Modeling and Control of a 600 kW Closed Hydraulic Wind Turbine with an Energy Storage System

Abstract

:1. Introduction

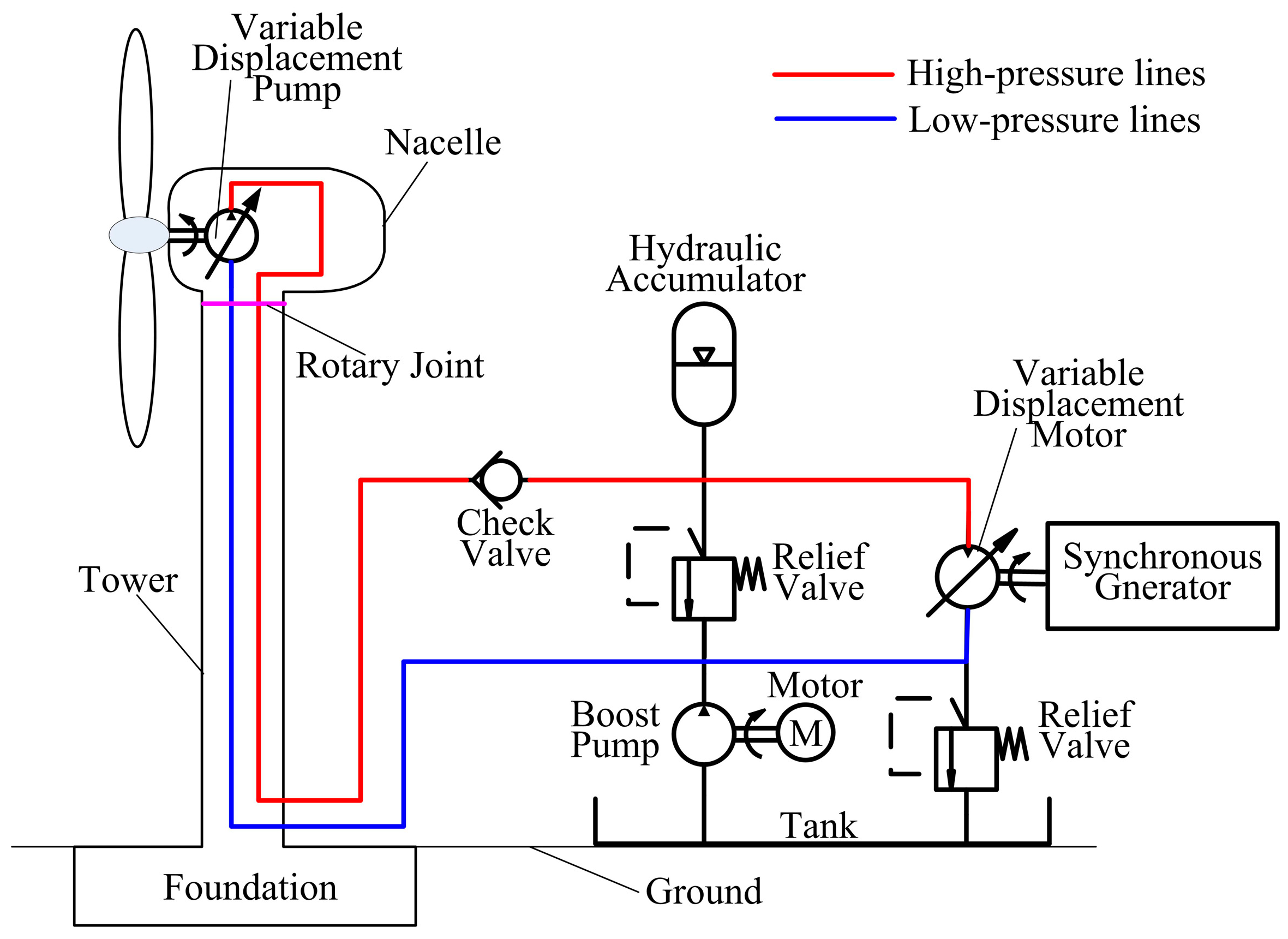

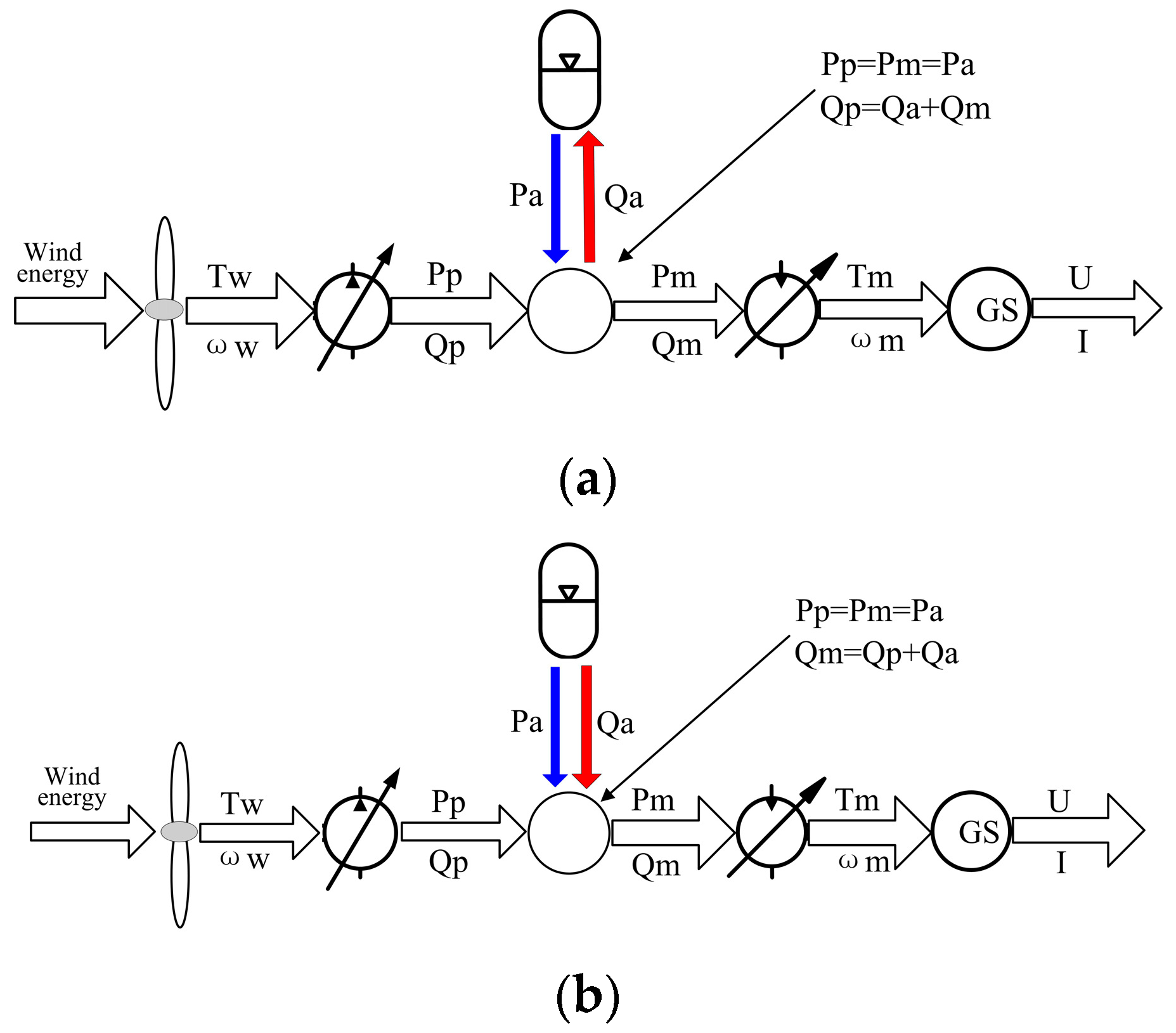

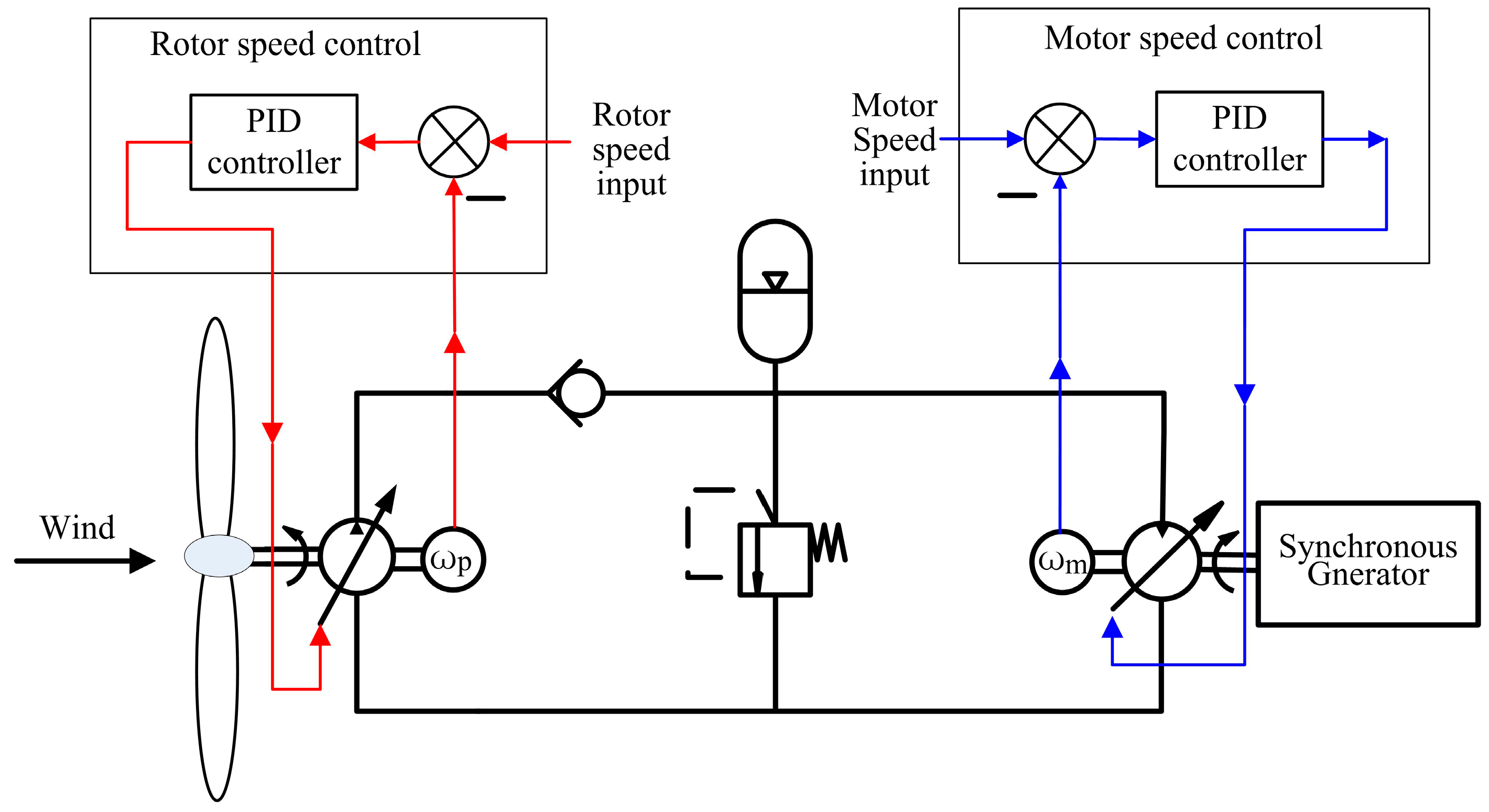

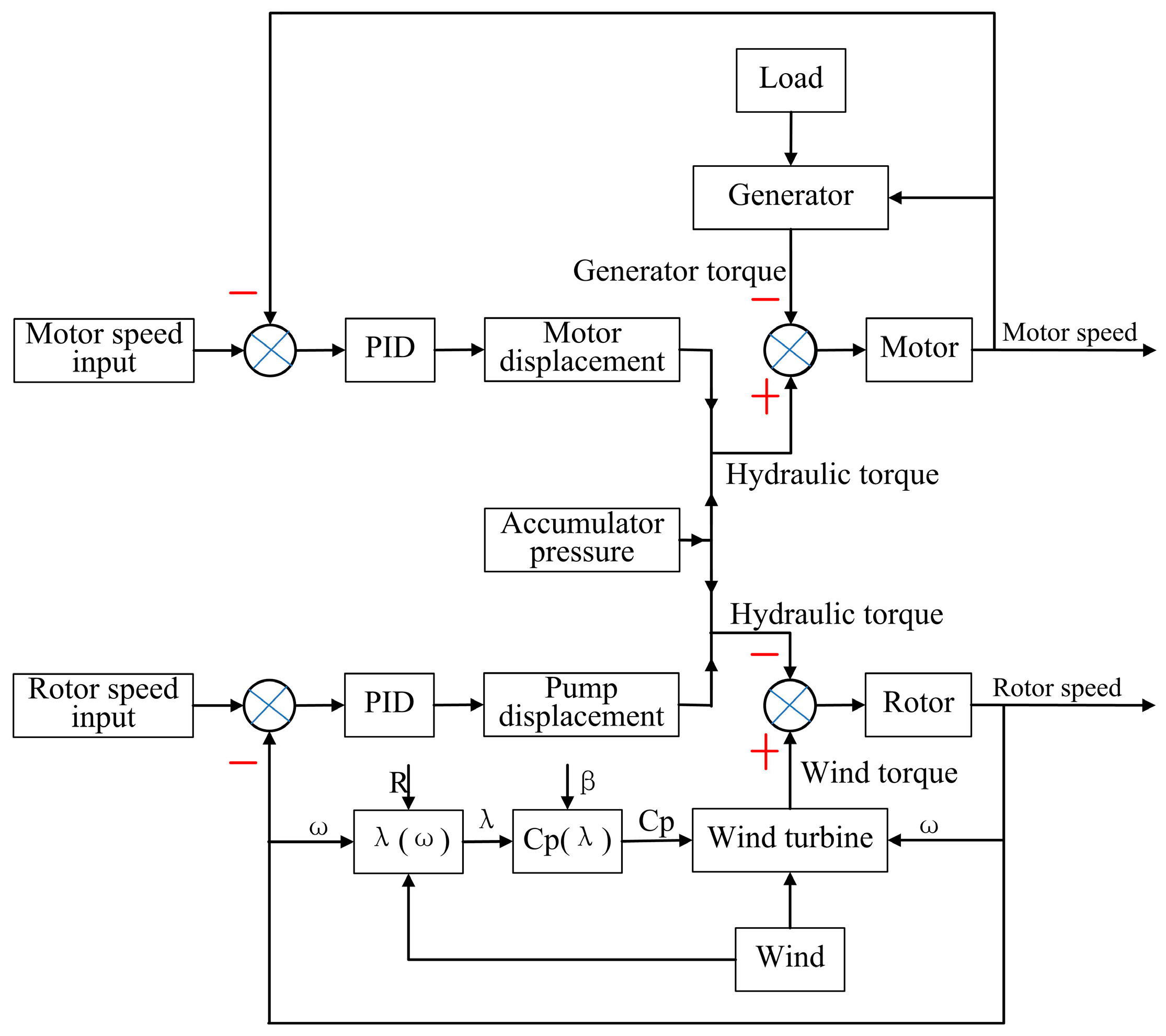

2. System Overview

3. Mathematical Model

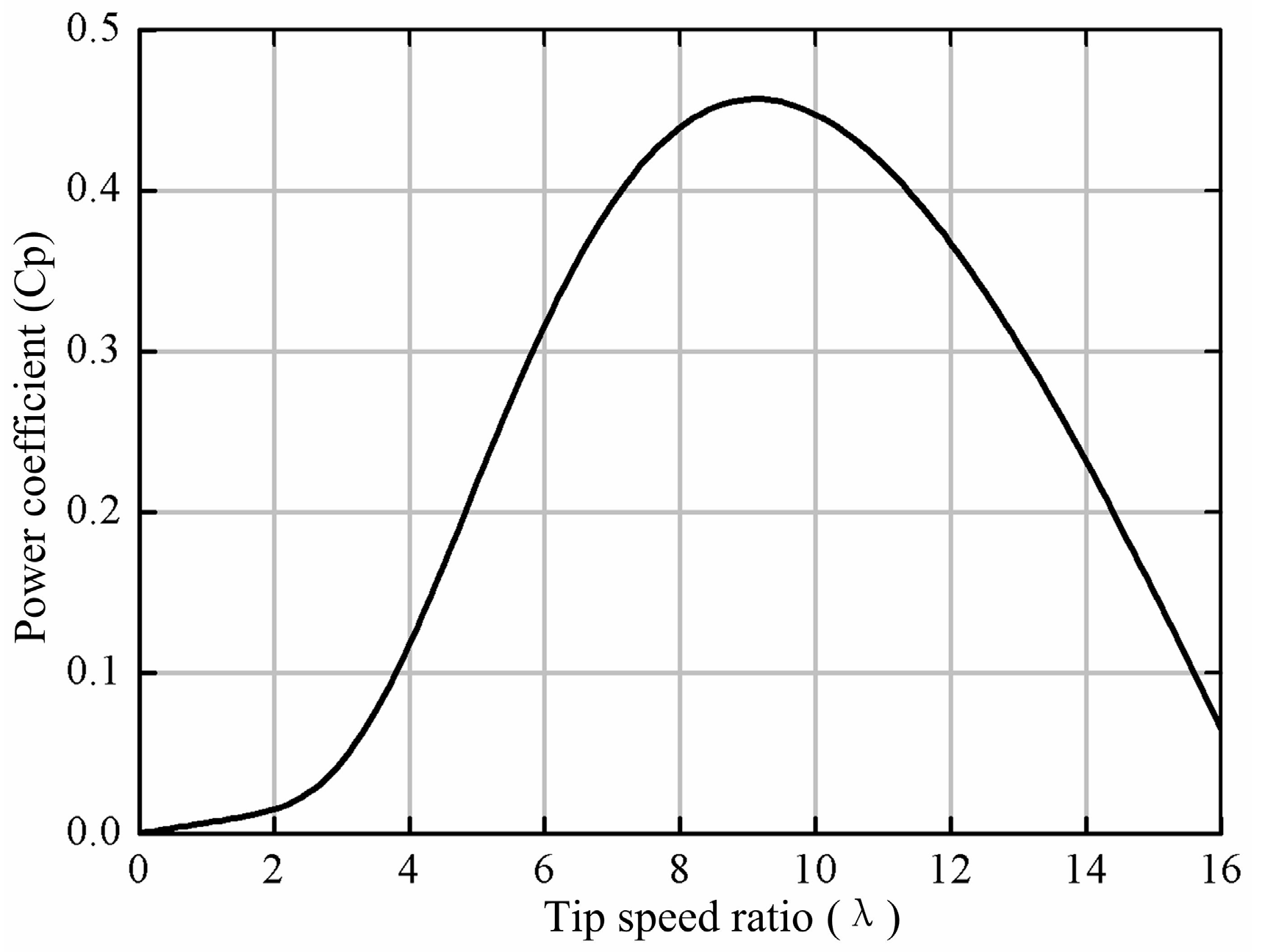

3.1. Wind Turbine

3.2. Variable Pump

3.3. Check Valve

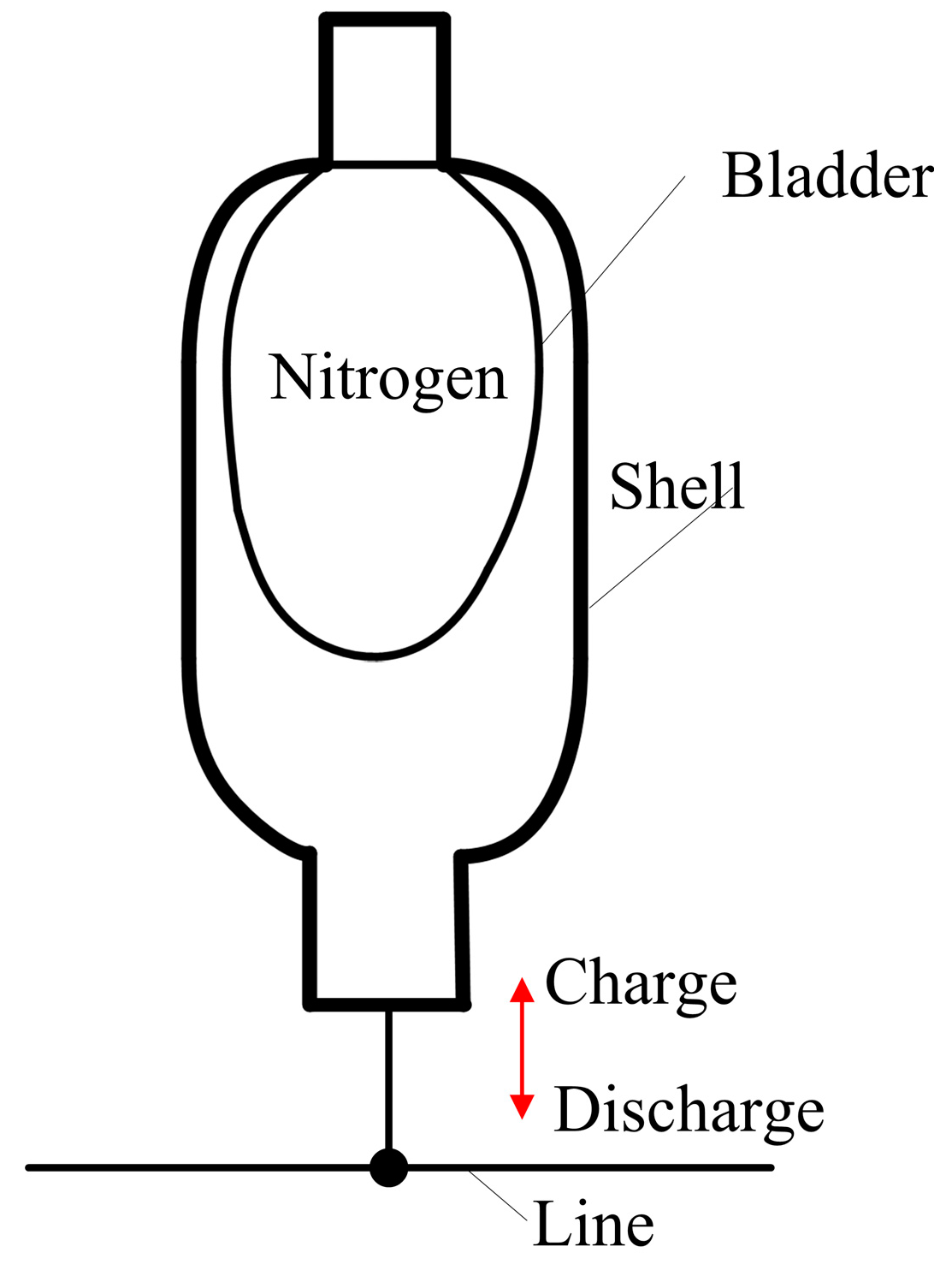

3.4. Hydraulic Accumulator

3.5. Relief Valve

3.6. Variable Motor

3.7. Synchronous Generator

4. Control Scheme

5. Simulation and Discussion

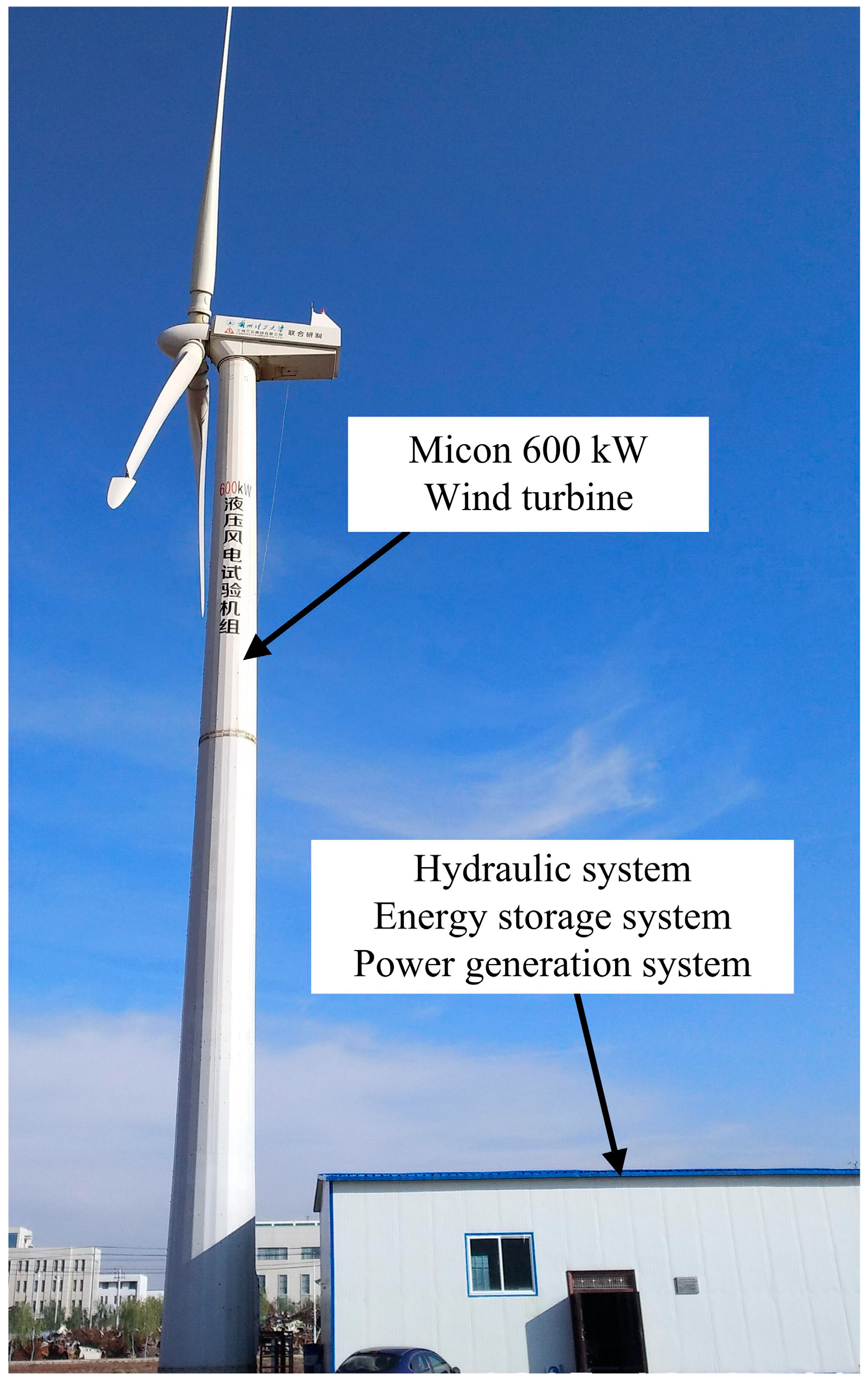

5.1. The Design of the Experimental Prototype

5.1.1. Wind Turbine and Variable Pump

5.1.2. Energy Storage System

5.1.3. Variable Motor and Synchronous Generator

5.2. Simulation Results

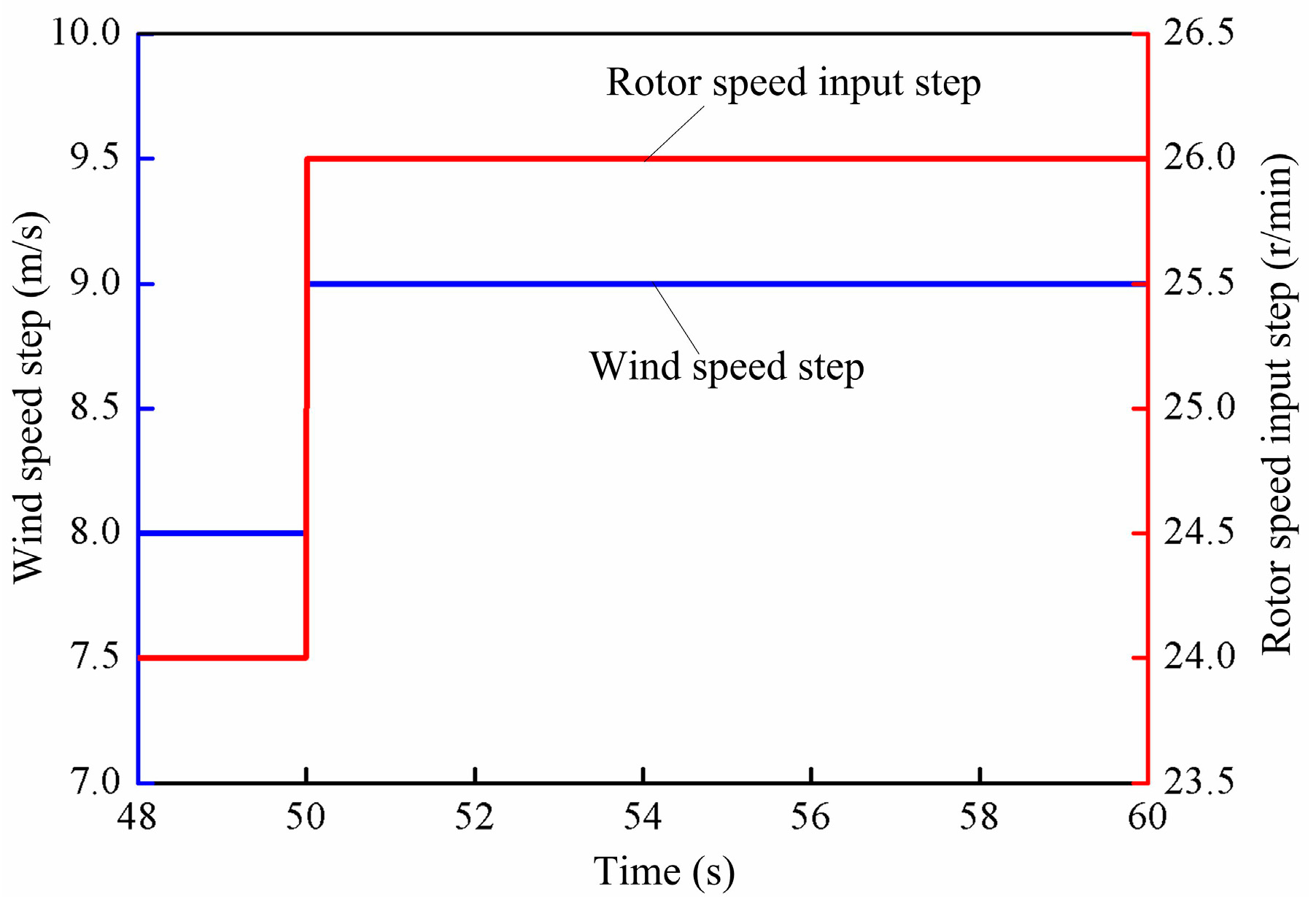

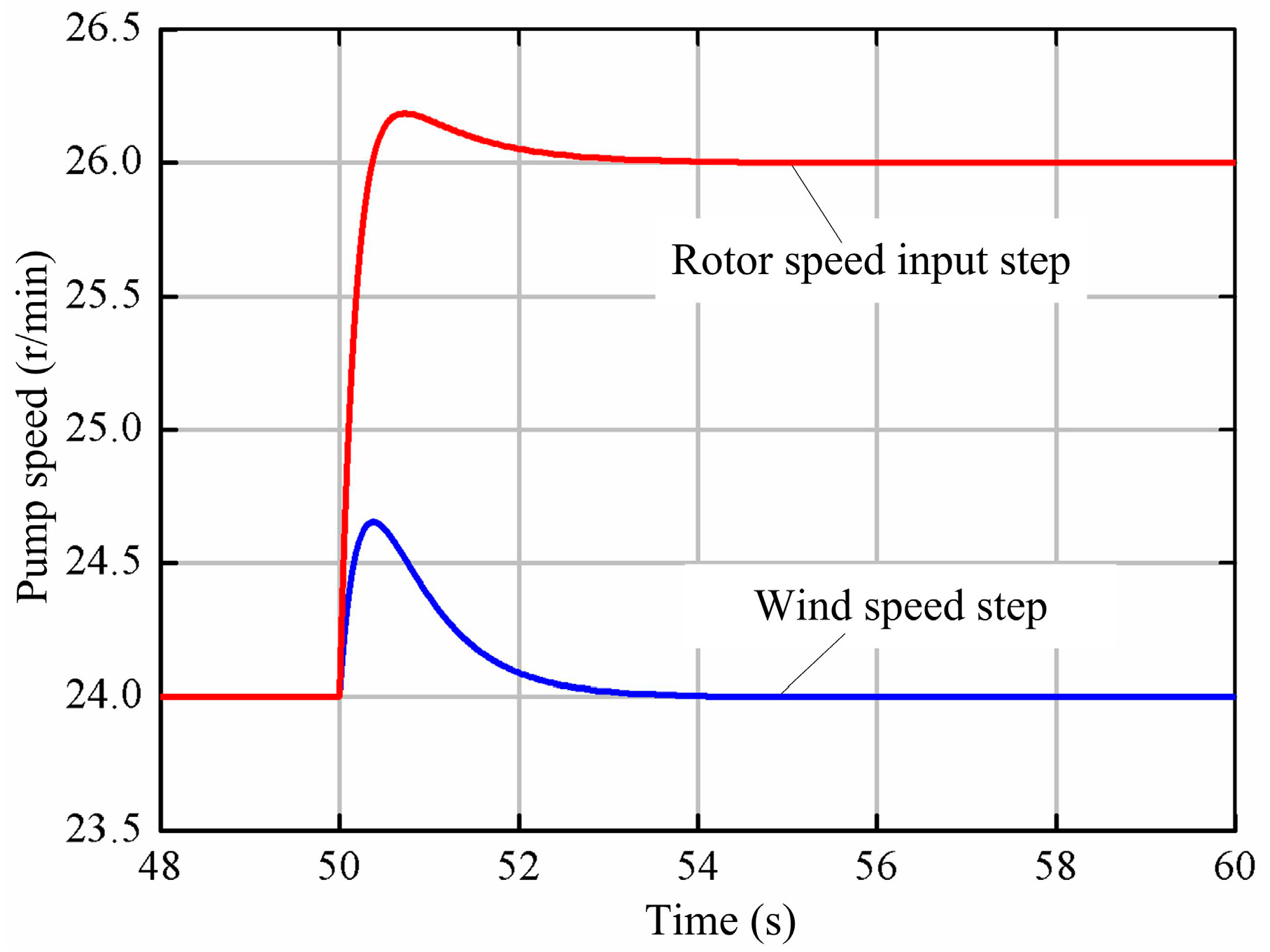

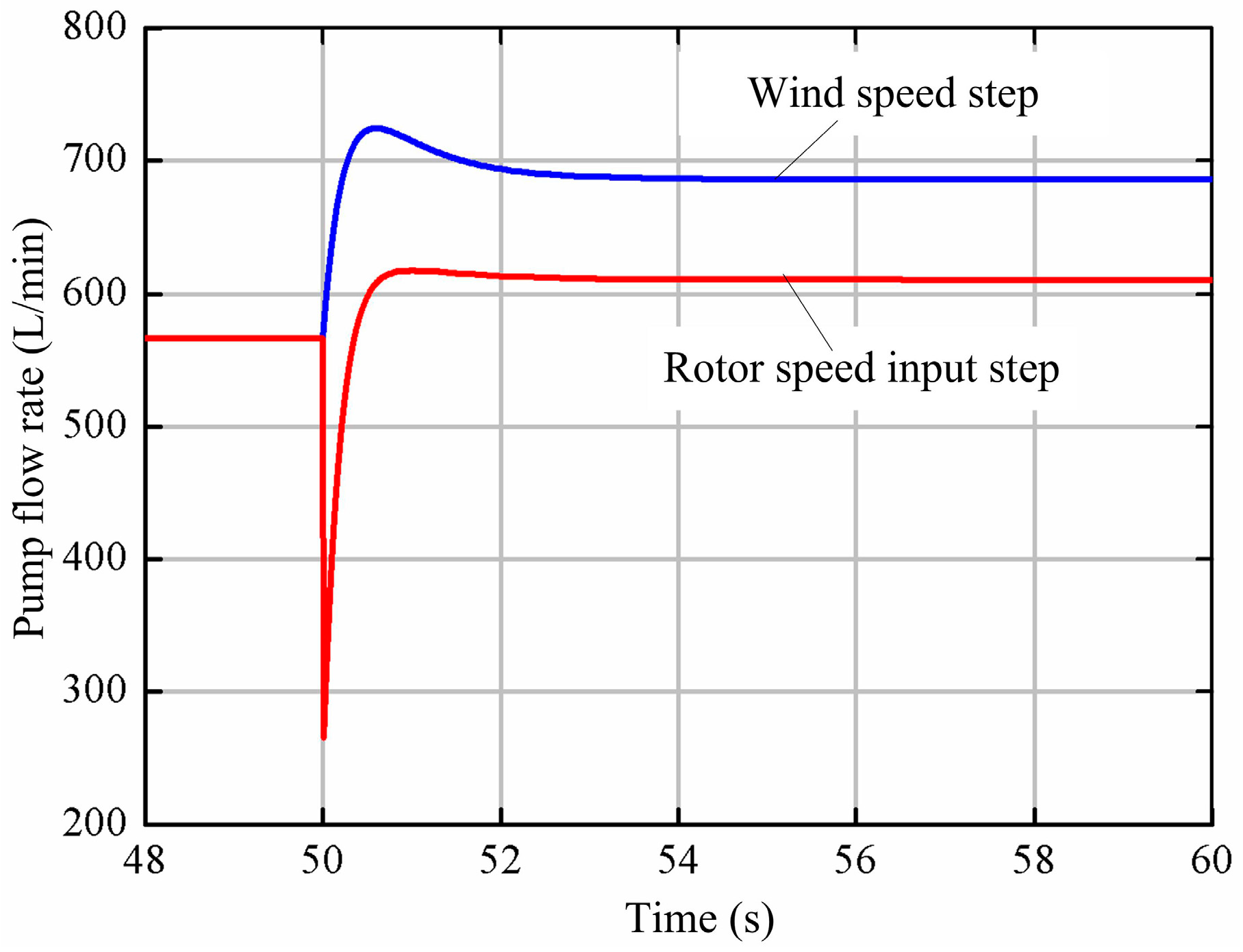

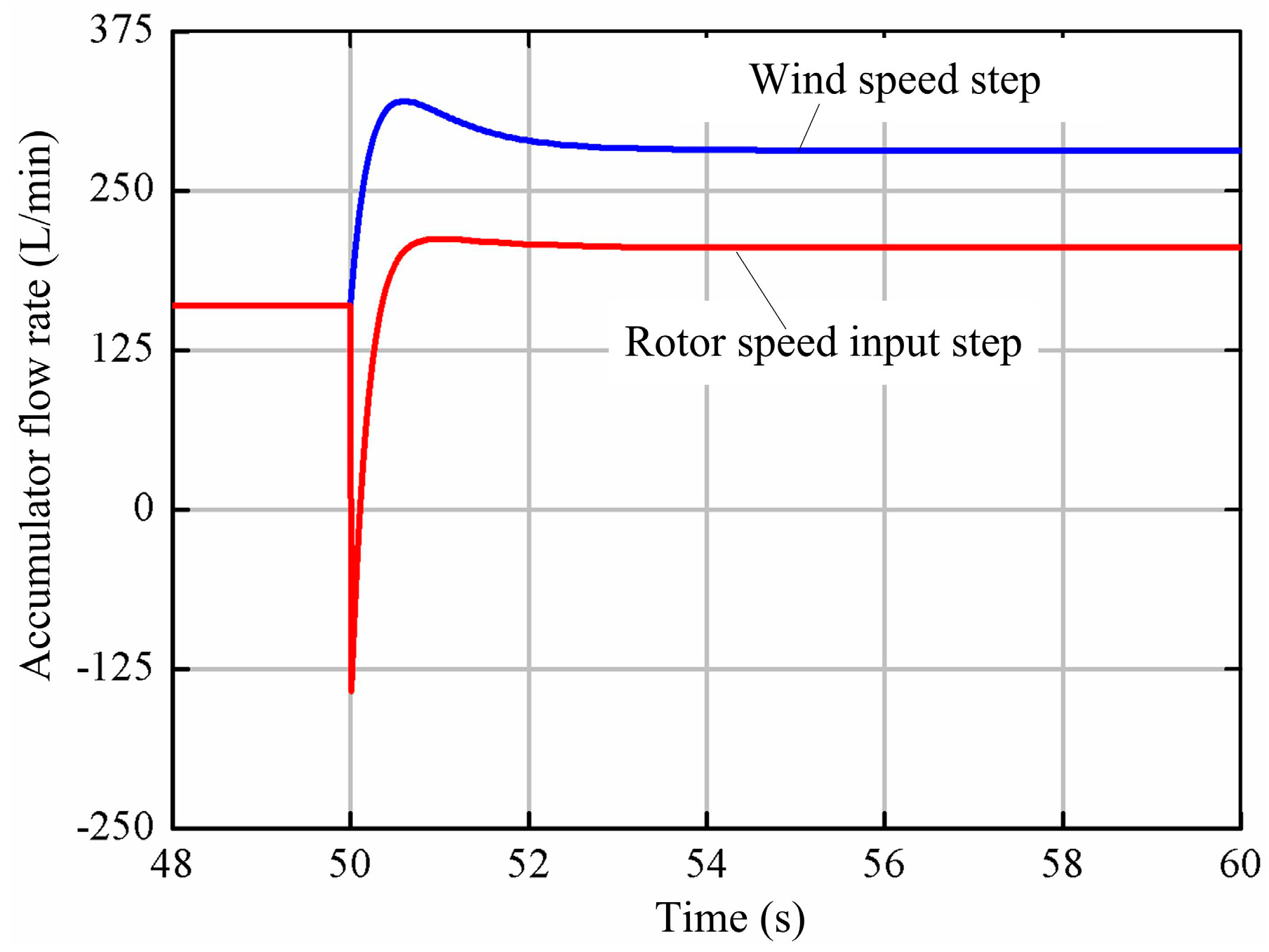

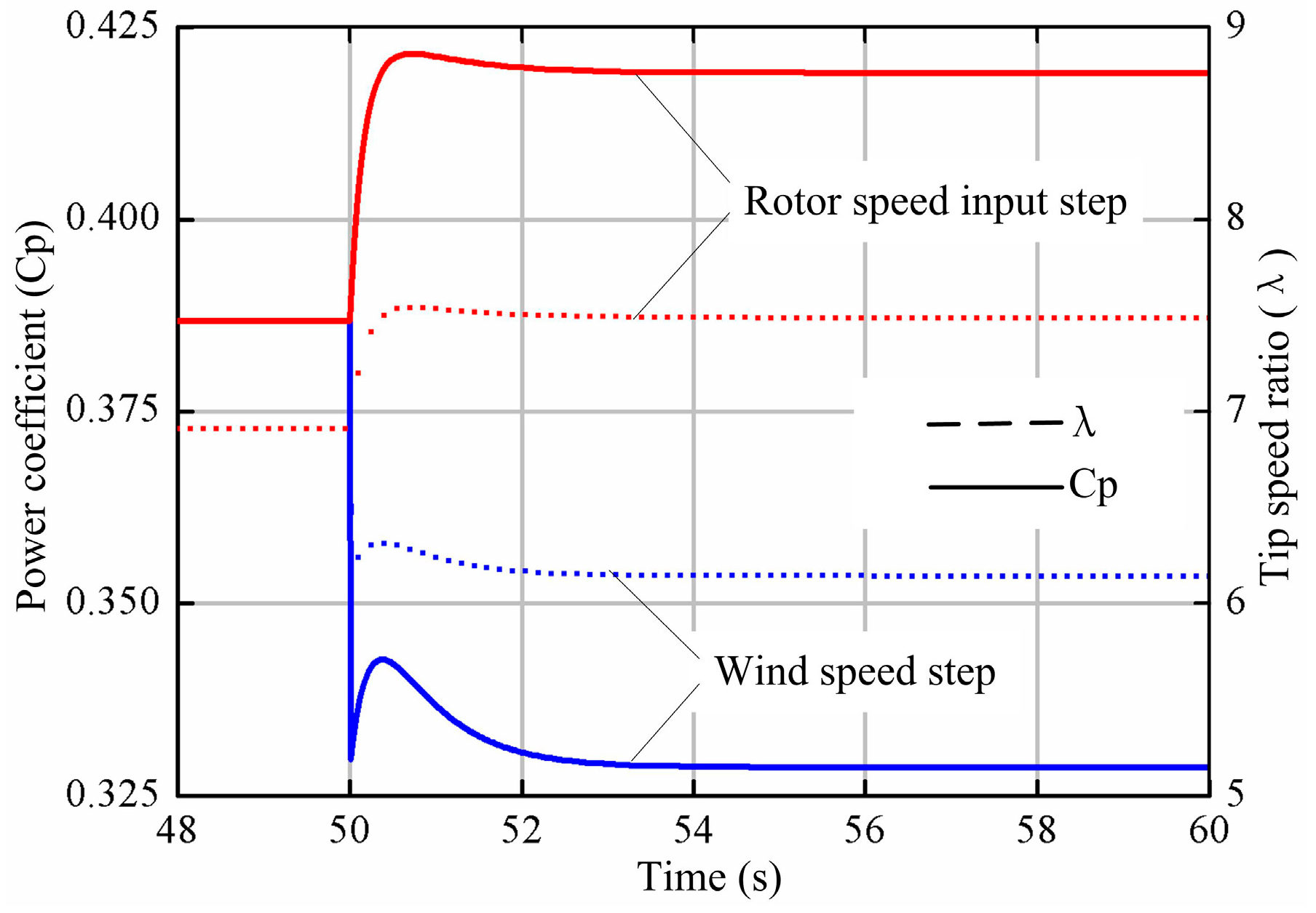

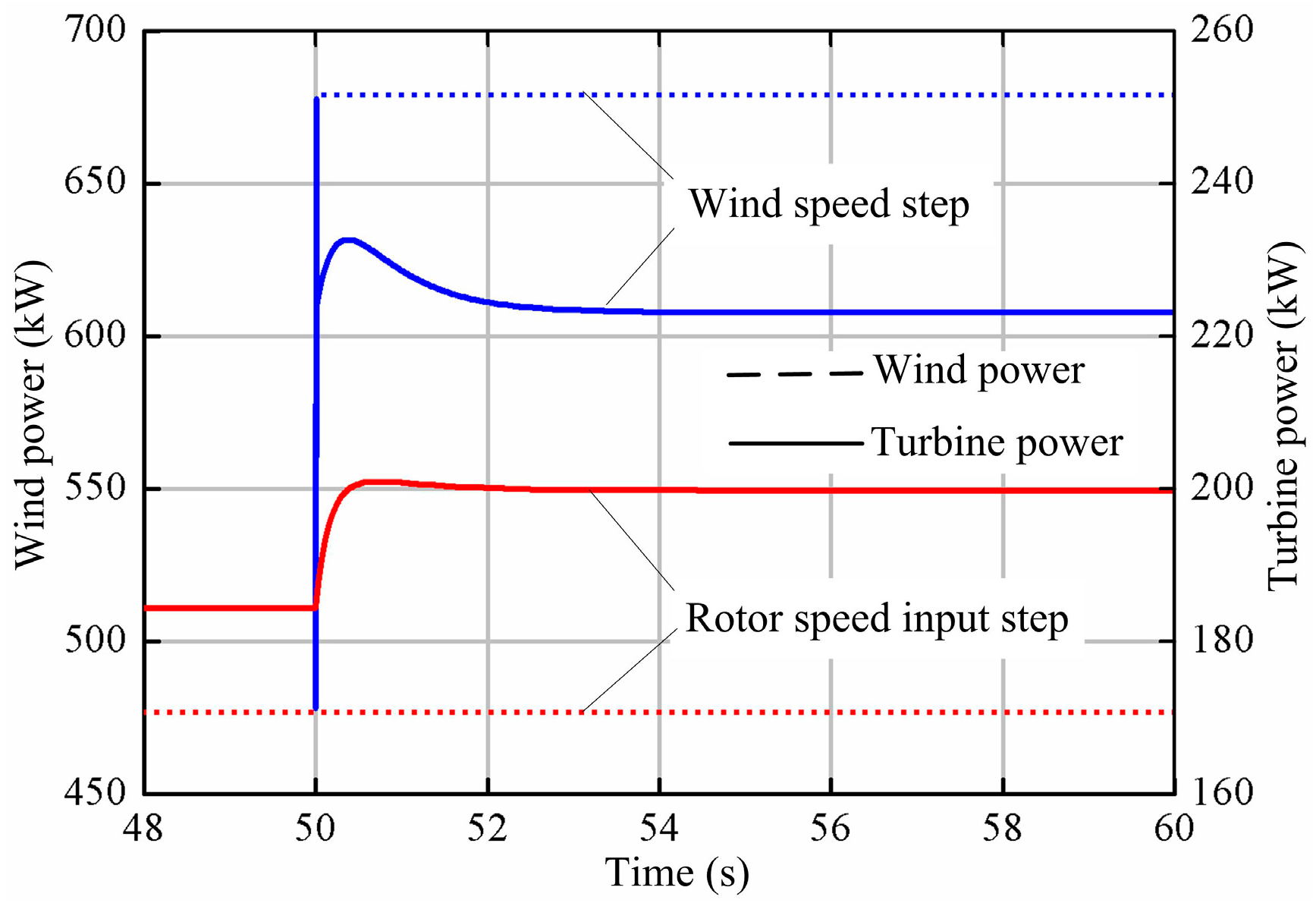

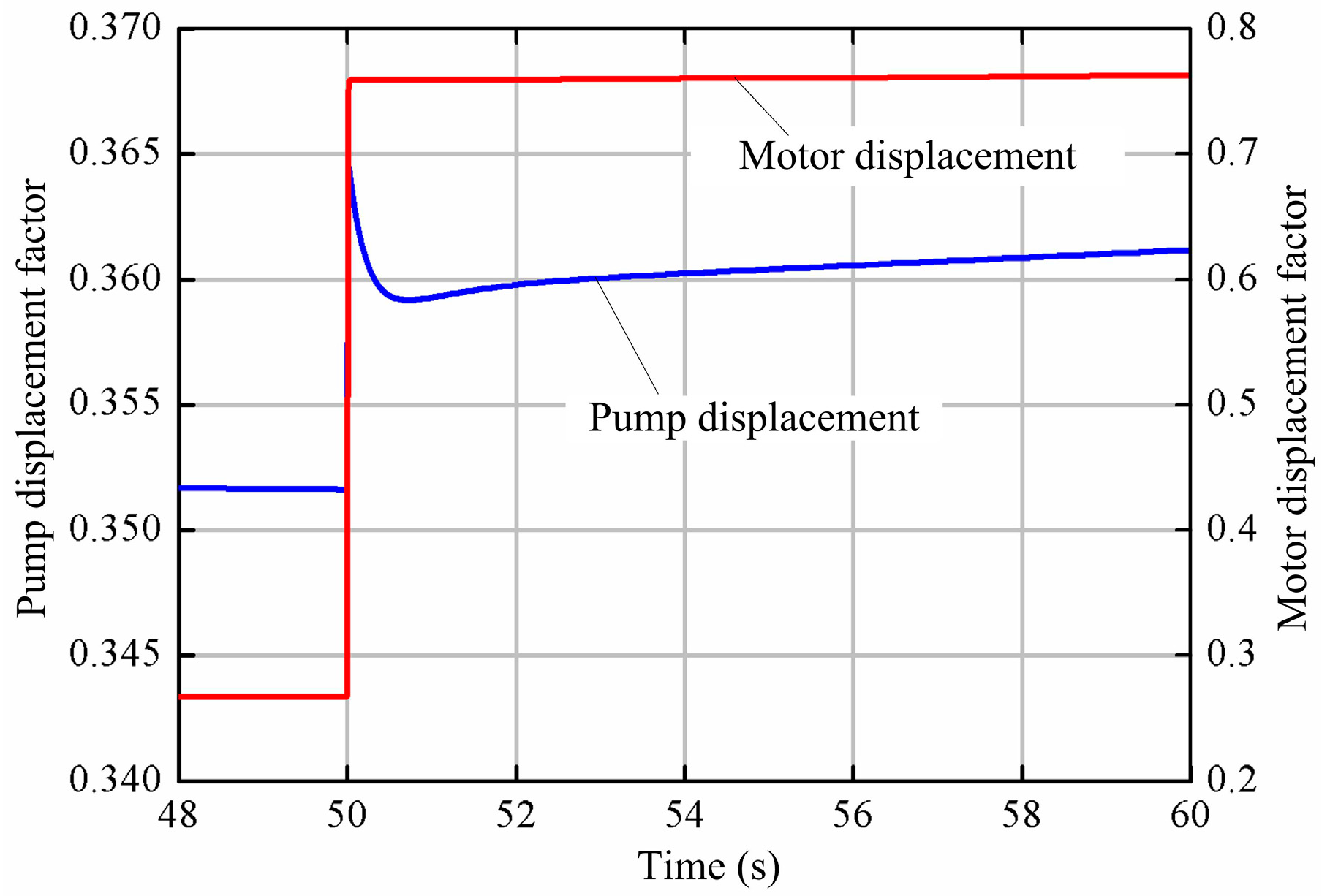

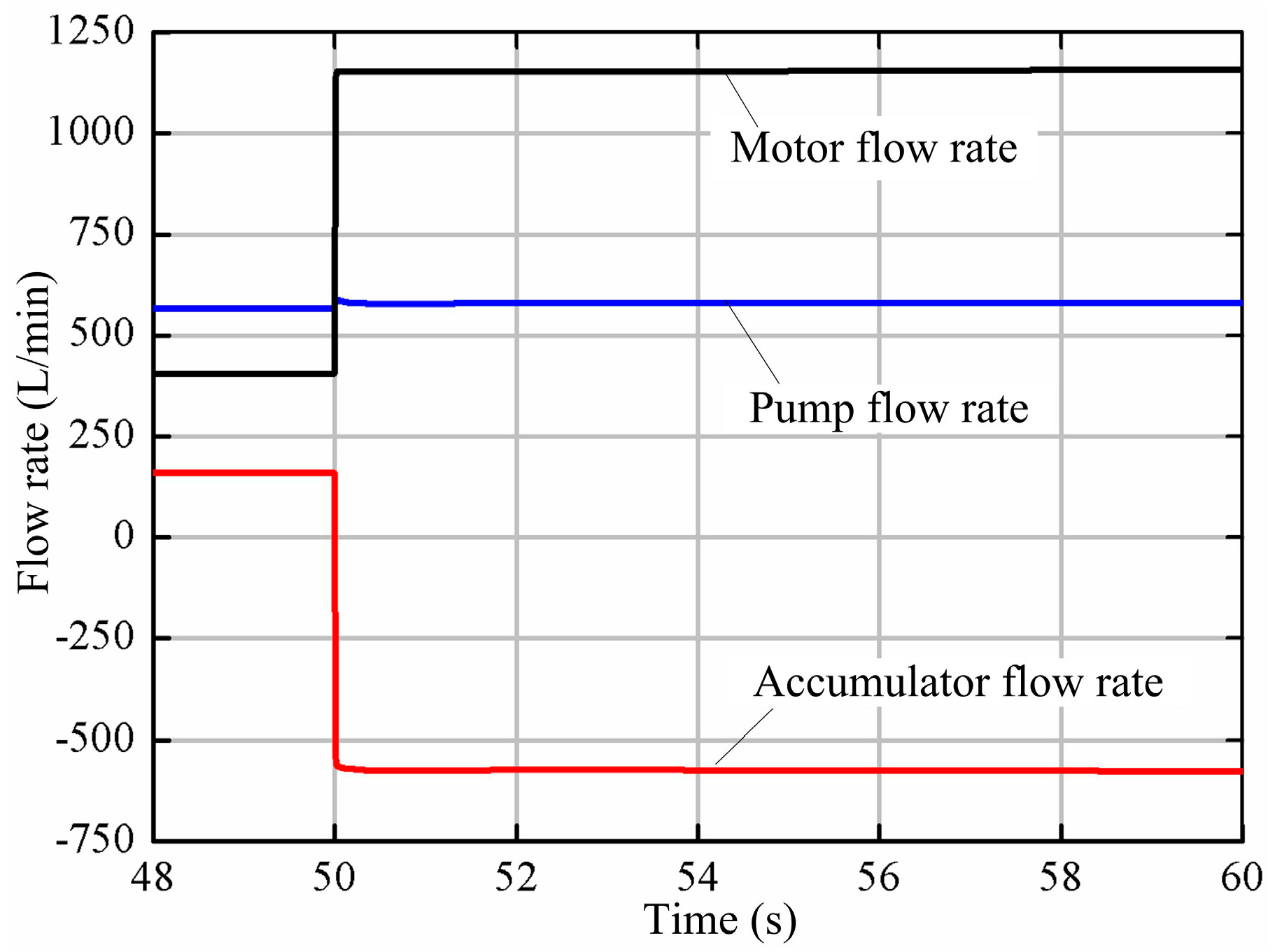

5.2.1. Step Changes of Wind Speed and Rotor Speed Input

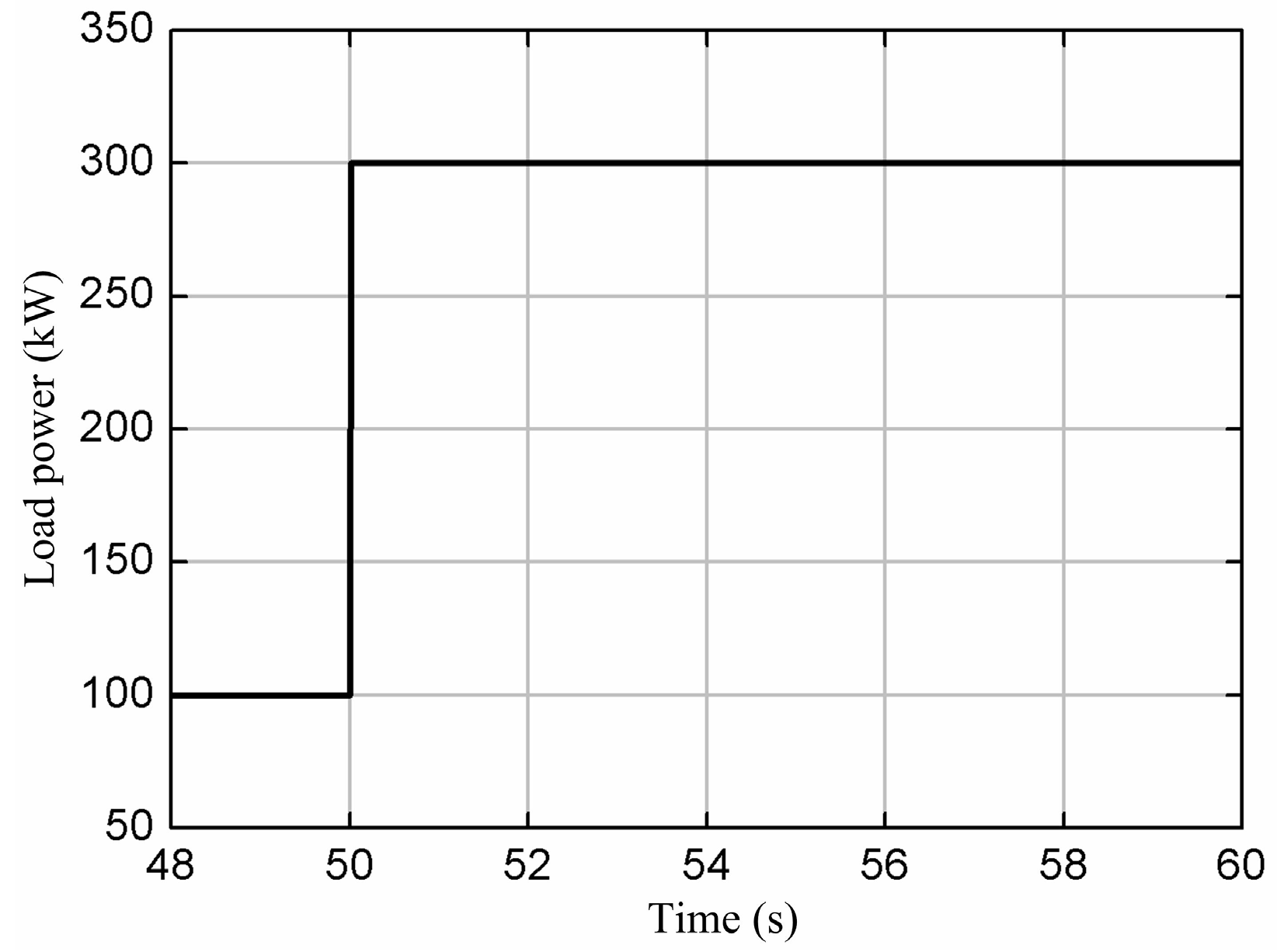

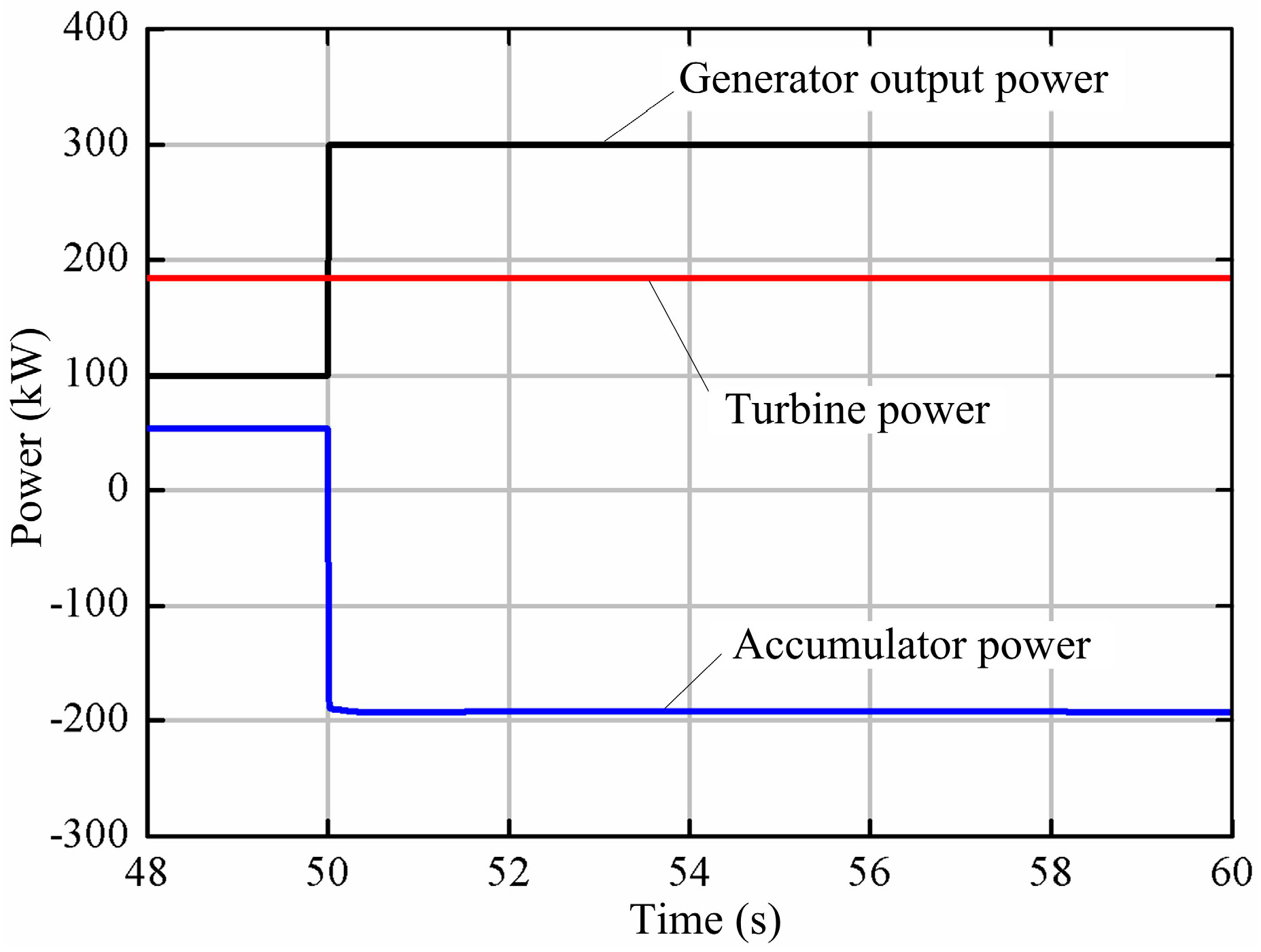

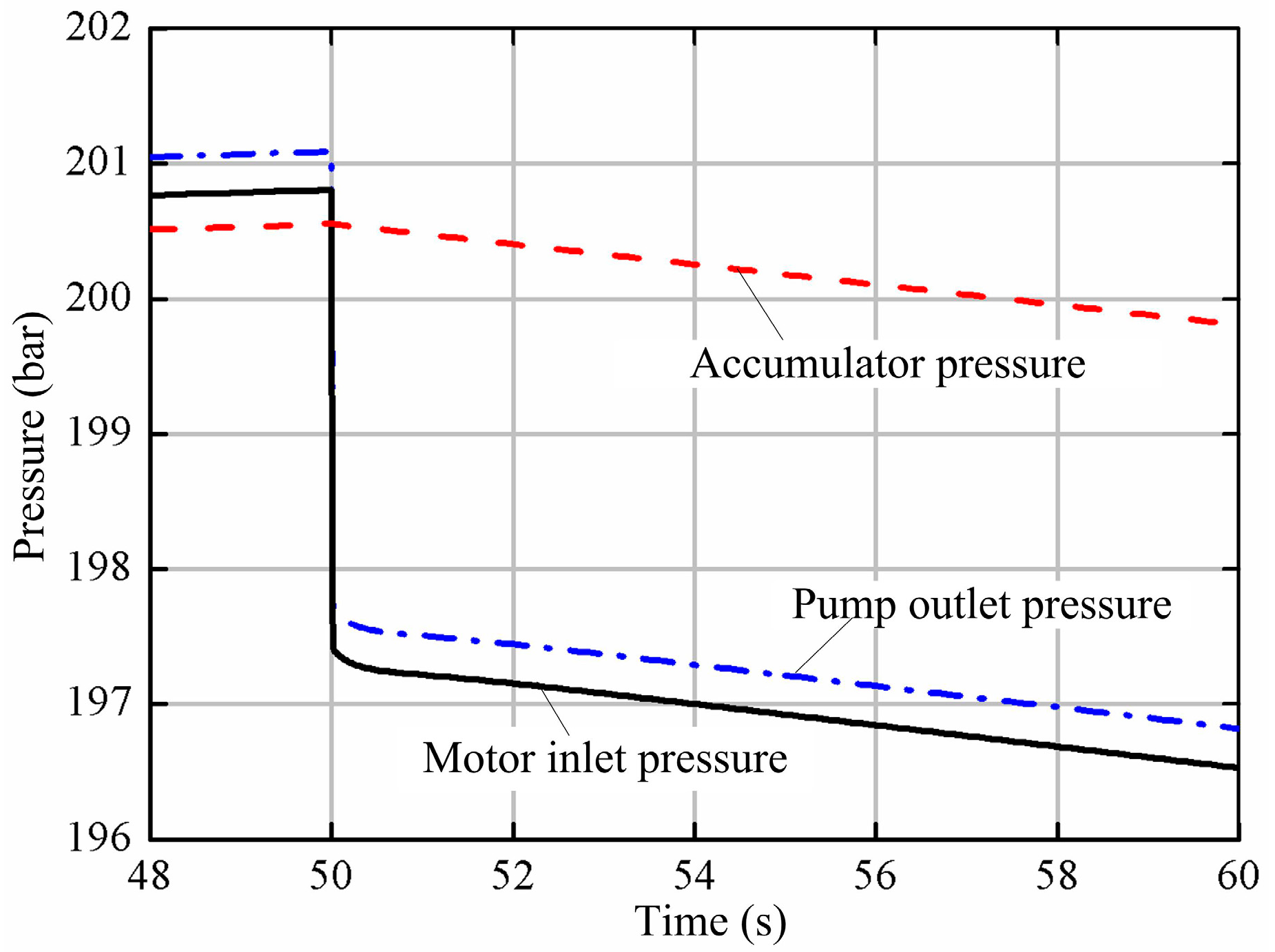

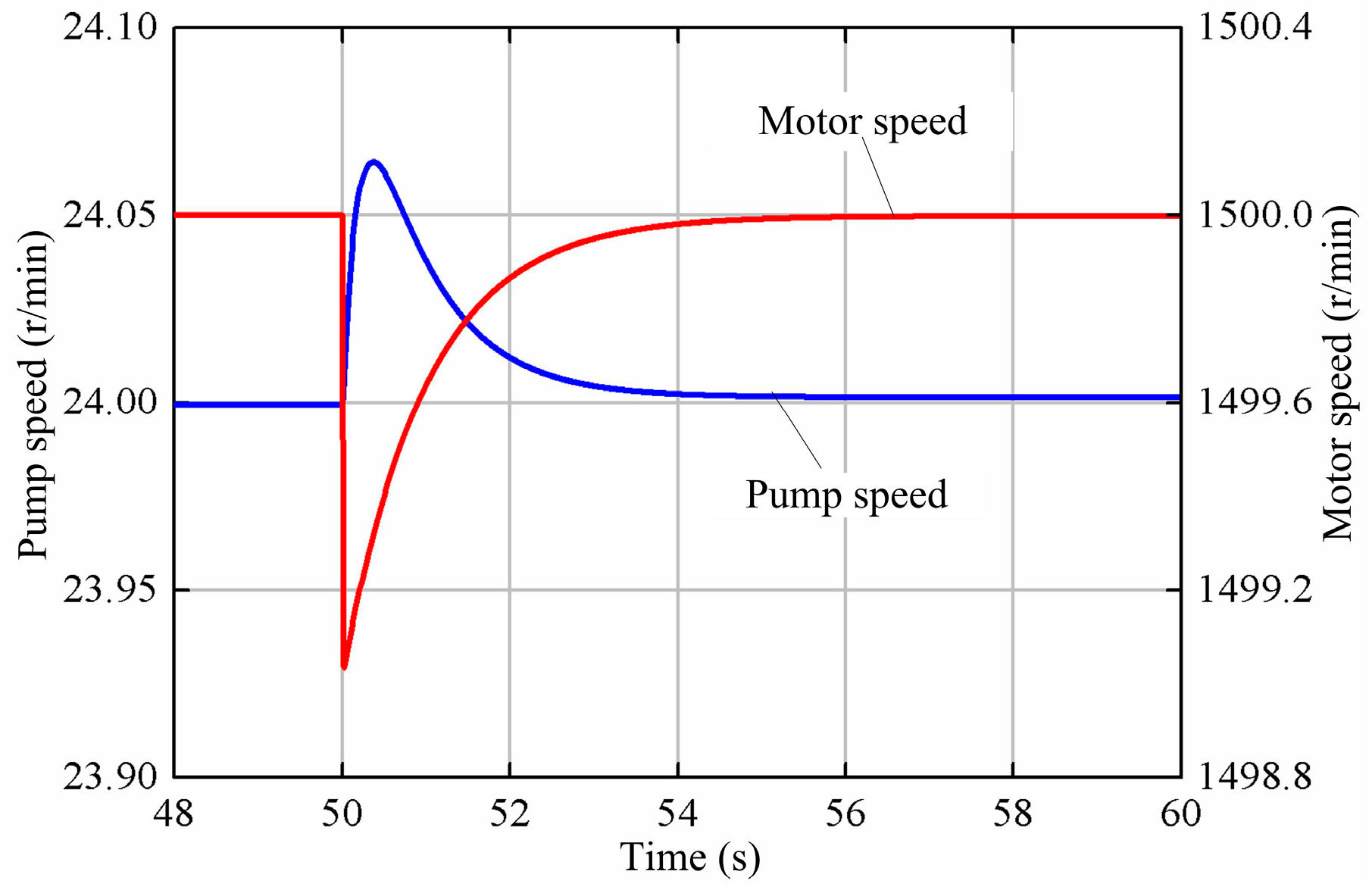

5.2.2. Step Change of Load Power

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Cheng, M.; Zhu, Y. The state of the art of wind energy conversion systems and technologies: A review. Energy Convers. Manag. 2014, 88, 332–347. [Google Scholar] [CrossRef]

- BoroumandJazi, G.; Rismanchi, B.; Saidur, R. Technical characteristic analysis of wind energy conversion systems for sustainable development. Energy Convers. Manag. 2013, 69, 87–94. [Google Scholar] [CrossRef]

- Global Wind Energy Council (GWEC). Global Wind Report: Annual Market Update; GWEC: Brussels, Belgium, 2016. [Google Scholar]

- Ribrant, J.; Bertling, L. Survey of failures in wind power systems with focus on Swedish wind power plants during 1997–2005. In Proceedings of the 2007 IEEE Power Engineering Society General Meeting, Tampa, FL, USA, 24–28 June 2007. [Google Scholar]

- Polinder, H.; Van der Pijl, F.F.; De Vilder, G.J.; Tavner, P.J. Comparison of direct-drive and geared generator concepts for wind turbines. IEEE Trans. Energy Convers. 2006, 21, 725–733. [Google Scholar] [CrossRef]

- Diepeveen, N.F.B.; Jarquin Laguna, A. Dynamic modeling of fluid power transmissions for wind turbines. In Proceedings of the EWEA Offshore 2011 Conference, Amsterdam, The Netherlands, 29 November–1 December 2011. [Google Scholar]

- Cai, M.; Wang, Y.; Jiao, Z.; Shi, Y. Review of fluid and control technology of hydraulic wind turbines. Front. Mech. Eng. 2017, 12, 312–320. [Google Scholar] [CrossRef] [Green Version]

- Pusha, A.; Izadian, A.; Hamzehlouia, S.; Girrens, N.; Anwar, S. Modeling of gearless wind power transfer. In Proceedings of the 2011 37th Annual Conference on IEEE Industrial Electronics Society (IECON), Melbourne, Australia, 7–10 November 2011. [Google Scholar]

- Dolan, B.; Aschemann, H. Control of a wind turbine with a hydrostatic transmission—An extended linearisation approach. In Proceedings of the 2012 17th International Conference on Methods and Models in Automation and Robotics (MMAR), Miedzyzdrojie, Poland, 27–30 August 2012. [Google Scholar]

- Skaare, B.; Hörnsten, B.; Nielsen, F.G. Modeling, simulation and control of a wind turbine with a hydraulic transmission system. Wind Energy 2013, 16, 1259–1276. [Google Scholar] [CrossRef]

- Izadian, A.; Hamzehlouia, S.; Deldar, M.; Anwar, S. A hydraulic wind power transfer system: Operation and modeling. IEEE Trans. Sustain. Energy 2014, 5, 457–465. [Google Scholar] [CrossRef]

- Do, H.; Ahn, K. A Study of Wind Energy Conversion System by a Secondary Control Hydrostatic Transmission. J. Drive Control 2013, 10, 21–28. [Google Scholar] [CrossRef] [Green Version]

- Díaz-González, F.; Sumper, A.; Gomis-Bellmunt, O.; Villafáfila-Robles, R. A review of energy storage technologies for wind power applications. Renew. Sustain. Energy Rev. 2012, 16, 2154–2171. [Google Scholar] [CrossRef]

- Martínez-Lucas, G.; Sarasúa, J.I.; Sánchez-Fernández, J.Á. Frequency Regulation of a Hybrid. Wind–Hydro Power Plant in an Isolated Power System. Energies 2018, 11, 239. [Google Scholar] [CrossRef]

- Martínez-Lucas, G.; Sarasúa, J.I.; Sánchez-Fernández, J.Á. Eigen analysis of wind–hydro joint frequency regulation in an isolated power system. Int. J. Electr. Power Energy Syst. 2018, 103, 511–524. [Google Scholar] [CrossRef]

- Weitzel, T.; Glock, C.H. Energy management for stationary electric energy storage systems: A systematic literature review. Eur. J. Oper. Res. 2018, 264, 582–606. [Google Scholar] [CrossRef]

- Marchi, B.; Pasetti, M.; Zanoni, S. Life cycle cost analysis for BESS optimal sizing. Energy Procedia 2017, 113, 127–134. [Google Scholar] [CrossRef]

- Vaezi, M.; Izadian, A. Energy storage techniques for hydraulic wind power systems. In Proceedings of the 2014 International Conference on Renewable Energy Research and Application (ICRERA), Milwaukee, WI, USA, 19–22 October 2014. [Google Scholar]

- Saadat, M.; Shirazi, F.A.; Li, P.Y. Modeling and control of an open accumulator Compressed Air Energy Storage (CAES) system for wind turbines. Appl. Energy 2015, 137, 603–616. [Google Scholar] [CrossRef]

- Fan, Y.; Mu, A.; Ma, T. Study on the application of energy storage system in offshore wind turbine with hydraulic transmission. Energy Convers. Manag. 2016, 110, 338–346. [Google Scholar] [CrossRef]

- Fan, Y.; Mu, A.; Ma, T. Modeling and control of a hybrid wind-tidal turbine with hydraulic accumulator. Energy 2016, 112, 188–199. [Google Scholar] [CrossRef]

- Ali, A.E.; Libardi, N.C.; Anwar, S.; Izadian, A. Design of a compressed air energy storage system for hydrostatic wind turbines. AIMS Energy 2018, 6, 229–244. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, G.; Wei, L.; Yue, D. Variable speed and constant frequency control of hydraulic wind turbine with energy storage system. Adv. Mech. Eng. 2017, 9, 1–10. [Google Scholar] [CrossRef]

- Heier, S. Grid Integration of Wind Energy: Onshore and Offshore Conversion Systems, 3rd ed.; John Wiley & Sons: Chichester, UK, 2014; pp. 43–44. ISBN 978-1-119-96294-6. [Google Scholar]

- Xu, M.; Yu, X.; Wu, X.M.; Chen, G.J. State-space modeling and analysis of power assist unit-based variable-speed pump-controlled-motor drive system. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 1–8. [Google Scholar] [CrossRef]

- Merritt, H. Hydraulic Control Systems; John Wiley & Sons: Hoboken, NJ, USA, 1991; pp. 152–156. ISBN 978-0-471-59617-2. [Google Scholar]

- Jen, Y.; Lee, C. Robust speed control of a pump-controlled motor system. IEE Proc. D Control Theory Appl. 1992, 139, 503–510. [Google Scholar] [CrossRef]

- Hernandez, R.G.; Ramirez, R.G. Modeling and control of a wind turbine synchronous generator. In Proceedings of the Electronics, Robotics and Automotive Mechanics Conference (CERMA), Cuernavaca, Mexico, 15–18 November 2011. [Google Scholar]

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Rotor diameter | D | 43 | m |

| Swept area | A | 1453 | m2 |

| Hub height | H | 46 | m |

| Cut-in wind speed | Vin | 3.5 | m/s |

| Cut-out wind speed | Vout | 25 | m/s |

| Rated wind speed | Vrated | 15.5 | m/s |

| Rated power | Prated | 600 | kW |

| Maximum rotor speed | Rp | 27 | r/min |

| Pump maximum displacement | Vp | 67,000 | cm3/rev |

| Moment of inertia | Jp | 20,000 | kg·m2 |

| Coefficient of viscosity | Bp | 50 | Nm/(r/min) |

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Accumulator volume | V0 | 6000 | L |

| Gas precharge pressure | P0 | 120 | bar |

| Accumulator pressure | Pa | 210 | bar |

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Motor maximum displacement | Vm | 500 | cm3/rev |

| Number of pole pairs | P | 2 | |

| Stator winding resistance | Ra | 0.006 | Ω |

| Synchronous speed | Rg | 1500 | r/min |

| Moment of inertia | Jm | 60 | kg·m2 |

| Coefficient of viscosity | Bm | 0.05 | Nm/(r/min) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, L.; Liu, Z.; Zhao, Y.; Wang, G.; Tao, Y. Modeling and Control of a 600 kW Closed Hydraulic Wind Turbine with an Energy Storage System. Appl. Sci. 2018, 8, 1314. https://doi.org/10.3390/app8081314

Wei L, Liu Z, Zhao Y, Wang G, Tao Y. Modeling and Control of a 600 kW Closed Hydraulic Wind Turbine with an Energy Storage System. Applied Sciences. 2018; 8(8):1314. https://doi.org/10.3390/app8081314

Chicago/Turabian StyleWei, Liejiang, Zengguang Liu, Yuyang Zhao, Gang Wang, and Yanhua Tao. 2018. "Modeling and Control of a 600 kW Closed Hydraulic Wind Turbine with an Energy Storage System" Applied Sciences 8, no. 8: 1314. https://doi.org/10.3390/app8081314