Research on the Simplified Design of a Centrifugal Compressor Impeller Based on Meridional Plane Modification

Abstract

:1. Introduction

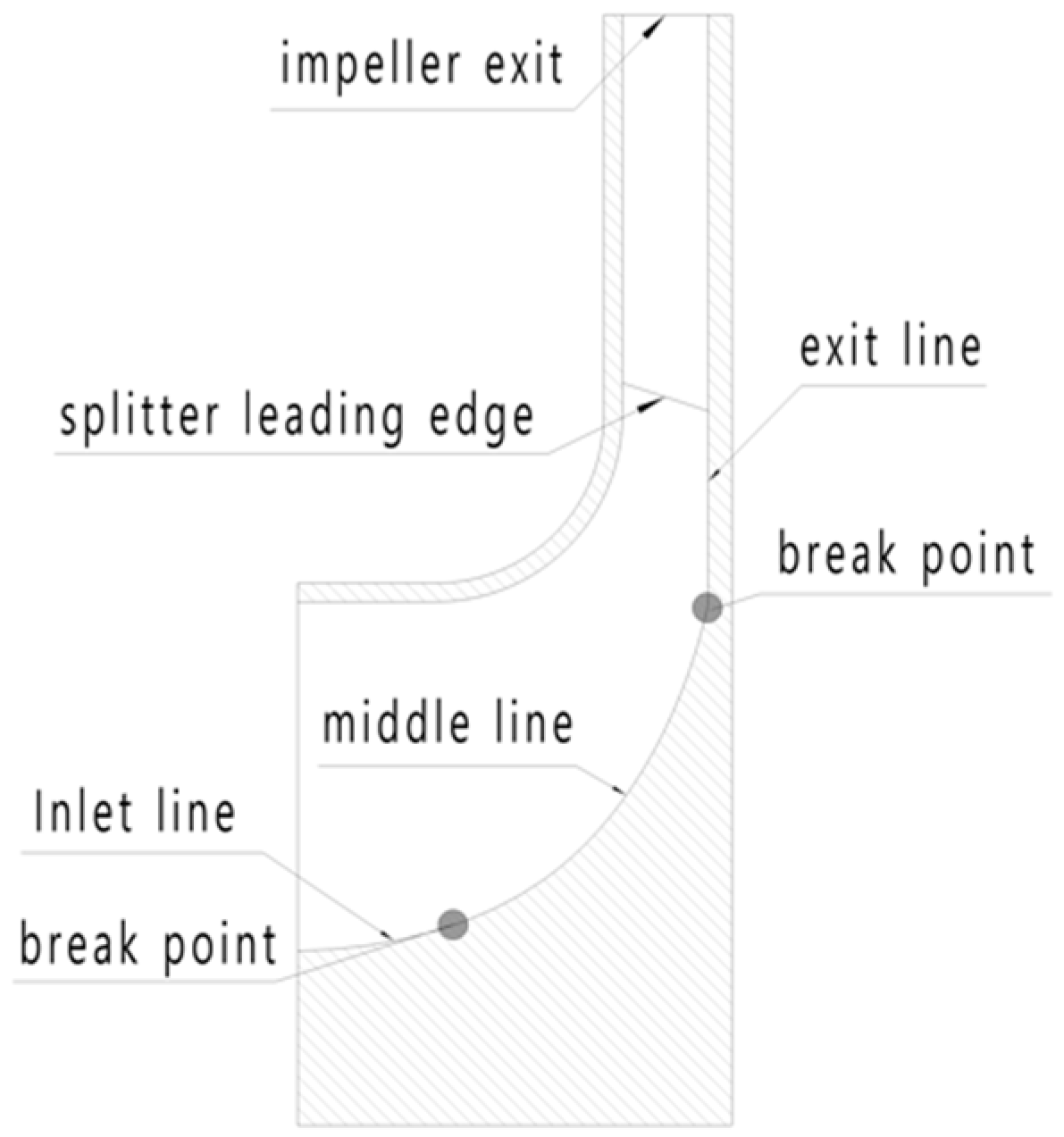

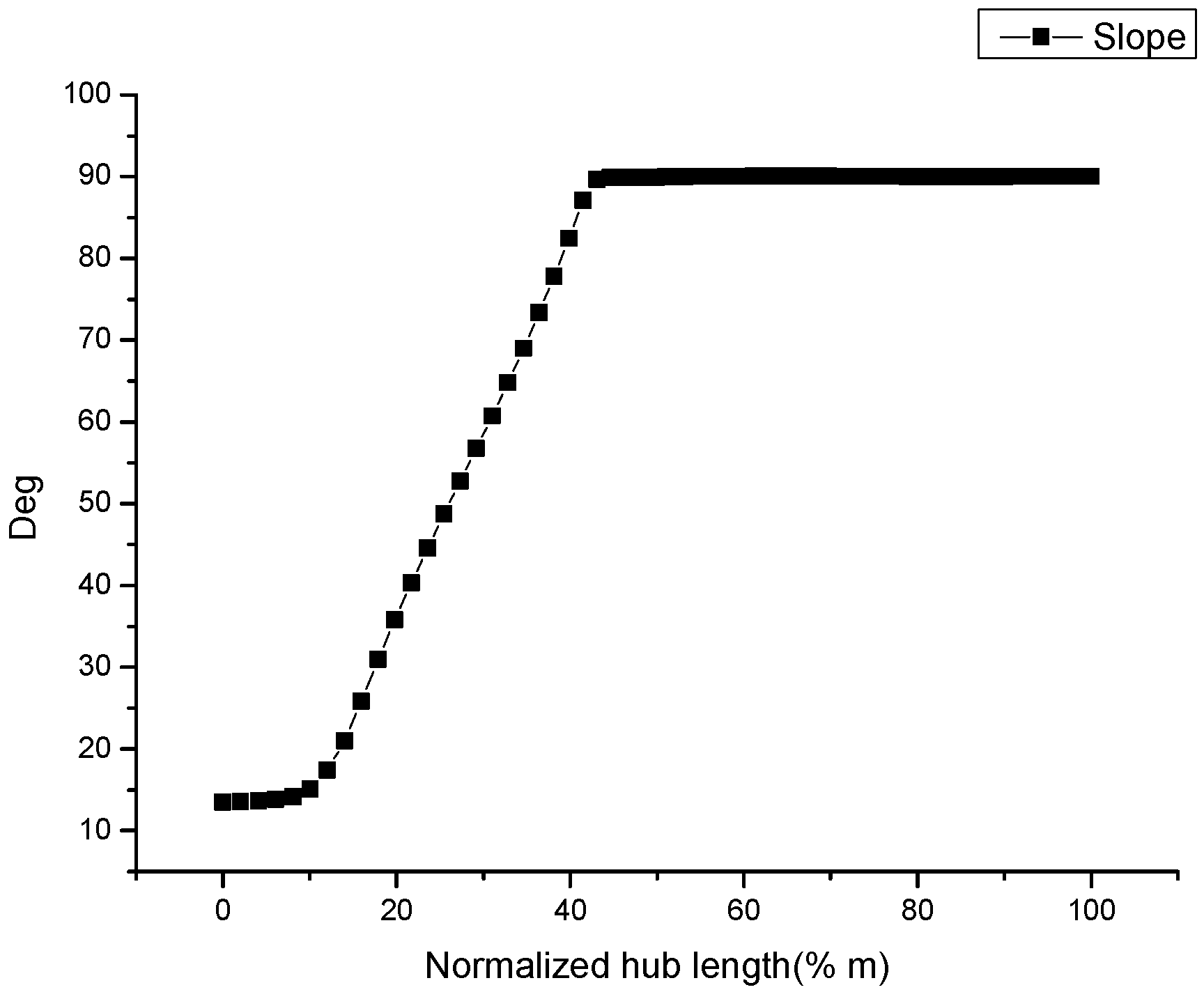

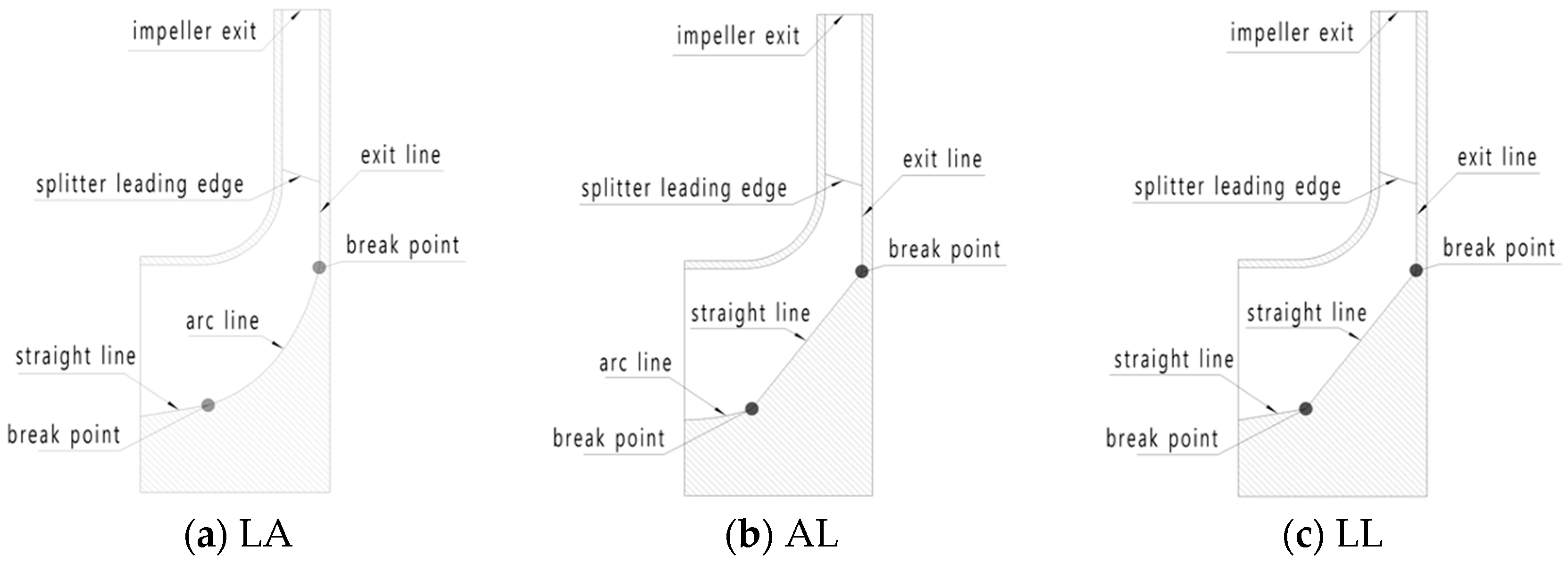

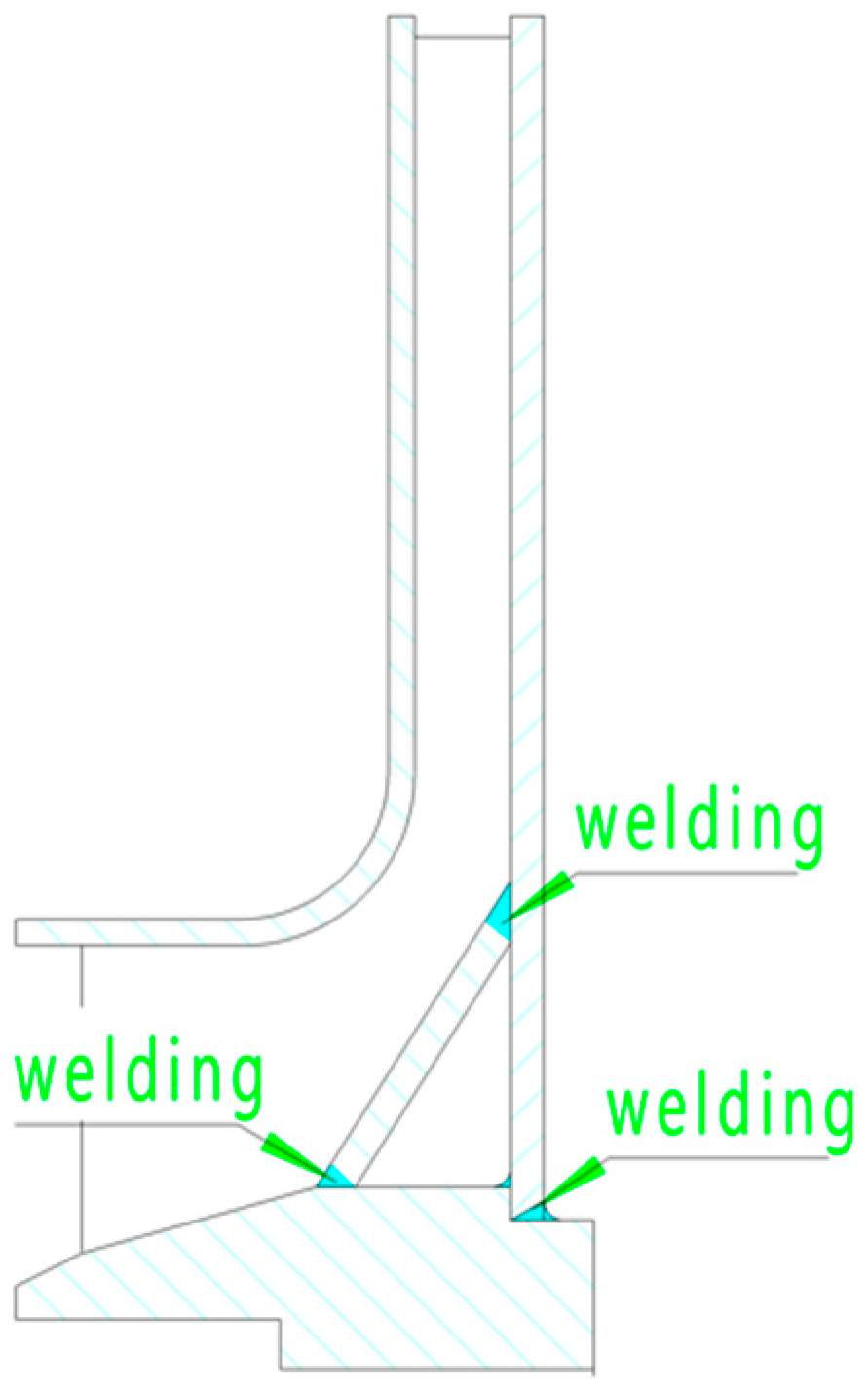

2. Meridional Shape Design

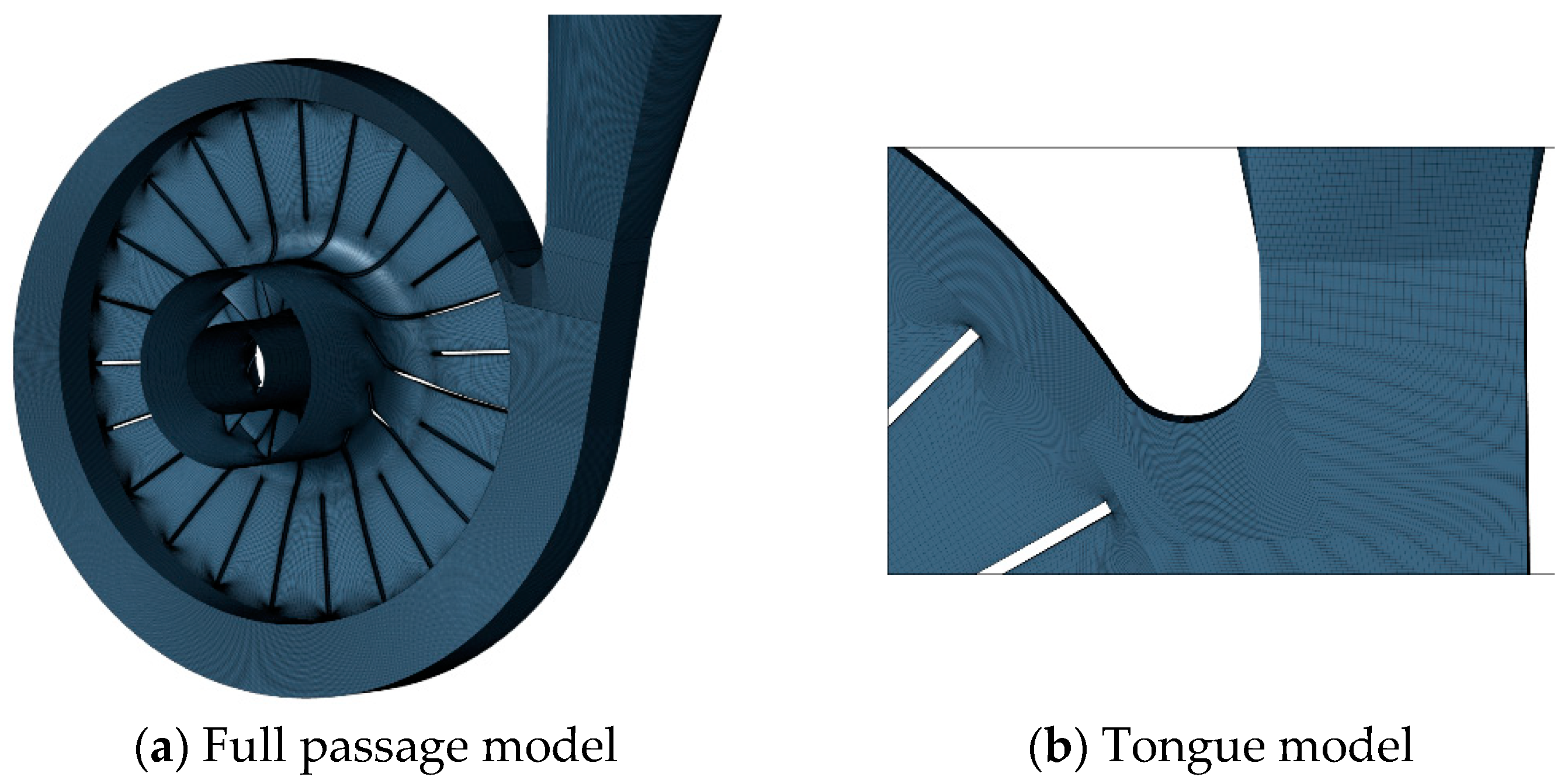

3. Numerical Methods

4. Results and Analysis

4.1. Single Passage Model

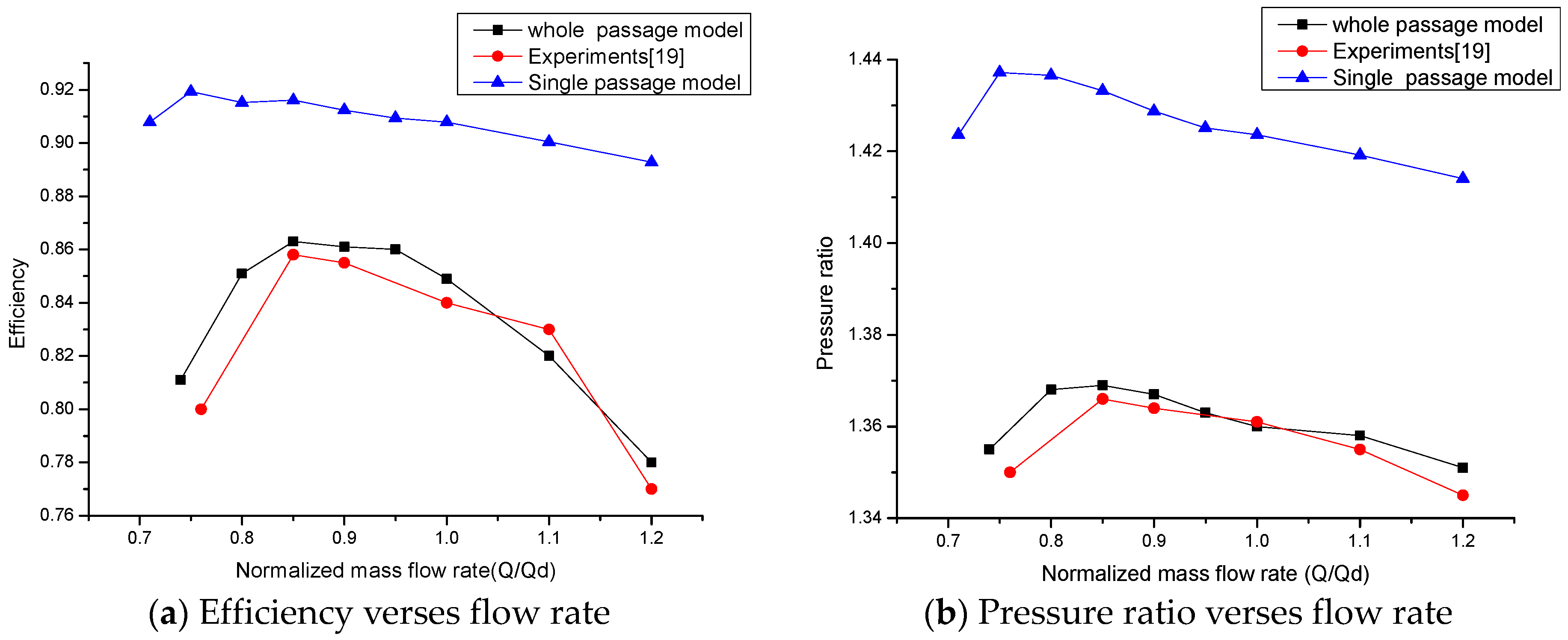

4.1.1. Overall Performance

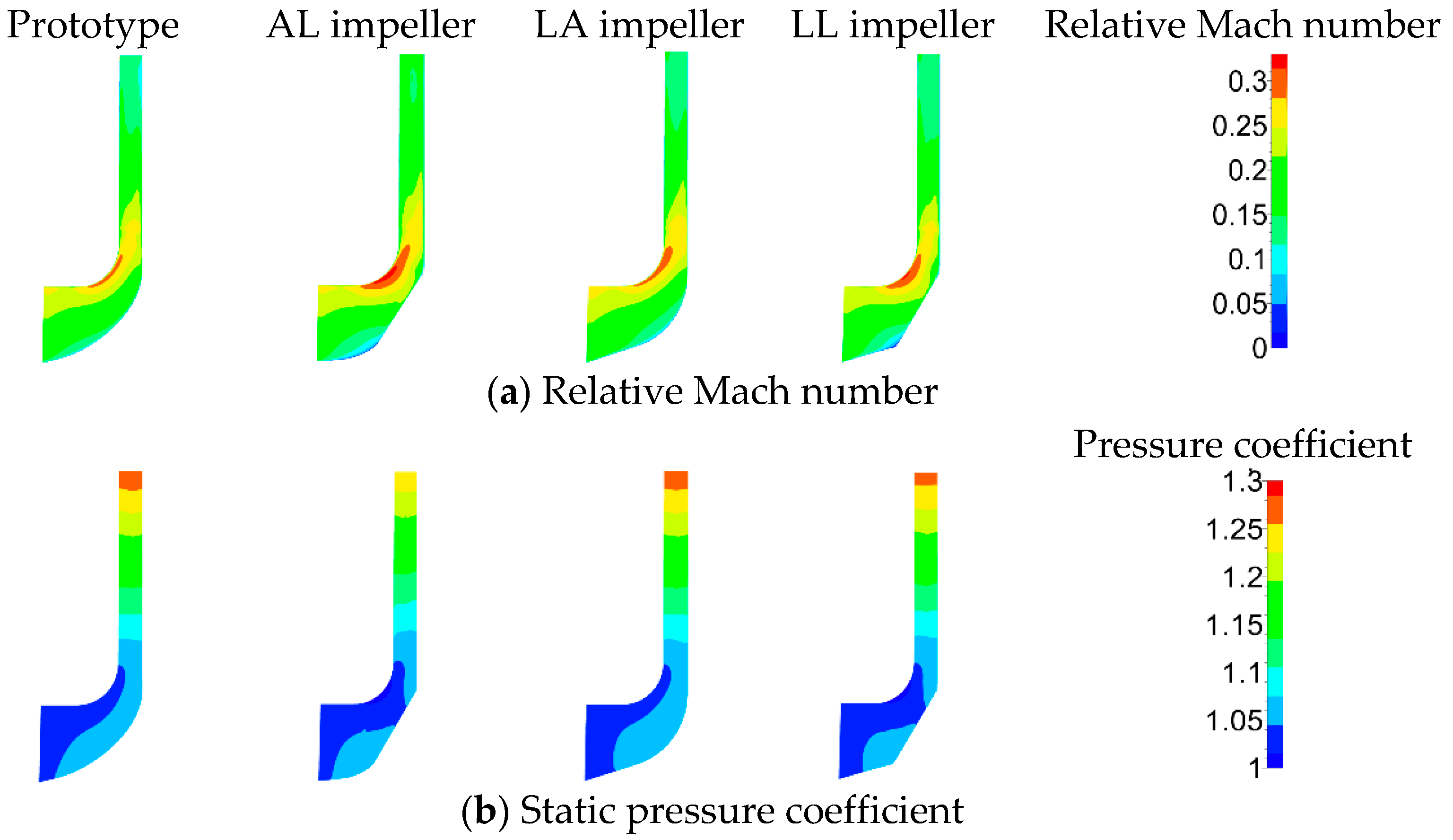

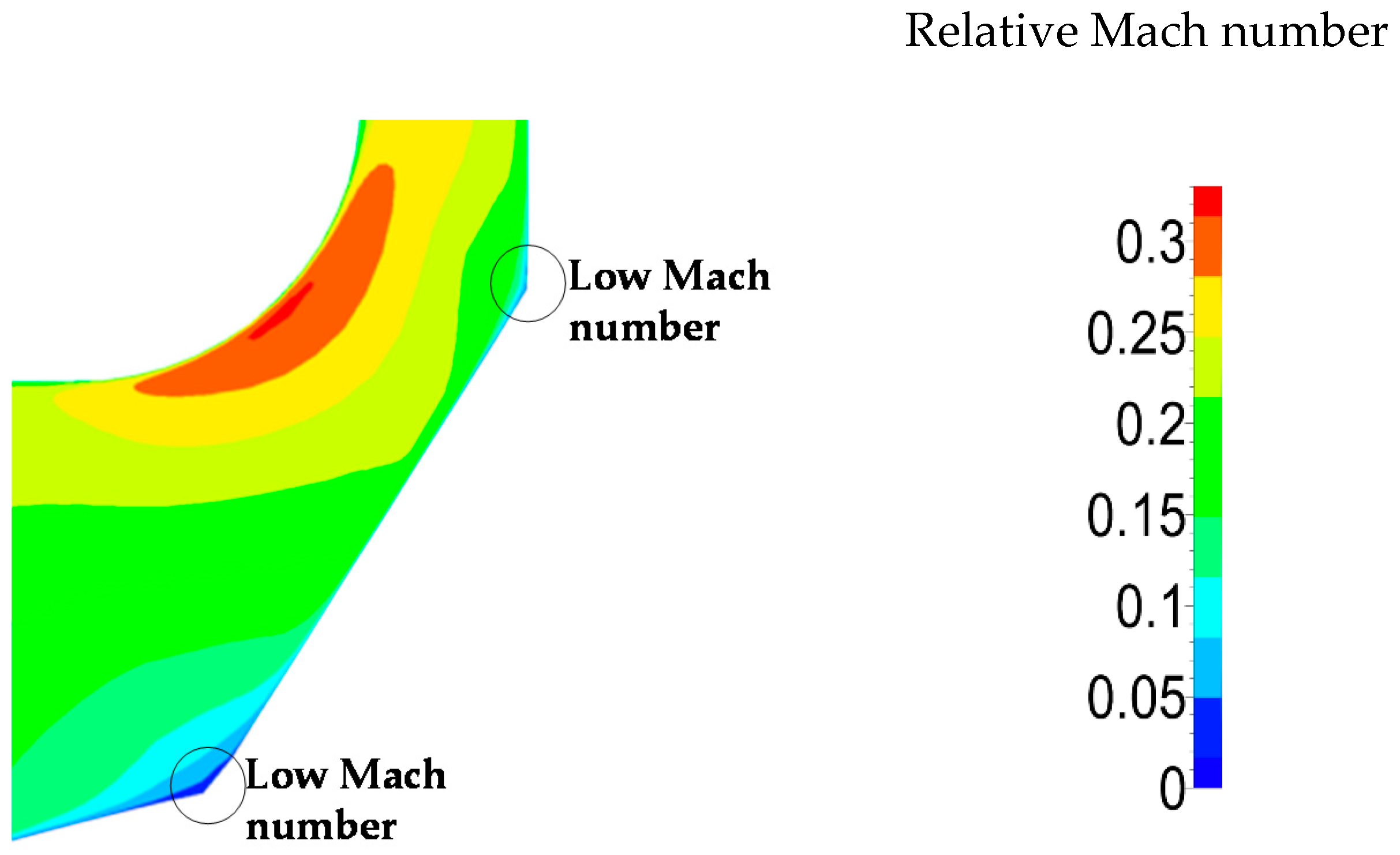

4.1.2. Meridional Plane

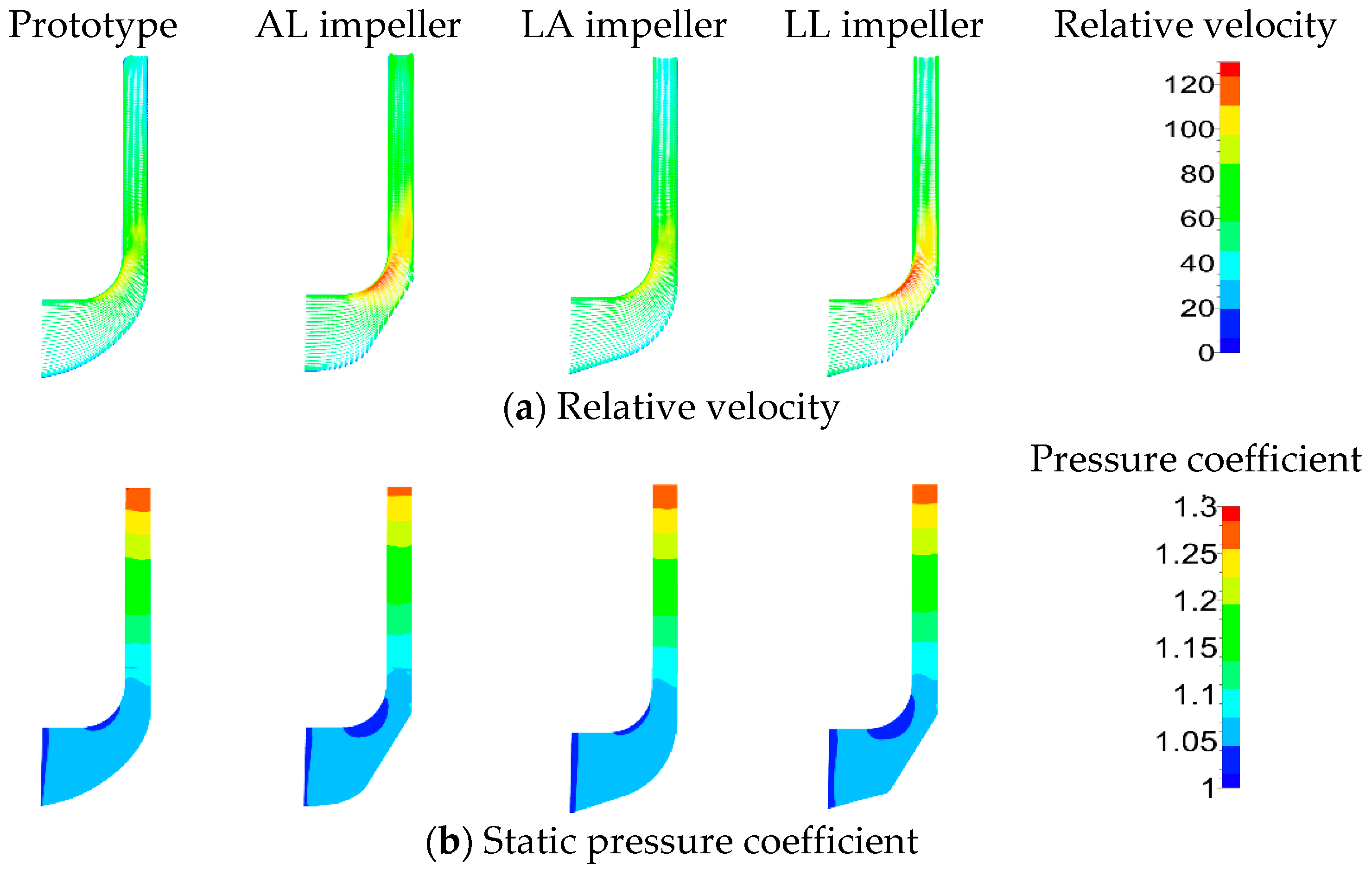

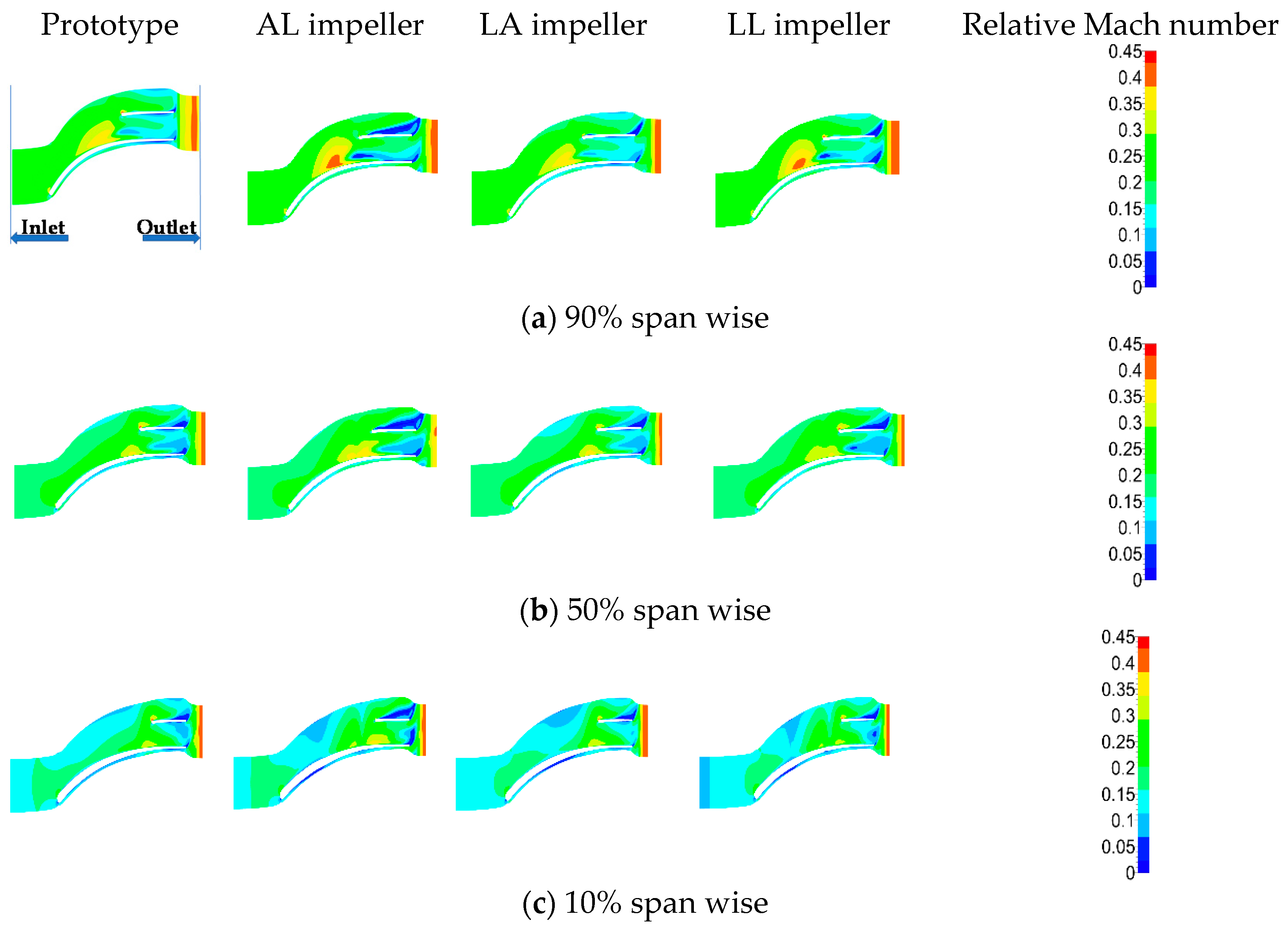

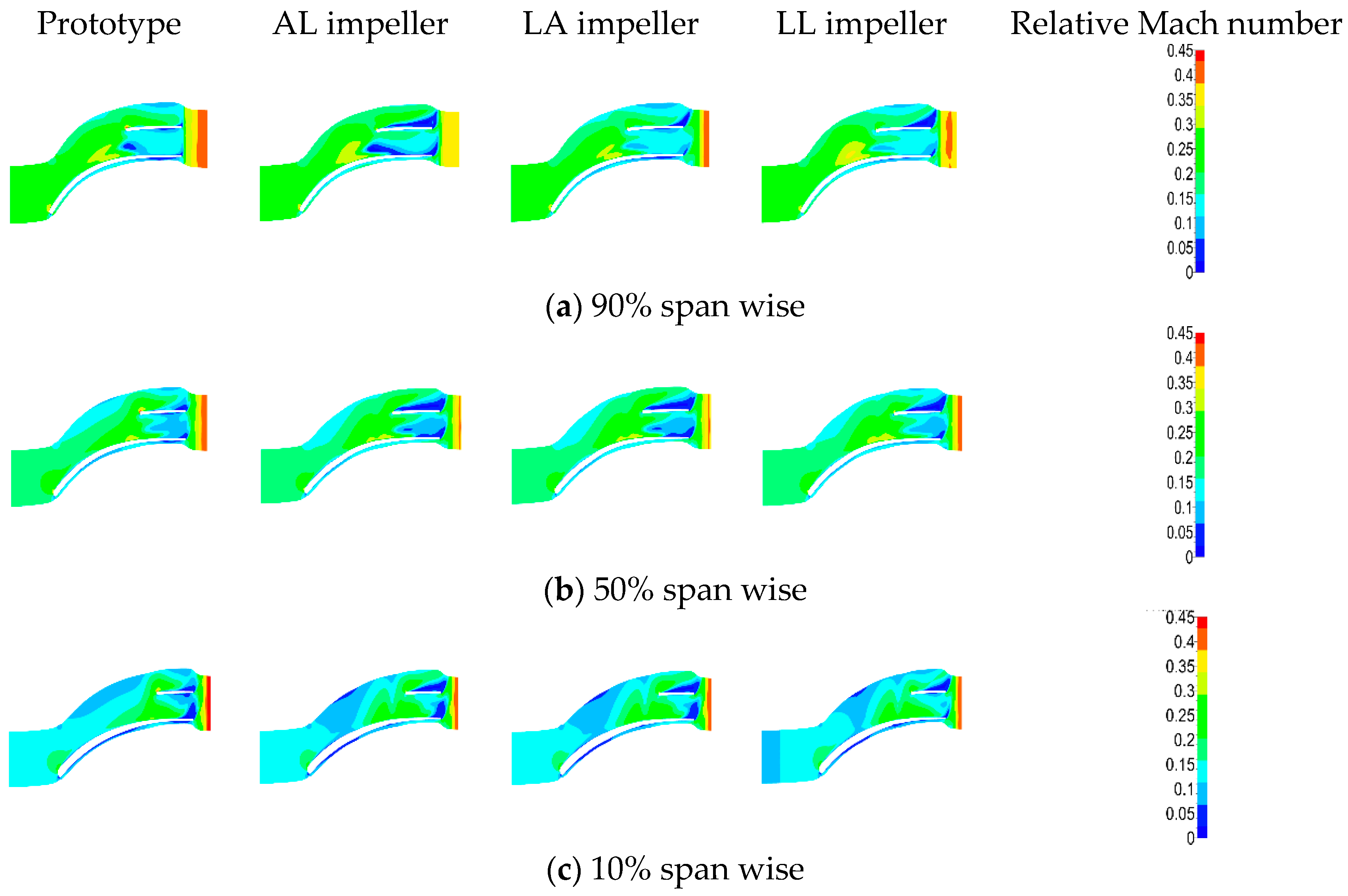

4.1.3. Blade to Blade Surface

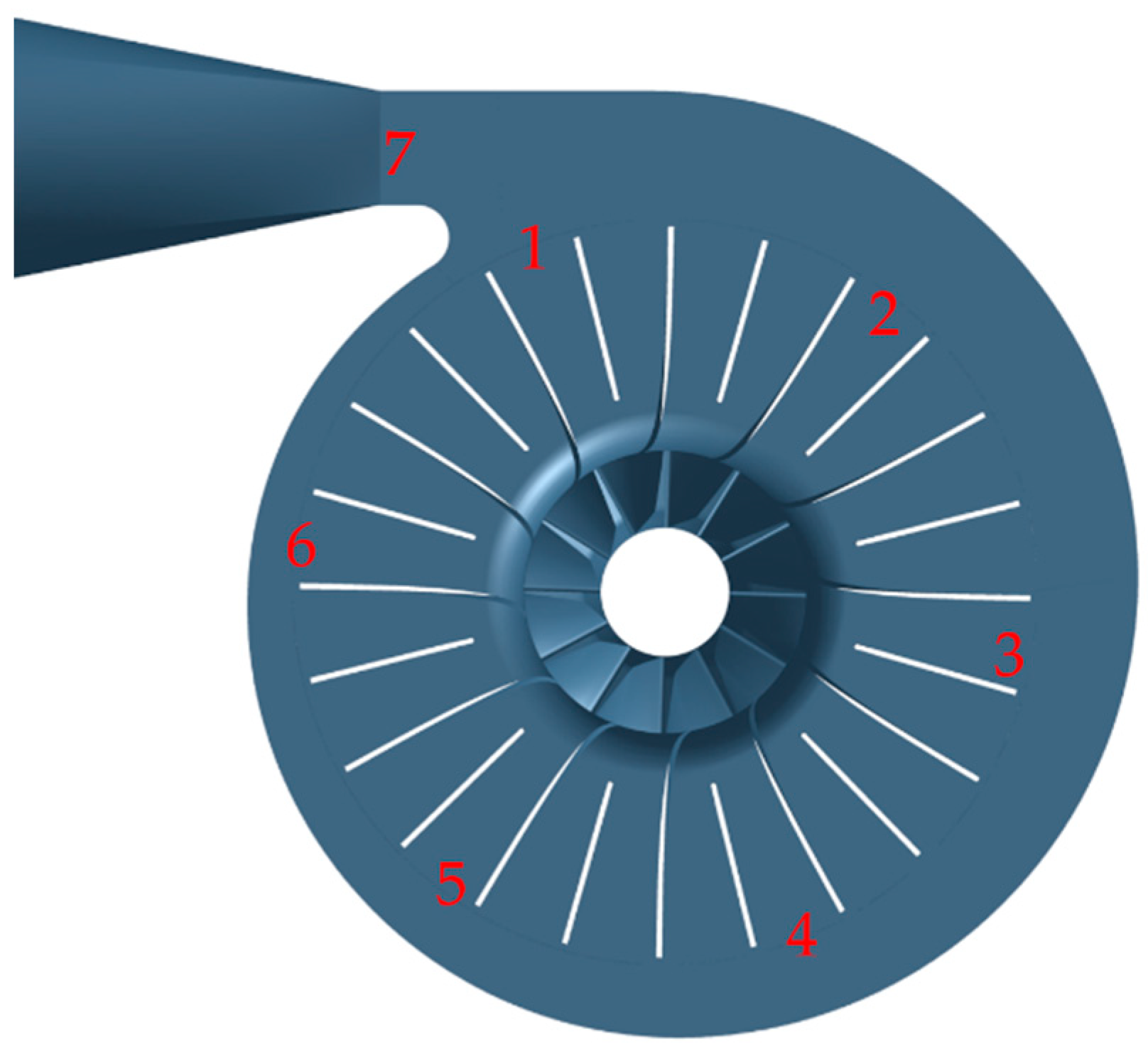

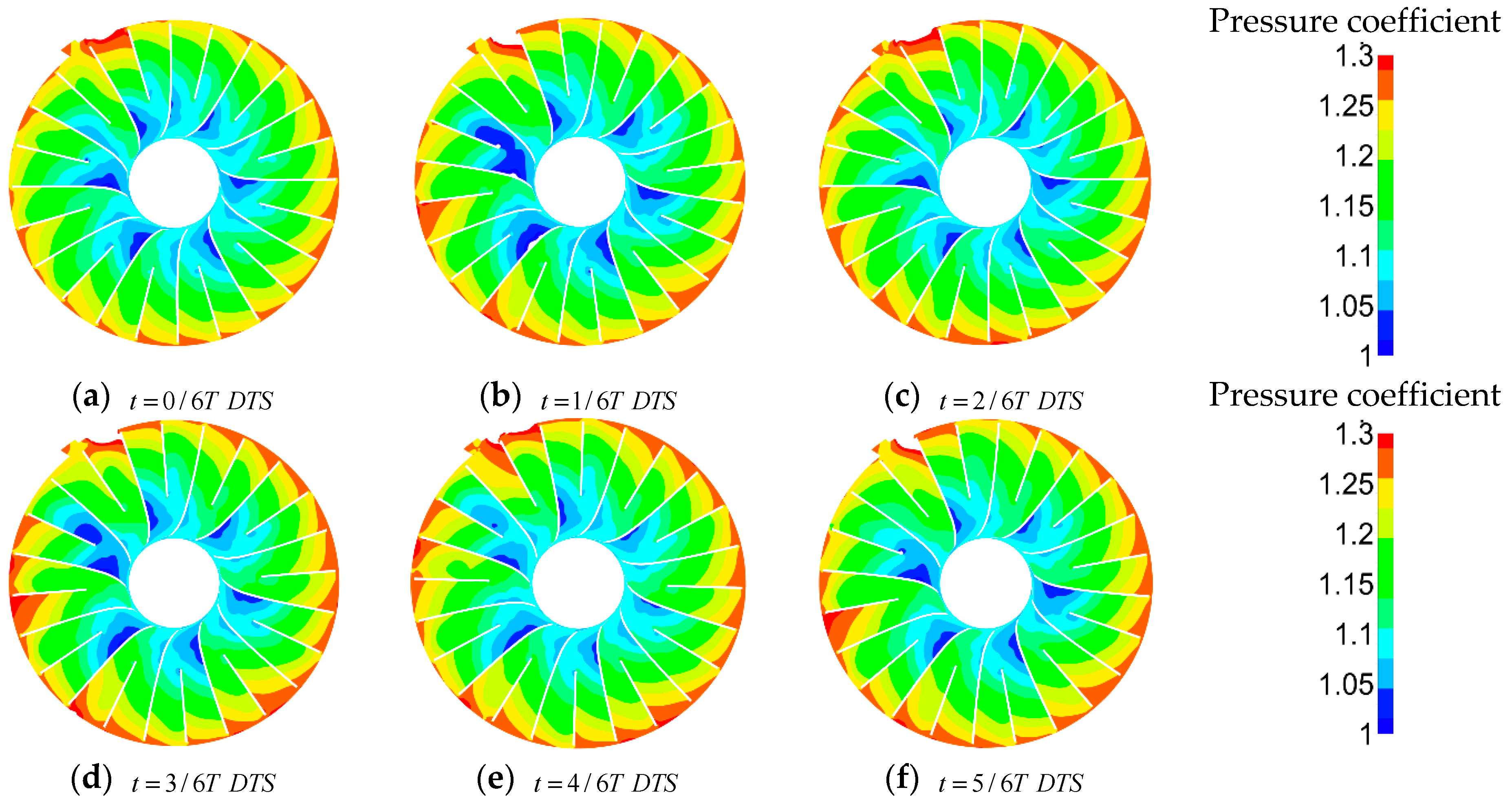

4.2. Full Passage

4.2.1. Overall Performance

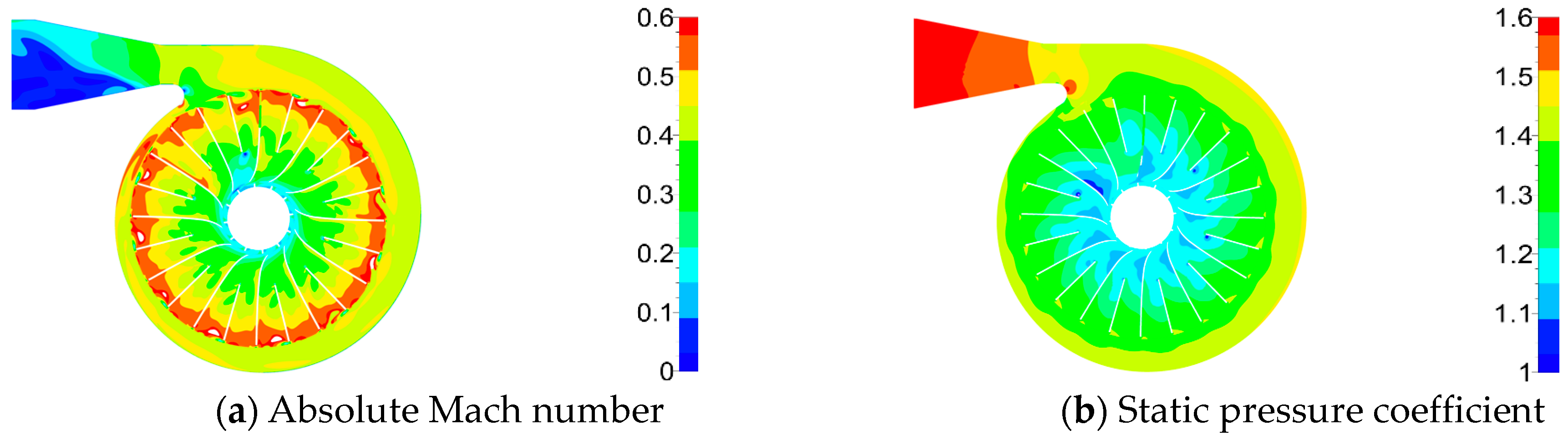

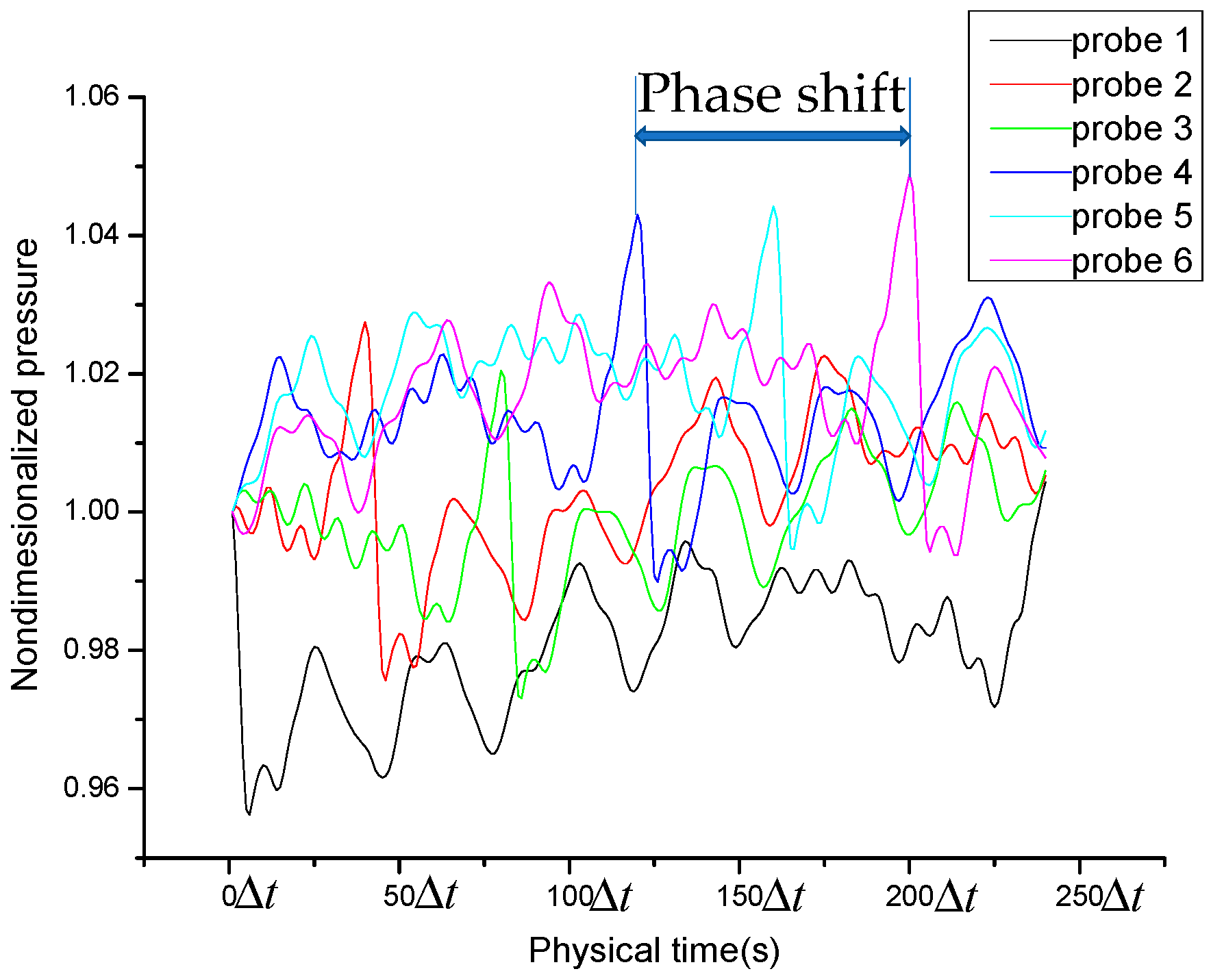

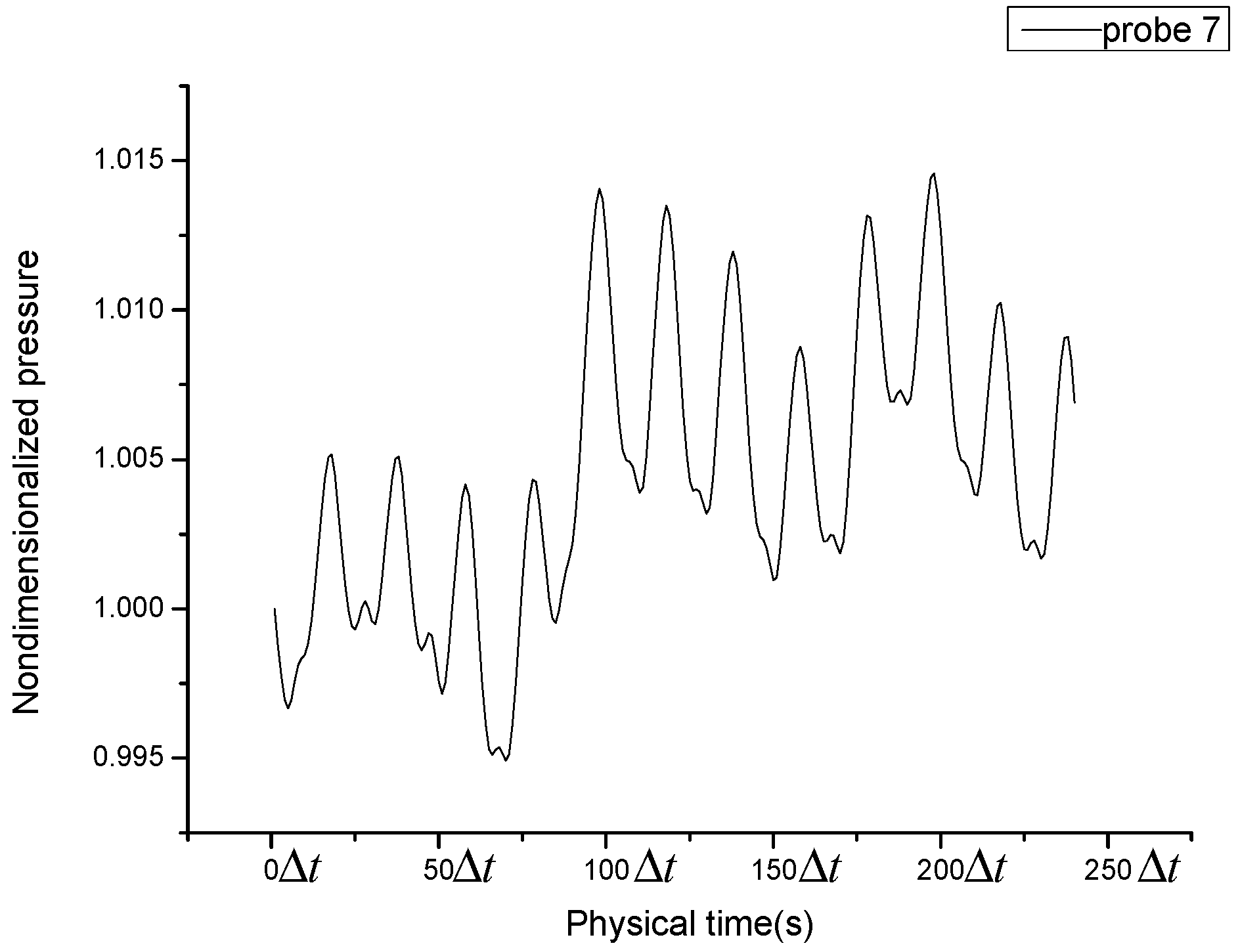

4.2.2. Unsteady Results

5. Discussions

6. Conclusions

- The processing time and manufacturing cost are reduced because the hub is described by the straight line for the optimized impeller, LL impeller. Moreover, the hollow geometry in the disk may also be beneficial to the rotor dynamic design and bearing design.

- Within the operating range, the prototype impeller has stable performance. Nevertheless, its operating range cannot fully match the industrial requirement. Meanwhile, the simplified impeller, LL impeller, is improved with excellent stall margin as well as its efficiency and pressure ratio are decreased little.

- The calculation result of the full passage model is matched with experiments very well. So, in order to obtain comprehensive performance of a centrifugal compressor, full passage model with volute is necessary to be considered.

- In this case, unsteady calculation is conducted due to 0.12, but the unsteady characteristics of the steam compressor is not obvious. Meanwhile, the amplitude of pressure oscillation around volute tongue is only about 1.5%. Thus, for this case, the steady numerical simulation result is accurate enough to investigate asymmetric circumferential flow pattern.

Author Contributions

Funding

Conflicts of Interest

References

- Shibata, T.; Yagi, M.; Nishida, H.; Kobayashi, H.; Tanaka, M. Performance Improvement of a Centrifugal Compressor Stage by Increasing Degree of Reaction and Optimizing Blade Loading of a 3D-Impeller. ASME Turbo Expo. Power Land Sea Air 2009, 7, 1305–1315. [Google Scholar] [CrossRef]

- Xu, C.C.; Amano, R.S. The Development of Centrifugal Compressor Impeller. ASME Turbo Expo. Power Land Sea Air 2008, 7, 539–544. [Google Scholar] [CrossRef]

- Kim, S.; Park, J.; Ahn, K.; Baek, J. Improvement of the Performance of a Centrifugal Compressor by Modifying the Volute Inlet. ASME J. Fluids Eng. 2010, 132. [Google Scholar] [CrossRef]

- Xu, C. The Development of High Performance Centrifugal Compressor using CFD and other considerations. Int. Conf. Power Eng. 2017, 2. [Google Scholar] [CrossRef]

- Jansen, W.; Kirschner, A.M. Impeller Blade Design Method for Centrifugal Compressors. Fluid Mech. Acoust. Des. Turbomach. 1974, SP-304, 537–563. [Google Scholar]

- Casey, M.V. A Computational Geometry for the Blades and Internal Flow Channels of Centrifugal Compressors. ASME J. Eng. Power 1983, 105, 288–295. [Google Scholar] [CrossRef]

- Wang, P.; Ruan, X.; Zou, J.; Fu, X. Medial Axis Transform Method for Shape Design of Hub and Shroud Contours of Impellers. J. Fluids Eng. 2011, 133, 034502. [Google Scholar] [CrossRef]

- Borges, J.E. A Three-Dimensional Inverse Method for Turbomachinery: Part, I.—Theory. ASME J. Turbomach. 1990, 112, 346–354. [Google Scholar] [CrossRef]

- Benini, E. Optimal Navierâ Stokes Design of Compressor Impellers Using Evolutionary Computation. Int. J. Comput. Fluid Dyn. 2003, 17, 357–369. [Google Scholar] [CrossRef]

- Sun, H.; Shin, H.; Lee, S. Analysis and optimization of aerodynamic noise in a centrifugal compressor. J. Sound Vib. 2006, 289, 999–1018. [Google Scholar] [CrossRef]

- Cho, S.Y.; Ahn, K.Y.; Lee, Y.D.; Kim, Y.C. Optimal Design of a Centrifugal Compressor Impeller Using Evolutionary Algorithms. Math. Prob. Eng. 2012, 2012, 1094–1099. [Google Scholar] [CrossRef]

- Casey, M.; Gersbach, F.; Robinson, C. An Optimization Technique for Radial Compressor Impellers. ASME Turbo Expo. Power Land Sea Air 2008, 6, 2401–2411. [Google Scholar] [CrossRef]

- Mueller, L.; Alsalihi, Z.; Verstraete, T. Multidisciplinary Optimization of a Turbocharger Radial Turbine. J. Turbomach. 2012, 135, 1965–1976. [Google Scholar] [CrossRef]

- Numeca FineTM/Turbo; Version 10.1; NUMECA: Beijing, China.

- Wu, T.; Cao, Y.; Yang, J. Analysis of the Influence of Blade’s Machining Error on Aerodynamic Performance of Impeller Based on NUMECA. Procedia Cirp 2015, 27, 155–162. [Google Scholar] [CrossRef]

- Yang, M.; Zheng, X.; Zhang, Y.; Bamba, T.; Tamaki, H.; Huenteler, J.; Li, Z. Stability Improvement of High-Pressure-Ratio Turbocharger Centrifugal Compressor by Asymmetric Flow Control—Part I: Non-Axisymmetrical Flow in Centrifugal Compressor. ASME J. Turbomach. 2012, 135, 021006. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Assam, A.; Kalkote, N.N.; Sharma, V.; Sharma, V.; Eswaran, V. An Automatic Wall Treatment for Spalart–Allmaras Turbulence Model. J. Fluids Eng. 2018, 140, 061403. [Google Scholar] [CrossRef]

- Kim, S.; Park, J.; Baek, J. A numerical study of the effects of blade angle distribution on the performance and loss generation of centrifugal compressor impellers. Proc. Inst. Mech. Eng. Part A J. Power Energy 2011, 226. [Google Scholar] [CrossRef]

- Wang, J.N. Experiments Results of Low Speed Steam Centrifugal Compressor; Industrial Research Report No. 2018-SCOM-8003; Nantong Datong Bao Fu Co., Ltd: Nantong, China, 2018. [Google Scholar]

- Fatsis, A.; Pierret, S.; Braembussche, R.V.D. Three-Dimensional Unsteady Flow and Forces in Centrifugal Impellers with Circumferential Distortion of the Outlet Static Pressure. J. Turbomach. 1997, 119, 94–102. [Google Scholar] [CrossRef]

- Gu, F.; Engeda, A. A Numerical Investigation on the Volute/Impeller Steady-State Interaction due to Circumferential Distortion. ASME Turbo Expo. Power Land Sea Air 2001, 1, V001T03A030. [Google Scholar] [CrossRef]

- Sicot, F.; Dufour, G.; Gourdain, N. A Time-Domain Harmonic Balance Method for Rotor/Stator Interactions. ASME. J. Turbomach. 2011, 134, 011001. [Google Scholar] [CrossRef]

- Xu, C.; Amano, R. Centrifugal compressor performance improvements through compressor splitter location. J. Energy Resour. Technol. 2017, 140, 051201. [Google Scholar] [CrossRef]

| Parameters | Unit | Value |

|---|---|---|

| Inlet total pressure | kPa | 94.3 |

| Inlet total temperature | K | 371.15 |

| Mass flow rate | kg/s | 2.37 |

| Total-to-total pressure ratio | - | 1.4 |

| Number of impeller blades | - | 12/12 main/splitter blades |

| Impeller inlet tip diameter, D1 | m | 0.3464 |

| Impeller outlet diameter, D2 | m | 0.897 |

| Design rotational speed | rpm | 5600 |

| Exit blade angle (meridional) | deg | 0 |

| Impeller | Prototype | AL | LA | LL |

|---|---|---|---|---|

| SM | 0.17 | 0.27 | 0.15 | 0.29 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, H.; Song, M.; Liu, X.; Yang, B.; Gu, C. Research on the Simplified Design of a Centrifugal Compressor Impeller Based on Meridional Plane Modification. Appl. Sci. 2018, 8, 1339. https://doi.org/10.3390/app8081339

Xie H, Song M, Liu X, Yang B, Gu C. Research on the Simplified Design of a Centrifugal Compressor Impeller Based on Meridional Plane Modification. Applied Sciences. 2018; 8(8):1339. https://doi.org/10.3390/app8081339

Chicago/Turabian StyleXie, Hong, Moru Song, XiaoLan Liu, Bo Yang, and Chuangang Gu. 2018. "Research on the Simplified Design of a Centrifugal Compressor Impeller Based on Meridional Plane Modification" Applied Sciences 8, no. 8: 1339. https://doi.org/10.3390/app8081339

APA StyleXie, H., Song, M., Liu, X., Yang, B., & Gu, C. (2018). Research on the Simplified Design of a Centrifugal Compressor Impeller Based on Meridional Plane Modification. Applied Sciences, 8(8), 1339. https://doi.org/10.3390/app8081339