1. Introduction

The demands for processing complex parts with a free-form surface have resulted in increased use of 5-axis machine tools in automotive, aerospace, die making, and many other industries [

1,

2]. The role of the machine tool is to ensure the precise movement relationship between the tool and the workpiece. Meanwhile, the moving parts of machine tools consume large amounts of energy [

3]. Therefore, precision and energy consumption are guidelines for machine tool design, and are influenced by many factors including the stiffness error caused by structural deformation, assembly error results in tool position error, system dynamic responses under excitation of operational loads, and so on [

4,

5,

6,

7]. In order to reduce energy consumption, lightweight design and optimization techniques are applied to decrease the moving masses and improve the mass-to-payload ratio [

8,

9]. Over the last few decades, to improve the accuracy, stiffness, and dynamic performance of machine tools, various lightweight and optimization design methods and strategies have been investigated by many researchers at the early design stage; consequently, structural optimization and lightweight methods have been successfully applied in optimizing dynamical systems and lightweight machines [

10,

11,

12,

13,

14,

15,

16,

17,

18].

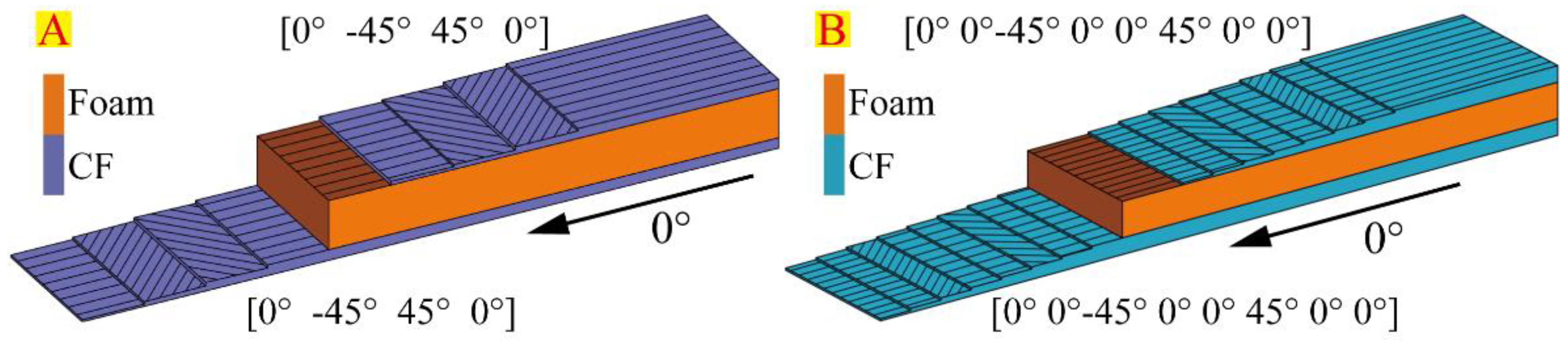

Lightweight design countermeasures are usually taken through appropriate material selection and implementing a structural optimization method. Kim et al. [

12] presented a method using composite–foam–resin concrete sandwich structures instead of metal materials for the lightweight design of micro-EDM machines. Li et al. [

13] reported a stiffness design of machine tool structures based on a biologically inspired topology optimization method, while Kroll et al. [

14] discussed the general influence of lightweight design approaches on energy efficiency in machine tools, as well as restrictions on the maximum mass reduction for structural components. Li and Lu [

15] reported a design scheme of a lightweight wind turbine tower based on the integration of nanostructured materials produced by a surface mechanical attrition treatment process; the study results revealed that there is sufficient margin for further weight reduction in the traditional wind turbine tower design. In optimization design, Strano et al. [

16] proposed an optimization model suitable for press frame designs with respect to energy efficiency. Wu et al. [

17] presented an optimization approach for the concept design of machine tools; the results showed that the principal dimensions of all structural parts could be determined while minimizing the weight of the machine and maintaining sufficient stiffness. In order to analyze the dynamic behavior and tool deviations, a dynamic model of a 3-axis gantry milling machine considering axis coupling effects was proposed by Wang et al. [

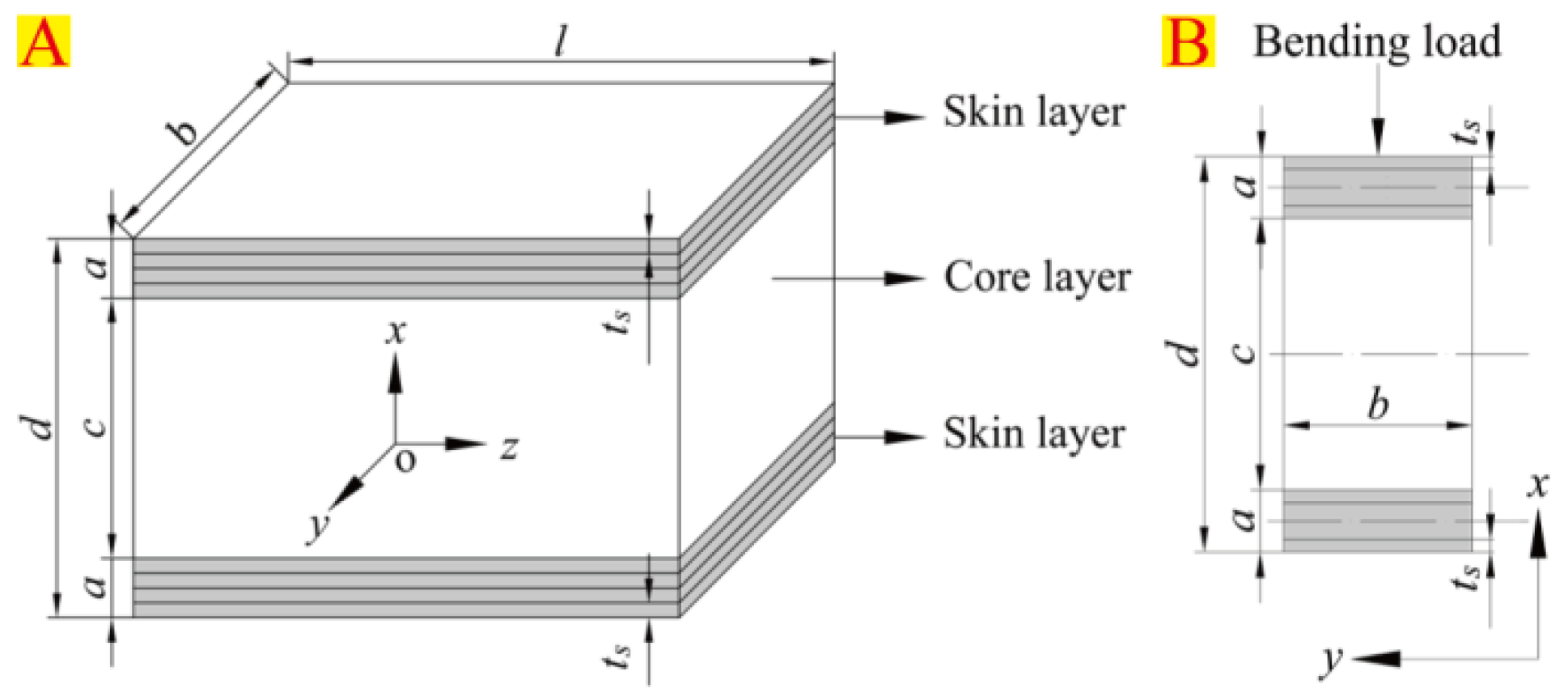

18]. Sandwich structures are commonly used materials for lightweight designs, and their mechanical behaviors are based on their structural features: They are built from two layers, i.e., a stiff and strong skin layer, and a compliant and lightweight core layer [

19]. There have been a number of applications in civil and military aircrafts, launch vehicles, wind turbine blades, and marine structures in which composite and sandwich material systems were used as primary structures [

20]. Sandwich structures can often sustain large deformations under constant load, enabling them to absorb significant amounts of energy, and to have higher mechanical properties [

21,

22,

23,

24,

25,

26,

27].

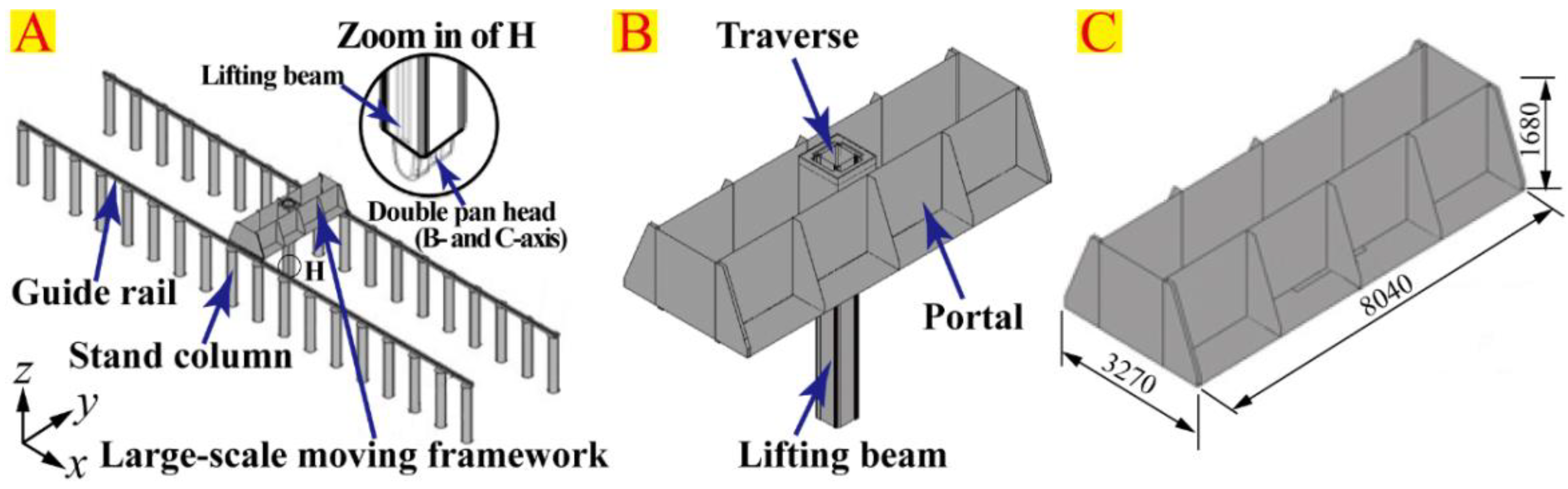

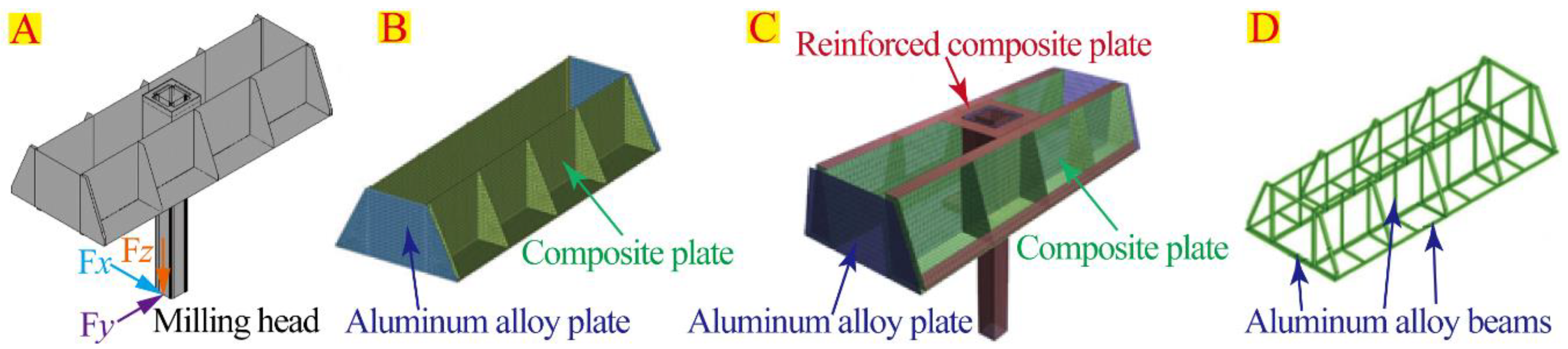

The structure design methods in existing literatures cannot be directly adapted to the design optimization framework for a large 5-axis machining center (L5AMC) due to the large dimensions in the

x,

y, and

z work space and high machining speed. The traditional machine tool design method makes the amount of metal used to build the large-scale moving framework account for most of the total weight, and thus, it seriously impacts the dynamic performance and results in significant energy consumption. Hence, using sandwich structures of composite materials to replace metal materials to improve dynamic performance and reduce energy consumption has been a key technology for large-scale moving framework structure design. However, this kind of substitution is generally believed to be difficult because foam-filled sandwich structures usually show nonlinear characteristics and must balance the moving mass, material costs, and structural stiffness. Although studies on lightweight and optimized machine tool structures have long been presented, the design optimization of a large-scale moving framework to improve structural performance and reduce energy consumption still exhibits many challenges, such as how to avert the sandwich panel to generate the well-known “curtain effect” [

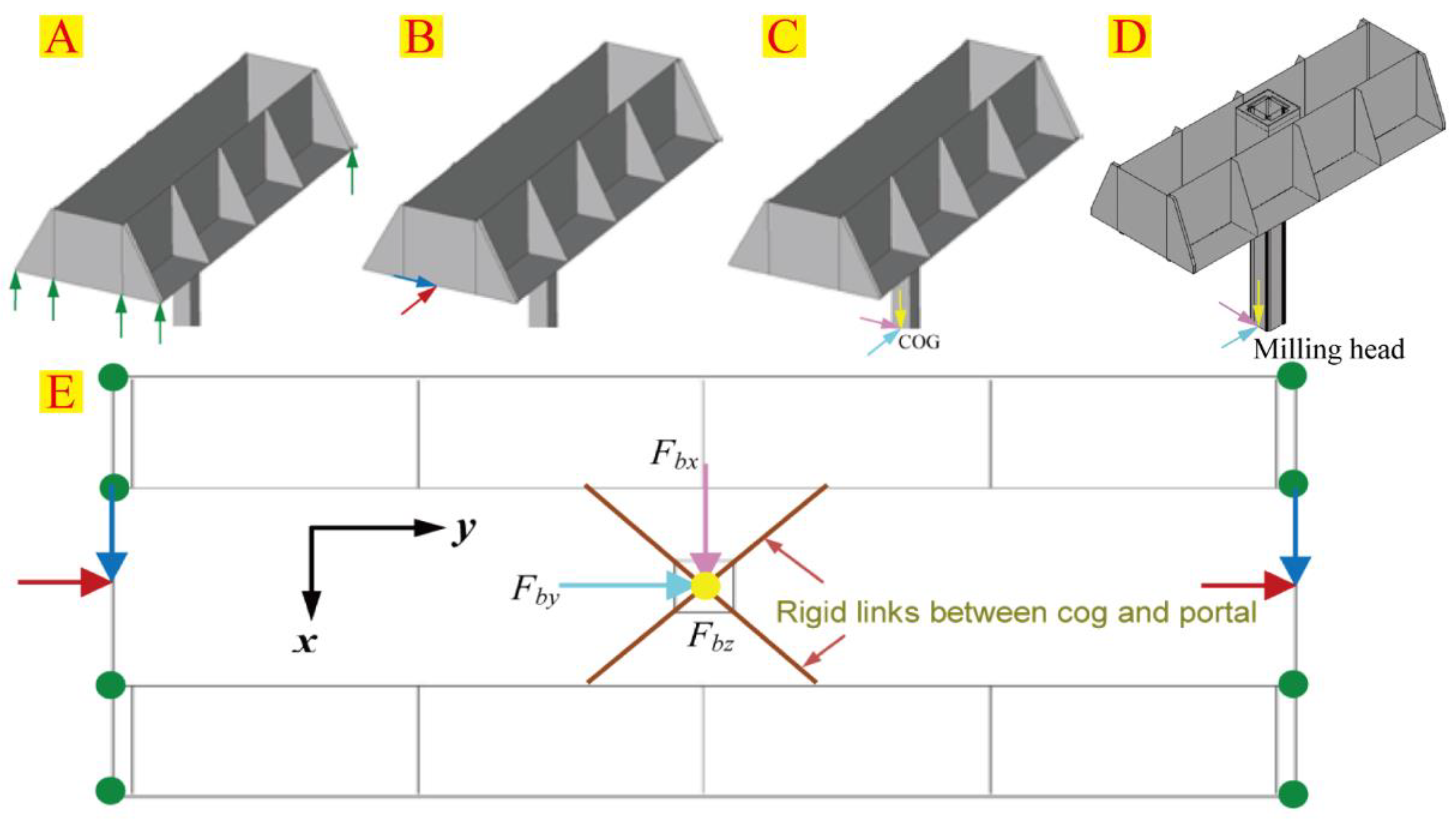

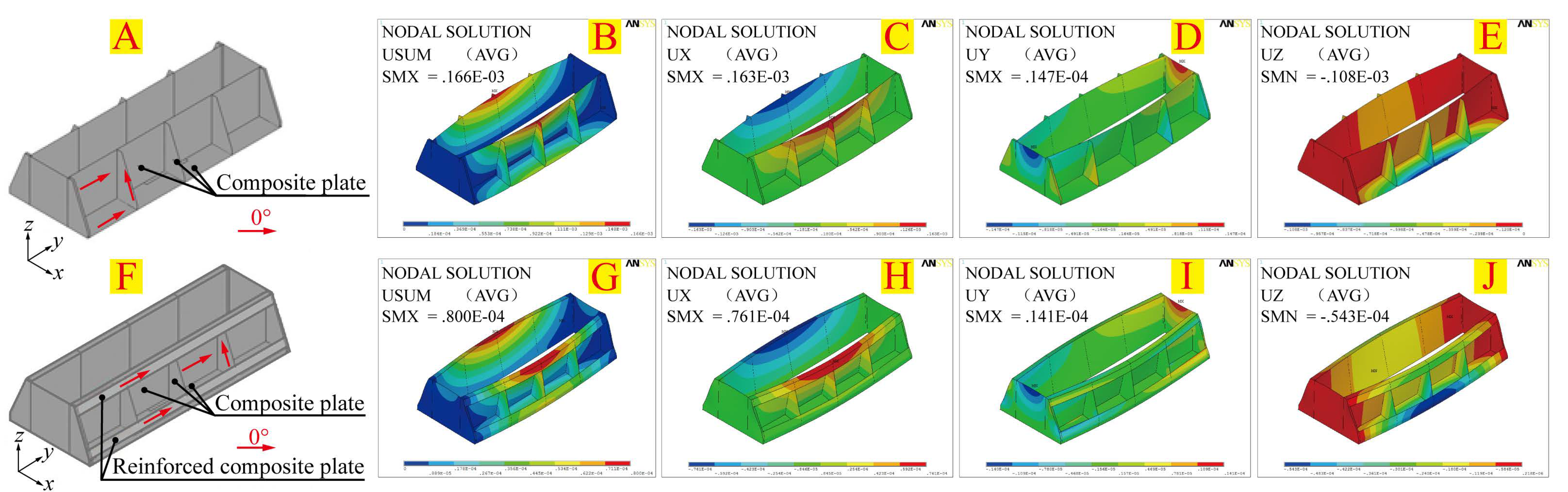

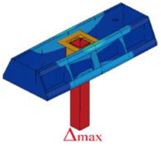

28] due to the large dimensions of the framework structure, how to guarantee high machining speed, lightweight moving mass, and the higher structural rigidity. Therefore, the primary objective of this study was to propose a design optimization framework approach for L5AMC to meet the large dimensions in the work space, and to minimize the displacements of the milling head while maintaining lightweight design for good dynamic drive performance, higher structural stiffness, and low material costs. To achieve these goals, the present study presented an improved approach, named the 3-step design optimization, to obtain the optimum framework structures and solve the contradiction between the moving mass, material costs, and structural stiffness. This approach was based on multi-objective optimization and finite element analysis method.

6. Prototype Verification

To evaluate the performances of the large-scale moving framework, a 40 m × 6 m × 4 m L5AMC prototype was manufactured. Then, design precision inspections, error compensation, and machining precision tests were carried out to verify the structural integrity of the framework. The actual tests scenes are shown in

Figure 7.

Detailed position geometric error modeling, identification, and compensation for the L5AMC prototype have been reported [

1].

Table 8 presents some inspection results of the L5AMC prototype related to the framework.

According to the inspection results in

Table 8, the large-scale moving framework exhibits a great comprehensive accuracy. Using sandwich structures of composite materials to replace metal materials makes the mass of the framework lightweight. The total mass of the framework with composite materials was 64.57% compared with metal materials. Zulaika et al. [

35] reported 13% less energy due to mass reduction above 20% in mobile structural components. Therefore, the actual verification results indicated that the large-scale moving framework based on the proposed 3-step design optimization approach fully met the design requirements of the L5AMC and reduced energy consumption.