Rheological and Flocculation Analysis of Microfibrillated Cellulose Suspension Using Optical Coherence Tomography

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

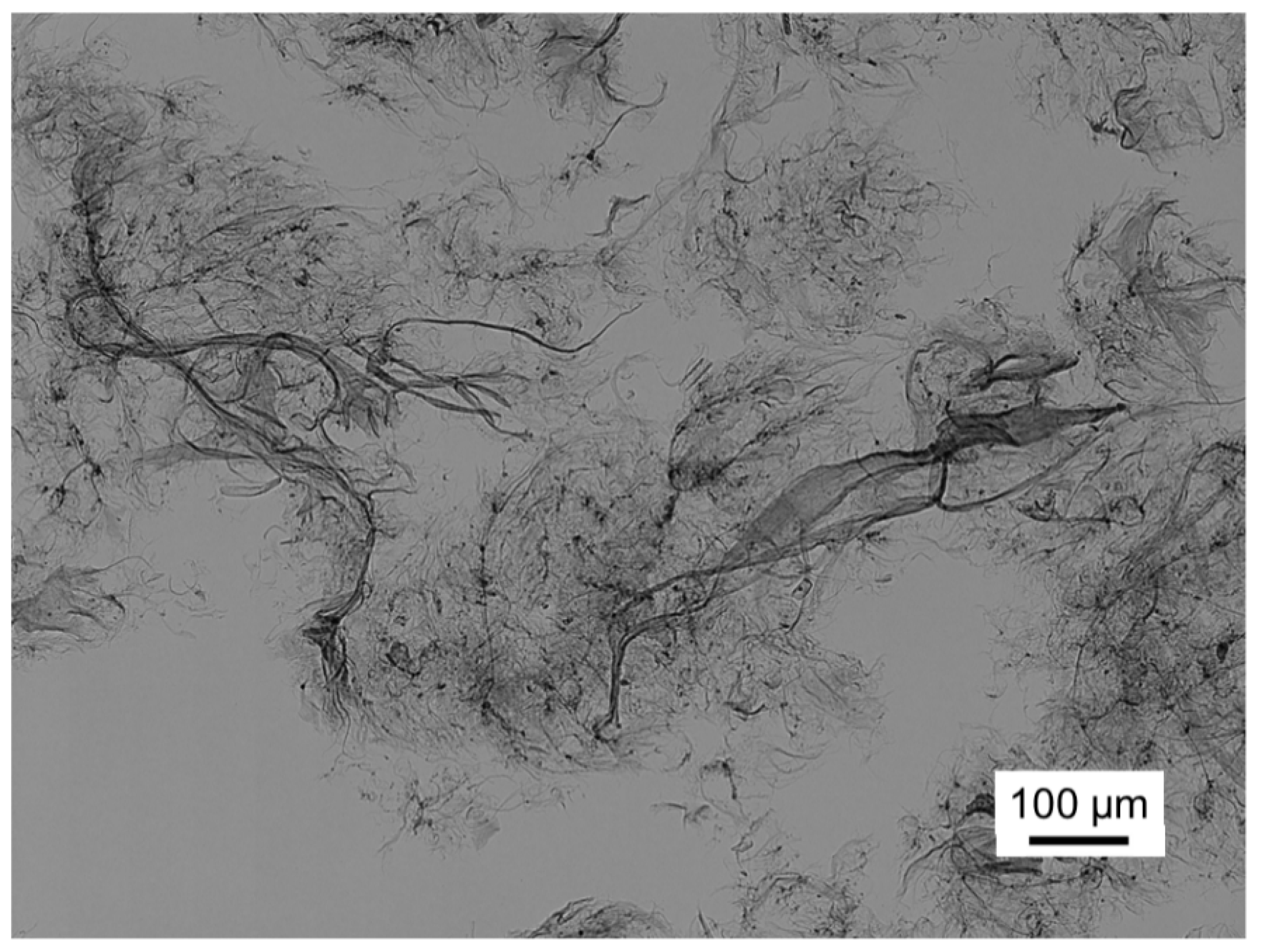

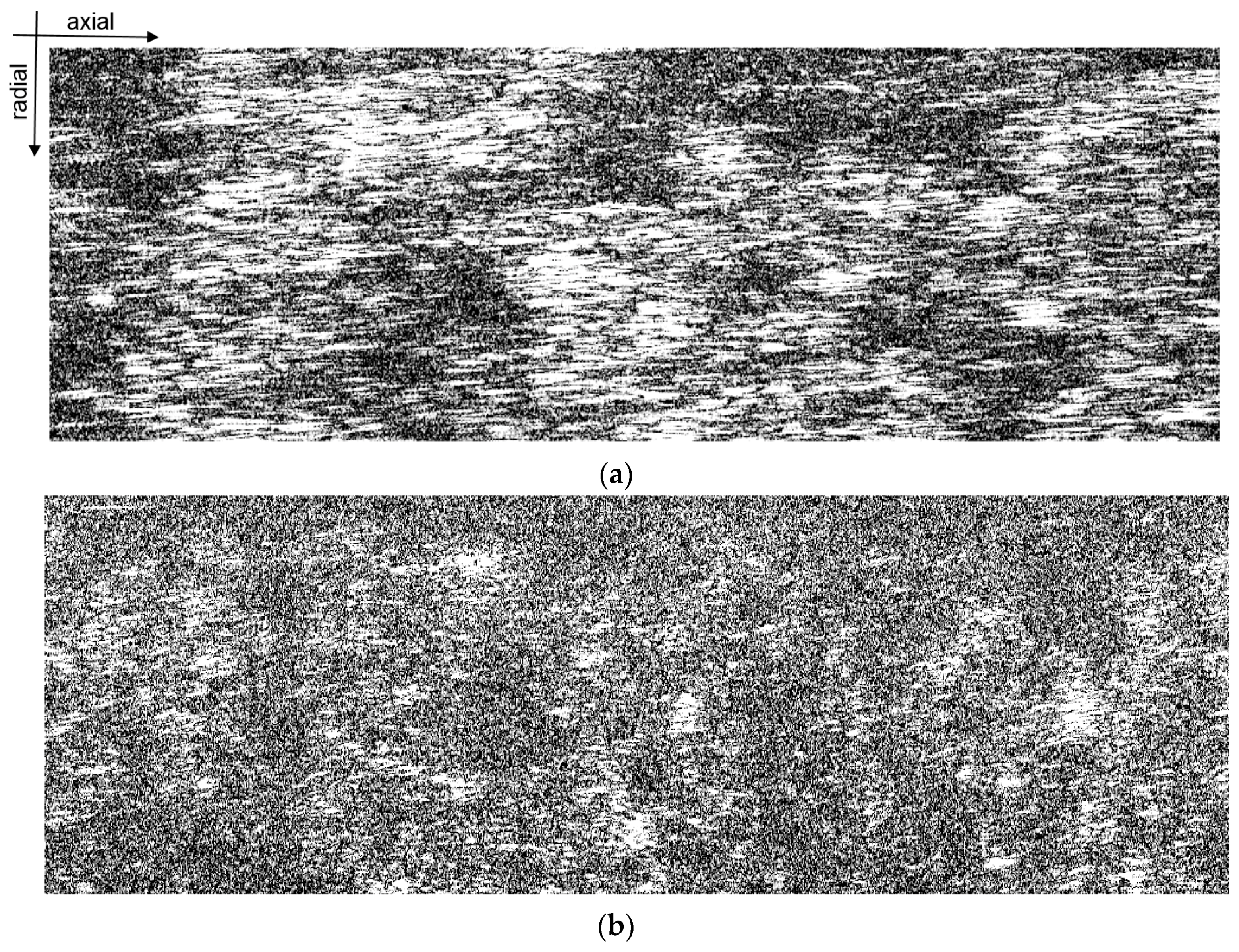

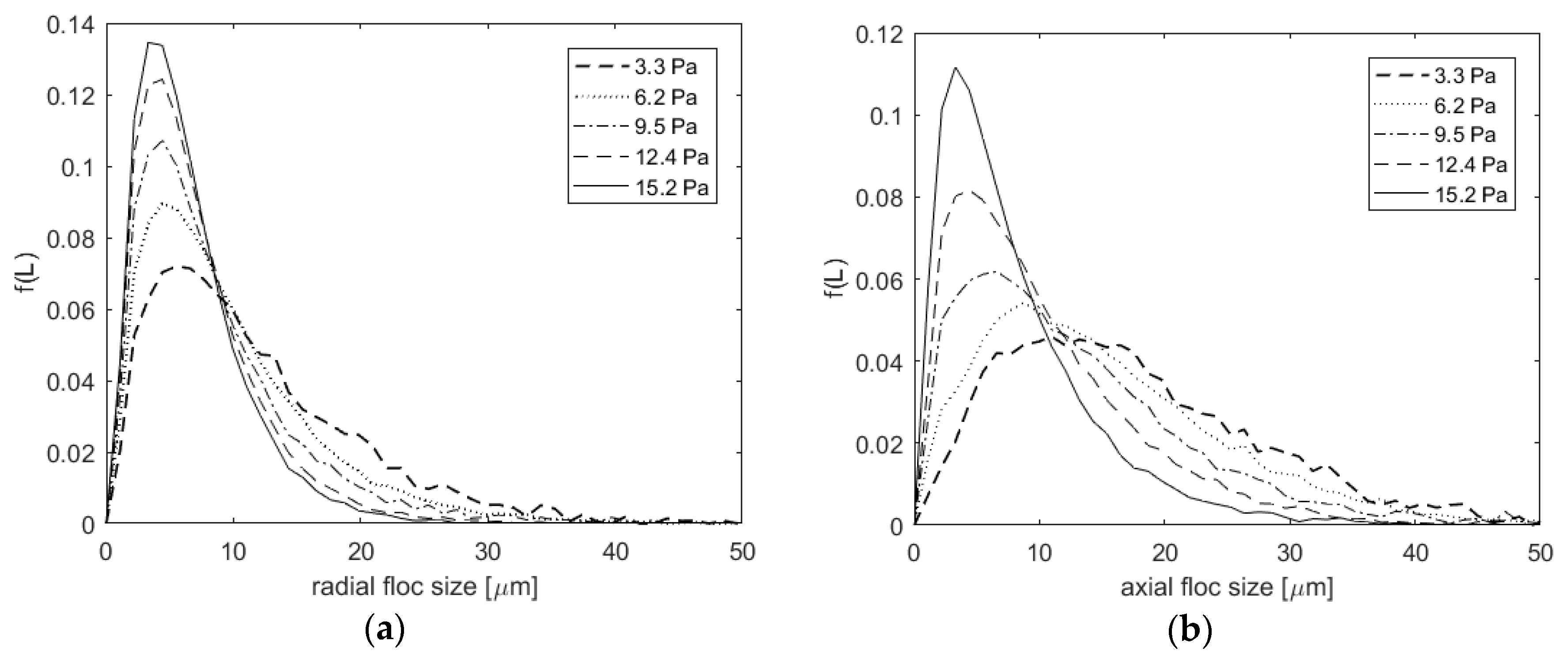

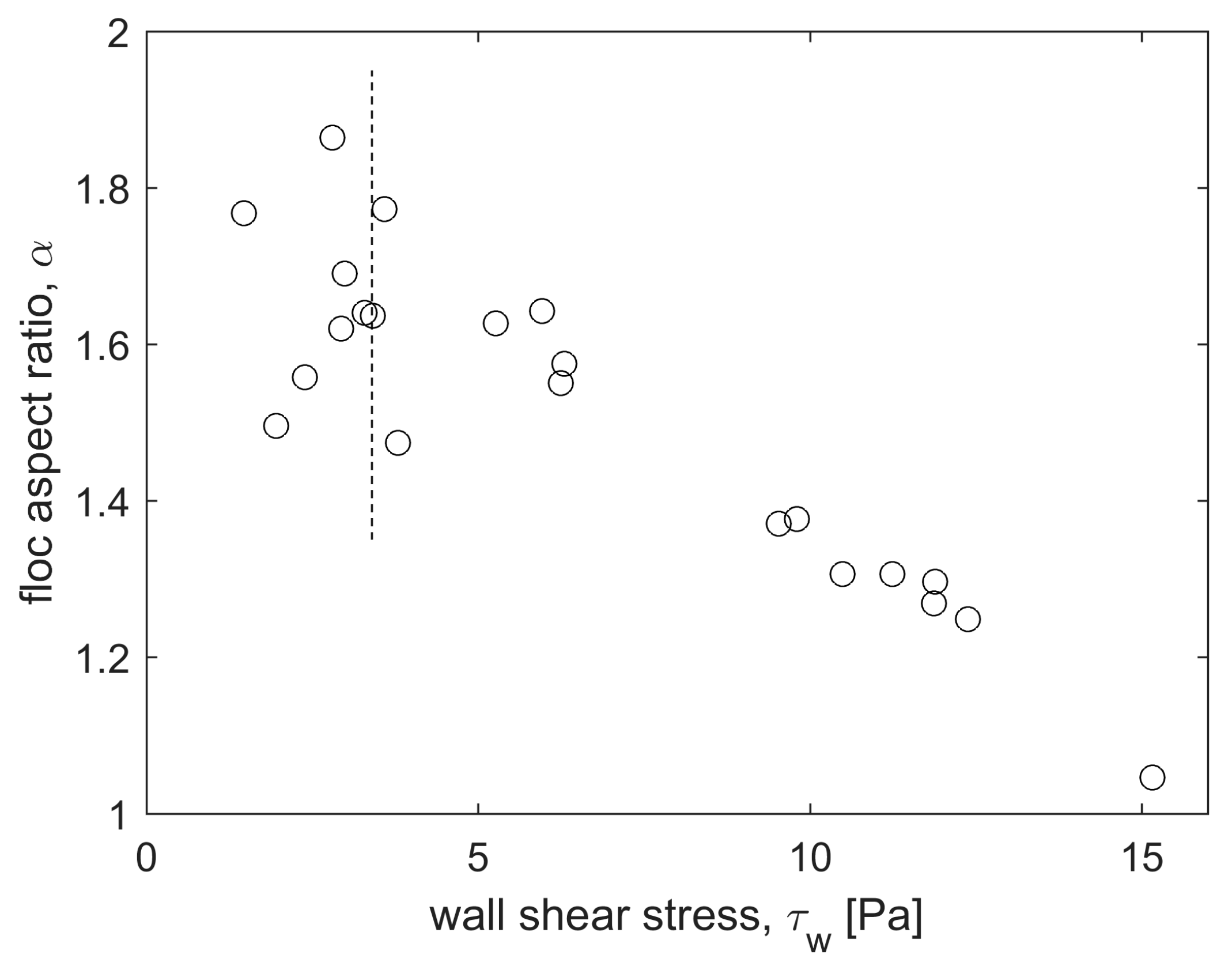

3. Results and Discussion

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Isogai, A. Wood nanocelluloses: Fundamentals and applications as new bio-based nanomaterials. J. Wood Sci. 2013, 59, 449–459. [Google Scholar] [CrossRef]

- Klemm, D.; Kramer, F.; Moritz, S.; Lindström, T.; Ankerfors, M.; Gray, D.; Dorris, A. Nanocelluloses: A New Family of Nature-Based Materials. Angew. Chem. Int. Ed. 2011, 50, 5438–5466. [Google Scholar] [CrossRef] [PubMed]

- Moon, R.J.; Schueneman, G.T.; Simonsen, J. Overview of Cellulose Nanomaterials, Their Capabilities and Applications. JOM 2016, 68, 2383–2394. [Google Scholar] [CrossRef]

- Naderi, A.; Lindström, T. Rheological measurements on nanofibrillated cellulose systems: A science in progress. In Cellulose and Cellulose Derivatives: Synthesis, Modification and Applications; Mondal, M.I.H., Ed.; Nova Science Publishers: New York, NY, USA, 2015. [Google Scholar]

- Nazari, B.; Kumar, V.; Bousfield, D.W.; Toivakka, M. Rheology of cellulose nanofibers suspensions: Boundary driven flow. J. Rheol. 2016, 60, 1151–1159. [Google Scholar] [CrossRef]

- Kumar, V.; Nazari, B.; Bousfield, D.W.; Toivakka, M. Rheology of microfibrillated cellulose suspensions in pressure-driven flow. Appl. Rheol. 2016, 26, 43534. [Google Scholar] [CrossRef]

- Karppinen, A.; Saarinen, T.; Salmela, J.; Laukkanen, A.; Nuopponen, M.; Seppälä, J. Flocculation of microfibrillated cellulose in shear flow. Cellulose 2012, 19, 1807–1819. [Google Scholar] [CrossRef]

- Saarikoski, E.; Saarinen, T.; Salmela, J.; Seppälä, J. Flocculated flow of microfibrillated cellulose water suspensions: An imaging approach for characterisation of rheological behaviour. Cellulose 2012, 19, 647–659. [Google Scholar] [CrossRef]

- Saarinen, T.; Haavisto, S.; Sorvari, A.; Salmela, J.; Seppälä, J. The effect of wall depletion on the rheology of microfibrillated cellulose water suspensions by optical coherence tomography. Cellulose 2014, 21, 1261–1275. [Google Scholar] [CrossRef]

- Lauri, J.; Koponen, A.; Haavisto, S.; Czajkowski, J.; Fabritius, T. Analysis of rheology and wall depletion of microfibrillated cellulose suspension using optical coherence tomography. Cellulose 2017, 24, 4715–4728. [Google Scholar] [CrossRef]

- Swerin, A.; Ödberg, L.; Lindström, T. Deswelling of hardwood kraft pulp fibers by cationic polymers. Nord. Pulp. Pap. Res. J. 1990, 5, 188–196. [Google Scholar] [CrossRef]

- Huang, D.; Swanson, E.; Lin, C.; Schuman, J.; Stinson, W.; Chang, W.; Hee, M.; Flotte, T.; Gregory, K.; Puliafito, C.; et al. Optical coherence tomography. Science 1991, 254, 1178–1181. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Chen, Z.; Saxer, C.; Xiang, S.; de Boer, J.F.; Nelson, J.S. Phase-resolved optical coherence tomography and optical Doppler tomography for imaging blood flow in human skin with fast scanning speed and high velocity sensitivity. Opt. Lett. 2000, 25, 114–116. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.J.; Milner, T.E.; Nelson, J.S. Characterization of fluid flow velocity by optical Doppler tomography. Opt. Lett. 1995, 20, 1337–1339. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.K. High-resolution visualization of fluid dynamics with Doppler optical coherence tomography. Meas. Sci. Technol. 2004, 15, 725–733. [Google Scholar] [CrossRef]

- Bonesi, M.; Churmakov, D.; Meglinski, I. Study of flow dynamics in complex vessels using Doppler optical coherence tomography. Meas. Sci. Technol. 2007, 18, 3279–3286. [Google Scholar] [CrossRef]

- Lauri, J.; Bykov, A.V.; Priezzhev, A.V.; Myllylä, R. Experimental study of the multiple scattering effect on the flow velocity profiles measured in Intralipid phantoms by DOCT. Laser Phys. 2011, 21, 813–817. [Google Scholar] [CrossRef]

- Haavisto, S.; Salmela, J.; Koponen, A. Accurate velocity measurements of boundary-layer flows using Doppler optical coherence tomography. Exp. Fluids 2015, 56, 96. [Google Scholar] [CrossRef]

- Malm, A.V.; Waigh, T.A. Elastic turbulence in entangled semi-dilute DNA solutions measured with optical coherence tomography velocimetry. Sci. Rep. 2017, 7, 1186. [Google Scholar] [CrossRef] [PubMed]

- Harvey, M.; Waigh, T.A. Optical coherence tomography velocimetry in controlled shear flow. Phys. Rev. E 2011, 83, 031502. [Google Scholar] [CrossRef] [PubMed]

- Jaradat, S.; Harvey, M.; Waigh, T.A. Shear-banding in polyacrylamide solutions revealed via optical coherence tomography velocimetry. Soft Matter 2012, 8, 11677–11686. [Google Scholar] [CrossRef]

- Lauri, J.; Bykov, A.V.; Myllyla, R. Determination of suspension viscosity from the flow velocity profile measured by Doppler Optical Coherence Tomography. Photonics Lett. Pol. 2011, 3, 82–84. [Google Scholar] [CrossRef]

- Haavisto, S.; Salmela, J.; Jäsberg, A.; Saarinen, T.; Karppinen, A.; Koponen, A. Rheological characterization of microfibrillated cellulose suspension using optical coherence tomography. TAPPI J. 2015, 14, 291–302. [Google Scholar]

- Czajkowski, J.; Vilmi, P.; Lauri, J.; Sliz, R.; Fabritius, T.; Myllyla, R. Characterization of ink-jet printed RGB color filters with spectral domain optical coherence tomography. In Proceedings of the SPIE 8493, Interferometry XVI: Techniques and Analysis, San Diego, CA, USA, 16 July 2012; pp. 849308–849308-7. [Google Scholar] [CrossRef]

- Lauri, J.; Czajkowski, J.; Myllylä, R.; Fabritius, T. Measuring flow dynamics in a microfluidic chip using optical coherence tomography with 1 µm axial resolution. Flow Meas. Instrum. 2015, 43, 1–5. [Google Scholar] [CrossRef]

- Barnes, H.A. A review of the slip (wall depletion) of polymer solutions, emulsions and particle suspensions in viscometers: Its cause, character, and cure. J. Non Newton. Fluid Mech. 1995, 56, 221–251. [Google Scholar] [CrossRef]

- Petrich, M.P.; Koch, D.L.; Cohen, C. An experimental determination of the stress-microstructure relationship in semi-concentrated fiber suspensions. J. Non Newton. Fluid Mech. 2000, 95, 101–133. [Google Scholar] [CrossRef]

- Bounoua, S.; Lemaire, E.; Férec, J.; Ausias, G.; Kuzhir, P. Shear-thinning in concentrated rigid fiber suspensions: Aggregation induced by adhesive interactions. J. Rheol. 2016, 60, 1279–1300. [Google Scholar] [CrossRef]

- Agoda-Tandjawa, G.; Durand, S.; Berot, S.; Blassel, C.; Gaillard, C.; Garnier, C.; Doublier, J.-L. Rheological characterization of microfibrillated cellulose suspensions after freezing. Carbohydr. Polym. 2010, 80, 677–686. [Google Scholar] [CrossRef]

- Iotti, M.; Gregersen, Ø.W.; Moe, S.; Lenes, M. Rheological Studies of Microfibrillar Cellulose Water Dispersions. J. Polym. Environ. 2011, 19, 137–145. [Google Scholar] [CrossRef]

- Mykhaylyk, O.O.; Warren, N.J.; Parnell, A.J.; Pfeifer, G.; Laeuger, J. Applications of shear-induced polarized light imaging (SIPLI) technique for mechano-optical rheology of polymers and soft matter materials. J. Polym. Sci. Pol. Phys. 2016, 54, 2151–2170. [Google Scholar] [CrossRef]

- Hourani, M.J. Fiber flocculation in pulp suspension flow: Part 2. Experimental results. TAPPI J. 1988, 71, 186–189. [Google Scholar]

- Hourani, M.J. Fiber flocculation in pulp suspension: Part 1. Theoretical model. TAPPI J. 1988, 71, 115–118. [Google Scholar]

- Coufort, C.; Dumas, C.; Bouyer, D.; Liné, A. Analysis of floc size distributions in a mixing tank. Chem. Eng. Process. Process Intensif. 2008, 47, 287–294. [Google Scholar] [CrossRef]

- Shin, J.H.; Son, M.; Lee, G. Stochastic Flocculation Model for Cohesive Sediment Suspended in Water. Water 2015, 7, 2527–2541. [Google Scholar] [CrossRef]

- Kerekes, R.J. Pulp floc behaviour in entry flow to constrictions [Paper industry]. TAPPI J. 1983, 66, 88–91. [Google Scholar]

- Thomas, D.N.; Judd, S.J.; Fawcett, N. Flocculation modelling: A review. Water Res. 1999, 33, 1579–1592. [Google Scholar] [CrossRef]

- Jarvis, P.; Jefferson, B.; Gregory, J.; Parsons, S.A. A review of floc strength and breakage. Water Res. 2005, 39, 3121–3137. [Google Scholar] [CrossRef] [PubMed]

- Cui, H.; Grace, J.R. Flow of pulp fibre suspension and slurries: A review. Int. J. Multiph. Flow 2007, 33, 921–934. [Google Scholar] [CrossRef]

- Keshtkar, M.; Heuzey, M.C.; Carreau, P.J. Rheological behavior of fiber-filled model suspensions: Effect of fiber flexibility. J. Rheol. 2009, 53, 631–650. [Google Scholar] [CrossRef]

- Son, M.; Hsu, T.-J. The effect of variable yield strength and variable fractal dimension on flocculation of cohesive sediment. Water Res. 2009, 43, 3582–3592. [Google Scholar] [CrossRef] [PubMed]

- François, R.J. Strength of aluminium hydroxide flocs. Water Res. 1987, 21, 1023–1030. [Google Scholar] [CrossRef]

- Sonntag, R.C.; Russel, W.B. Structure and breakup of flocs subjected to fluid stresses. J. Colloid Interface Sci. 1986, 113, 399–413. [Google Scholar] [CrossRef]

- Biggs, C.A.; Lant, P.A. Activated sludge flocculation: On-line determination of floc size and the effect of shear. Water Res. 2000, 34, 2542–2550. [Google Scholar] [CrossRef]

- Hubbe, M. Flocculation and redispersion of cellulosic fiber suspensions: A review of effects of hydrodynamic shear and polyelectrolytes. BioResources 2007, 2, 296–331. [Google Scholar]

- Blaser, S. Break-up of flocs in contraction and swirling flows. Colloid Surface A 2000, 166, 215–223. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koponen, A.I.; Lauri, J.; Haavisto, S.; Fabritius, T. Rheological and Flocculation Analysis of Microfibrillated Cellulose Suspension Using Optical Coherence Tomography. Appl. Sci. 2018, 8, 755. https://doi.org/10.3390/app8050755

Koponen AI, Lauri J, Haavisto S, Fabritius T. Rheological and Flocculation Analysis of Microfibrillated Cellulose Suspension Using Optical Coherence Tomography. Applied Sciences. 2018; 8(5):755. https://doi.org/10.3390/app8050755

Chicago/Turabian StyleKoponen, Antti I., Janne Lauri, Sanna Haavisto, and Tapio Fabritius. 2018. "Rheological and Flocculation Analysis of Microfibrillated Cellulose Suspension Using Optical Coherence Tomography" Applied Sciences 8, no. 5: 755. https://doi.org/10.3390/app8050755

APA StyleKoponen, A. I., Lauri, J., Haavisto, S., & Fabritius, T. (2018). Rheological and Flocculation Analysis of Microfibrillated Cellulose Suspension Using Optical Coherence Tomography. Applied Sciences, 8(5), 755. https://doi.org/10.3390/app8050755