Renewable Energy Output Tracking Control Algorithm Based on the Temperature Control Load State-Queuing Model

Abstract

:1. Introduction

2. State-Queuing Model of Thermostatically-Controlled Loads

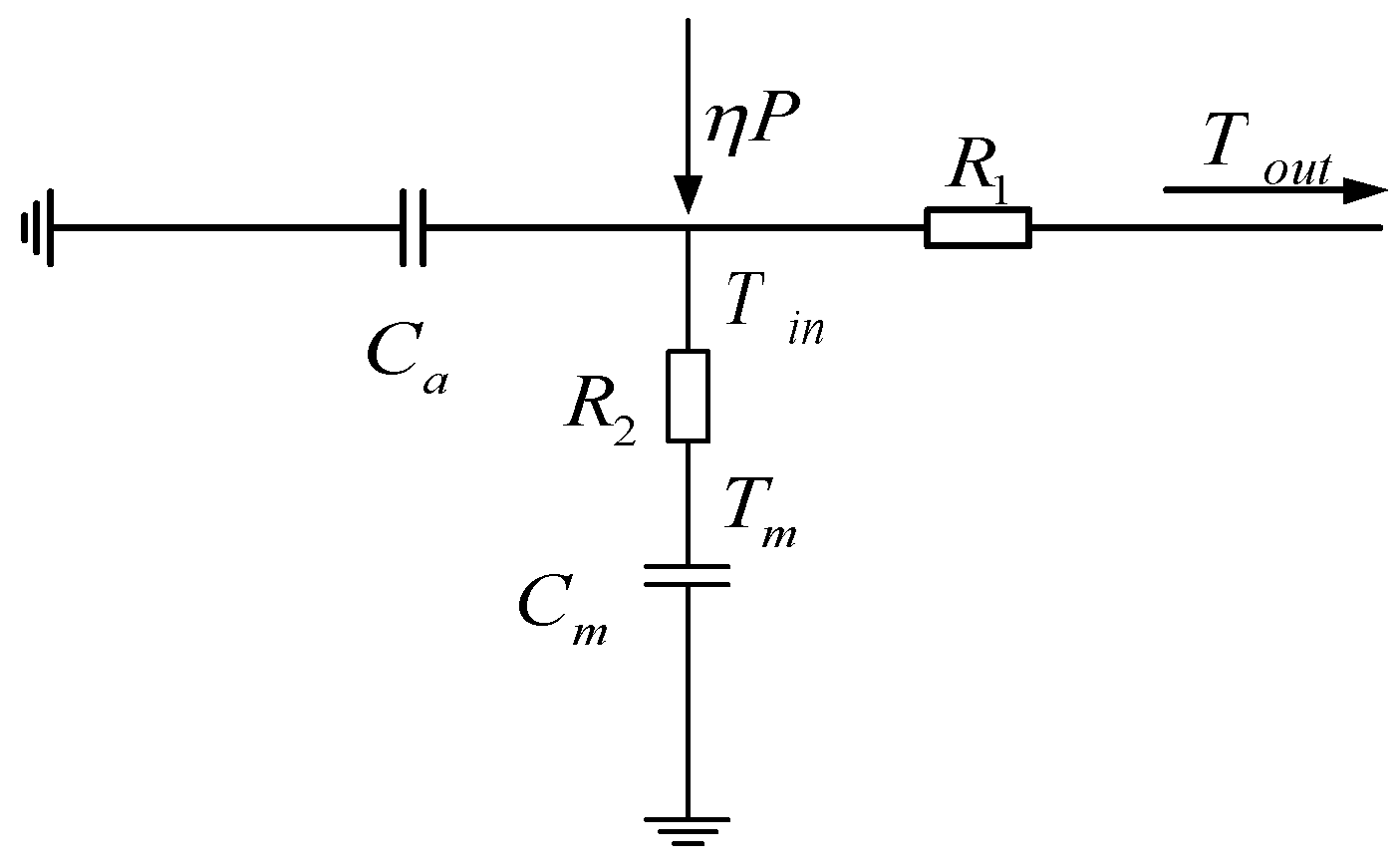

2.1. Thermodynamic Model of Single Air Conditioning

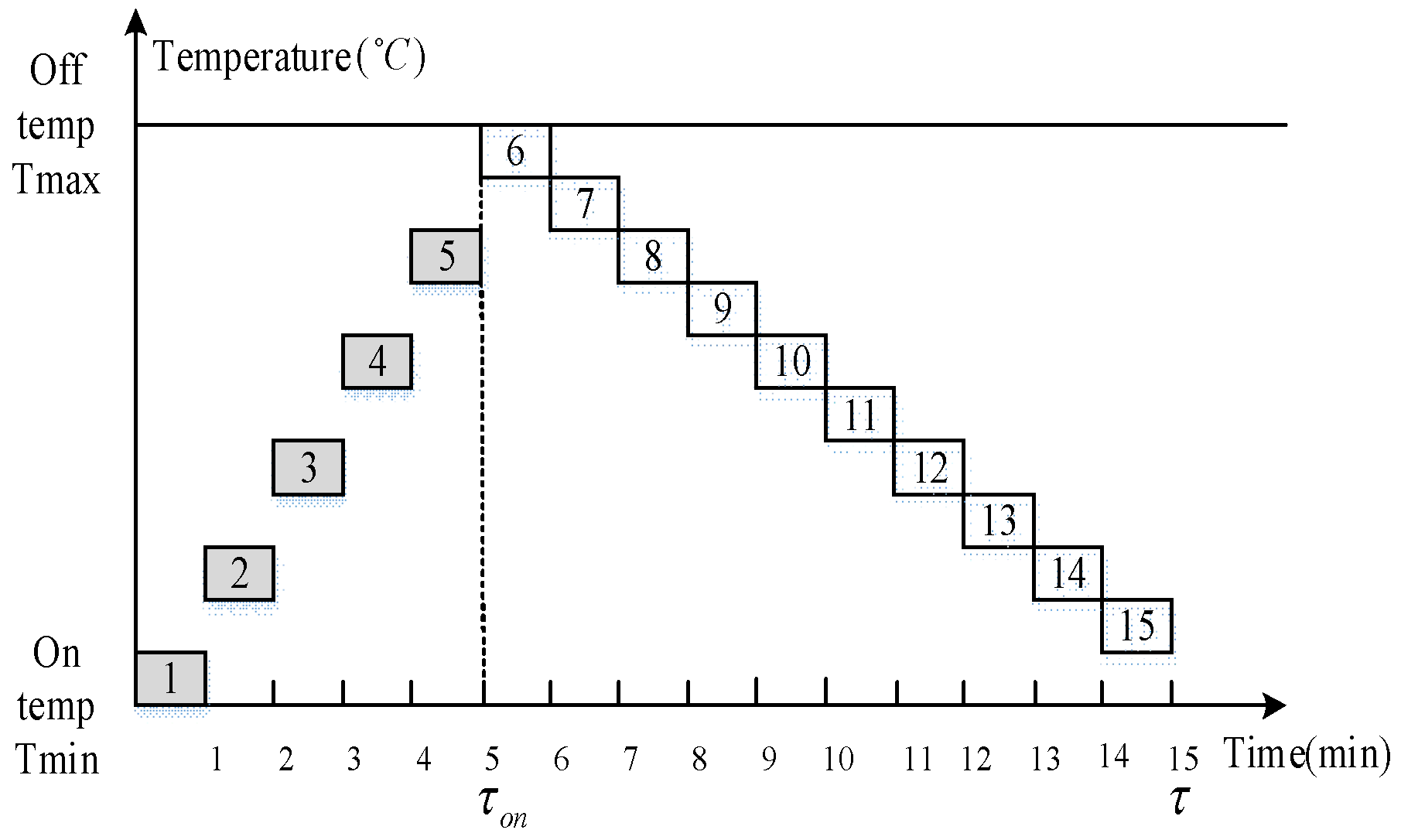

2.2. A State-Queuing Model of Aggregate Air Conditionings

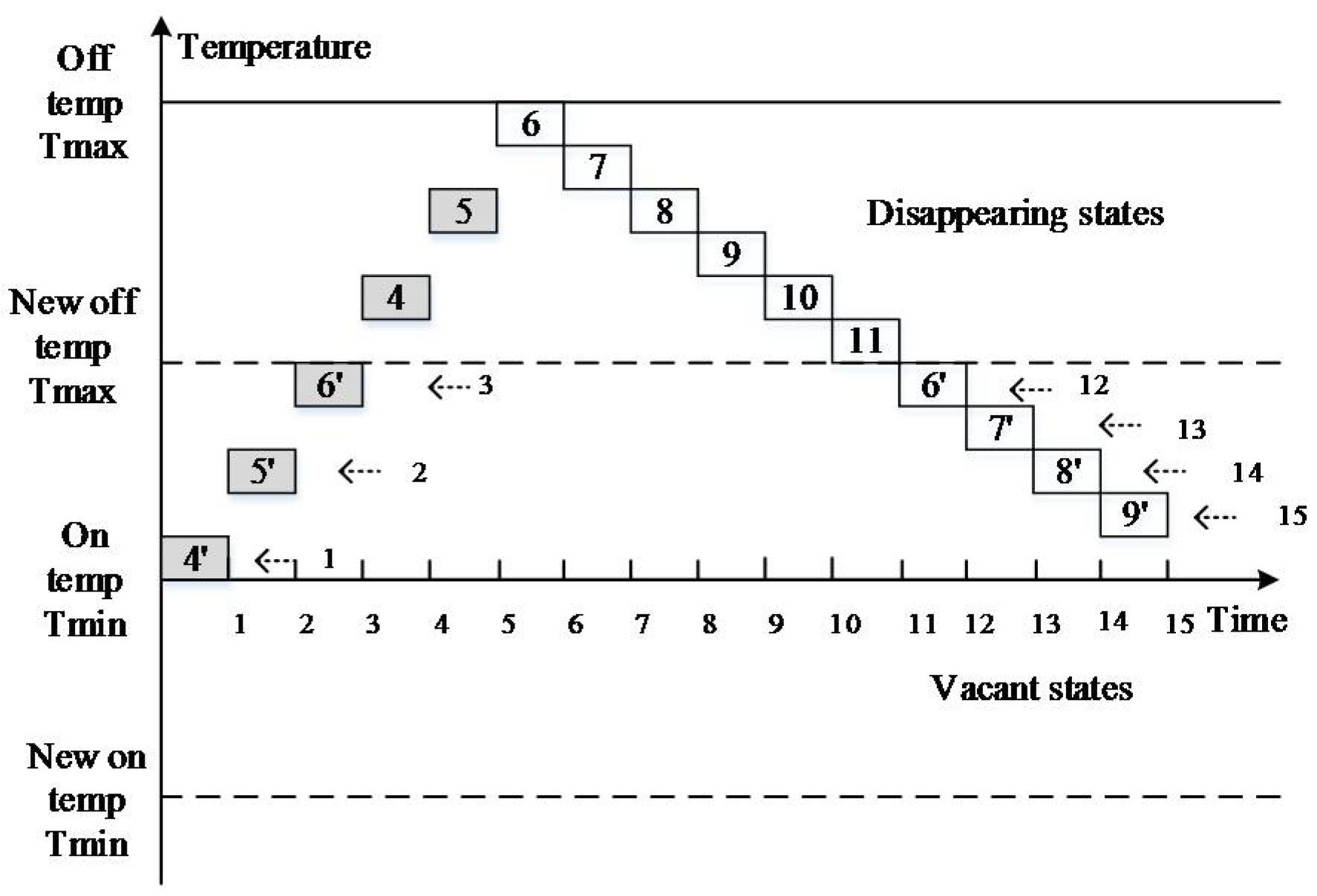

2.3. Characteristics of the State-Queuing Model

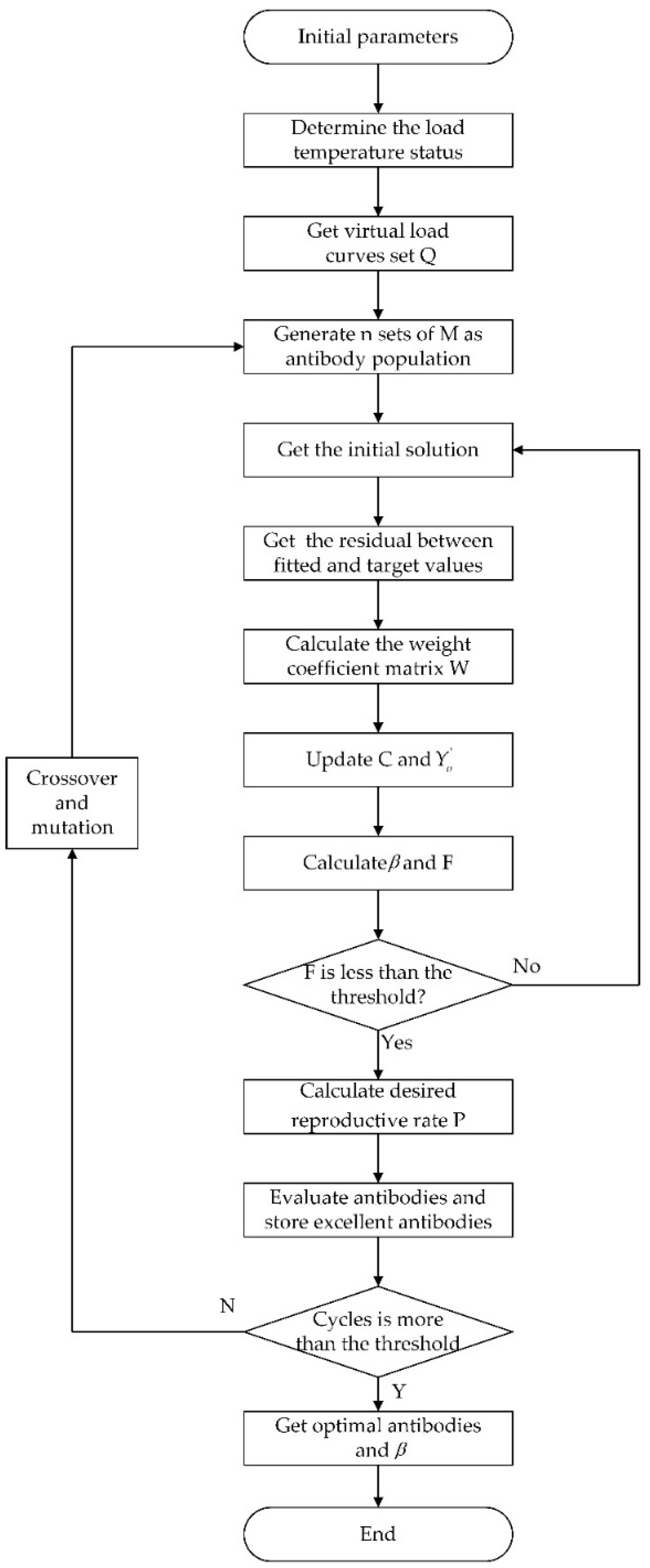

3. Control Algorithm

3.1. Objective Function

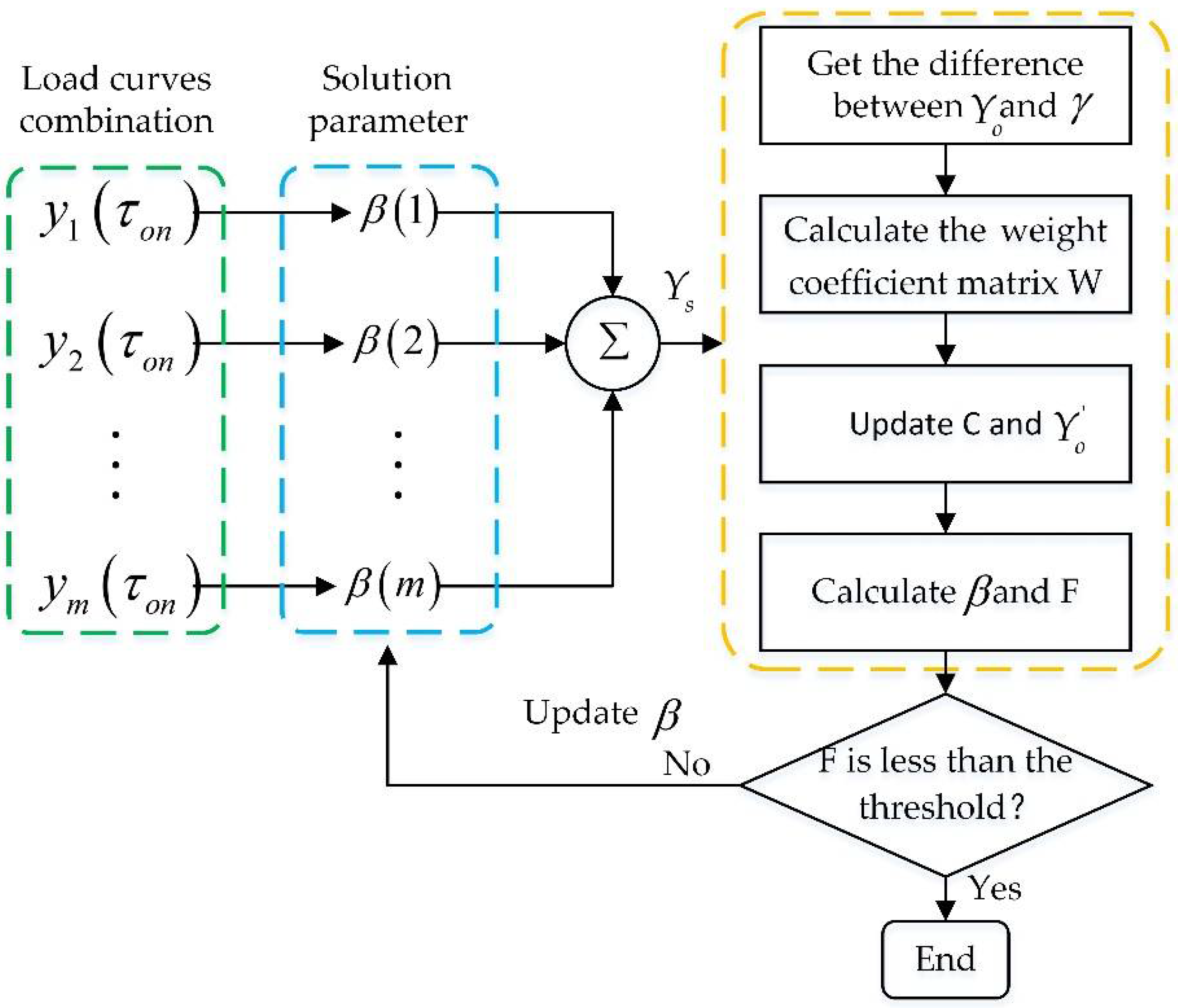

3.2. Solution of the Objective Function

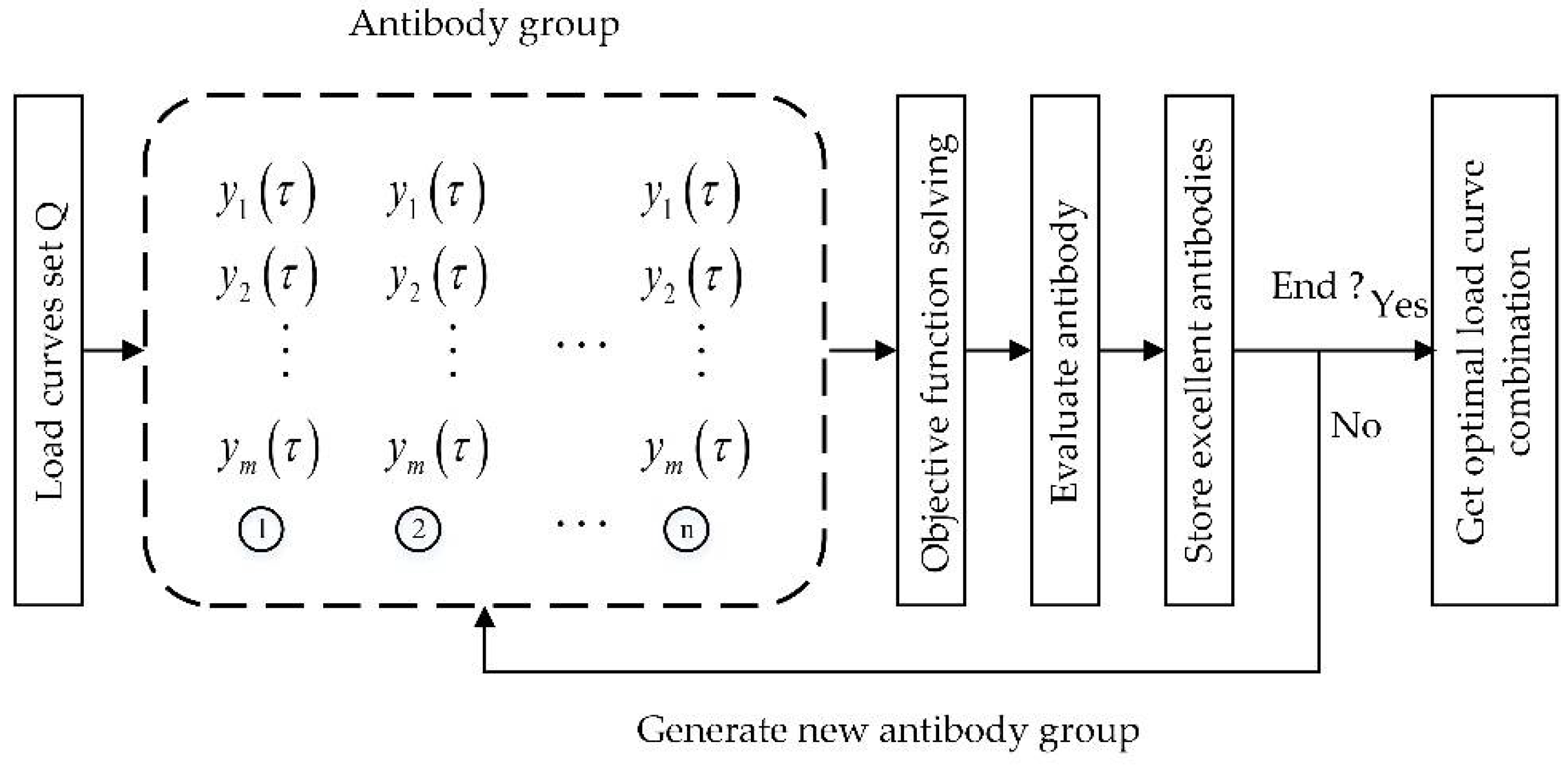

3.3. The Process of Optimization

4. Experimental Results and Simulation

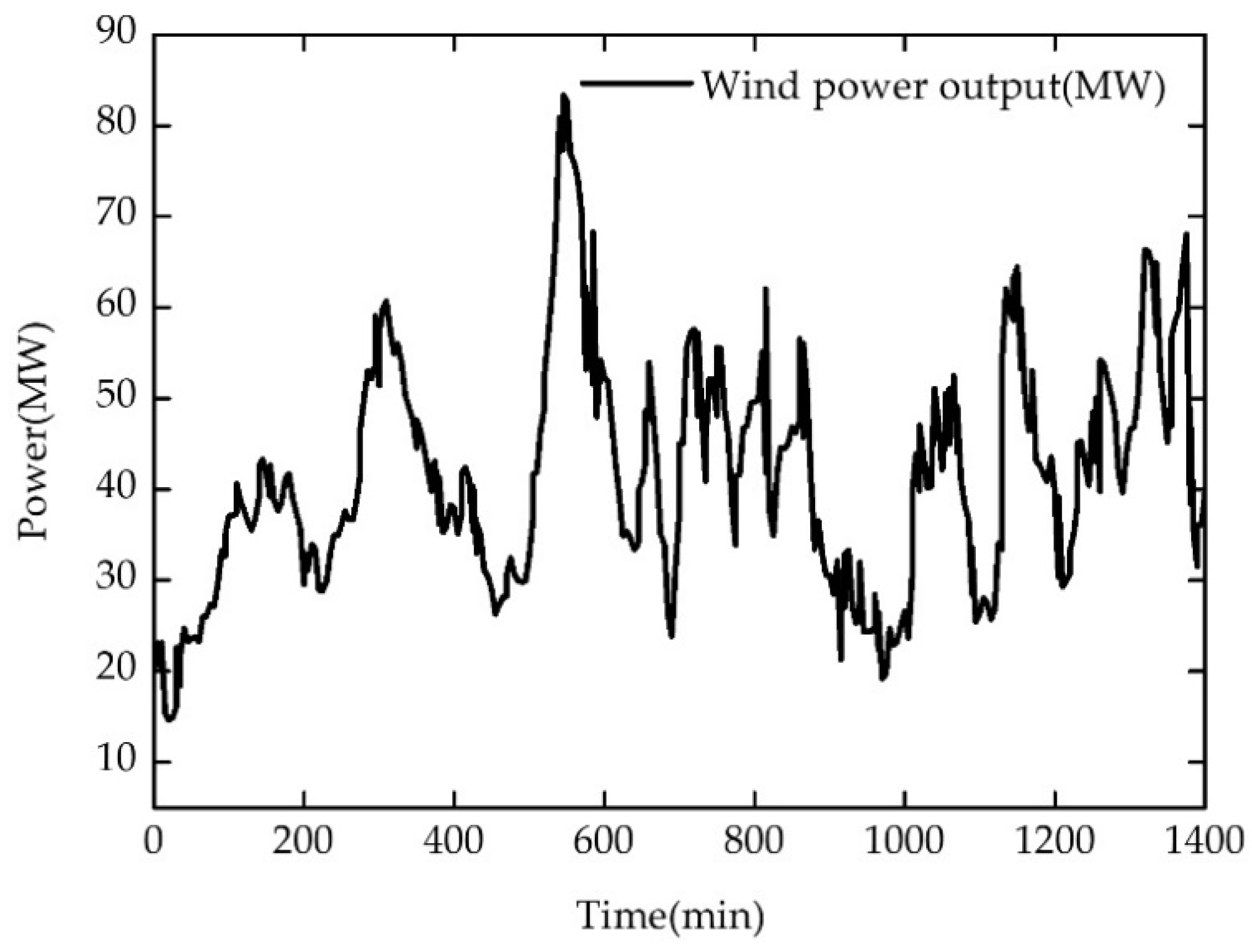

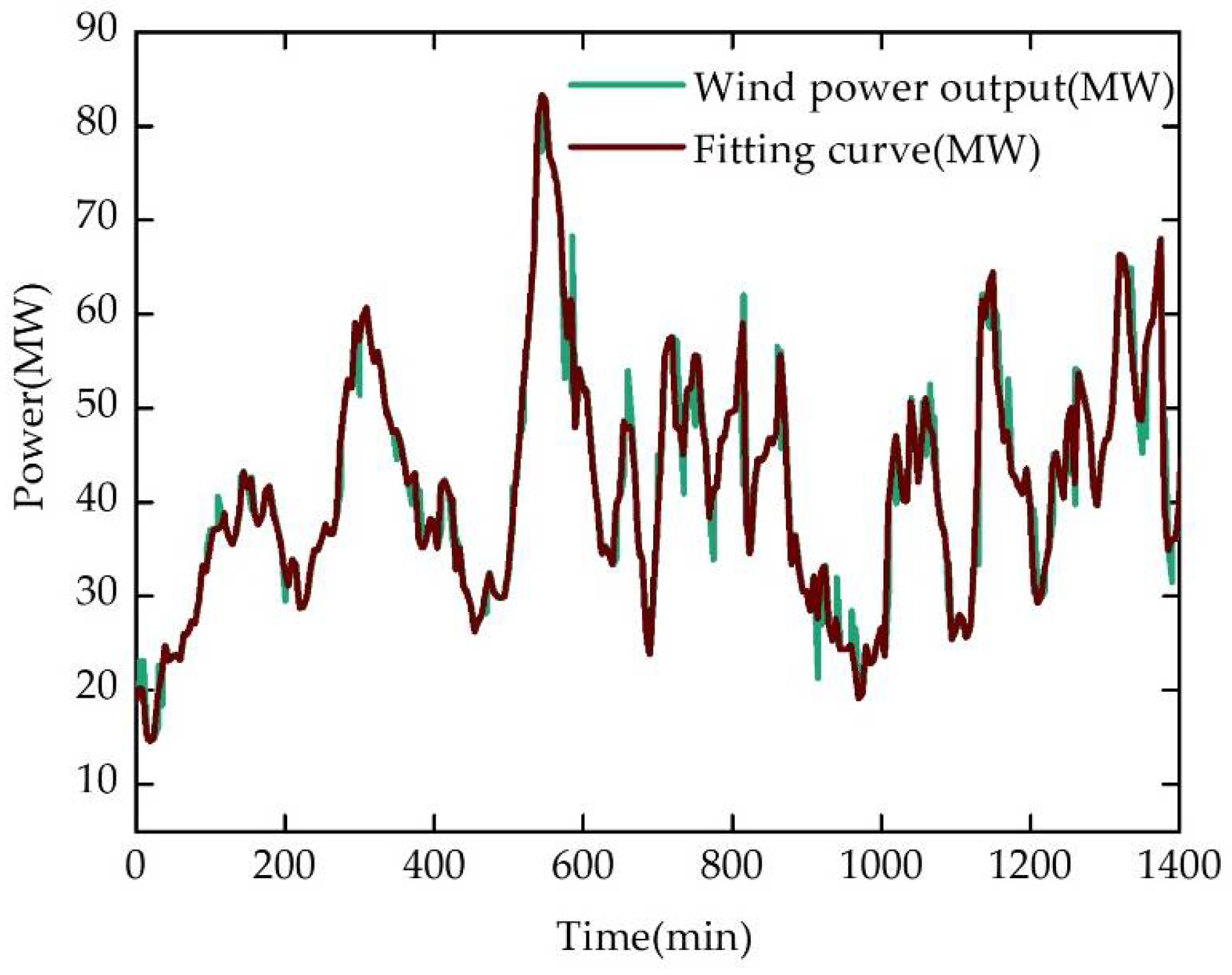

4.1. Target Value and Simulation Parameter Setting

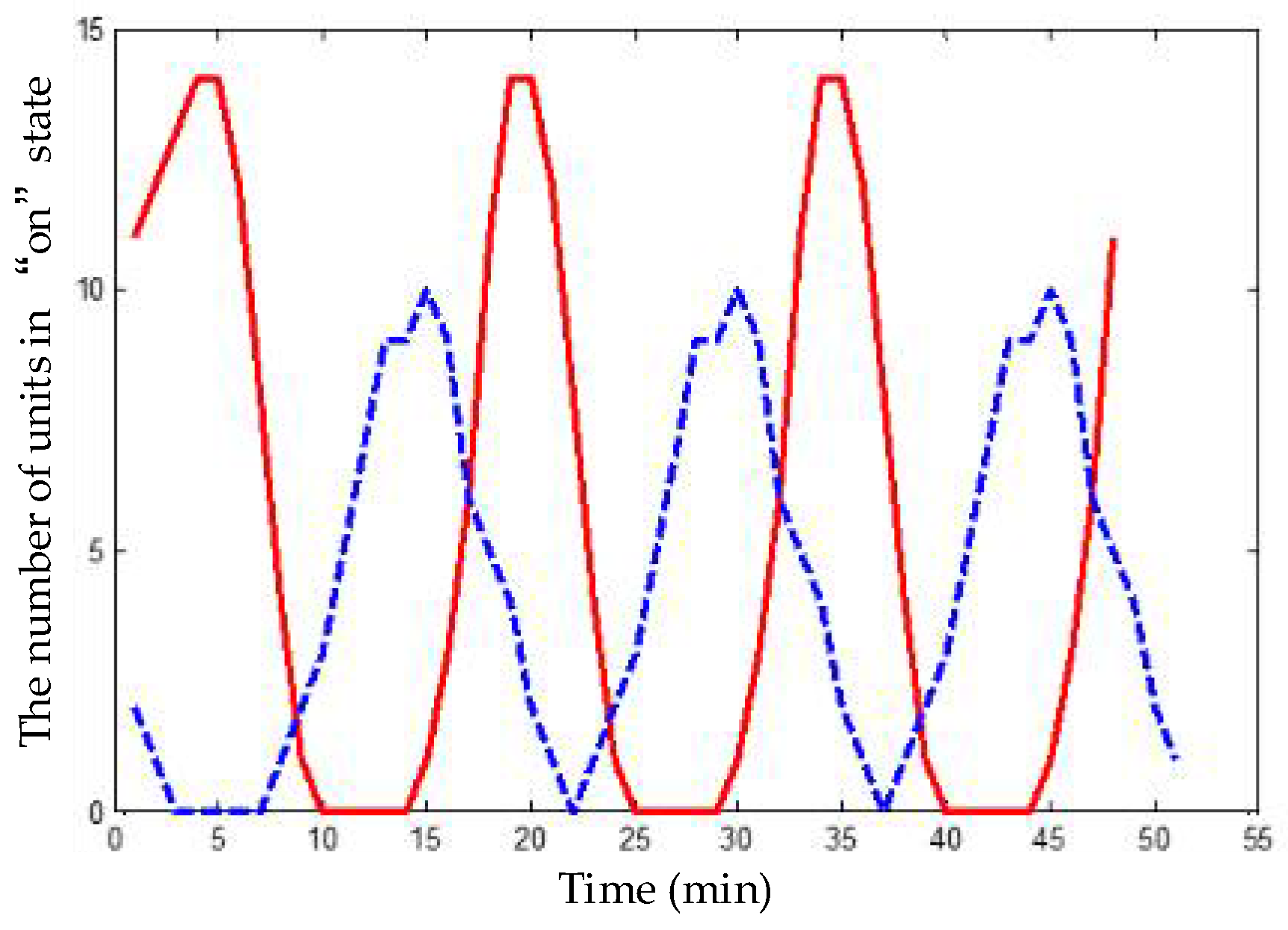

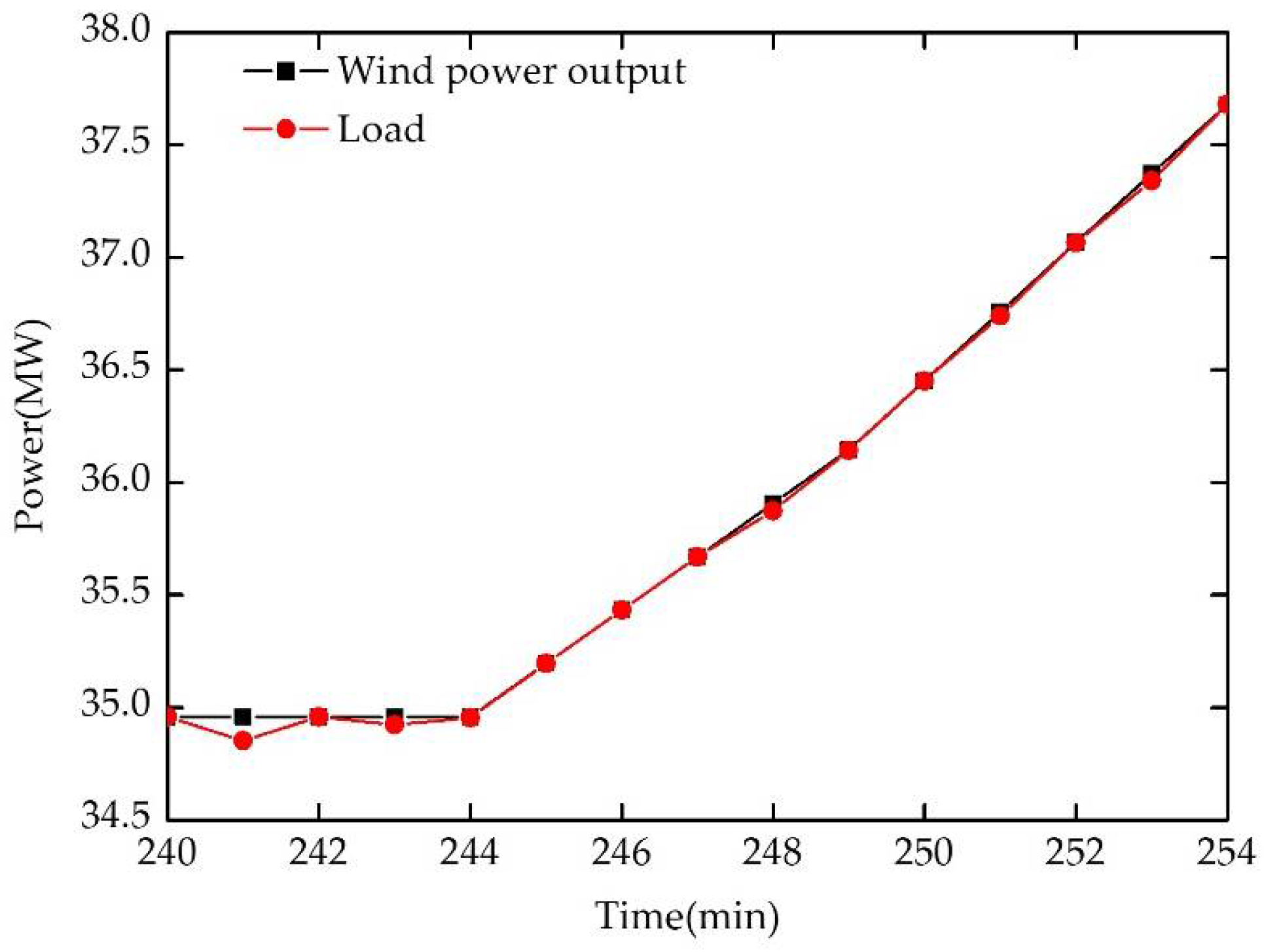

4.2. Load Control and Tracking Results

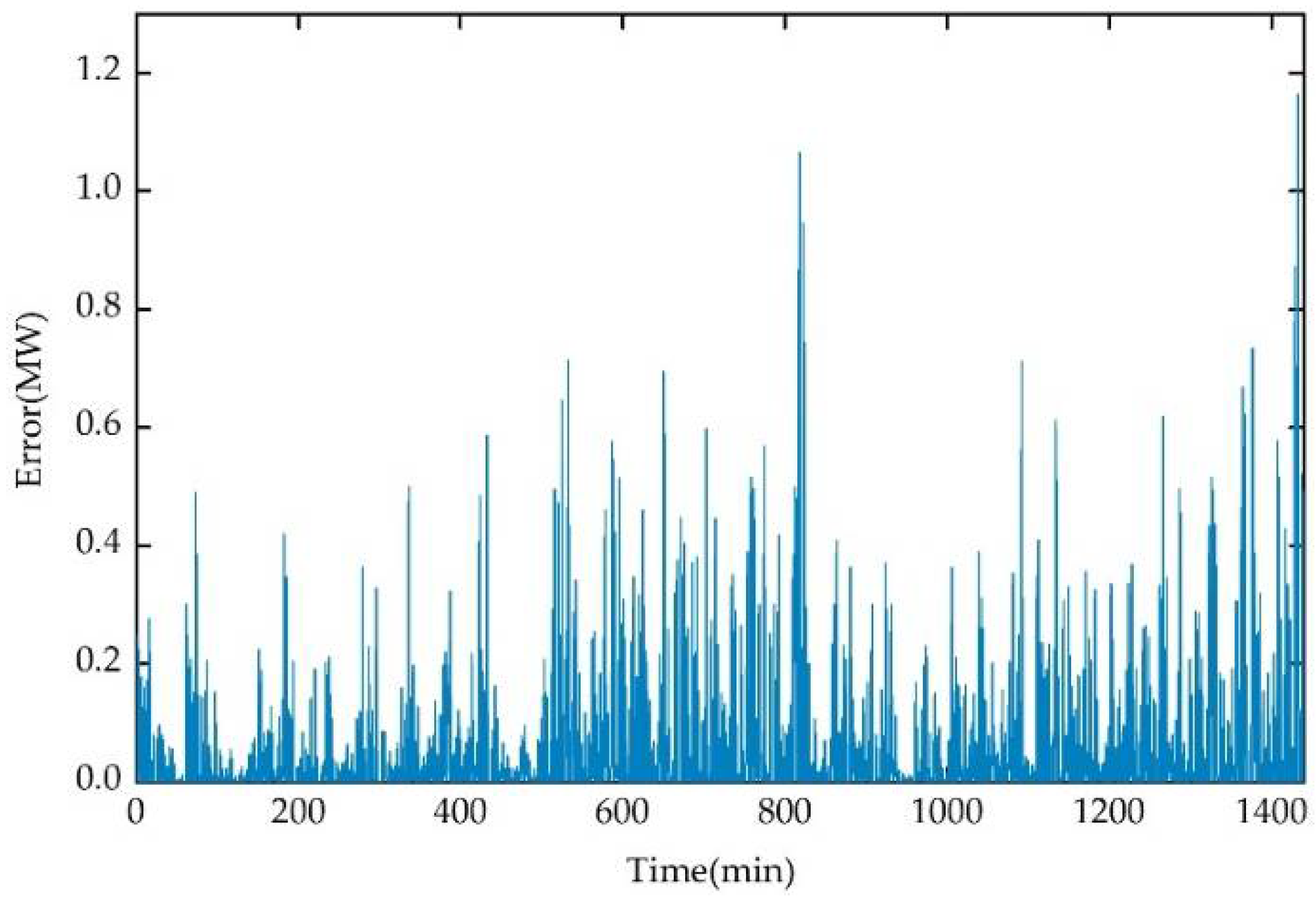

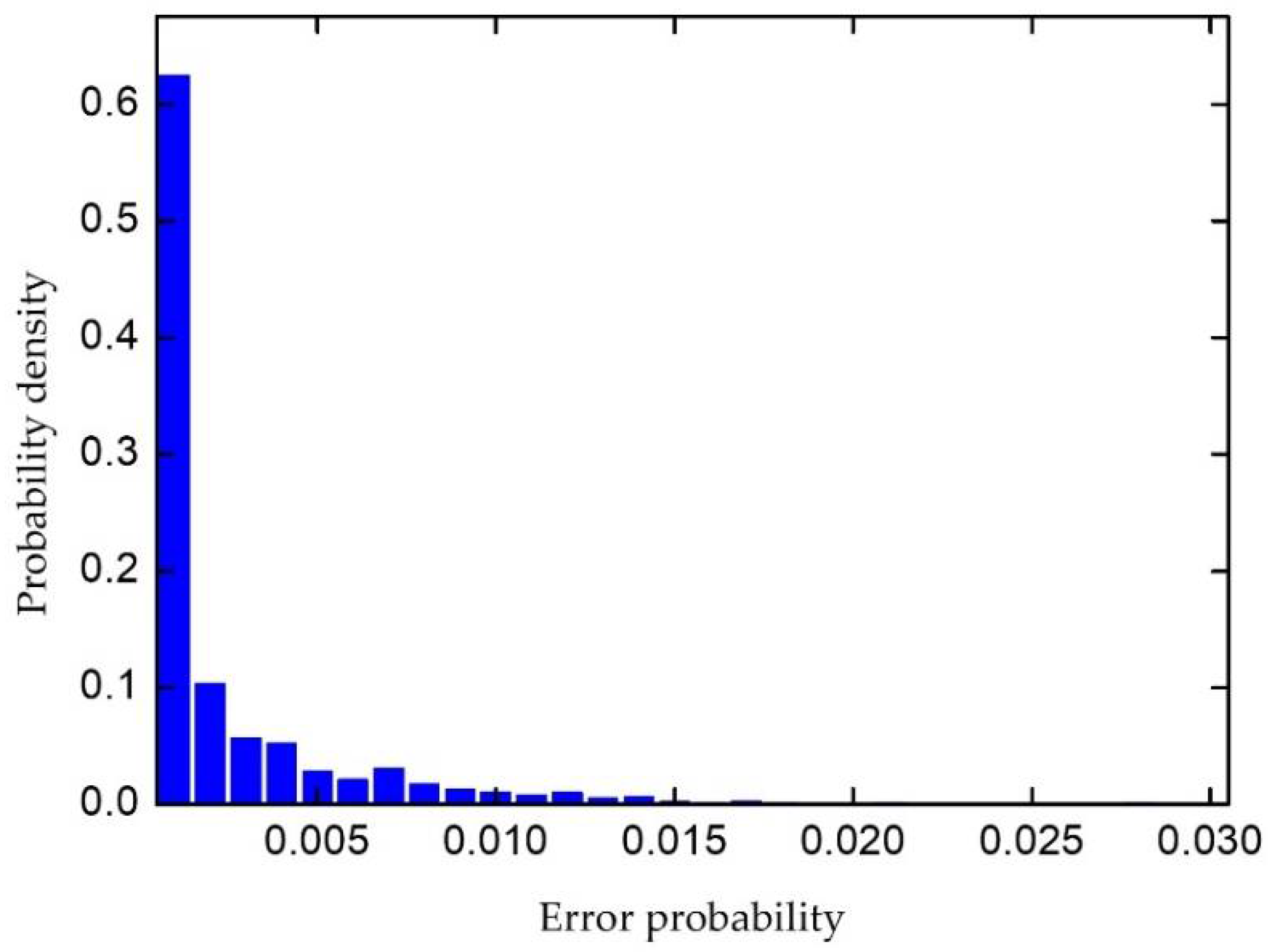

4.3. Error Evaluation of Experimental Results

5. Discussion

Author Contributions

Funding

Conflicts of Interest

References

- Su, H.; Zhang, T.; Qian, L.; Wang, Z.; Cai, Q.; Wang, B. Consensus control strategy of inverter air conditioning group for renewable energy consumption based on distributed adaptive system. In Proceedings of the 2017 IEEE 2nd Information Technology, Networking, Electronic and Automation Control Conference (ITNEC), Chengdu, China, 15–17 December 2017; pp. 92–96. [Google Scholar]

- Mahdavi, N.; Braslavsky, J.H.; Seron, M.M. Model predictive control of distributed air-conditioning loads to compensate fluctuations in solar power. IEEE Trans. Smart Grid. 2017, 8, 3055–3065. [Google Scholar] [CrossRef]

- Al Jabery, K.; Xu, Z.; Yu, W. Demand-side management of domestic electric water heaters using approximate dynamic programming. IEEE Trans. Comput.-Aided Des. Integr. Circuits Syst. 2017, 36, 775–788. [Google Scholar] [CrossRef]

- Xu, Z.; Diao, R.; Lu, S. Modeling of electric water heaters for demand response: A baseline PED model. IEEE Trans. Smart Grid. 2014, 5, 2203–2210. [Google Scholar] [CrossRef]

- Sossan, F.; Kosek, A.M.; Martinenas, S. Scheduling of domestic water heater power demand for maximizing PV self-consumption using model predictive control. In Proceedings of the 2013 IEEE Innovative Smart Grid Technologies Europe, Lyngby, Denmark, 6–9 October 2013; pp. 1–5. [Google Scholar]

- Shah, J.J.; Nielsen, M.C.; Shaffer, T.S. Cost-optimal consumption-aware electric water heating via thermal storage under time-of-use pricing. IEEE Trans. Smart Grid. 2016, 7, 592–599. [Google Scholar] [CrossRef]

- Kondoh, J.; Lu, N.; Hammerstrom, D.J. An Evaluation of the water heater load potential for providing regulation service. In Proceedings of the 2011 IEEE Power and Energy Society General Meeting, Detroit, MI, USA, 24–29 July 2011; Volume 26, pp. 1309–1316. [Google Scholar]

- Pourmousavi, S.A.; Patrick, S.N.; Nehrir, M.H. Real-time demand response through aggregate electric water heaters for load shifting and balancing wind generation. In Proceedings of the 2014 IEEE PES General Meeting|Conference & Exposition, National Harbor, MD, USA, 27–31 July 2014; Volume 5, pp. 769–778. [Google Scholar]

- Goya, T.; Senjyu, T.; Yona, A. Optimal operation of controllable load and battery considering transmission constraint in smart grid. In Proceedings of the 2010 Conference Proceedings, Singapore, 27–29 October 2010. [Google Scholar]

- Liu, M.; Quilumba, F.L.; Lee, W.J. A collaborative design of aggregated residential appliances and renewable energy for demand response participation. IEEE Trans. Ind. Appl. 2015, 51, 3561–3569. [Google Scholar] [CrossRef]

- Qingqi, Z.; Ming, L.; Huaguang, Z. Dispatching strategy of responsive load using ant colony algorithm. Proc. CSEE 2006, 26, 15–21. [Google Scholar]

- Lingling, S.; Ciwei, G.; Jian, T. Load aggregation technology and its applications. Autom. Electr. Power Syst. 2017, 41, 159–167. [Google Scholar]

- Melhem, F.Y.; Grunder, O.; Hammoudan, Z. Optimization and energy management in smart home considering photovoltaic, wind, and battery storage system with integration of electric vehicles. Can. J. Electr. Comput. Eng. 2017, 40, 128–138. [Google Scholar]

- Takigawa, F.Y.K.; Fernandes, R.C.; Tenfen, D. Energy management by the consumer with photovoltaic generation: Brazilian market. IEEE Lat. Am. Trans. 2016, 14, 2226–2232. [Google Scholar] [CrossRef]

- Wong, S.; Pinard, J.P. Opportunities for smart electric thermal storage on electric grids with renewable energy. IEEE Trans. Smart Grid. 2017, 8, 1014–1022. [Google Scholar] [CrossRef]

- Iacovella, S.; Ruelens, F.; Vingerhoets, P. Cluster control of heterogeneous thermostatically controlled loads using tracer devices. IEEE Trans. Smart Grid. 2017, 8, 528–536. [Google Scholar] [CrossRef]

- Soudjani, S.E.Z.; Abate, A. Aggregation and control of populations of thermostatically controlled loads by formal abstractions. IEEE Trans. Control Syst. Technol. 2015, 23, 975–990. [Google Scholar] [CrossRef]

- Masuta, T.; Yokoyama, A. Supplementary load frequency control by use of a number of both electric vehicles and heat pump water heaters. IEEE Trans. Smart Grid. 2012, 3, 1253–1262. [Google Scholar] [CrossRef]

- Ciwei, G.; Qianyu, L.; Yang, L. Bi-level optimal dispatch and control strategy for air-conditioning load based on direct load control. Proc. CSEE 2014, 34, 1546–1555. [Google Scholar]

- Lu, N.; Chassin, D.P. A state-queueing model of thermostatically controlled appliances. IEEE Trans. Power Syst. 2004, 19, 1666–1673. [Google Scholar] [CrossRef]

- Lei, Z.; Yang, L.; Ciwei, G. Improvement of temperature adjusting method for aggregated air-conditioning loads and its control stratergy. Proc. CSEE 2014, 34, 5579–5589. [Google Scholar]

- Callaway, D.S. Tapping the energy storage potential in electric loads to deliver load following and regulation, with application to wind energy. Eng. Conver. Manag. 2009, 50, 1389–1400. [Google Scholar] [CrossRef]

- Bashash, S.; Fathy, H.K. Modeling and control of aggregate air conditioning loads for robust renewable power management. IEEE Trans. Control Syst. Technol. 2013, 21, 1318–1327. [Google Scholar] [CrossRef]

- Lu, N. An evaluation of the HVAC load potential for providing load balancing service. IEEE Tran. Smart Grid. 2012, 3, 1263–1270. [Google Scholar] [CrossRef]

- Fanti, M.P.; Mangini, A.M.; Roccotelli, M.A. District energy management based on thermal comfort satisfaction and real-time power balancing. IEEE Trans. Autom. Sci. Eng. 2015, 12, 1271–1284. [Google Scholar] [CrossRef]

- Lawson, C.L.; Hanson, R.J. Solving least square problems. Camb. Univ Pr. 1974, 77, 673–682. [Google Scholar]

- Wenxian, Z.; Xing, F.; Jingnan, L. Weighted total least squares algorithm with inequality constraints. Acta Geod. Cartogr. Sin. 2014, 43, 1013–1018. [Google Scholar]

- Wei, L.; Changdong, L.; Deren, S. Research on optimazation of unit commitment based on immune algorithm. Proc. CSEE 2004, 24, 241–245. [Google Scholar]

- Liang, Z.; Song, R.; Lin, Q.A. Double-module immune algorithm for multi-objective optimization problems. Appl. Soft Comput. 2015, 35, 161–174. [Google Scholar] [CrossRef]

- Lin, Q.; Chen, J.; Zhan, Z.H. A Hybrid Evolutionary Immune Algorithm for Multiobjective Optimization Problems. IEEE Trans. Evol. Comput. 2016, 20, 711–729. [Google Scholar] [CrossRef]

- Peteghem, V.V.; Vanhoucke, M. An artificial immune system algorithm for the resource availability cost problem. Flex. Serv. Manuf. J. 2013, 25, 122–144. [Google Scholar] [CrossRef]

- Bagheri, A.; Zandieh, M.; Mahdavi, I. An artificial immune algorithm for the flexible job-shop scheduling problem. Future Gener. Comput. Syst. 2010, 26, 533–541. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, Q.; Wang, W. A parallel immune algorithm for traveling salesman problem and its application on cold rolling scheduling. Inf. Sci. 2011, 181, 1212–1223. [Google Scholar] [CrossRef]

| State | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | on |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 5 |

| 2 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 1 | 5 |

| 3 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 1 | 2 | 5 |

| 4 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 1 | 2 | 3 | 5 |

| 5 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 1 | 2 | 3 | 4 | 5 |

| 6 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 1 | 2 | 3 | 4 | 5 | 5 |

| 7 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 1 | 2 | 3 | 4 | 5 | 6 | 5 |

| 8 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 5 |

| 9 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 5 |

| 10 | 10 | 11 | 12 | 13 | 14 | 15 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 5 |

| 11 | 11 | 12 | 13 | 14 | 15 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 5 |

| 12 | 12 | 13 | 14 | 15 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 5 |

| 13 | 13 | 14 | 15 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 5 |

| 14 | 14 | 15 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 5 |

| 15 | 15 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 5 |

| 16 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 5 |

| State | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | on |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 4 | 5 | 6 | off | off | off | off | off | off | off | off | 6 | 7 | 8 | 9 | 2 |

| 2 | 5 | 6 | 7 | off | off | off | off | off | off | off | 6 | 7 | 8 | 9 | 10 | 1 |

| 3 | 6 | 7 | 8 | 6 | off | off | off | off | off | 6 | 7 | 8 | 9 | 10 | 11 | 0 |

| 4 | 7 | 8 | 9 | 7 | off | off | off | off | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 0 |

| 5 | 8 | 9 | 10 | 8 | 6 | off | off | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 0 |

| 6 | 9 | 10 | 11 | 9 | 7 | off | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 0 |

| 7 | 10 | 11 | 12 | 10 | 8 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 0 |

| 8 | 11 | 12 | 13 | 11 | 9 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 1 | 1 |

| 9 | 12 | 13 | 14 | 12 | 10 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 1 | 2 | 2 |

| 10 | 13 | 14 | 15 | 13 | 11 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 1 | 2 | 3 | 3 |

| 11 | 14 | 15 | 1 | 14 | 12 | 10 | 11 | 12 | 13 | 14 | 15 | 1 | 2 | 3 | 4 | 5 |

| 12 | 15 | 1 | 2 | 15 | 13 | 11 | 12 | 13 | 14 | 15 | 1 | 2 | 3 | 4 | 5 | 7 |

| 13 | 1 | 2 | 3 | 1 | 14 | 12 | 13 | 14 | 15 | 1 | 2 | 3 | 4 | 5 | 6 | 9 |

| 14 | 2 | 3 | 4 | 2 | 15 | 13 | 14 | 15 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 9 |

| 15 | 3 | 4 | 5 | 3 | 1 | 14 | 15 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 10 |

| 16 | 4 | 5 | 6 | 4 | 2 | 15 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 9 |

| 17 | 5 | 6 | 7 | 5 | 3 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 8 |

| 18 | 6 | 7 | 8 | 6 | 4 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 5 |

| 19 | 7 | 8 | 9 | 7 | 5 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 4 |

| 20 | 8 | 9 | 10 | 8 | 6 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 2 |

| 21 | 9 | 10 | 11 | 9 | 7 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 1 |

| Parameters | Values | Formula |

|---|---|---|

| Population size | 50 | — |

| Memory capacity | 15 | — |

| Cycle times | 50 | — |

| Crossover probability | 0.4 | — |

| Mutation probability | 0.5 | — |

| Diversity parameter | 0.95 | — |

| Reproductive rate | — | Equation (16) |

| — | Equation (13) | |

| — | Equation (15) | |

| Antibody concentration | — | Equation (14) |

| Time | Groups | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 4 | 9 | 20 | 21 | 24 | 26 | 58 | 67 | 77 | 83 | |

| 1 | 6 | 14 | 0 | 0 | 0 | 0 | 2 | 9 | 4 | 1 |

| 2 | 11 | 12 | 0 | 0 | 0 | 0 | 3 | 10 | 2 | 0 |

| 3 | 14 | 8 | 0 | 0 | 0 | 1 | 5 | 9 | 1 | 0 |

| 4 | 14 | 4 | 0 | 0 | 1 | 3 | 7 | 8 | 0 | 0 |

| 5 | 12 | 1 | 0 | 1 | 3 | 6 | 9 | 5 | 1 | 0 |

| 6 | 8 | 0 | 1 | 3 | 6 | 11 | 9 | 4 | 2 | 0 |

| 7 | 4 | 0 | 3 | 6 | 11 | 14 | 10 | 2 | 3 | 0 |

| 8 | 1 | 0 | 6 | 11 | 14 | 14 | 9 | 1 | 5 | 0 |

| 9 | 0 | 0 | 11 | 14 | 14 | 12 | 8 | 0 | 7 | 0 |

| 10 | 0 | 0 | 14 | 14 | 12 | 8 | 5 | 1 | 9 | 1 |

| 11 | 0 | 1 | 14 | 12 | 8 | 4 | 4 | 2 | 9 | 3 |

| 12 | 0 | 3 | 12 | 8 | 4 | 1 | 2 | 3 | 10 | 5 |

| 13 | 0 | 6 | 8 | 4 | 1 | 0 | 1 | 5 | 9 | 7 |

| 14 | 1 | 11 | 4 | 1 | 0 | 0 | 0 | 7 | 8 | 8 |

| 15 | 3 | 14 | 1 | 0 | 0 | 0 | 1 | 9 | 5 | 9 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, X.; Liang, K.; Han, X. Renewable Energy Output Tracking Control Algorithm Based on the Temperature Control Load State-Queuing Model. Appl. Sci. 2018, 8, 1099. https://doi.org/10.3390/app8071099

Wu X, Liang K, Han X. Renewable Energy Output Tracking Control Algorithm Based on the Temperature Control Load State-Queuing Model. Applied Sciences. 2018; 8(7):1099. https://doi.org/10.3390/app8071099

Chicago/Turabian StyleWu, Xin, Kaixin Liang, and Xiao Han. 2018. "Renewable Energy Output Tracking Control Algorithm Based on the Temperature Control Load State-Queuing Model" Applied Sciences 8, no. 7: 1099. https://doi.org/10.3390/app8071099

APA StyleWu, X., Liang, K., & Han, X. (2018). Renewable Energy Output Tracking Control Algorithm Based on the Temperature Control Load State-Queuing Model. Applied Sciences, 8(7), 1099. https://doi.org/10.3390/app8071099