Optimization Scheme for Construction Ventilation in Large-Scale Underground Oil Storage Caverns

Abstract

:1. Introduction

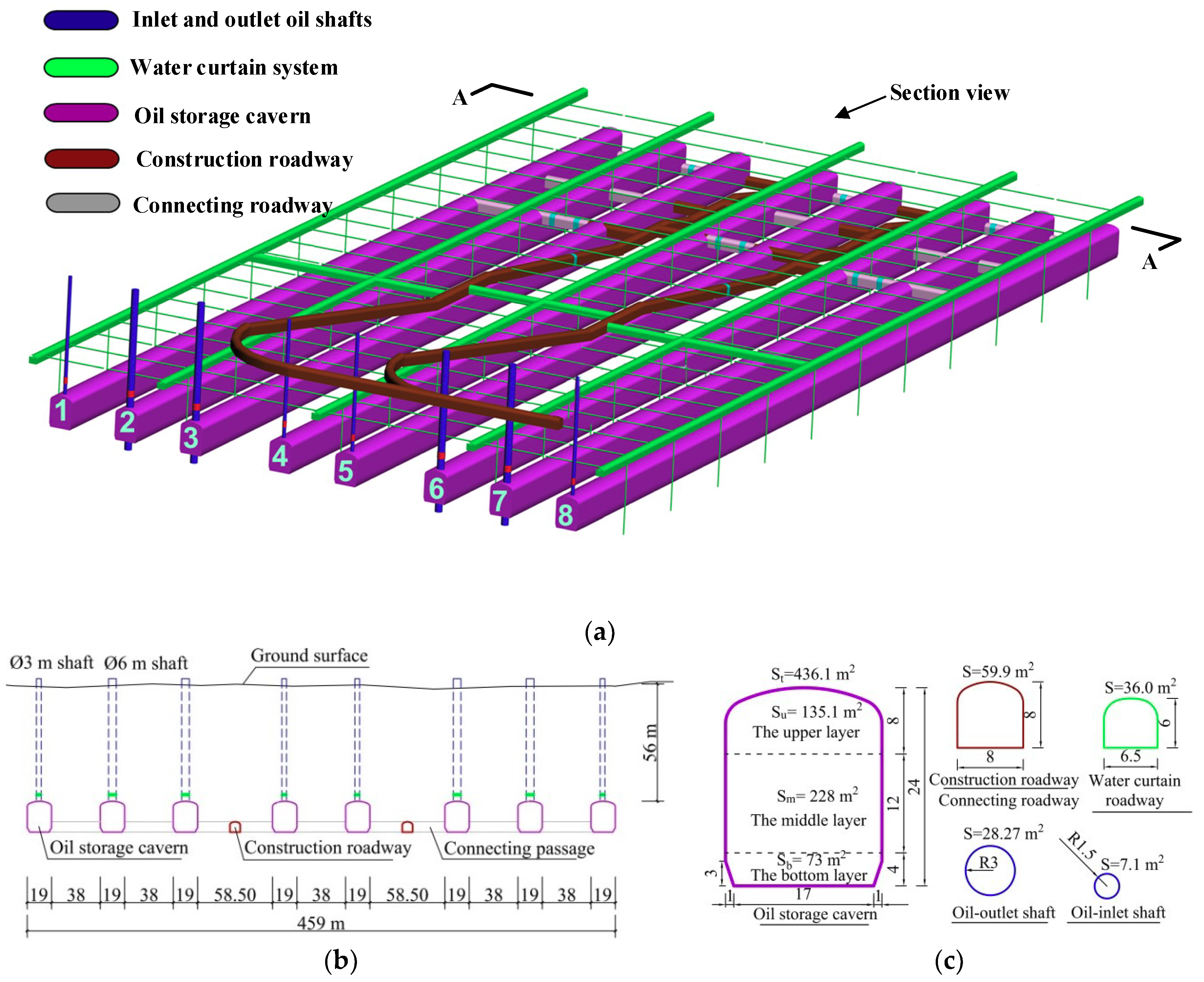

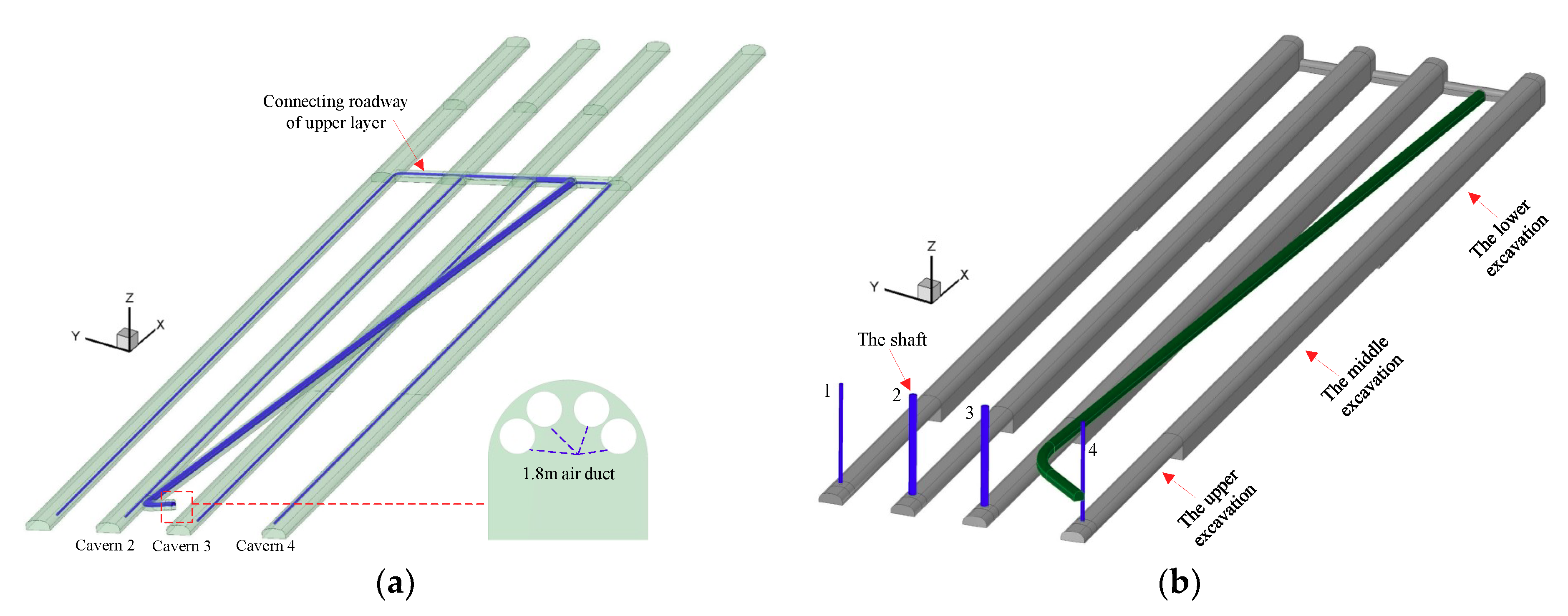

2. Project Description

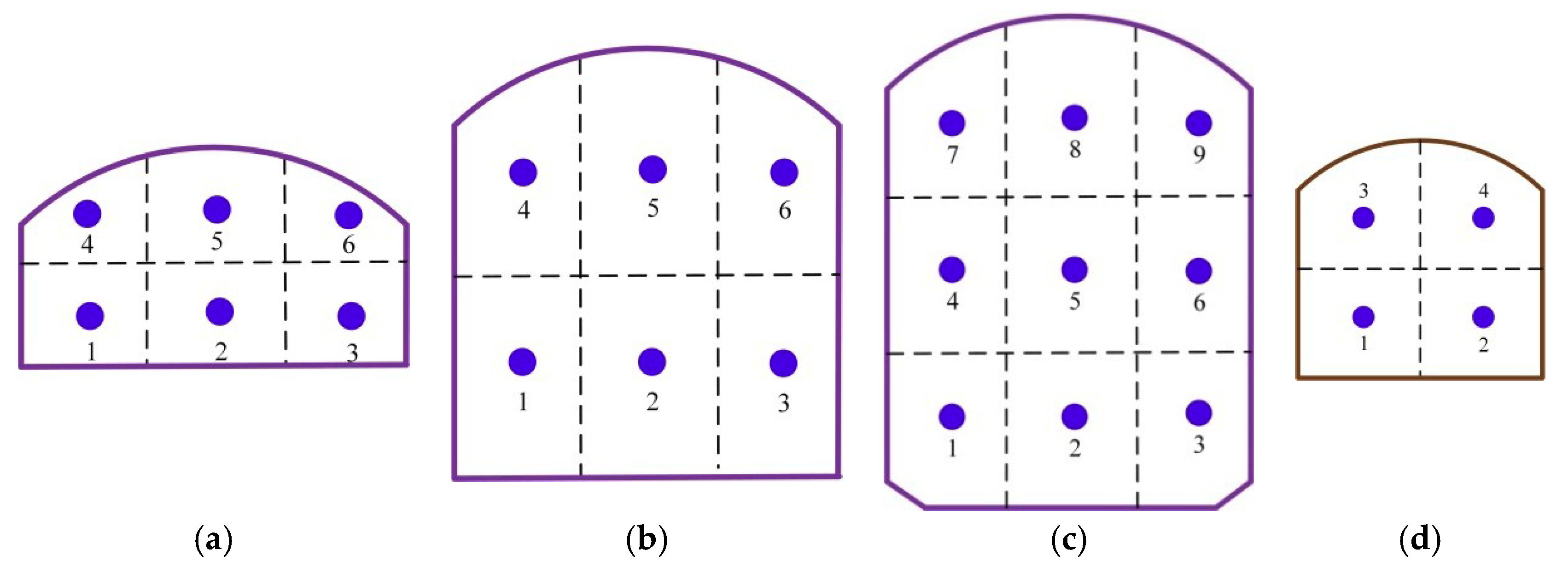

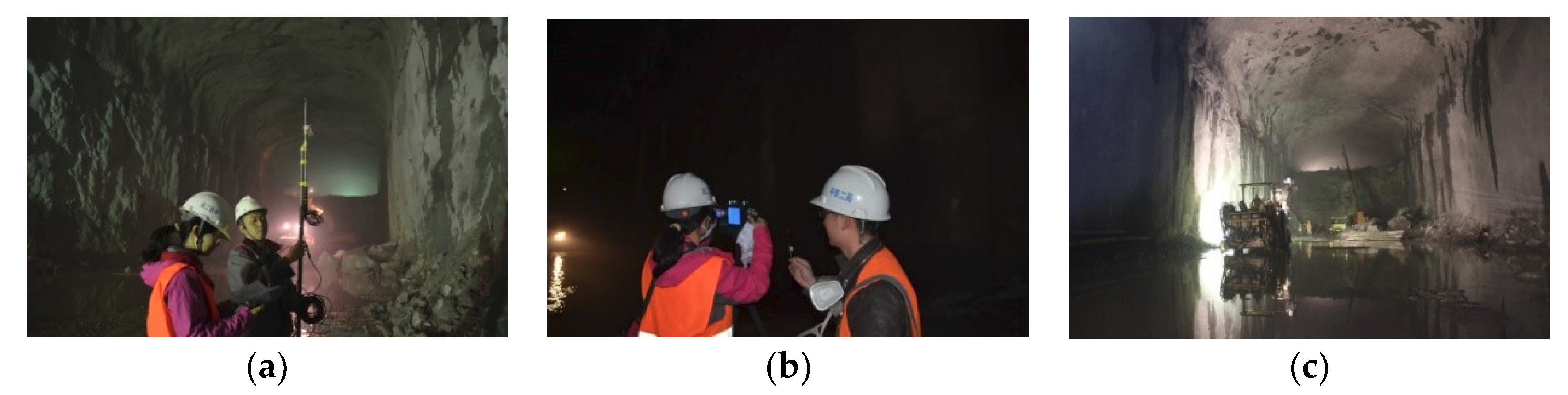

3. Field Test

4. CFD Simulations

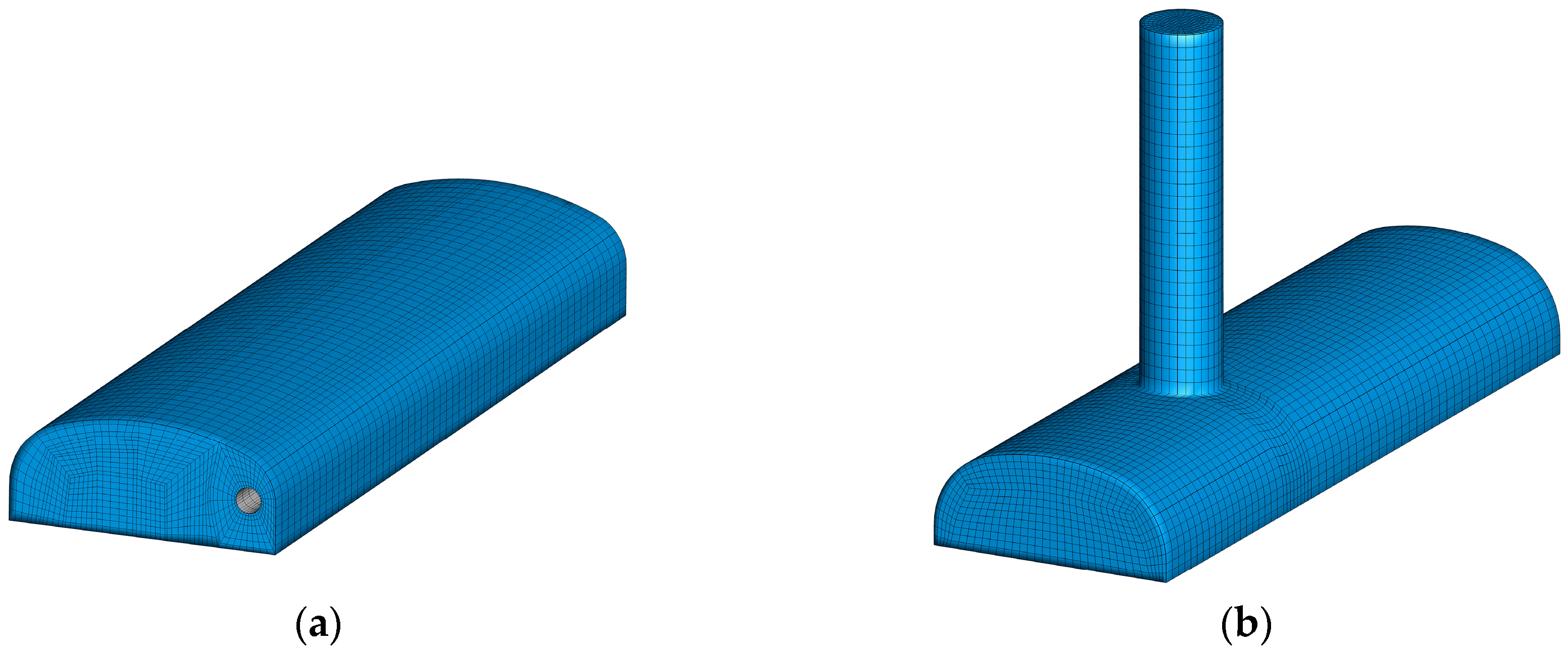

4.1. Computational Domain and Grid

4.2. Boundary Conditions

4.3. Others Computational Settings

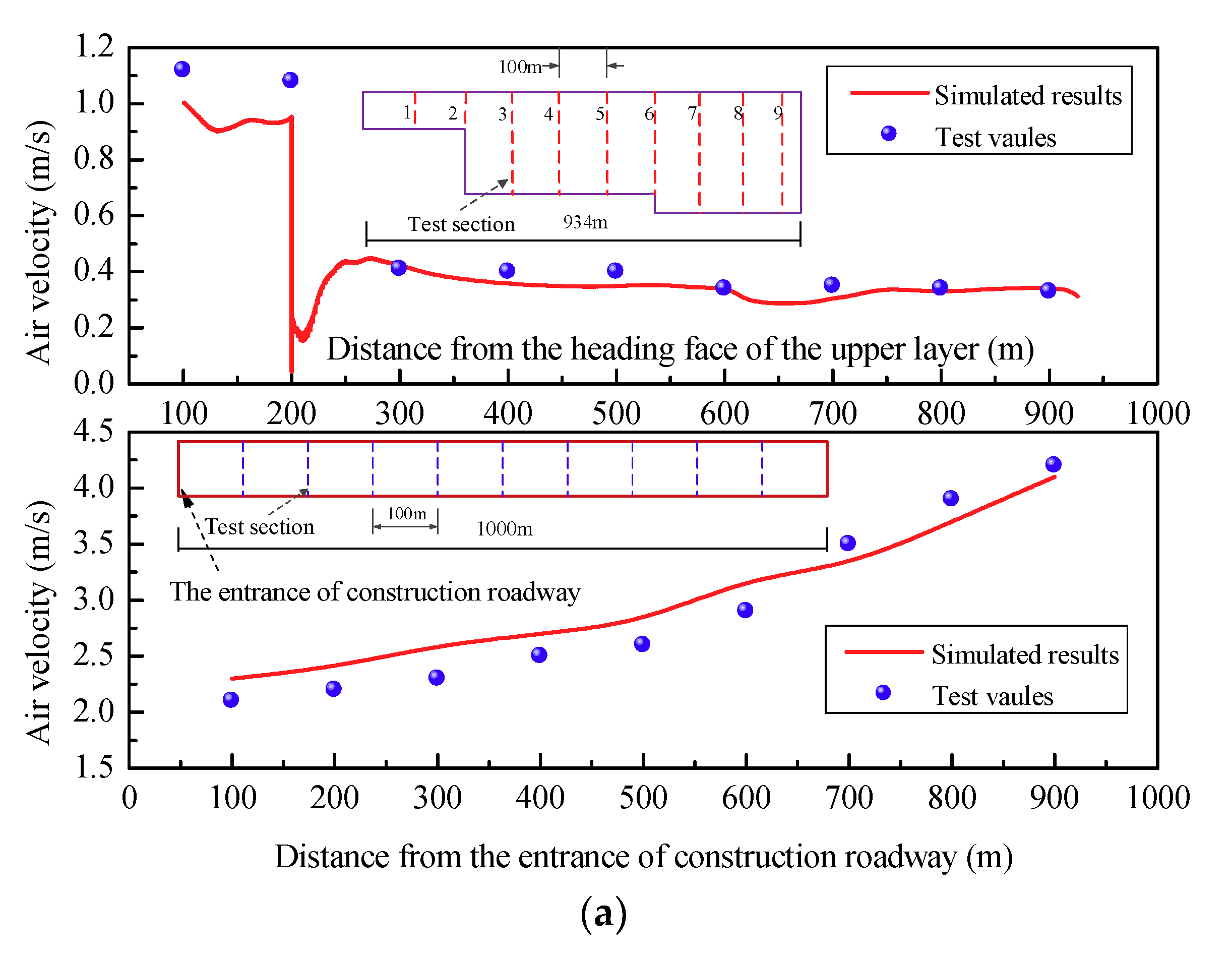

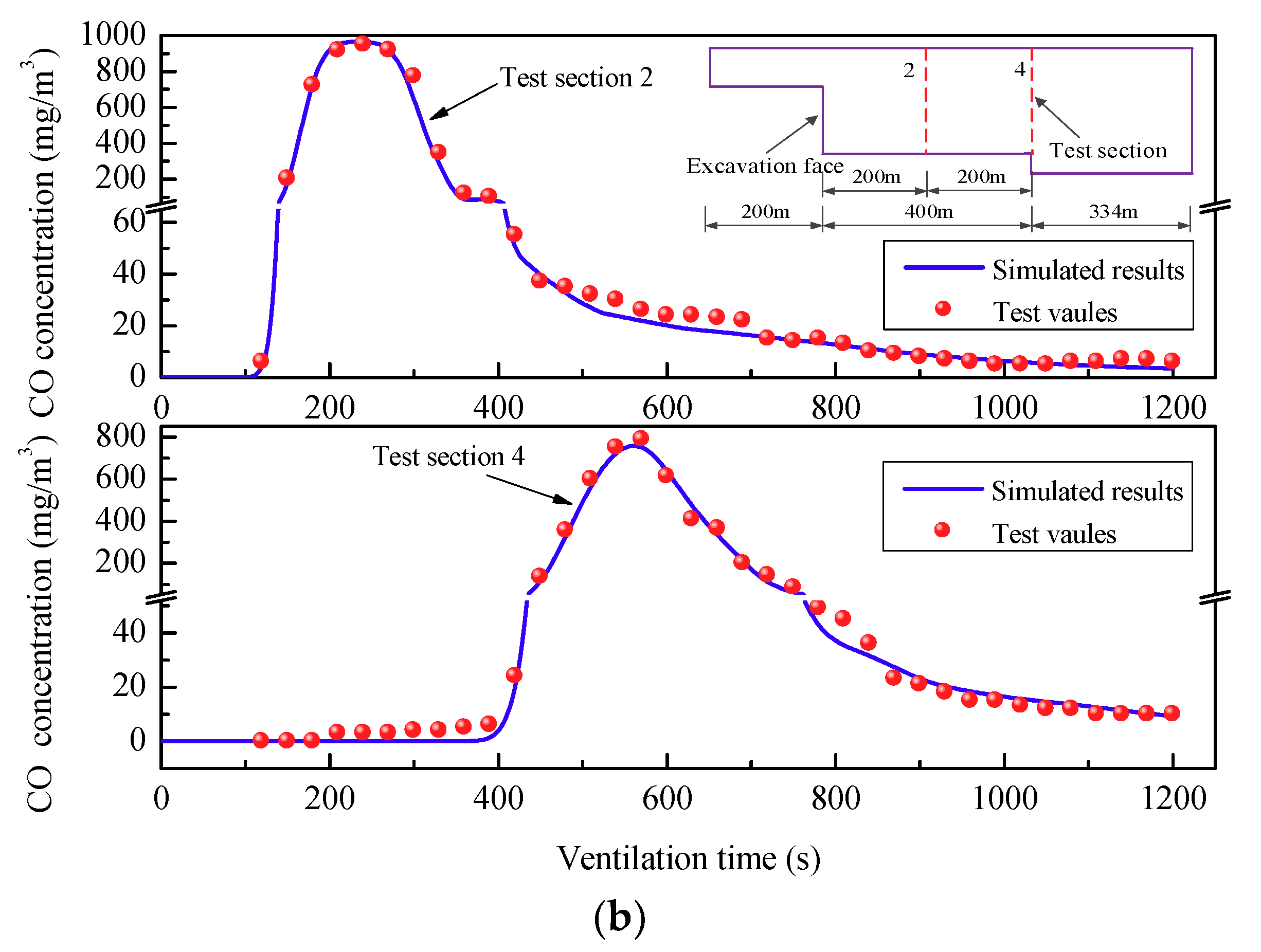

4.4. Validation

5. Results and Discussion

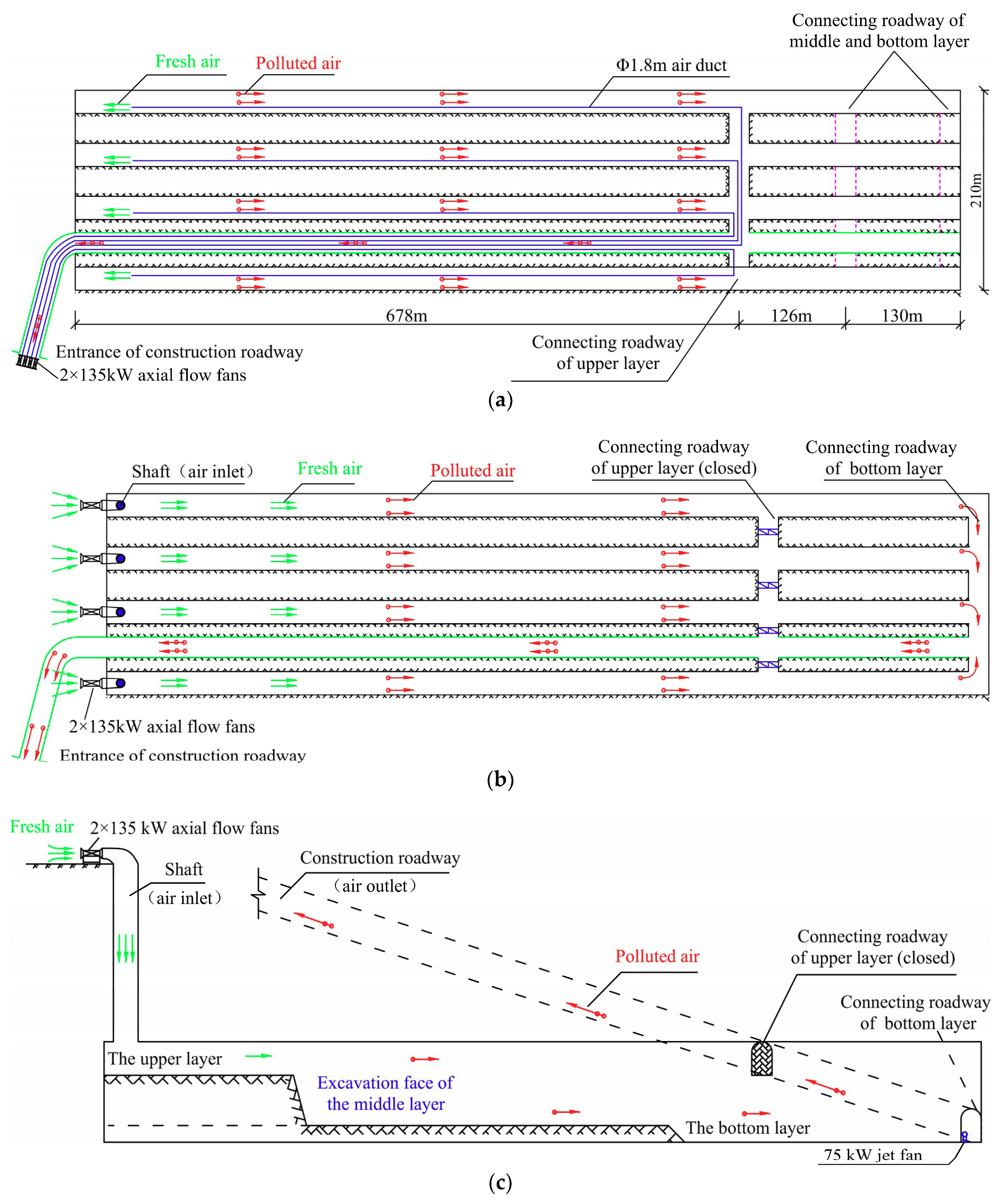

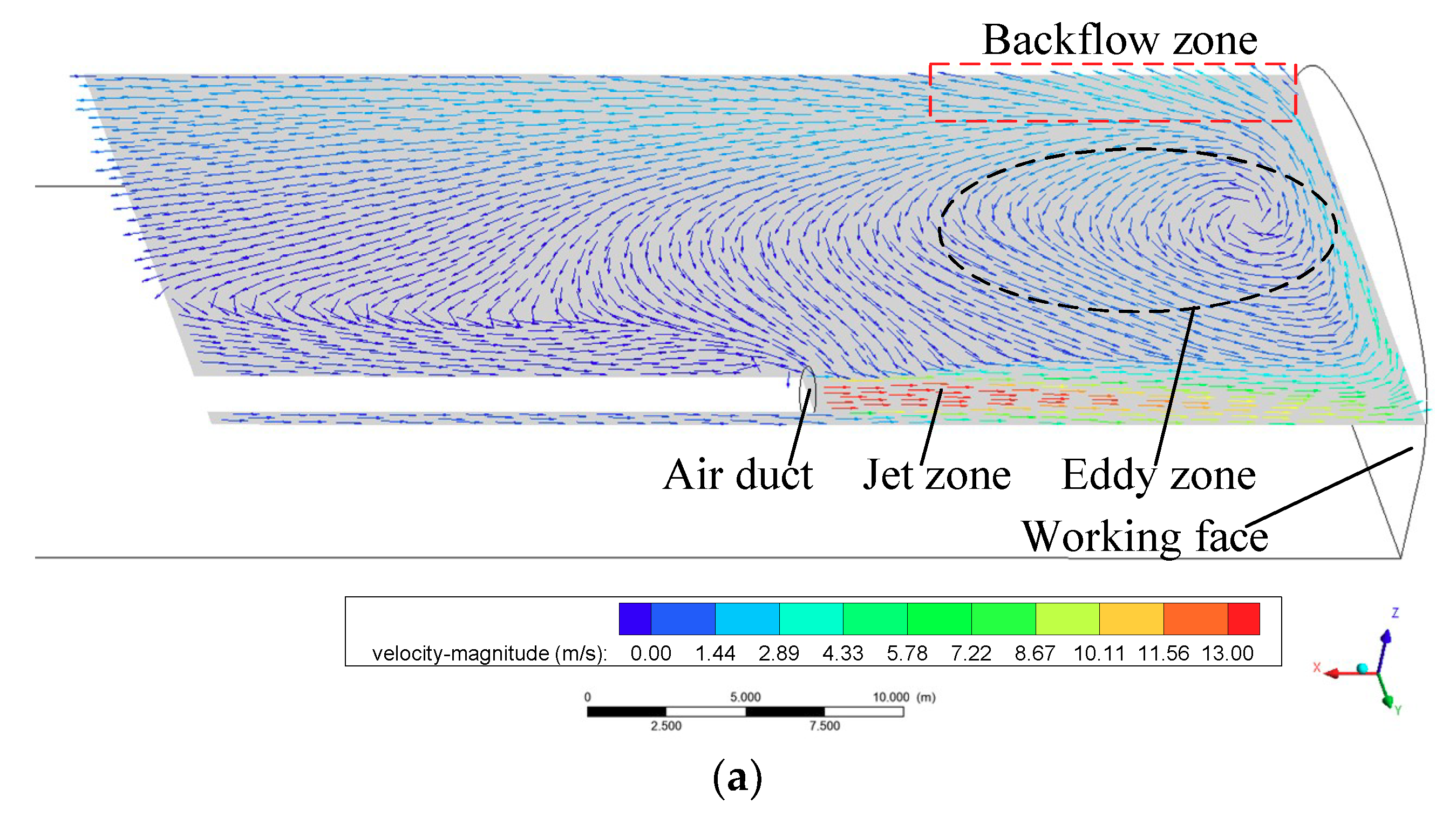

5.1. Original Scheme of Forced Ventilation

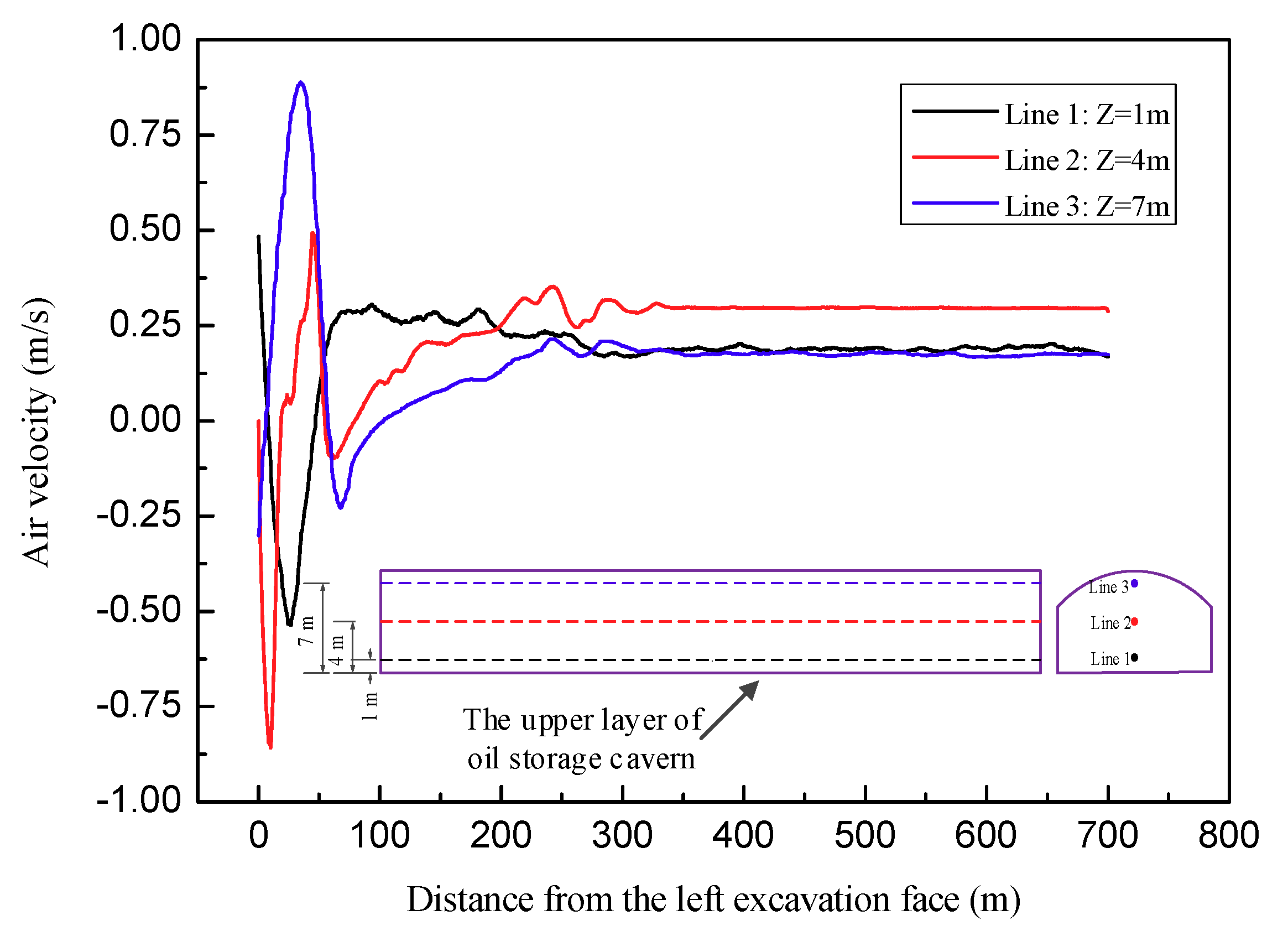

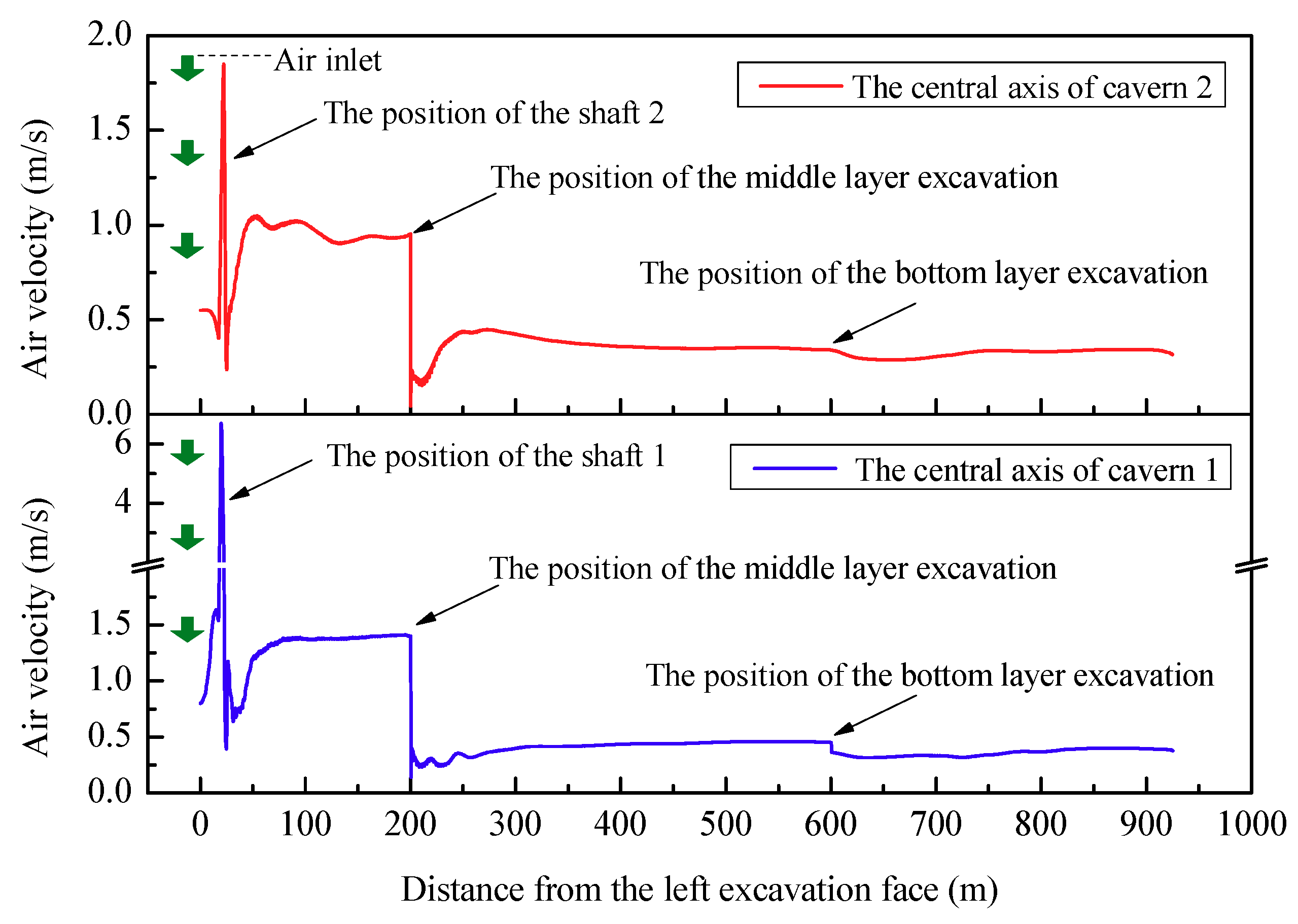

5.1.1. Air Velocity Field

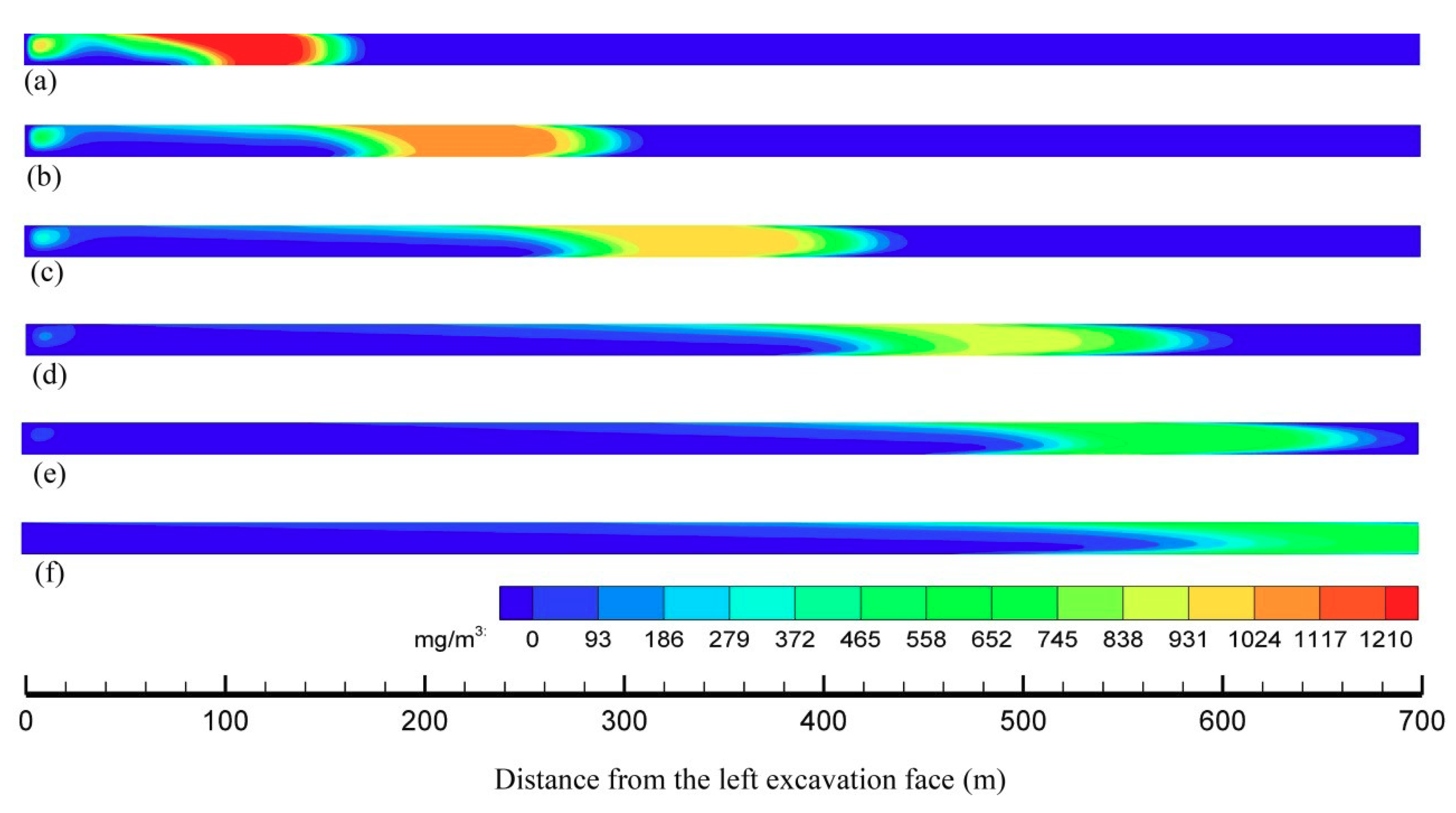

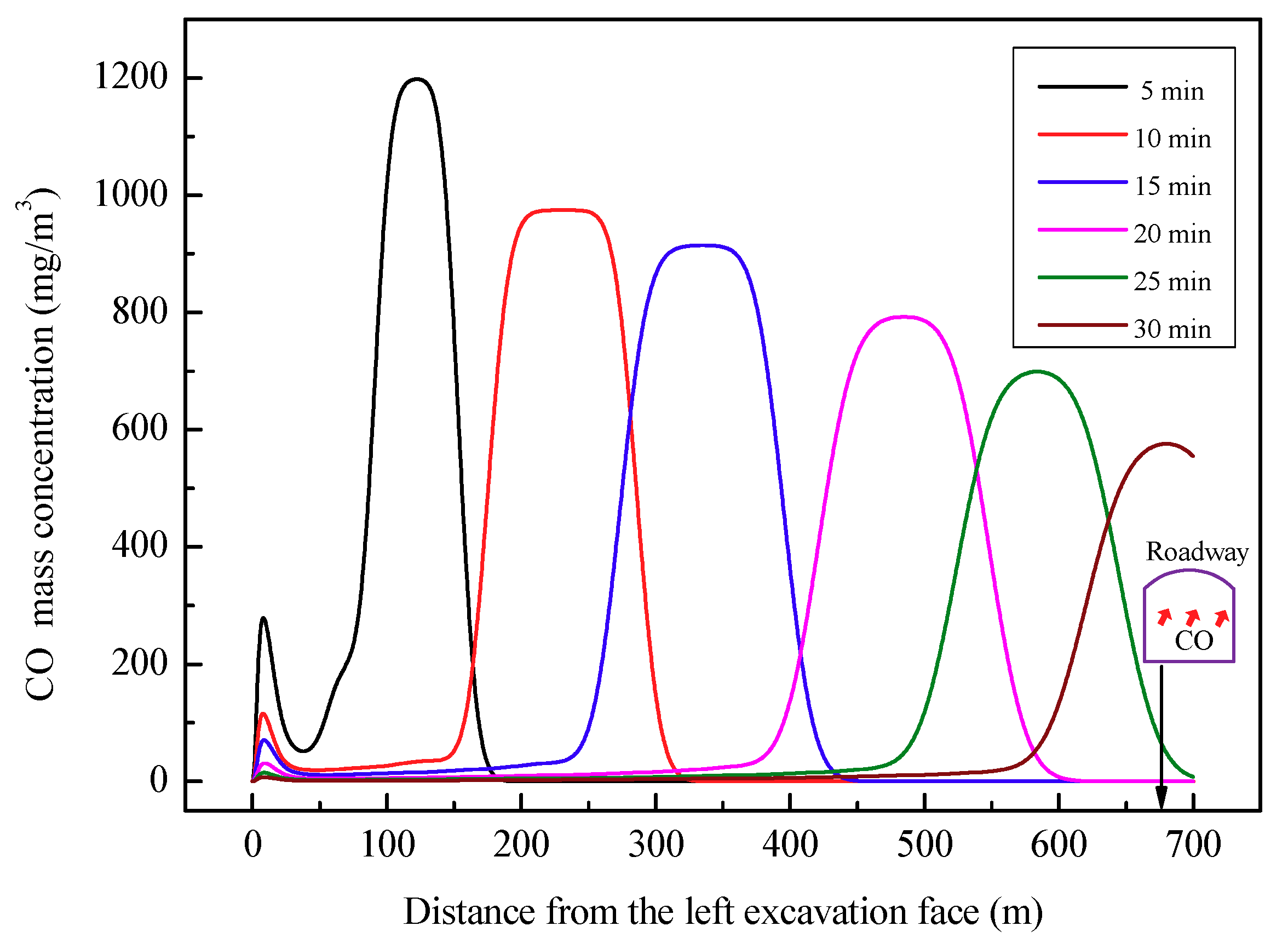

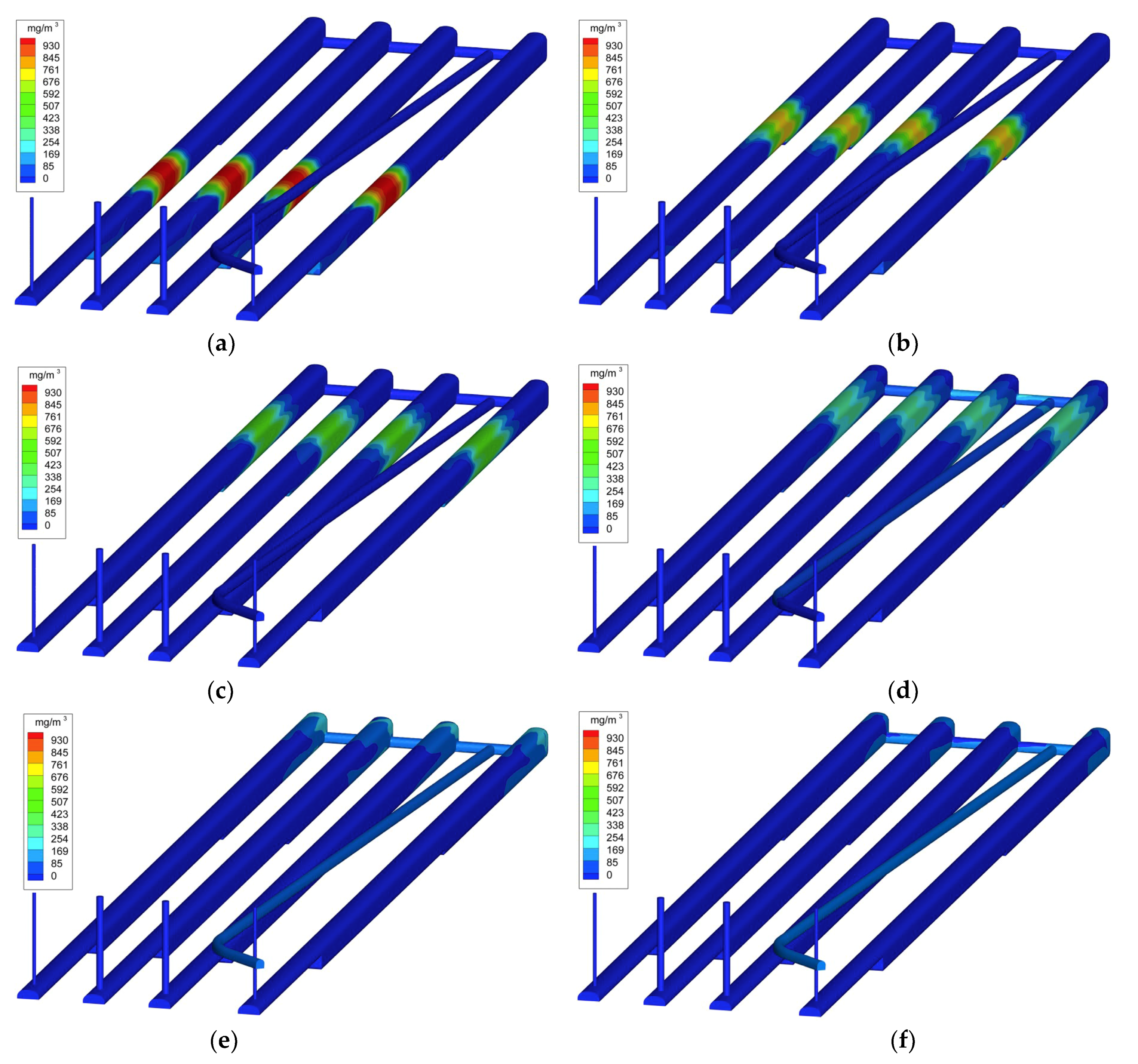

5.1.2. CO Concentration Field

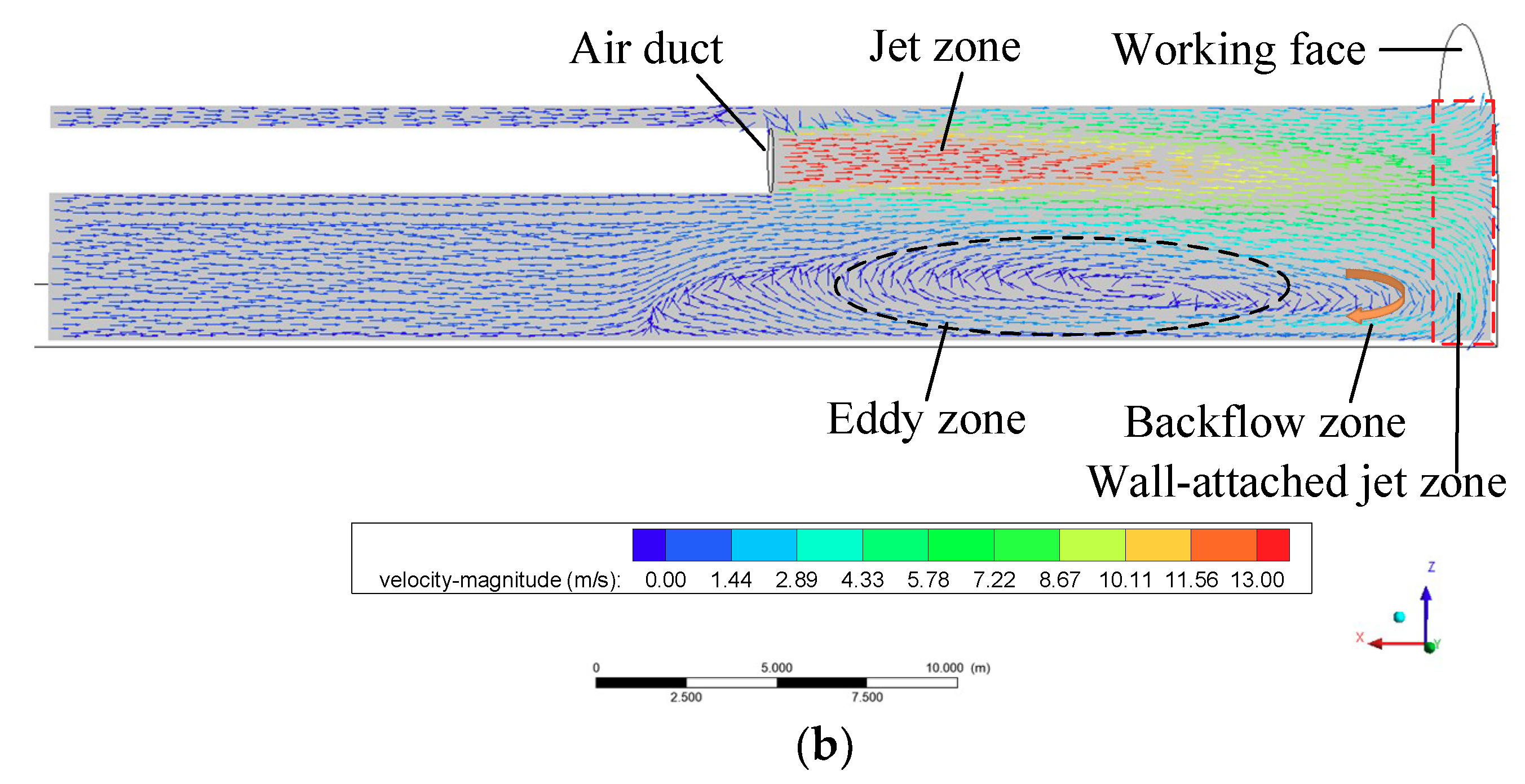

5.2. Axial-Flow Gallery Ventilation Scheme

5.2.1. Air Velocity Field

5.2.2. CO Concentration Field

6. Conclusions

- (1)

- The construction of large underground caverns usually adopts layered excavation, and the forced ventilation method is mostly applied in the upper layer construction. Due to the restriction of the construction roadway size and the clearance requirements for transportation, the duct diameter and air volume cannot be increased Consequently, the ventilation quality cannot meet the requirements of the cavern environment. Because the ventilation distance exceeds 1500 m, the stable air velocity in the cavern is only 0.15 m/s, which is below the minimum air velocity requirement of the relevant standards. In addition, there is a very complicated eddy zone in the area of about 20 m from the heading face.

- (2)

- The axial-flow gallery ventilation scheme is carried out when the excavation of the cavern upper layer is completed and connected with the shaft. The scheme utilizes the shafts as the fresh air inlet and the construction roadway as the polluted air outlet to create the gallery ventilation. It can ensure that the direction of the airflow is the same as that of heavy trucks, fresh air is always near the excavation face, and the disturbance of the process is greatly reduced. It reduces energy consumption and has good prospects for popularization and application.

- (3)

- There is no need to set up the air duct in the axial-flow gallery ventilation scheme, which greatly facilitates the cavern construction and avoids duct damage caused by blasting. The scheme is suitable for the large-scale caverns with a ventilation distance less than 2 km, each channel is effectively used, and the intermediate construction shaft is not needed. If the ventilation distance exceeds than 2 km, it is possible to use jet fans to assist the axial flow gallery ventilation mode or to completely adopt jet-flow gallery ventilation.

- (4)

- The power of the axial fan and the jet fan should be no less than 135 kW and 75 kW, respectively. The jet fan should be arranged at the airflow steering place. The axial fan placed at the top and bottom of the shaft has little impact on the field ventilation effect, so the position can be selected independently according to the convenience of the fan installation.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hong, K.R. Development and Prospects of Tunnels and Underground Works in China in Recent Two Years. Tunn. Constr. 2017, 37, 123–134. [Google Scholar] [CrossRef]

- Lin, F.; Ren, F.; Luan, H.B.; Ma, G.W.; Chen, S.G. Effectiveness Analysis of Water-sealing for Underground LPG Storage. Tunn. Undergr. Space Technol. 2016, 51, 270–290. [Google Scholar] [CrossRef]

- Wang, L.; Xie, X.P.; He, S.W.; Li, X.L. Effect Analysis on Application of Large-diameter Ducts in Ventilation of Underground Caverns. Tunn. Constr. 2008, 28, 19–21. [Google Scholar]

- Niu, X.K.; Zhang, D.L.; Su, J.; Guo, H. Parameter Optimization on the Forced Ventilation of Symmetric Tunnel Construction Based on the Super-Short Bench-Cut Method. Symmetry 2018, 10, 49. [Google Scholar] [CrossRef]

- Li, Y.L.; Yin, Q.; Mo, Z.Y.; Tang, C.Z.; Chen, X.; Yang, X.G. Optimization of Construction Ventilation Scheme for Large-scale Underground Cavern Group of Xiangjiaba Hydropower Station Based on Numerical Simulation. J. Sichuan Univ. (Eng. Sci. Ed.) 2010, 42, 1–6. [Google Scholar] [CrossRef]

- Zhang, H.; Sun, J.C.; Lin, F.; Wang, L. Optimization on Energy Saving Ventilation of Gallery-type Combined Construction Shaft Exhaust in Extra Long Tunnel. Procedia Eng. 2017, 205, 1777–1784. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, S.G.; Yang, J.S. Ventilation Technology in Super Long Group Tunnelling with Trackless Transportation and No Outcrop. J. Saf. Environ. 2013, 13, 229–231. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, R.K.; Zhang, W.H. Measures of Improving Ventilation Efficiency during Construction in Complex Caverns. J. Yangtze River Sci. Res. Inst. 2014, 8, 117–121. [Google Scholar] [CrossRef]

- Zhang, H.; Lin, F.; Zhang, K.; Yang, J.S.; Chen, S.G. Establishment of a Ventilation Network and the Shaft Ventilation Effect in a Large Underground Cavern Group. Mod. Tunn. Technol. 2018, 55, 203–209. [Google Scholar] [CrossRef]

- Parra, M.T.; Villafruela, J.M.; Castro, F.; Méndez, C. Numerical and Experimental Analysis of Different Ventilation Systems in Deep Mines. Build. Environ. 2006, 41, 87–93. [Google Scholar] [CrossRef]

- Fang, Y.; Fan, J.; Kenneally, B.; Mooney, M. Air Flow Behavior and Gas Dispersion in the Recirculation Ventilation System of a Twin-tunnel Construction. Tunn. Undergr. Space Technol. 2016, 58, 30–39. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, X.L.; Cheng, Z.F.; Sun, R.R.; Zhang, A.L. Simulation of Construction Ventilation in Deep Diversion Tunnels Using Euler–Lagrange Method. Comput. Fluids 2014, 105, 28–38. [Google Scholar] [CrossRef]

- Kurnia, J.C.; Sasmito, A.P.; Mujumdar, A.S. Simulation of a Novel Intermittent Ventilation System for Underground Mines. Tunn. Undergr. Space Technol. 2014, 42, 206–215. [Google Scholar] [CrossRef]

- Wang, X.L.; Liu, X.P.; Sun, Y.F.; An, J.; Zhang, J.; Chen, H.C. Construction Schedule Simulation of a Diversion Tunnel Based on the Optimized Ventilation Time. J. Hazard. Mater. 2009, 165, 933–943. [Google Scholar] [CrossRef] [PubMed]

- Torno, S.; Toraño, J.; Ulecia, M.; Allende, C. Conventional and Numerical Models of Blasting Gas Behaviour in Auxiliary Ventilation of Mining Headings. Tunn. Undergr. Space Technol. 2013, 34, 73–81. [Google Scholar] [CrossRef]

- Shao, S.; Yang, X.G.; Zhou, J.W. Numerical Analysis of Different Ventilation Schemes During the Construction Process of Inclined Tunnel Groups at the Changheba Hydropower Station, China. Tunn. Undergr. Space Technol. 2016, 59, 157–169. [Google Scholar] [CrossRef]

- Xia, Y.M.; Yang, D.; Hu, C.H.; Wu, C.Z.; Han, J.L. Numerical Simulation of Ventilation and Dust Suppression System for Open-type TBM Tunneling Work Area. Tunn. Undergr. Space Technol. 2016, 56, 70–78. [Google Scholar] [CrossRef]

- Nan, C.Z.; Ma, J.M.; Luo, Z.; Zheng, S.L.; Wang, Z.W. Numerical Study on the Mean Velocity Distribution Law of Air Backflow and the Effective Interaction Length of Airflow in Forced Ventilated Tunnels. Tunn. Undergr. Space Technol. 2015, 46, 104–110. [Google Scholar] [CrossRef]

- Hargreaves, D.M.; Lowndes, I.S. The Computational Modeling of the Ventilation Flows within a Rapid Development Drivage. Tunn. Undergr. Space Technol. 2007, 22, 150–160. [Google Scholar] [CrossRef]

- Klemens, R.; Kosinski, P.; Wolanski, P.; Korobeinikov, V.P.; Markov, V.V.; Menshov, I.S.; Semenov, I.V. Numerical Study of Dust Lifting in a Channel with Vertical Obstacles. J. Loss Prev. Process Ind. 2001, 14, 469–473. [Google Scholar] [CrossRef]

- Toraño, J.; Torno, S.; Menéndez, M.; Gent, M. Auxiliary Ventilation in Mining Roadways Driven with Road Headers: Validated CFD modelling of dust behavior. Tunn. Undergr. Space Technol. 2011, 26, 201–210. [Google Scholar] [CrossRef]

- Diego, I.; Torno, S.; Toraño, J.; Menéndez, M.; Gent, M. A Practical Use of CFD for Ventilation of Underground Works. Tunn. Undergr. Space Technol. 2011, 26, 189–200. [Google Scholar] [CrossRef]

- ANSYS ICEM CFD 17.0. User Manual, Hexa; ANSYS, Inc.: Canonsburg, PA, USA, 2016; pp. 37–47. [Google Scholar]

- Yang, L.X.; Hong, K.R.; Liu, Z.W.; Luo, Z.F. Modern Tunneling Ventilation Technology, 1st ed.; China Communications Press: Beijing, China, 2012; pp. 201–205. ISBN 978-7-114-09621-1. [Google Scholar]

- Launder, B.E.; Spalding, D.B. The Numerical Computation of Turbulent Flows. Comput. Methods Appl. Mech. Eng. 1974, 3, 269–289. [Google Scholar] [CrossRef]

- Zhang, Z.Q.; Zhang, H.; Tan, Y.J.; Yang, H.Y. Natural wind utilization in the vertical shaft of a super-long highway tunnel and its energy saving effect. Build. Environ. 2018, 145, 140–152. [Google Scholar] [CrossRef]

- Wang, F.; Wang, M.N.; He, S.; Deng, Y.Y. Computational Study of Effects of Traffic Force on the Ventilation in Highway Curved Tunnels. Tunn. Undergr. Space Technol. 2011, 26, 481–489. [Google Scholar] [CrossRef]

- Wang, F.; Wang, M.N.; He, S.; Zhang, J.S.; Deng, Y.Y. Computational Study of Effects of Jet Fans on the Ventilation of a Highway Curved Tunnel. Tunn. Undergr. Space Technol. 2010, 25, 382–390. [Google Scholar] [CrossRef]

- Liu, Y.C.; Wang, S.C.; Deng, Y.B.; Ma, W.W.; Ma, Y. Numerical simulation and experimental study on ventilation system for powerhouses of deep underground hydropower stations. Appl. Therm. Eng. 2016, 105, 151–158. [Google Scholar] [CrossRef]

- Zhang, H.; Fang, L.; Sun, J.C.; Zhou, Z.L. CFD Analysis of Tunnel Construction Ventilation Effect Based on Typical Wall Roughness Model. China Railw. Sci. 2016, 37, 58–65. [Google Scholar] [CrossRef]

- Wu, Z.L. Ventilation in Heading Face after Blasting, 1st ed.; Metallurgical Industry Press: Beijing, China, 1959; pp. 1–3. [Google Scholar]

- Issa, R. Solution of Implicitly Discretized Fluid Flow Equations by Operator Splitting. J. Comput. Phys. 1986, 62, 40–65. [Google Scholar] [CrossRef]

- Mukhtar, A.; Ng, K.C.; Yusoff, M.Z. Design Optimization for Ventilation Shafts of Naturally-Ventilated Underground Shelters for Improvement of Ventilation Rate and Thermal Comfort. Renew. Energy 2018, 115, 183–198. [Google Scholar] [CrossRef]

- Fluent Inc. Fluent 6.3 User’s Guide; Fluent Inc.: Lebanon, NH, USA, 2006. [Google Scholar]

- Wang, M.; Wu, C.; Wang, C.L. Digital Simulation of Smoke-fume Discharge from Large-scale Underground Chambers under the Construction and the Calculation Method of the Air Volume Needed. J. Saf. Environ. 2014, 14, 209–213. [Google Scholar] [CrossRef]

- Safety Operation Regulations for Tunnel Drilling and Blasting. Available online: http://www.safehoo.com/Rules/Traffic/201011/155705.shtml (accessed on 1 November 2010).

- Ministry of Communications of PRC. Technical Specifications for Construction of Highway Tunnel (JTG F60-2009); China Communications Press: Beijing, China, 2009. [Google Scholar]

- State Administration of Work Safety of PRC. Safety Regulations for Coal Mines; China Coal Industry Publishing House: Beijing, China, 2016. [Google Scholar]

| Test Content | Test Instrument | Test Resolution | Control Value |

|---|---|---|---|

| Air velocity | Hot wire anemometer | 0.01 m/s | / |

| CO | M4 gas detector | 0.1 ppm | ≤30 mg/m3 |

| SO2 | M4 gas detector | 0.1 ppm | ≤14.3 mg/m3 |

| H2S | M4 gas detector | 0.1 ppm | ≤10 mg/m3 |

| Above 10% free SiO2 dust | CCZ-1000 direct-reading dust detector | 0.1 mg/m3 | ≤2 mg/m3 |

| Below 10% free SiO2 dust | CCZ-1000 direct-reading dust detector | 0.1 mg/m3 | ≤4 mg/m3 |

| Section | A (m2) | G (kg) | LOT (m) | The Amount of CO (m3) | C0 (mg/m3) |

|---|---|---|---|---|---|

| Upper layer | 135.1 | 320 | 79 | 12.8 | 1499.1 |

| Middle layer | 228 | 420 | 99 | 16.8 | 930.4 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Sun, J.; Lin, F.; Chen, S.; Yang, J. Optimization Scheme for Construction Ventilation in Large-Scale Underground Oil Storage Caverns. Appl. Sci. 2018, 8, 1952. https://doi.org/10.3390/app8101952

Zhang H, Sun J, Lin F, Chen S, Yang J. Optimization Scheme for Construction Ventilation in Large-Scale Underground Oil Storage Caverns. Applied Sciences. 2018; 8(10):1952. https://doi.org/10.3390/app8101952

Chicago/Turabian StyleZhang, Heng, Jianchun Sun, Fang Lin, Shougen Chen, and Jiasong Yang. 2018. "Optimization Scheme for Construction Ventilation in Large-Scale Underground Oil Storage Caverns" Applied Sciences 8, no. 10: 1952. https://doi.org/10.3390/app8101952

APA StyleZhang, H., Sun, J., Lin, F., Chen, S., & Yang, J. (2018). Optimization Scheme for Construction Ventilation in Large-Scale Underground Oil Storage Caverns. Applied Sciences, 8(10), 1952. https://doi.org/10.3390/app8101952