Real-Time Estimation for Cutting Tool Wear Based on Modal Analysis of Monitored Signals

Abstract

:1. Introduction

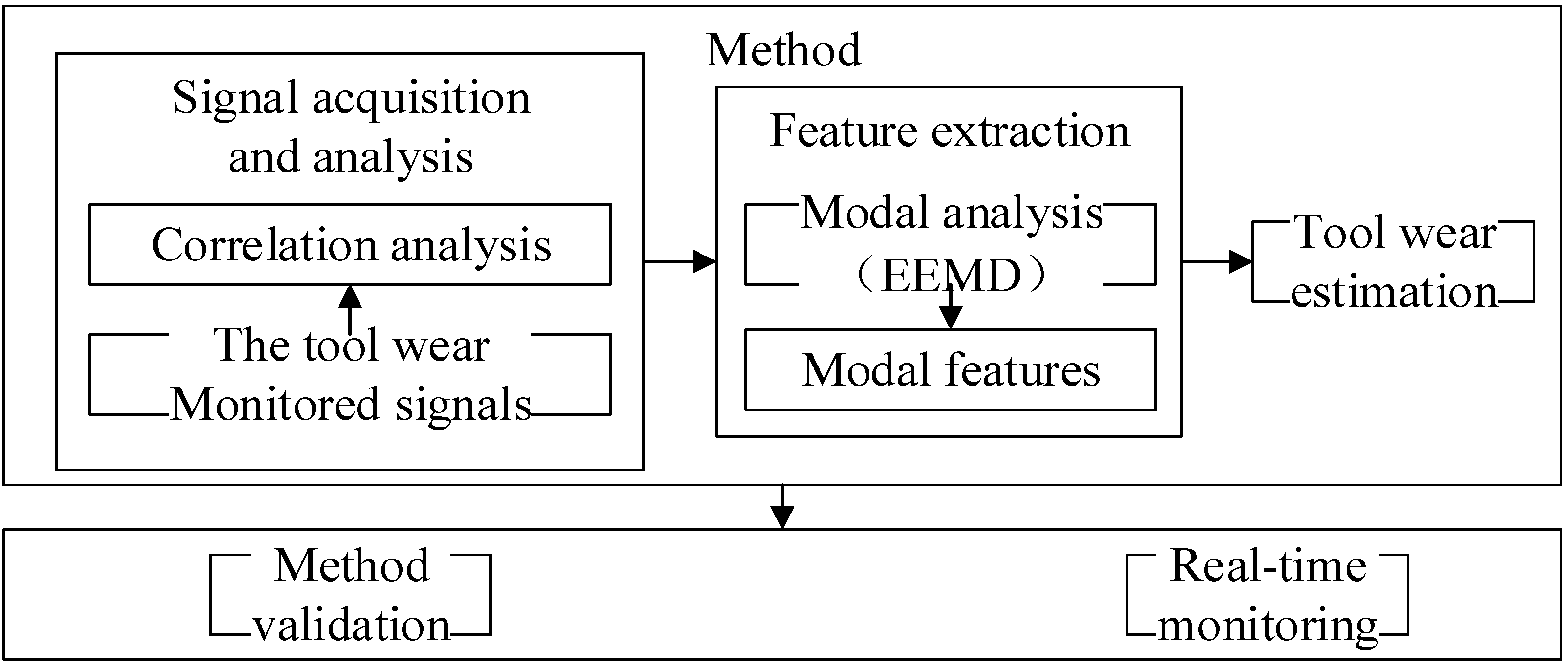

2. Algorithm Theory and Method

2.1. Method Flowchart

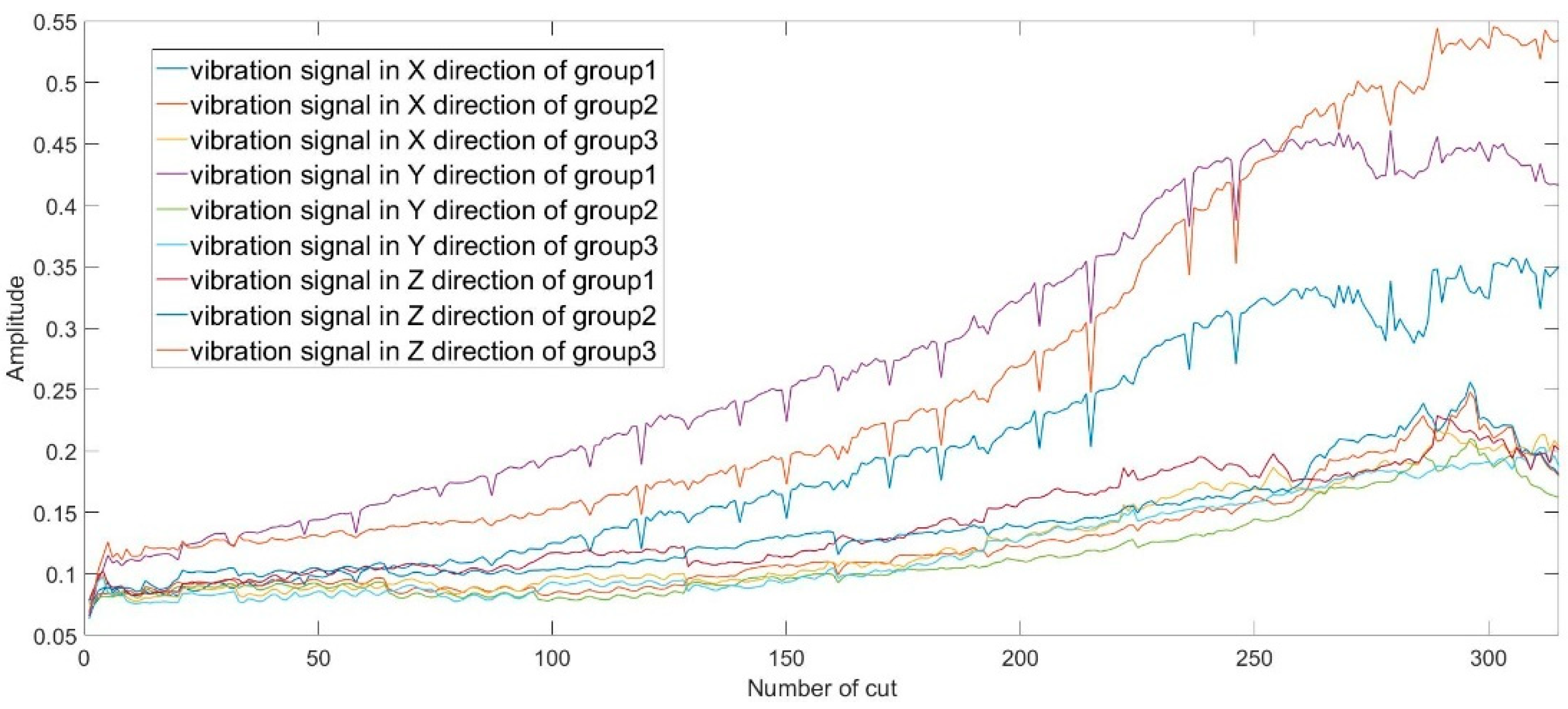

2.2. Monitored Signals and Tool Wear

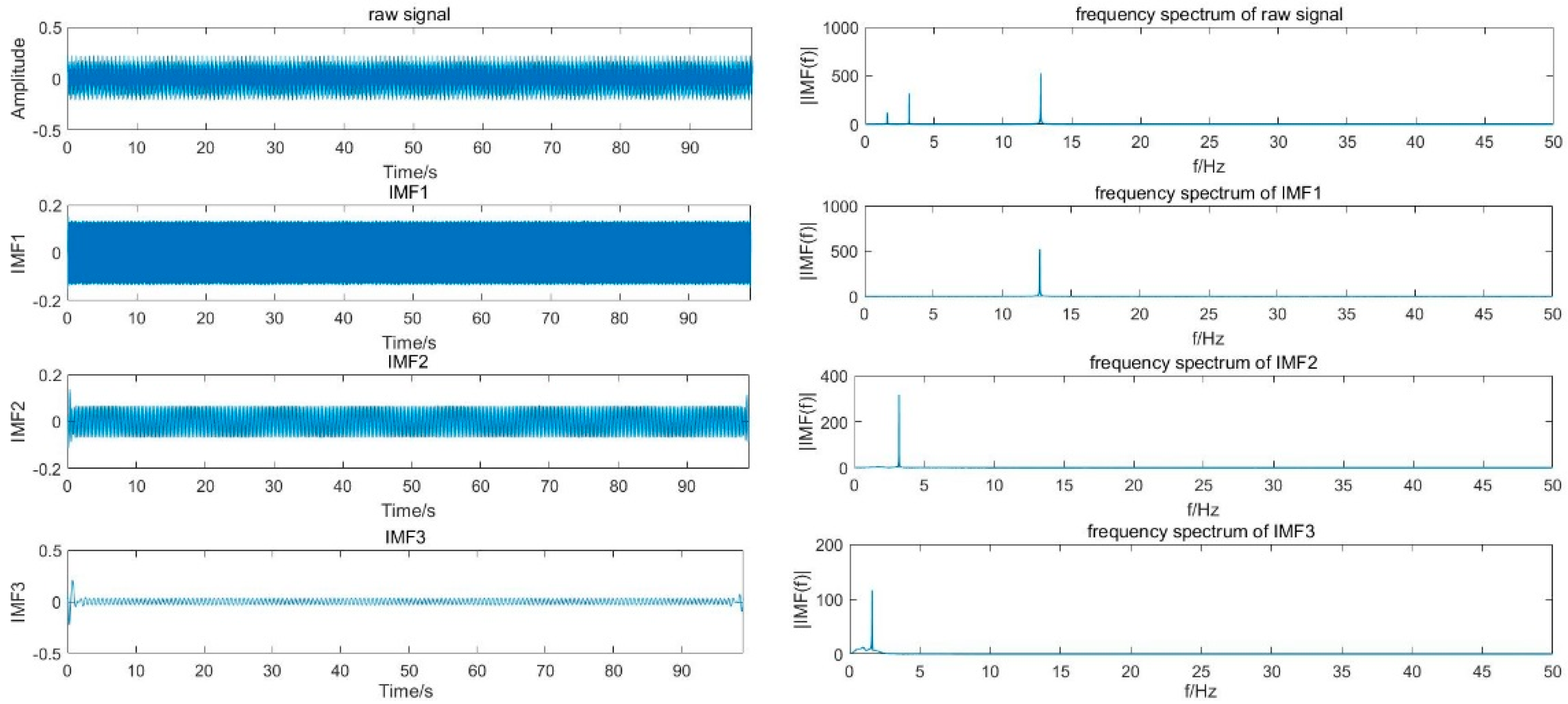

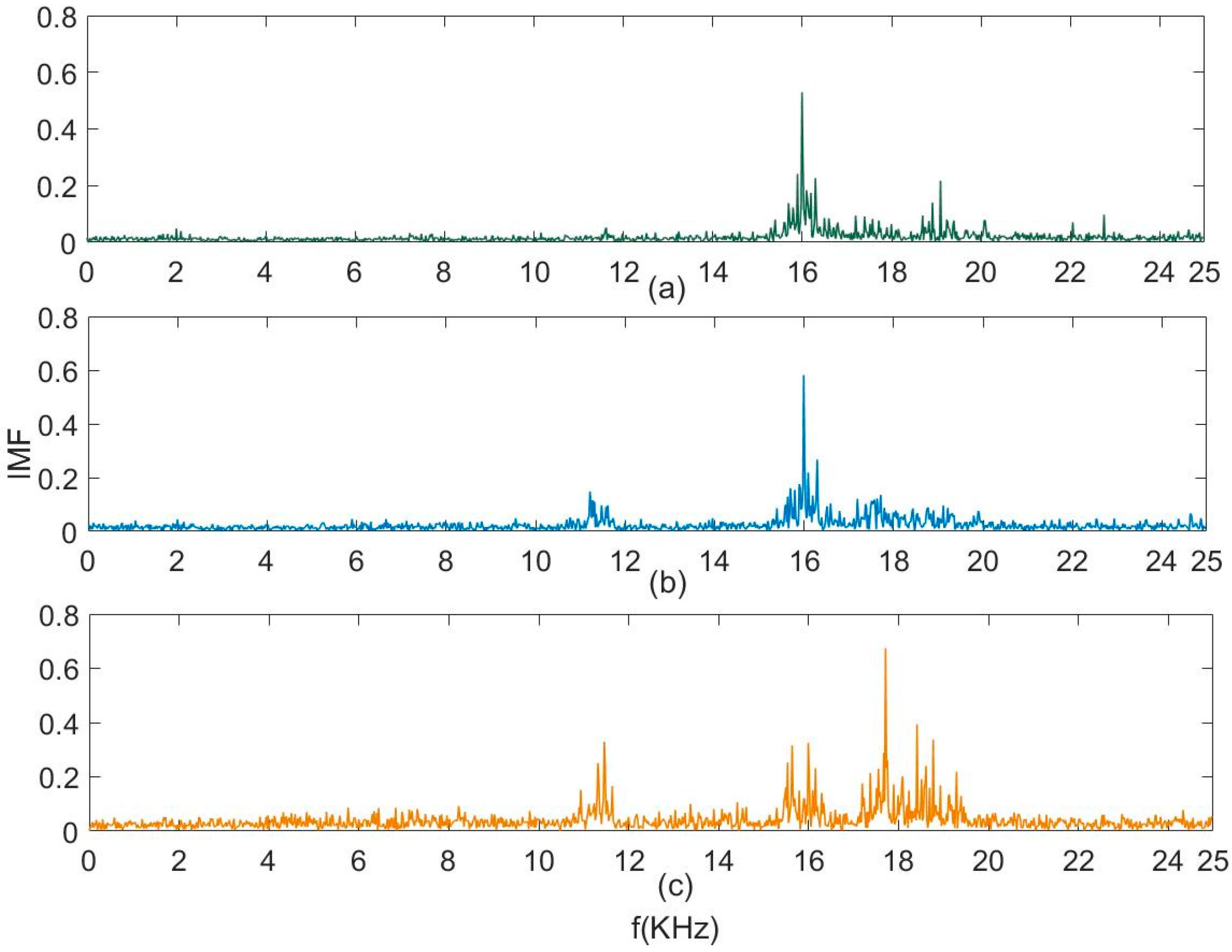

2.3. Modal Feature Extraction Based on Empirical Mode Decomposition (EEMD)

- Step 1: add a white noise series to the targeted data.

- Step 2: decompose the data with added white noise into intrinsic mode function (IMF).

- Step 3: repeat step 1 and step 2 again and again, but with different white noise series each time.

- Step 4: obtain the ensemble means of corresponding IMFs of the decompositions as the final result.

2.4. Curve Fitting of Tool Wear

3. Experimental Study

3.1. Milling Experiments

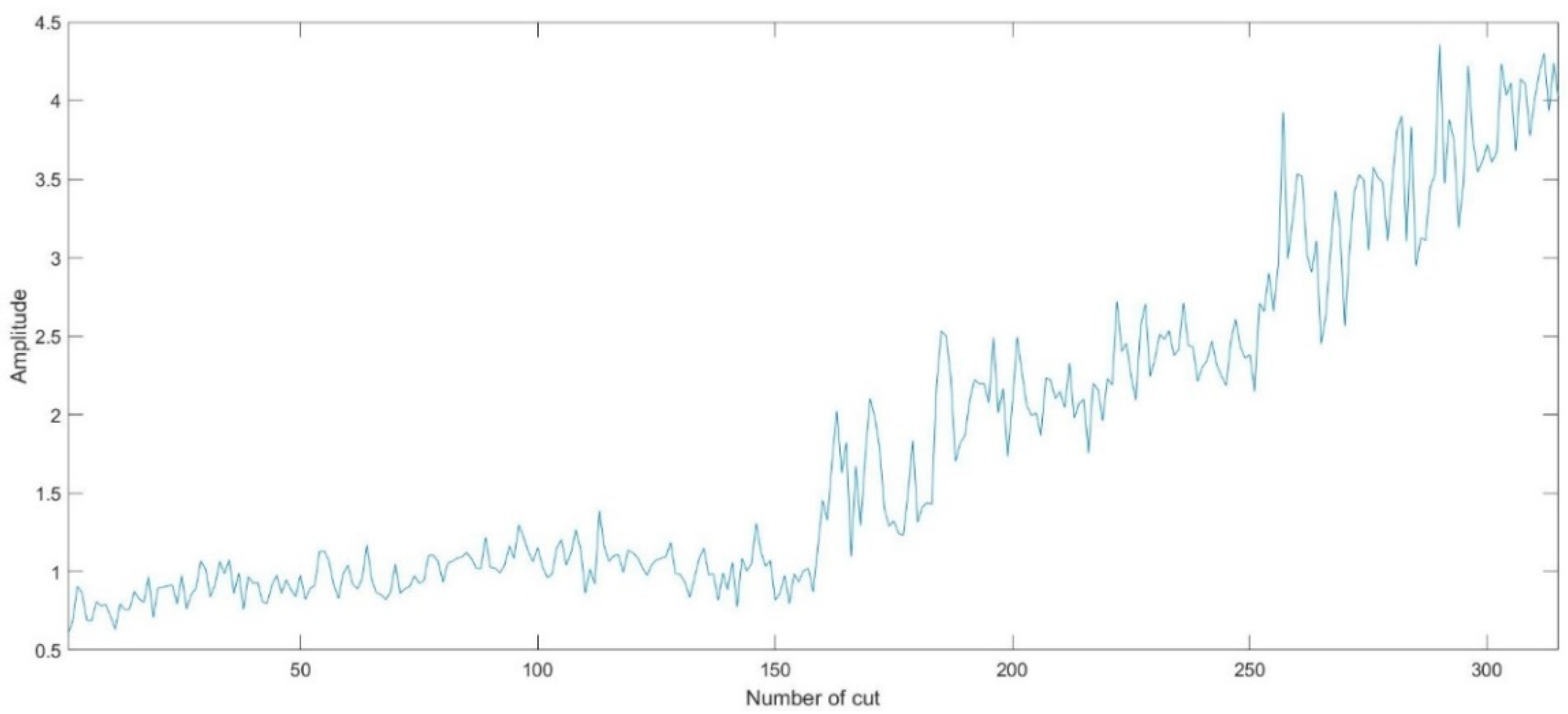

3.2. Correlation Analysis of Signals

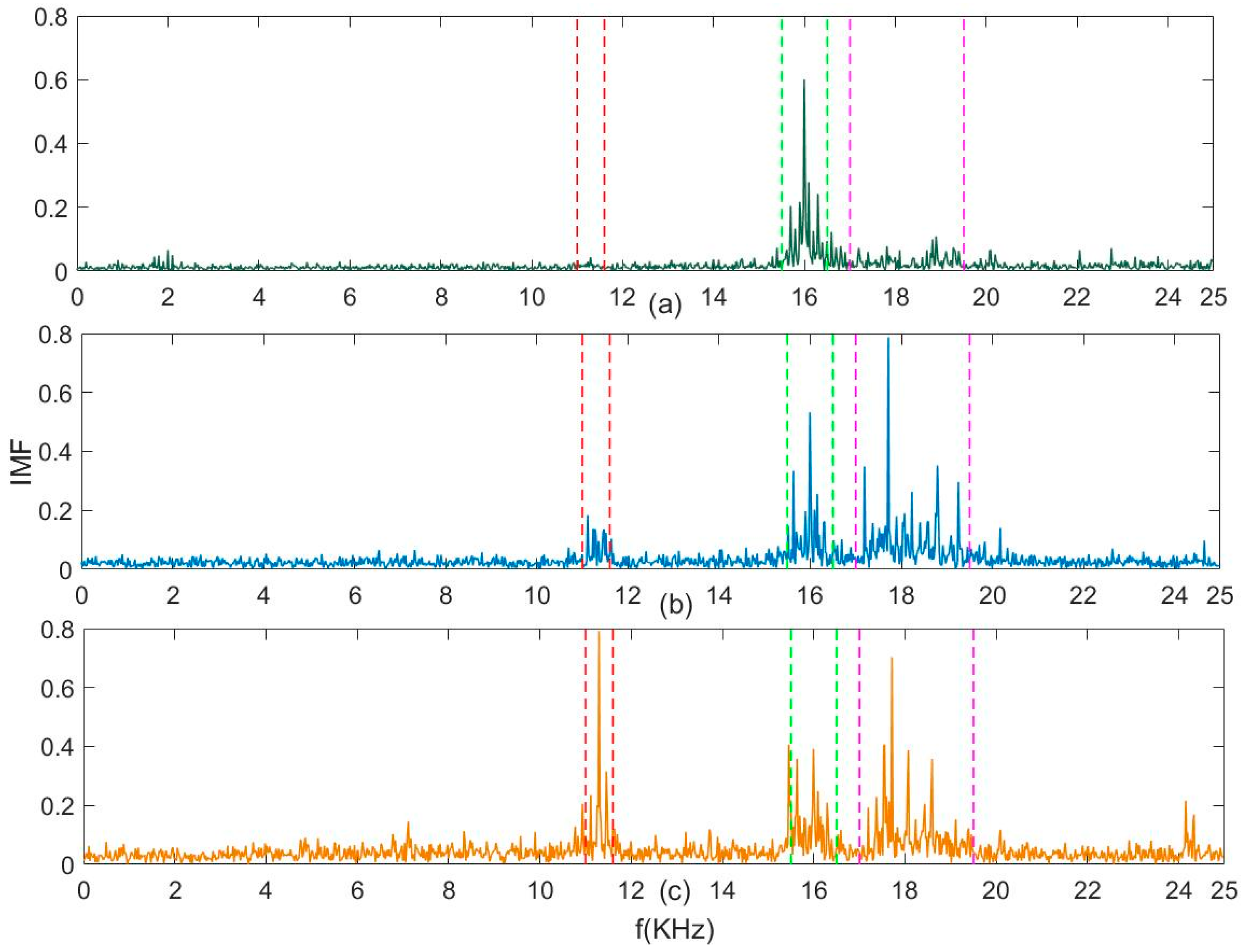

3.3. Feature Extraction of Test Data

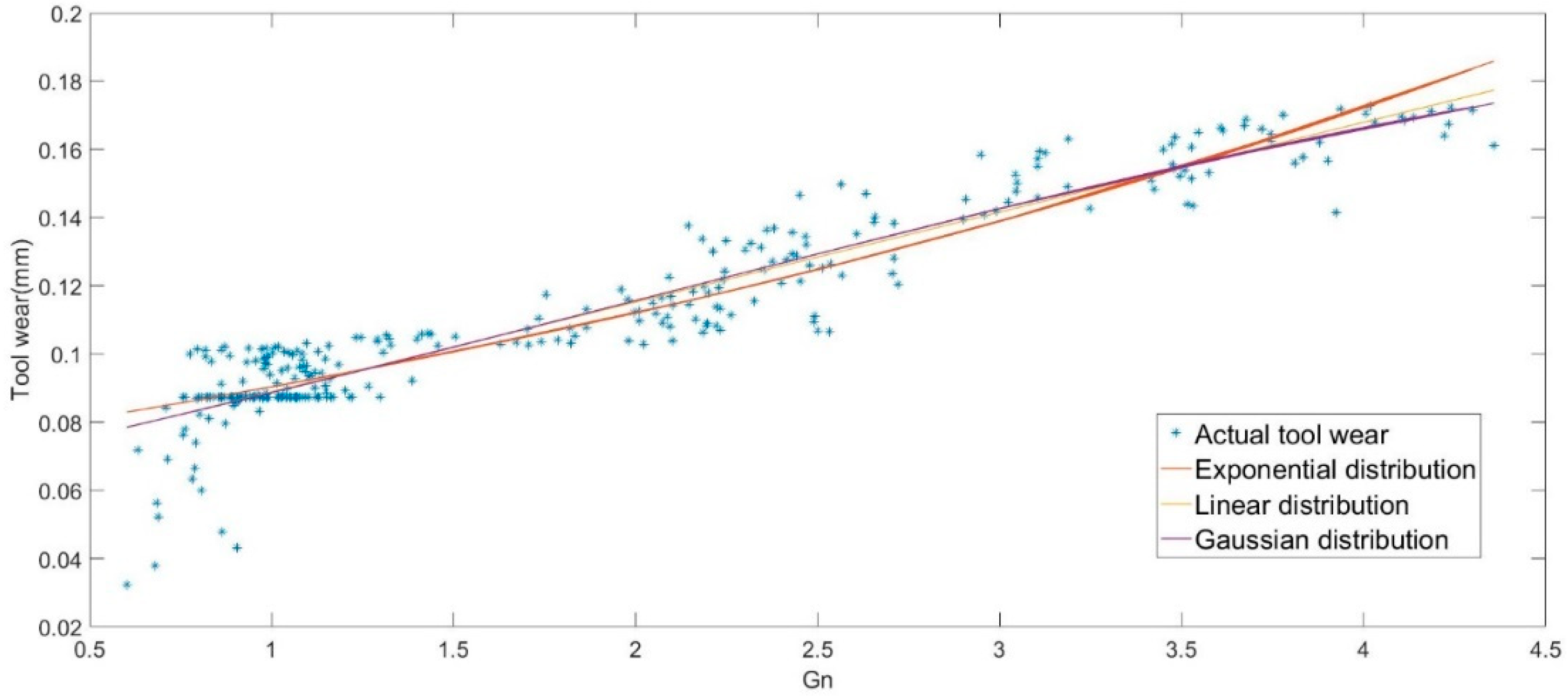

3.4. Tool Wear Distribution Fitting and Parameters Calculation

4. Method Validation and Application

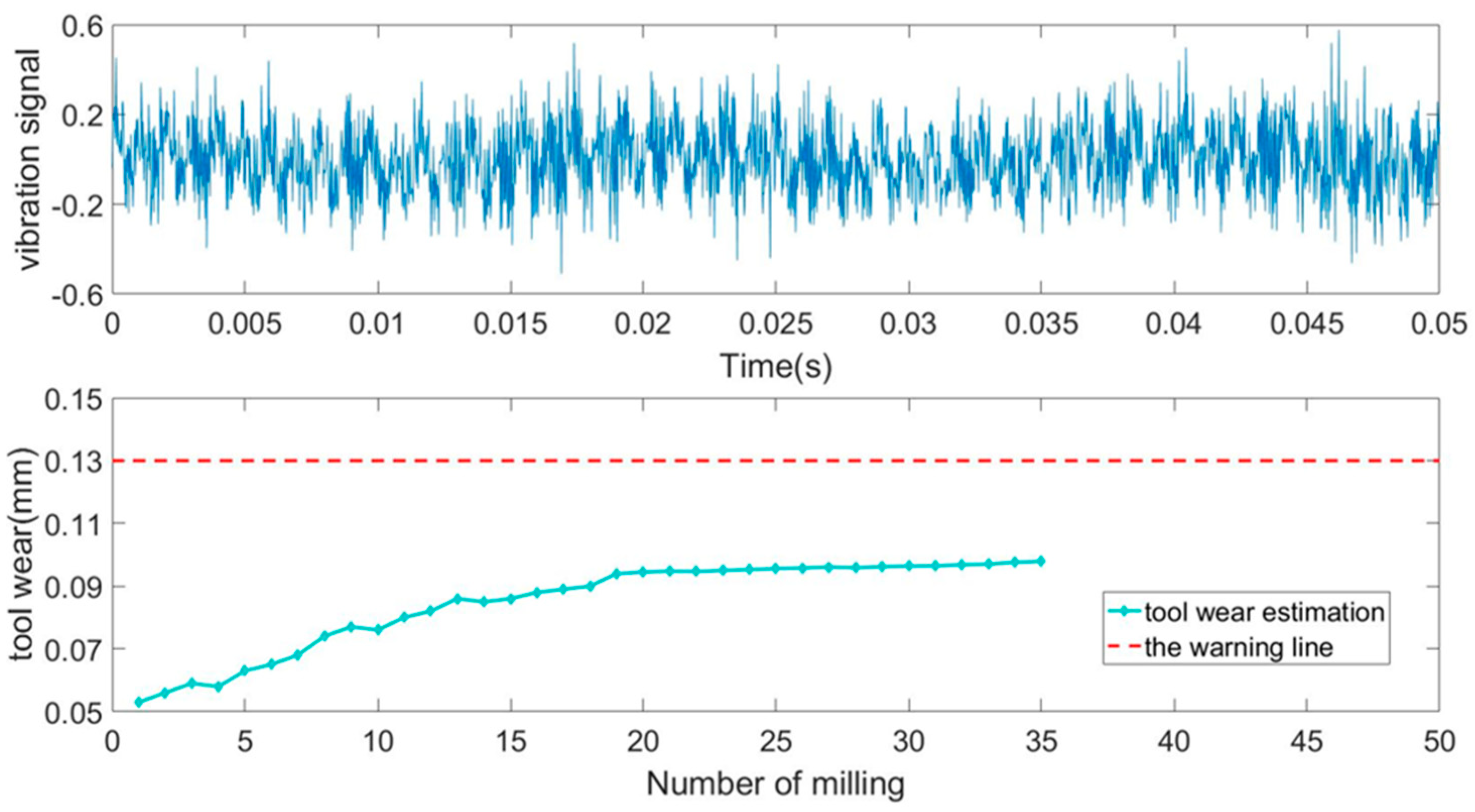

4.1. Validity of Tool Wear Estimation

4.2. Tool Wear Real-Time Estimation and Early Warning

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Wang, Y.; Jia, Y.; Yu, J.; Zheng, Y.; Yi, S. Failure probabilistic model of CNC lathes. Reliab. Eng. Syst. Saf. 1999, 65, 307–314. [Google Scholar] [CrossRef]

- Dai, Y.; Zhou, Y.F.; Jia, Y.Z. Distribution of time between failures of machining center based on type I censored data. Reliab. Eng. Syst. Saf. 2003, 79, 377–379. [Google Scholar] [CrossRef]

- Li, X.; Lim, B.S.; Zhou, J.H.; Huang, S.; Phua, S.J.; Shaw, K.C.; Er, M.J. Fuzzy neural network modelling for tool wear estimation in dry milling operation. In Proceedings of the Annual Conference of the Prognostics and Health Management Society, San Diego, CA, USA, 27 September–1 October 2009; pp. 1–11. [Google Scholar]

- Li, H.; Wang, Y.; Zhao, P.; Zhang, X.; Zhou, P. Cutting tool operational reliability prediction based on acoustic emission and logistic regression model. J. Intell. Manuf. 2015, 26, 923–931. [Google Scholar] [CrossRef]

- Wang, S.M.; Chen, Y.S.; Lee, C.Y.; Yeh, C.C.; Wang, C.C. Methods of In-Process On-Machine Auto-Inspection of Dimensional Error and Auto-Compensation of Tool Wear for Precision Turning. Appl. Sci. 2016, 6, 107. [Google Scholar] [CrossRef]

- Liu, G.; Chen, H.; Huang, Z.; Gao, F.; Chen, T. Surface Quality of Staggered PCD End Mill in Milling of Carbon Fiber Reinforced Plastics. Appl. Sci. 2017, 7, 199. [Google Scholar] [CrossRef]

- Kilickap, E.; Yardimeden, A.; Çelik, Y.H. Mathematical Modelling and Optimization of Cutting Force, Tool Wear and Surface Roughness by Using Artificial Neural Network and Response Surface Methodology in Milling of Ti-6242S. Appl. Sci. 2017, 7, 1064. [Google Scholar] [CrossRef]

- Caggiano, A. Tool Wear Prediction in Ti-6Al-4V Machining through Multiple Sensor Monitoring and PCA Features Pattern Recognition. Sensors 2018, 18, 823. [Google Scholar] [CrossRef] [PubMed]

- Rock, M.; Chen, J.; Tin, M. A Comprehensive Study on Tool-Wear Monitoring in High-Speed Machining Process by Using Multi-Sensor Operation. In Proceedings of the International Conference on Machining and Machinability of Materials, Venice, Italy, 8–9 August 2016. [Google Scholar]

- Cong, Y.; Lian, Y.; Guo, Y. Research on the Signal Processing Method for Balancing Measurement System Based on EEMD. In Proceedings of the 2015 8th International Symposium on Computational Intelligence and Design (ISCID), Hangzhou, China, 12–13 December 2015; pp. 418–421. [Google Scholar] [CrossRef]

- Lei, Y.; Kong, D.; Naipeng, L.I.; Lin, J. Adaptive Ensemble Empirical Mode Decomposition and Its Application to Fault Detection of Planetary Gearboxes. J. Mech. Eng. 2014, 50, 64. [Google Scholar] [CrossRef]

- Jiang, H.; Li, C.; Li, H. An improved EEMD with multiwavelet packet for rotating machinery multi-fault diagnosis. Mech. Syst. Signal Process. 2013, 36, 225–239. [Google Scholar] [CrossRef]

- Lei, Y.; Zuo, M.J. Fault diagnosis of rotating machinery using an improved HHT based on EEMD and sensitive IMFs. Meas. Sci. Technol. 2009, 20, 125701. [Google Scholar] [CrossRef]

- Li, T.; Zhang, F.; Jiang, J. Structural modal parameters indentification method based on hilbert-huang transform and independent component technique. Foreign Electron. Meas. Technol. 2014, 3, 42–45. [Google Scholar]

- Huang, S.N.; Tan, K.K.; Wong, Y.S.; Silva, C.W.D.; Goh, H.L.; Tan, W.W. Tool wear detection and fault diagnosis based on cutting force monitoring. Int. J. Mach. Tools Manuf. 2007, 47, 444–451. [Google Scholar] [CrossRef]

- Sharma, V.S.; Sharma, S.K.; Sharma, A.K. Cutting tool wear estimation for turning. J. Intell. Manuf. 2008, 19, 99–108. [Google Scholar] [CrossRef]

- Alonso, F.J.; Salgado, D.R. Analysis of the structure of vibration signals for tool wear detection. Mech. Syst. Signal Process. 2008, 22, 735–748. [Google Scholar] [CrossRef]

- Snr, D.E.D. The Correlation of Vibration Signal Features to Cutting Tool Wear in a Metal Turning Operation. Int. J. Adv. Manuf. Technol. 2002, 19, 705–713. [Google Scholar]

- Wu, Z.; Huang, N.E. Ensemble Empirical mode decomposition: A noise-assisted data analysis method. Adv. Adapt. Data Anal. 2009, 1, 1–41. [Google Scholar] [CrossRef]

| Groups | In X Direction | In Y Direction | In Z Direction |

|---|---|---|---|

| 1 | 0.9605 | 0.9574 | 0.9337 |

| 2 | 0.9328 | 0.9278 | 0.9467 |

| 3 | 0.9370 | 0.9406 | 0.9220 |

| Distribution | Linear | Exponential | Gaussian |

|---|---|---|---|

| a | 0.02635 | 0.07289 | 0.192 |

| b | 0.06255 | 0.2148 | 6.261 |

| c | - | - | 5.985 |

| root mean square error (RMSE) | 0.0094 | 0.0099 | 0.0093 |

| Number of Cut | 85 | 185 | 285 |

|---|---|---|---|

| Gn | 1.1210 | 2.5329 | 2.9481 |

| Time (s) | Estimated Tool Wear (mm) | Actual Tool Wear (mm) | Absolute Error (mm) |

|---|---|---|---|

| 376 | 0.0918 | 0.0874 | 0.0044 |

| 816 | 0.1303 | 0.1065 | 0.0238 |

| 1256 | 0.1413 | 0.1583 | 0.017 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chi, Y.; Dai, W.; Lu, Z.; Wang, M.; Zhao, Y. Real-Time Estimation for Cutting Tool Wear Based on Modal Analysis of Monitored Signals. Appl. Sci. 2018, 8, 708. https://doi.org/10.3390/app8050708

Chi Y, Dai W, Lu Z, Wang M, Zhao Y. Real-Time Estimation for Cutting Tool Wear Based on Modal Analysis of Monitored Signals. Applied Sciences. 2018; 8(5):708. https://doi.org/10.3390/app8050708

Chicago/Turabian StyleChi, Yongjiao, Wei Dai, Zhiyuan Lu, Meiqing Wang, and Yu Zhao. 2018. "Real-Time Estimation for Cutting Tool Wear Based on Modal Analysis of Monitored Signals" Applied Sciences 8, no. 5: 708. https://doi.org/10.3390/app8050708

APA StyleChi, Y., Dai, W., Lu, Z., Wang, M., & Zhao, Y. (2018). Real-Time Estimation for Cutting Tool Wear Based on Modal Analysis of Monitored Signals. Applied Sciences, 8(5), 708. https://doi.org/10.3390/app8050708