Multi-Scale Evaluation of the Interphase Zone between the Overlay and Concrete Substrate: Methods and Descriptors

Abstract

:1. Introduction

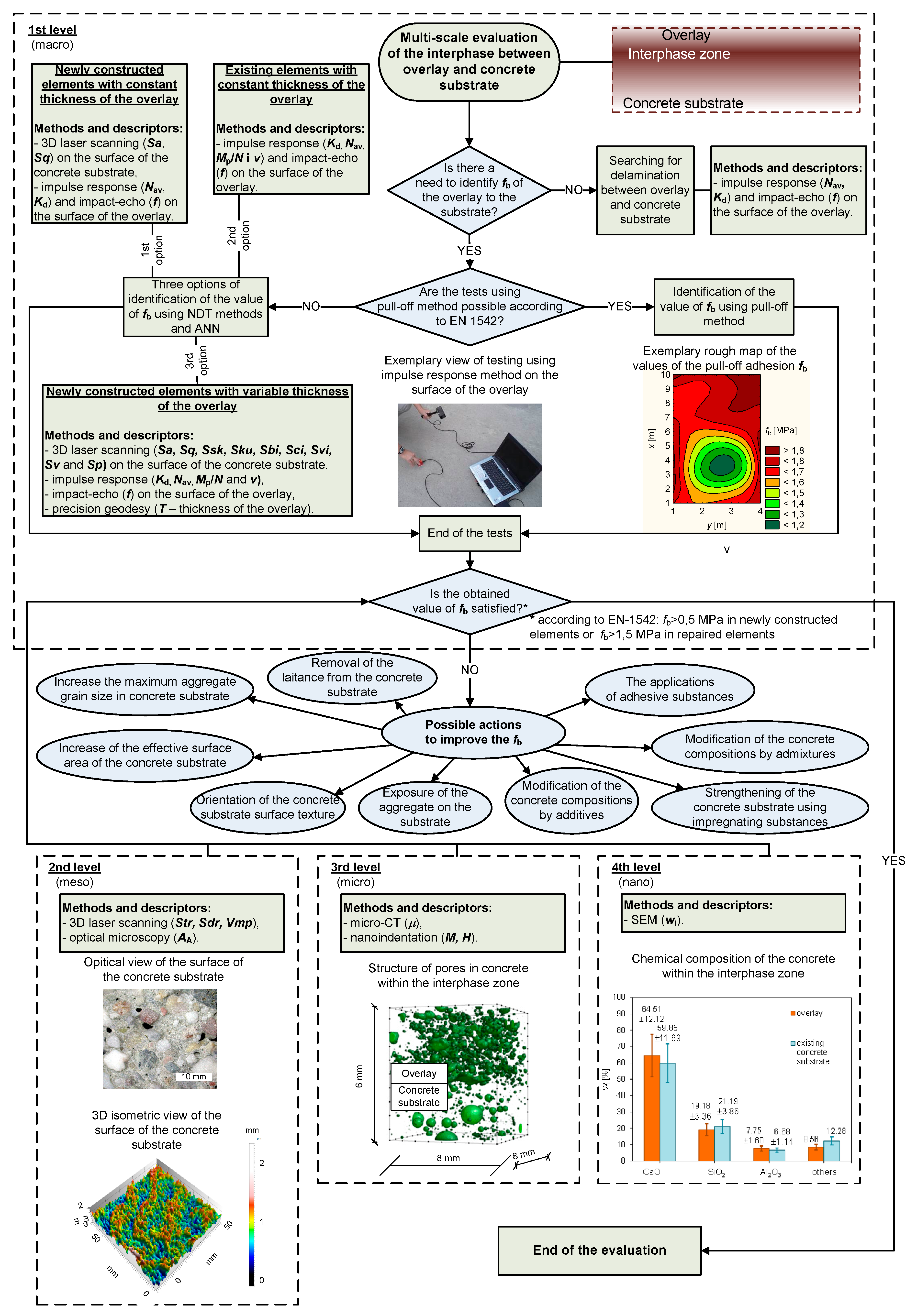

- appropriate treatment of the surface of the substrate, resulting in an increase in the effective relative surface area, orientation of the surface texture, removal of the cement laitance, surface exposure of the aggregate, etc.,

- increase the maximum aggregate grain size in concrete substrate,

- the applications of different adhesive substances,

- strengthening of the concrete substrate using impregnating and bonding agents,

- modification of the concrete composition, especially the overlay, with additives and nano-additives that “seal” its structure,

- modification of the concrete composition, especially the overlay, with admixtures that affect the viscosity of the concrete mix.

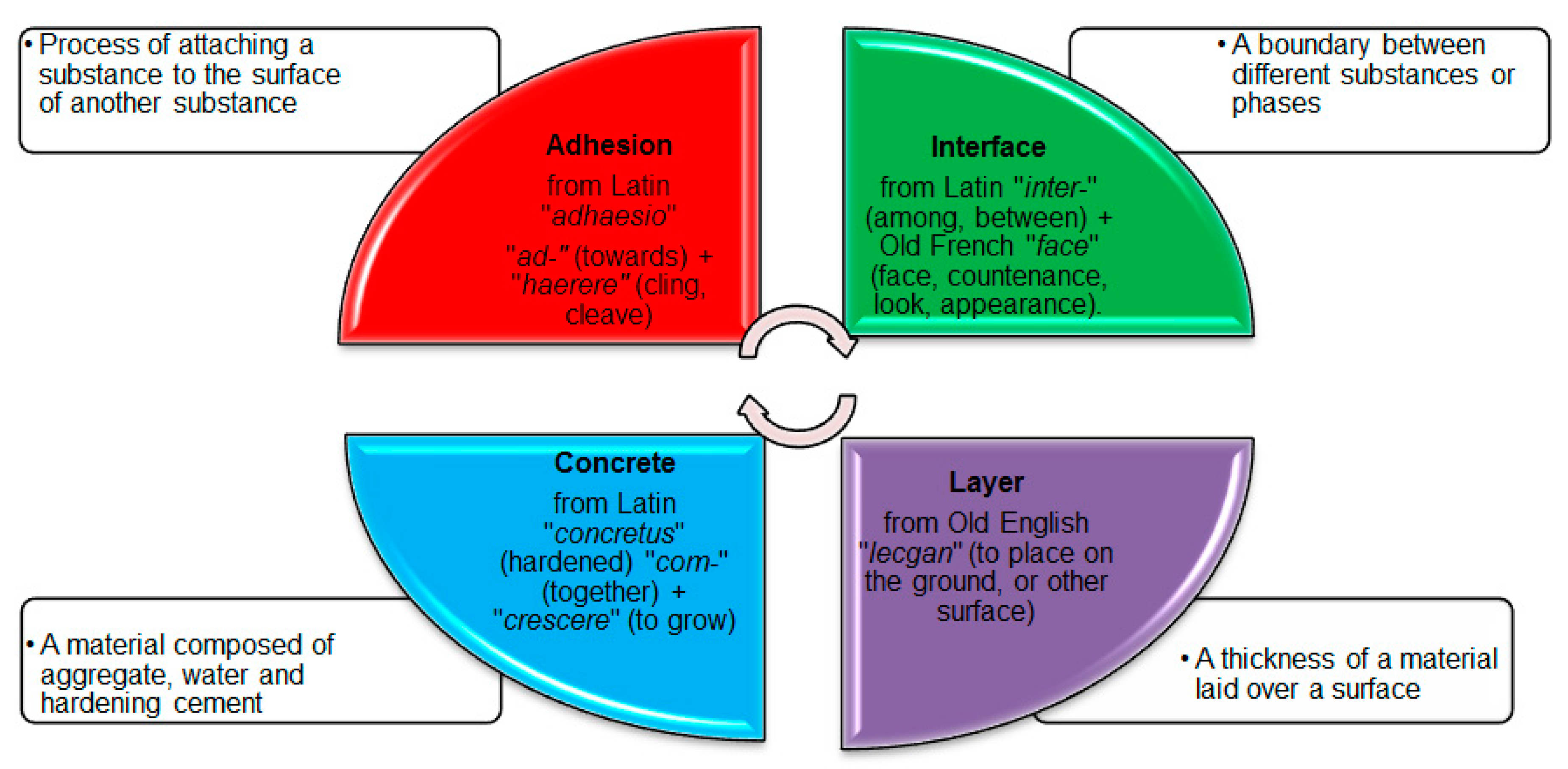

2. Literature Review

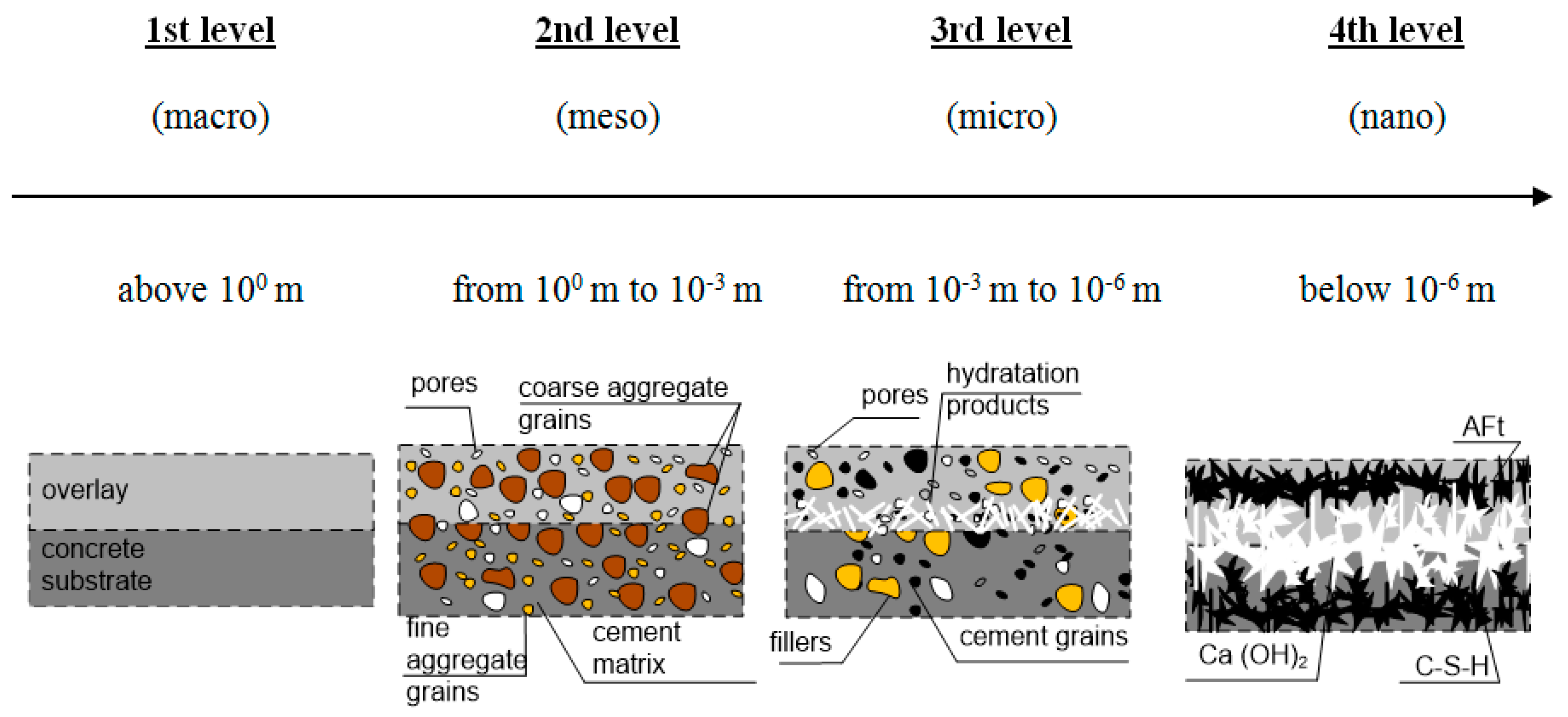

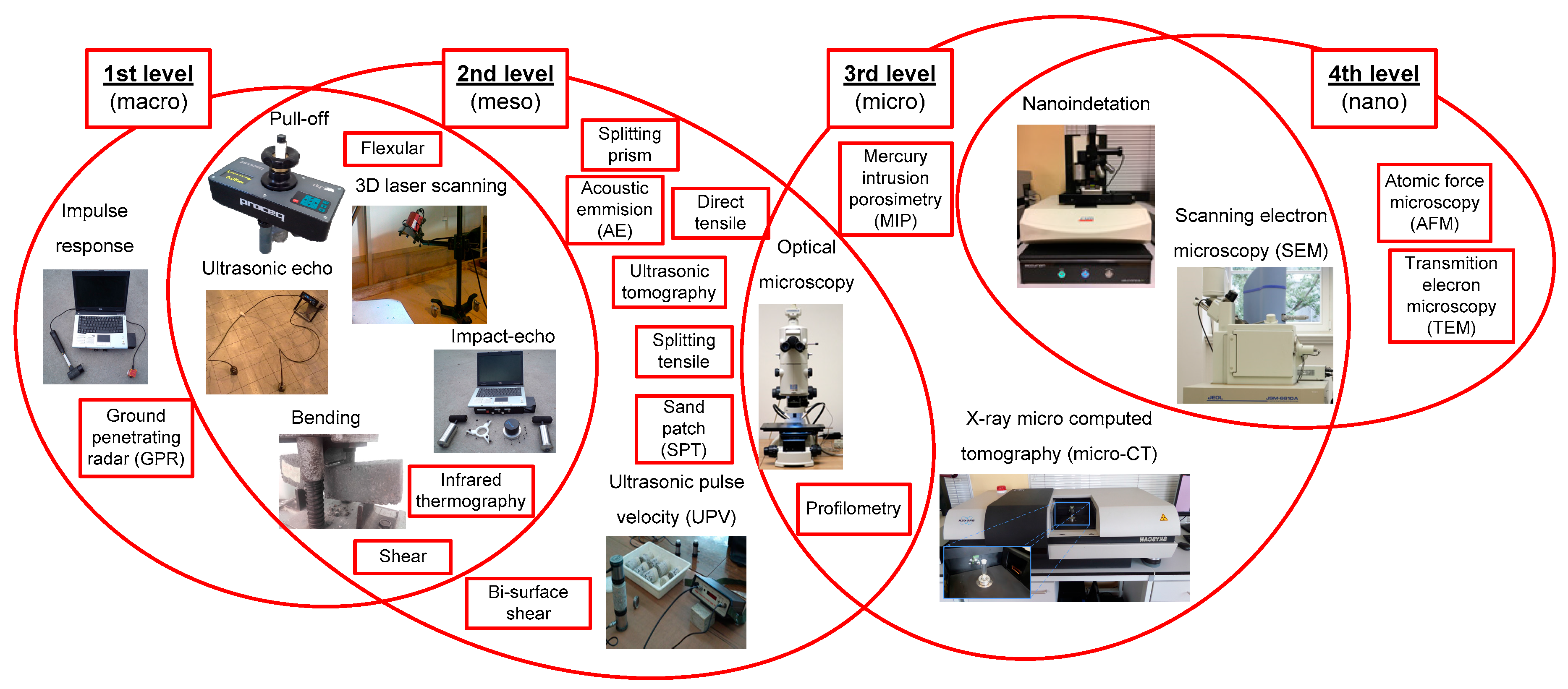

3. Levels of Examination of the Interphase Zone between the Overlay and Concrete Substrate

- 1st level (macro)—at this level, the interphase zone between layers is assessed primarily on the basis of destructive tests (or semi-nondestructive). Interlayer adhesion, which is useful, e.g., to create the so-called “adhesion maps”, is then evaluated,

- 2nd level (meso)—at this level the interphase zone is evaluated on the basis of the physical and mechanical properties of the concrete of the substrate layer and the overlay, as well as on the basis of the surface morphology of the substrate layer,

- 3rd level (micro)—at this level the density, air pore structure and hardness of the concrete within the interphase zone are evaluated, as well as the changes of these properties over time,

- 4th level (nano)—at this level the interphase zone is evaluated by investigating the effects of valence intermolecular forces occurring between the contacting surfaces, and also the migration of elements from layer to layer at the atom, intermolecular level and molecular levels.

4. The Proposed Methodology for the Evaluation of the Interphase Zone between the Overlay and Concrete Substrate

5. Summary

- 1st level (macro)—at this level the interphase zone between layers is assessed primarily on the basis of destructive tests,

- 2nd level (meso)—at this level the interphase zone is evaluated on the basis of the physical and mechanical properties of the concrete of the substrate layer and the overlay, as well as on the basis of the surface morphology of the substrate,

- 3rd level (micro)—at this level the density, air pore structure and hardness of the concrete within the interphase zone are evaluated, as well as the changes of these properties over time,

- 4th level (nano)—at this level the interphase zone is evaluated by investigating the effects of valence intermolecular forces occurring between the contacting surfaces, and also the migration of elements from layer to layer at the atom, intermolecular level and molecular levels.

Acknowledgments

Conflicts of Interest

References

- Czarnecki, L.; Łukowski, P.; Garbacz, A. The Protection and Repair of Concrete Structures; Comment to PN-EN 1504; PWN: Warsaw, Poland, 2016. (In Polish) [Google Scholar]

- Safiuddin, M. Concrete Damage in Field Conditions and Protective Sealer and Coating Systems. Coatings 2017, 7, 90. [Google Scholar] [CrossRef]

- Czarnecki, L.; Chmielewska, B. Factors affecting the adhesion in building joints. Cem. Lime Concr. 2005, 10, 74–85. [Google Scholar]

- Sadowski, Ł.; Mathia, T.G. Multi-scale metrology of concrete surface morphology: Fundamentals and specificity. Constr. Build. Mater. 2016, 113, 613–621. [Google Scholar] [CrossRef]

- EN 1542:2000. Products and Systems for the Protection and Repair of Concrete Structures. Test Methods. Measurements of Bond Strength by Pull-Off; European Committee for Standardization: Belgium, Brussels, 2000. [Google Scholar]

- Douglas, H. Online Etymology Dictionary. 2007. Available online: http://www.etymonline.com/index.php (accessed on 20 August 2017).

- Bissonnette, B.; Courard, L.; Garbacz, A. Concrete Surface Engineering; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Girhammar, U.A.; Pajari, M. Tests and analysis on shear strength of composite slabs of hollow core units and concrete topping. Constr. Build. Mater. 2008, 22, 1708–1722. [Google Scholar] [CrossRef]

- Adawi, A.; Youssef, M.A.; Meshaly, M.E. Experimental investigation of the composite action between hollowcore slabs with machine-cast finish and concrete topping. Eng. Struct. 2015, 91, 1–15. [Google Scholar] [CrossRef]

- Halicka, A. Influence new-to-old concrete interface qualities on the behaviour of support zones of composite concrete beams. Constr. Build. Mater. 2011, 25, 4072–4078. [Google Scholar] [CrossRef]

- Mansour, F.R.; Bakar, S.A.; Vafaei, M.; Alih, S.C. Effect of substrate surface roughness on the flexural performance of concrete slabs strengthened with a steel-fiber-reinforced concrete layer. PCI J. 2017, 62, 78–89. [Google Scholar]

- Niwa, J.; Matsumoto, K.; Sato, Y.; Yamada, M.; Yamauchi, T. Experimental study on shear behavior of the interface between old and new deck slabs. Eng. Struct. 2016, 126, 278–291. [Google Scholar] [CrossRef]

- Cavaco, E.; Camara, J. Experimental research on the behaviour of concrete-to-concrete interfaces subjected to a combination of shear and bending moment. Eng. Struct. 2017, 132, 278–287. [Google Scholar] [CrossRef]

- Fernandes, H.; Lúcio, V.; Ramos, A. Strengthening of RC slabs with reinforced concrete overlay on the tensile face. Eng. Struct. 2017, 132, 540–550. [Google Scholar] [CrossRef]

- Mansour, F.R.; Bakar, S.A.; Ibrahim, I.S.; Marsono, A.K.; Marabi, B. Flexural performance of a precast concrete slab with steel fiber concrete topping. Constr. Build. Mater. 2015, 75, 112–120. [Google Scholar] [CrossRef]

- Perez, F.; Bissonnette, B.; Gagné, R. Parameters affecting the debonding risk of bonded overlays used on reinforced concrete slab subjected to flexural loading. Mater. Struct. 2009, 42, 645–662. [Google Scholar] [CrossRef]

- Czarnecki, L.; Garbacz, A.; Krystosiak, M. On the ultrasonic assessment of adhesion between polymer coating and concrete substrate. Cem. Concr. Compos. 2006, 28, 360–369. [Google Scholar] [CrossRef]

- Sadowski, Ł.; Hoła, J. ANN modeling of pull-off adhesion of concrete layers. Adv. Eng. Softw. 2015, 89, 17–27. [Google Scholar] [CrossRef]

- Sadowski, Ł.; Hoła, J.; Czarnecki, S. Non-destructive neural identification of the bond between concrete layers in existing elements. Constr. Build. Mater. 2016, 127, 49–58. [Google Scholar] [CrossRef]

- Sadowski, Ł.; Nikoo, M.; Nikoo, M. Hybrid Metaheuristic-Neural Assessment of the Adhesion in Existing Cement Composites. Coatings 2017, 7, 1–12. [Google Scholar] [CrossRef]

- Sadowski, Ł.; Nikoo, M.; Nikoo, M. Principal Component Analysis combined with a Self Organization Feature Map to determine the pull-off adhesion between concrete layers. Constr. Build. Mater. 2015, 78, 386–396. [Google Scholar] [CrossRef]

- Sadowski, Ł.; Hoła, J.; Czarnecki, S.; Wang, D. Pull-off adhesion value prediction of variable thick overlay to the substrate. Autom. Constr. 2017. under review. [Google Scholar]

- Sadowski, Ł. Non-destructive identification of pull-off adhesion between concrete layers. Autom. Constr. 2015, 57, 146–155. [Google Scholar] [CrossRef]

- Sadowski, Ł.; Hoła, J. New nondestructive way of identifying the values of pull-off adhesion between concrete layers in floors. J. Civ. Eng. Manag. 2014, 20, 561–569. [Google Scholar] [CrossRef]

- Courard, L.; Piotrowski, T.; Garbacz, A. Near-to-surface properties affecting bond strength in concrete repair. Cem. Concr. Compos. 2014, 46, 73–80. [Google Scholar] [CrossRef]

- Roy, M.; Ray, I.; Davalos, J.F. High-performance fiber-reinforced concrete: Development and evaluation as a repairing material. J. Mater. Civ. Eng. 2013, 26, 04014074. [Google Scholar] [CrossRef]

- Huang, H.; Liu, B.; Xi, K.; Wu, T. Interfacial tensile bond behavior of permeable polymer mortar to concrete. Constr. Build. Mater. 2016, 121, 210–221. [Google Scholar] [CrossRef]

- Naderi, M. Adhesion of different concrete repair systems exposed to different environments. J. Adhes. 2008, 84, 78–104. [Google Scholar] [CrossRef]

- Mauroux, T.; Turcry, P.; Benboudjema, F.; Aït-Mokhtar, A. Influence of the time of demoulding on adhesion of cement-based mortar modified with cellulose ether. Eur. J. Environ. Civ. Eng. 2014, 18, 1157–1166. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Bakar, B.A.; Johari, M.M.; Ratnam, M.M. The relationship between substrate roughness parameters and bond strength of ultra high-performance fiber concrete. J. Adhes. Sci. Technol. 2013, 27, 1790–1810. [Google Scholar] [CrossRef]

- Horszczaruk, E.; Brzozowski, P. Bond strength of underwater repair concretes under hydrostatic pressure. Constr. Build. Mater. 2014, 72, 167–173. [Google Scholar] [CrossRef]

- Cleland, D.J.; Basheer, L. Pull-off adhesion testing for concrete repairs. Mag. Concr. Res. 2007, 59, 771–776. [Google Scholar] [CrossRef]

- Skominas, R.; Gurskis, V.; Sadzevicius, R.; Damulevicius, V.; Radzevicius, A. Evaluation of cement mortar suitability for repairing concrete in hydraulic structures. KSCE J. Civ. Eng. 2017, 1–7. [Google Scholar] [CrossRef]

- Harris, D.K.; Muñoz, M.A.C.; Gheitasi, A.; Ahlborn, T.M.; Rush, S.V. The challenges related to interface bond characterization of ultra-high-performance concrete with implications for bridge rehabilitation practices. Adv. Civ. Eng. Mater. 2014, 4, 75–101. [Google Scholar] [CrossRef]

- Stolz, C.M.; Masuero, A.B.; Pagnussat, D.T.; Kirchheim, A.P. Influence of substrate texture on the tensile and shear bond strength of rendering mortars. Constr. Build. Mater. 2016, 128, 298–307. [Google Scholar] [CrossRef]

- Mallat, A.; Alliche, A. Mechanical investigation of two fiber-reinforced repair mortars and the repaired system. Constr. Build. Mater. 2011, 25, 1587–1595. [Google Scholar] [CrossRef]

- Lanzoni, L.; Soragni, M.; Tarantino, A.M.; Viviani, M. Concrete beams stiffened by polymer-based mortar layers: Experimental investigation and modeling. Constr. Build. Mater. 2016, 105, 321–335. [Google Scholar] [CrossRef]

- Tsioulou, O.T.; Lampropoulos, A.P.; Dritsos, S.E. Experimental investigation of interface behaviour of RC beams strengthened with concrete layers. Constr. Build. Mater. 2013, 40, 50–59. [Google Scholar] [CrossRef]

- Zhang, D.; Ueda, T.; Furuuchi, H. Fracture mechanisms of polymer cement mortar: Concrete interfaces. J. Eng. Mech. 2012, 139, 167–176. [Google Scholar] [CrossRef]

- Minafò, G. A practical approach for the strength evaluation of RC columns reinforced with RC jackets. Eng. Struct. 2015, 85, 162–169. [Google Scholar] [CrossRef]

- Saldanha, R.; Júlio, E.; Dias-da-Costa, D.; Santos, P. A modified slant shear test designed to enforce adhesive failure. Constr. Build. Mater. 2013, 41, 673–680. [Google Scholar] [CrossRef]

- Zanotti, C.; Banthia, N.; Plizzari, G. A study of some factors affecting bond in cementitious fiber reinforced repairs. Cem. Concr. Res. 2014, 63, 117–126. [Google Scholar] [CrossRef]

- Santos, P.M.; Julio, E.N. Correlation between concrete-to-concrete bond strength and the roughness of the substrate surface. Constr. Build. Mater. 2007, 21, 1688–1695. [Google Scholar] [CrossRef]

- Santos, P.M.D.; Júlio, E.N.B.S. Development of a laser roughness analyser to predict in situ the bond strength of concrete-to-concrete interfaces. Mag. Concr. Res. 2008, 60, 329–338. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Abu Bakar, B.H.; Megat Johari, M.A.; Ratnam, M.M. Existing concrete textures: Their effect on adhesion with fibre concrete overlay. Proc. Inst. Civ. Eng. Struct. Build. 2014, 167, 355–368. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Bakar, B.A.; Johari, M.M. Characterization of the interfacial bond between old concrete substrate and ultra high performance fiber concrete repair composite. Mater. Struct. 2013, 46, 743–753. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Bakar, B.A.; Johari, M.M.; Voo, Y.L. Mechanical and permeability properties of the interface between normal concrete substrate and ultra high performance fiber concrete overlay. Constr. Build. Mater. 2012, 36, 538–548. [Google Scholar] [CrossRef]

- Lee, M.G.; Wang, Y.C.; Chiu, C.T. A preliminary study of reactive powder concrete as a new repair material. Constr. Build. Mater. 2007, 21, 182–189. [Google Scholar] [CrossRef]

- Al-Osta, M.A.; Isa, M.N.; Baluch, M.H.; Rahman, M.K. Flexural behavior of reinforced concrete beams strengthened with ultra-high performance fiber reinforced concrete. Constr. Build. Mater. 2017, 134, 279–296. [Google Scholar] [CrossRef]

- Diab, A.M.; Elmoaty, A.E.M.A.; Eldin, M.R.T. Slant shear bond strength between self compacting concrete and old concrete. Constr. Build. Mater. 2017, 130, 73–82. [Google Scholar] [CrossRef]

- Mirmoghtadaei, R.; Mohammadi, M.; Samani, N.A.; Mousavi, S. The impact of surface preparation on the bond strength of repaired concrete by metakaolin containing concrete. Constr. Build. Mater. 2015, 80, 76–83. [Google Scholar] [CrossRef]

- Mohammadi, M.; Moghtadaei, R.M.; Samani, N.A. Influence of silica fume and metakaolin with two different types of interfacial adhesives on the bond strength of repaired concrete. Constr. Build. Mater. 2014, 51, 141–150. [Google Scholar] [CrossRef]

- Hussein, H.H.; Walsh, K.K.; Sargand, S.M.; Steinberg, E.P. Interfacial properties of ultrahigh-performance concrete and high-strength concrete bridge connections. J. Mater. Civ. Eng. 2016, 28, 04015208. [Google Scholar] [CrossRef]

- Beushausen, H.; Alexander, M.G. Bond strength development between concretes of different ages. Mag. Concr. Res. 2008, 60, 65–74. [Google Scholar] [CrossRef]

- Belaidi, A.S.E.; Benabed, B.; Soualhi, H. Physical and mechanical properties of concrete repair materials in dry and hot-dry environment. J. Adhes. Sci. Technol. 2015, 29, 543–554. [Google Scholar] [CrossRef]

- Aykac, S.; Kalkan, I.; Tankut, T. Flexural strengthening and repair of RC slabs by adding a new RC layer. Struct. Concr. 2016, 17, 896–909. [Google Scholar] [CrossRef]

- Zhou, J.; Ye, G.; van Breugel, K. Cement hydration and microstructure in concrete repairs with cementitious repair materials. Constr. Build. Mater. 2016, 112, 765–772. [Google Scholar] [CrossRef]

- Lampropoulos, A.P.; Paschalis, S.A.; Tsioulou, O.T.; Dritsos, S.E. Strengthening of reinforced concrete beams using ultra high performance fibre reinforced concrete (UHPFRC). Eng. Struct. 2016, 106, 370–384. [Google Scholar] [CrossRef]

- Qian, Y.; Zhang, D.; Ueda, T. Interfacial Tensile Bond between Substrate Concrete and Repairing Mortar under Freeze-Thaw Cycles. J. Adv. Concr. Technol. 2016, 14, 421–432. [Google Scholar] [CrossRef]

- Espeche, A.D.; León, J. Estimation of bond strength envelopes for old-to-new concrete interfaces based on a cylinder splitting test. Constr. Build. Mater. 2011, 25, 1222–1235. [Google Scholar] [CrossRef]

- Zhang, J.; Ding, X.; Zhao, Q. Experimental and numerical investigation of scattering gravels on the surface bond strength of self-compacting concrete. Constr. Build. Mater. 2017, 145, 11–19. [Google Scholar] [CrossRef]

- Carbonell Muñoz, M.A.; Harris, D.K.; Ahlborn, T.M.; Froster, D.C. Bond performance between ultrahigh-performance concrete and normal-strength concrete. J. Mater. Civ. Eng. 2013, 26, 04014031. [Google Scholar] [CrossRef]

- Widodo, S. Bond Strength between Hybrid Fiber Reinforced Lightweight Aggregate Concrete Substrate and Self-Compacting Concrete as Topping Layer. Adv. Civ. Eng. 2017, 2017. [Google Scholar] [CrossRef]

- Santos, D.S.; Santos, P.M.; Dias-da-Costa, D. Effect of surface preparation and bonding agent on the concrete-to-concrete interface strength. Constr. Build. Mater. 2012, 37, 102–110. [Google Scholar] [CrossRef]

- Mohamad, M.E.; Ibrahim, I.S.; Abdullah, R.; Rahman, A.A.; Kueh, A.B.H.; Usman, J. Friction and cohesion coefficients of composite concrete-to-concrete bond. Cem. Concr. Compos. 2015, 56, 1–14. [Google Scholar] [CrossRef]

- Siewczyńska, M. Method for determining the parameters of surface roughness by usage of a 3D scanner. Arch. Civ. Mech. Eng. 2012, 12, s83–s89. [Google Scholar] [CrossRef]

- Hoła, J.; Sadowski, Ł.; Reiner, J.; Stach, S. Usefulness of 3D surface roughness parameters for nondestructive evaluation of pull-off adhesion of concrete layers. Constr. Build. Mater. 2015, 84, 111–120. [Google Scholar] [CrossRef]

- Sadowski, Ł.; Czarnecki, S.; Hoła, J. Evaluation of the morphology of concrete substrate and their adhesion to epoxy resin. Int. J. Adhes. Adhes. 2016, 67, 3–13. [Google Scholar] [CrossRef]

- Garbacz, A. Application of stress based NDT methods for concrete repair bond quality control. Bull. Polish Acad. Sci. Tech. Sci. 2015, 63, s77–s85. [Google Scholar] [CrossRef]

- Garbacz, A.; Piotrowski, T.; Courard, L.; Kwaśniewski, L. On the evaluation of interface quality in concrete repair system by means of impact-echo signal analysis. Constr. Build. Mater. 2017, 134, 311–323. [Google Scholar] [CrossRef]

- Garbacz, A. Non-Destructive Testing of Concrete-Like Polymeric Composites Using Elastic Waves—Evaluation of Repair Efficiency; Publishing House of Warsaw University of Technology: Warsaw, Poland, 2007; p. 208. [Google Scholar]

- Tsioulou, O.; Lampropoulos, A.; Paschalis, S. Combined Non-Destructive Testing (NDT) method for the evaluation of the mechanical characteristics of Ultra High Performance Fibre Reinforced Concrete (UHPFRC). Constr. Build. Mater. 2017, 131, 66–77. [Google Scholar] [CrossRef]

- Szymanowski, J.; Sadowski, Ł. Adhesion Assessment between Concrete Layers Using the Ultrasonic Pulse Velocity Method. Appl. Mech. Mater. 2015, 797, 145–150. [Google Scholar] [CrossRef]

- Prem, P.R.; Murthy, A.R. Acoustic emission and flexural behaviour of RC beams strengthened with UHPC overlay. Constr. Build. Mater. 2016, 123, 481–492. [Google Scholar] [CrossRef]

- Iowa Department of Transportation, Donohue & Associates, Inc. Engineers & Architects. Evaluation of Bond Retainage in Portland Cement Concrete Overlays by Infrared Thermography and Ground Penetrating Radar, HR-537, 1988; Iowa Department of Transportation, Donohue & Associates, Inc.: Fort Wayne, IN, USA, 1988.

- Beushausen, H.; Höhlig, B.; Talotti, M. The influence of substrate moisture preparation on bond strength of concrete overlays and the microstructure of the OTZ. Cem. Concr. Res. 2017, 92, 84–91. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Abu Bakar, B.H.; Megat Johari, M.A.; Zeyad, A.M. Microstructural analysis of the adhesion mechanism between old concrete substrate and UHPFC. J. Adhes. Sci. Technol. 2014, 28, 1846–1864. [Google Scholar] [CrossRef]

- Satoh, A.; Yamada, K. FEM simulation of tension struts on adhesion performance of mortar–repair interface. Eng. Fract. Mech. 2016, 167, 84–100. [Google Scholar] [CrossRef]

- Lukovic, M.; Ye, G. Effect of moisture exchange on interface formation in the repair system studied by X-ray absorption. Materials 2015, 9. [Google Scholar] [CrossRef] [PubMed]

- Sadowski, Ł.; Stefaniuk, D. Microstructural Evolution within the Interphase between Hardening Overlay and Existing Concrete Substrates. Appl. Sci. 2017, 7. [Google Scholar] [CrossRef]

- Luković, M.; Šavija, B.; Dong, H.; Schlangen, E.; Ye, G. Micromechanical study of the interface properties in concrete repair systems. J. Adv. Concr. Technol. 2014, 12, 320–339. [Google Scholar] [CrossRef]

- Czarnecki, L.; Garbacz, A. Adhesion of Interfaces of Building Materials: A Multi-Scale Approach. Advances in Materials Science and Restoration; Aedificatio Publishers: Freiburg im Breisgau, Germany, 2007; p. 260. [Google Scholar]

- Petrie, E.M. Handbook of Adhesives and Sealants; McGraw-Hill: New York, NY, USA, 2000; p. 765. [Google Scholar]

- Sadowski, Ł.; Popek, M.; Czarnecki, S.; Mathia, T.G. Morphogenesis in solidification phases of lightweight concrete surface at early ages. Constr. Build. Mater. 2017, 148, 96–103. [Google Scholar] [CrossRef]

| Method Name | Basic Descriptors | Suitability |

|---|---|---|

| Pull-off | fb—pull-off adhesion | 1, 2 |

| Bending | Crack propagation | 1, 2 |

| Shear | Bond strength, | 1, 2 |

| σn—normal stress, | ||

| τn—shear stress, | ||

| c—cohesion coefficient | ||

| Flexural | Bond strength | 1, 2 |

| Direct tensile, | Bond strength | 2 |

| Splitting prism, | ||

| Bi-surface shear. | ||

| Splitting tensile | ft—tensile strength of the interface | 2 |

| Sand patch | SRI—Surface Roughness Index | 2 |

| Profilometry | Rp—“peak-to-mean” roughness, | 2 |

| Rz—mean peak-to-valley height | ||

| 3D laser scanning | Sku—kurtosis, | 1, 2 |

| Str—texture aspect ratio, | ||

| Sbi—surface bearing index, | ||

| Sci—core fluid rentention index, | ||

| Svi—valley fluid retention index, | ||

| Sa—arithmetical mean height, | ||

| Sv—maximum pit height, | ||

| Sp—maximum peak height, | ||

| Sdr—developed interfacial area ratio, | ||

| Sq—root mean square height, | ||

| Ssk—skewness, | ||

| Vmp—peak material volume | ||

| Impulse response | Kd—dynamic stiffness, | 1 |

| Mp/N—mobility slope, | ||

| Nav—average mobility, | ||

| v—voids index | ||

| Impact-echo | A—amplitude of transmit dilatational stress wave, | 1, 2 |

| f—the frequency of the dilatational stress wave | ||

| Infrared thermography | CT—thermal contrast | 1, 2 |

| UPV 1 | t—time of the ultrasonic wave transiting | 2 |

| AE 2 | Crack propagation | 2 |

| Optical microscopy | AA—exposed aggregate share | 2, 3 |

| X-ray micro-CT 3 | μ—attenuation coefficient | 3 |

| Nanoindentation | H—hardness, | 3 |

| M—indentation modulus | ||

| SEM | wi—percentage share of the element | 3, 4 |

© 2017 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sadowski, Ł. Multi-Scale Evaluation of the Interphase Zone between the Overlay and Concrete Substrate: Methods and Descriptors. Appl. Sci. 2017, 7, 893. https://doi.org/10.3390/app7090893

Sadowski Ł. Multi-Scale Evaluation of the Interphase Zone between the Overlay and Concrete Substrate: Methods and Descriptors. Applied Sciences. 2017; 7(9):893. https://doi.org/10.3390/app7090893

Chicago/Turabian StyleSadowski, Łukasz. 2017. "Multi-Scale Evaluation of the Interphase Zone between the Overlay and Concrete Substrate: Methods and Descriptors" Applied Sciences 7, no. 9: 893. https://doi.org/10.3390/app7090893

APA StyleSadowski, Ł. (2017). Multi-Scale Evaluation of the Interphase Zone between the Overlay and Concrete Substrate: Methods and Descriptors. Applied Sciences, 7(9), 893. https://doi.org/10.3390/app7090893