Experimental Study on the Efficacy of Water Infusion for Underground Mining of a Coal Seam

Abstract

:1. Introduction

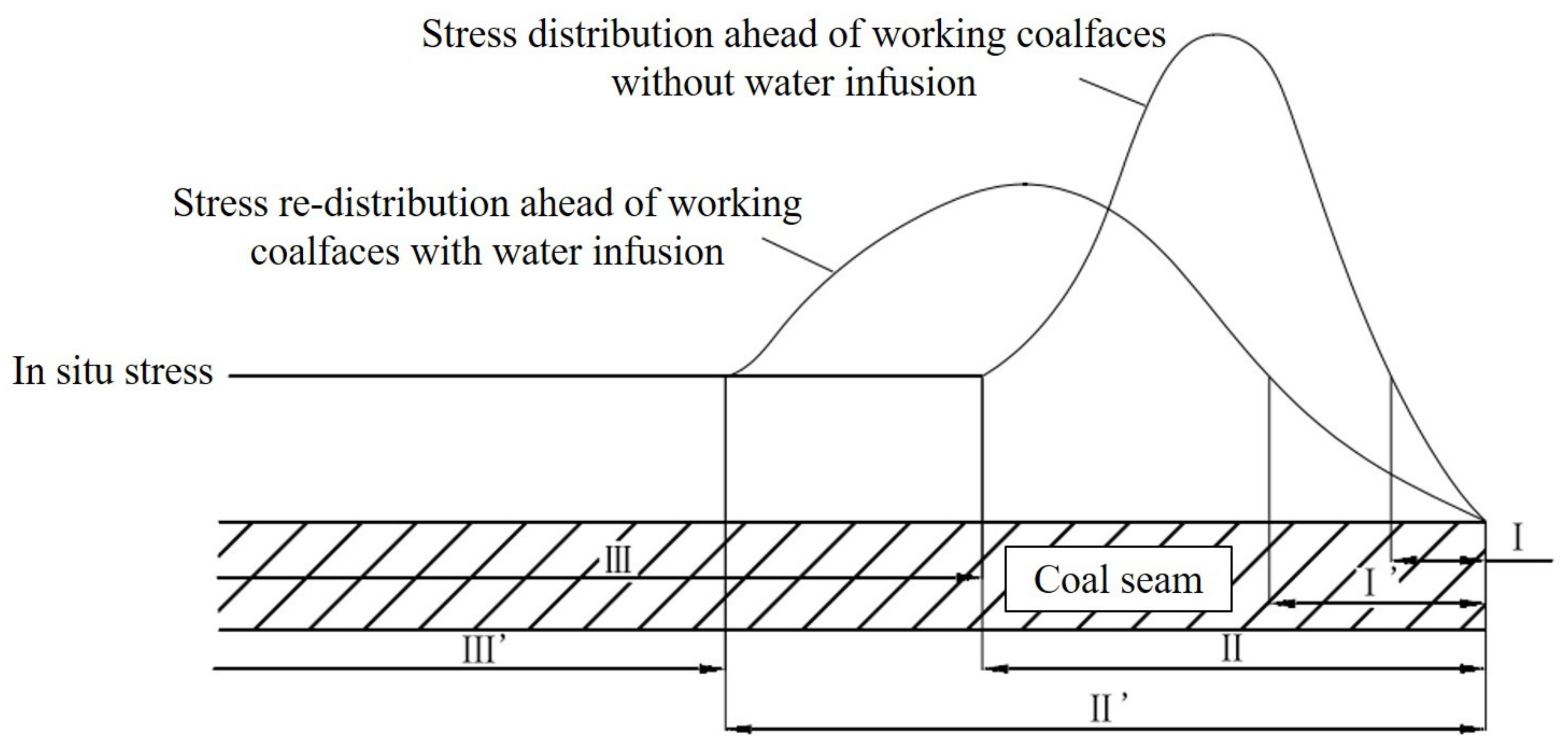

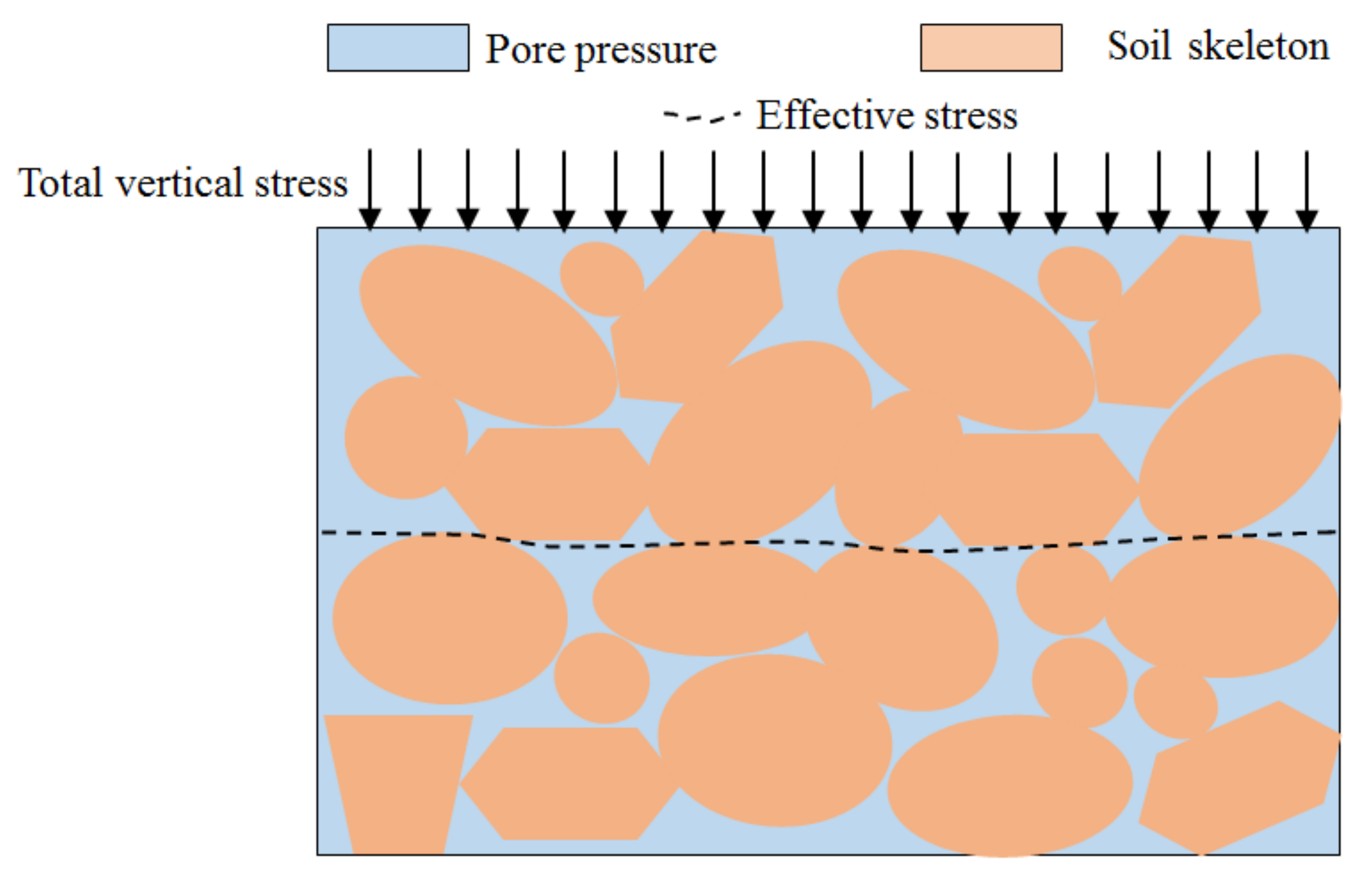

2. Stress Re-Distribution Ahead of Working Coalfaces of a Coal Seam with Water Infusion

3. Experimental Program

3.1. Laboratory Test Program

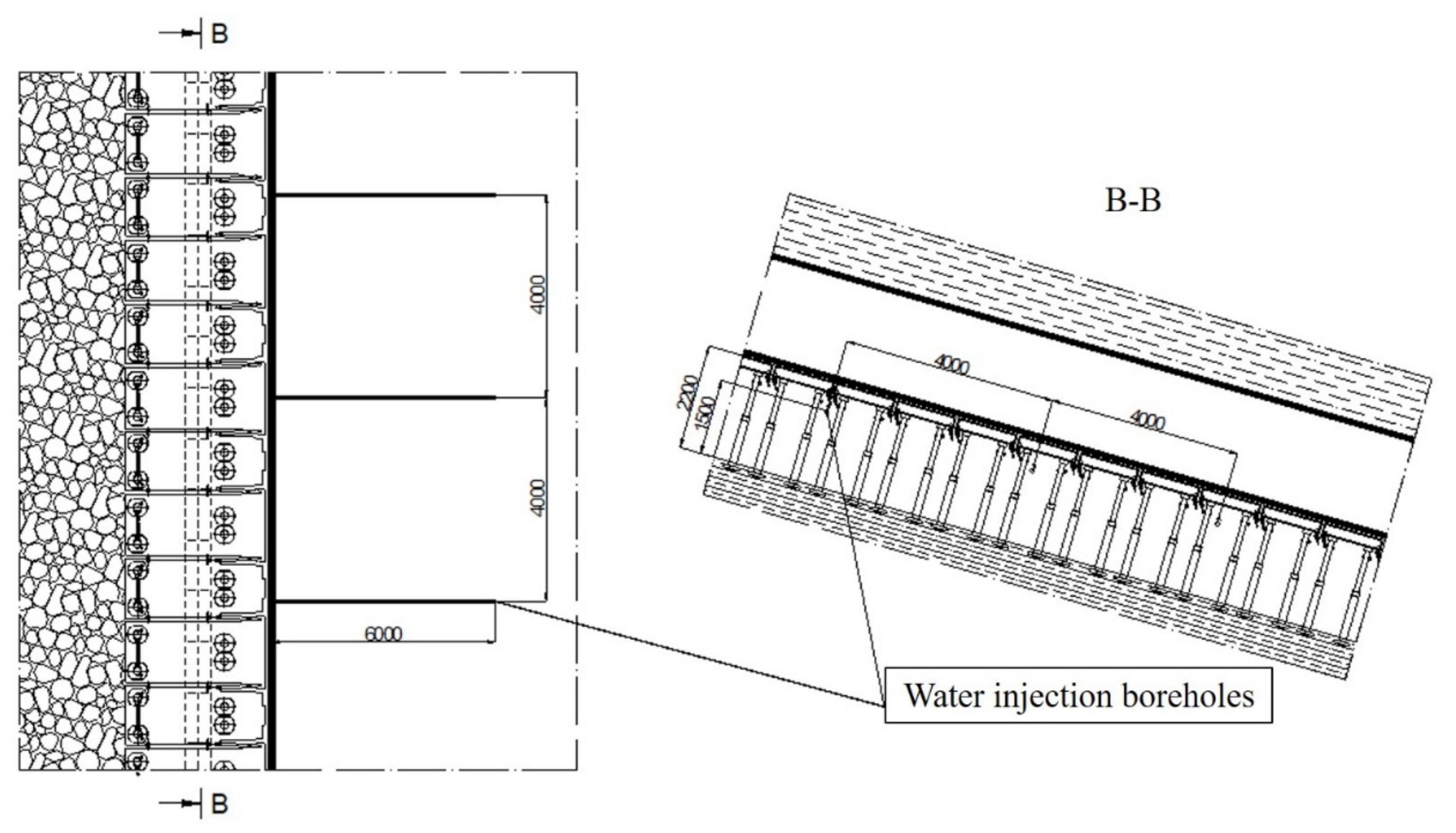

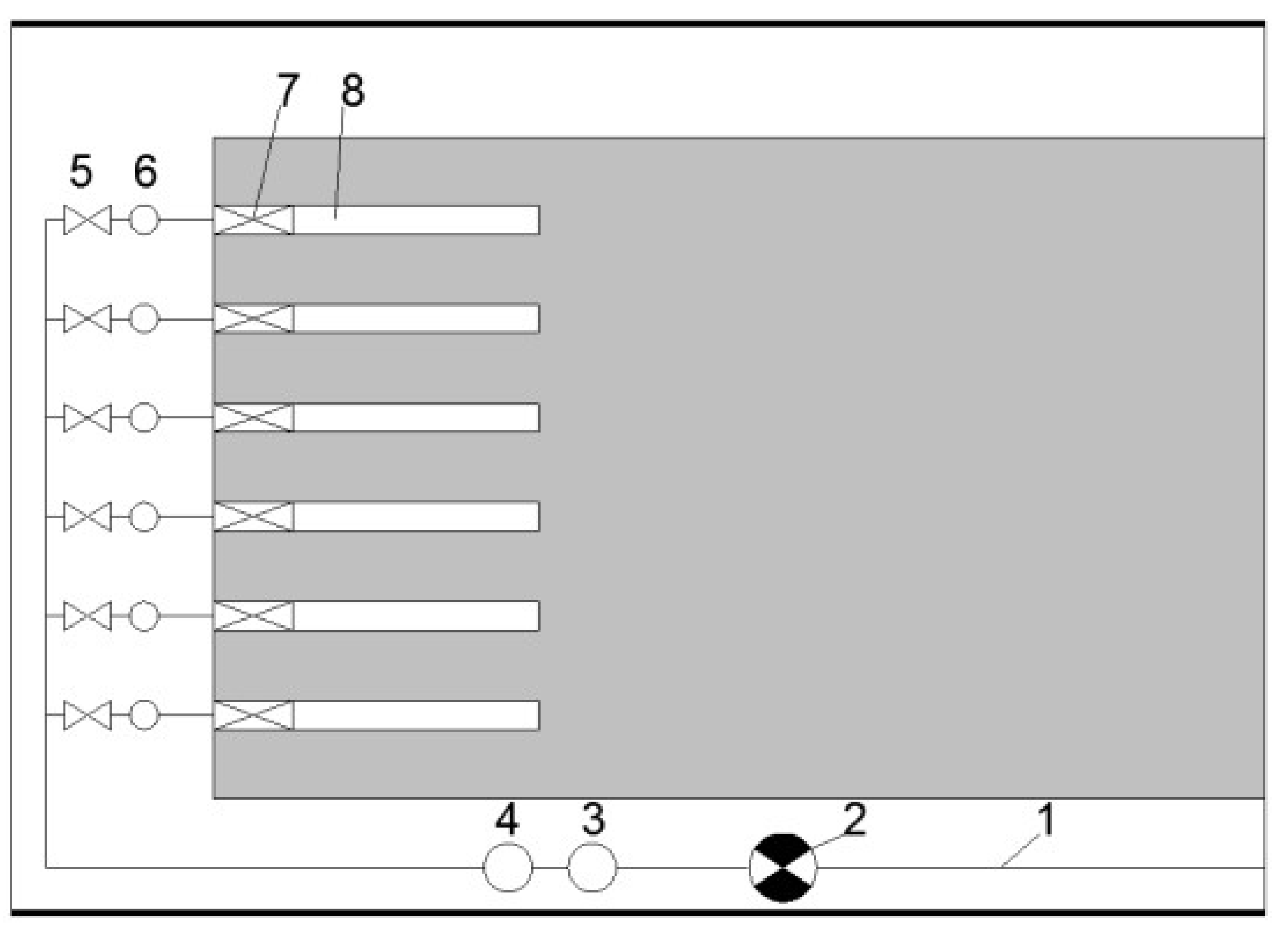

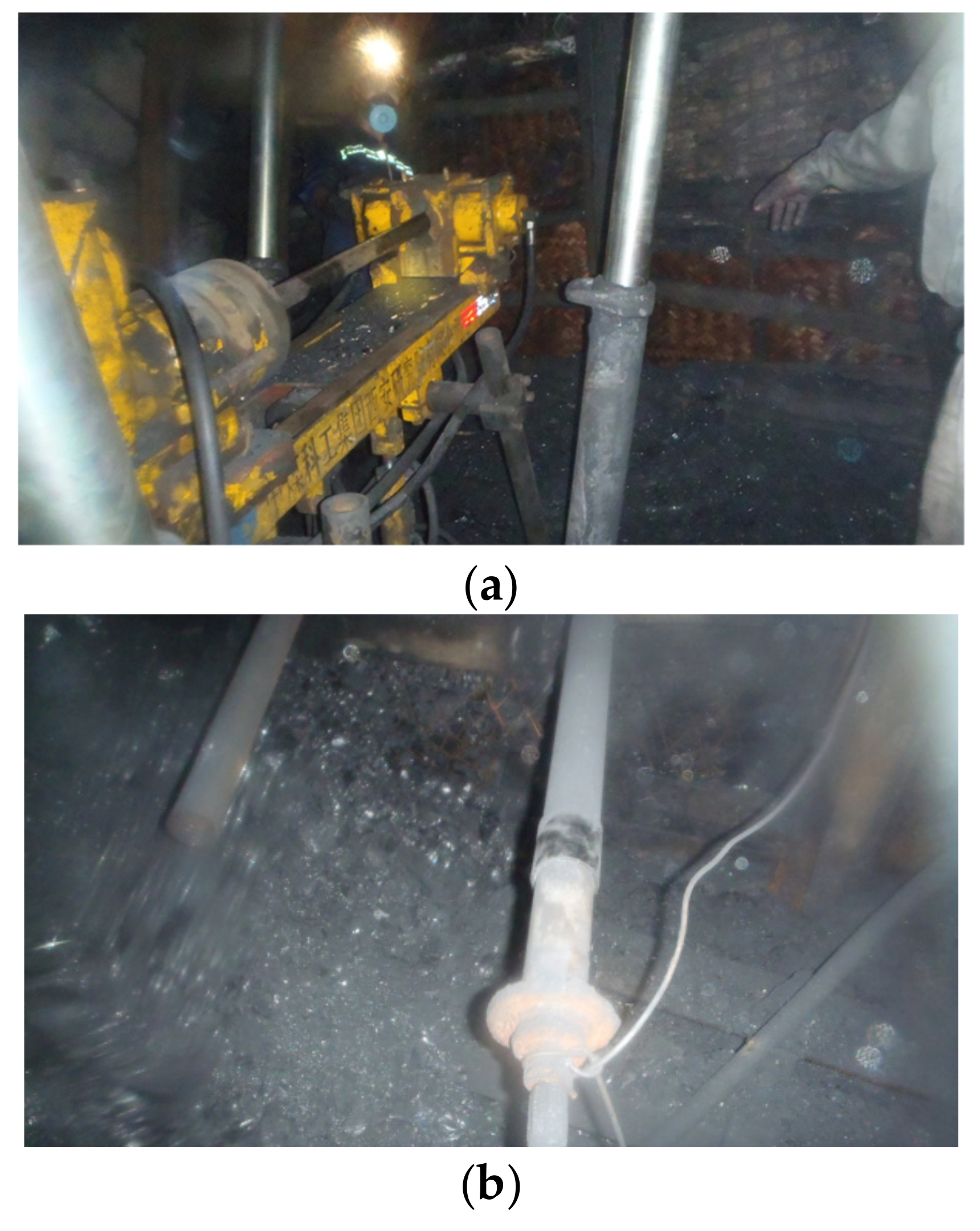

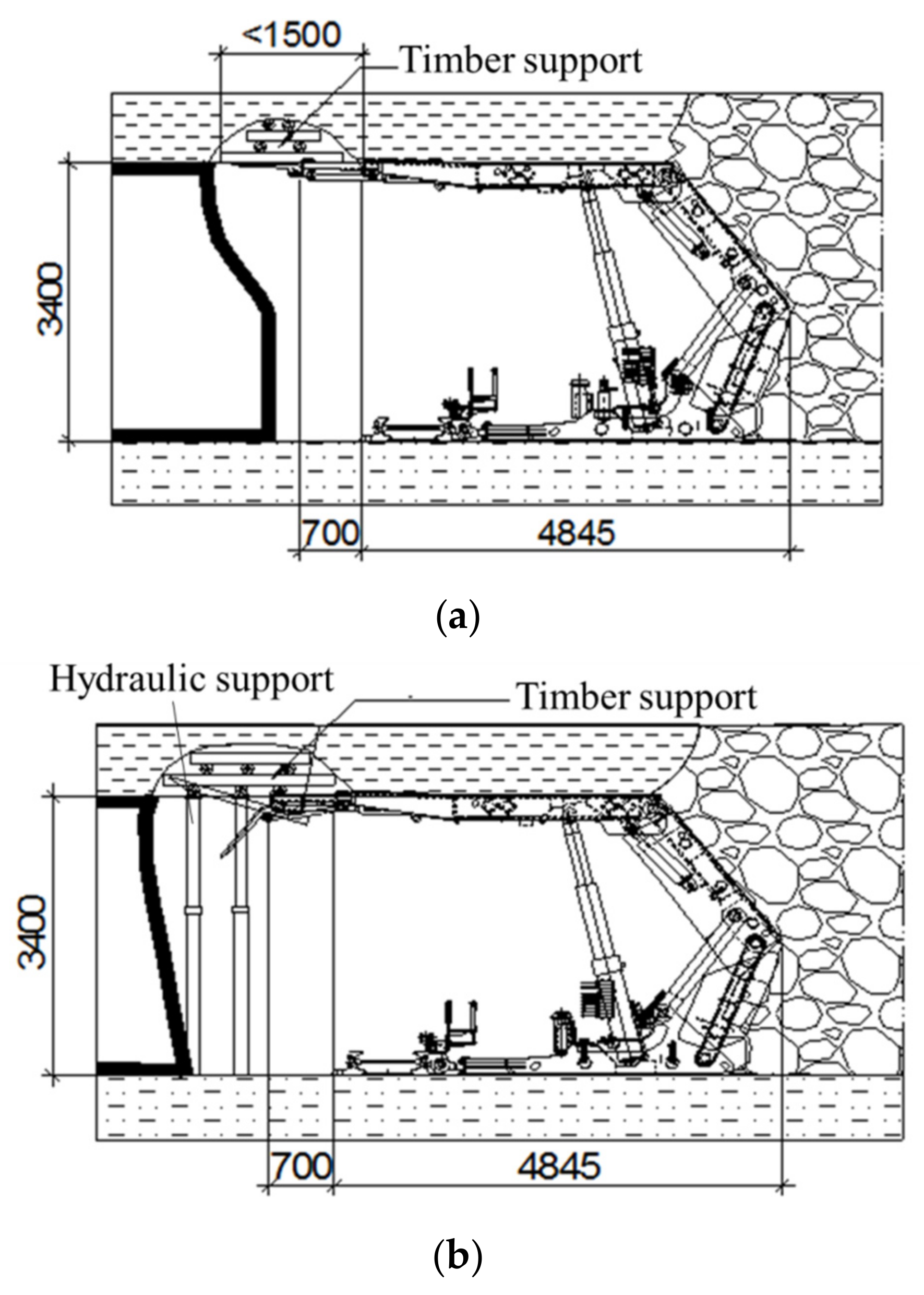

3.2. Field Test Set Up

4. Results and Discussion

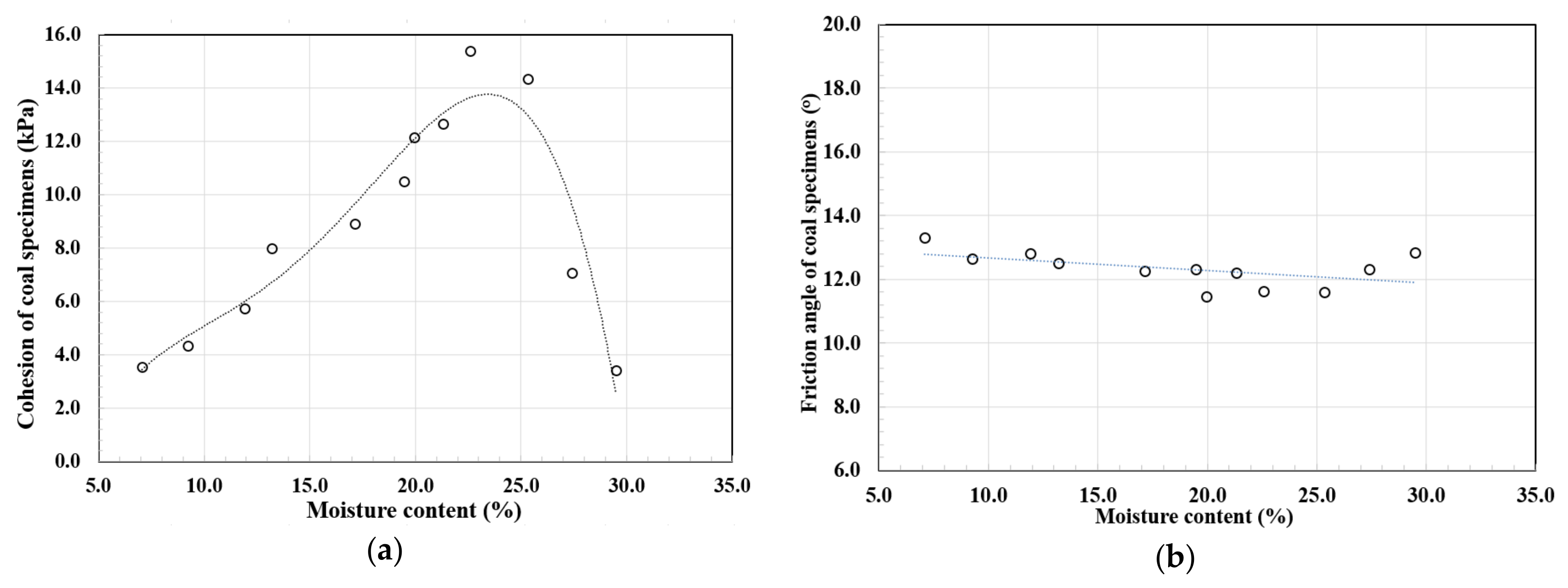

4.1. Laboratory Test Results and Discussion

4.1.1. Effect of Moisture Content on the Strength Properties of Coal

4.1.2. Effect of Water Injection Time on the Strength Properties of Coal

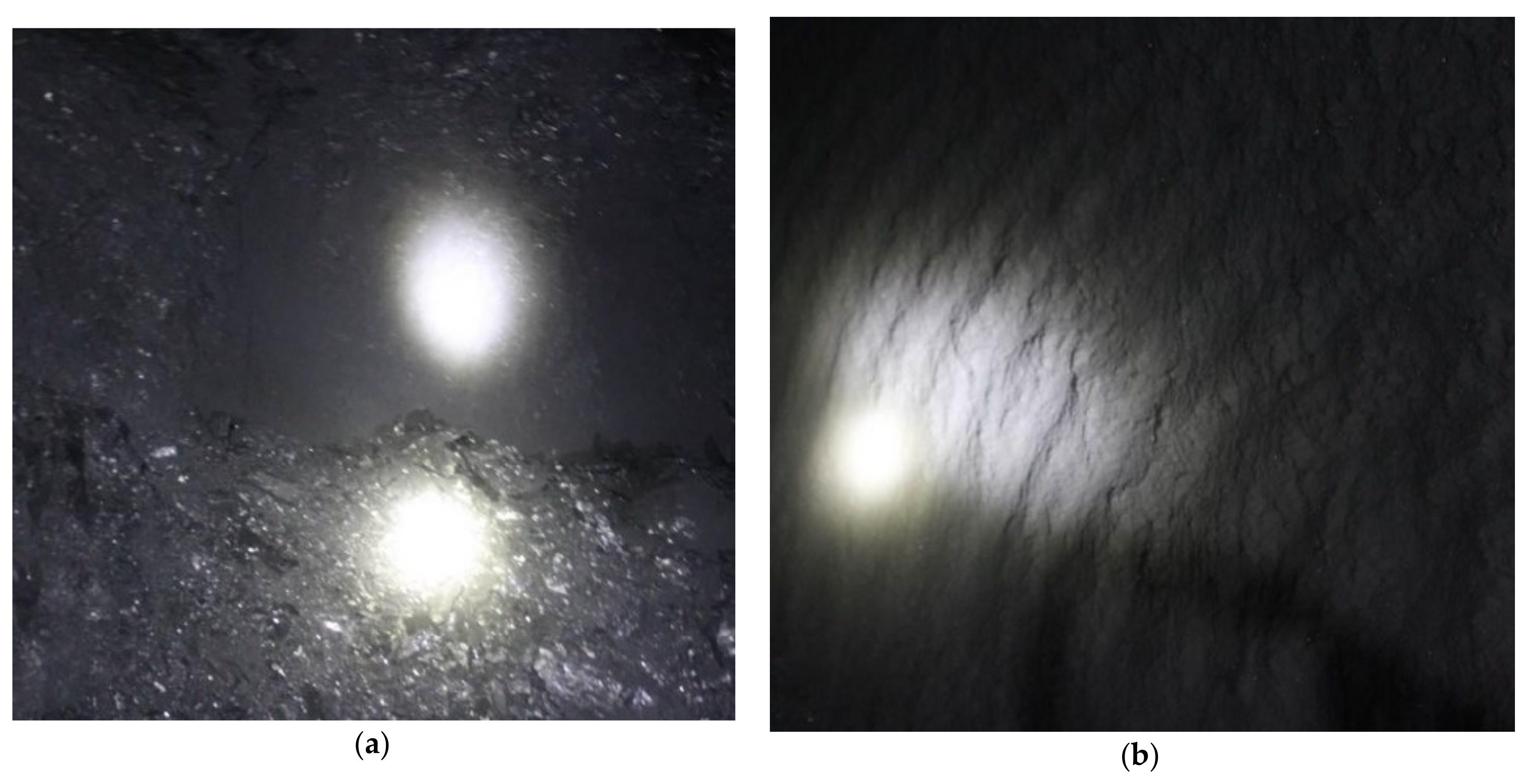

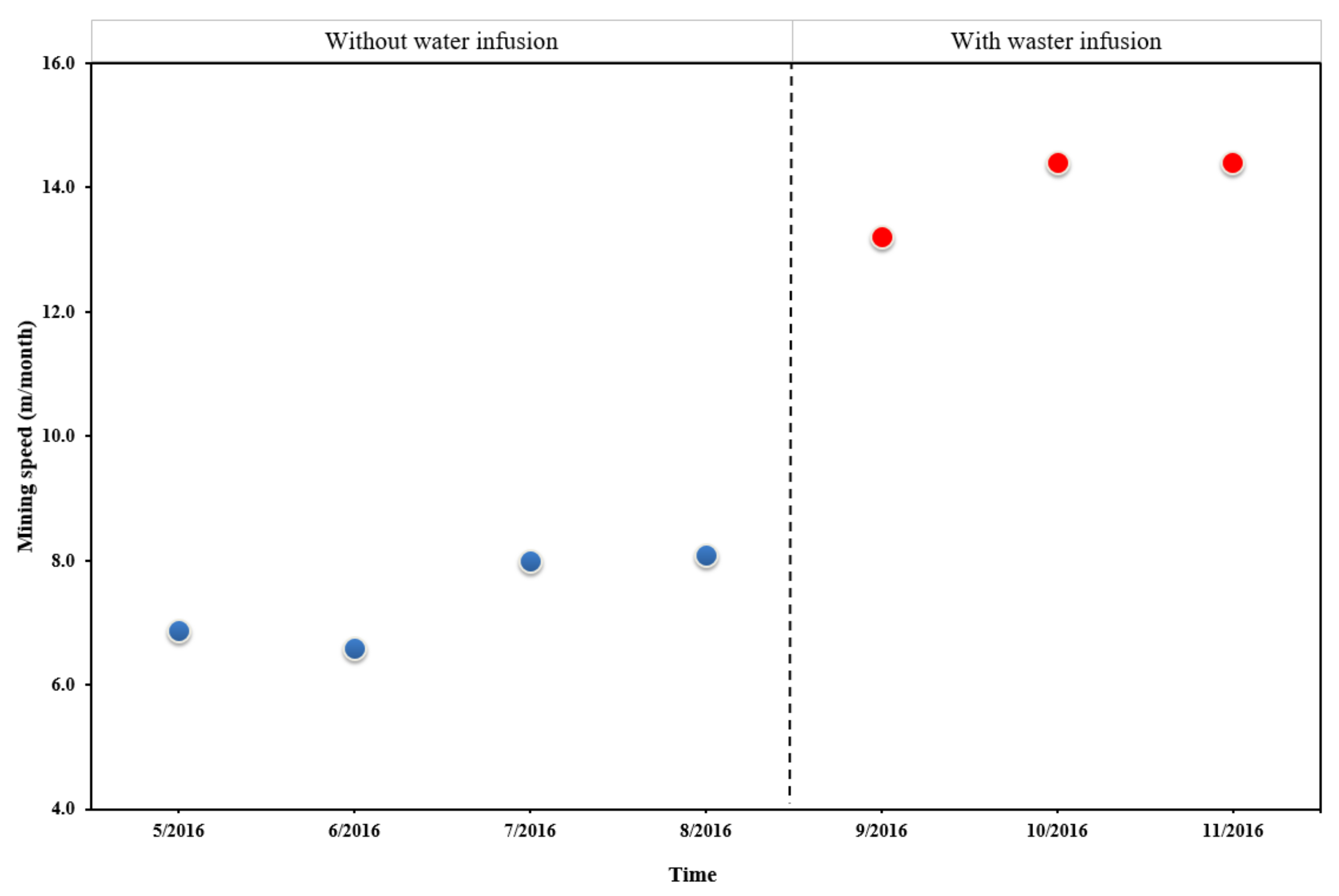

4.2. Field Test Results and Discussion

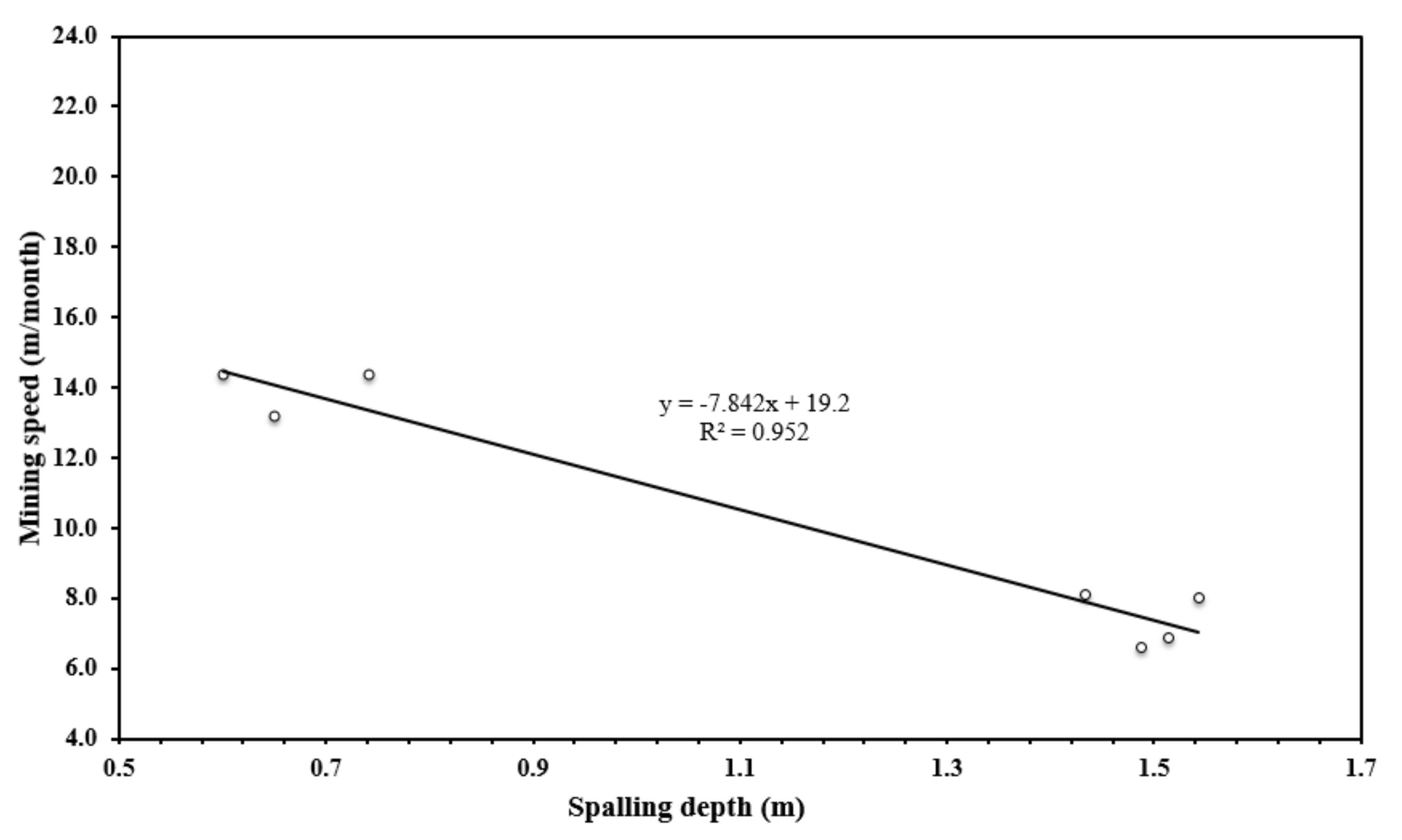

- MS = mining speed (m/month);

- SD = spalling depth (m).

5. Conclusions

- The strength properties of the coal specimens were found to be functions of the moisture content and water injection time. The optimum moisture content (22.58%) and appropriate water injection time (within 20 h) were experimentally determined from the laboratory testing program. These obtained values were then employed to evaluate the efficacy of the water infusion method for the actual coal seam;

- The physical efficacy (i.e., less longwall face failure) of water infusion for underground mining of the coal seam could be visibly observed first at the coalfaces. In addition, the quantitative results obtained from the field indicated that smaller spalling depths and faster mining speeds were attained in the coalfaces using the water infusion technique than those without using the water infusion technique, expectedly. The mining speed of the coal seam rose to 14.4 m/month (i.e., increasing 1.8 times) compared to that of coalfaces without using water infusion, due to the smaller spalling depths (i.e., decreasing 2.8 times);

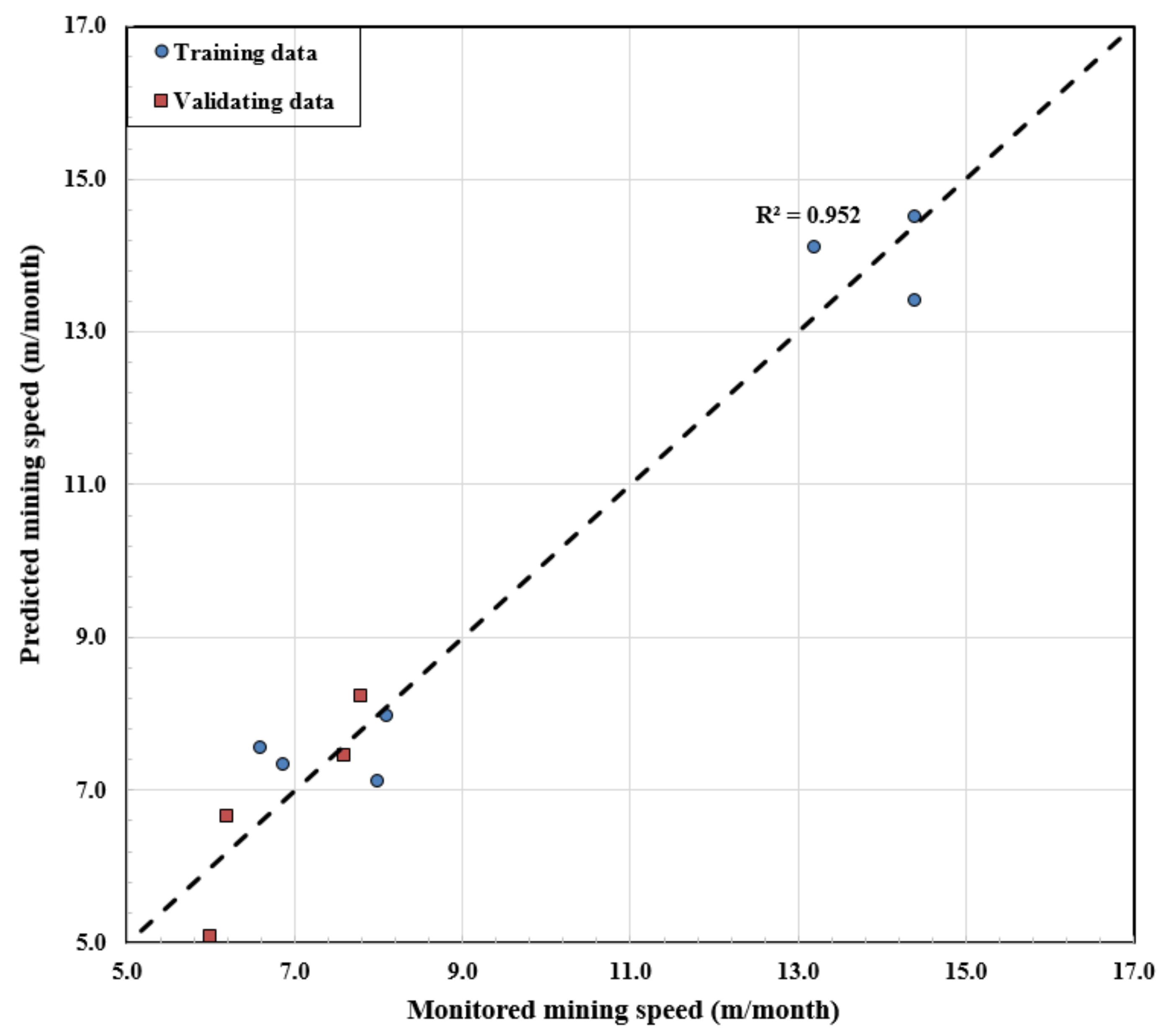

- A linear relationship between spalling depth and mining speed was also discovered from the field test results; that is, the smaller the spalling depth, the faster the mining speed. In addition, the mining speed prediction equation was proposed for the field of underground mining construction. This proposed equation was verified and well-matched results (i.e., in both training data and validating data) of the predicted and measured data were clearly observed. However, the spalling depth and mining speed could be changed, depending on the coal seam and surrounding rock conditions, such as the natural moisture of a coal seam. Therefore, the prediction model is only applicable for coalfaces in the coal seam used in this study. It should be noted that the water infusion method will be continued in the future for other coal seams. Hence, the prediction model could be verified with upcoming data;

- In conclusion, the greater stability and faster mining speed of the coalfaces using the water infusion technique than those without the water infusion technique, obtained from the field test, strongly reinforced the efficacy of water infusion techniques for the underground mining of a coal seam.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gao, Y.; Liu, D.; Zhang, X.; He, M. Analysis and Optimization of entry stability in underground longwall mining. Sustainability 2017, 9, 19. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, J.; Wei, J.; Ren, T.; Xu, X. Coal seam water infusion for dust control: A technical review. Environ. Sci. Pollut. Res. 2019, 26, 4537–4554. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z. The Research on Seepage Charaeteristie of Water Infusion for Coal Seam and Numerieal Simulation Analysis. Master’s Thesis, Anhui University of Science & Technology, Hefei, China, 2011. [Google Scholar]

- Cervik, J.; Sainato, A.; Deul, M. Water Infusion of Coalbeds for Methane and Dust Control; United States Department of the Interior: Washington, DC, USA, 1977; Volume 73, pp. 253–256.

- Cervik, J.; Sainato, A.; Baker, E. Water Infusion—An Effective and Economical Longwall Dust Control; US Department of the Interior, Bureau of Mines: Washington, DC, USA, 1983; Volume 8838.

- McClelland, J.J. Water Infusion for Coal Mine Dust Control: Three Case Studies; Report of Investigations; United States Department of the Interior, Bureau of Mines: Avondale, MD, USA, 1987; Volume 9096, 17p.

- Junqing, M.; Bi, Z.; Yechao, M. Numerical simulation study on the coal seam pulse water infusion. J. Appl. Sci. 2014, 14, 684–690. [Google Scholar] [CrossRef]

- Zhou, G.; Yin, W.-j.; Wei, X. Numerical simulations on the low-pressure water-injection-induced seepage rules of coal with pre-existing plane/surface fractures. Geotech. Geol. Eng. 2019, 37, 3283–3297. [Google Scholar] [CrossRef]

- Song, D.; Wang, E.; Xu, J.; Liu, X.; Shen, R.; Xu, W. Numerical simulation of pressure relief in hard coal seam by water jet cutting. Geomech. Eng. 2015, 8, 495–510. [Google Scholar] [CrossRef]

- Ren, T.; Wang, Z.; Cooper, G. CFD modelling of ventilation and dust flow behaviour above an underground bin and the design of an innovative dust mitigation system. Tunn. Undergr. Space Technol. 2014, 41, 241–254. [Google Scholar] [CrossRef]

- Hu, G.Z.; Huang, X.; Xu, J.L.; Wang, H.T. A co-extraction technology of coal and CBM based on the law of gas advanced relieving pressure of in-seam coalface. Disaster Adv. 2012, 5, 1351–1356. [Google Scholar]

- Wang, J.; Wang, Z. Systematic principles of surrounding rock control in longwall mining within thick coal seams. Int. J. Min. Sci. Technol. 2019, 29, 65–71. [Google Scholar] [CrossRef]

- Shu, J.; Jiang, L.; Kong, P.; Wang, P.; Zhang, P. Numerical modeling approach on mining-induced strata structural behavior by considering the fracture-weakening effect on rock mass. Appl. Sci. 2019, 9, 1832. [Google Scholar] [CrossRef]

- Huang, J.; Tian, C.; Xiong, L.; Bian, Z.; Miao, X. Green and sustainable mining: Underground coal mine fully mechanized solid dense stowing-mining method. Sustainability 2017, 9, 18. [Google Scholar] [CrossRef]

- Nguyen, V.D.; Nguyen, P.H. Evaluation on Efficacy of Water Infusion for Underground Mining of a Coal Seam No 14-5 (Khe Cham III Coal Mine, Quangninh, Vietnam); VinaComin: Quangninh, Vietnam, 2018. (In Vietnamese) [Google Scholar]

- Wesley, L.D. Principle of Effective Stress. Fundamentals of Soil Mechanics for Sedimentary and Residual Soils; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2009; pp. 77–87. [Google Scholar]

- Huang, K.; Wan, J.-w.; Chen, G.; Zeng, Y. Testing study of relationship between water content and shear strength of unsaturated soils. Rock Soil Mech. 2012, 33, 2600–2604. [Google Scholar]

- Liu, Q.Y.; Zhu, Z.Q. Shear characteristics of siltized intercalation in red sandstone at different water contents. Shenyang Gongye Daxue Xuebao J. Shenyang Univ. Technol. 2012, 34, 220–235. [Google Scholar]

- Wang, L.; Zhu, C.; Yin, Z.; Hou, J. Research on soft coal mechanics characteristic test for moisture content effect. J. Min. Saf. Eng. 2016, 33, 1145–1151. [Google Scholar]

- Zhang, H.; Wan, Z.; Ma, D.; Zhang, B.; Zhou, P. Coupled effects of moisture content and inherent clay minerals on the cohesive strength of remodelled coal. Energies 2017, 10, 1234. [Google Scholar] [CrossRef]

- Zhang, H.W.; Fu, X.; Shen, Y.Z. Study on rib spalling mechanism and spalling depth in large mining height fully-mechanized face. In Proceedings of the 2016 Coal Operators’ Conference, Wollongong, Australia, 10–12 February 2016. [Google Scholar]

| Properties | Section 1 | Section 1 | Section 1 |

|---|---|---|---|

| Moisture content (%) | 4.901 | 4.85 | 4.617 |

| Unit weight (g/cm3) | 1.422 | 1.414 | 1.419 |

| Specific gravity | 1.521 | 1.51 | 1.518 |

| Permeability (cm/s) | 0.000380 | 0.000339 | 0.000362 |

| Color | Black | Black | Black |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, D.V.; Nguyen, H.P.; Do, T.M. Experimental Study on the Efficacy of Water Infusion for Underground Mining of a Coal Seam. Appl. Sci. 2019, 9, 3820. https://doi.org/10.3390/app9183820

Nguyen DV, Nguyen HP, Do TM. Experimental Study on the Efficacy of Water Infusion for Underground Mining of a Coal Seam. Applied Sciences. 2019; 9(18):3820. https://doi.org/10.3390/app9183820

Chicago/Turabian StyleNguyen, Dung Van, Hung Phi Nguyen, and Tan Manh Do. 2019. "Experimental Study on the Efficacy of Water Infusion for Underground Mining of a Coal Seam" Applied Sciences 9, no. 18: 3820. https://doi.org/10.3390/app9183820

APA StyleNguyen, D. V., Nguyen, H. P., & Do, T. M. (2019). Experimental Study on the Efficacy of Water Infusion for Underground Mining of a Coal Seam. Applied Sciences, 9(18), 3820. https://doi.org/10.3390/app9183820