Vibration Reduction of an Existing Glass Window through a Viscoelastic Material-Based Retrofit

Abstract

:1. Introduction

- The use of both air-film damping technology and viscoelastic material. Lewis and Parin developed a window damping system that employs both air-film damping technology and viscoelastic damping materials to improve mechanical and/or acoustic vibration damping in window structures [46].

- The use of laminates with a viscoelastic layer. Krois et al. [47] proposed an experiment showing that the use of a two-phase adhesive applied via a co-extrusion method with a low-viscosity core can dramatically lower the overall level of vibrations in window glass by 30–50 percent, and in particular, can bring about a flattening of the resonance peaks in the all-important roll vibration range between 100 Hz and 500 Hz. Bagaev et al. [48] found that multilayer window glass structures with polymer materials in a transient state reduced the amplitude of vibration of window glass. Fan et al. [49] experimentally verified the effects of vibration and noise reduction of laminated viscoelastic materials for the windows of railway vehicles. Other reported methods of increasing window damping through laminates include References [50,51,52,53]. Please note that this type of method applies to the manufacturing of new windows.

2. Proposed Method and Experimental Set-Up

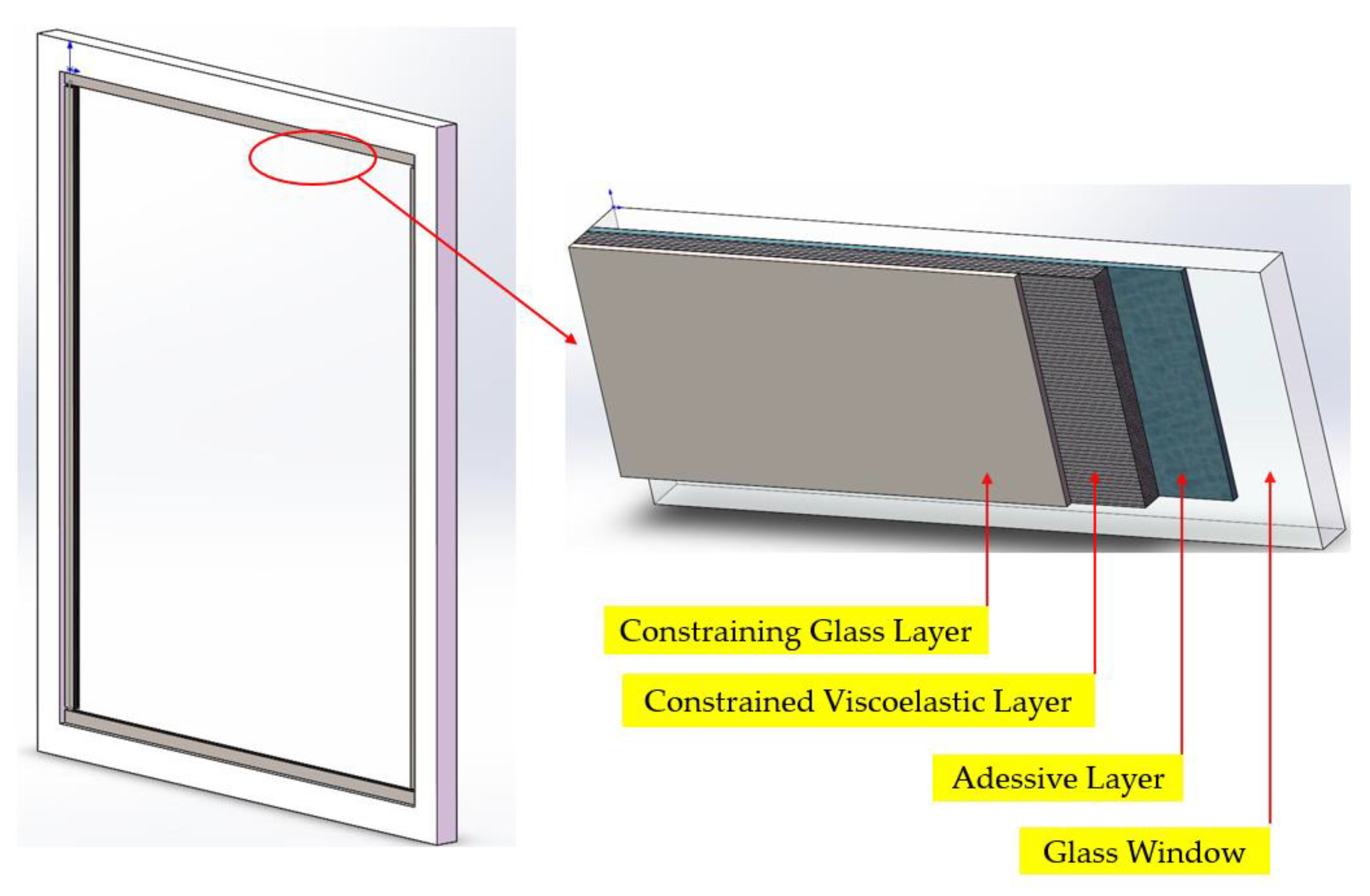

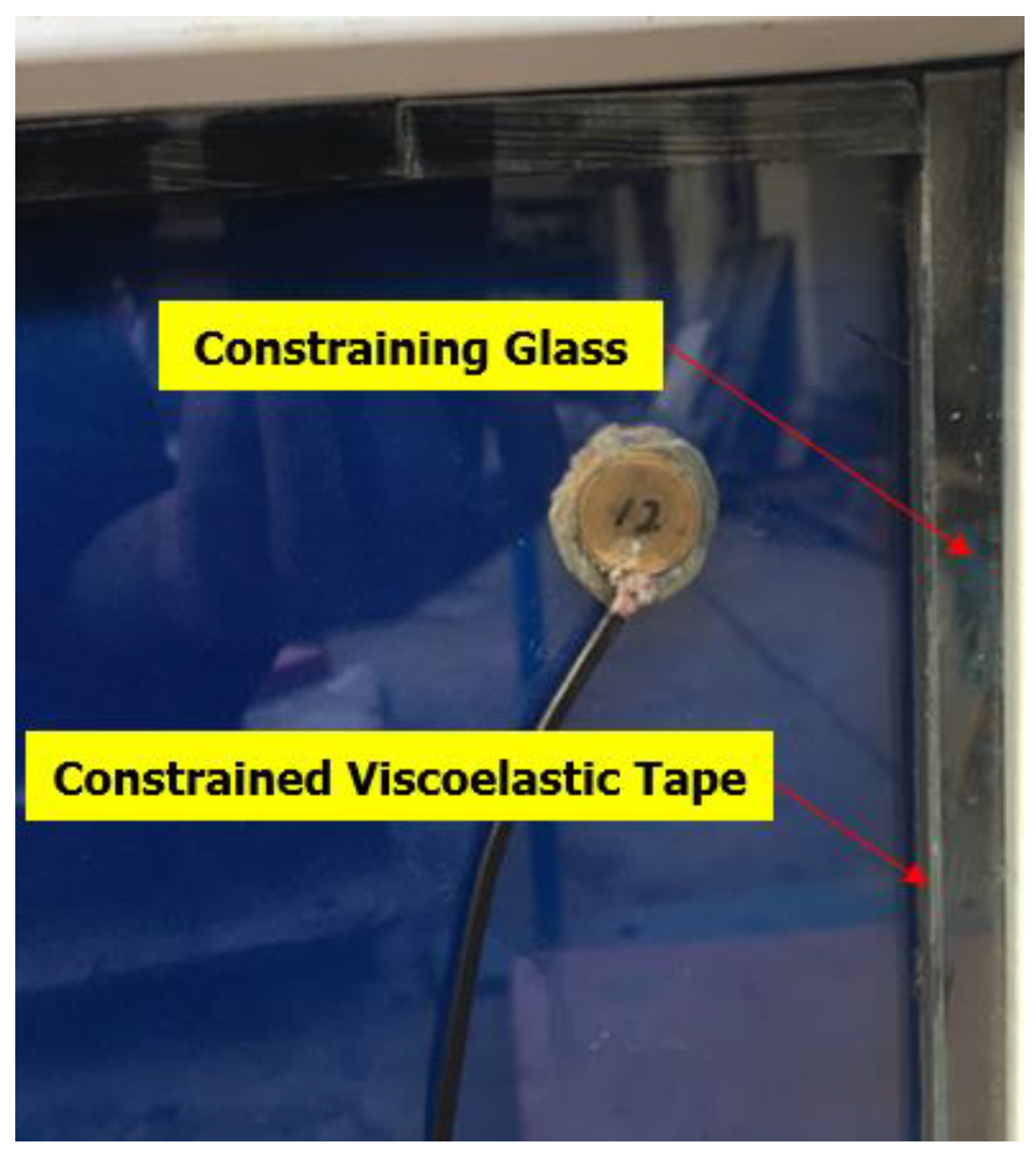

2.1. Vibration Damping Enhancement through Constrained Viscoelastic Materials

2.2. Experimental Set-Up

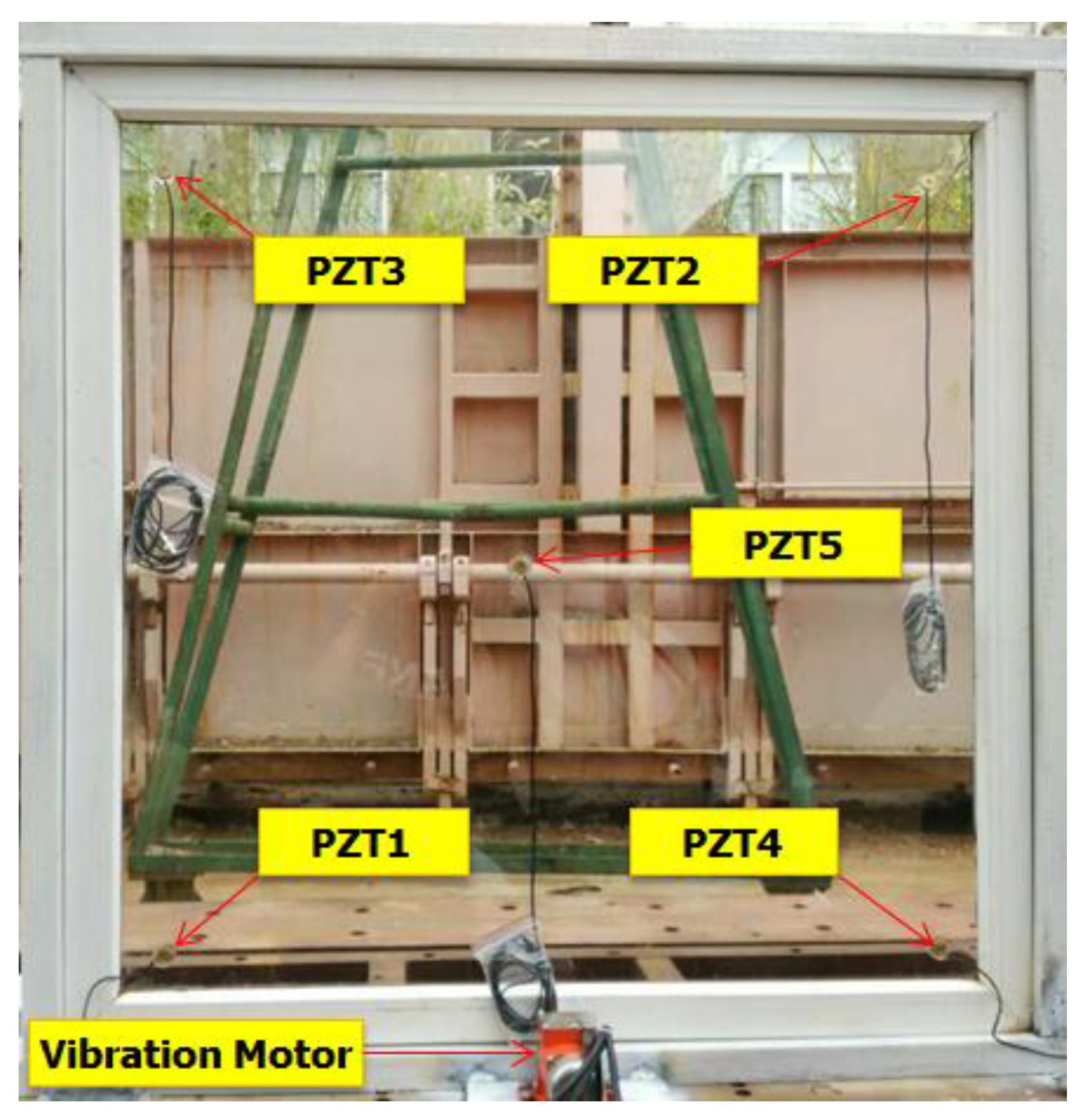

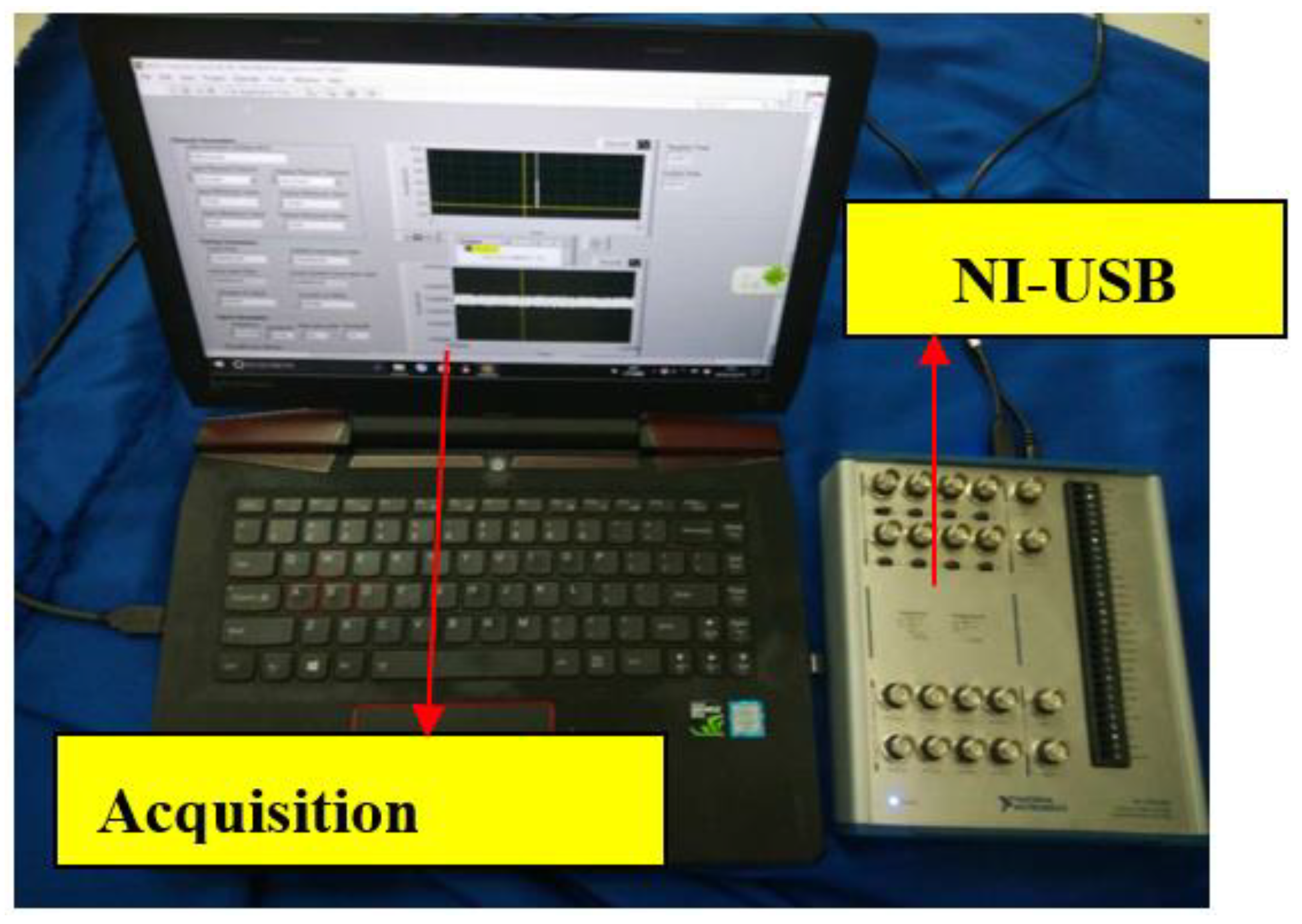

2.3. PZT Patches as Vibration Sensors and Instrumentation

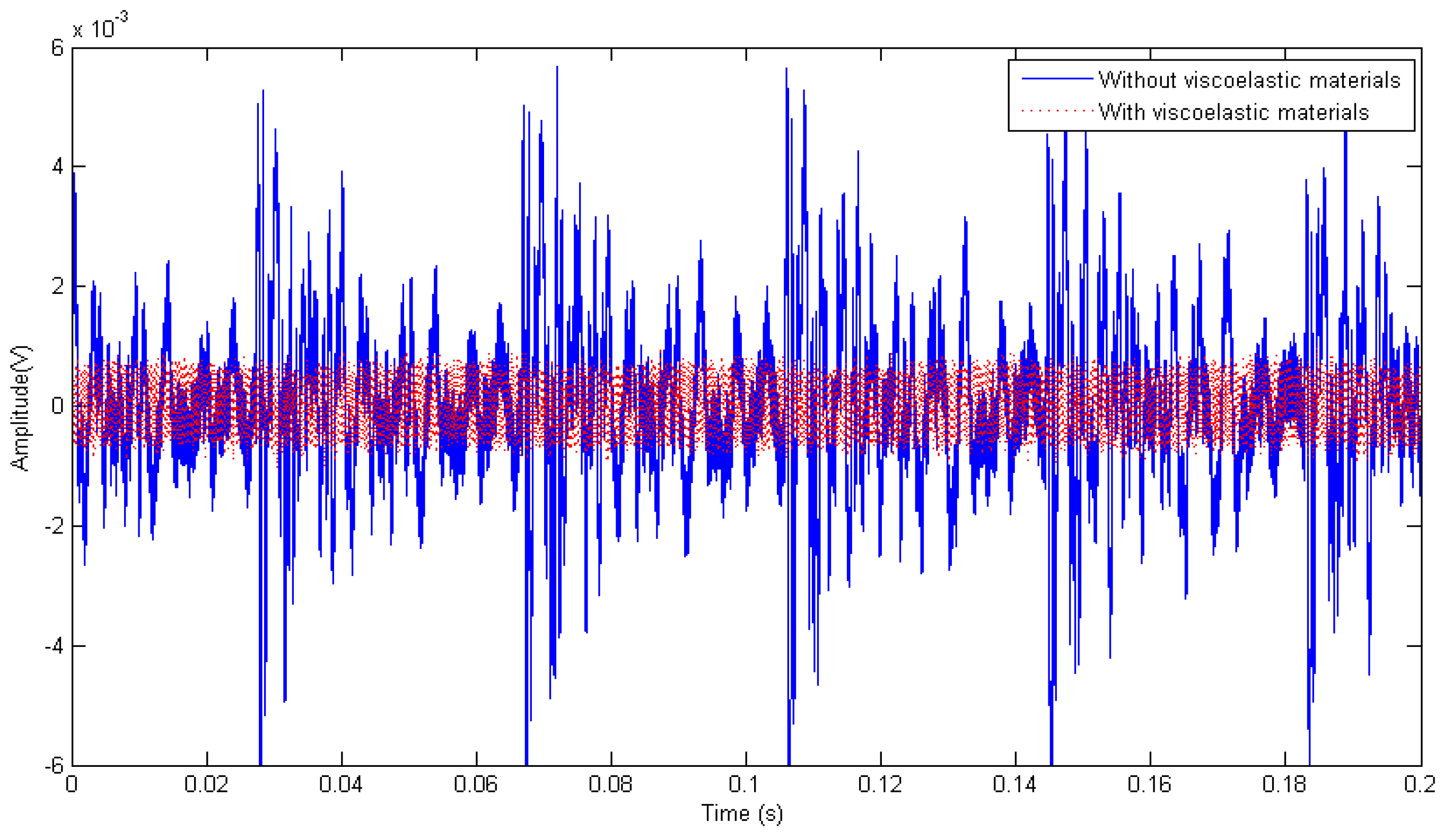

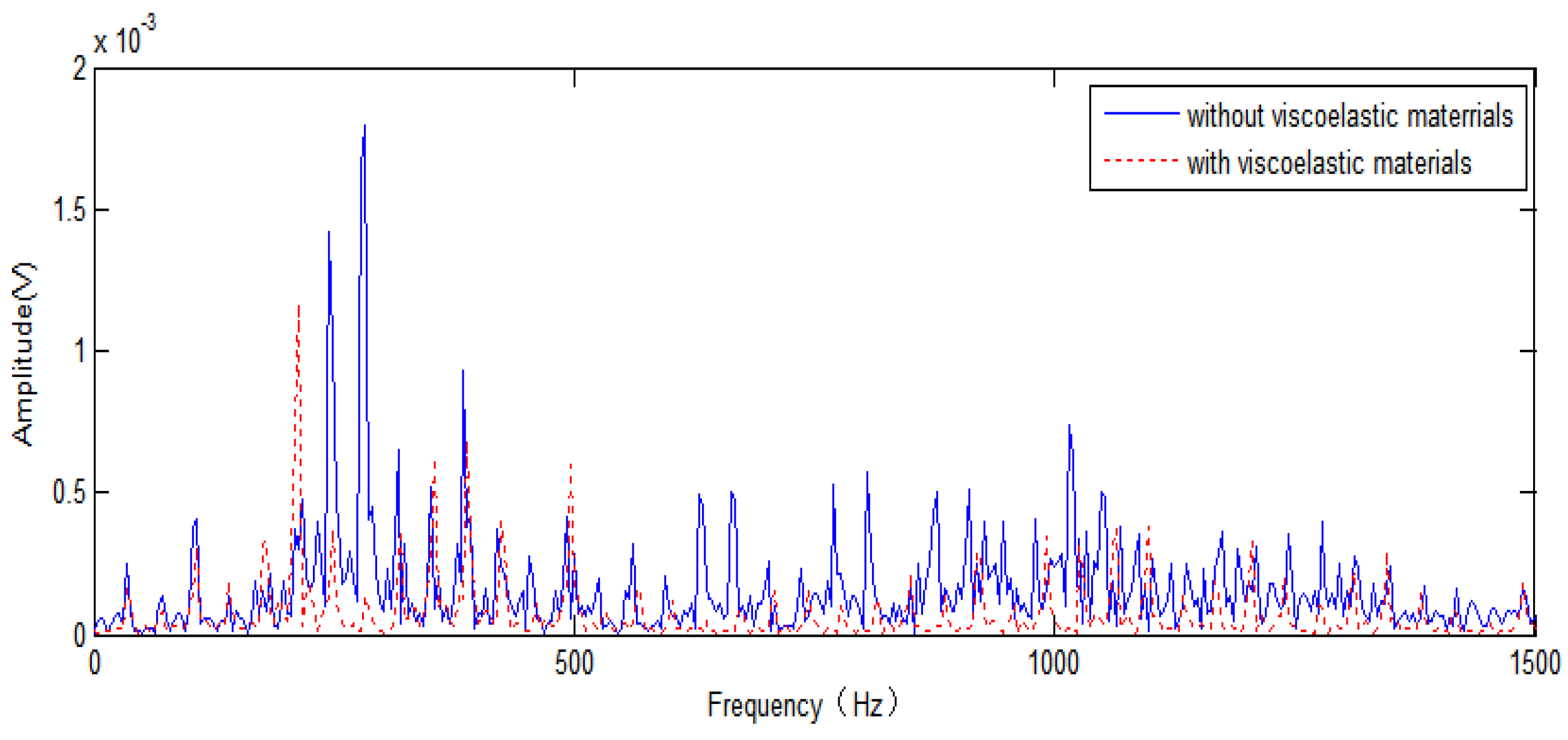

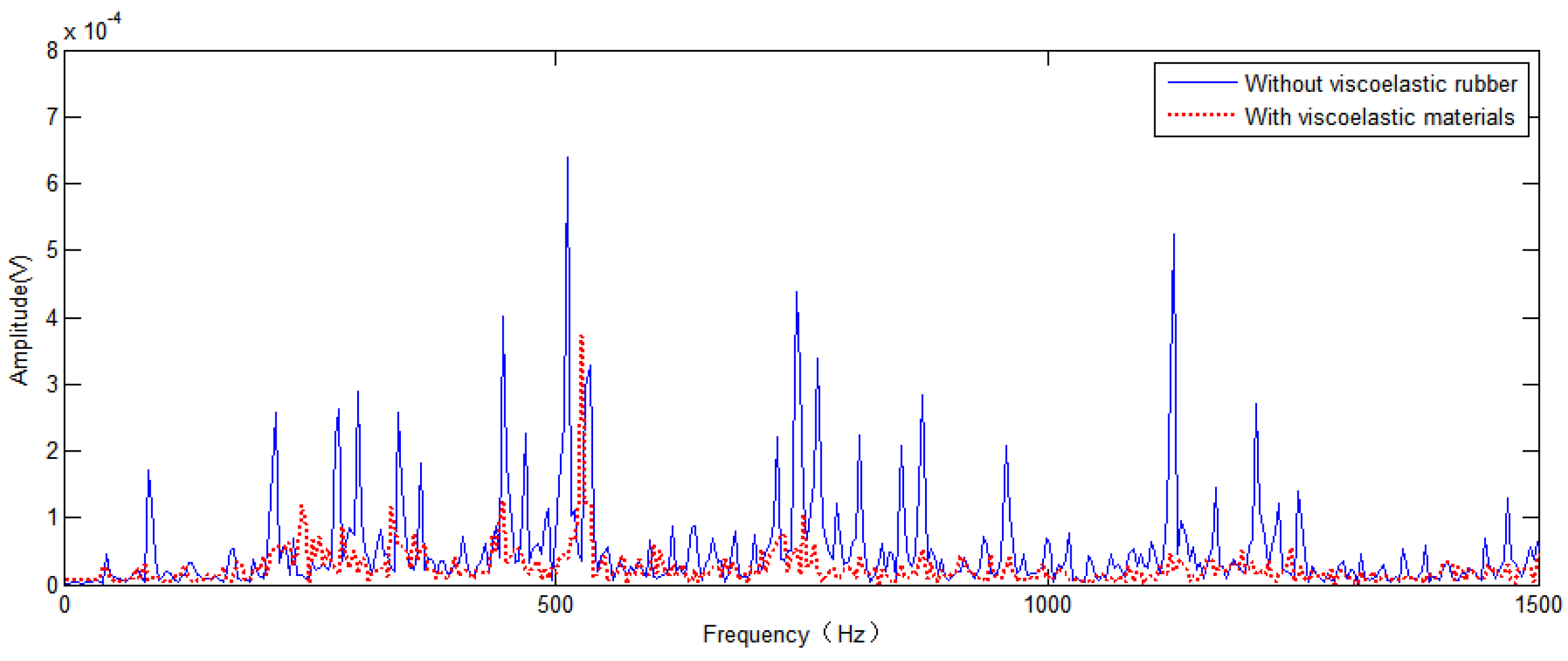

3. Experimental Results and Analyses

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Naqash, T.; Formisano, A.; De Matteis, G. Design and performance testing of a skylight in Qatar. Key Eng. Mater. 2016, 710, 262–267. [Google Scholar] [CrossRef]

- Feng, Q.; Zhang, Y.; Zhu, N.; Wang, H. Design of remote real time monitoring system based on gprs for railway roadbed subsidence. J. Geod. Geodyn. 2013, 33, 155–157. [Google Scholar]

- Song, G.; Cai, S.C.S.; Li, H.-N. Energy dissipation and vibration control: Modeling, algorithm, and devices. Appl. Sci. 2017, 7, 801. [Google Scholar] [CrossRef]

- Rana, R.; Soong, T.T. Parametric study and simplified design of tuned mass dampers. Eng. Struct. 1998, 20, 193–204. [Google Scholar] [CrossRef]

- Wang, W.; Hua, X.; Wang, X.; Chen, Z.; Song, G. Numerical modeling and experimental study on a novel pounding tuned mass damper. J. Vib. Control 2017, 2. [Google Scholar] [CrossRef]

- Tian, L.; Rong, K.; Zhang, P.; Liu, Y. Vibration control of a power transmission tower with pounding tuned mass damper under multi-component seismic excitations. Appl. Sci. 2017, 7, 477. [Google Scholar] [CrossRef]

- Song, G.B.; Zhang, P.; Li, L.Y.; Singla, M. Vibration control of a pipeline structure using pounding tuned mass damper. J. Eng. Mech. 2016, 142, 04016031. [Google Scholar] [CrossRef]

- Wang, W.; Dalton, D.; Hua, X.; Wang, X.; Chen, Z.; Song, G. Experimental study on vibration control of a submerged pipeline model by eddy current tuned mass damper. Appl. Sci. 2017, 7, 987. [Google Scholar] [CrossRef]

- Chen, J.; Lu, G.; Li, Y.; Wang, T.; Wang, W.; Song, G. Experimental study on robustness of an eddy current-tuned mass damper. Appl. Sci. 2017, 7, 895. [Google Scholar] [CrossRef]

- Papalou, A.; Masri, S.F. An Experimental investigation of particle dampers under harmonic excitation. J. Vib. Control 1998, 4, 361–379. [Google Scholar] [CrossRef]

- Lu, Z.; Wang, D.; Zhou, Y. Experimental parametric study on wind-induced vibration control of particle tuned mass damper on a benchmark high-rise building. Struct. Des. Tall Spec. Build. 2017, 26. [Google Scholar] [CrossRef]

- Papalou, A.; Strepelias, E.; Roubien, D.; Bousias, S.; Triantafillou, T. Seismic protection of monuments using particle dampers in multi-drum columns. Soil Dyn. Earthq. Eng. 2015, 77, 360–368. [Google Scholar] [CrossRef]

- Lu, Z.; Chen, X.; Zhang, D.; Dai, K. Experimental and analytical study on the performance of particle tuned mass dampers under seismic excitation. Earthq. Eng. Struct. Dyn. 2017, 46, 697–714. [Google Scholar] [CrossRef]

- Chen, X.; Yang, T.Y.; Shi, W. Influence of isolation hysteresis on the seismic performance of isolated buildings. Struct. Control Health Monit. 2015, 22, 631–647. [Google Scholar] [CrossRef]

- Huang, B.; Zhang, H.; Wang, H.; Song, G. Passive base isolation with superelastic nitinol SMA helical springs. Smart Mater. Struct. 2014, 23, 065009. [Google Scholar] [CrossRef]

- Fu, W.; Zhang, C.; Sun, L.; Askari, M.; Samali, B.; Chung, K.L.; Sharafi, P. Experimental investigation of a base isolation system incorporating MR dampers with the high-order single step control algorithm. Appl. Sci. 2017, 7, 344. [Google Scholar] [CrossRef]

- Gandhi, F.; Anusonti-Inthra, P. Adaptive control of semi-active variable stiffness devices for narrow-band disturbance rejection. J. Intell. Mater. Syst. Struct. 2003, 14, 191–201. [Google Scholar] [CrossRef]

- Yang, J.N.; Bobrow, J.; Jabbari, F.; Leavitt, J.; Cheng, C.P.; Lin, P.Y. Full-scale experimental verification of resetable semi-active stiffness dampers. Earthq. Eng. Struct. Dyn. 2010, 36, 1255–1273. [Google Scholar] [CrossRef]

- Gavin, H.P.; Hanson, R.D.; Filisko, F.E. Electrorheological dampers, part I: Analysis and design. J. Appl. Mech. 1996, 63, 669–675. [Google Scholar] [CrossRef]

- Noresson, V.; Ohlson, N.G.; Nilsson, M. Design of electrorheological dampers by means of finite element analysis: Theory and applications. Mater. Des. 2002, 23, 361–369. [Google Scholar] [CrossRef]

- Lim, K.H.; Choi, S.B.; Sun, K.G.; Han, Y.M. Discrete-time fuzzy sliding mode control of vehicle suspension system featuring electrorheological damper. Smart Mater. Struct. 2015, 16, 798–808. [Google Scholar]

- Cho, S.W.; Jung, H.J.; Lee, I.W. Smart passive system based on magnetorheological damper. Smart Mater. Struct. 2005, 14, 707–714. [Google Scholar] [CrossRef]

- Dyke, S.J.; Spencer, B.F.J.; Sain, M.K.; Carlson, J.D. Modeling and control of magnetorheological dampers for seismic response reduction. Smart Mater. Struct. 1996, 5, 565. [Google Scholar] [CrossRef]

- Liu, M.; Song, G.; Li, N. Non-model based semi-active vibration suppression of stay cables using Magneto-Rheological (MR) fluid damper. Smart Mater. Struct. 2007, 16, 1447–1452. [Google Scholar] [CrossRef]

- Motra, G.B.; Mallik, W.; Chandiramani, N.K. Semi-active vibration control of connected buildings using magnetorheological dampers. J. Intell. Mater. Syst. Struct. 2011, 22, 1811–1827. [Google Scholar] [CrossRef]

- Liu, M.; Sethi, V.; Song, G. Investigation of locking force for stay cable vibration control using magneto-rheological fluid damper. J. Vib. Acoust. Trans. ASME 2008, 130, 054504. [Google Scholar] [CrossRef]

- Dominguez, A.; Sedaghati, R.; Stiharu, I. Semi-active vibration control of adaptive structures using magnetorheological dampers. AIAA J. 2005, 44, 1563–1571. [Google Scholar] [CrossRef]

- Yang, G.; Spencer, B.F., Jr.; Carlson, J.D.; Sain, M.K. Large-scale MR fluid dampers: Modeling and dynamic performance considerations. Eng. Struct. 2002, 24, 309–323. [Google Scholar] [CrossRef]

- Kwok, N.M.; Ha, Q.P.; Nguyen, M.T.; Li, J.; Samali, B. Bouc-Wen model parameter identification for a MR fluid damper using computationally efficient GA. ISA Trans. 2007, 46, 167. [Google Scholar] [CrossRef] [PubMed]

- Milecki, A.; Myszkowski, A.; Sędziak, D. Investigation of dynamic properties and control method influences on MR fluid dampers performance. J. Intell. Mater. Syst. Struct. 2015, 13, 453–458. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, H. Analysis of a high-rise steel structure with viscous damped outriggers. Struct. Des. Tall Spec. Build. 2014, 23, 963–979. [Google Scholar] [CrossRef]

- Zhou, Y.; Lu, X.; Weng, D.; Zhang, R. A practical design method for reinforced concrete structures with viscous dampers. Eng. Struct. 2012, 39, 187–198. [Google Scholar] [CrossRef]

- Jia, J.; Du, J.; Yu, W.; Hongxing, H. Design method for fluid viscous dampers. Arch. Appl. Mech. 2008, 78, 737–746. [Google Scholar]

- Lu, X.; Zhou, Y.; Yan, F. Shaking table test and numerical analysis of RC frames with viscous wall dampers. J. Struct. Eng. 2008, 134, 64–76. [Google Scholar] [CrossRef]

- Mcnamara, R.J.; Taylor, D.P. Fluid viscous dampers for high-rise buildings. Struct. Des. Tall Spec. Build. 2003, 12, 145–154. [Google Scholar] [CrossRef]

- Lin, W.H.; Chopra, A.K. Earthquake response of elastic SDF systems with non-linear fluid viscous dampers. Earthq. Eng. Struct. Dyn. 2002, 31, 1623–1642. [Google Scholar] [CrossRef]

- Mohan, D.R. Recent applications of viscoelastic damping for noise control in automobiles and commercial airplanes. J. Sound Vib. 2003, 262, 457–474. [Google Scholar]

- Tsai, C.S.; Lee, H.H. Applications of viscoelastic dampers to high-rise buildings. J. Struct. Eng. 1993, 119, 1222–1233. [Google Scholar] [CrossRef]

- Tsai, C.S.; Lee, H.H. Applications of viscoelastic damper to jointed structures for seismic mitigation. Eng. Mech. 1992, 408, 685–688. [Google Scholar]

- Li, P.; Liu, S.; Lu, Z. Experimental study on the performance of polyurethane-steel sandwich structure under debris flow. Appl. Sci. 2017, 7, 1018. [Google Scholar] [CrossRef]

- Zhang, R.H.; Soong, T.T.; Mahmoodi, P. Seismic response of steel frame structures with added viscoelastic dampers. Earthq. Eng. Struct. Dyn. 1996, 18, 389–396. [Google Scholar] [CrossRef]

- Shukla, A.K.; Datta, T.K. Optimal use of viscoelastic dampers in building frames for seismic force. J. Struct. Eng. 1999, 125, 401–409. [Google Scholar] [CrossRef]

- Kim, J.; Ryu, J.; Chung, L. Seismic performance of structures connected by viscoelastic dampers. Eng. Struct. 2006, 28, 183–195. [Google Scholar] [CrossRef]

- Park, J.H.; Kim, J.; Min, K.W. Optimal design of added viscoelastic dampers and supporting braces. Earthq. Eng. Struct. Dyn. 2010, 33, 465–484. [Google Scholar] [CrossRef]

- Kasparek, M. Glass window vibrations analysis used for positioning of piezoelectric damping elements. In Proceedings of the 2014 15th International Carpathian Control Conference (ICCC), Velke Karlovice, Czech Republic, 28–30 May 2014; pp. 223–226. [Google Scholar]

- Lewis, T.M.; Parin, M.L. Vibration damping apparatus for windows using viscoelastic damping materials. J. Acoust. Soc. Am. 2010, 128, 3271. [Google Scholar] [CrossRef]

- Krois, M.; Dilger, K.; Böhm, S.; Koch, S. Use of compliant adhesive layers in direct glazing of road vehicles for improved sound attenuation. Int. J. Adhes. Adhes. 2003, 23, 413–425. [Google Scholar] [CrossRef]

- Bagaev, A.S.; Vasilieva, I.E.; Gerasimenko, V.G.; Katkow, B.G. Damping of window glass vibrations caused by speech signals circulating in the room. Telecommun. Radio Eng. 2004, 62, 903–909. [Google Scholar] [CrossRef]

- Fan, R.; Meng, G.; Yang, J.; He, C. Experimental study of the effect of viscoelastic damping materials on noise and vibration reduction within railway vehicles. J. Sound Vib. 2009, 319, 58–76. [Google Scholar] [CrossRef]

- Pyper, J. Laminated glass provides noise barrier benefits in automotive and architectural applications. Sound Vib. 2001, 35, 10–16. [Google Scholar]

- Barrett, D.J. Vibration-Damping Structural Component: Acoustical Society of America. U.S. Patent 5,368,914, 29 November 1994. [Google Scholar]

- Landin, D.T.; Gregl, B.V.; Coratti, T. Damped Glass and Plastic Laminates. U.S. Patent 2,273,371 A1, 17 October 1998. [Google Scholar]

- Rehfeld, M.; Fournier, D.; Boure, J.P.; Payen, C. Viscoelastic Plastic Interlayer for Vibro-Acoustic Damping and Glazing Comprising such an Interlayer. U.S. Patent 20,130,316,158, 28 November 2013. [Google Scholar]

- Kroiss, M.; Schneeweiss, H.; Muehlhofer, G.; Reichelt, M. Vibration Damping Strip for Vehicle Window. German Patent 1,980,6122A, 14 February 1999. [Google Scholar]

- Masayuki, S. Window Plate with Vibration Damping Member, and Vibration Damping Member. U.S. Patent 0094470, 10 November 2017. [Google Scholar]

- Yamaguchi, T.; Kurosawa, Y.; Enomoto, H. Damped vibration analysis using finite element method with approximated modal damping for automotive double walls with a porous material. J. Sound Vib. 2009, 325, 436–450. [Google Scholar] [CrossRef]

- Ghiringhelli, G.L.; Terraneo, M.; Vigoni, E. Improvement of structures vibro-acoustics by widespread embodiment of viscoelastic materials. Aerosp. Sci. Technol. 2013, 28, 227–241. [Google Scholar] [CrossRef]

- Wang, J.; Xu, Y.; Zhang, W. Finite element simulation of PMMA aircraft windshield against bird strike by using a rate and temperature dependent nonlinear viscoelastic constitutive mode. Compos. Struct. 2014, 108, 21–30. [Google Scholar] [CrossRef]

- Jones, C.J.C.; Thompson, D.J. Rolling noise generated by railway wheels with viscoelastic layers. J. Sound Vib. 2000, 231, 779–790. [Google Scholar] [CrossRef]

- Sun, D.; Song, Y.; Zhang, X.; Zhang, L. Research on development of the viscoelastic suspensions used in construction vehicles. In Proceedings of the International Technology and Innovation Conference 2006 (ITIC 2006), Hangzou, China, 6–7 November 2006; pp. 2227–2230. [Google Scholar]

- Zhang, R.T.; Zhao, Y.S. Damping and noise reduction technology for high Speed Trains. Foreign Rolling Stock 2005, 42, 10–17. [Google Scholar]

- He, C.; Yuan, J.; Lin, S.; Yang, J.; Sun, X.; Meng, G. Analysis on noise inside high-speed railway passenger cars and research on control techniques of noise. J. Vib. Eng. 2004, 17, 1047–1050. [Google Scholar]

- Sucuoǧlu, H.; Girija Vallabhan, C.V. Behaviour of window glass panels during earthquake. Eng. Struct. 1997, 19, 685–694. [Google Scholar] [CrossRef]

- Rainer, J.H. Effect of vibrations on historic buildings: An overview. Bull. Assoc. Preserv. Technol. 1982, 14, 2–10. [Google Scholar] [CrossRef]

- Behr, R.A.; Karson, M.J.; Minor, J.E. Reliability analysis of window glass failure pressure data. Struct. Saf. 1991, 11, 43–58. [Google Scholar] [CrossRef]

- Class, J.B.; Chu, S.G. The viscoelastic properties of rubber–resin blends. I. The effect of resin structure. J. Appl. Polym. Sci. 2003, 30, 805–814. [Google Scholar] [CrossRef]

- Miehe, C.; Göktepe, S. A micro–macro approach to rubber-like materials. Part II: The micro-sphere model of finite rubber viscoelasticity. J. Mech. Phys. Solids 2005, 53, 2231–2258. [Google Scholar] [CrossRef]

- Zhang, P.; Huo, L.; Song, G. Impact fatigue of viscoelastic materials subjected to pounding. Appl. Sci. 2018, 8, 117. [Google Scholar] [CrossRef]

- Class, J.B.; Chu, S.G. The viscoelastic properties of rubber–resin blends. III. The effect of resin concentration. J. Appl. Polym. Sci. 1985, 30, 825–842. [Google Scholar] [CrossRef]

- Wang, J.; Sun, D.; Liu, S.; Zhang, X. Damping characteristics of viscoelastic damping structure under coupled condition. Math. Comput. Appl. 2017, 22, 27. [Google Scholar] [CrossRef]

- Guo, T.; Gu, Y.; Wang, L.; Chen, J.; Ma, S. Experimental study on dynamic mechanical properties of ZN-35 silicone rubber. J. Beijing Univ. Technol. 2016, 42, 1623–1628. [Google Scholar]

- Zhao, Y. Properties and applications of ZN series viscoelastic damping materials. Aerosp. Mater. Technol. 2001, 2, 19–23. [Google Scholar]

- Kong, Q.; Robert, R.H.; Silva, P.; Mo, Y.L. Cyclic crack monitoring of a reinforced concrete column under simulated pseudo-dynamic loading using piezoceramic-based smart aggregates. Appl. Sci. 2016, 6, 341. [Google Scholar] [CrossRef]

- Yin, H.; Wang, T.; Yang, D.; Liu, S.; Shao, J.; Li, Y. A smart washer for bolt looseness monitoring based on piezoelectric active sensing method. Appl. Sci. 2016, 6, 320. [Google Scholar] [CrossRef]

- Du, G.; Kong, Q.; Zhou, H.; Gu, H. Multiple cracks detection in pipeline using damage index matrix based on piezoceramic transducer-enabled stress wave propagation. Sensors 2017, 17, 1812. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Wang, Q.; Wang, H.; Zhu, H. Experimental study on damage detection in timber specimens based on an electromechanical impedance technique and RMSD-based mahalanobis distance. Sensors 2016, 16, 1765. [Google Scholar] [CrossRef] [PubMed]

- Venugopal, V.P.; Wang, G. Modeling and analysis of Lamb wave propagation in a beam under Lead Zirconate Titanate actuation and sensing. J. Intell. Mater. Syst. Struct. 2015, 26, 1679–1698. [Google Scholar] [CrossRef]

- Shao, J.; Wang, T.; Yin, H.; Yang, D.; Li, Y. Bolt looseness detection based on piezoelectric impedance frequency shift. Appl. Sci. 2016, 6, 298. [Google Scholar] [CrossRef]

- Karaiskos, G.; Flawinne, S.; Sener, J.Y.; Deraemaeker, A. Design and validation of embedded piezoelectric transducers for damage detection applications in concrete structures. Key Eng. Mater. 2013, 569, 805–811. [Google Scholar] [CrossRef]

- Hu, Y.; Yang, Y. Wave propagation modeling of the PZT sensing region for structural health monitoring. Smart Mater. Struct. 2007, 16, 706. [Google Scholar] [CrossRef]

| Solutions | Authors | Pros | Cons |

|---|---|---|---|

| Employing both air-film damping technology and viscoelastic damping materials | Lewis et al. [46] | Extensive applications; better vibro-acoustic damping properties; good optical quality. | Damping materials integrated during fabrication; not suitable for retrofitting existing windows. |

| Utilizing laminates or multilayer technology to improve the vibration damping of window glass | Krois et al. [47]; Bagaev et al. [48]; Fan et al. [49]; Pyper [50]; Barrett et al. [51]; Landin et al. [52]; Rehfeld et al. [53] | Increased resistance to vibratory load; better vibro-acoustic damping properties. | Damping materials integrated during fabrication; not suitable for retrofitting existing windows. |

| Increasing the damping between the glass and the window frame | Kroiss M et al. [54]; Masayuki S et al. [55] | Good design flexibility; sufficient damping; efficient. | Damping materials integrated during fabrication or the installation process; not suitable for retrofitting existing windows. |

| Physical Property | Tensile Strength (MPa) | 15 |

| Elongation (%) | 400 | |

| Permanent Deformation (%) | 18 | |

| Hardness (Shore A) | 72 | |

| 70 °C × 72 h Aging Coefficient | 1.09 | |

| Specific Gravity (g/cm3) | 1.27 | |

| Damping Property | βmax | 1.4 |

| Tβmax (°C) | 25 | |

| Eβmax (N/m) | 5 × 107 | |

| Δtβmax = 0.7 (°C) | 0–50 | |

| ΔEβmax = 0.7 (N/m) | 107–108 |

| Voltage (V) | Power (W) | Rotation Speed | Motor Control | Frequency Range (Hz) |

|---|---|---|---|---|

| 220 | 30 | 0–3000 r/min | Level 1–Level 10 | 0–50 |

| Levels | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Excitation Force (N) | 3.5 | 14.0 | 31.5 | 56.0 | 87.5 | 126.0 | 171.5 | 224.0 | 283.5 | 350.0 |

| Measuring Points | Level 5 Conditions | Level 7 Conditions | Level 9 Conditions | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Without VE | With VE | Reduction Ratio (%) | Without VE | With VE | Reduction Ratio (%) | Without VE | With VE | Reduction Ratio (%) | |

| 1 | 4.5 × 10−5 | 1.5 × 10−5 | 66.7 | 1.8 × 10−3 | 1.1 × 10−3 | 38.9 | 2.8 × 10−3 | 1.1 × 10−3 | 60.7 |

| 2 | 3.75 × 10−5 | 3.2 × 10−5 | 14.7 | 2.0 × 10−3 | 1.3 × 10−3 | 35.0 | 1.9 × 10−3 | 1.0 × 10−3 | 47.4 |

| 3 | 4.0 × 10−5 | 3.5 × 10−5 | 12.5 | 3.0 × 10−3 | 1.2 × 10−3 | 60.0 | 1.6 × 10−3 | 8.0 × 10−4 | 50.0 |

| 4 | 2.5 × 10−5 | 1.2 × 10−5 | 52.0 | 1.8 × 10−3 | 1.3 × 10−3 | 27.8 | 3.7 × 10−3 | 2.0 × 10−3 | 45.9 |

| 5 | 9.0 × 10−6 | 6.0 × 10−6 | 33.3 | 3.0 × 10−4 | 2.0 × 10−4 | 33.3 | 6.0 × 10−4 | 2.5 × 10−4 | 58.3 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, Q.; Fan, L.; Huo, L.; Song, G. Vibration Reduction of an Existing Glass Window through a Viscoelastic Material-Based Retrofit. Appl. Sci. 2018, 8, 1061. https://doi.org/10.3390/app8071061

Feng Q, Fan L, Huo L, Song G. Vibration Reduction of an Existing Glass Window through a Viscoelastic Material-Based Retrofit. Applied Sciences. 2018; 8(7):1061. https://doi.org/10.3390/app8071061

Chicago/Turabian StyleFeng, Qian, Liming Fan, Linsheng Huo, and Gangbing Song. 2018. "Vibration Reduction of an Existing Glass Window through a Viscoelastic Material-Based Retrofit" Applied Sciences 8, no. 7: 1061. https://doi.org/10.3390/app8071061

APA StyleFeng, Q., Fan, L., Huo, L., & Song, G. (2018). Vibration Reduction of an Existing Glass Window through a Viscoelastic Material-Based Retrofit. Applied Sciences, 8(7), 1061. https://doi.org/10.3390/app8071061