1. Introduction

The electrohydrodynamic-jet (EHD jet) has emerged as a fine patterning tool for various applications [

1]. The EHD jet process uses the high DC voltage applied at the nozzle part to charge ink and produce an electrical field for jetting [

2,

3,

4,

5,

6]. For drop-on-demand (DOD) EHD jetting, an additional pulse voltage has been used to produce one droplet per pulse voltage. To design the pulse voltage shape for proper jetting, Mishra et al. proposed a pulse width modulation method [

5], whilst Kwon et al. presented the use of trapezoidal pulse voltage [

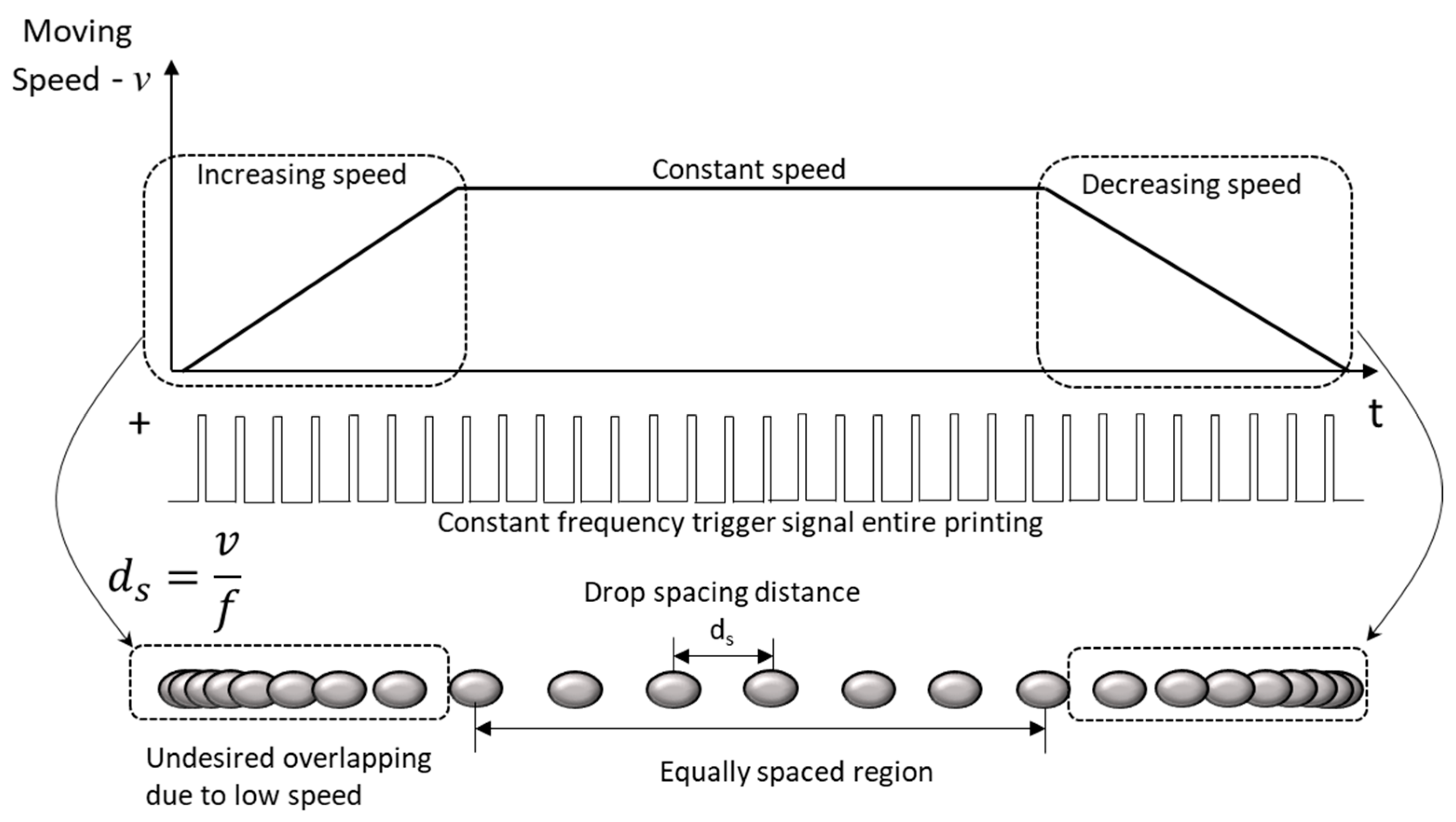

6]. For EHD printing, most previous works have used AC or pulse voltage with constant frequency [

4,

5,

6,

7,

8]. In such cases, there will be a large amount of deposited droplets at the starting and end points, which is caused by printing speed variation. Uniformity in the printed pattern is important for most fine patterning applications, including conductive patterning, semi-conductor applications, and repair application for broken circuits. As a result, the EHD applications can be limited to the case of low printing speed, and there has been a trade-off relationship between the printing speed and print quality. Nevertheless, to the best of the author’s knowledge, few papers have discussed the printing uniformity issue of the end points of the EHD printed lines.

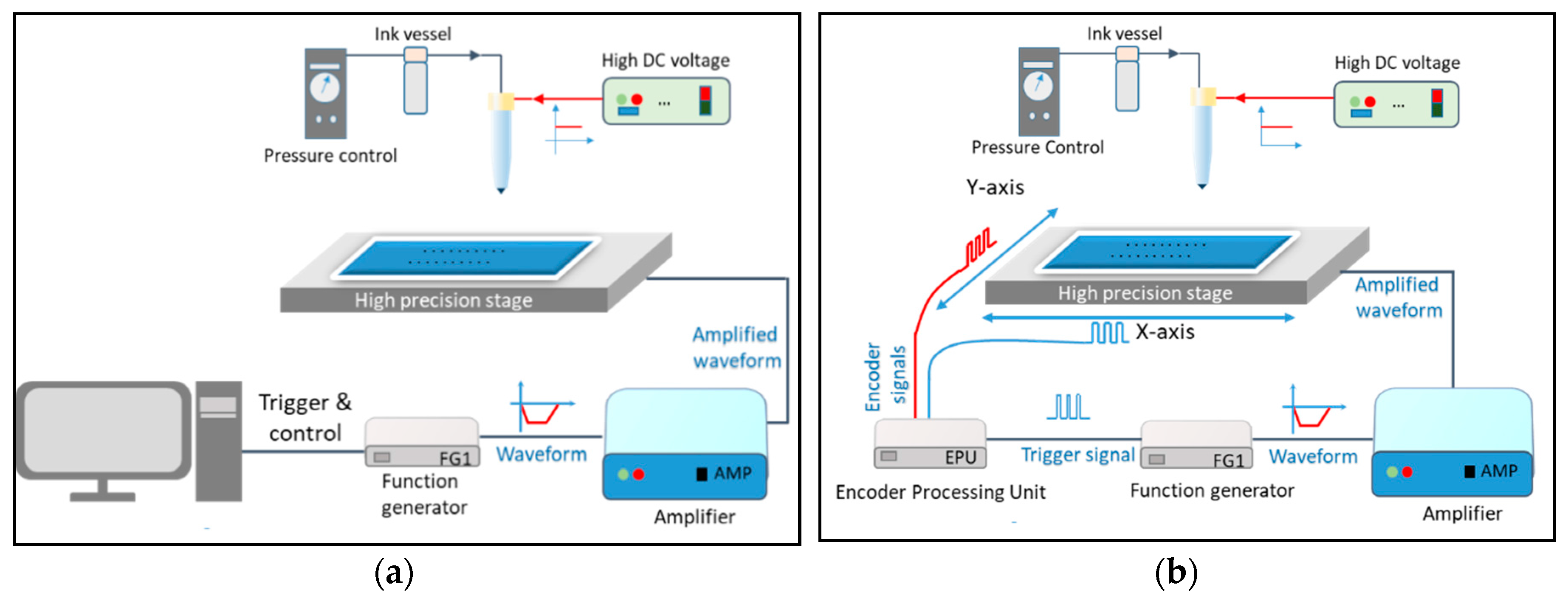

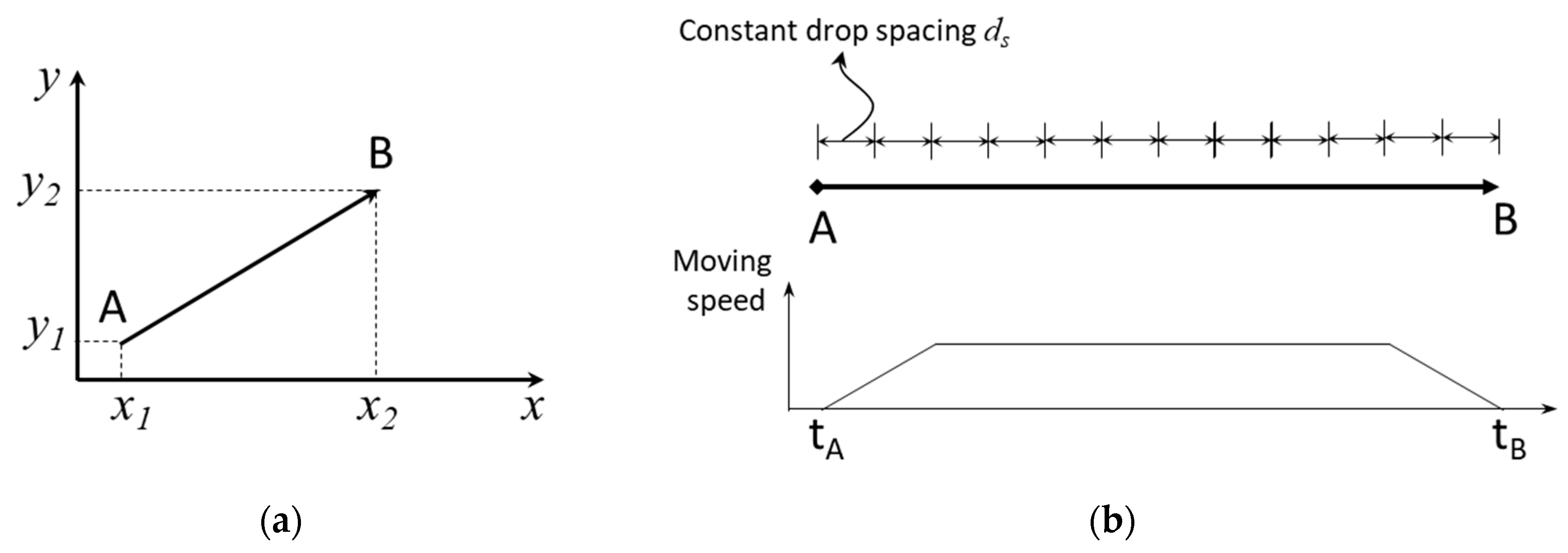

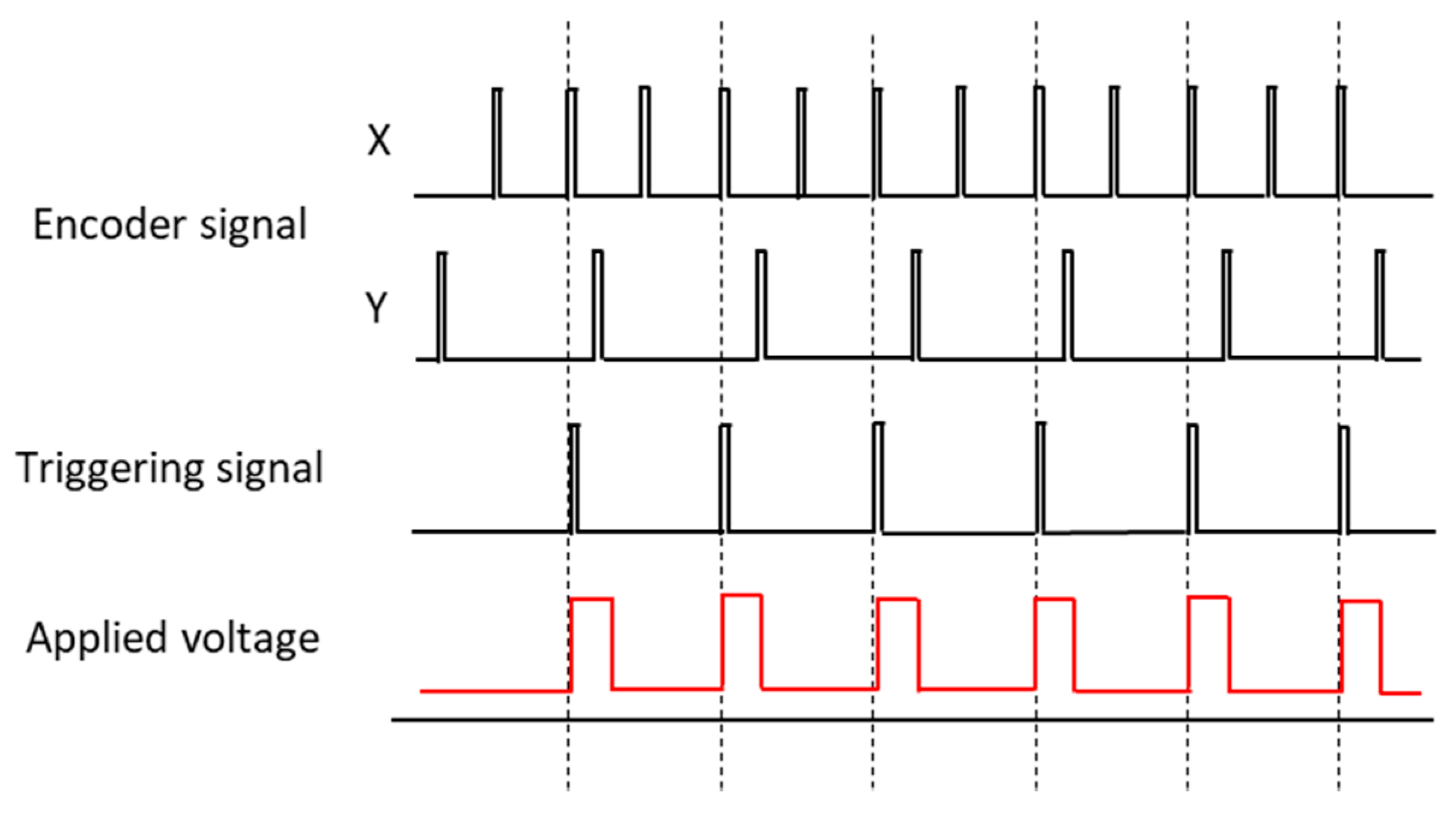

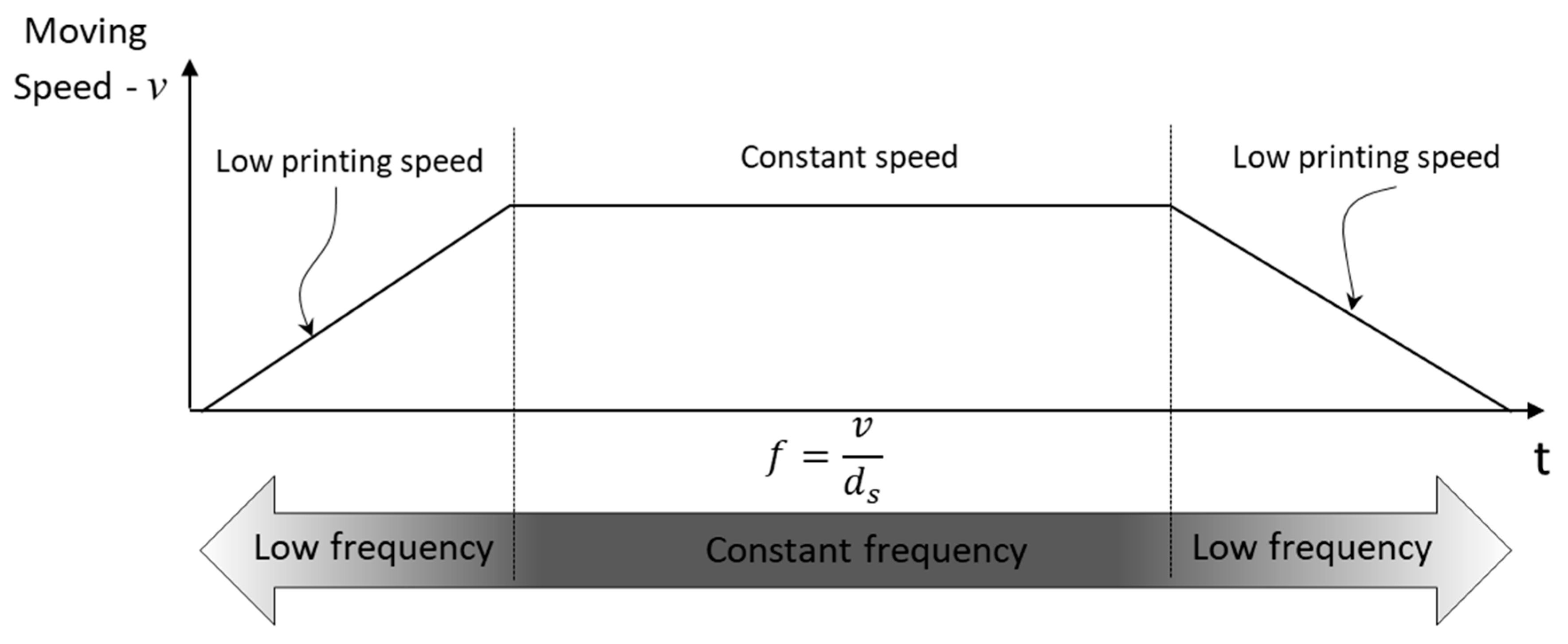

In the case of conventional piezo-based inkjet application, the encoder signals (positioning sensors in stages) have been used for bitmap printing to obtain equally spaced printing irrespective of the printing speed. However, the conventional inkjet printing uses only one axis of the encoder signal for the main direction printing, while the other axis is used for movement of the printing location for the next swath. The conventional method using encoder signals from a single axis is useful to print bitmap images by using inkjet heads with many nozzles. However, in the case of EHD printing, a single nozzle is more commonly used, since the multi-nozzle EHD head is difficult to implement, because of the electrical crosstalk effects from adjacent nozzles. In such a case, vector printing using a single nozzle rather than bitmap image printing is more suitable for its application. Vector printing commonly involves the vector motion of stages that require the simultaneous movement of more than two axes. Therefore, the hardware and software algorithm requirements for vector printing should be different from those for bitmap printing.

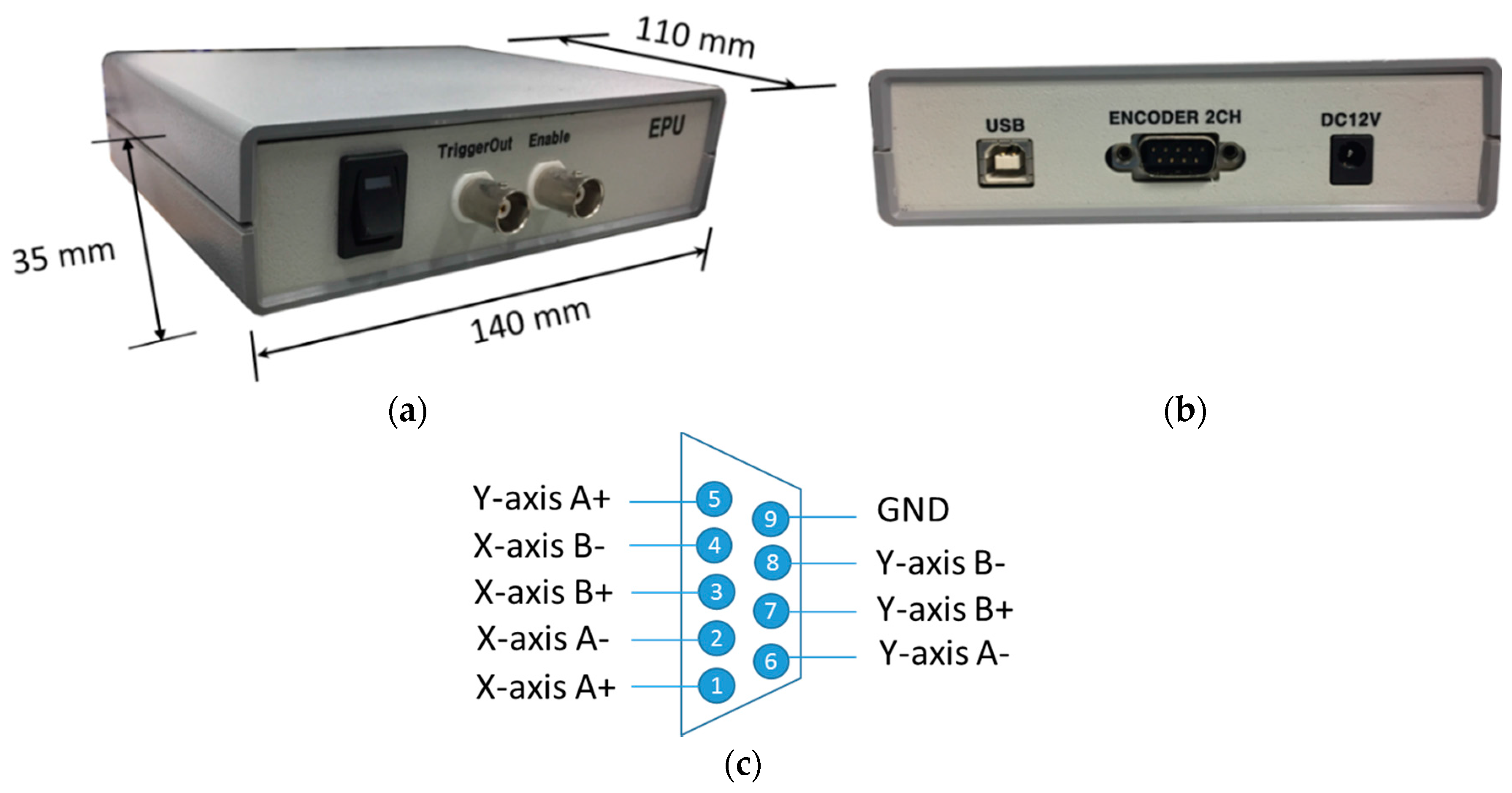

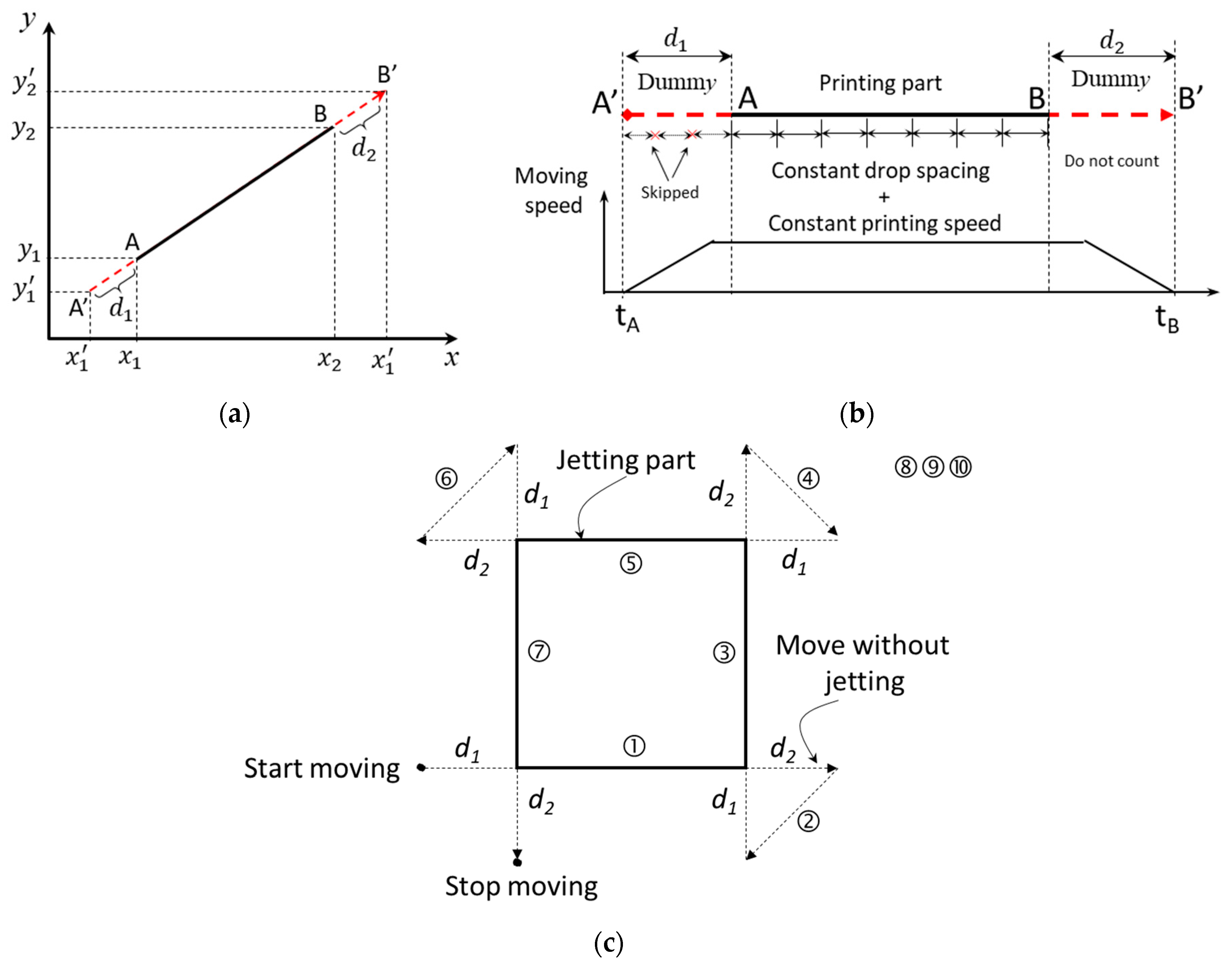

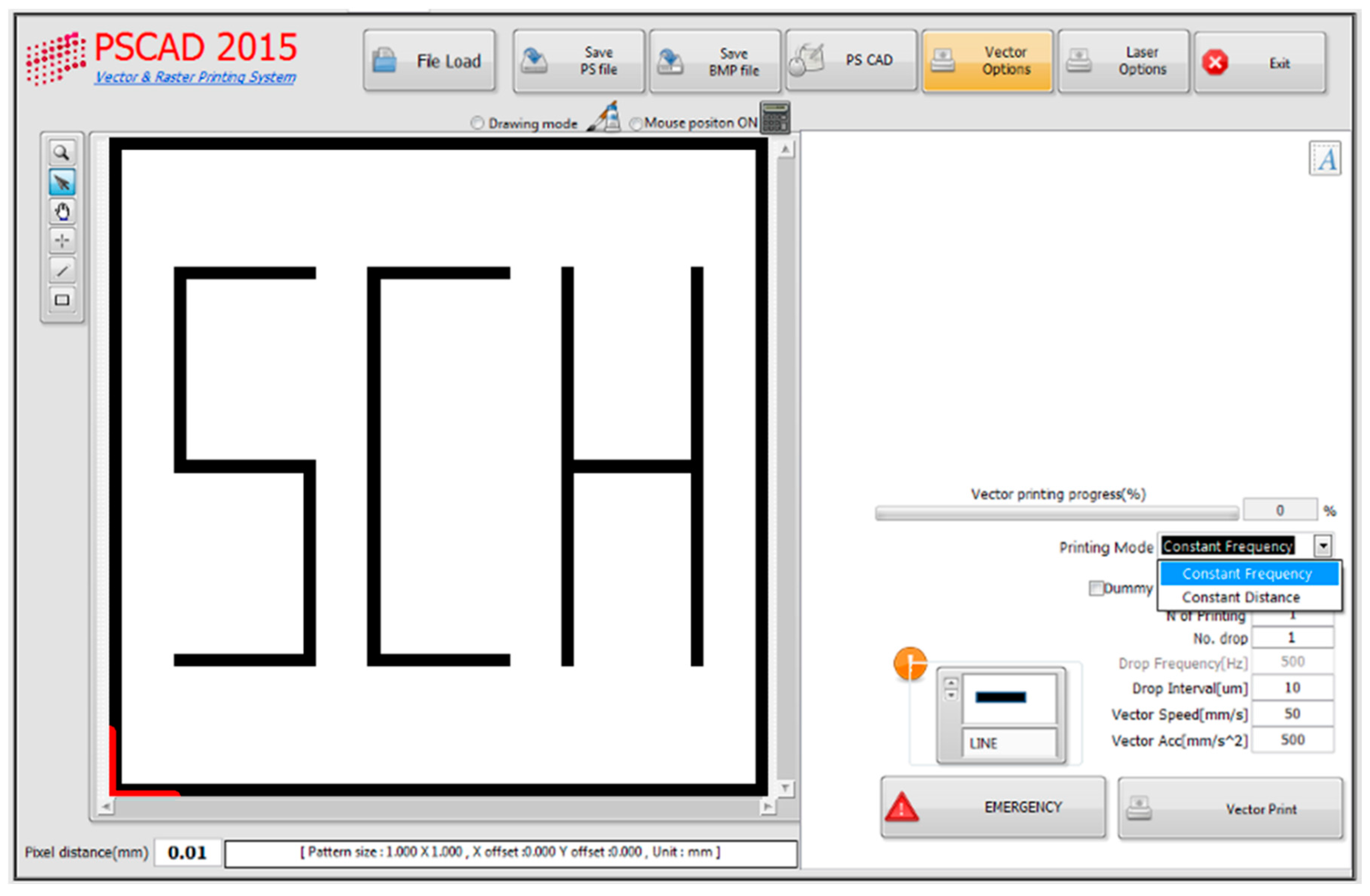

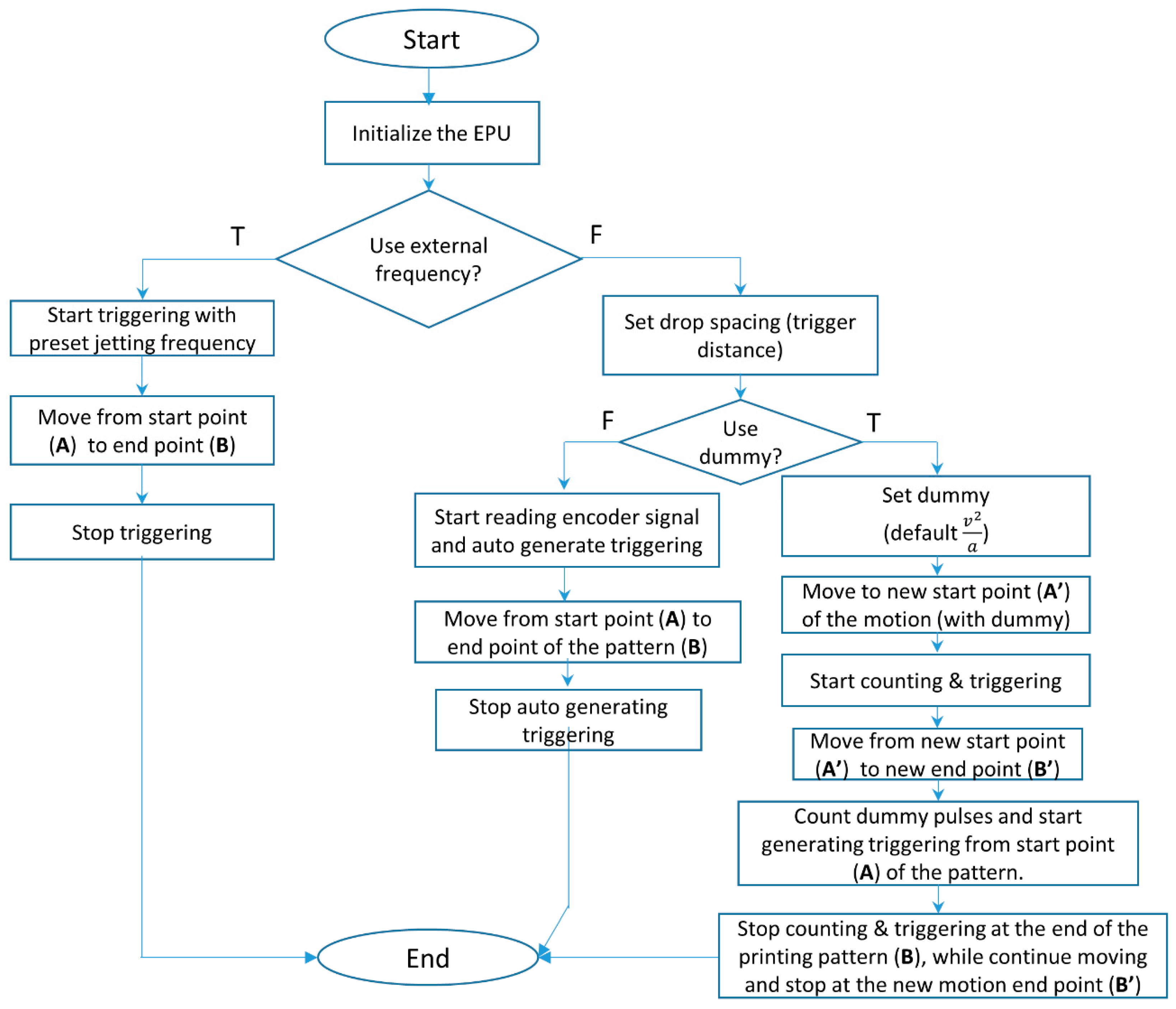

In this article, we propose a new vector printing method for EHD jet printing to print uniform lines by printing dots with equal spacing, irrespective of printing speed variation. For this purpose, the jetting trigger pulses are generated at each equally spaced distance based on two position encoder sensors. Here, two different approaches are proposed: (1) the printing method, including acceleration and deceleration regions; and (2) the printing method using only the constant printing speed region, excluding the acceleration and deceleration regions. To implement the proposed method, a so-called encoder processing unit (EPU) and a built-in computer-aided design (CAD) printing software were developed, so that positioning sensors from two axes (two encoder signals) could generate the trigger pulses at each pre-set distance along the printing line. Finally, we compared our proposed printing methods with the conventional method by investigating the end points of the printed lines according to the printing speed.

3. Experimental Results and Discussion

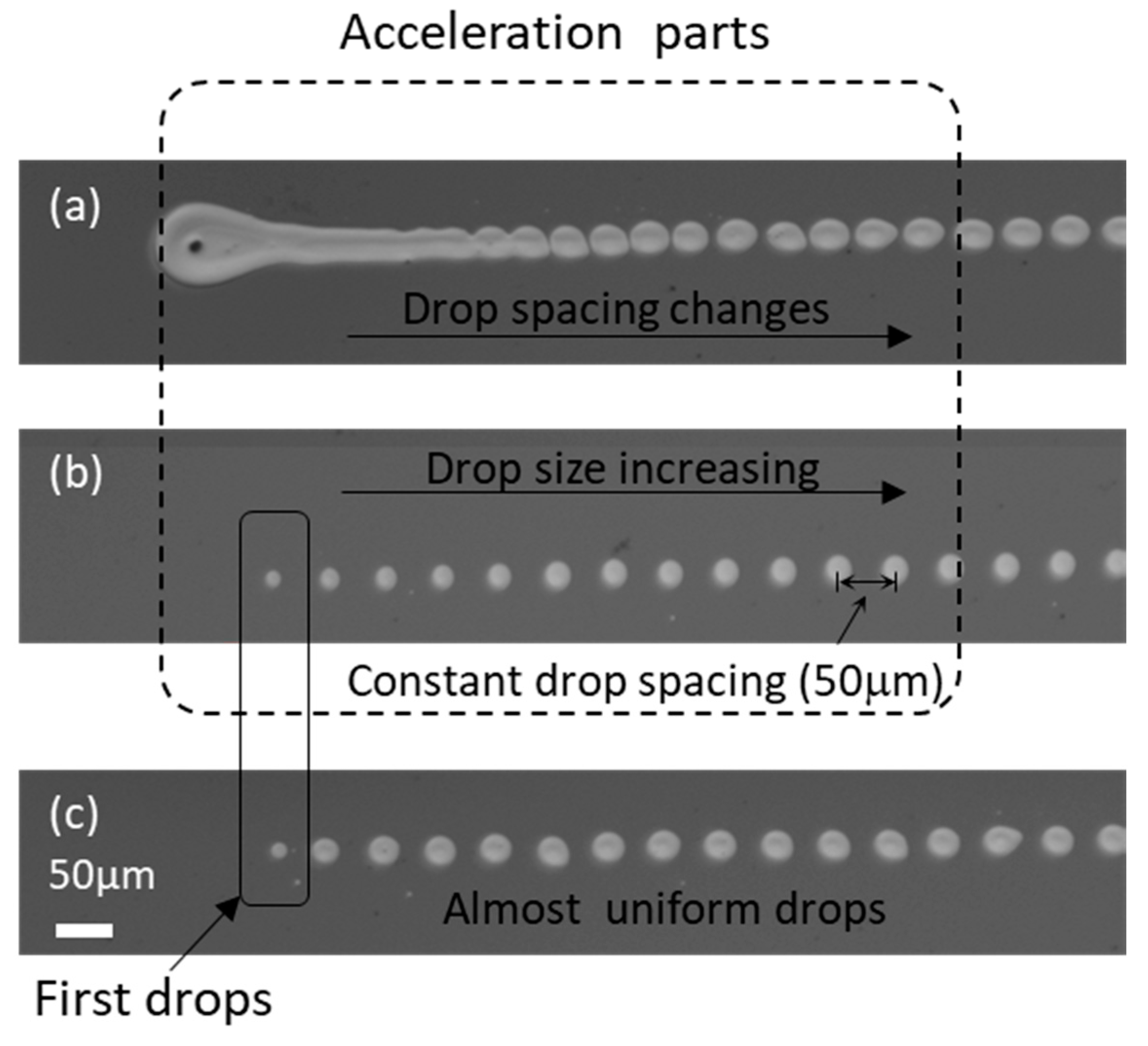

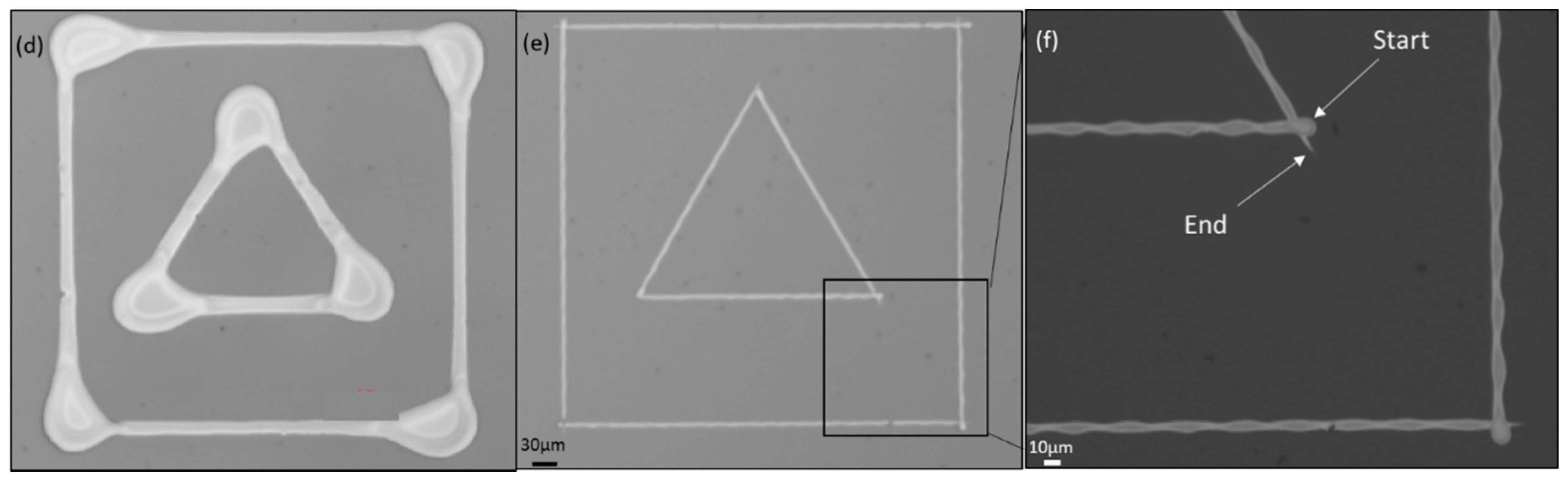

To investigate the EPU effects on printing quality, we used the printing parameters of jetting frequency of 500 Hz, target drop placement spacing of 50 µm, and printing speed of 25 mm/s. To clearly understand the effect according to the printing methods, printed dots are intended to be separated as shown in

Figure 11.

Figure 11a shows the printed result using the conventional constant frequency jetting for comparison purpose. As shown in the figure, the drop spacing increased from zero to target values during the acceleration region. As a result, a large number of droplets are overlapped at the initial part of the pattern. However, in the case of using encoder sensors to generate jetting triggers, there are no significant overlaps at the starting part (

Figure 11b,c), and dots are placed at equally spaced distance, irrespective of printing speed.

Figure 11b shows the printed results of using automatic trigger generation, including the acceleration and deceleration parts. This shows that the droplet size is smaller in the initial part in which the printing speed is low and becomes larger in the printing direction, until it reaches the target printing speed. The droplet amount is related to the jet frequency, and it becomes larger as the jet frequency increases [

6,

8]. Note that in the acceleration and deceleration part, the jetting frequency should be very low to print dots at each equally spaced distance when it is compared to the target printing speed part. On the other hand,

Figure 11c shows that using the so-called dummy distance approach significantly improved the droplet size uniformity. Nonetheless, the first droplet is smaller than the rest of the droplets. This might be related to the equivalent DC voltage behavior due to high-frequency pulse voltage, which will be discussed in detail later.

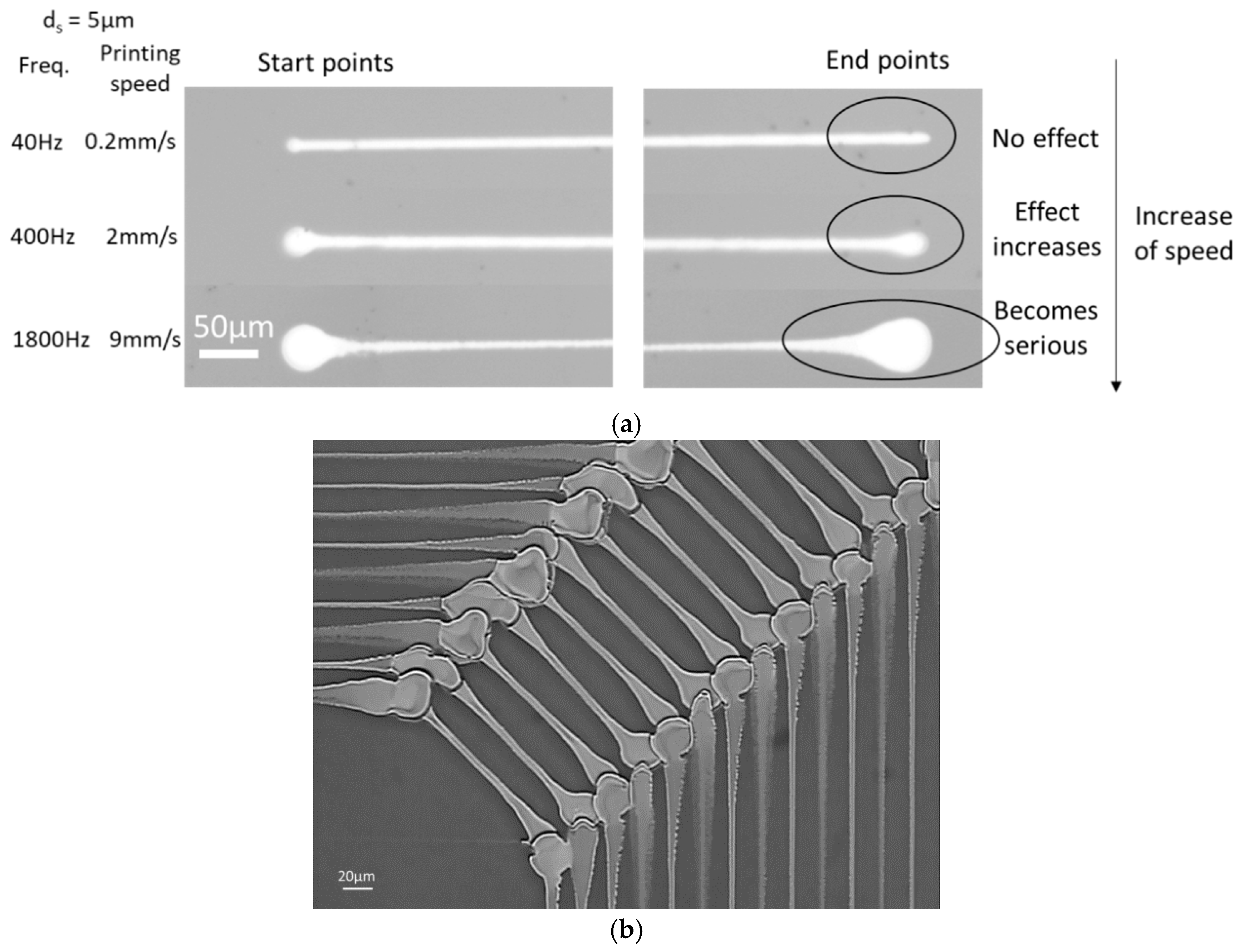

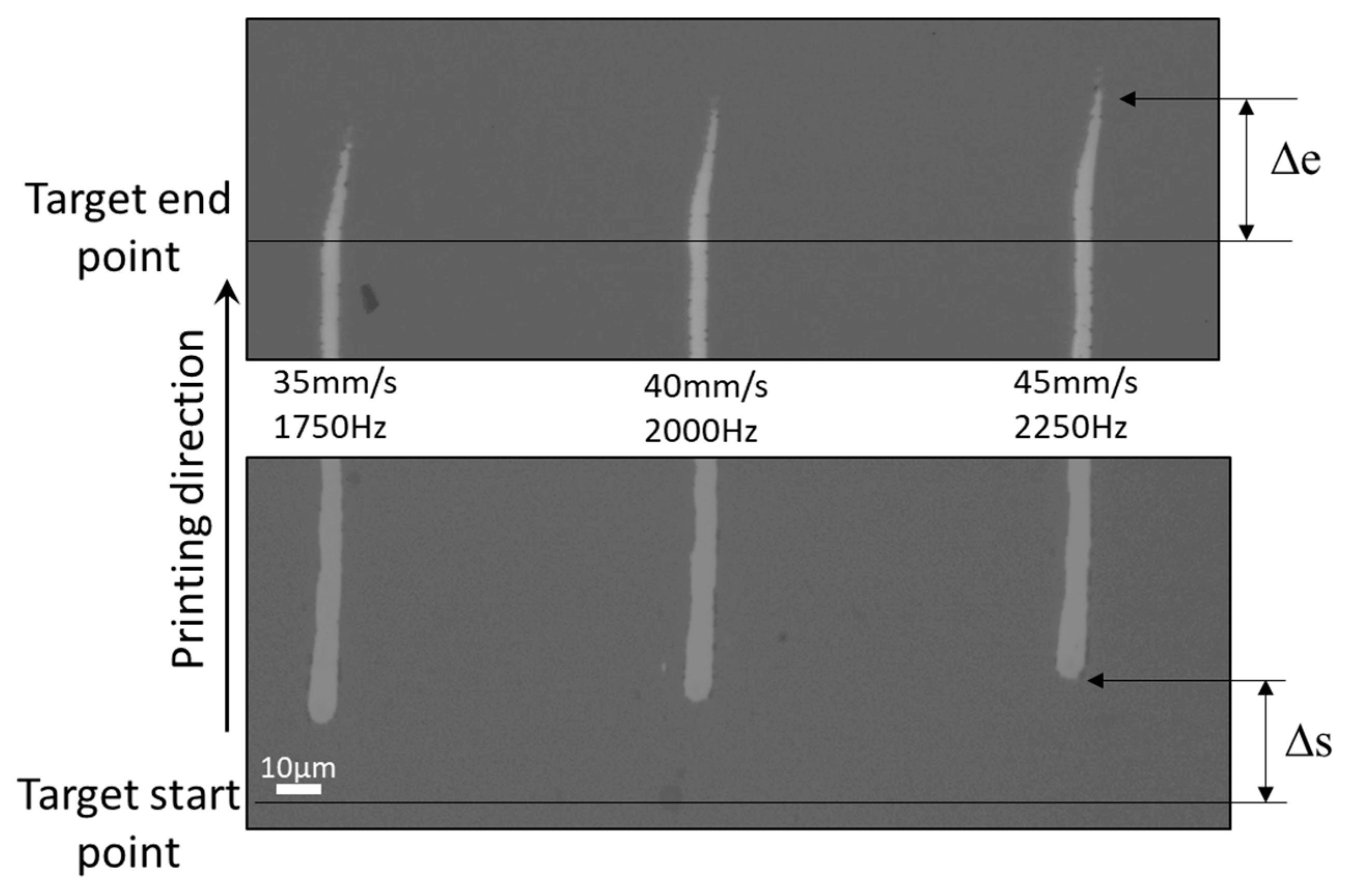

In the case of high jetting frequency of more than 1 kHz and printing speed of more than 30 mm/s, the printing behavior might be slightly different, as shown in

Figure 12, which shows that uniform line width at the initial part can be achieved by using the high jetting frequency. Here, dummy length is used to exclude the acceleration and deceleration regions. From the printing results shown in

Figure 12, there are two interesting behaviors in the printing using high-frequency jetting: (1) There is printing position shift from the target location, and (2) There is a prolonged tail at the end of the printing line. The position shift is also related to the printing speed and increases slightly according to the printing speed increase.

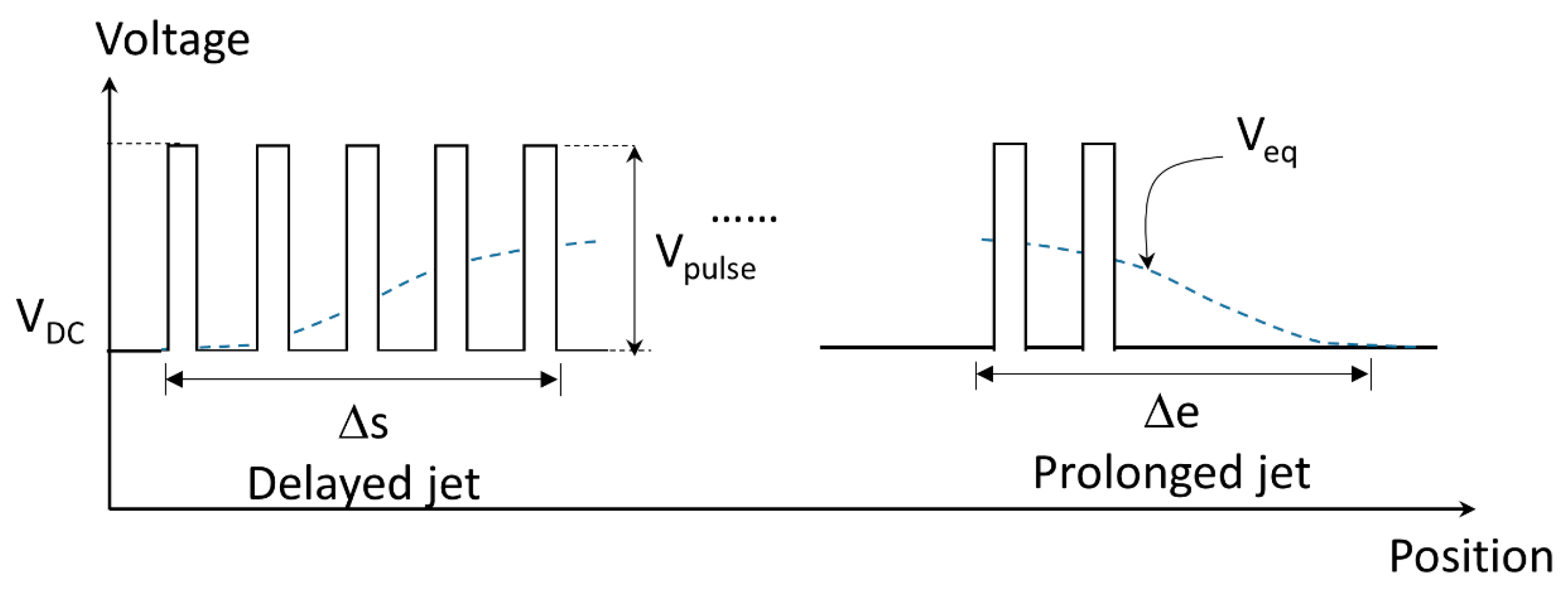

In the case of high-frequency jetting at more than 1.5 kHz, the equivalent DC voltage effects dominate the pulse voltage effects. The equivalent DC voltage effect can be written as:

in which

Veq,

Vdc,

Vp, and

Vp_ave and

T are the equivalent DC voltage, DC background voltage, pulse voltage for jetting, average of pulse voltage, and time of interest, respectively. Here,

Vp_ave will increase as the jetting frequency increases. To illustrate the equivalent DC voltage effect, the typical effect of

Veq was plotted as dotted overlaid line in

Figure 13. The figure shows that the equivalent DC voltage may be smaller in the initial jetting, which might result in non-jetting condition or smaller droplet size in the case of the first few jetting triggers, as shown in

Figure 11c. In addition, the printing location can be shifted in the printing direction (Δs), as shown in

Figure 12. Also, after termination of the pulse voltage, the effects of the equivalent DC voltage could last a while. So, a small amount of jetting can occur after printing, which is indicated as Δe. However, it should be noted that there could be additional reason to cause shift in the printing direction. The fast stage movement can result in additional position error in the moving direction, since the substrate can move a significant distance relative to the nozzle while the jet travels to the substrate. If it is desired to connect multiple lines, the position shift in the printed line could result in the disconnection of lines. In the case of conductive line printing, this could result in open circuit failure problems. Note that the printing position may be affected by other causes, such as jet frequency, pulse voltage shape, and ink properties.

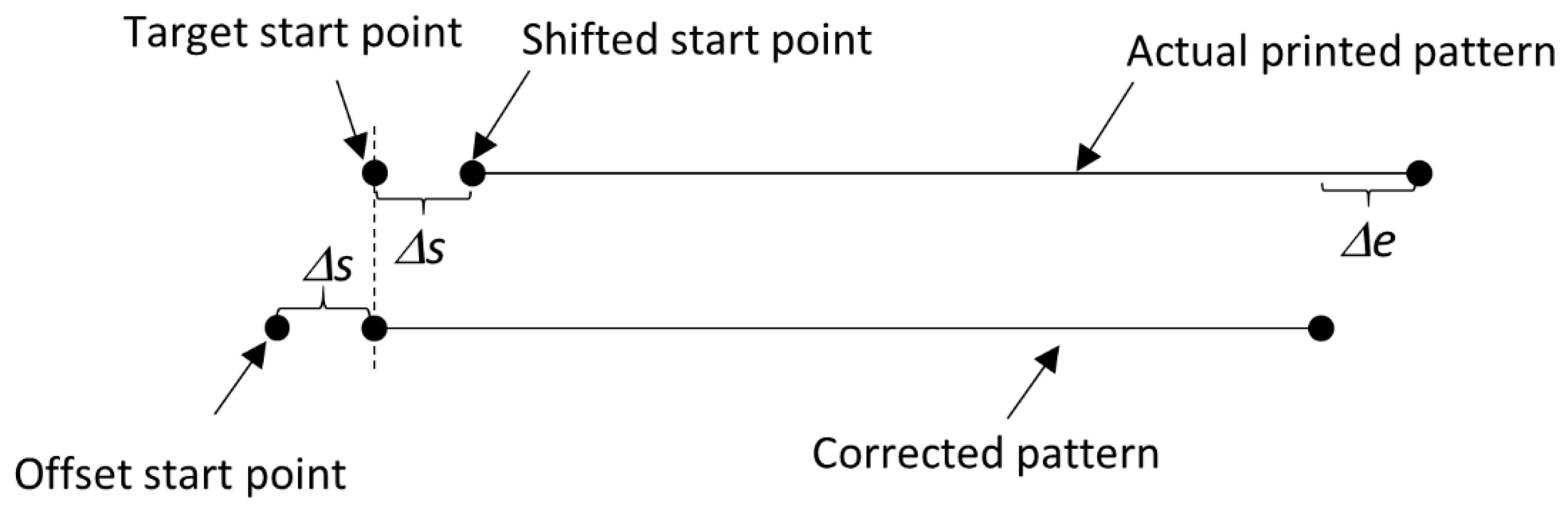

To ensure the connectivity of the patterns in the case of high-speed 2D patterning, the offset compensation method is considered in this study, as shown in

Figure 14. Note that the shifted position is usually small and could be easily compensated by means of software.

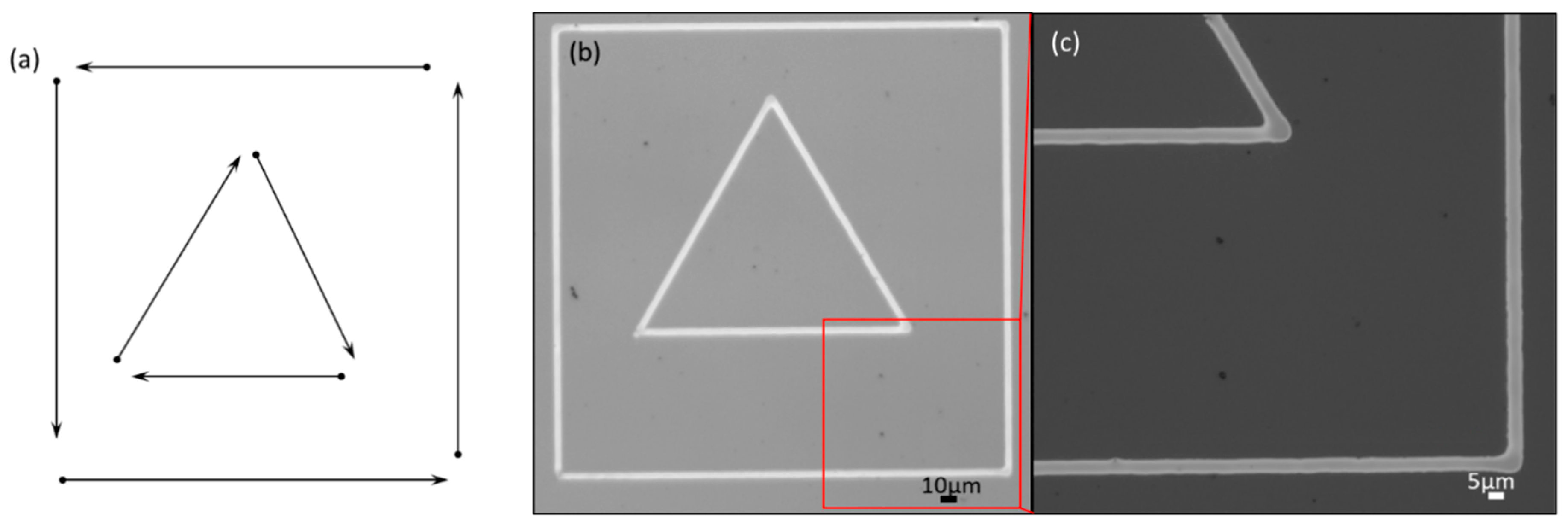

To demonstrate our proposed method, we used 2D patterns with the pattern size of (0.5 mm × 0.5 mm), as shown in

Figure 15a. In the case of printing by using the conventional constant jetting frequency approach, the printing speed was set to be as low as 0.05 mm/s to minimize the end point effects, as shown in

Figure 15b.

Figure 15c shows the magnified image of the printed results, and no end point effects can be found. However, if the printing speed is too low, it is not efficient, because it will take considerable time to print the desired pattern. To increase the printing speed, the frequency also needs to be increased accordingly.

Figure 15d shows the printed results using the conventional constant frequency jetting of 1750 Hz with target printing speed of 52.5 mm/s. Here, the acceleration and deceleration are set to 1 m/s

2. However, considering the acceleration and deceleration, when printing the lines with length less than 0.5 mm, the printing speed cannot reach the target speed, which means the printing speed varies throughout the printing process.

Figure 15d shows that in the case of using conventional methods, a large amount of overlapping droplets are deposited at the end points of jetting.

However,

Figure 15e,f shows that in the case of printing using encoder sensors signals, there is no significant overlapping at the end points of the patterns, in spite of the high printing speed of 52.5 mm/s. In this experiment, a sufficient dummy length of 3 mm was used, so that printing speed would be constant at 52.5 mm/s throughout line printing. Note that 30 μm offset of printing location is considered to compensate for the possible shift in the printing location. Note also that in

Figure 15f, the start point and the end point show a slight difference in shape, due to the equivalent DC voltage behavior, as discussed in

Figure 12. Nonetheless, when the printing speed is increased to more than 52.5 mm/s, the printed results in

Figure 15e,f show reasonable uniformity of printed line. Here, trigger signals are generated at each distance of 30 μm to print lines, and the corresponding jet frequency would be 1750 Hz. Note that in the case of higher frequency than 1.5 kHz, the equivalent DC voltage effects dominate the pulse voltage effects. As a result, the line can be connected by trigger signal based on a relatively large dot distance of 30 μm. For better understanding, kindly refer to the video in Ref. [

10].

4. Conclusions

In conventional EHD vector printing based on constant frequency jetting, to print uniform line pattern, the printing speed should be no more than 1 mm/s.

To increase the printing speed for EHD vector printing, we proposed a vector printing method using encoder sensor signals from two axes to generate trigger signals for jetting at each pre-set distance. To implement the method, we developed the so-called encoder processing unit (EPU) module, which is capable of changing various jetting parameters, such as dot spacing, the dummy distance, and the printing mode via printing software. By using the EPU, trigger pulses for jetting can be generated based on pre-set spacing distance, irrespective of the printing speed. By using the EPU, the printing speed can be increased by more than 10 mm/s without affecting the deposition amount in the end points.

However, in the case of increasing the printing speed further, there are two uniformity issues at both ends: dot size (or deposition amount) variance and offset position in the printing direction. The main reason for slight dot size deviation of the first few droplets is that the jetting amount is related to the jet frequency. The jet frequency in the acceleration and deceleration regions is much lower than in the constant target speed region. As a result, the droplet amount is likely to be smaller than in the other region.

To reduce the dot size variation, we implemented an additional counting function in the EPU, so that the acceleration and deceleration region can be excluded for printing. Nevertheless, in the case of using high jetting frequency, there were persistent printing uniformity problems at the end point, because the equivalent DC voltage due to pulse voltage dominated the pulse voltage. The equivalent DC voltage at the initial printing part is slightly lower than at the rest of the printing region. As a result, the equivalent DC voltage can shift the starting printing positon of lines in the printing direction. Another possible reason for the printed line offset is due to fast moving of the printing substrate relative to the nozzle, because the target positon can be moved to the moving direction, before the jet is deposited on the substrate. The shift in printing can result in disconnection in lines, if connected lines are needed. So, we proposed the use of a position offset compensation method in the case of high-speed application and showed successful implementation in the case of a printing speed of 50 mm/s.

As a result of our proposed methods, uniform patterns could be printed in arbitrary printing direction for patterning with a printing speed of more than 50 mm/s, which is significantly higher than the conventional printing speed of less than 1 mm/s.