Microscopic Elastic and Plastic Inhomogeneous Deformations and Height Changes on the Surface of a Polycrystalline Pure-Titanium Plate Specimen under Cyclic Tension

Abstract

Featured Application

Abstract

1. Introduction

2. Experimental Procedures

2.1. Specimen and Tensile Test

2.2. Digital Holographic Microscope and Digital Height Correlation Method (DHCM)

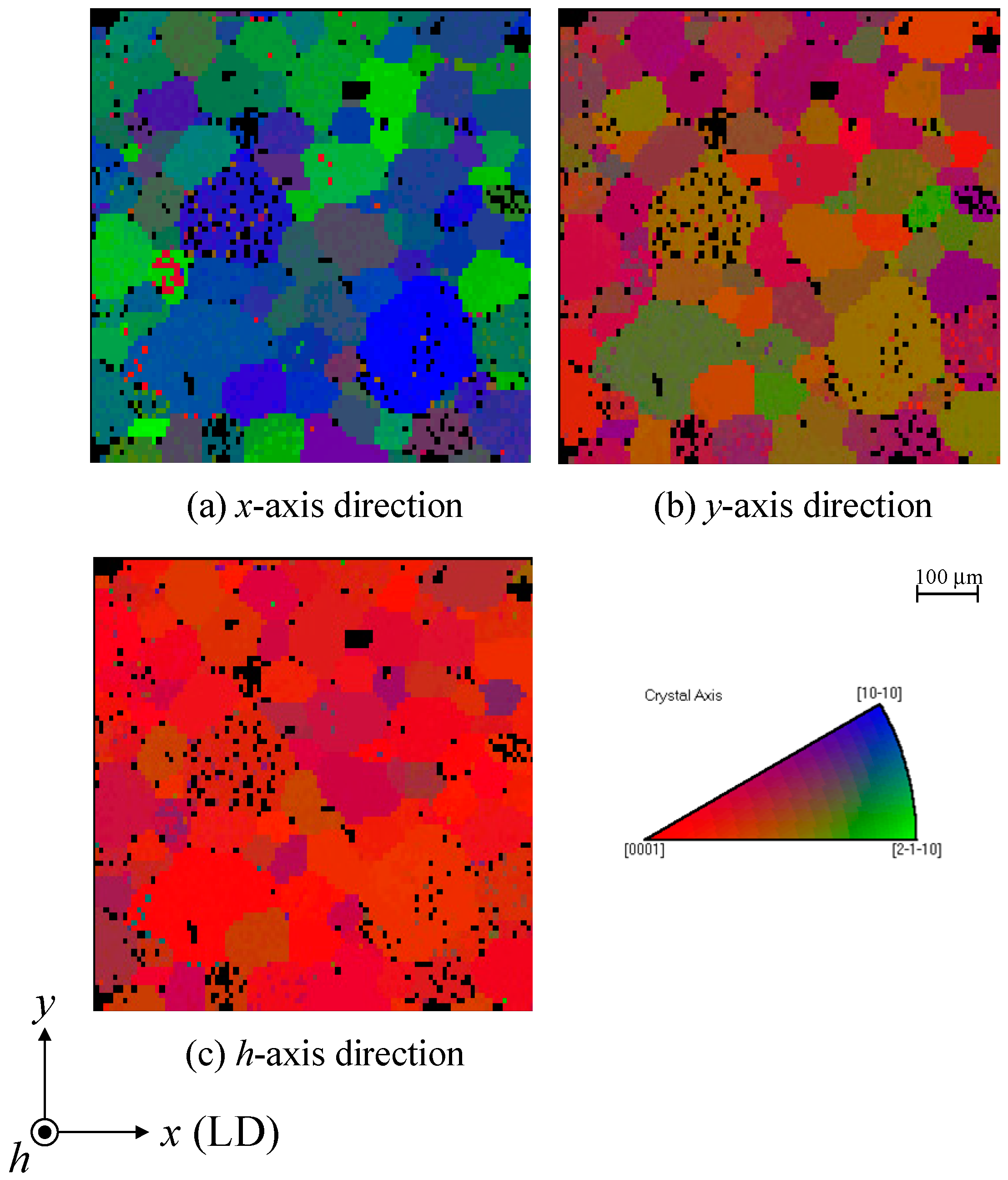

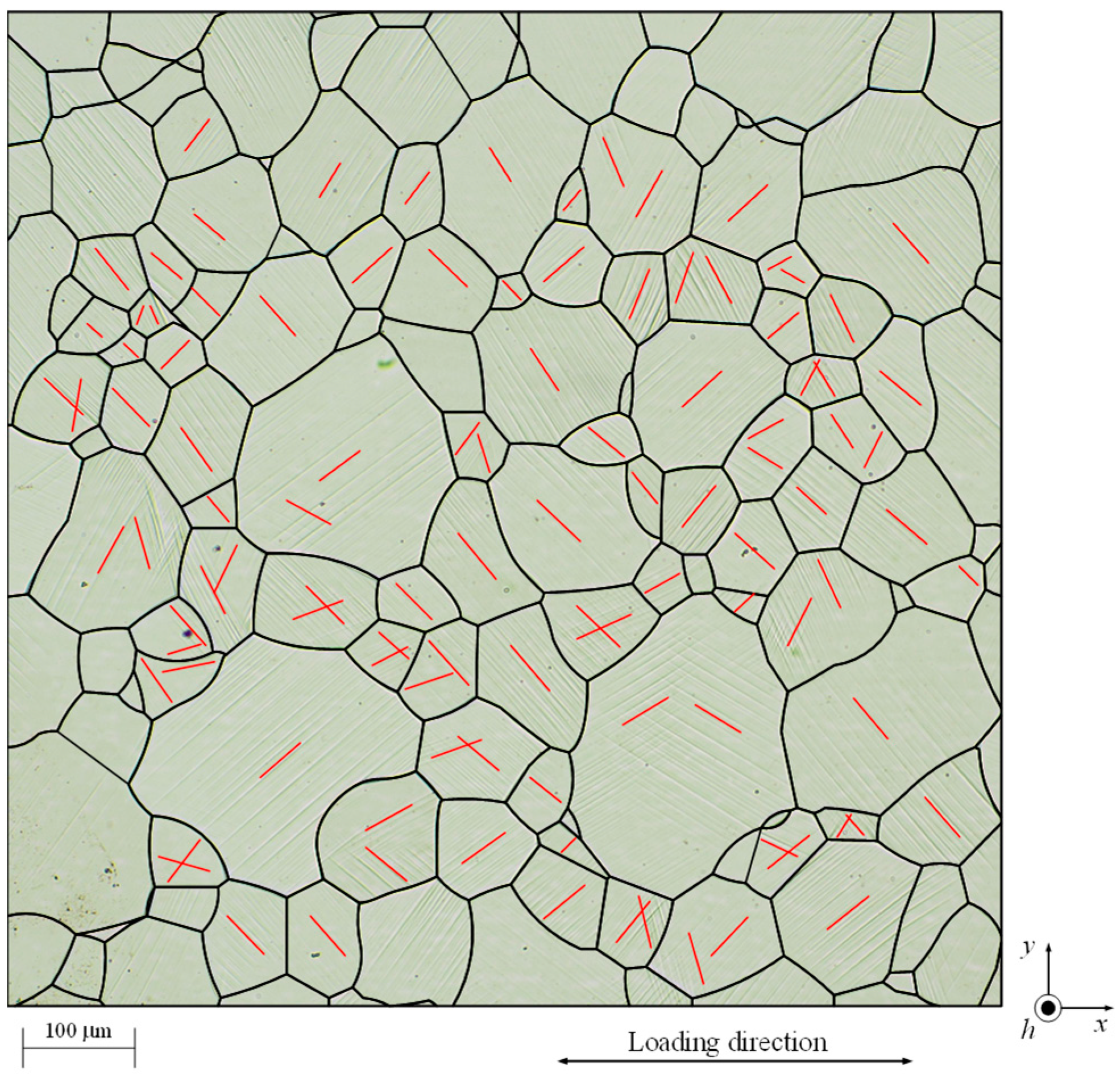

2.3. Observation Area and Average Height of Grains

3. Results and Discussion

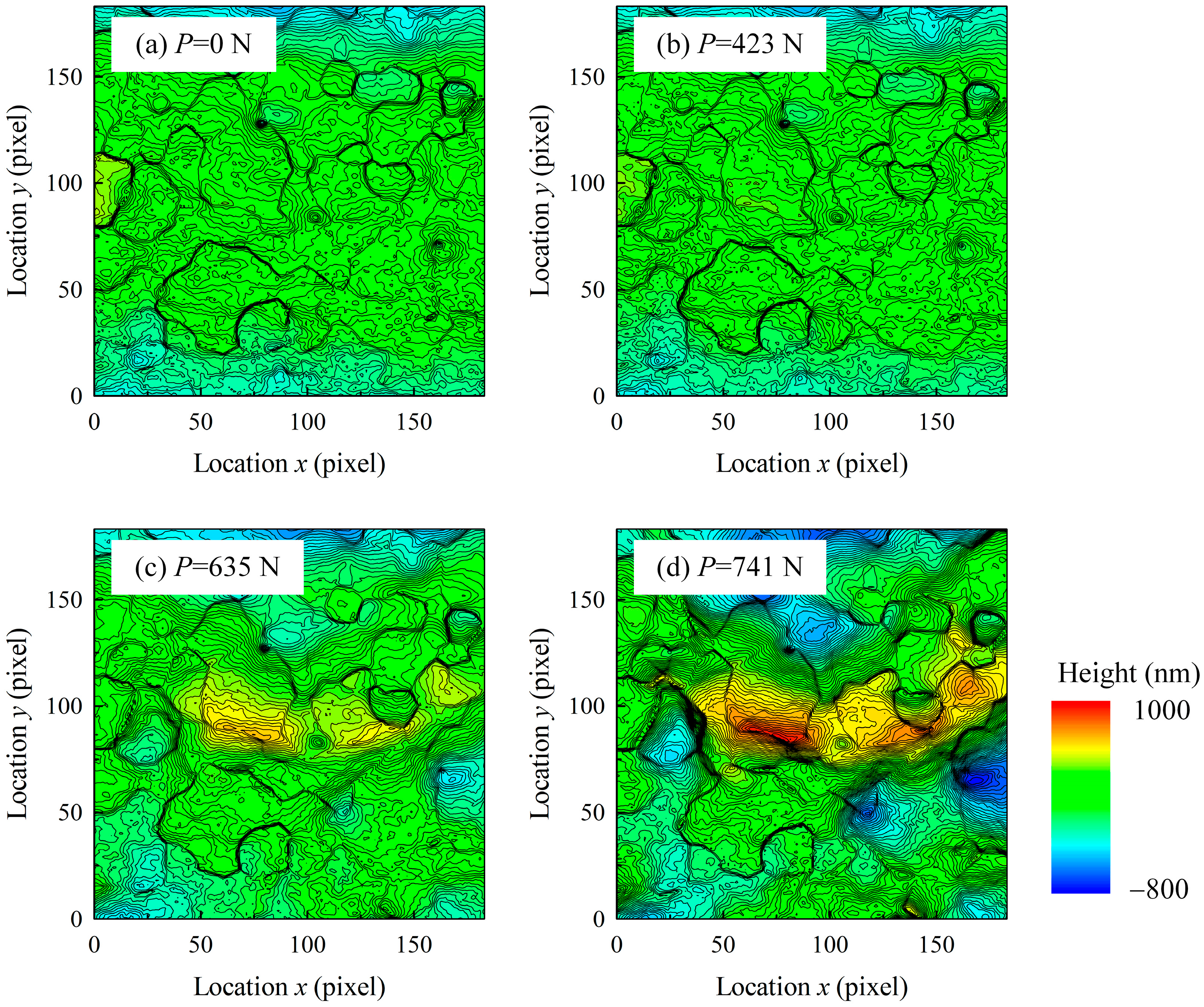

3.1. Height Distribution in the Observation Area

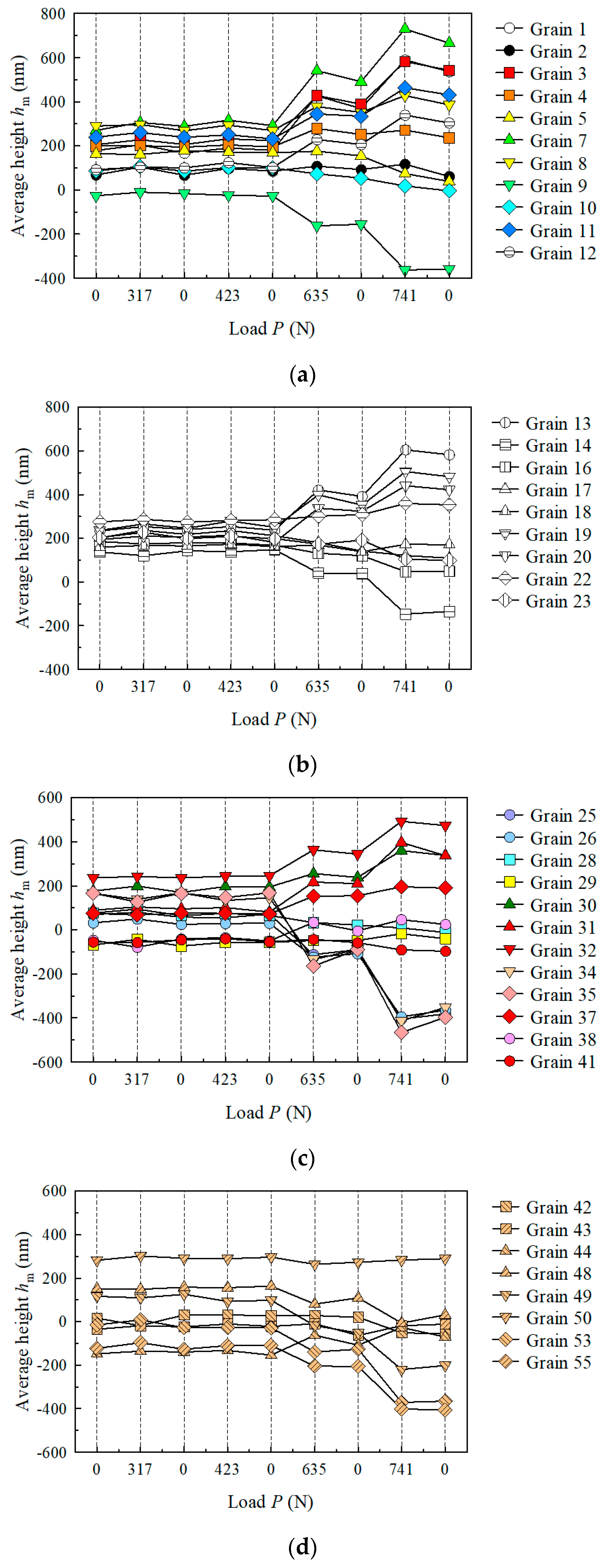

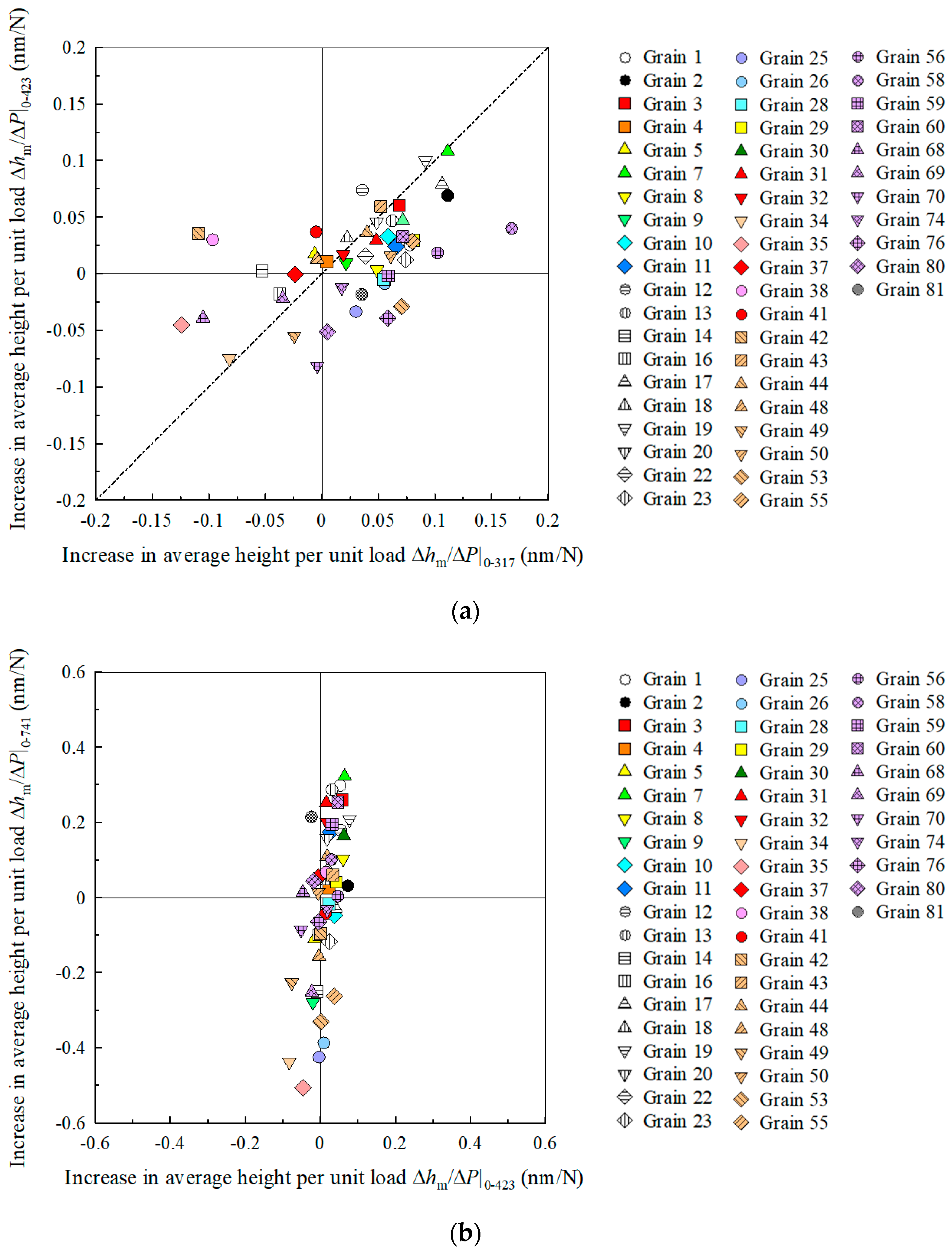

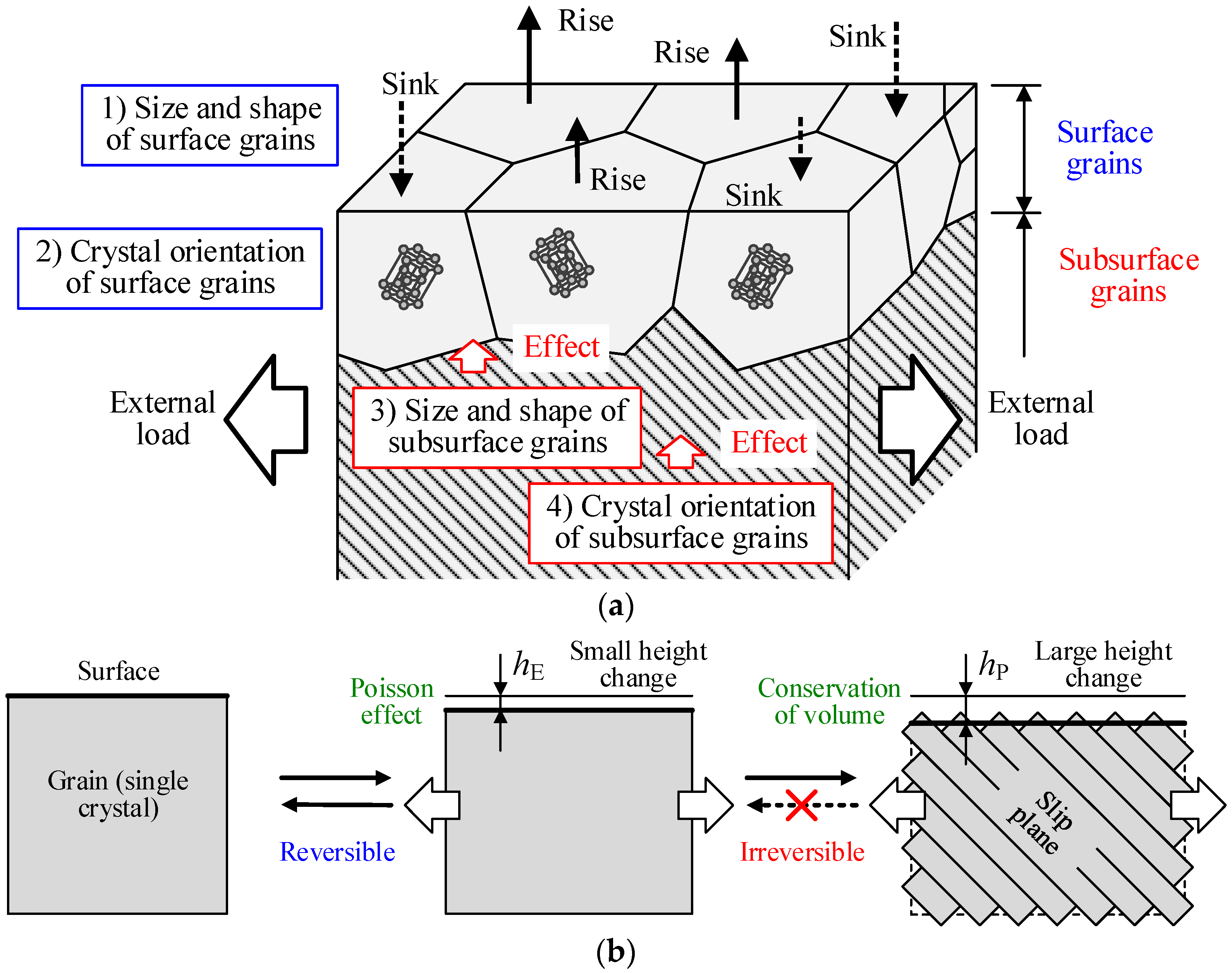

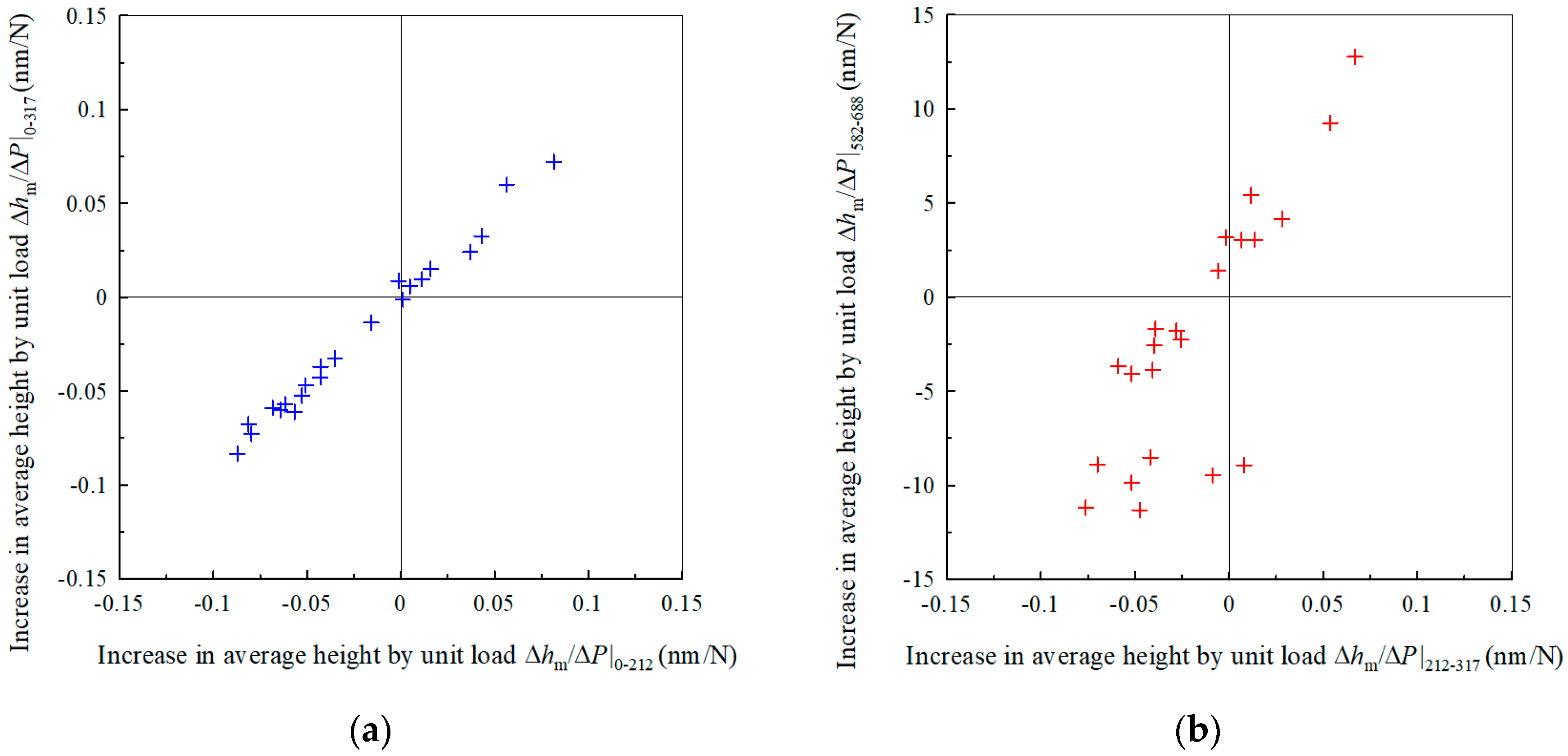

3.2. Change in Average Height of Grains under Elastic and Plastic Conditions

3.3. Plastic Deformation of Grains, and Slip Line Angles

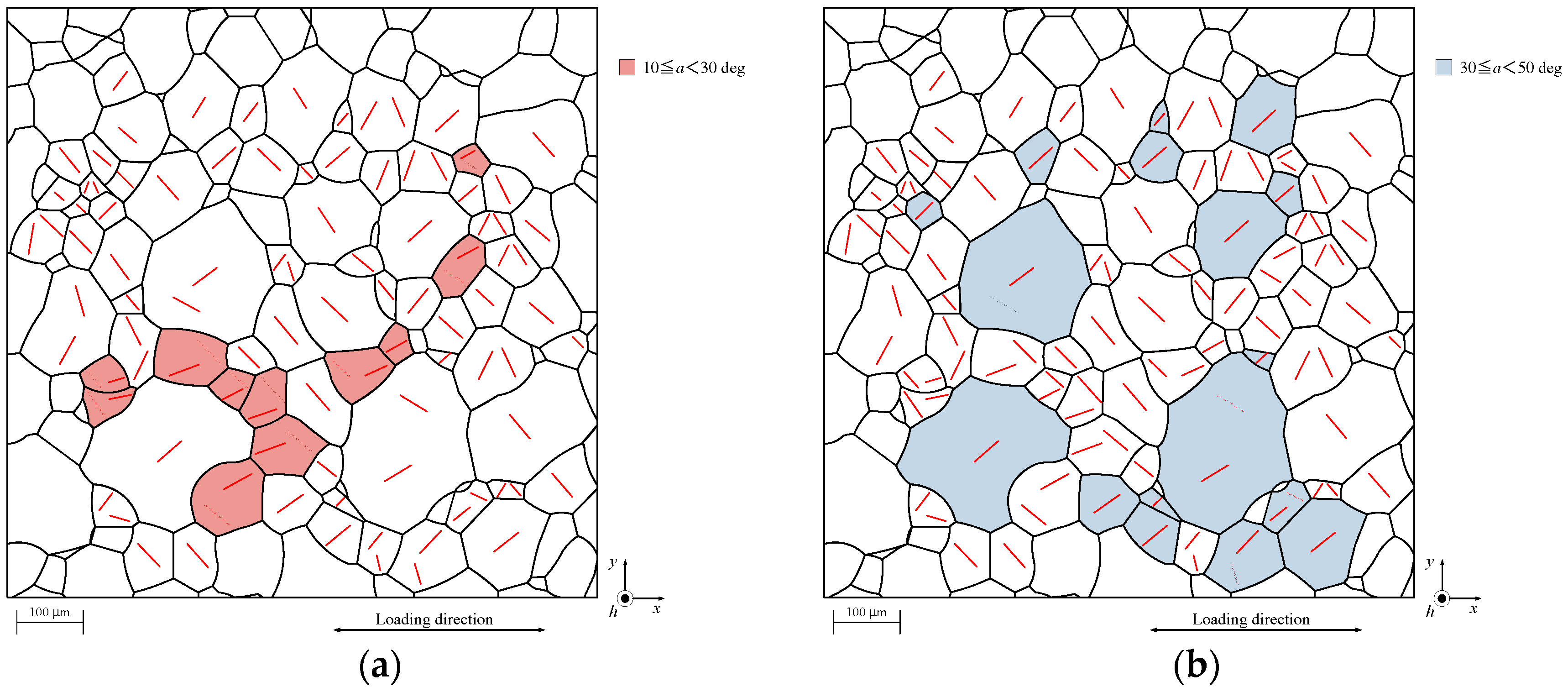

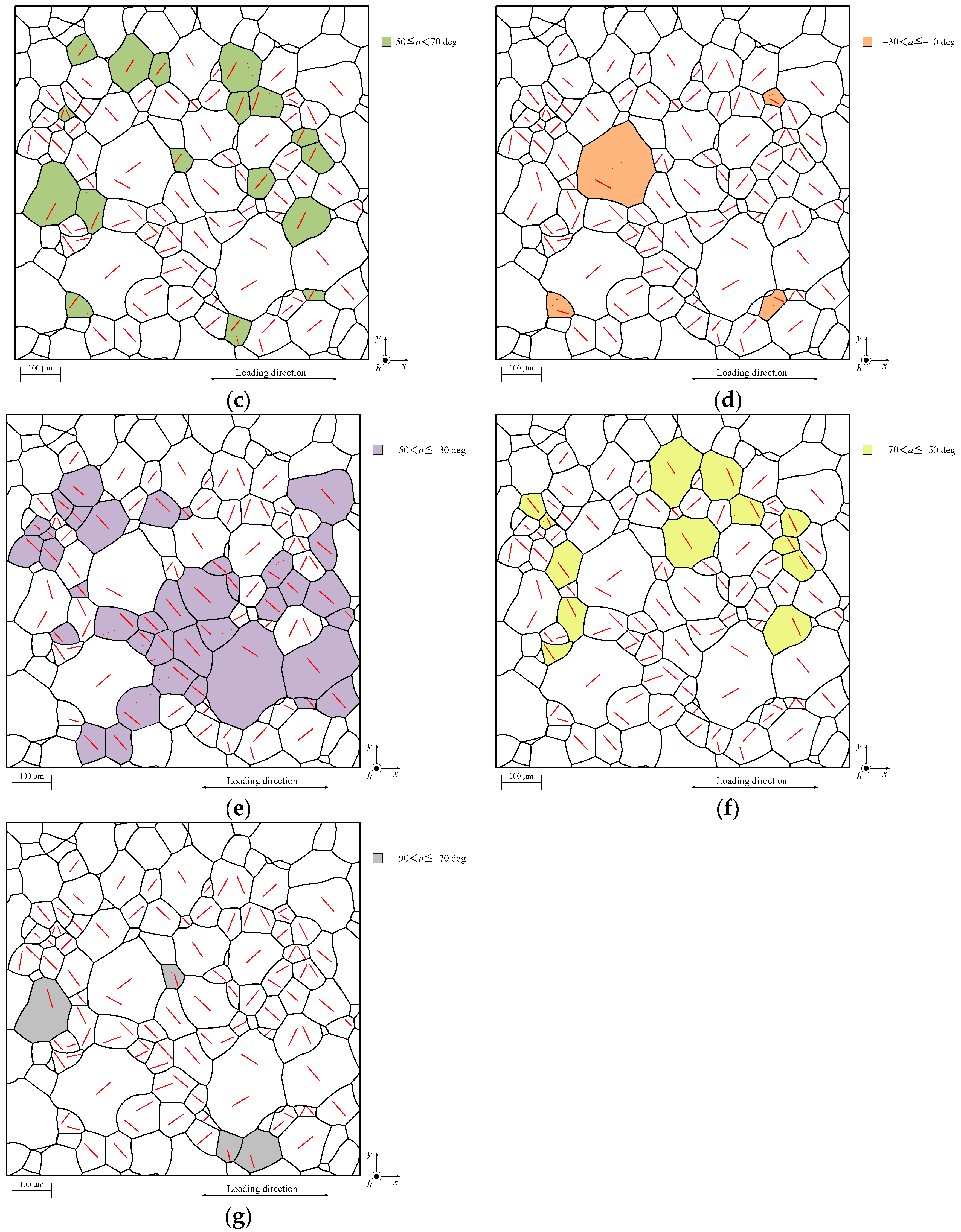

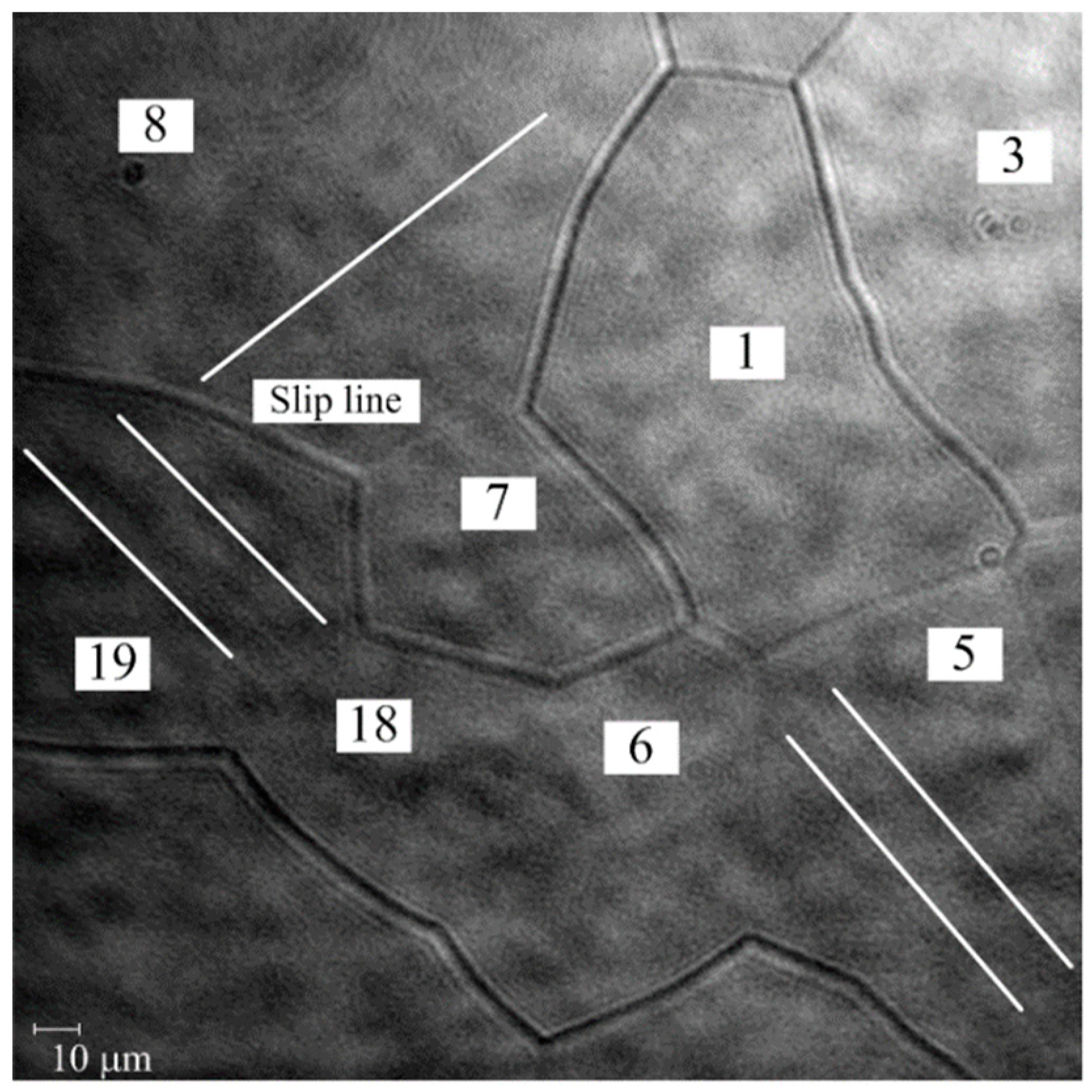

3.4. Slip Lines and Active Slip Systems

3.5. Elastic and Plastic Deformation and Height Changes of Grains

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Randle, V. Microtexture Determination and Its Applications; Maney: London, UK, 2003. [Google Scholar]

- Sutton, M.A.; Orteu, J.J.; Schreier, H. Image Correlation for Shape, Motion and Deformation Measurements; Springer: New York, NY, USA, 2009. [Google Scholar]

- Yang, Y.; Wang, L.; Zambaldi, C.; Eisenlohr, P.; Barabash, R.; Liu, W.; Stoudt, M.R.; Crimp, M.A. Characterization and modelling of heterogeneous deformation in commercial purity titanium. JOM 2011, 63, 66–73. [Google Scholar] [CrossRef]

- Zhao, Z.; Ramesh, M.; Raabe, D.; Cuitino, A.M.; Radovitzky, R. Investigation of three-dimensional aspects of grain-scale plastic surface deformation of an aluminum oligocrystal. Int. J. Plast. 2008, 24, 2278–2297. [Google Scholar] [CrossRef]

- Wang, L.; Barabash, R.I.; Yang, Y.; Bieler, T.R.; Crimp, M.A.; Eisenlohr, P.; Liu, W.; Ice, G.E. Experimental characterization and crystal plasticity modeling of heterogeneous deformation in polycrystalline α-Ti. Metall. Mater. Trans. A 2011, 42, 626–635. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, L.; Bieler, T.R.; Eisenlohr, P.; Crimp, M.A. Quantitative atomic force microscopy characterization and crystal plasticity finite element modeling of heterogeneous deformation in commercial purity titanium. Metall. Mater. Trans. A 2011, 42, 636–644. [Google Scholar] [CrossRef]

- Abe, T.; Nagaki, S.; Akase, T. Material inhomogeneity and surface roughening during plastic deformation. Trans. Jpn. Soc. Mech. Eng. 1984, A50, 1236–1244. [Google Scholar] [CrossRef]

- Lim, H.; Carroll, J.D.; Battaile, C.C.; Buchheit, T.E.; Boyce, B.L.; Weinberger, C.R. Grain-scale experimental validation of crystal plasticity finite element simulations of tantalum oligocrystals. Int. J. Plast. 2014, 60, 1–18. [Google Scholar] [CrossRef]

- Di Gioacchino, F.; Quinta da Fonseca, J. Plastic strain mapping with sub-micron resolution using digital image correlation. Exp. Mech. 2013, 53, 743–754. [Google Scholar] [CrossRef]

- Kammers, A.D.; Daly, S. Digital image correlation under scanning electron microscopy: Methodology and validation. Exp. Mech. 2013, 53, 1743–1761. [Google Scholar] [CrossRef]

- Chen, Z.; Daly, S.H. Active slip system identification in polycrystalline metals by digital image correlation (DIC). Exp. Mech. 2017, 57, 115–127. [Google Scholar] [CrossRef]

- Stinville, J.C.; Echlin, M.P.; Texier, D.; Bridier, F.; Bocher, P.; Pollock, T.M. Sub-grain scale digital image correlation by electron microscopy for polycrystalline materials during elastic and plastic deformation. Exp. Mech. 2017, 56, 197–216. [Google Scholar] [CrossRef]

- Efstathiou, C.; Sehitoglu, H.; Lambros, J. Multiscale strain measurements of plastically deforming polycrystalline titanium: Role of deformation heterogeneities. Int. J. Plast. 2010, 26, 93–106. [Google Scholar] [CrossRef]

- Ravindran, S.; Koohbor, B.; Kidane, A. Experimental characterization of meso-scale deformation mechanisms and the RVE size in plastically deformed carbon steel. Strain 2016, 53, e12217. [Google Scholar] [CrossRef]

- Sutton, M.A.; Ke, X.; Lessner, S.M.; Goldbach, M.; Yost, M.; Zhao, F.; Schreier, H.W. Strain field measurements on mouse carotid arteries using microscopic three-dimensional digital image correlation. J. Biomed. Mater. Res. 2008, 84A, 178–190. [Google Scholar] [CrossRef] [PubMed]

- Koohbor, B.; Ravindran, S.; Kidane, A. Experimental determination of representative volume element (RVE) Size in woven composites. Opt. Lasers Eng. 2017, 90, 59–71. [Google Scholar] [CrossRef]

- Furusawa, T.; Masuda, T.; Manabe, K.; Alexandrov, S. Prediction of free surface roughening by 2d and 3d model considering material inhomogeneity. J. Solid Mech. Mater. Eng. 1984, 5, 978–990. [Google Scholar]

- Tada, N.; Yagi, N.; Shimizu, I.; Uchida, M. Regional Identification by Digital Height Correlation of Nanolevel Surface Profile. In Proceedings of the Final Program and Abstracts, SEM 2009 Fall Symposium and Workshop, Columbia, SC, USA, 5–7 October 2009; The Society for Experimental Mechanics: Bethel, CT, USA, 2009; p. 15. [Google Scholar]

- Tada, N.; Uemori, T.; Nakata, T. Elastic and plastic microscopic undulation on the surface of polycrystalline pure titanium under tension. J. Pressure Vessel Technol. 2017, 139, 061403. [Google Scholar] [CrossRef]

- Tada, N.; Matsukawa, Y.; Uemori, T.; Nakata, T. Microscopic Deformation of Polycrystalline Pure Copper Wire during Tension. In Proceedings of the 10th International Microsystems, Packaging, Assembly and Circuits Technology Conference, Taipei, Taiwan, 21–23 October 2015; pp. 420–423. [Google Scholar]

- Tada, N.; Hamada, S.; Teramae, T.; Yoshino, S.; Suzuki, T. A Method of Crack Detection in the Turbine Blade Using Digital Holographic Microscopy. In Proceedings of the ASME 2011 Pressure Vessels and Piping Conference, Baltimore, MD, USA, 17–21 July 2011; The American Society of Mechanical Engineers: New York, NY, USA, 2011; pp. 211–216. [Google Scholar]

- Tada, N.; Uchida, M.; Uenoyama, Y. Non-Destructive Crack Detection by Nanometric Change in Surface Profile Using Digital Holographic Microscope. In Proceedings of the ASME 2012 Pressure Vessels and Piping Conference, Toronto, ON, Canada, 15–19 July 2012; The American Society of Mechanical Engineers: New York, NY, USA, 2012; pp. 251–257. [Google Scholar]

- Tada, N.; Uchida, M.; Matsukawa, Y. Non-Destructive Detection of Crack in HDPE Plate by Nanometric Change in Surface Profile. In Proceedings of the ASME 2013 Pressure Vessels and Piping Conference, Paris, France, 14–18 July 2013; The American Society of Mechanical Engineers: New York, NY, USA, 2013. [Google Scholar]

- Tada, N. Microscopic Height Change on the Surface of Polycrystalline Pure Titanium under Cyclic Tension. In International Digital Imaging Correlation Society, Proceedings of the First Annual Conference, Philadelphia, PA, USA, 7–10 November 2016; The Society for Experimental Mechanics: Bethel, CT, USA, 2017; pp. 267–271. [Google Scholar]

- Haghshenas, A.; Khonsari, M.M. Damage accumulation and crack initiation detection based on the evolution of surface roughness parameters. Int. J. Fatigue 2018, 107, 130–144. [Google Scholar] [CrossRef]

- Akhtar, A. Basal slip and twinning in a-titanium singe crystal. Metall. Trans. A 1975, 6A, 1105–1113. [Google Scholar] [CrossRef]

- Gong, J.; Wilkinson, A.J. Anisotropy in the plastic flow properties of single-crystal titanium determined from micro-cantilever beams. Acta Mater. 2009, 57, 5693–5705. [Google Scholar] [CrossRef]

- Sun, Q.; Guo, Q.; Yao, X.; Xiao, L.; Greer, J.R.; Sun, J. Size effects in strength and plasticity of single-crystalline titanium micropillars with prismatic slip orientation. Acta Mater. 2011, 65, 473–476. [Google Scholar] [CrossRef]

- Warwick, J.L.; Jones, N.G.; Rahman, K.M.; Dye, D. Lattice strain evolution during tensile and compressive loading of CP Ti. Acta Mater. 2012, 60, 6720–6731. [Google Scholar] [CrossRef]

- Salem, A.A.; Kalidindi, S.R.; Semiatin, S.L. Strain hardening due to deformation twinning in α-titanium: Constitutive relations and crystal-plasticity modeling. Acta Mater. 2005, 53, 3495–3502. [Google Scholar] [CrossRef]

- Zambaldi, C.; Yang, Y.; Wang, L.; Bieler, T.R. Orientation informed nanoindentation of α-titanium: Indentation pileup in hexagonal metals deforming by prismatic slip. J. Mater. Res. 2012, 27, 356–367. [Google Scholar] [CrossRef]

- Lie, H.; Mason, D.E.; Bieler, T.R.; Boehlert, C.J.; Crimp, M.A. Methodology for estimating the critical resolved shear stress ratios of α-phase Ti using EBSD-based trace analysis. Acta Mater. 2013, 61, 7555–7567. [Google Scholar] [CrossRef]

- Bieler, T.R.; Crimp, M.A.; Yang, Y.; Wang, L.; Eisenlohr, P.; Mason, D.E.; Liu, W.; Ice, G.E. Strain heterogeneity and damage nucleation at grain boundaries during monotonic deformation in commercial purity titanium. JOM 2009, 61, 45–52. [Google Scholar] [CrossRef]

- Hemery, S.; Nait-Ali, A.; Villechaise, P. Combination of In-situ SEM tensile test and FFT-based crystal elasticity simulations of Ti-6Al-4V for an improved description of the onset of plastic slip. Mech. Mater. 2017, 109, 1–10. [Google Scholar] [CrossRef]

| Step | Load P (N) | Nominal Stress σn (MPa) | Nominal Strain εn (%) |

|---|---|---|---|

| 0 (before test) | 0 | 0 | 0 |

| 1 | 317 | 113 | 0.129 |

| 2 | 0 | 0 | 0 |

| 3 | 423 | 151 | 0.258 |

| 4 | 0 | 0 | 0.129 |

| 5 | 635 | 226 | 0.873 |

| 6 | 0 | 0 | 0.515 |

| 7 | 741 | 264 | 1.36 |

| 8 (after test) | 0 | 0 | 1.23 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tada, N.; Uemori, T. Microscopic Elastic and Plastic Inhomogeneous Deformations and Height Changes on the Surface of a Polycrystalline Pure-Titanium Plate Specimen under Cyclic Tension. Appl. Sci. 2018, 8, 1907. https://doi.org/10.3390/app8101907

Tada N, Uemori T. Microscopic Elastic and Plastic Inhomogeneous Deformations and Height Changes on the Surface of a Polycrystalline Pure-Titanium Plate Specimen under Cyclic Tension. Applied Sciences. 2018; 8(10):1907. https://doi.org/10.3390/app8101907

Chicago/Turabian StyleTada, Naoya, and Takeshi Uemori. 2018. "Microscopic Elastic and Plastic Inhomogeneous Deformations and Height Changes on the Surface of a Polycrystalline Pure-Titanium Plate Specimen under Cyclic Tension" Applied Sciences 8, no. 10: 1907. https://doi.org/10.3390/app8101907

APA StyleTada, N., & Uemori, T. (2018). Microscopic Elastic and Plastic Inhomogeneous Deformations and Height Changes on the Surface of a Polycrystalline Pure-Titanium Plate Specimen under Cyclic Tension. Applied Sciences, 8(10), 1907. https://doi.org/10.3390/app8101907