A Novel Hybrid Boundary-Type Meshless Method for Solving Heat Conduction Problems in Layered Materials

Abstract

:1. Introduction

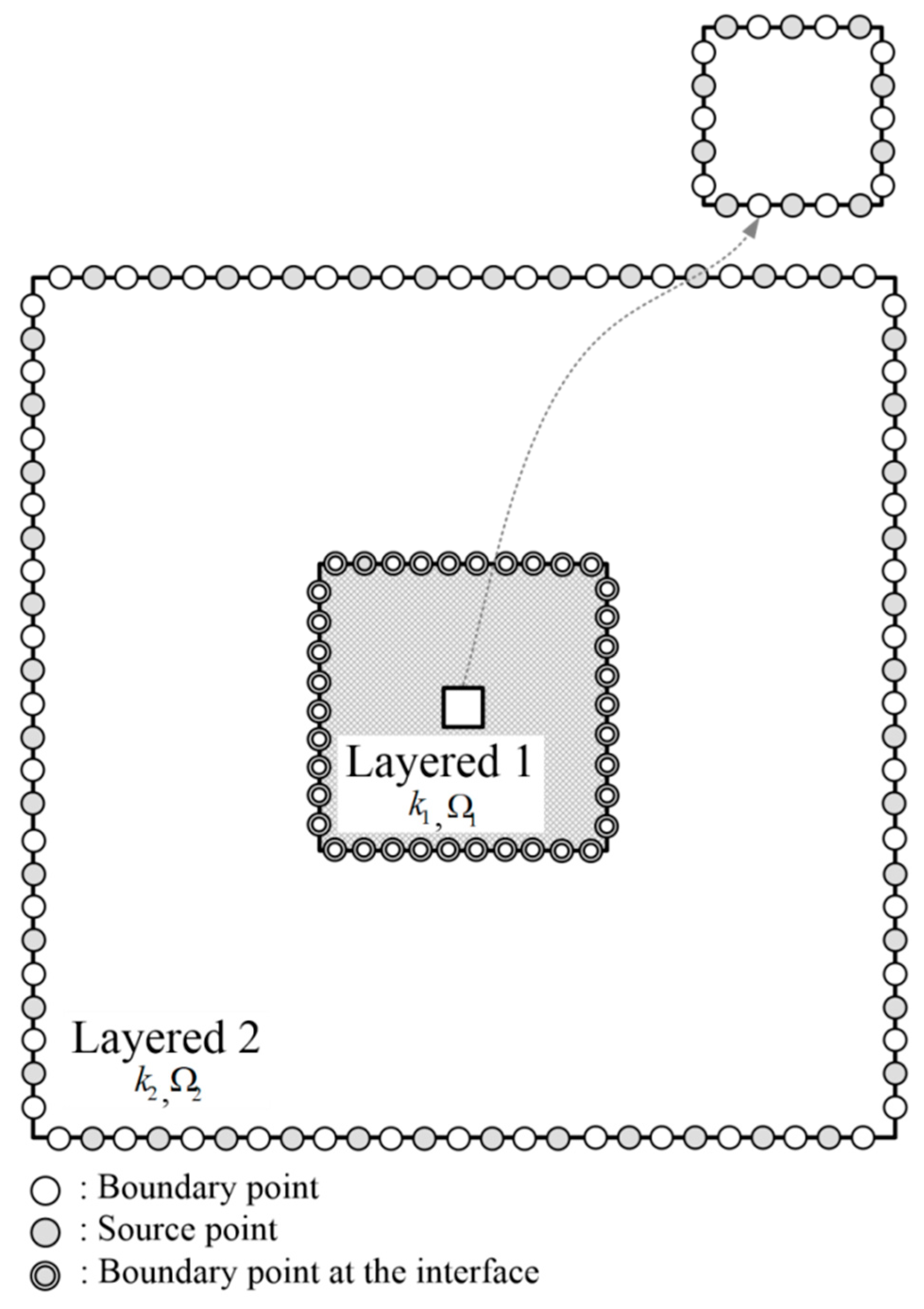

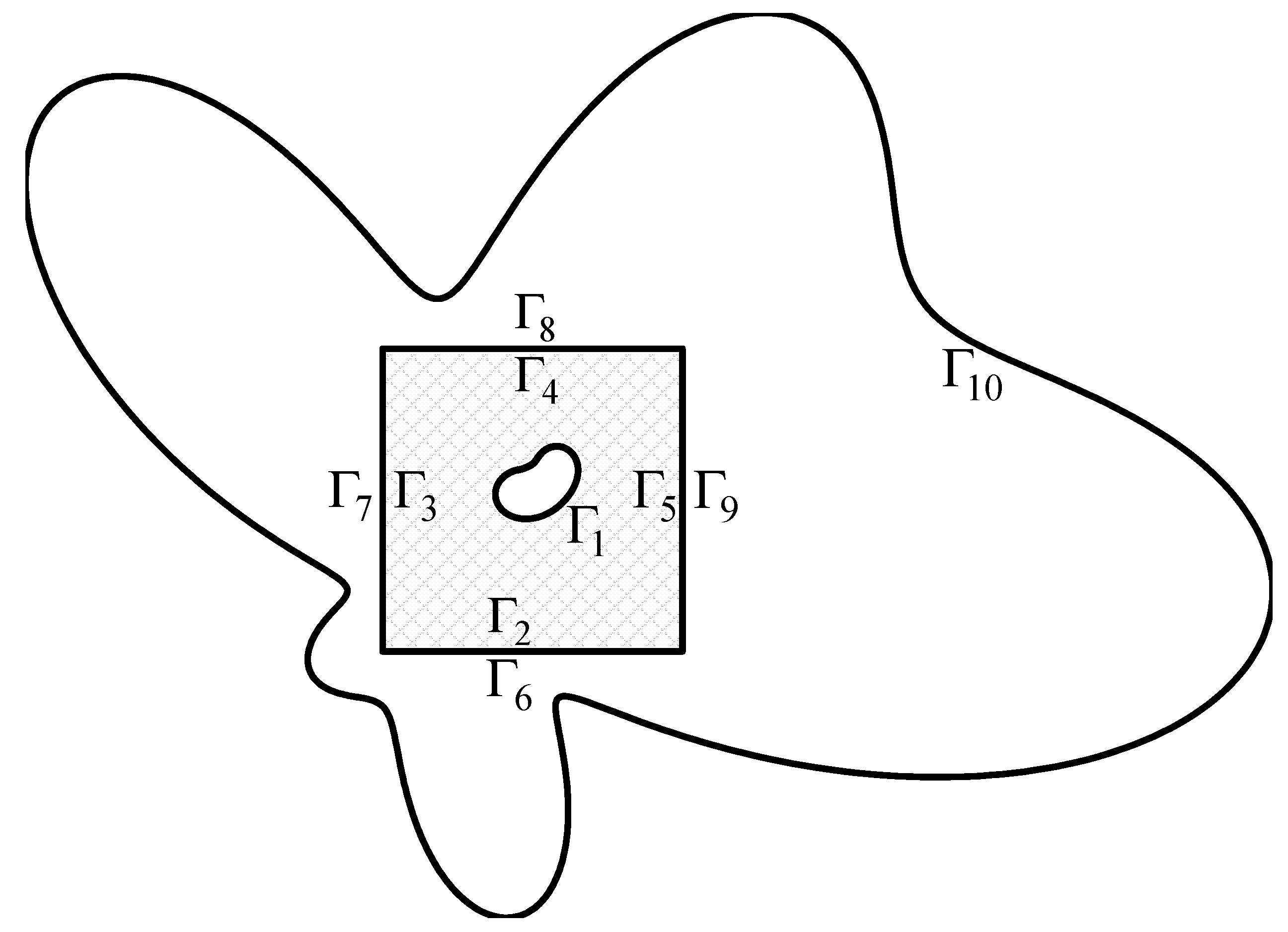

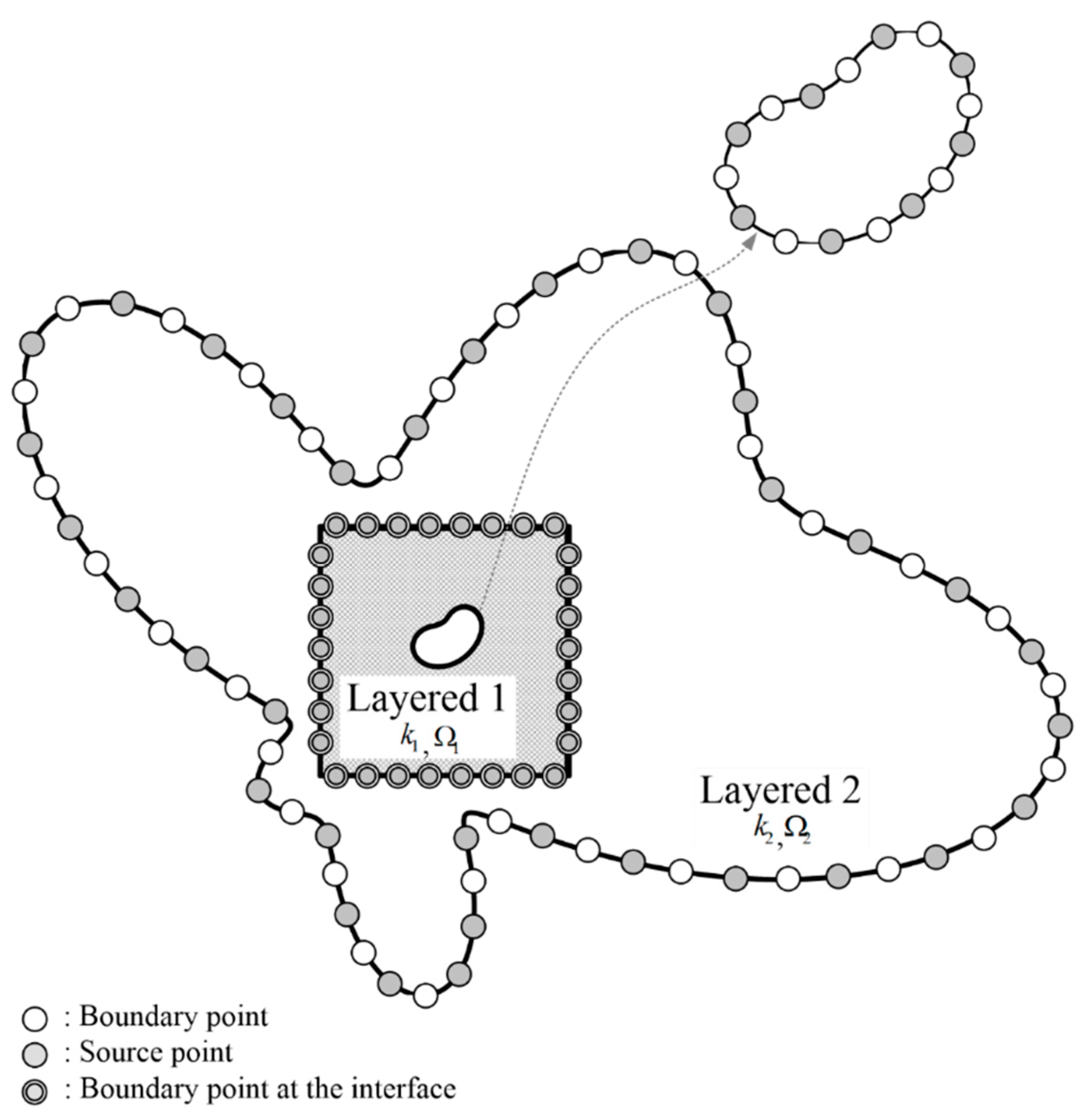

2. Problem Statement

3. Hybrid Boundary-Type Meshless Method for Modeling Heat Conduction Problems

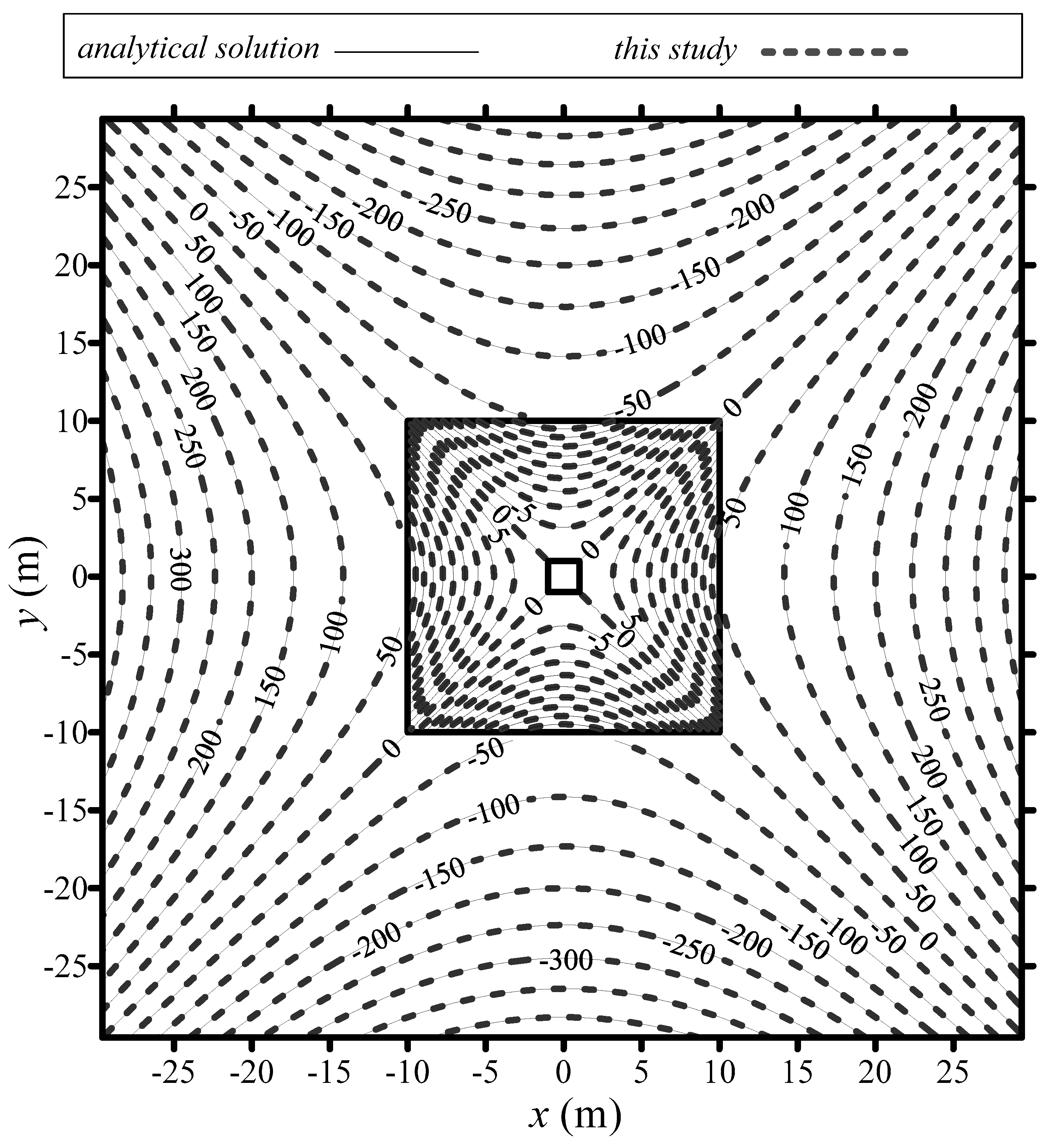

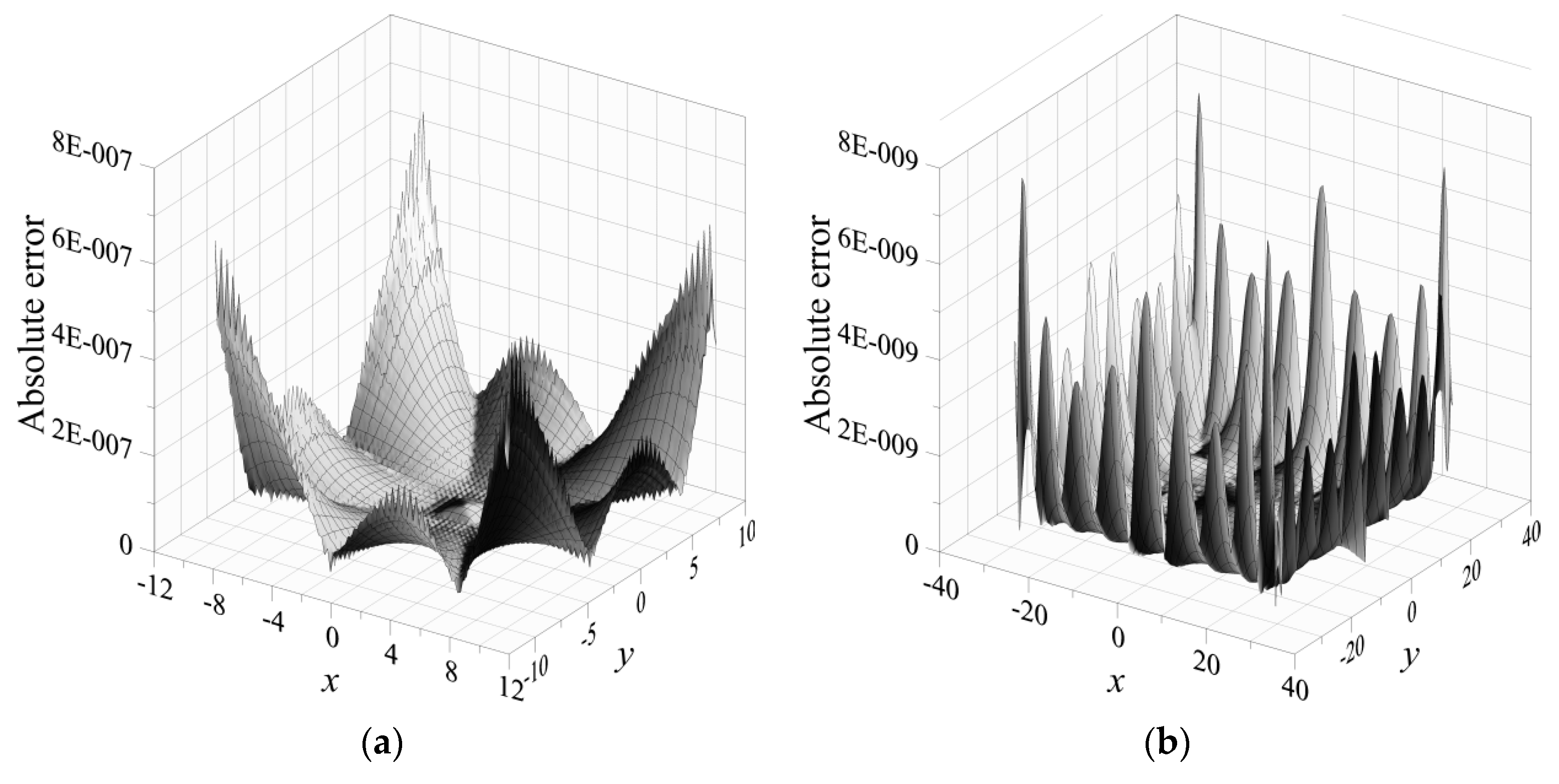

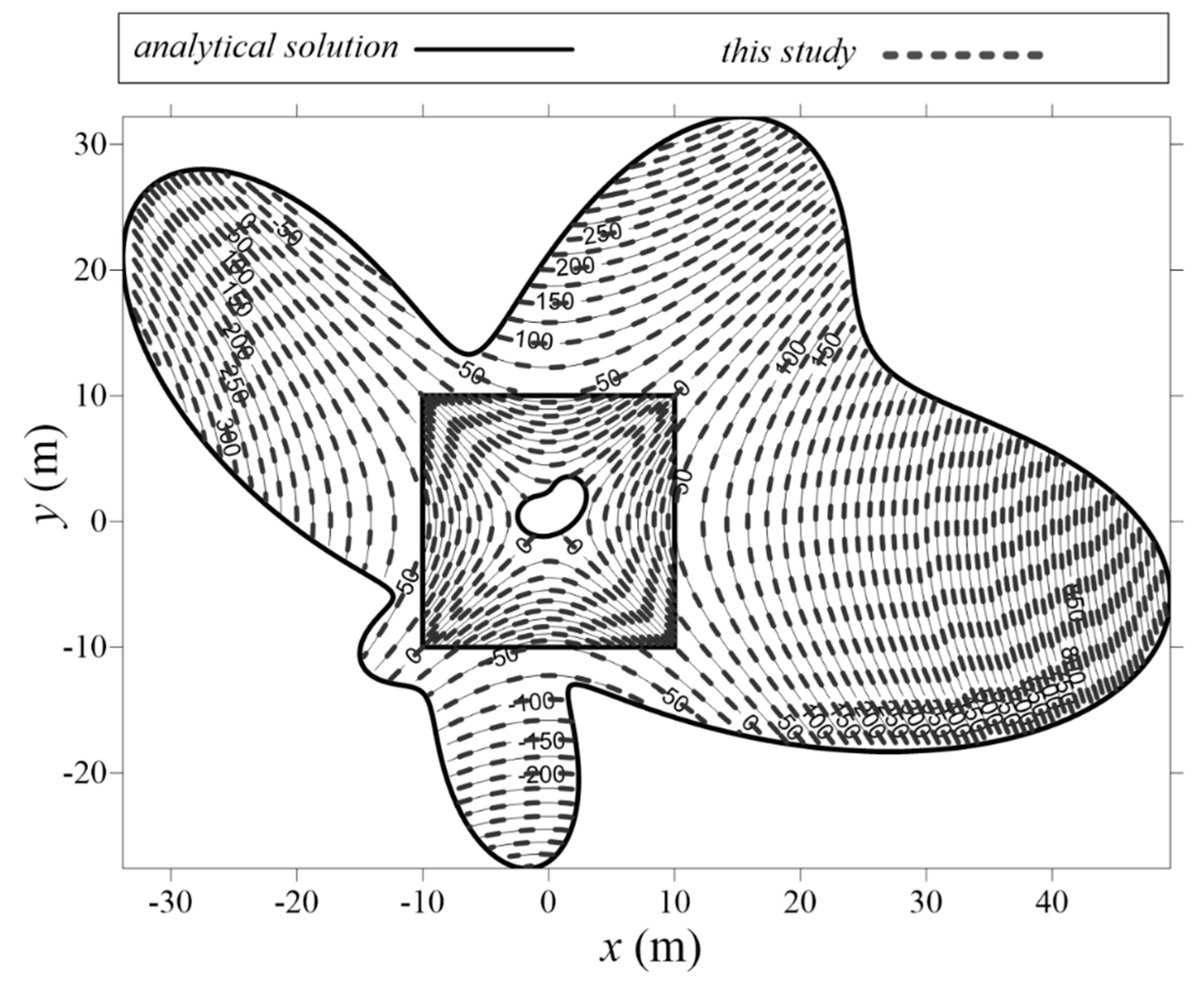

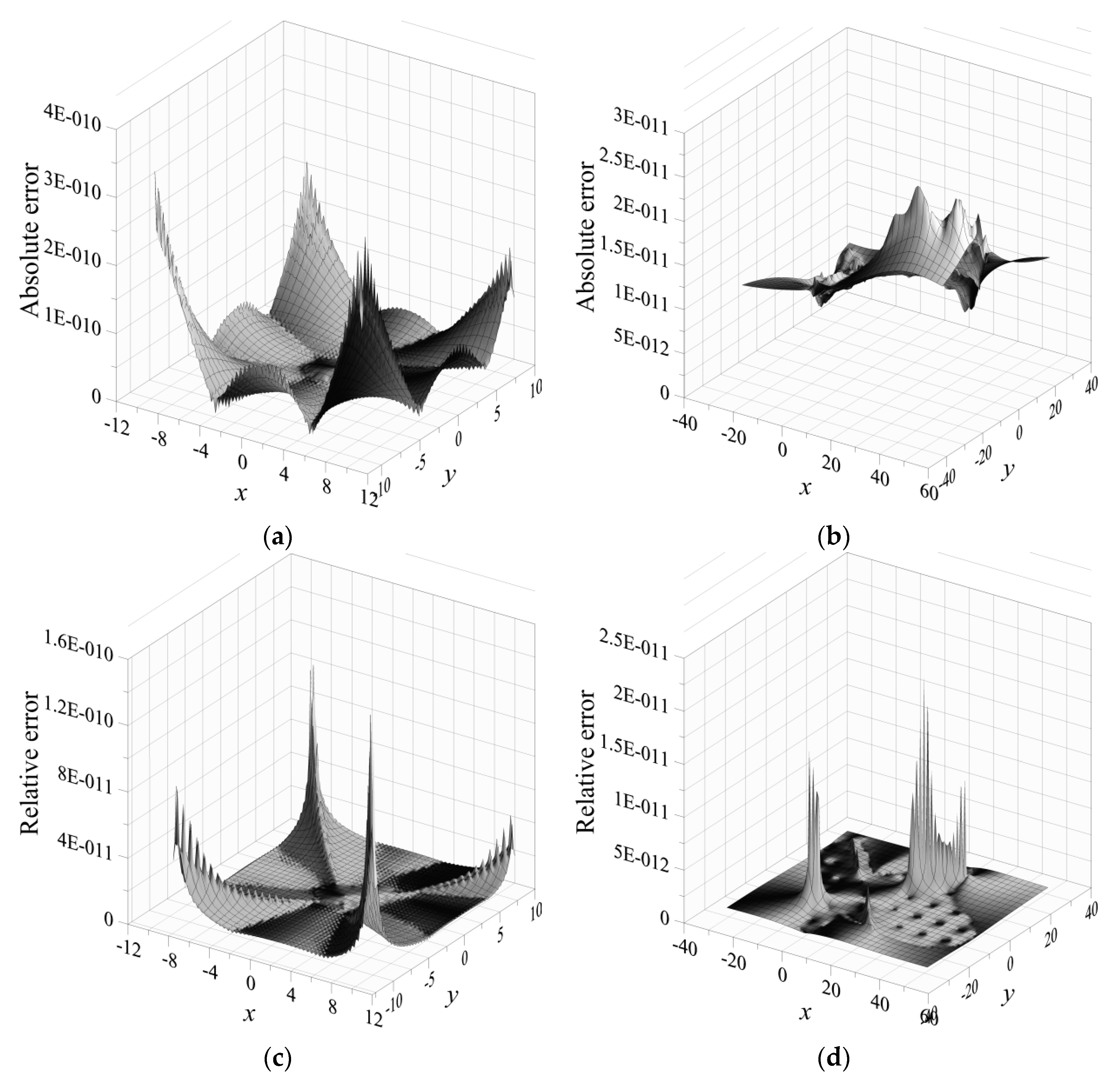

4. Numerical Examples

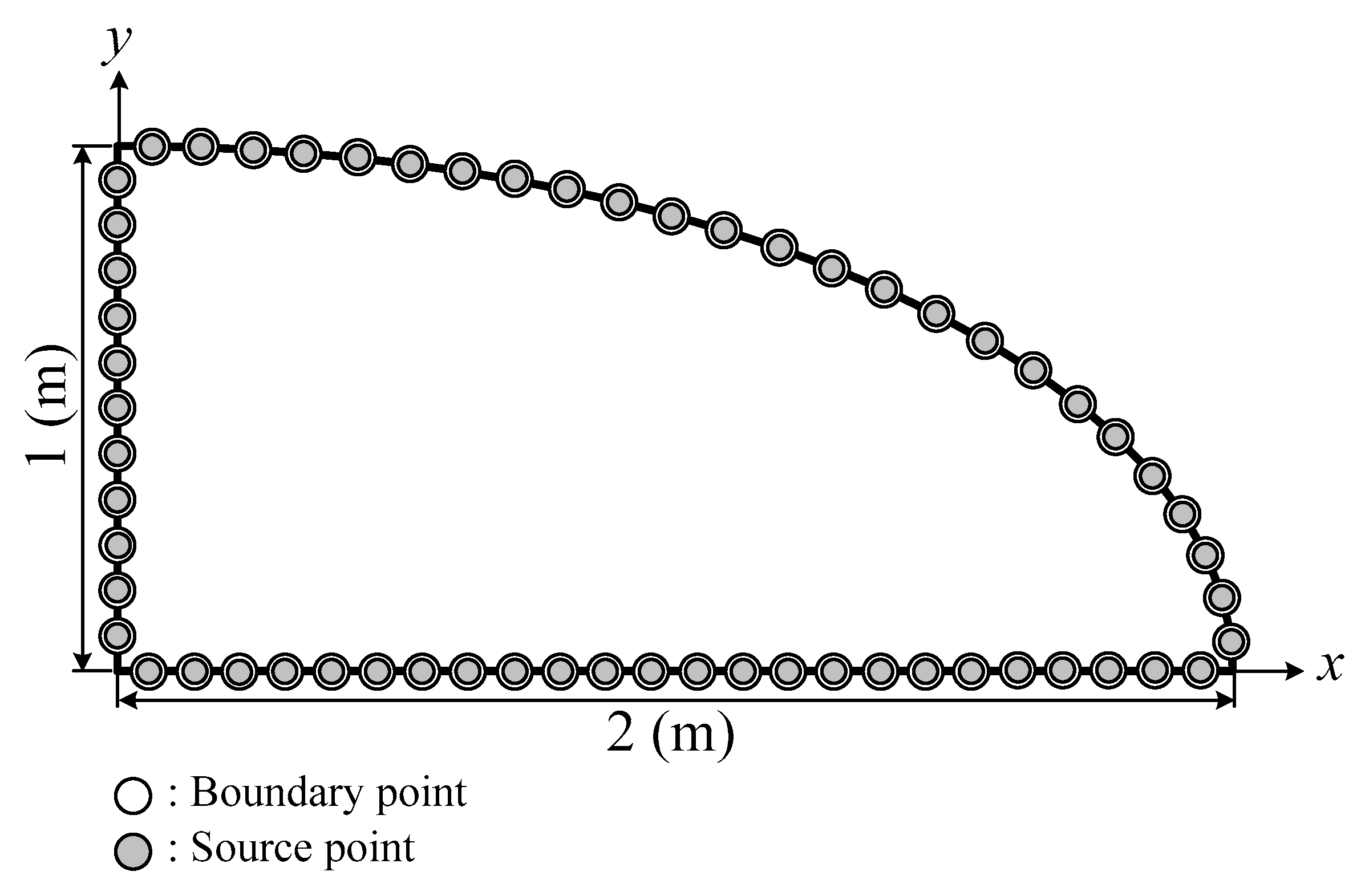

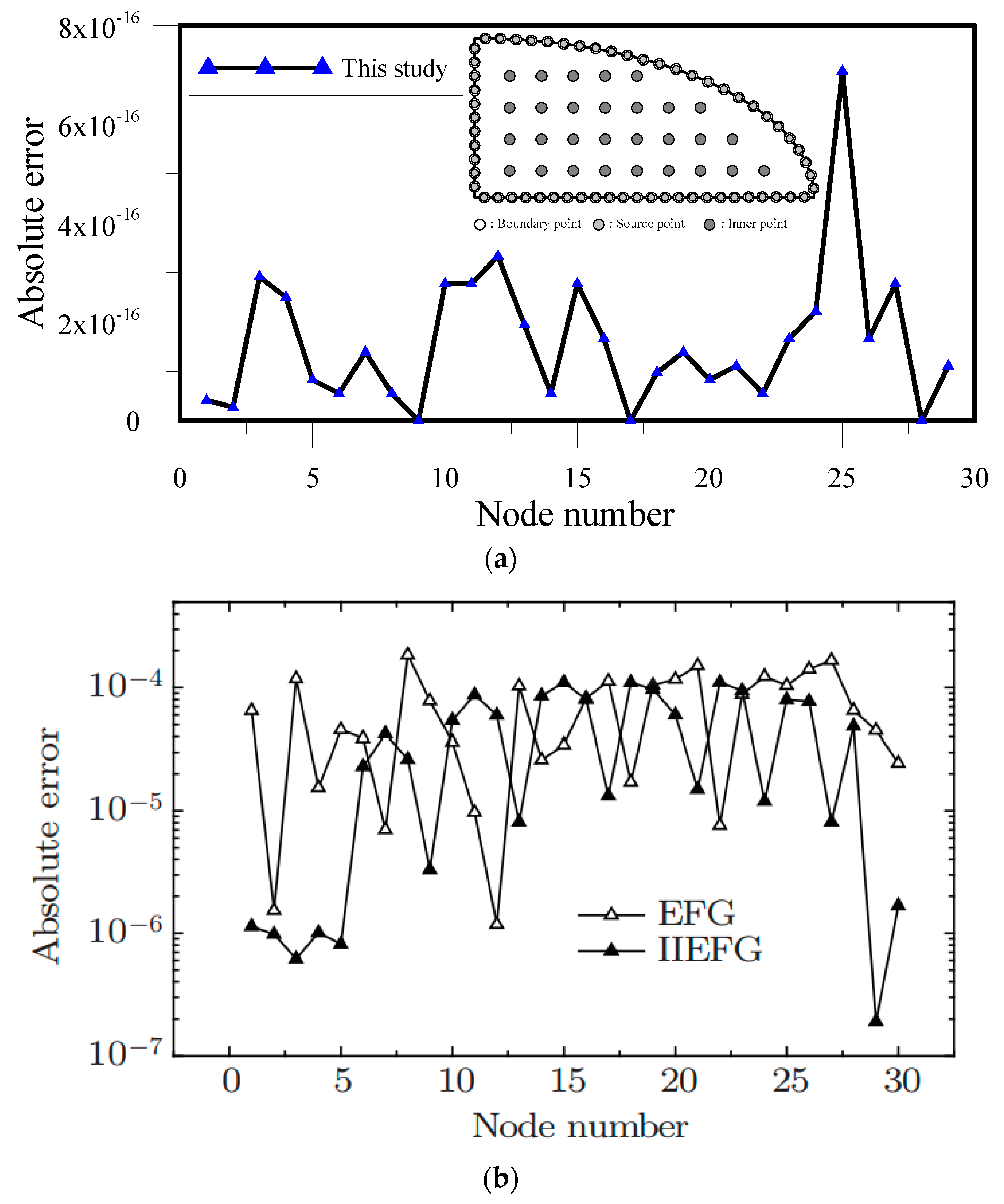

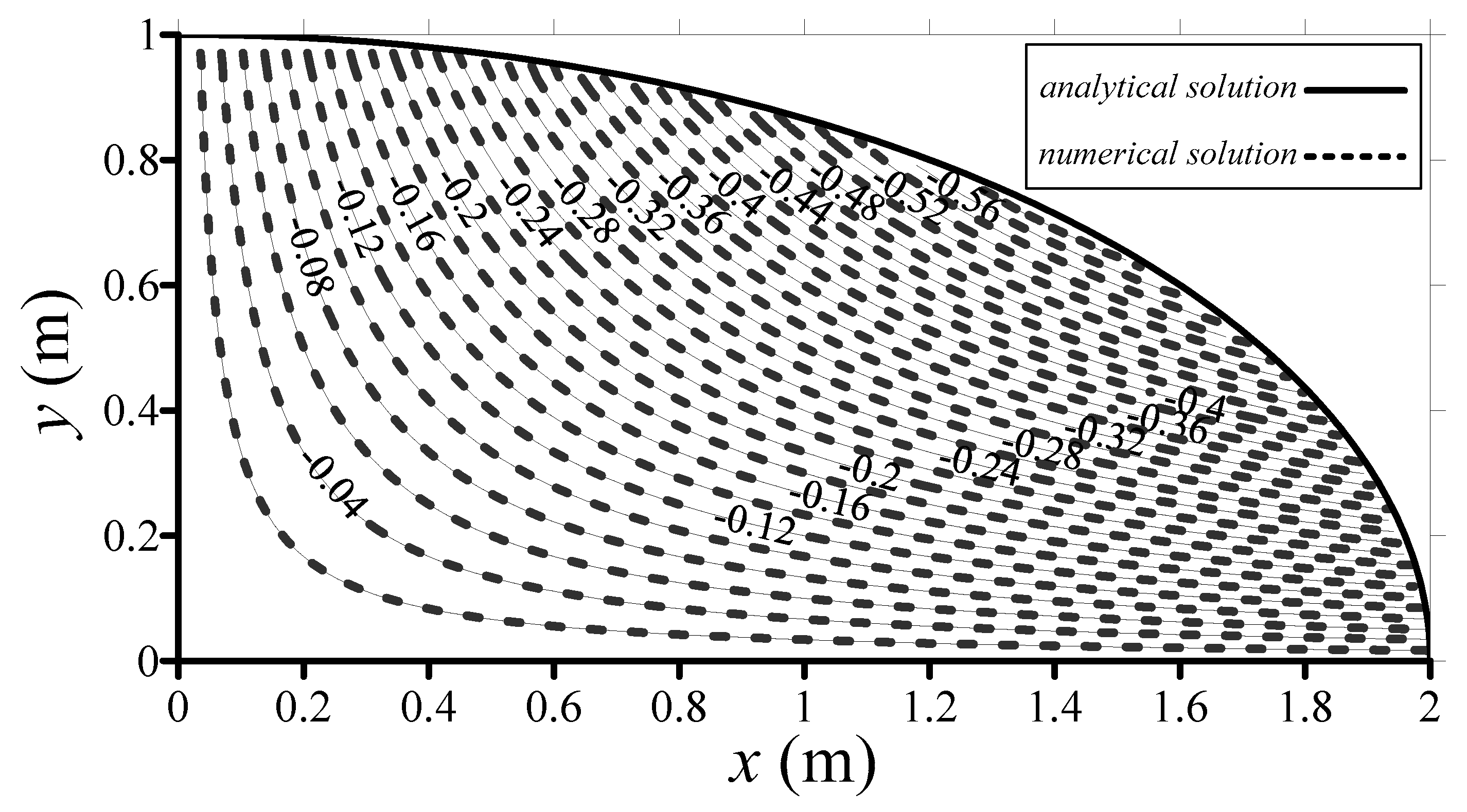

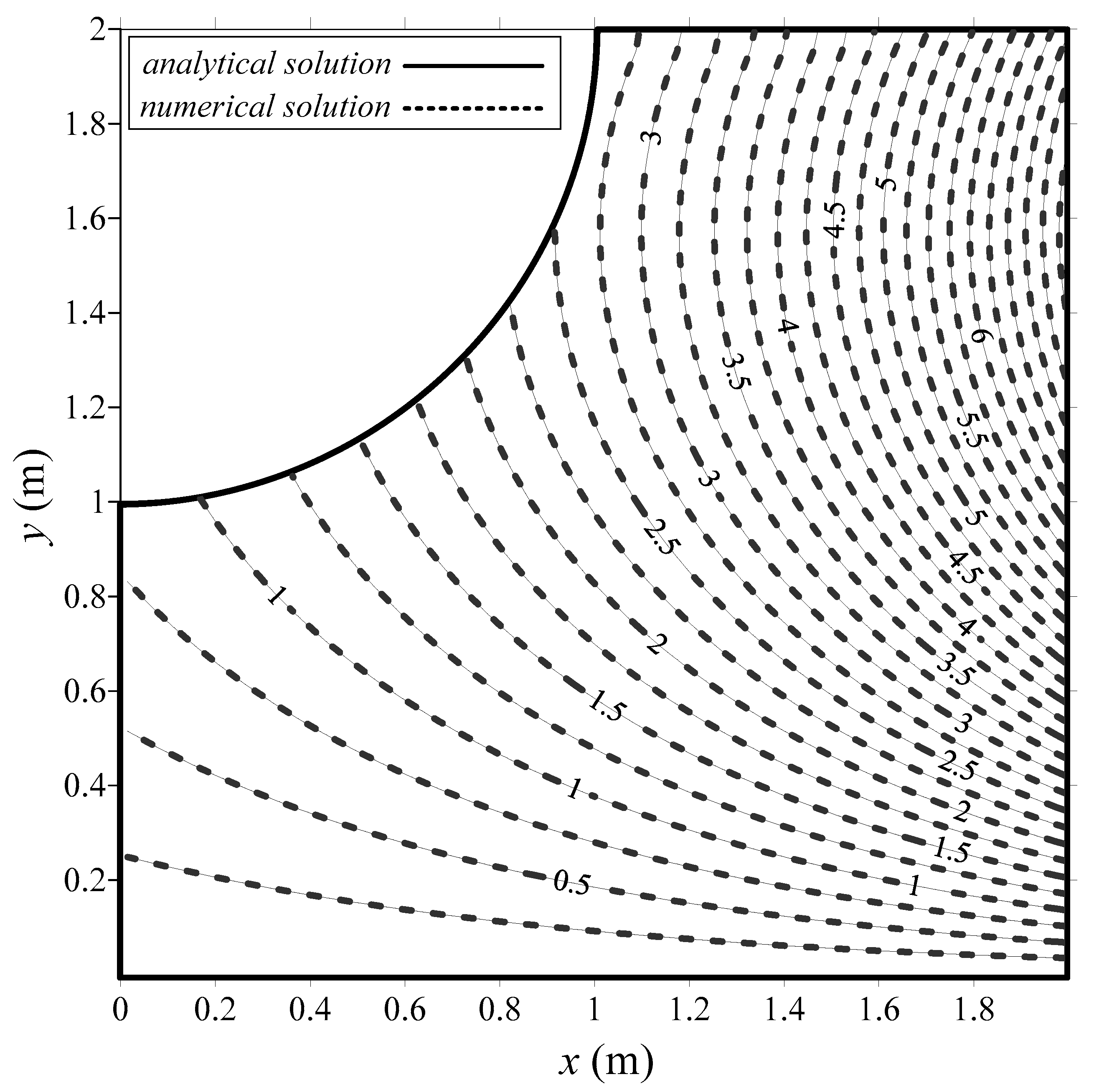

4.1. Example 1

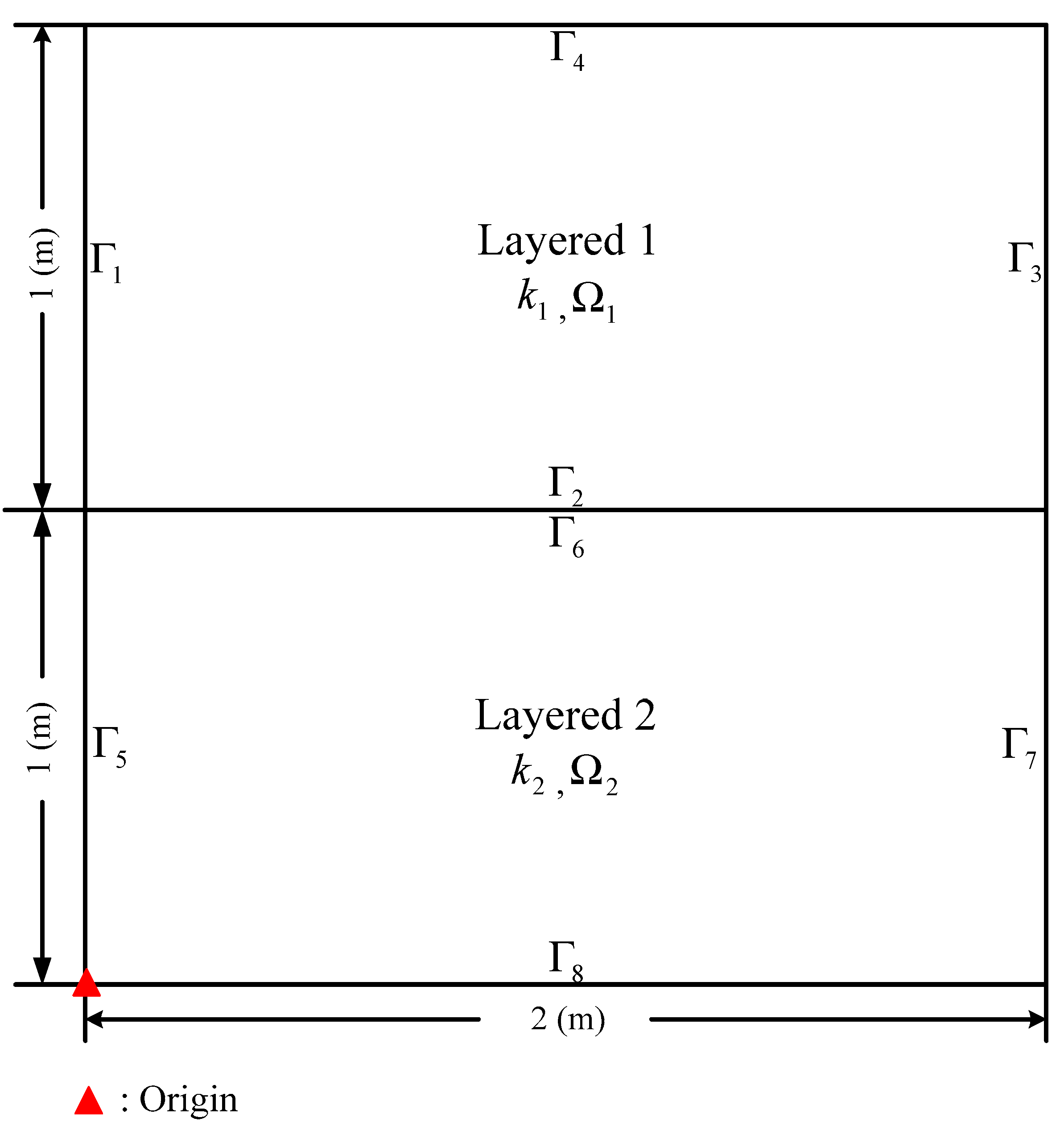

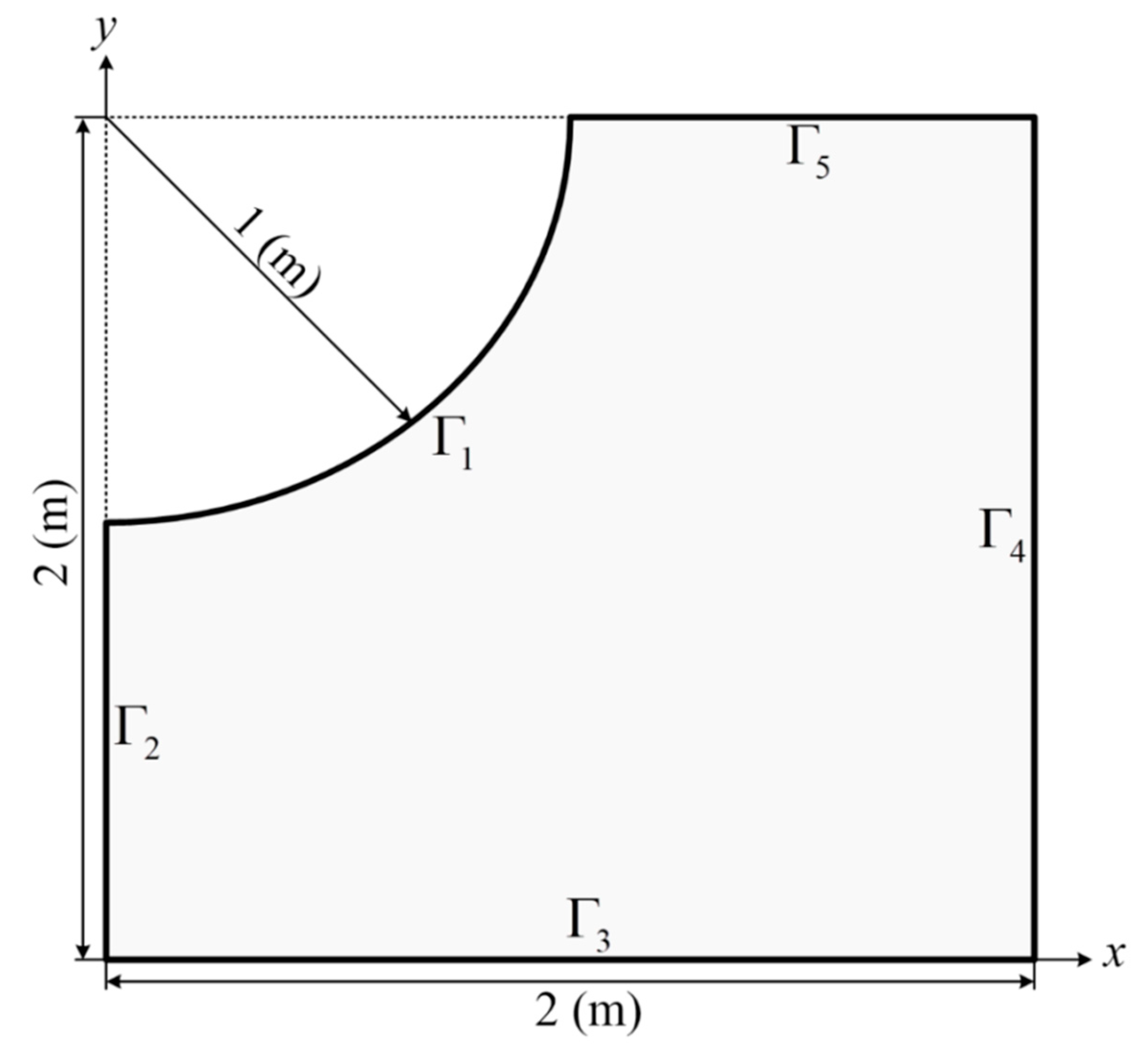

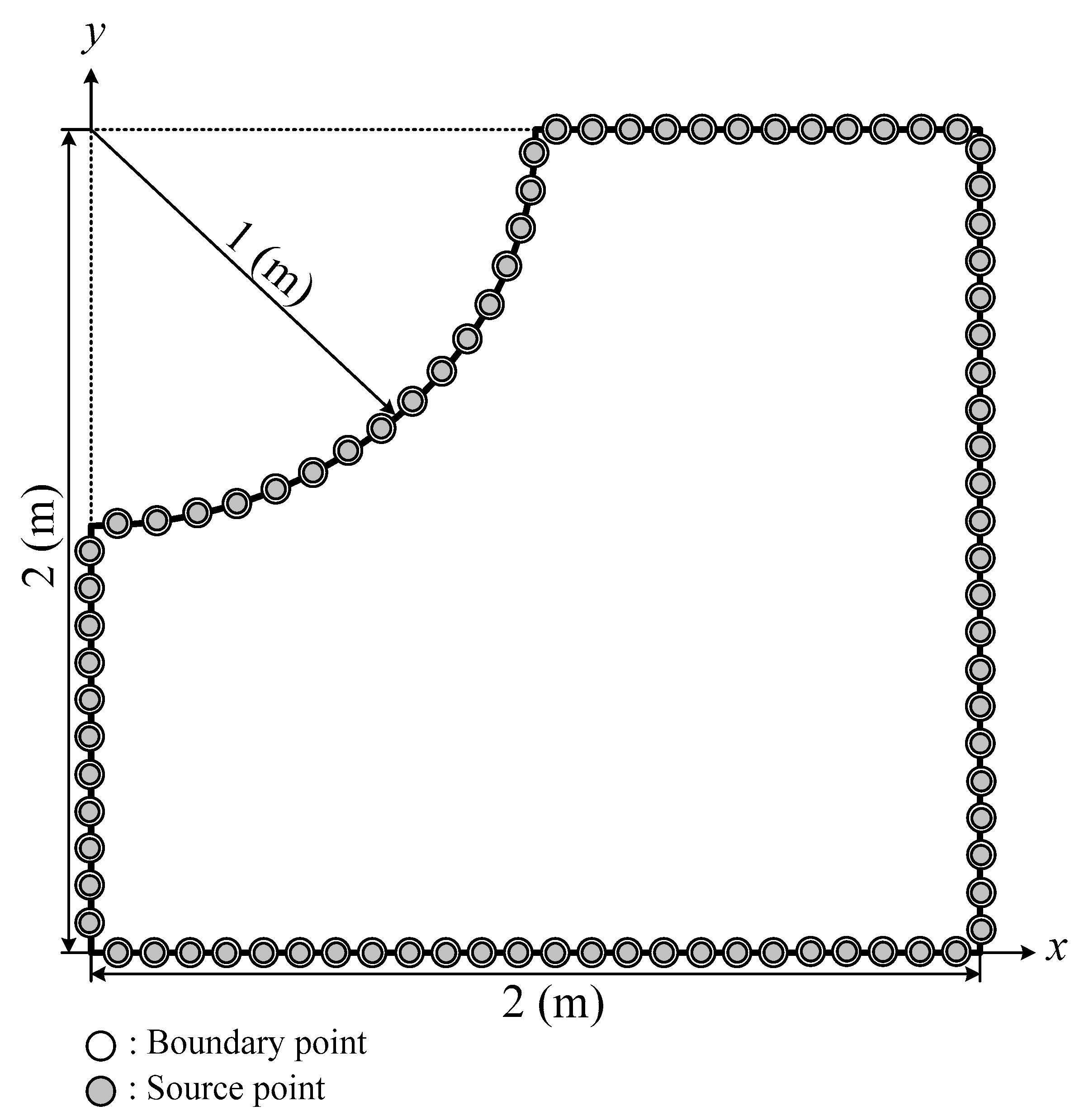

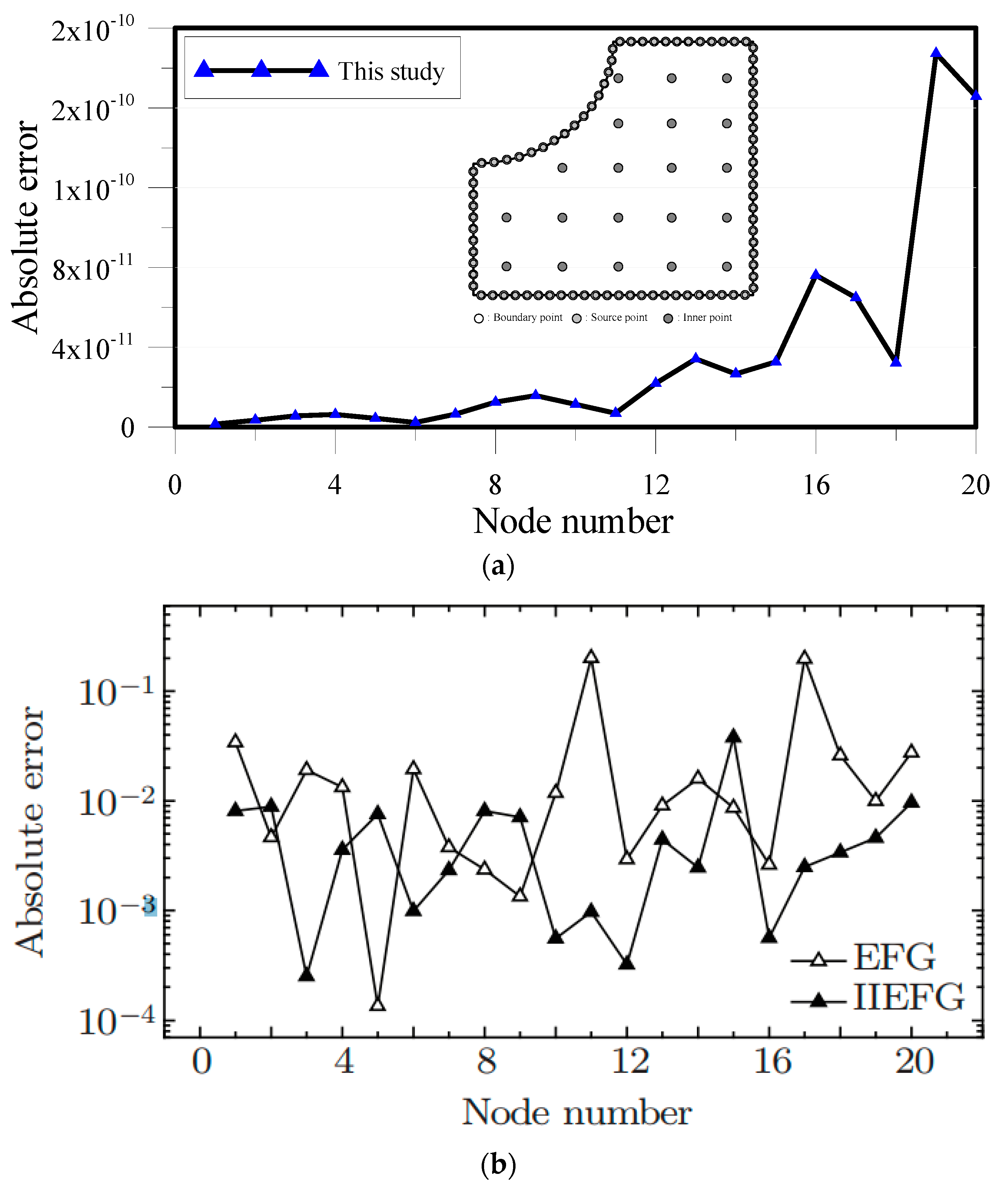

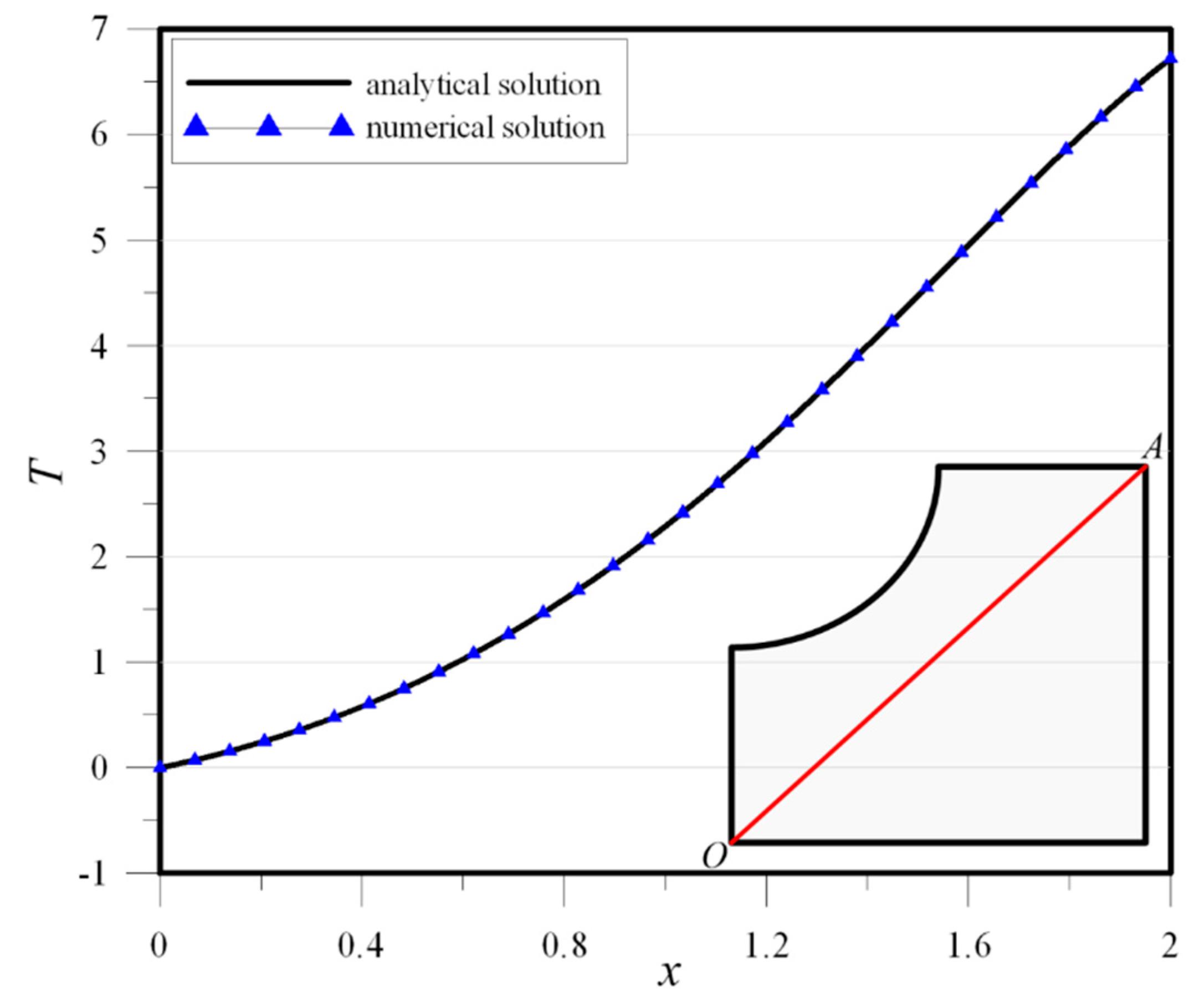

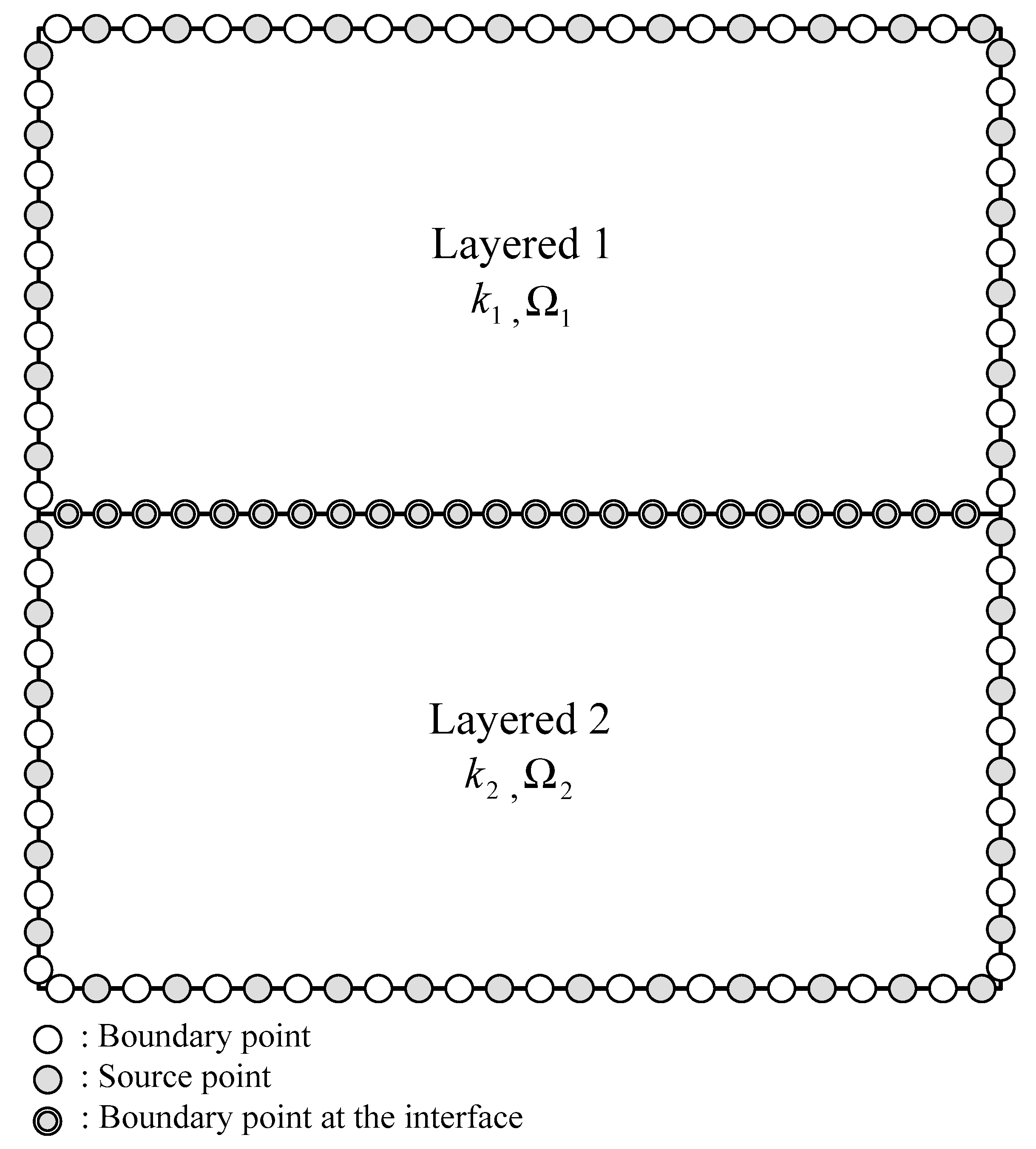

4.2. Example 2

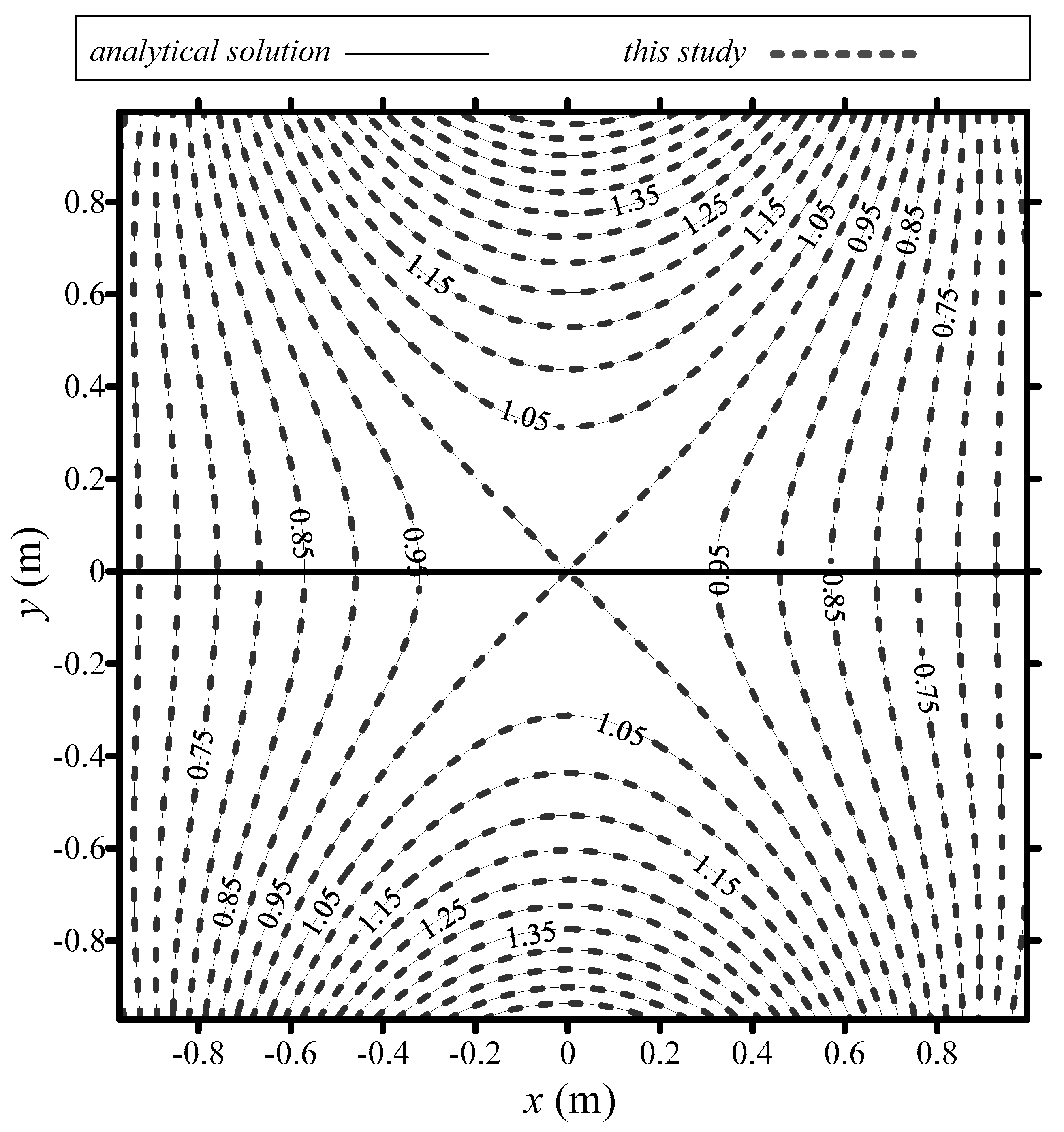

4.3. Example 3

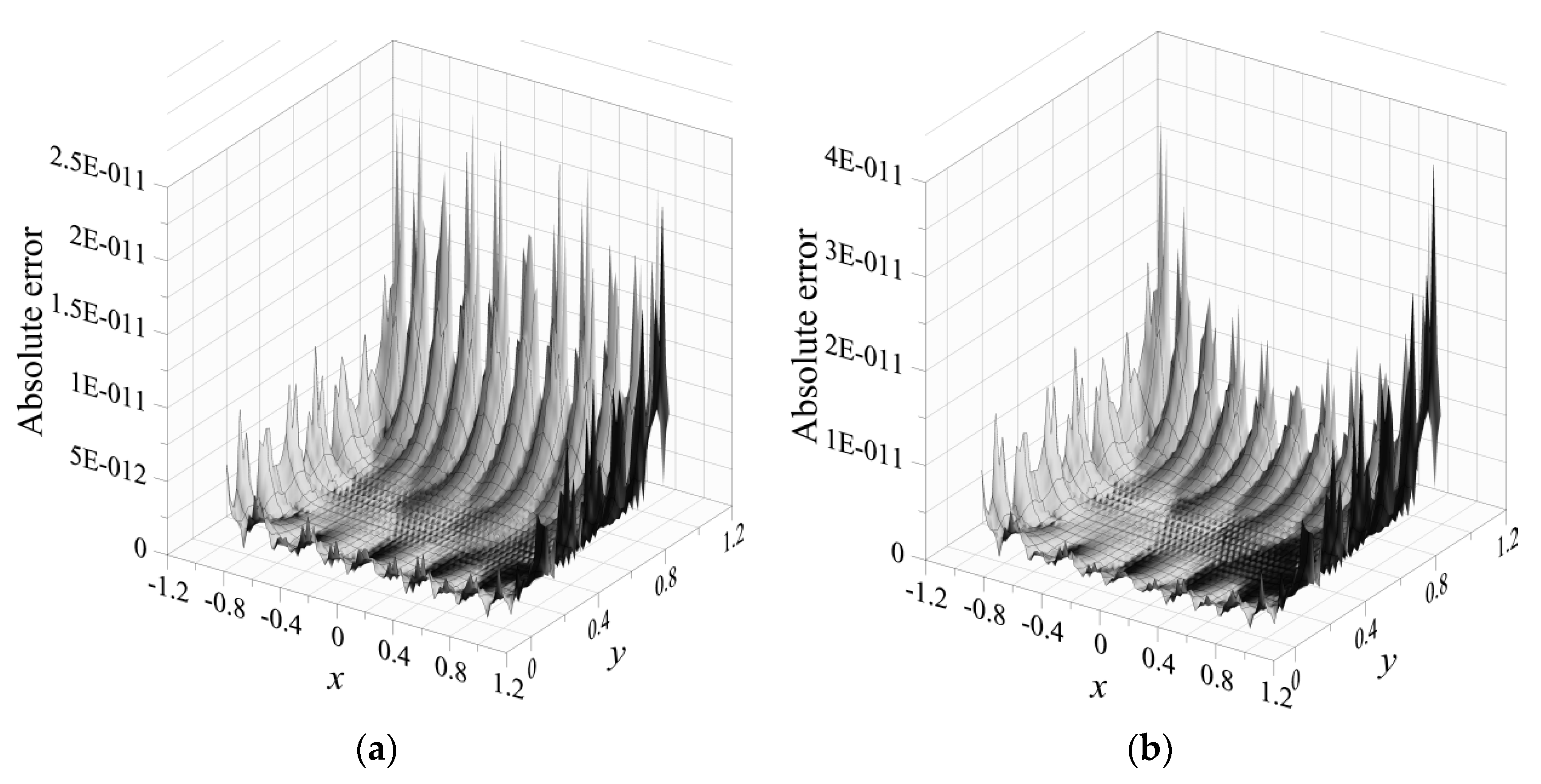

4.4. Example 4

4.5. Example 5

5. Discussion

6. Conclusions

- Most applications of the boundary-type meshless method are still limited to homogeneous problems. This study presents pioneering work to investigate the numerical solutions of two-dimensional stationary heat conduction problems in layered heterogeneous composite materials using the novel boundary-type meshless method. We apply the DDM successfully for modeling composite materials in which the domain is split into smaller subdomains. The subdomains intersecting at the interface must satisfy flux conservation and the continuity of the temperature for the problem. It is found that the proposed method provides a promising solution for solving heat conduction problems with heterogeneity.

- In the proposed study, we only needed to place collocation points on the boundary. This demonstrated the advantages of the proposed boundary-type meshless method, including the boundary collocation only and high accuracy. Compared to the mesh-based approach, the proposed method is relatively simple and highly accurate. It is therefore advantageous for the analysis of heat conduction problems with a complex shape. Thus, the results obtained show that the proposed method is highly accurate and computationally efficient for modeling heat conduction problems, especially in heterogeneous multi-layer composite materials compared with other meshless methods. Nevertheless, the proposed method is still limited to problems with constant thermal conductivity. Future studies are suggested for problems involving nonlinear behavior.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lubin, G. Handbook of Composites, 1st ed.; Van Norstrand Reinhold Publishing: New York, NY, USA, 1982. [Google Scholar]

- Davies, P. Environmental degradation of composites for marine structures: New materials and new applications. Philos. Trans. R. Soc. Math. Phys. Eng. Sci. 2016, 374, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Yang, B.-F.; Yue, Z.-F.; Geng, X.-L.; Wang, P.-Y. Temperature effects on transverse failure modes of carbon fiber/bismaleimides composites. J. Compos. Mater. 2017, 51, 261–272. [Google Scholar] [CrossRef]

- Wang, B.-L.; Han, J.-C.; Sun, Y.-G. A finite element/finite difference scheme for the non-classical heat conduction and associated thermal stresses. Finite Elem. Anal. Des. 2012, 50, 201–206. [Google Scholar] [CrossRef]

- Wang, L.; Tian, F.-B. Heat transfer in non-Newtonian flows by a hybrid immersed boundary–Lattice Boltzmann and finite difference method. Appl. Sci. 2018, 8, 1–17. [Google Scholar] [CrossRef]

- Chun, C.-K.; Park, S.-O. A Fixed-grid finite-difference method for phase-change problems. Numer. Heat Transf. Part B Fundam. 2000, 38, 59–73. [Google Scholar]

- Wang, B.-L. Transient one-dimensional heat conduction problems solved by finite element. Int. J. Mech. Sci. 2005, 47, 303–317. [Google Scholar] [CrossRef]

- He, K.-F.; Yang, Q.; Xiao, D.-M.; Li, X.-J. Analysis of thermo-elastic fracture problem during aluminium alloy MIG welding using the extended finite element method. Appl. Sci. 2017, 7, 1–20. [Google Scholar] [CrossRef]

- Li, W.; Yu, B.; Wang, X.; Wang, P.; Sun, S. A finite volume method for cylindrical heat conduction problems based on local analytical solution. Int. J. Heat Mass Transf. 2012, 55, 5570–5582. [Google Scholar] [CrossRef]

- Hassanzadeh, P.; Raithby, G.-D. Finite-volume solution of the second-order radiative transfer equation: Accuracy and solution cost. Numer. Heat Transf. Part B Fundam. 2008, 53, 374–382. [Google Scholar] [CrossRef]

- Yang, C.-Z.; Liu, G.-X.; Chen, C.-M.; Xu, M. Numerical simulation of temperature fields in a three-dimensional SiC crystal growth furnace with axisymmetric and spiral coils. Appl. Sci. 2018, 8, 1–12. [Google Scholar] [CrossRef]

- DeSilva, S.-J.; Chan, C.-L. Coupled boundary element method and finite difference method for the heat conduction in laser processing. Appl. Math. Model. 2008, 32, 2429–2458. [Google Scholar] [CrossRef]

- Gao, X.-W.; Wang, J. Interface integral BEM for solving multi-medium heat conduction problems. Eng. Anal. Bound. Elem. 2009, 33, 539–546. [Google Scholar] [CrossRef]

- Huang, F.-K.; Chuang, M.-H.; Wang, G.-S.; Yeh, H.-D. Tide-induced groundwater level fluctuation in a U-shaped coastal aquifer. J. Hydrol. 2015, 530, 291–305. [Google Scholar] [CrossRef]

- Kupradze, V.-D.; Aleksidze, M.-A. The method of functional equations for the approximate solution of certain boundary value problems. USSR Comput. Math. Math. Phys. 1964, 4, 82–126. [Google Scholar] [CrossRef]

- Katsurada, M.; Okamoto, H. The collocation points of the fundamental solution method for the potential problem. Comput. Math. Appl. 1996, 31, 123–137. [Google Scholar] [CrossRef]

- Chen, J.-T.; Wu, C.-S.; Lee, Y.-T.; Chen, K.-H. On the equivalence of the Trefftz method and method of fundamental solutions for Laplace and biharmonic equations. Comput. Math. Appl. 2007, 53, 851–879. [Google Scholar] [CrossRef]

- Fu, Z.-J.; Xi, Q.; Chen, W.; Cheng, A. A boundary-type meshless solver for transient heat conduction analysis of slender functionally graded materials with exponential variations. Comput. Math. Appl. 2018, 76, 760–773. [Google Scholar] [CrossRef]

- Kita, E.; Kamiya, N. Trefftz method: An overview. Adv. Eng. Softw. 1995, 24, 1–3. [Google Scholar] [CrossRef]

- Kita, E.; Kamiya, N.; Iio, T. Application of a direct Trefftz method with domain decomposition to 2D potential problems. Eng. Anal. Bound. Elem. 1999, 23, 539–548. [Google Scholar] [CrossRef]

- Lv, H.; Hao, F.; Wang, Y.; Chen, C.-S. The MFS versus the Trefftz method for the Laplace equation in 3D. Eng. Anal. Bound. Elem. 2017, 83, 133–140. [Google Scholar] [CrossRef]

- Amaziane, B.; Naji, A.; Ouazar, D. Radial basis function and genetic algorithms for parameter identification to some groundwater flow problems. Comput. Mater. Contin. 2004, 1, 117–128. [Google Scholar]

- Fasshauer, G.-E.; Zhang, J.-G. On choosing optimal shape parameters for RBF approximation. Numer. Algorithms 2007, 45, 345–368. [Google Scholar] [CrossRef]

- Kansa, E.-J. Multiquadrics-a scattered data approximation scheme with applications to computational fluid-dynamics-I surface approximations and partial derivative estimates. Comput. Math. Appl. 1990, 19, 127–145. [Google Scholar] [CrossRef]

- Kansa, E.-J. Multiquadrics-a scattered data approximation scheme with applications to computational fluid-dynamics-II solutions to parabolic, hyperbolic and elliptic partial differential equations. Comput. Math. Appl. 1990, 19, 147–161. [Google Scholar] [CrossRef]

- Belytschko, T.; Lu, Y.-Y.; Gu, L. Element-free Galerkin methods. Int. J. Numer. Methods Eng. 1994, 37, 229–256. [Google Scholar] [CrossRef]

- Liu, W.-K.; Jun, S.; Zhang, Y.-F. Reproducing kernel particle methods. Int. J. Numer. Methods Fluids 1995, 20, 1081–1106. [Google Scholar] [CrossRef]

- Chen, J.-S.; Pan, C.; Wu, C.-T.; Liu, W.-K. Reproducing kernel particle methods for large deformation analysis of nonlinear structures. Comput. Methods Appl. Mech. Eng. 1996, 139, 195–227. [Google Scholar] [CrossRef]

- Chang, C.-W.; Liu, C.-H.; Wang, C.-C. A modified polynomial expansion algorithm forsolving the steady-state Allen-Cahn equation forheat transfer in thin films. Appl. Sci. 2018, 8, 1–16. [Google Scholar] [CrossRef]

- Zhu, T.; Zhang, J.; Atluri, S.-N. Meshless numerical method based on the local boundary integral equation (LBIE) to solve linear and non-linear boundary value problems. Eng. Anal. Bound. Elem. 1999, 23, 375–389. [Google Scholar] [CrossRef]

- Sladek, J.; Sladek, V.; Atluri, S.-N. Local boundary integral equation (LBIE) method for solving problems of elasticity with nonhomogeneous material properties. Comput. Mech. 2000, 24, 456–462. [Google Scholar] [CrossRef]

- Ku, C.-Y.; Kuo, C.-L.; Fan, C.-M.; Liu, C.-S.; Guan, P.-C. Numerical solution of three-dimensional Laplacian problems using the multiple scale Trefftz method. Eng. Anal. Bound. Elem. 2015, 24, 157–168. [Google Scholar] [CrossRef]

- Liu, C.-S. Improving the Ill-conditioning of the Method of Fundamental Solutions for 2D Laplace Equation. Comput. Model. Eng. Sci. 2015, 24, 157–168. [Google Scholar]

- Cisilino, A.-P.; Sensale, B. Application of a simulated annealing algorithm in the optimal placement of the source points in the method of the fundamental solutions. Comput. Mech. 2002, 28, 129–136. [Google Scholar] [CrossRef]

- Nishimura, R.; Nishimori, K.; Ishihara, N. Determining the arrangement of fictitious charges in charge simulation method using genetic algorithms. J. Electrost. 2000, 49, 95–105. [Google Scholar] [CrossRef]

- Chen, C.-S.; Karageorghis, A.; Li, Y. On choosing the location of the sources in MFS. Numer. Algorithms 2016, 72, 107–130. [Google Scholar] [CrossRef]

- Young, D.-L.; Fan, C.-M.; Tsai, C.-C.; Chen, C.-W. The method of fundamental solutions and domain decomposition method for degenerate seepage flow net problems. J. Chin. Inst. Eng. 2006, 29, 63–73. [Google Scholar] [CrossRef]

- Ku, C.-Y.; Xiao, J.-E.; Liu, C.-Y.; Yeih, W. On the accuracy of the collocation Trefftz method for solving two- and three-dimensional heat equations. Numer. Heat Transf. Part B Fundam. Int. J. Comput. Methodol. 2016, 69, 334–350. [Google Scholar] [CrossRef]

- Wang, J.-F.; Sun, F.-X.; Cheng, Y.-M. An improved interpolating element-free Galerkin method with a nonsingular weight function for two-dimensional potential problems. Chin. Phys. B 2012, 21, 1–7. [Google Scholar] [CrossRef]

- Zheng, B.; Lin, J.; Chen, W. Simulation of heat conduction problems in layered materials using the meshless singular boundary method. Eng. Anal. Bound. Elem. 2018, 2018, 1–7. [Google Scholar] [CrossRef]

| This Study | Singular Boundary Method | |||

|---|---|---|---|---|

| 1st Layer | 2nd Layer | 1st Layer | 2nd Layer | |

| Maximum absolute error with the analytical solution | ||||

| Maximum relative error with the analytical solution | ||||

| This Study | Singular Boundary Method | |||

|---|---|---|---|---|

| 1st Layer | 2nd Layer | 1st Layer | 2nd Layer | |

| Maximum absolute error with the analytical solution | ||||

| Maximum relative error with the analytical solution | ||||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, J.-E.; Ku, C.-Y.; Huang, W.-P.; Su, Y.; Tsai, Y.-H. A Novel Hybrid Boundary-Type Meshless Method for Solving Heat Conduction Problems in Layered Materials. Appl. Sci. 2018, 8, 1887. https://doi.org/10.3390/app8101887

Xiao J-E, Ku C-Y, Huang W-P, Su Y, Tsai Y-H. A Novel Hybrid Boundary-Type Meshless Method for Solving Heat Conduction Problems in Layered Materials. Applied Sciences. 2018; 8(10):1887. https://doi.org/10.3390/app8101887

Chicago/Turabian StyleXiao, Jing-En, Cheng-Yu Ku, Wei-Po Huang, Yan Su, and Yung-Hsien Tsai. 2018. "A Novel Hybrid Boundary-Type Meshless Method for Solving Heat Conduction Problems in Layered Materials" Applied Sciences 8, no. 10: 1887. https://doi.org/10.3390/app8101887

APA StyleXiao, J.-E., Ku, C.-Y., Huang, W.-P., Su, Y., & Tsai, Y.-H. (2018). A Novel Hybrid Boundary-Type Meshless Method for Solving Heat Conduction Problems in Layered Materials. Applied Sciences, 8(10), 1887. https://doi.org/10.3390/app8101887