strength without any negative impact on the workability performance. A slightly lower water to binder ratio had to be used to ensure the strength of materials. The appropriate addition of quartz sand formed a stable micro-support framework and improved the distribution of binders within the matrix. The expected values of quartz sand to binder ratio and the silica fume to cement ratio are 0.4 and 1.3, respectively.

- The activities of AE signals were proportional to the fiber content. The damage fracture process of BFRPC under flexural stress could be accurately divided based on the slope variability of cumulative AE energy. The value of AE amplitude also symbolized the switch of damage stage, which could be used as an early warning of fracture.

- The fracture mode of BFRPC under flexural test was gradually dominated by shear with the increase of basalt fiber content. This demonstrated the improvement of the fibers against the weak tensile properties and toughness of concrete. It was shown that AE technology can recognize the fracture patterns of specimens by average frequency and RA value, which could assist the damage assessment.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Richard, P.; Cheyrezy, M. Composition of reactive powder concretes. Cem. Concr. Res. 1995, 25, 1501–1511. [Google Scholar] [CrossRef]

- Zdeb, T. Ultra-high performance concrete—Properties and technology. Bull. Pol. Acad. Sci. Tech. Sci. 2013, 61, 183–193. [Google Scholar] [CrossRef]

- Yunsheng, Z.; Wei, S.; Sifeng, L.; Chujie, J.; Jianzhong, L. Preparation of C200 green reactive powder concrete and its static–dynamic behaviors. Cem. Concr. Compos. 2008, 30, 831–838. [Google Scholar] [CrossRef]

- Wille, K.; Boisvert-Cotulio, C. Material efficiency in the design of ultra-high performance concrete. Constr. Build. Mater. 2015, 86, 33–43. [Google Scholar] [CrossRef]

- Ipek, M.; Yilmaz, K.; Sümer, M.; Saribiyik, M. Effect of pre-setting pressure applied to mechanical behaviours of reactive powder concrete during setting phase. Constr. Build. Mater. 2011, 25, 61–68. [Google Scholar] [CrossRef]

- Bae, B.-I.; Choi, H.-K.; Lee, B.-S.; Bang, C.-H. Compressive Behavior and Mechanical Characteristics and Their Application to Stress-Strain Relationship of Steel Fiber-Reinforced Reactive Powder Concrete. Adv. Mater. Sci. Eng. 2016, 2016, 1–11. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Biolzi, L.; Ozbakkaloglu, T. High-performance fiber-reinforced concrete: A review. J. Mater. Sci. 2016, 51, 6517–6551. [Google Scholar] [CrossRef]

- Sim, J.; Park, C.; Moon, D.Y. Characteristics of basalt fiber as a strengthening material for concrete structures. Compos. Part B Eng. 2005, 36, 504–512. [Google Scholar] [CrossRef]

- Branston, J.; Das, S.; Kenno, S.Y.; Taylor, C. Mechanical behaviour of basalt fibre reinforced concrete. Constr. Build. Mater. 2016, 124, 878–886. [Google Scholar] [CrossRef]

- Wang, D.; Ju, Y.; Shen, H.; Xu, L. Mechanical properties of high performance concrete reinforced with basalt fiber and polypropylene fiber. Constr. Build. Mater. 2019, 197, 464–473. [Google Scholar] [CrossRef]

- Ayub, T.; Shafiq, N.; Nuruddin, M.F. Mechanical Properties of High-performance Concrete Reinforced with Basalt Fibers. Procedia Eng. 2014, 77, 131–139. [Google Scholar] [CrossRef]

- Nair, A.; Cai, C.S. Acoustic emission monitoring of bridges: Review and case studies. Eng. Struct. 2010, 32, 1704–1714. [Google Scholar] [CrossRef]

- Prem, P.R.; Murthy, A.R. Acoustic emission and flexural behaviour of RC beams strengthened with UHPC overlay. Constr. Build. Mater. 2016, 123, 481–492. [Google Scholar] [CrossRef]

- Farhidzadeh, A.; Salamone, S.; Luna, B.; Whittaker, A. Acoustic emission monitoring of a reinforced concrete shear wall by b-value-based outlier analysis. Struct. Health Monit. 2013, 12, 3–13. [Google Scholar] [CrossRef]

- Zhang, X.C.; Shan, W.C.; Zhang, Z.W.; Li, B. AE monitoring of reinforced concrete squat wall subjected to cyclic loading with information entropy-based analysis. Eng. Struct. 2018, 165, 359–367. [Google Scholar] [CrossRef]

- Sagar, R.V. A parallel between earthquake sequences and acoustic emissions released during fracture process in reinforced concrete structures under flexural loading. Constr. Build. Mater. 2016, 114, 772–793. [Google Scholar] [CrossRef]

- Siracusano, G.; Lamonaca, F.; Tomasello, R.; Garesci, F.; La Corte, A.; Carni, D.L.; Carpentieri, M.; Grimaldi, D.; Finocchio, G. A framework for the damage evaluation of acoustic emission signals through Hilbert-Huang transform. Mech. Syst. Signal Process. 2016, 75, 109–122. [Google Scholar] [CrossRef]

- Mhamdi, L.; Schumacher, T. A Comparison Between Time-of-Arrival and Novel Phased Array Approaches to Estimate Acoustic Emission Source Locations in a Steel Plate. J. Nondestruct. Eval. 2015, 34, 38. [Google Scholar] [CrossRef]

- Aggelis, D.G.; Soulioti, D.V.; Sapouridis, N.; Barkoula, N.M.; Paipetis, A.S.; Matikas, I.E. Acoustic emission characterization of the fracture process in fibre reinforced concrete. Constr. Build. Mater. 2011, 25, 4126–4131. [Google Scholar] [CrossRef]

- Kurz, J.H.; Grosse, C.U.; Reinhardt, H.W. Strategies for reliable automatic onset time picking of acoustic emissions and of ultrasound signals in concrete. Ultrasonics 2005, 43, 538–546. [Google Scholar] [CrossRef] [PubMed]

- Mpalaskas, A.C.; Matilzas, T.E.; Van Hemelrijck, D.; Papakitsos, G.S.; Aggelis, D.G. Acoustic emission monitoring of granite under bending and shear loading. Arch. Civ. Mech. Eng. 2016, 16, 313–324. [Google Scholar] [CrossRef]

- Carpinteri, A.; Lacidogna, G.; Accornero, F.; Mpalaskas, A.C.; Matikas, T.E.; Aggelis, D.G. Influence of damage in the acoustic emission parameters. Cem. Concr. Comp 2013, 44, 9–16. [Google Scholar] [CrossRef]

- Tragazikis, I.K.; Dassios, K.G.; Exarchos, D.A.; Dalla, P.T.; Matikas, T.E. Acoustic emission investigation of the mechanical performance of carbon nanotube-modified cement-based mortars. Constr. Build. Mater. 2016, 122, 518–524. [Google Scholar] [CrossRef]

- Ohno, K.; Ohtsu, M. Crack classification in concrete based on acoustic emission. Constr. Build. Mater. 2010, 24, 2339–2346. [Google Scholar] [CrossRef]

- National Standard of the People’s Republic of China. Test Methods for Cement and Concrete for Highway Engineering (JTG E30-2005); Ministry of Transport of the People’s Republic of China: Beijing, China, 2006.

- National Standard of the People’s Republic of China. Method of Testing Cements-Determination of Strength (GB/T 17671-1999); Quality and Technology Supervision Bureau of the People’s Republic of China: Beijing, China, 1999.

- Fan, X.Q.; Hu, S.W.; Lu, J.; Wei, C.J. Acoustic emission properties of concrete on dynamic tensile test. Constr. Build. Mater. 2016, 114, 66–75. [Google Scholar]

- Kim, J.S.; Lee, K.S.; Cho, W.J.; Choi, H.J.; Cho, G.C. A Comparative Evaluation of Stress-Strain and Acoustic Emission Methods for Quantitative Damage Assessments of Brittle Rock. Rock Mech. Rock Eng. 2015, 48, 495–508. [Google Scholar] [CrossRef]

- Chan, Y.W.; Chu, S.H. Effect of silica fume on steel fiber bond characteristics in reactive powder concrete. Cem. Concr. Res. 2004, 34, 1167–1172. [Google Scholar] [CrossRef]

- Kizilkanat, A.B.; Kabay, N.; Akyuncu, V.; Chowdhury, S.; Akca, A.R. Mechanical properties and fracture behavior of basalt and glass fiber reinforced concrete: An experimental study. Constr. Build. Mater. 2015, 100, 218–224. [Google Scholar] [CrossRef]

- Behnia, A.; Chai, H.K.; Yorikawa, M.; Momoki, S.; Terazawa, M.; Shiotani, T. Integrated non-destructive assessment of concrete structures under flexure by acoustic emission and travel time tomography. Constr. Build. Mater. 2014, 67, 202–215. [Google Scholar] [CrossRef]

- Li, D.S.; Du, F.Z. Monitoring and evaluating the failure behavior of ice structure using the acoustic emission technique. Cold Reg. Sci. Technol. 2016, 129, 51–59. [Google Scholar] [CrossRef]

- Soulioti, D.; Barkoula, N.M.; Paipetis, A.; Matikas, T.E.; Shiotani, T.; Aggelis, D.G. Acoustic emission behavior of steel fibre reinforced concrete under bending. Constr. Build. Mater. 2009, 23, 3532–3536. [Google Scholar] [CrossRef]

| Items | Chemical Compositions (%) | |||||

|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | |

| Cement | 22.6 | 5.6 | 4.3 | 62.7 | 1.7 | 2.5 |

| Silica fume (SF) | 93.3 | 0.73 | 0.49 | 0.85 | 1.21 | 1.02 |

| Fiber Type | Length (mm) | Diameter (μm) | Linear Density (tex) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Breaking Strength (N/tex) | Elongation (%) |

|---|---|---|---|---|---|---|---|

| Basalt fiber | 22 | 23 | 2392 | 2836 | 62 | 0.69 | 3 |

| Component | SiO2 | Fe | Al2O3 | K2O | Na2O | H2O |

|---|---|---|---|---|---|---|

| Content (%) | 99.68 | 0.0062 | 0.0122 | 0.0011 | 0.002 | 0.02 |

| Mix | W/B | SF/C | QS/C | Materials (kg/m³) | |||||

|---|---|---|---|---|---|---|---|---|---|

| Cement | SF | QS | Water | SP | BF | ||||

| BF1 | 0.18 | 0.4 | 1.6 | 769 | 308 | 1230 | 194 | 97 | 10 |

| BF2 | 0.2 | 0.4 | 1.6 | 762 | 308 | 1230 | 215 | 97 | 10 |

| BF3 | 0.22 | 0.4 | 1.6 | 756 | 308 | 1230 | 237 | 97 | 10 |

| BF4 | 0.2 | 0.2 | 1.3 | 756 | 154 | 999 | 185 | 83 | 14 |

| BF5 | 0.2 | 0.4 | 1.3 | 912 | 308 | 999 | 215 | 97 | 14 |

| BF6 | 0.2 | 0.6 | 1.3 | 839 | 461 | 999 | 246 | 111 | 14 |

| BF7 | 0.2 | 0.4 | 1.0 | 776 | 308 | 769 | 215 | 97 | 10 |

| BF8 | 0.2 | 0.4 | 1.3 | 933 | 308 | 999 | 215 | 97 | 10 |

| BF9 | 0.2 | 0.4 | 1.3 | 839 | 308 | 1230 | 194 | 97 | 6 |

| Mix | BF1 | BF2 | BF3 | BF4 | BF5 | BF6 | BF7 | BF8 | BF9 |

|---|---|---|---|---|---|---|---|---|---|

| Fluidity (mm) | 124 | 139 | 154 | 161 | 150 | 139 | 166 | 152 | 155 |

| Compressive strength (MPa) | 129.6 | 109.5 | 86.4 | 121.1 | 131.8 | 98.8 | 120.1 | 136.6 | 129.4 |

| Flexural strength (MPa) | 13.6 | 11.6 | 10.8 | 9.9 | 13.1 | 12.2 | 11.7 | 12.6 | 11.9 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Liu, S.; Zhou, P.; Zhang, Y.; Jiao, Y. Mechanical Properties and Crack Classification of Basalt Fiber RPC Based on Acoustic Emission Parameters. Appl. Sci. 2019, 9, 3931. https://doi.org/10.3390/app9183931

Liu H, Liu S, Zhou P, Zhang Y, Jiao Y. Mechanical Properties and Crack Classification of Basalt Fiber RPC Based on Acoustic Emission Parameters. Applied Sciences. 2019; 9(18):3931. https://doi.org/10.3390/app9183931

Chicago/Turabian StyleLiu, Hanbing, Shiqi Liu, Peilei Zhou, Yuwei Zhang, and Yubo Jiao. 2019. "Mechanical Properties and Crack Classification of Basalt Fiber RPC Based on Acoustic Emission Parameters" Applied Sciences 9, no. 18: 3931. https://doi.org/10.3390/app9183931

APA StyleLiu, H., Liu, S., Zhou, P., Zhang, Y., & Jiao, Y. (2019). Mechanical Properties and Crack Classification of Basalt Fiber RPC Based on Acoustic Emission Parameters. Applied Sciences, 9(18), 3931. https://doi.org/10.3390/app9183931