1. Introduction

Understanding the wave propagation in a pipe is of fundamental importance to some engineering systems such as oil and gas pipeline systems and urban water distribution networks. Pipelines are extensively used to transport energy products like crude oil and gas, and for water transport and distribution. Corrosion flaws can begin to develop as pipelines age, and it is therefore vital to develop ways to inspect them efficiently. Many industrial pipelines are buried in the ground and are mostly isolated and inaccessible. Therefore, there is a need to employ remote sensing techniques to monitor the development of flaws in such pipelines. The acoustic wave propagation technique has become a very attractive, non-destructive testing technique for the remote monitoring of pipelines. The wave propagation technique has the advantage of full volumetric inspection, and can be used to find the characteristics of flow in a fluid-filled pipeline. The acoustic wave propagation technique operates in elongated geometrical bodies with constant or variable cross-sections, e.g., pipes. Sound generated in these bodies is constrained to propagate in the pipe wall, as well as in the fluid inside the pipe, and is reflected back to the generation point when a change in impedance (discontinuity) occurs. Therefore, acoustic wave propagation can only occur when there is a medium in which to propagate.

Acoustic wave propagation phenomena along pipelines have been investigated theoretically and experimentally. Several modifications of the acoustic wave equation to more complex equations have been established. For instance, for a fluid flowing with varying density and acoustic velocity, Bergmann [

1] previously proposed an equation that is widely used in underwater acoustics problems, whereas Pierce [

2] derived a generalized wave equation for an inhomogeneous fluid in motion whose flow profile differs in time and position. Chen and Shen [

3] proposed a method to analyze the surface waves propagating on a grounded anisotropic slab. They considered the field variation in the direction parallel to the wave propagation. The wave propagation characteristics were derived on the basis of Maxwell’s equation and boundary conditions.

Recent developments showed that acoustic wave propagation using the Finite Element Method (FEM) has been utilized in pipeline detection. The sound propagation within a fluid flow in a pipe can be evaluated, taking the flow profile as a boundary condition for the simulation task. The FEA solvers for linear and non-linear acoustic wave equations vary. This leads to a symmetric matrix formulation for fluid-structure interaction [

4], and this is being used in several computation solvers for acoustics. Mohamed and Walied [

5] developed a finite element model of a surface acoustic wave sensor using the ANSYS simulation tool; the model was tested for hydrogen detection. Another numerical FEA approach was proposed for the calculation of non-linear propagation of acoustic waves by Kagawa et al. [

6].

Eccardt et al. [

7] presented an FEA method based on a modified wave equation, and compared their results with previously developed techniques like the Holtz-Kirchhoff integral and ray tracing method. They obtained sets of primary and secondary wave equations, and for numerical implementation, they employed the Finite Element Method to discretize and solve the equation integral scheme with respect to time. The numerical result shows that the equations are valid, but with more pronounced discretization error for the secondary waves. An FE numerical technique for simulating a 3D acoustic-wave correlator was presented by Tikka et al. [

8]. They presented and discussed the results of the analysis of device responses for variable acoustic modes and differences in electrical response in the system. They concluded that FEA provides an effective means of analysing the correlator’s response to various propagating modes.

Kutiš et al. [

9] used FEM in modelling and simulation of surface acoustic wave sensor. They performed modal and transient piezoelectric analysis to determine the eigenmodes and frequencies of the system that were used to investigate the harmonic wave propagation characteristics of the system. Yu and Yan [

10] conducted a series of numerical studies using FEA to investigate the wave propagation behaviour in wooden poles. Their results showed that a higher elastic modulus in longitudinal direction always generated higher guided wave behaviour in a wooden pole, and experimental testing was performed to validate their findings. Many works have been conducted with the aim of improving the computational efficiency and accuracy of the convectional FEA method. Owowo and Oyadiji [

11] investigated the effect of leakage on acoustic wave propagation in an air-filled pipe using the FEA method and experimental testing. Their predicted and measured data was subsequently used to identify and locate the leakage using a Time-of-Flight approach.

Other numerical techniques have been used for predicting acoustic wave propagation. These include the Boundary Element Method (BEM), Statistical Energy Analysis (SEA), and the SWAN (Simulating Waves Nearshore) spectral phase averaged wave model. For example, Chen et al. [

12] used the Finite Element Method and Boundary Element Method (FEM-BEM) to analyse acoustic fluid-structure interaction. An algorithm based on FEM-BEM was presented for simulation of fluid-structure interaction in their work. The accuracy of the simulation was improved by evaluating the single integrals in boundary integral equations using the Cauchy principal value and the Hadamard finite part integral method.

In order to understand the mechanism of acoustic wave propagation in a body, the noise propagation in ship structures was investigated by Weryk et al. [

13], and was tested in several vessels using Statistic Energy Analysis (SEA). Their predicted result was compared with the experimental results obtained from tests carried out using similar vessels. Eugen [

14] studied the patterns by which wave energy propagates in the western side of the Black sea and simulated the propagation using the SWAN spectral phase averaged wave model. The study shows that there is a tendency for the waves to travel faster along the Black sea surface.

A field experiment to assess the feasibility of using commercially available accelerometers and related signal condition to analyse acoustic wave propagation in a pipe was recently conducted [

15]. Results from the experiments confirmed that attenuation is the most important factor that affects the viability of acoustic wave propagation for impact detection. In another work, a sound intensity measurement technique was used to investigate how sound energy propagates around organ pipes [

16]. The authors obtained the sound intensity distributions around the pipes, and the directions of the acoustic energy flow were presented. Papadopoulou et al. [

17] used the acoustics pulse reflectometer technique for flaw detection in pipes in the time domain.

The use of analytical equations to investigate acoustic- or pressure-wave propagation in a fluid-filled pipeline might be straight-forward and easily implemented for a simple straight pipe. However, when pipe networks are involved, the prediction of acoustic or pressure wave propagation becomes very difficult to implement analytically. In such cases, the use of a numerical method, such as FEA, is imperative. However, large errors may also occur in the numerical predictions of acoustic wave propagation. For example, when FEA was used to predict acoustic wave propagation in an air-filled pipe, as in the work by Owowo and Oyadiji [

11], very large acoustic speed errors were obtained. They used 3D hexahedral acoustic elements whose structural counterparts usually give accurate predictions. They expected the 3D hexahedral acoustic elements to also give accurate predictions, but did not check to confirm the degree of their accuracy. Therefore, there is a need to further investigate the FEA of acoustic wave propagation in fluid-filled pipes using other acoustic finite elements in order to achieve accurate and efficient predictions.

In this paper, the simulation of acoustic wave propagation in a pipe using FEA is presented and verified using the Time of Flight approach to deduce the acoustic velocity associated with the predictions. The use of different acoustic element types of 2D-like and 3D formulations, and of linear and quadratic interpolations, are investigated in order to deduce the most accurate acoustic FEA approach, and thereby, to minimise the errors.

4. Acoustic Finite Element Analysis (AFEA) of Acoustic Wave Propagation in a Straight Pipe

4.1. Finite Element Modelling Description

To perform the acoustic wave propagation using FEA in a pipe, three stages must be considered in the numerical modelling: (i) pre-processing, (ii) analysis, and (iii) post-processing. The analysis starts from the development of the geometry of the air cavity (domain) of an air-filled pipe. This is followed by the discretization of the geometry into smaller discrete elements. The elements are joined together by nodes to form a mesh. The amount of elements used for a particular model is referred to as the mesh density. The acoustic finite element is a unique element designed for the simulation of a system undergoing small variation in acoustic pressure. The simulation process of the AFEA of the acoustic wave reflectometry method involves the integration of the geometrical description of a model with the parameters of the fluid-medium, such as: pressure, momentum, and energy across the elements of the domain. The AFEA then evaluates the medium responses at each of the integration points of the elements, thereby obtaining the responses at the nodes that join the elements together.

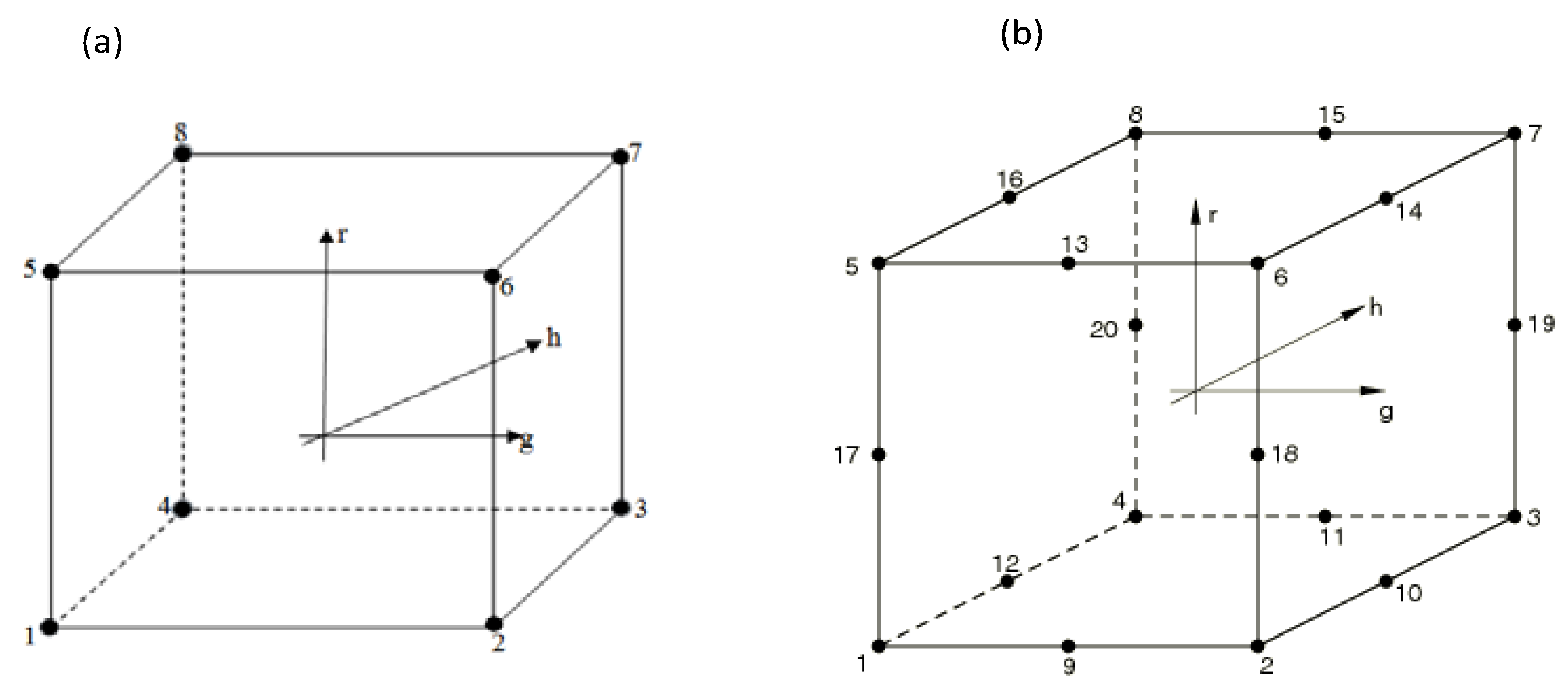

Thus, for any other point within the elements, results are obtained by interpolation from the nodal data. However, the geometrical order of interpolation is determined by the kind of element employed for the analysis. There are two principal interpolations, namely: linear interpolation used by element types ACAX4 and AC3D8, and quadratic interpolations used by element types ACAX8 and AC3D20 [

19].

4.2. Analysis Procedure and Boundary Conditions

In creating the intact pipe model using the solid elements AC3D8 and AC3D20, the 3-D modelling space of the Abaqus/CAE part module was used to create a single solid shape deformable cylinder that represents the model of the air volume that occupied the pipe cavity. In the case of the intact pipe model using the axisymmetric elements ACAX4 and ACAX8, a longitudinal sectional plane of the 3-D modelling space was used to part-define the model from which the full solid shape deformable cylinder was derived internally by revolving the plane about its axis. In both cases, only the fluid (air) content of the pipe was modelled without the inclusion of the pipe in the model. Since the specific acoustic impedance of the air medium is much smaller than the specific impedance of the wall of a metallic or plastic pipe, this assumption is reasonable. This eliminates contact interaction of the solid pipe wall and the fluid, and as a consequence, reduces computational time and resources.

The acoustic properties of air used for the intact models are density and bulk modulus which give an acoustic velocity of . Volumetric drag of the air medium was assumed to have negligible effect on the analysis and was ignored. The next step in creating the model involves defining and assigning material and section properties to the deformable domain.

In defining the analysis step for the simulation, the step module of the Abaqus/CAE was selected. The air properties were evaluated to define a general dynamic implicit step with a primary period of for the initial step, and with an increment size set at . Also, a fixed maximum number of time increments of was defined to guarantee convergence in the time increments. The solution technique used for the equation solver was the Full Newton, while the default analysis product that converts severe discontinuity iterations to propagate from the previous step was selected. The extrapolation of prior state of each increment was chosen as linear, while Alpha time integrator parameter was specified as −0.333.

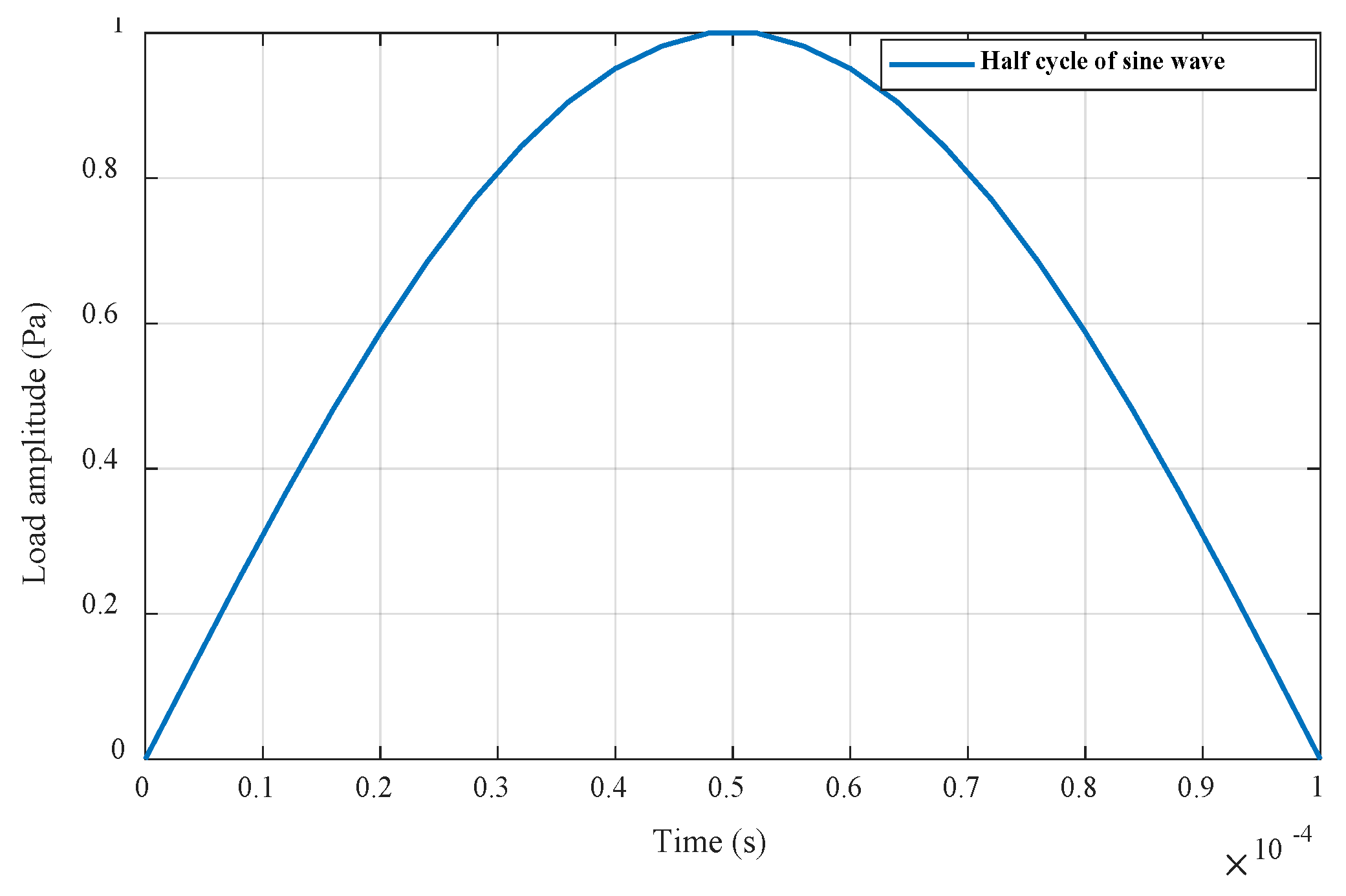

An acoustic impulse of a half sine wave, as shown in

Figure 3, was created. The pulse had a maximum amplitude of

, and was applied for a duration of

at the inlet. Similarly, at the pipe outlet region, a zero acoustic pressure was defined to create a profile of pressure damping from maximum to atmospheric at the pipe exit boundary.

4.3. Simulation Results

4.3.1. Verification of Results Using Time of Flight

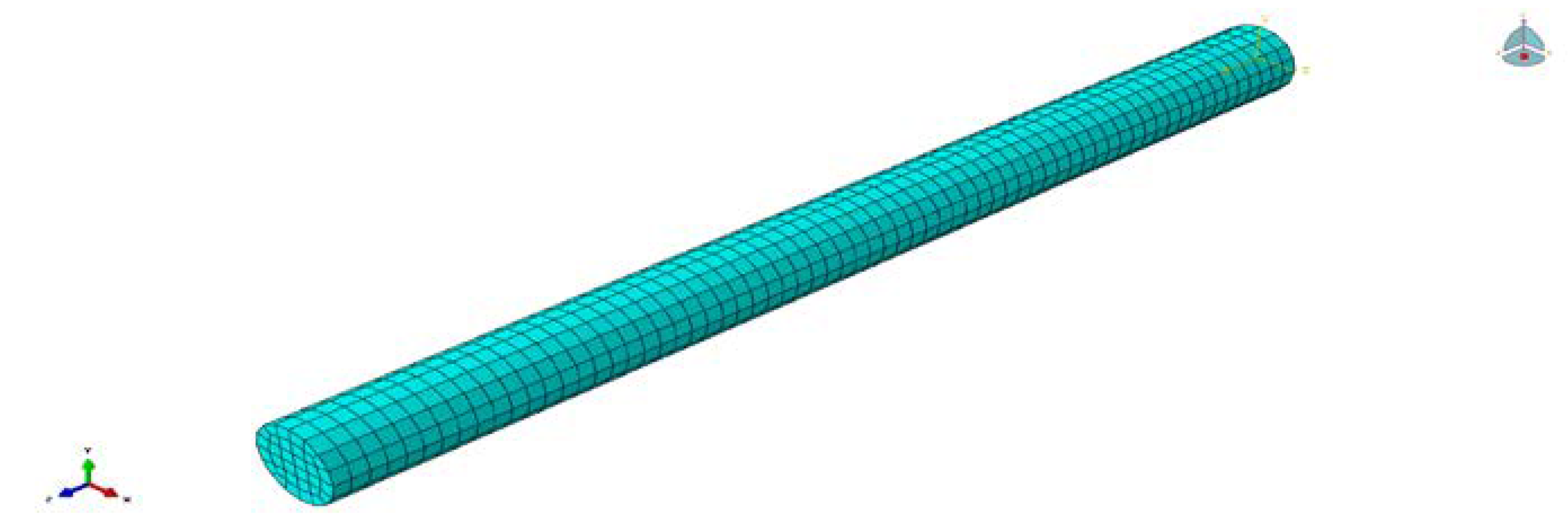

The FEA of acoustic wave propagation in a pipe of diameter

and of length 4.02 m was earlier conducted by Owowo and Oyadiji [

11]. A 20-node quadratic acoustic brick (AC3D20) element type was employed for their analysis, as illustrated in

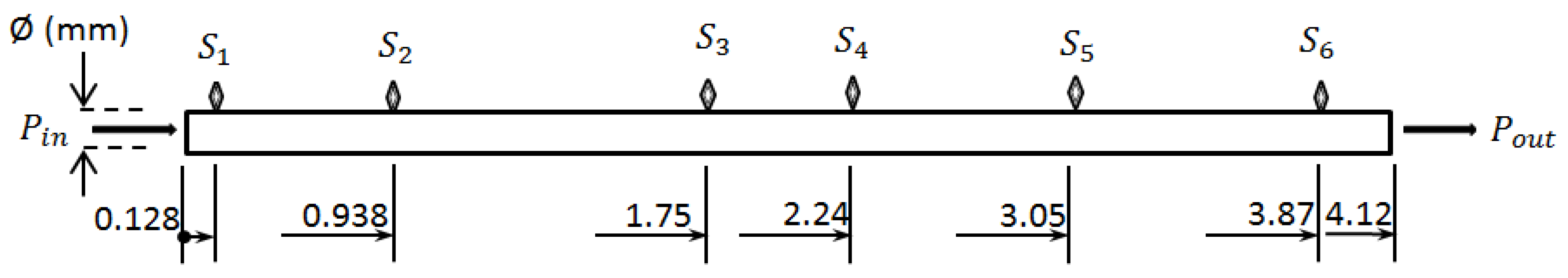

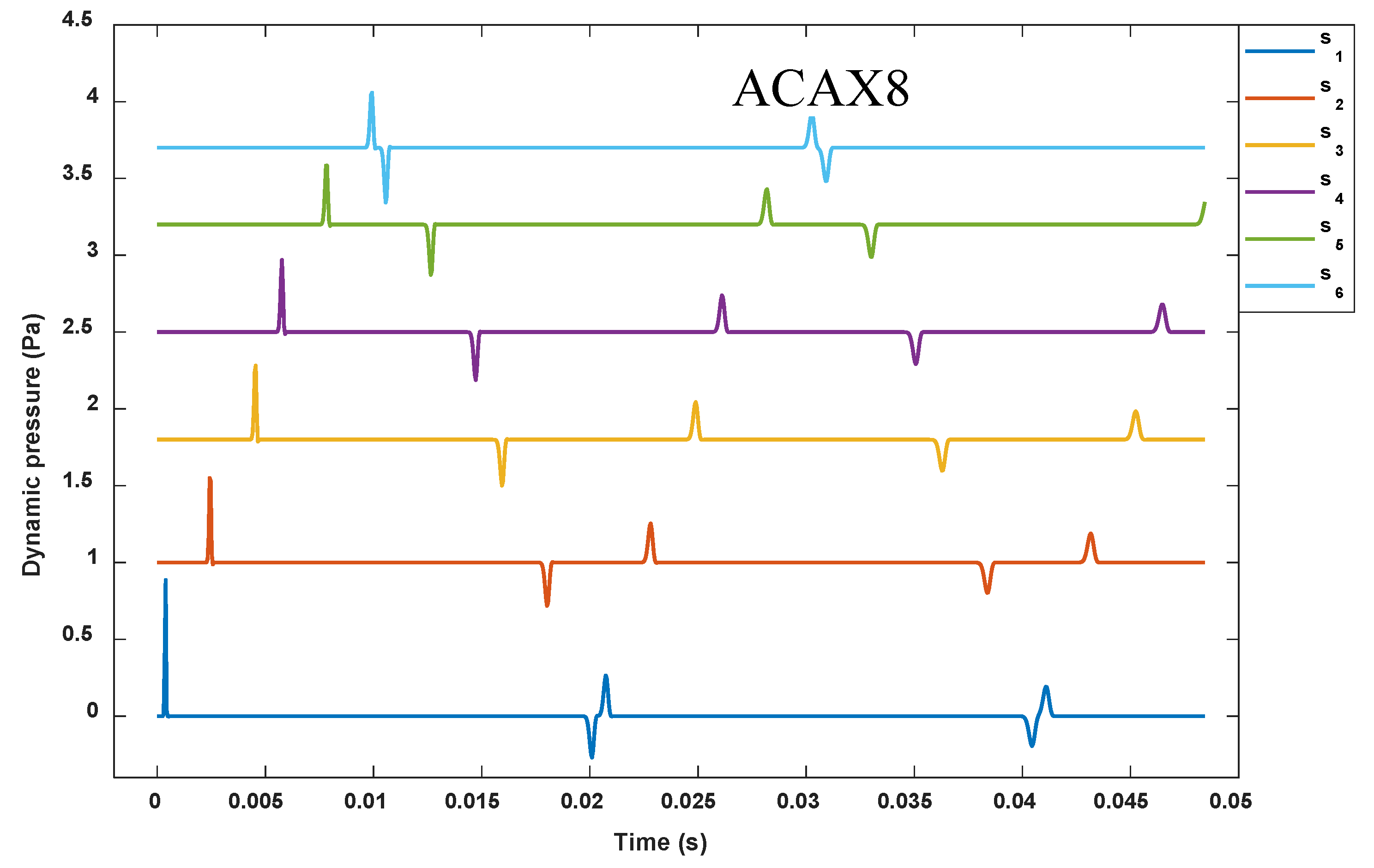

Figure 4. As a starting point in these investigations, the acoustic wave propagation in the same pipe was analysed using the AC3D20 element type and the same mesh seed size of 9 mm. The responses obtained at six monitoring points, which are designated as ‘sensor’ locations

to

, as shown in

Figure 5, are illustrated in

Figure 6. These results are identical to those shown in the paper by Owowo and Oyadiji [

11], and the Time of Flight approach was used to check their accuracy.

Figure 6 presents stacked plots of the dynamic pressure versus time waveforms at the six monitoring nodes identified in the intact pipe model. It should be noted that all the plots start with a dynamic pressure amplitude of zero. Thus, in all cases, the maximum peak amplitudes are less than 1.0 Pa. The stacking of the plots enables a direct comparison of the forward-going and backward-going (reflected) wavefronts at the different sensor locations. From the figure, the first positive peaks seen in each of the graphs indicate the arrival of the pressure pulse to the individual sensors. The compression pulse propagates past the respective sensors

in the order of time seen in the second column of

Table 1. On the other hand, the first negative peaks seen at the various sensor locations are the times taken by the wave to travel to the pipe outlet and back to the corresponding sensor locations. Thus, since

is located close to the pipe outlet, the reflection of the wave from

is first noticed by

, then followed by

, and subsequently to

and

, at times tabulated in the third column of

Table 1.

A magnified plot of the dynamic pressure versus time waveform predicted for sensor

is shown in

Figure 7. Considering the predicted times of flight, the wave speed can be deduced from the arrival times predicted for sensor locations

to

using the following relation:

where

is the pipe length

is the distance from the pipe inlet to sensor location

,

c is the wave speed,

is the time it takes the wave to travel from the inlet to the sensor then to the pipe exit and back to sensor location

and

is the time it takes the wave to travel from the inlet to sensor location

(

).

Substituting the respective data in Equation (16) for sensor

gives;

Similarly, the wave speed c, according to the time of flight for other sensor points (

) are computed and tabulated in

Table 1. Using the properties of air used for the AFE analysis, the actual speed of sound in air is approximately

. Comparison of the derived sound speed (derived from the predicted arrival times) with the actual sound speed used in the AFEA gives the errors

associated with each sensor location, as shown in the fifth column of

Table 1. These errors are rather large and unacceptable. They can be attributed to the coarseness of the mesh used in the Abaqus AFEA. Therefore, there is a need for mesh refinement, in order to get a more accurate result. This refinement is a bit challenging; as the model size will become bigger, the computation time will be too long and the grid cells will be too much to be numerically computed on a regular computer.

In order to use a finer mesh size without increasing the model size, axisymmetric element types were also used in the simulation. AFEA of acoustic wave propagation in an intact air-filled pipe was conducted using solid axisymmetric element type ACAX8, as illustrated in

Figure 8. With this axisymmetric element type, it was possible to use very refined element sizes of 1 mm, and even down to 0.01 mm, for the simulations on a desktop PC with standard specifications, whereas the use of the solid element types AC3D8 and AC3D20 was not possible for element mesh size less than 9 mm. The predicted wave propagation using element type ACAX8 for the smallest mesh size is shown in

Figure 9. Similarly, the Time of Flight approach was used to verify the acoustic speed results from the arrival time predicted for sensor locations

extracted from

Figure 10.

Similarly, by using the properties of air used for the FEA analysis, the actual speed of sound in air is approximately

. Comparison of the derived sound speed (derived from the predicted arrival times) with the actual sound speed used in the AFEA gives the errors (

) associated with each sensor location, as shown in the sixth column of

Table 1. These errors are very small in comparison to the errors associated with the use of the AC3D20 element. The relatively very small errors associated with the use of the ACAX8 element type indicate that the axisymmetric elements are better suited for acoustic wave propagation simulations than the AC3D20 element type. Nevertheless, it is seen from

Table 2 that the errors associated with sensor location

is about 3.5 to 7 times that of the errors associated with the other sensor locations. This is due to the closeness of sensor

to the end of the open-ended pipe outlet where the acoustic wave is reflected.

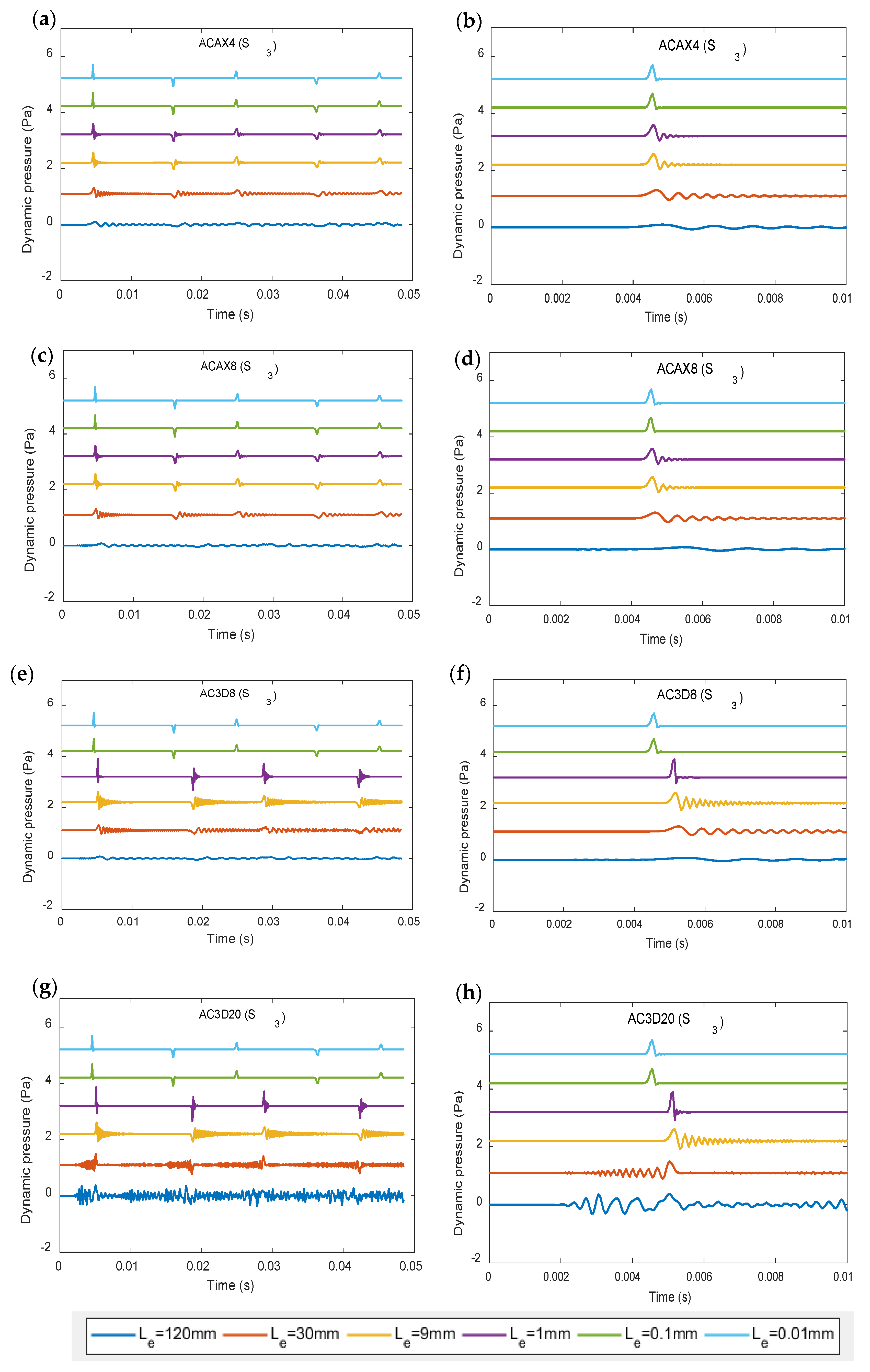

4.3.2. Sensitivity of Acoustic Finite Elements

In this section, a sensitivity analysis is developed for the meshing of the acoustic medium. The aim is to investigate the influence of mesh element type and mesh size in acoustic FEA. The AC3D20 element in the Abaqus FEA software produced a lot of computational errors in the derived acoustic speed, as seen in the sixth column of

Table 1. Most of the errors in the acoustic speed are more than 15%. To address this much more closely, the two axisymmetric element types ACAX4 and ACAX8 and the two solid element types AC3D8 and AC3D20 were used. Also, various mesh densities were employed involving element seed sizes of 120 mm down to 0.01 mm. While it was possible to run these analyses using the axisymmetric element types ACAX4 and ACAX8 on a regular desktop PC (which has a single processor), the analyses using the solid element types AC3D8 and AC3D20 could only be carried out on supercomputers using multiple cores (between 4 and 12 parallel processors). The results of these sensitivity analyses are shown in

Figure 11,

Figure 12 and

Figure 13.

Figure 11,

Figure 12 and

Figure 13 show the pressure vs. time histories predicted using the two axisymmetric element types, ACAX4 and ACAX8, and the two solid element types, AC3D8 and AC3D20, predicted at sensor locations

and

respectively. These pressure-time histories manifest the relationships between the element types chosen for the analyses, the mesh densities used, and the computational errors. The first waveforms for each set of pressure-time histories were also magnified in order to clearly show the differences in the predictions using different element types and mesh densities.

Firstly, the axisymmetric element type ACAX4 was used with a very coarse mesh density of element length L

e = 120 mm to discretise the model. It can be seen from

Figure 11a,

Figure 12a and

Figure 13a, and the corresponding enlarged plots of

Figure 11b,

Figure 12b and

Figure 13b, that the predicted waveforms are not well-separated pulses, but are rather wavy and very noisy curves. The model was refined using L

e = 30 mm; this resulted in a less noisy waveforms, but not well-defined pulses. By further refinement using L

e = 9 mm, the waveforms become a little clearer, with well-defined pulses and only a little noise. Very refined mesh density of L

e = 0.1 mm and L

e = 0.01 mm was further used, and the waveforms become very smooth, clear, identical, and well-defined. Thus, it can be deduced that the AFEA solution becomes more accurate when element type ACAX4 with length L

e = 0.1 mm is used for the analyses.

These analyses were repeated using the axisymmetric element ACAX8 with the same mesh densities as those previously used with the element type ACAX4. The predicted waveforms are shown in

Figure 11c,

Figure 12c, and

Figure 13c, and the corresponding enlarged plots of the first pulses are shown in

Figure 11d,

Figure 12d, and

Figure 13d, respectively. These figures show that the characteristics predicted by the ACAX8 element type are similar to those predicted by the ACAX4 element type. That is, the predicted waveforms are not well-separated pulses, but are rather wavy and very noisy curves when coarse mesh densities are used. However, when fine mesh densities are used, the waveforms become very smooth, clear, and well-defined. Furthermore, the converged waveforms predicted by the ACAX8 element type are identical to those predicted by the ACAX4 element type. The main difference between the two element types is that the ACAX8 element type required greater computational times.

In the introduction, it was stated that Owowo and Oyadiji [

11] used 3D hexahedral acoustic elements which they expected to give accurate predictions, just as the 3D hexahedral structural elements give accurate predictions for structural problems. But it was shown in the previous sub-section and in

Table 1 that the hexahedral acoustic element type AC3D20 gives large prediction errors even when the element size used is deemed to be reasonably small. In order to ascertain the mesh sensitivity versus accuracy of the hexahedral acoustic element types AC3D8 and AC3D20, they were also used in the acoustic simulations for the same mesh densities as those used with the axisymmetric element types ACAX4 and ACAX8.

Figure 11e–h,

Figure 12e–h, and

Figure 13e–h show that when coarse mesh densities (i.e., L

e = 120 mm, L

e = 30 mm and L

e = 9 mm) are used with element types AC3D8 and AC3D20, the predicted waveforms are worse than those predicted by the axisymmetric elements. The predicted waveforms are not well-separated pulses, but are rather very wavy and very noisy curves. When a fine mesh is used (L

e = 1 mm), the waveforms become less noisy and show well-defined pulses.

Figure 11 also shows that when the mesh is coarse, the waveforms predicted by the solid element type AC3D20 are less noisy than the waveforms predicted by the solid element types AC3D8. When the mesh is very fine (i.e., L

e = 0.1 mm and L

e = 0.01 mm), the predictions of the two element types are identical. However, the analysis using element type AC3D20 takes much more time to complete than with element type AC3D8. Furthermore, the use of AC3D20 elements generates a much bigger model and requires more static and dynamic storage than the use of AC3D8 elements.

In addition to the predicted waveforms not being sufficiently smooth with well-defined pulses when a fine mesh is used (Le = 1 mm), the figures also show that the predicted time intervals between the pulses is also larger, resulting in large errors in the predicted acoustic wave velocity. Thus, while it is important for the waveforms to be as smooth as possible, it is not sufficient to judge the accuracy of an acoustic wave propagation analysis by the waveform alone; it is also necessary to consider the accuracy of the Time of Flight.

The performance of the FEA solutions for different element types and mesh sizes is evaluated using three key variables, namely: (1) the waviness of the waveforms; (2) the computational time of the analysis; and (3) the predicted acoustic speed error. The variations of these variables are examined using different acoustic element types and sizes in the Abaqus FEA software. The relevant sensitive parameters employed by the analysis for each element type and element sizes are summarised in

Table 3.

4.3.3. Comparisons of Prediction Errors Due to Acoustic Element Type

Table 4 shows the acoustic wave speed derived from the waveforms predicted by the four acoustic element types using different mesh densities based on the Time of Flight approach. The percentage errors associated with these predicted velocities are also shown in the table. A summary of the requirements, performance, and associated errors for the four acoustic element types in the predictions of the acoustic wave propagation is shown in

Table 5.

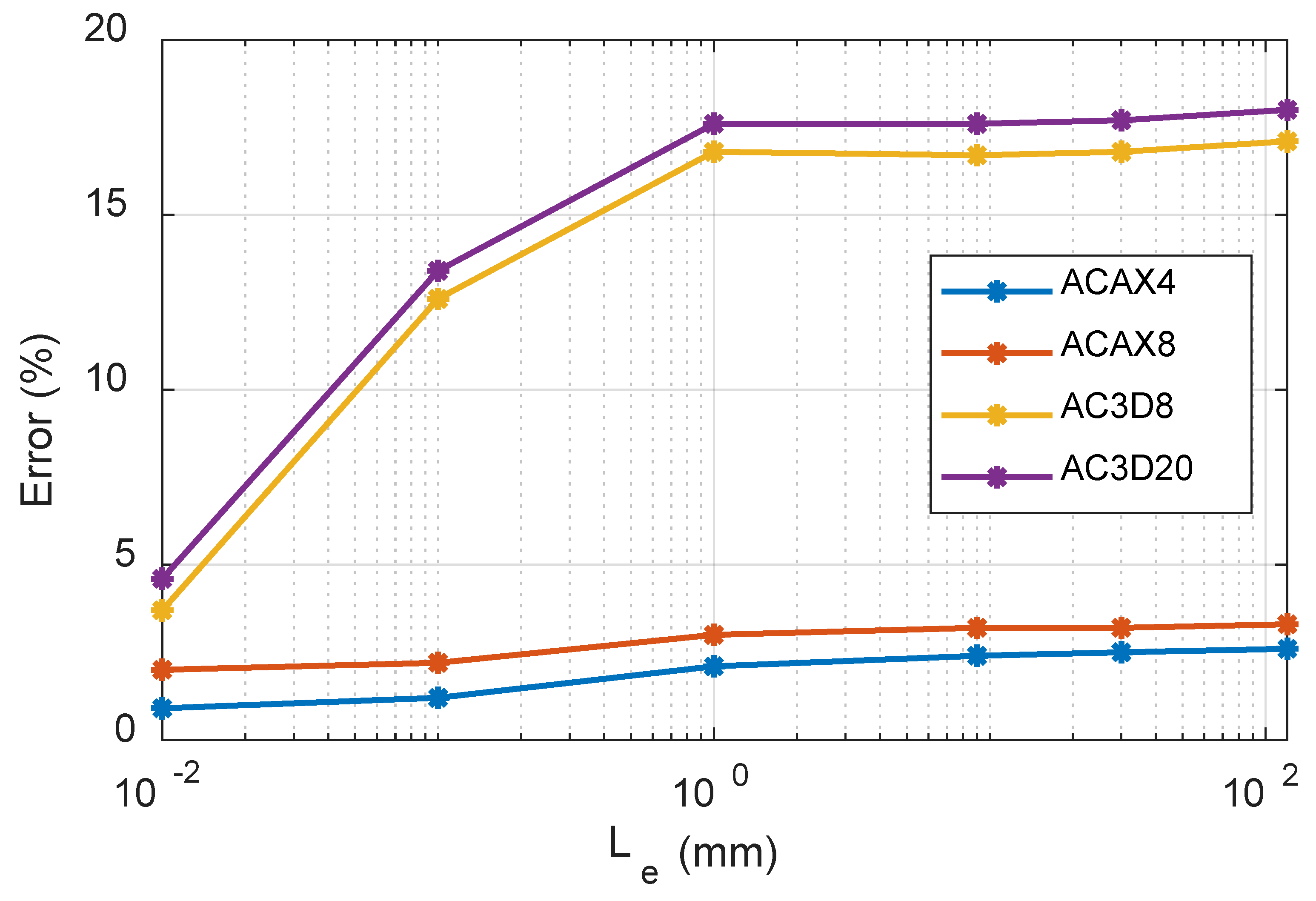

Figure 14 shows the variations of the percentage acoustic speed errors with the element sizes for the four acoustic element types. It is observed that the axisymmetric element type ACAX4 and ACAX8 produce less computational errors in the acoustic FEA. Also, it is clearly seen that the linear interpolation elements (ACAX4 and AC3D8) have less errors than the quadratic interpolation elements (ACAX8 and AC3D20).

Figure 14 shows that very large computational errors occur in the AFE analysis result when solid element types AC3D8 and AC3D20 are used. But when the axisymmetric element types ACAX4 and ACAX8 are used, the errors are minimised.

It is thus concluded that the solid element types AC3D8 and AC3D20 are not optimal in terms of speed, accuracy, and computation-resource requirements for AFE analysis of acoustic wave propagation in an air-filled pipe. Furthermore, considering the computational time and resources for each model as illustrated in

Table 5, the ACAX4 is the best element type for acoustic FEA. This is because it has the smallest model size, smallest computational time, and smallest computational errors.