Strength, Permeability, and Freeze-Thaw Durability of Pervious Concrete with Different Aggregate Sizes, Porosities, and Water-Binder Ratios

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mix Design

2.3. Testing Methods

3. Results and Discussion

3.1. Analysis of Orthogonal Test Results

3.1.1. Range Analysis

3.1.2. Variance Analysis

3.2. Influence Factor Analysis for PC Properties

3.2.1. Density and Porosity

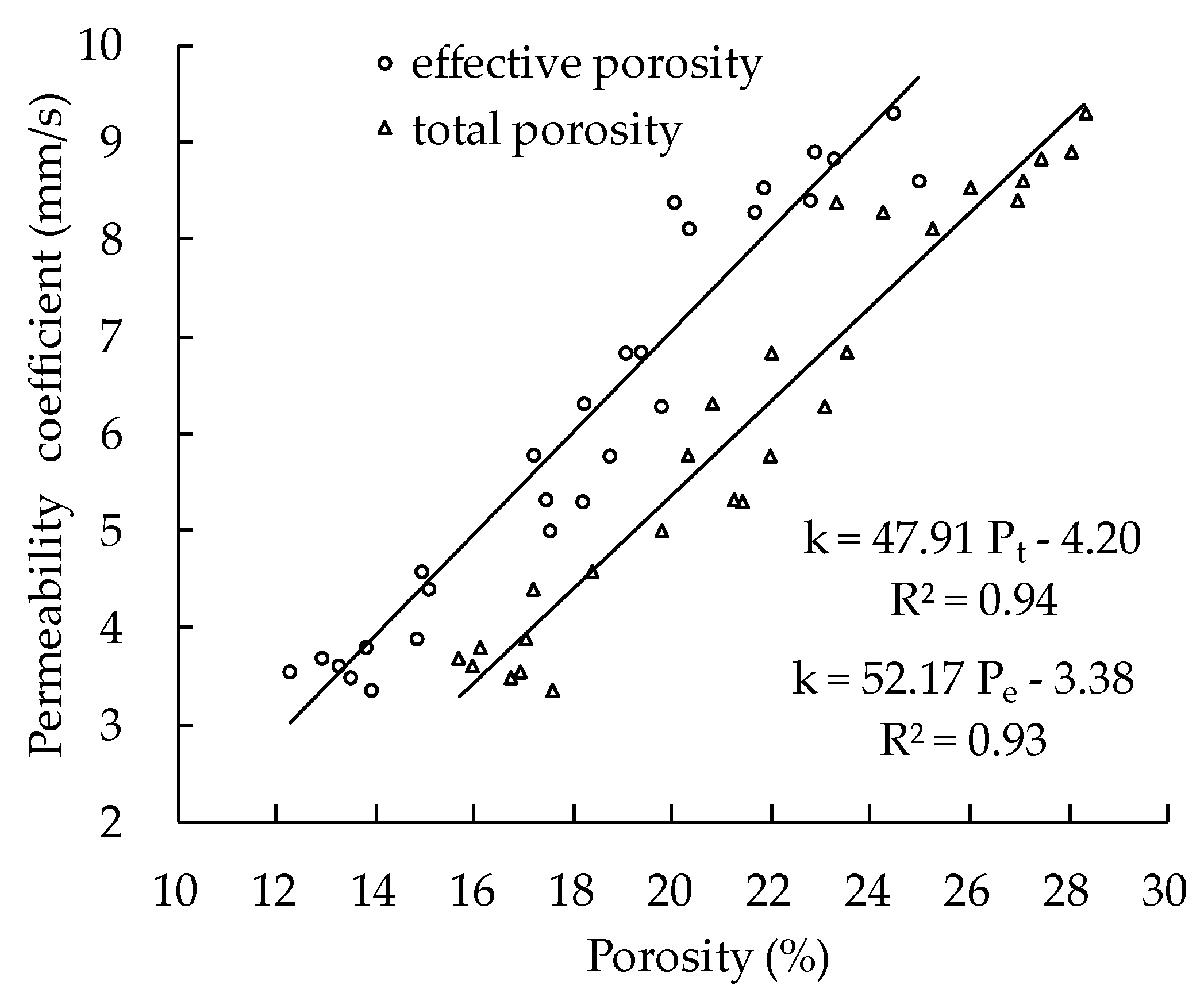

3.2.2. Permeability Coefficient

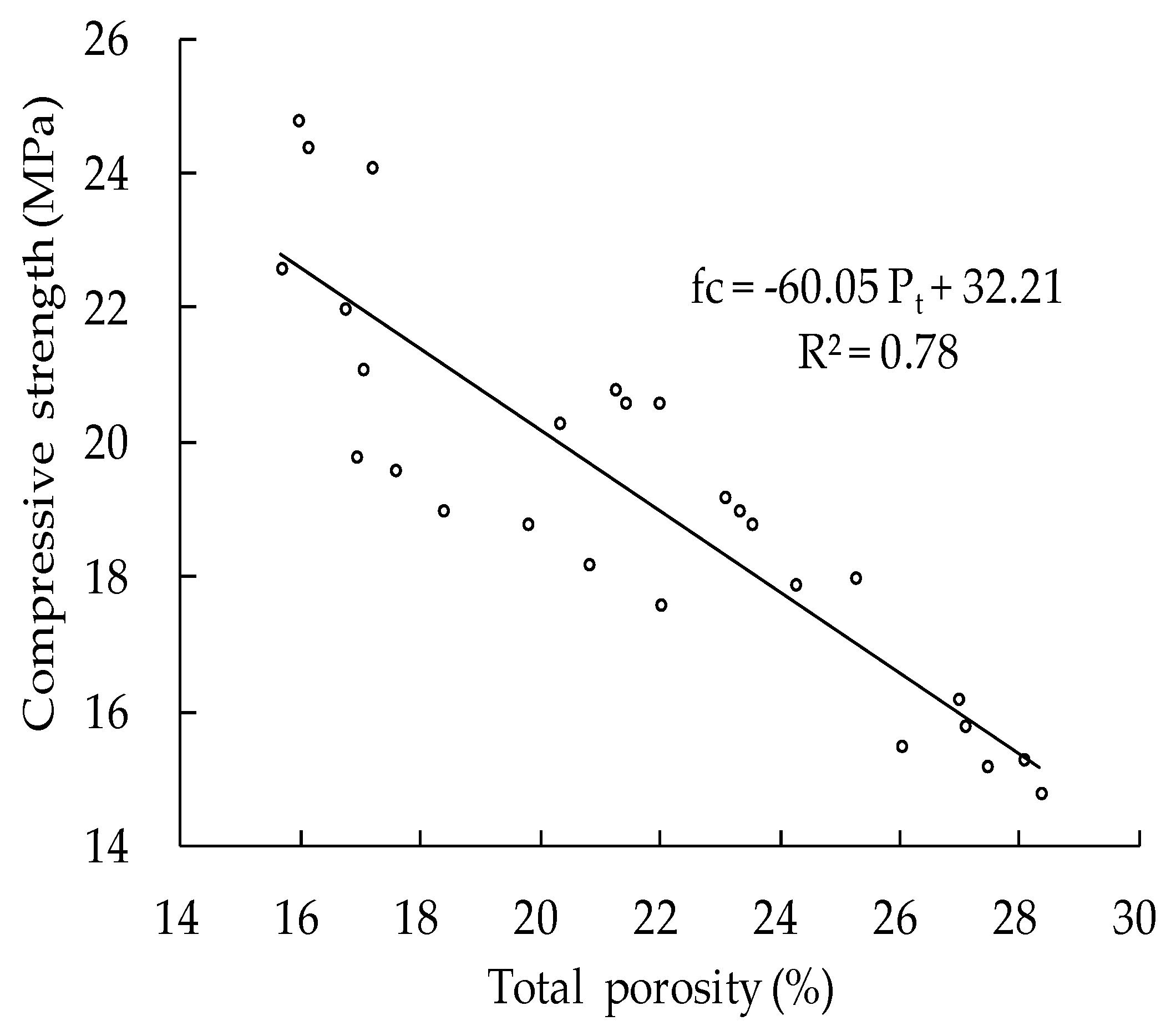

3.2.3. Compressive Strength

3.2.4. Flexural Strength

3.2.5. Freeze-Thaw Cycles

4. Conclusions

- The density of PC mixtures changes from 2061 kg/m3 to 1804 kg/m3 as total porosity increases from 16.4% to 27.1%. Density decreases with an increase of total porosity. Linearity can be used to describe the relationship between them, and the correlation coefficient reaches 0.94.

- The permeability of PC is about 3.70 mm/s to 8.82 mm/s when effective porosity is 13.7% to 23.8%. The variance analysis indicates that effective porosity is the determining factor influencing permeability. Coarse aggregate size and water-binder ratio have little contribution to permeability.

- Compressive strength of PC is 15.4 MPa to 24.4 MPa. Compressive strength decreases with the increase of total porosity. Coarse aggregate size also has an influence on compressive strength. Small coarse aggregate size is superior to large coarse aggregate size in improving compressive strength when porosity is the same. Flexural strength changes from 3.03 MPa to 4.83 MPa. The influences of coarse aggregate size and porosity on flexural strength are the same as on compressive strength.

- The freeze-thaw damage pattern of PC is different from that of ordinary concrete. It is not recommended to use the loss of mass as the evaluation index. Freeze-thaw cycles test indicates that coarse aggregate size is the main factor affecting PC freeze-thaw property. Small coarse aggregate size results in better freeze-thaw durability. In addition, porosity is another important factor that contributes to freeze-thaw durability. Higher porosity generates lower freeze-thaw durability.

- Porosity is the most important factor determining PC mixture properties (permeability, compressive strength, flexural strength, and freeze-thaw property). Higher porosity improves permeability but decreases the mechanical properties of PC. When establishing the optimum mix design, it is necessary to make a trade-off between permeability, mechanical strength, and freeze-thaw durability according to the practical engineering requirement.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bai, X.; Dawson, R.J.; Urge-Vorsatz, D.; Delgado, G.C.; Salisu Barau, A.; Dhakal, S.; Dodman, D.; Leonardsen, L.; Masson-Delmotte, V.; Roberts, D.C.; et al. Six research priorities for cities and climate change. Nature 2018, 555, 23–25. [Google Scholar] [CrossRef] [PubMed]

- Richards, D.R.; Edwards, P.J. Using water management infrastructure to address both flood risk and the urban heat island. Int. J. Water Resour. Dev. 2017, 34, 1–9. [Google Scholar] [CrossRef]

- Liu, Y.; Engel, B.A.; Flanagan, D.C.; Gitau, M.W.; McMillan, S.K.; Chaubey, I. A review on effectiveness of best management practices in improving hydrology and water quality: Needs and opportunities. Sci. Total Environ. 2017, 601, 580–593. [Google Scholar] [CrossRef] [PubMed]

- Peng, H.; Yin, J.; Song, W.M. Mechanical and hydraulic behaviors of eco-friendly pervious concrete incorporating fly ash and blast furnace slag. Appl. Sci. 2018, 8, 859. [Google Scholar] [CrossRef]

- Neithalath, N.; Sumanasooriya, M.S.; Deo, O. Characterizing pore volume, sizes, and connectivity in pervious concretes for permeability prediction. Mater. Charact. 2010, 61, 802–813. [Google Scholar] [CrossRef]

- Kim, H.K.; Lee, H.K. Acoustic absorption modeling of porous concrete considering the Gradation and shape of aggregate sand void ratio. J. Sound Vib. 2010, 329, 866–879. [Google Scholar] [CrossRef]

- Gonzalo, C.G.; Roque, B.T.; Luis, A.S.F. Influence of pervious pavement systems on heat dissipation from a horizontal geothermal system. Eur. J. Environ. Civ. Eng. 2013, 17, 956–967. [Google Scholar]

- Ngohpok, C.; Sata, V.; Satiennam, T.; Klungboonkrong, P.; Chindaprasirt, P. Mechanical properties, thermal conductivity, and sound absorption of pervious concrete containing recycled concrete and bottom ash aggregates. KSCE J. Civ. Eng. 2018, 22, 1369–1376. [Google Scholar] [CrossRef]

- Manan, A.; Ahamd, M.; Ahamd, A.; Basit, A.; Khan, M.N.A. Experimental investigation of compressive strength and infiltration rate of pervious concrete by fully reduction of sand. Civ. Eng. J. 2018, 4, 724–731. [Google Scholar] [CrossRef]

- Vadas, T.M.; Smith, M.; Luan, H.W. Leaching and retention of dissolved metals in particulate loaded pervious concrete columns. J. Environ. Manag. 2017, 190, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Shabalalaa, A.N.; Ekolua, S.O.; Diopb, S.; Solomon, F. Pervious concrete reactive barrier for removal of heavy metals from acid mine drainage−column study. J. Hazard. Mater. 2017, 323, 641–653. [Google Scholar] [CrossRef] [PubMed]

- Qin, Y.H.; Hiller, J.E. Water availability near the surface dominates the evaporation of pervious concrete. Constr. Build. Mater. 2016, 111, 77–84. [Google Scholar] [CrossRef]

- Hu, M.; Zhang, X.; Siu, Y.L.; Li, Y.; Tanaka, K.; Yang, H.; Xu, Y. Flood mitigation by permeable pavements in Chinese sponge city construction. Water 2018, 10, 172. [Google Scholar] [CrossRef]

- Ho, H.L.; Huang, R.; Hwang, L.C.; Lin, W.T.; Hsu, H.M. Waste-Based Pervious Concrete for Climate-Resilient Pavements. Materials 2018, 11, 900. [Google Scholar] [CrossRef] [PubMed]

- Andrés-Valeri, V.C.; Marchioni, M.; Sañudo-Fontaneda, L.A.; Giustozzi, F.; Becciu, G. Laboratory assessment of the infiltration capacity reduction in clogged porous mixture surfaces. Sustainability 2016, 8, 751. [Google Scholar] [CrossRef]

- Newman, A.P.; Aitken, D.; Antizar-Ladislao, B. Stormwater quality performance of a macropervious pavement car park installation equipped with channel drain based oil and silt retention devices. Water Res. 2013, 47, 7327–7336. [Google Scholar] [CrossRef] [PubMed]

- Brahim, A.; Mahmoud, E.; Yamin, M.; Patibandla, V.C. Experimental study on Portland cement pervious concrete mechanical and hydrological properties. Constr. Build. Mater. 2014, 50, 524–529. [Google Scholar] [CrossRef]

- Chandrappa, A.K.; Biligiri, K.P. Pervious concrete as a sustainable pavement material—Research findings and future prospects: A state-of-the-art review. Constr. Build. Mater. 2016, 111, 262–274. [Google Scholar] [CrossRef]

- Deo, O.; Neithalath, N. Compressive behavior of pervious concretes and a quantification of the influence of random pore structure features. Mater. Sci. Eng. A-Struct. 2010, 528, 402–412. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, K.J.; Wang, X.H.; Zhou, W.F. Strength, fracture and fatigue of pervious concrete. Constr. Build. Mater. 2013, 42, 97–104. [Google Scholar] [CrossRef]

- Li, Z.Y.; Yang, J.; Li, S.B.; Xu, X.Y.; Song, H.Z. Orthogonal Analysis of Water Permeability of Pervious Concrete. Asian J. Chem. 2014, 26, 1811–1815. [Google Scholar]

- Nguyen, D.H.; Sebaibi, N.; Boutouil, M.; Leleyter, L.; Baraud, F. A modified method for the design of pervious concrete mix. Constr. Build. Mater. 2014, 73, 271–282. [Google Scholar] [CrossRef]

- Kayhanian, M.; Anderson, D.; Harvey, J.T.; Jones, D.; Muhunthan, B. Permeability measurement and scan imaging to assess clogging of pervious concrete pavements in parking lots. J. Environ. Manag. 2012, 95, 114–123. [Google Scholar] [CrossRef] [PubMed]

- Chandrappa, A.K.; Biligiri, K.P. Comprehensive investigation of permeability characteristics of pervious concrete: A hydrodynamic approach. Constr. Build. Mater. 2016, 123, 627–637. [Google Scholar] [CrossRef]

- Zhong, R.; Xu, M.; Netto, R.V.; Wille, K. Influence of pore tortuosity on hydraulic conductivity of pervious concrete: Characterization and modeling. Constr. Build. Mater. 2016, 125, 1158–1168. [Google Scholar] [CrossRef]

- Gaedicke, C.; Torres, A.; Huynh, K.C.T.; Marines, A. A method to correlate splitting tensile strength and compressive strength of pervious concrete cylinders and cores. Constr. Build. Mater. 2016, 125, 271–278. [Google Scholar] [CrossRef]

- Zhong, R.; Wille, K. Compression response of normal and high strength pervious concrete. Constr. Build. Mater. 2016, 109, 177–187. [Google Scholar] [CrossRef]

- Zhong, R.; Wille, K. Linking pore system characteristics to the compressive behavior of pervious concrete. Cem. Concr. Compos. 2016, 70, 130–138. [Google Scholar] [CrossRef]

- Li, J.S.; Zhang, Y.; Liu, G.L.; Peng, X.H. Preparation and performance evaluation of an innovative pervious concrete pavement. Constr. Build. Mater. 2017, 138, 479–485. [Google Scholar] [CrossRef]

- Akand, L.; Yang, M.J.; Gao, Z.L. Characterization of pervious concrete through image based micromechanical modeling. Constr. Build. Mater. 2016, 114, 547–555. [Google Scholar] [CrossRef]

- Pieralisi, R.; Cavalaro, S.H.P.; Aguado, A. Discrete element modelling of the fresh state behavior of pervious concrete. Cem. Concr. Res. 2016, 90, 6–18. [Google Scholar] [CrossRef]

- Samuel, M.; Eric, S.; Fabien, P. Impact of Pervious Concrete Porosity on Permeability by 3D Image Analysis. In Proceedings of the Conference on Pervious Concrete, Tampa, FL, USA, 4 December 2011. [Google Scholar]

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Technical Specification for Pervious Cement Concrete Pavement; Ministry of Housing and Urban-Ural Construction of the People’s Republic of China: Beijing, China, 2009. (In Chinese)

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Standard for Test Method of Mechanical Properties on Ordinary Concrete; Ministry of Housing and Urban-Ural Construction of the People’s Republic of China: Beijing, China, 2002. (In Chinese)

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete; Ministry of Housing and Urban-Ural Construction of the People’s Republic of China: Beijing, China, 2009. (In Chinese)

- Neville, A.M. Property of Concrete, 4th ed.; China Architecture and Building Press: Beijing, China, 2009; pp. 199–203. ISBN 9787112127436. [Google Scholar]

| Density (g/cm3) | Specific Surface Area (m2/kg) | Setting Time (min) | Compressive Strength (MPa) | Flexural Strength (MPa) | |||

|---|---|---|---|---|---|---|---|

| Initial Setting | Final Setting | 3d | 28d | 3d | 28d | ||

| 3.16 | 385 | 91 | 145 | 39.3 | 62.2 | 7.0 | 9.1 |

| Size (mm) | Apparent Density (kg/m3) | Bulk Density (kg/m3) | Bulk Porosity (%) | Crushing Value (%) | Needle-Like Particle Content (%) | Water Absorption (%) |

|---|---|---|---|---|---|---|

| 4.75–9.5 | 2749 | 1409 | 48.7 | 9.9 | 7.7 | 1.71 |

| 9.5–13.2 | 2747 | 1459 | 46.9 | 13.4 | 5.4 | 1.66 |

| 13.2–16 | 2726 | 1500 | 45.0 | 14.5 | 4.2 | 1.61 |

| No. | Aggregate Size (mm) | Water-Binder Ratio | Designed Porosity (%) | Coarse Aggregate (kg/m3) | Cement (kg/m3) | Water (kg/m3) | Superplasticizer (kg/m3) |

|---|---|---|---|---|---|---|---|

| 1 | 4.75–9.5 | 0.25 | 15 | 1381 | 590 | 147 | 5.90 |

| 2 | 4.75–9.5 | 0.30 | 20 | 1381 | 465 | 140 | 4.65 |

| 3 | 4.75–9.5 | 0.35 | 25 | 1381 | 359 | 126 | 3.59 |

| 4 | 9.5–13.2 | 0.25 | 20 | 1430 | 475 | 119 | 4.75 |

| 5 | 9.5–13.2 | 0.30 | 25 | 1430 | 359 | 108 | 3.59 |

| 6 | 9.5–13.2 | 0.35 | 15 | 1430 | 478 | 167 | 4.78 |

| 7 | 13.2–16 | 0.25 | 25 | 1470 | 358 | 90 | 3.58 |

| 8 | 13.2–16 | 0.30 | 15 | 1470 | 487 | 146 | 4.87 |

| 9 | 13.2–16 | 0.35 | 20 | 1470 | 379 | 133 | 3.79 |

| No. | Density (kg/m3) | Pt (%) | Pe (%) | k (mm/s) | fc (MPa) | ff (MPa) | Freeze-Thaw Cycles | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean | Sd | Mean | Sd | Mean | Sd | Mean | Sd | Mean | Sd | Mean | Sd | Mode | |

| 1 | 2061 | 18 | 16.4 | 0.5 | 14.0 | 0.8 | 3.95 | 0.34 | 24.4 | 0.3 | 4.83 | 0.03 | 80 |

| 2 | 1943 | 10 | 21.5 | 0.3 | 18.1 | 0.5 | 5.47 | 0.22 | 20.7 | 0.1 | 4.21 | 0.05 | 70 |

| 3 | 1847 | 54 | 25.8 | 1.6 | 21.6 | 1.0 | 8.44 | 0.34 | 17.9 | 1.2 | 3.44 | 0.37 | 70 |

| 4 | 1899 | 47 | 22.3 | 1.4 | 18.8 | 1.1 | 6.31 | 0.43 | 19.4 | 0.6 | 3.64 | 0.09 | 60 |

| 5 | 1838 | 26 | 25.9 | 1.8 | 22.0 | 1.4 | 8.55 | 0.21 | 16.2 | 1.6 | 3.27 | 0.36 | 50 |

| 6 | 2110 | 7 | 16.5 | 0.6 | 13.7 | 0.8 | 3.70 | 0.16 | 21.9 | 0.6 | 4.21 | 0.08 | 70 |

| 7 | 1804 | 8 | 27.1 | 1.0 | 23.8 | 1.4 | 8.82 | 0.35 | 15.4 | 0.4 | 3.03 | 0.06 | 40 |

| 8 | 2044 | 37 | 17.6 | 0.6 | 13.7 | 1.1 | 3.84 | 0.54 | 19.5 | 0.3 | 4.04 | 0.05 | 60 |

| 9 | 1933 | 37 | 20.9 | 0.9 | 18.3 | 0.6 | 6.06 | 0.77 | 18.2 | 0.5 | 3.25 | 0.09 | 50 |

| Index | fc (MPa) | ff (MPa) | k (mm/s) | Freeze-Thaw Cycles | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | W/B | P | A | W/B | P | A | W/B | P | A | W/B | P | |

| K1 | 20.99 | 19.74 | 21.93 | 4.16 | 3.83 | 4.36 | 5.95 | 6.36 | 3.83 | 73.3 | 60.0 | 70.0 |

| K2 | 19.18 | 18.79 | 19.43 | 3.71 | 3.84 | 3.70 | 6.19 | 5.95 | 5.95 | 60.0 | 60.0 | 60.0 |

| K3 | 17.70 | 19.33 | 16.50 | 3.44 | 3.63 | 3.25 | 6.24 | 6.07 | 8.60 | 50.0 | 63.3 | 53.3 |

| R | 3.29 | 0.96 | 5.43 | 0.72 | 0.21 | 1.11 | 0.29 | 0.41 | 4.77 | 23.3 | 3.3 | 16.7 |

| Factors | F0.01 (2,2) | F0.05 (2,2) | fc | ff | k | Freeze-Thaw Cycles | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| F | Significance | F | Significance | F | Significance | F | Significance | |||

| A | 99.0 | 19.0 | 24.3 | * | 81.2 | * | 1.8 | – | 37.0 | * |

| W/B | 99.0 | 19.0 | 1.9 | – | 11.0 | – | 3.5 | – | 1.0 | – |

| P | 99.0 | 19.0 | 65.6 | * | 222.3 | ** | 451.6 | ** | 19.0 | * |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Luo, G.; Wei, H.; Yu, H. Strength, Permeability, and Freeze-Thaw Durability of Pervious Concrete with Different Aggregate Sizes, Porosities, and Water-Binder Ratios. Appl. Sci. 2018, 8, 1217. https://doi.org/10.3390/app8081217

Liu H, Luo G, Wei H, Yu H. Strength, Permeability, and Freeze-Thaw Durability of Pervious Concrete with Different Aggregate Sizes, Porosities, and Water-Binder Ratios. Applied Sciences. 2018; 8(8):1217. https://doi.org/10.3390/app8081217

Chicago/Turabian StyleLiu, Hanbing, Guobao Luo, Haibin Wei, and Han Yu. 2018. "Strength, Permeability, and Freeze-Thaw Durability of Pervious Concrete with Different Aggregate Sizes, Porosities, and Water-Binder Ratios" Applied Sciences 8, no. 8: 1217. https://doi.org/10.3390/app8081217

APA StyleLiu, H., Luo, G., Wei, H., & Yu, H. (2018). Strength, Permeability, and Freeze-Thaw Durability of Pervious Concrete with Different Aggregate Sizes, Porosities, and Water-Binder Ratios. Applied Sciences, 8(8), 1217. https://doi.org/10.3390/app8081217