Effects of Radial Gap Ratio between Impeller and Vaned Diffuser on Performance of Centrifugal Compressors

Abstract

:1. Introduction

2. Materials and Methods

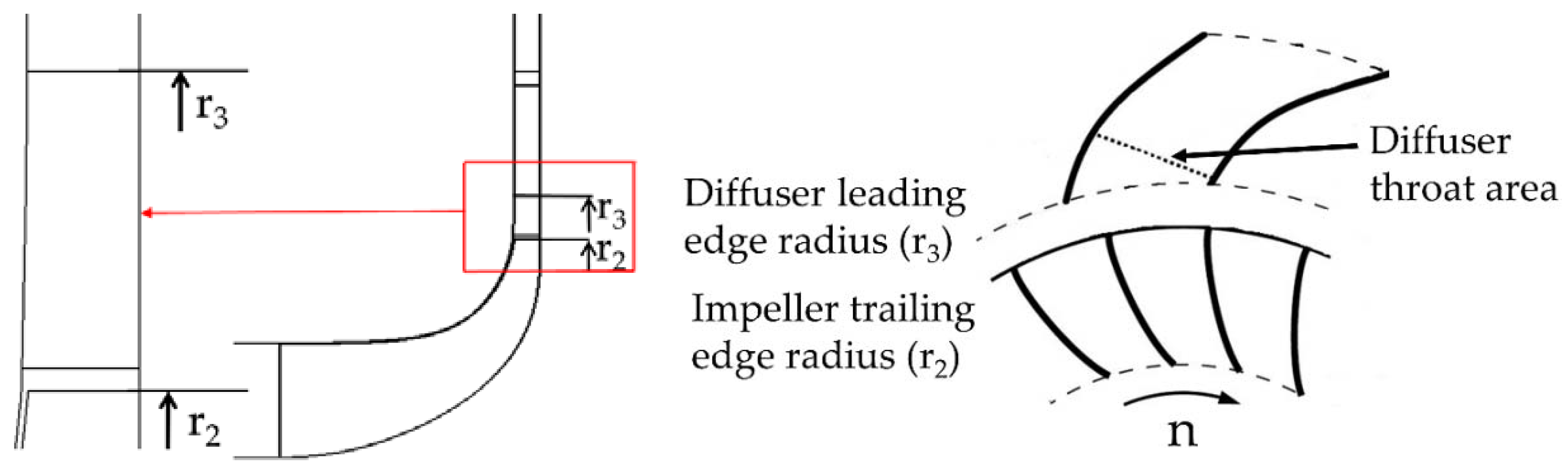

2.1. Investigated Compressor

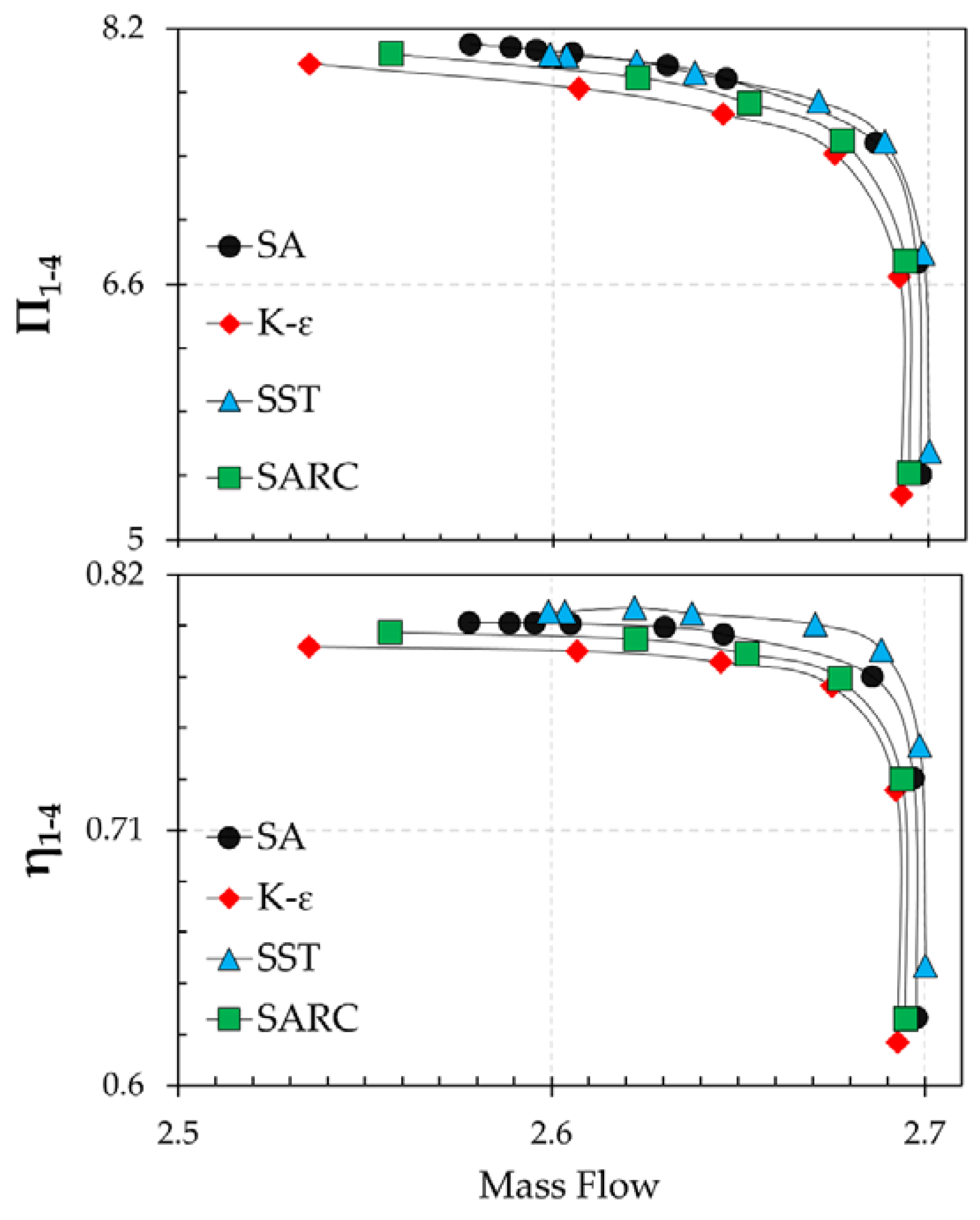

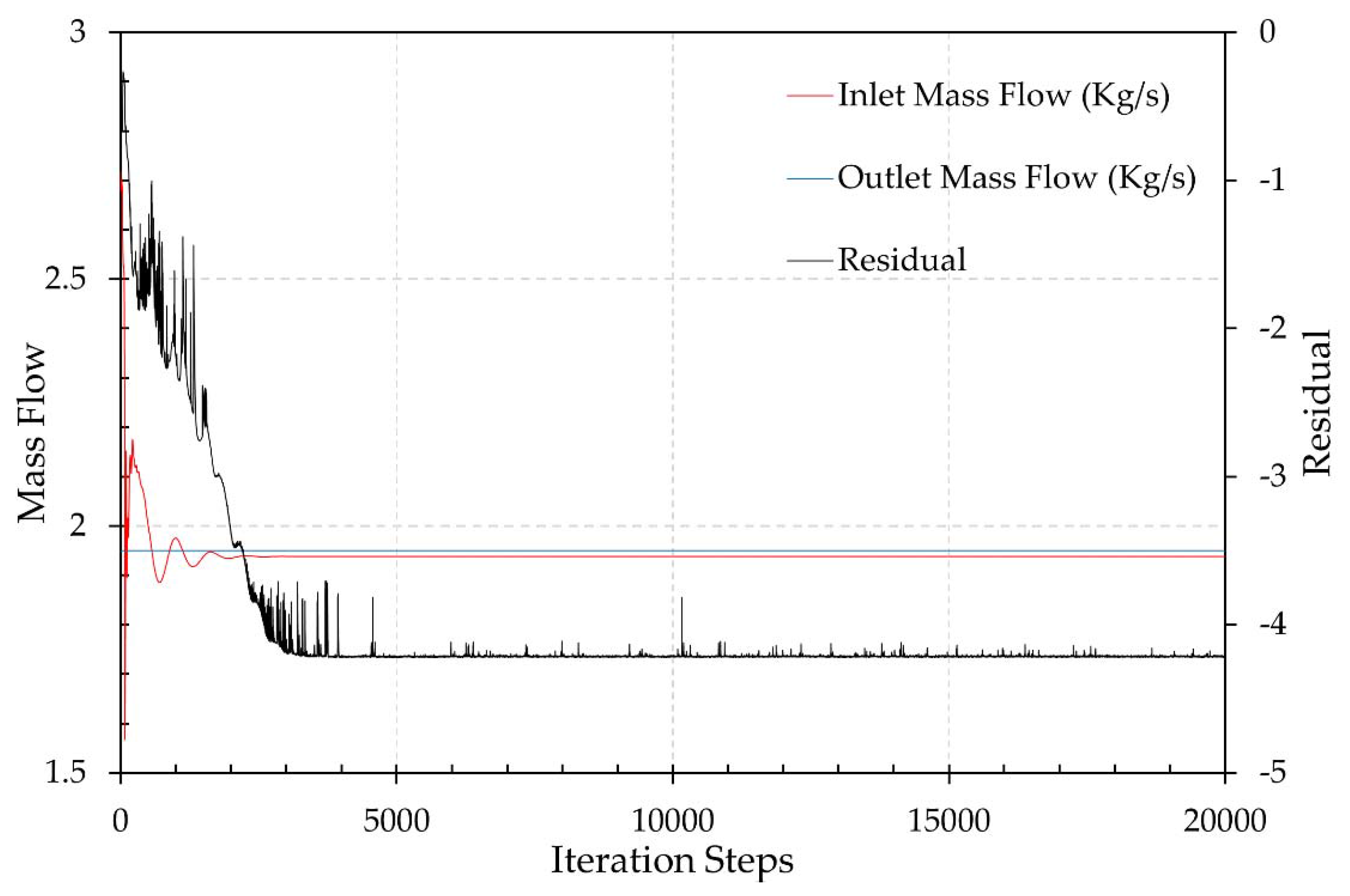

2.2. Numerical Methods of Steady Simulations

- All quantities do not vary more than 0.1% over at least 500 consecutive iterations.

- Global residual with order of lower than −4.

- The inlet and outlet mass flow rates level off within 0.5% of each other.

2.3. Numerical Methods of Unsteady Simulations

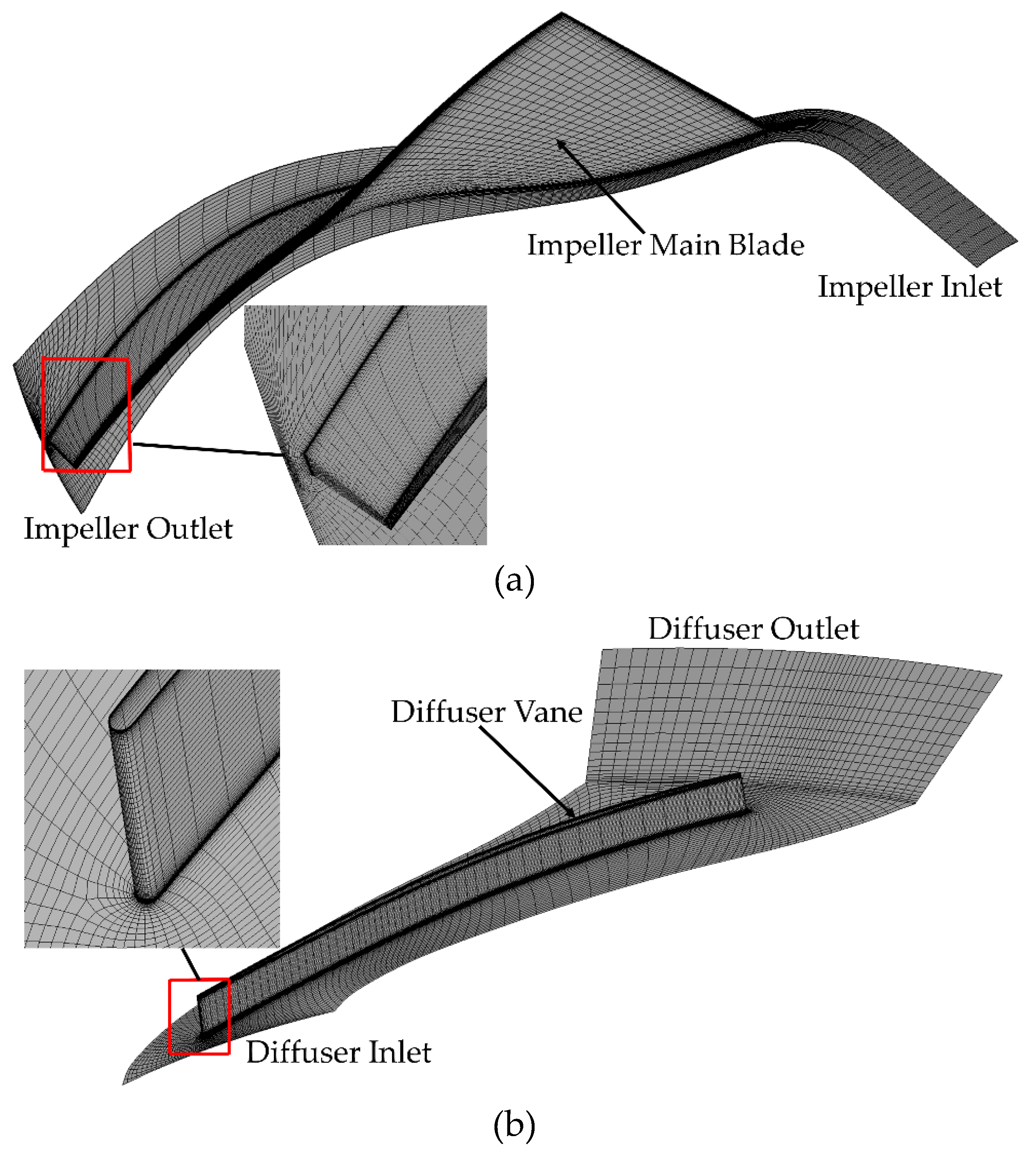

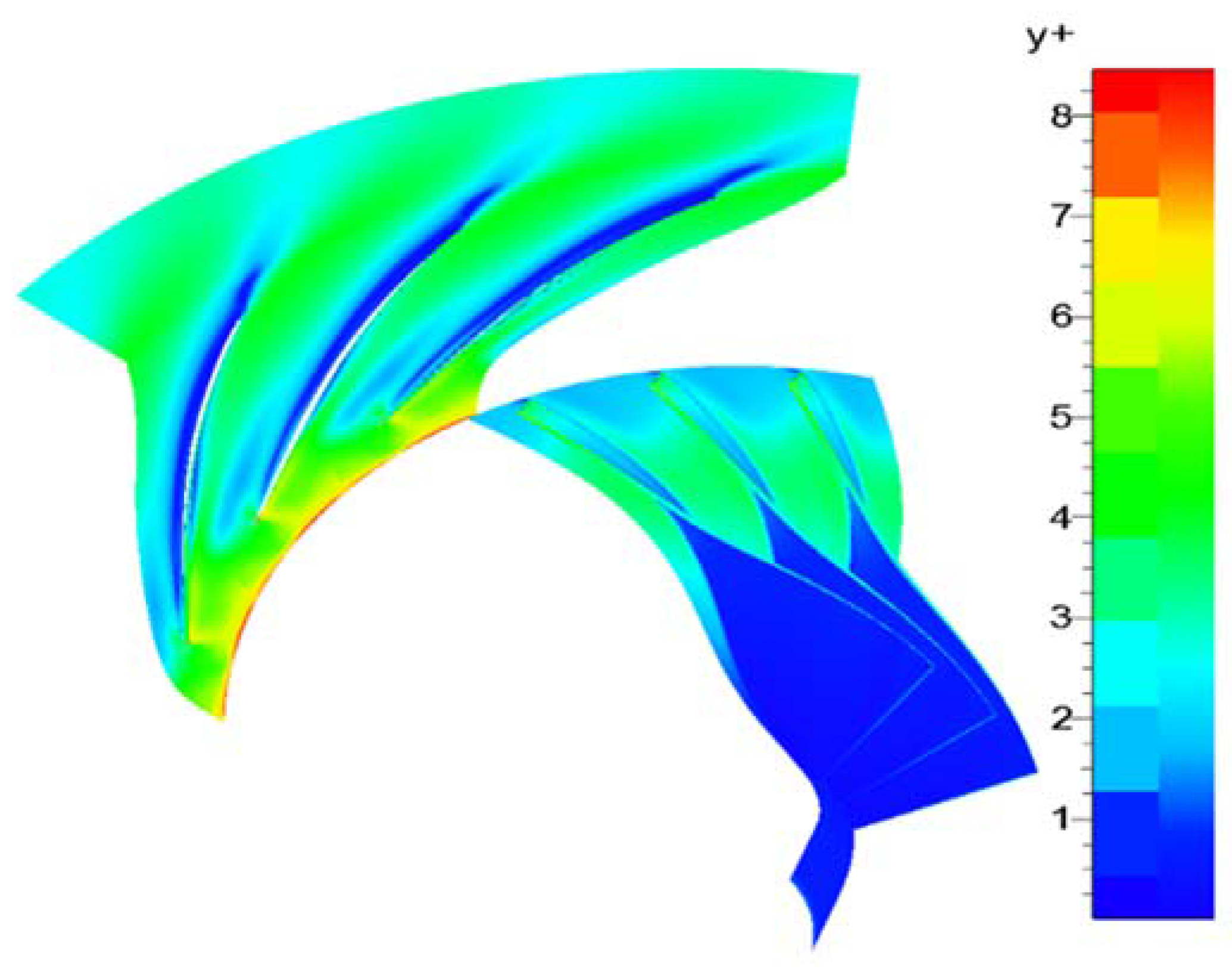

2.4. Meshing

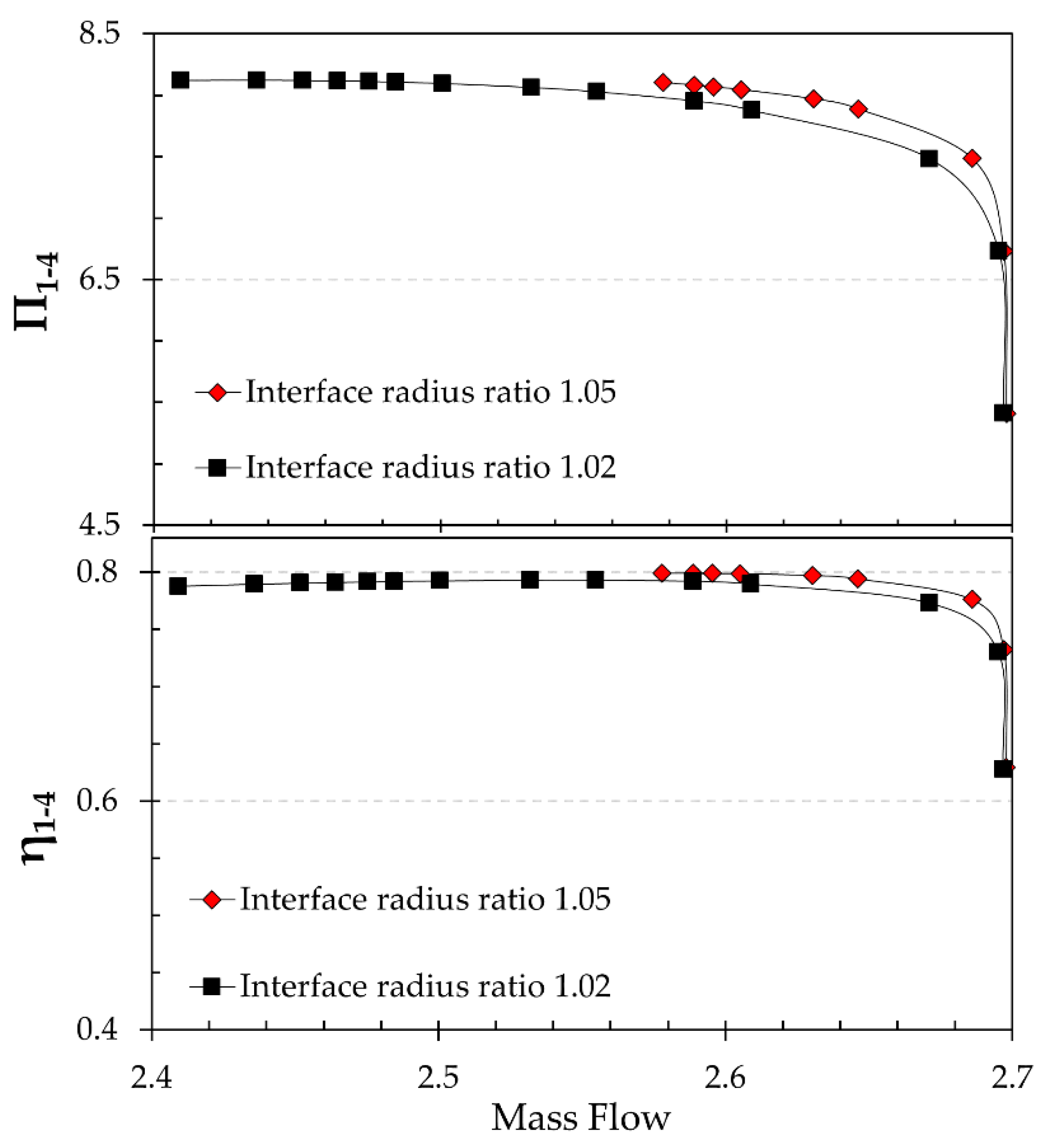

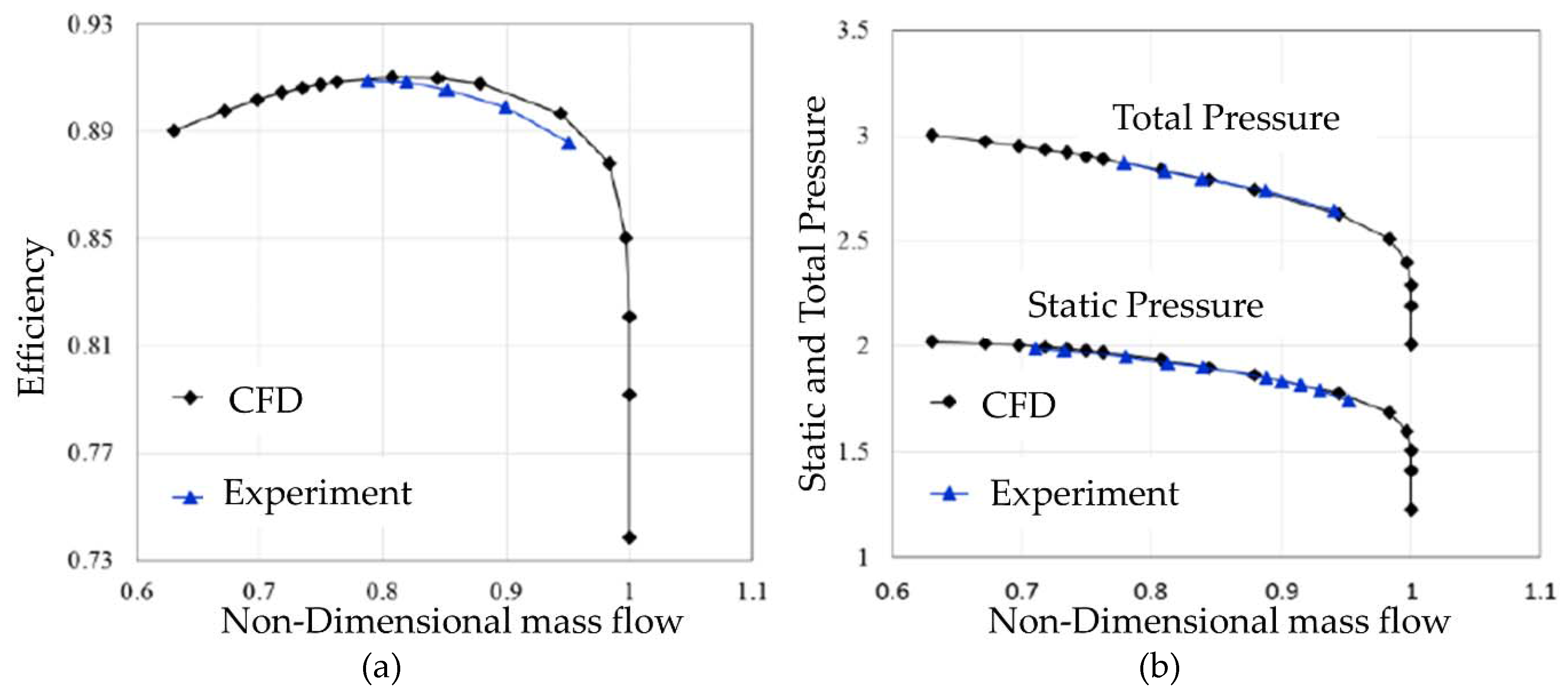

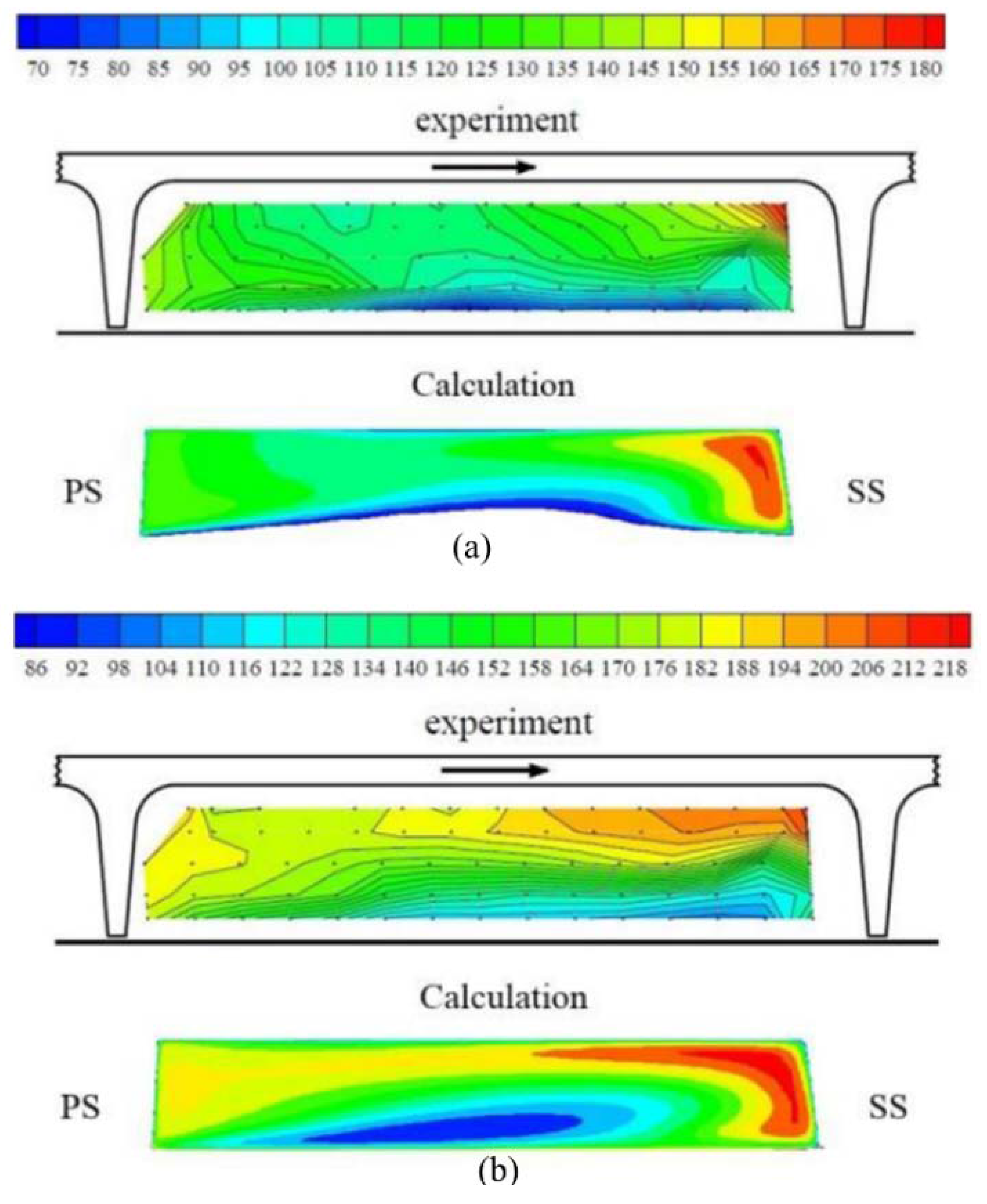

2.5. Validation with Experimental Data

3. Results and Discussion

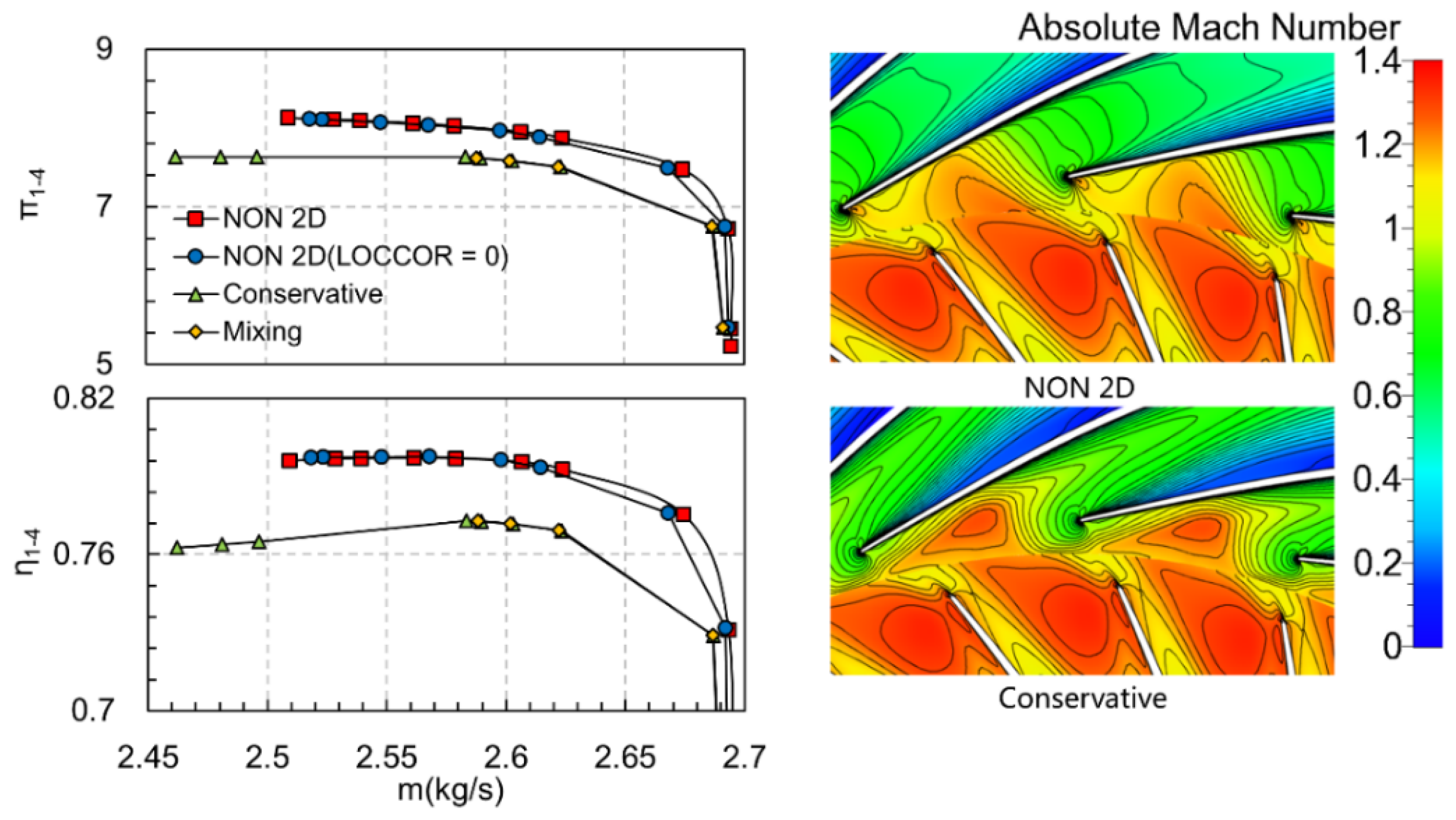

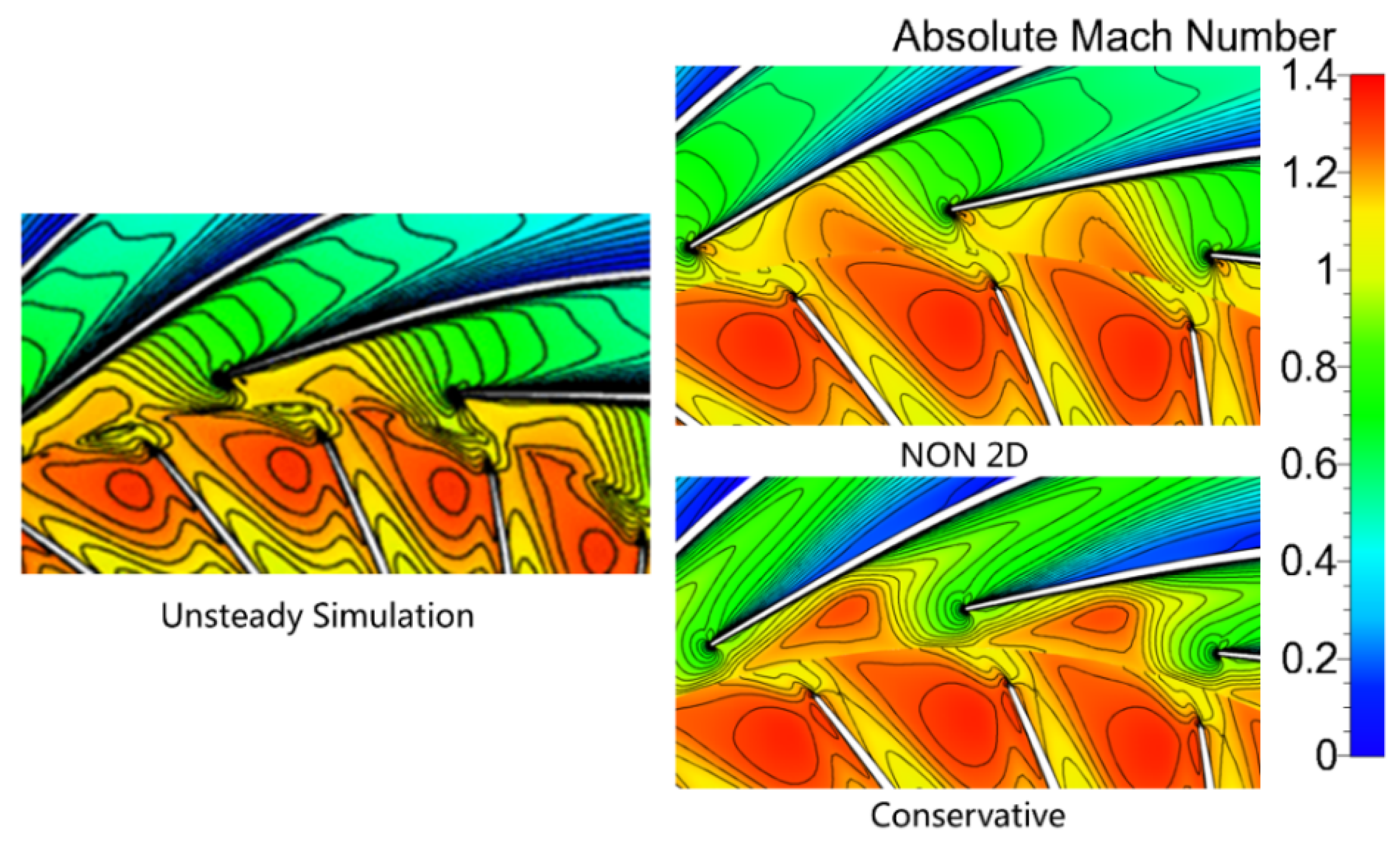

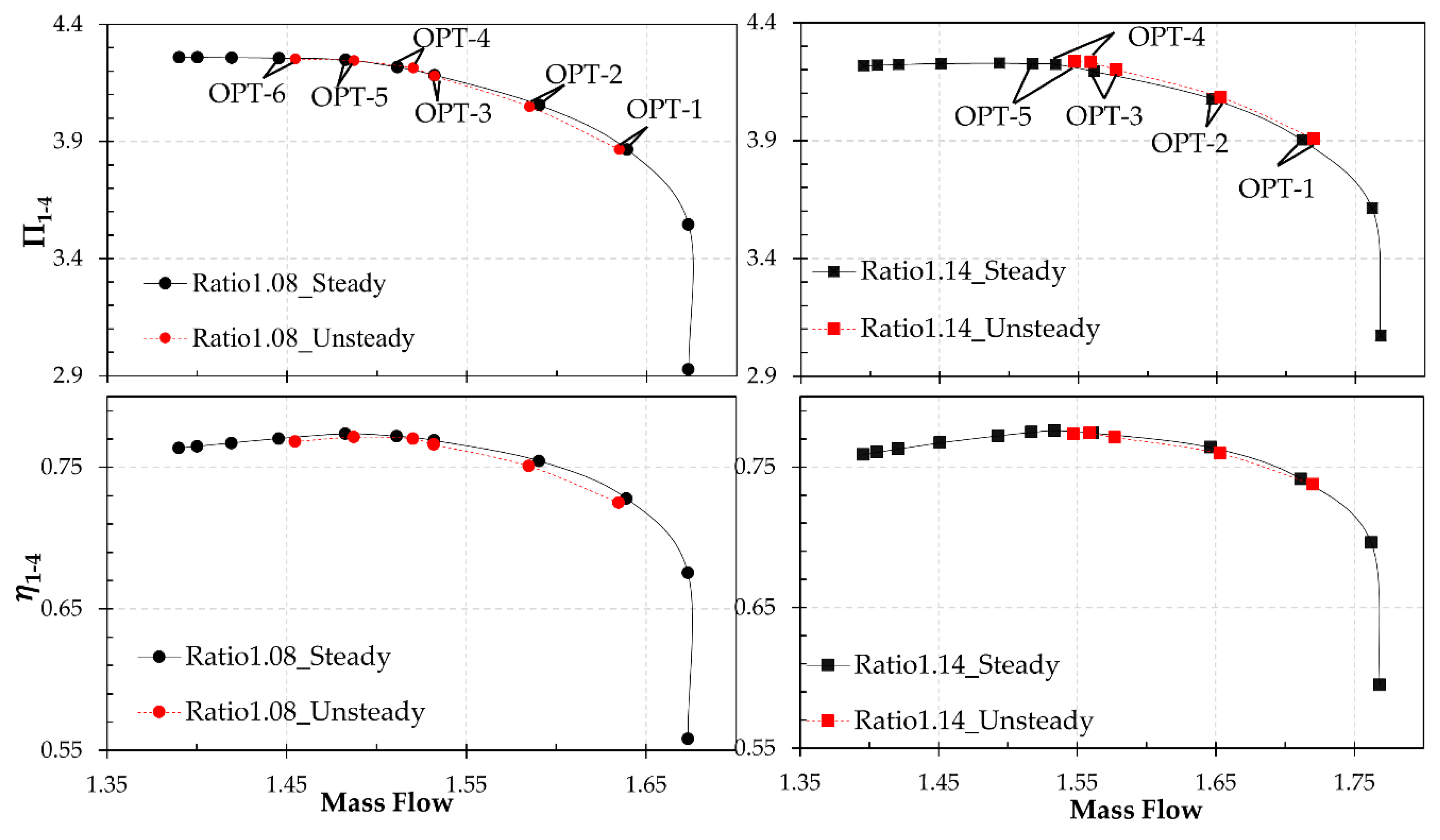

3.1. Comparison between Steady and Unsteady Results

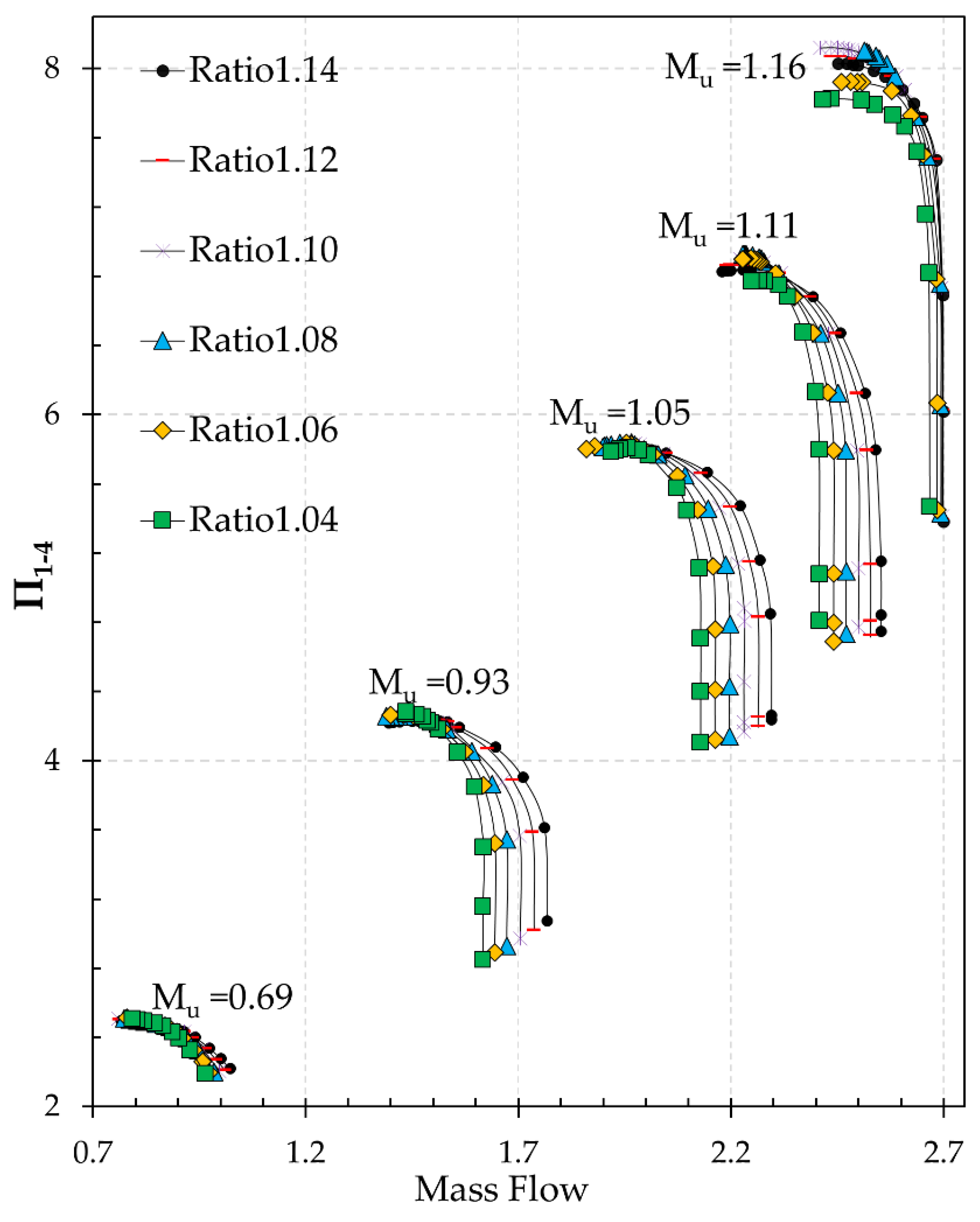

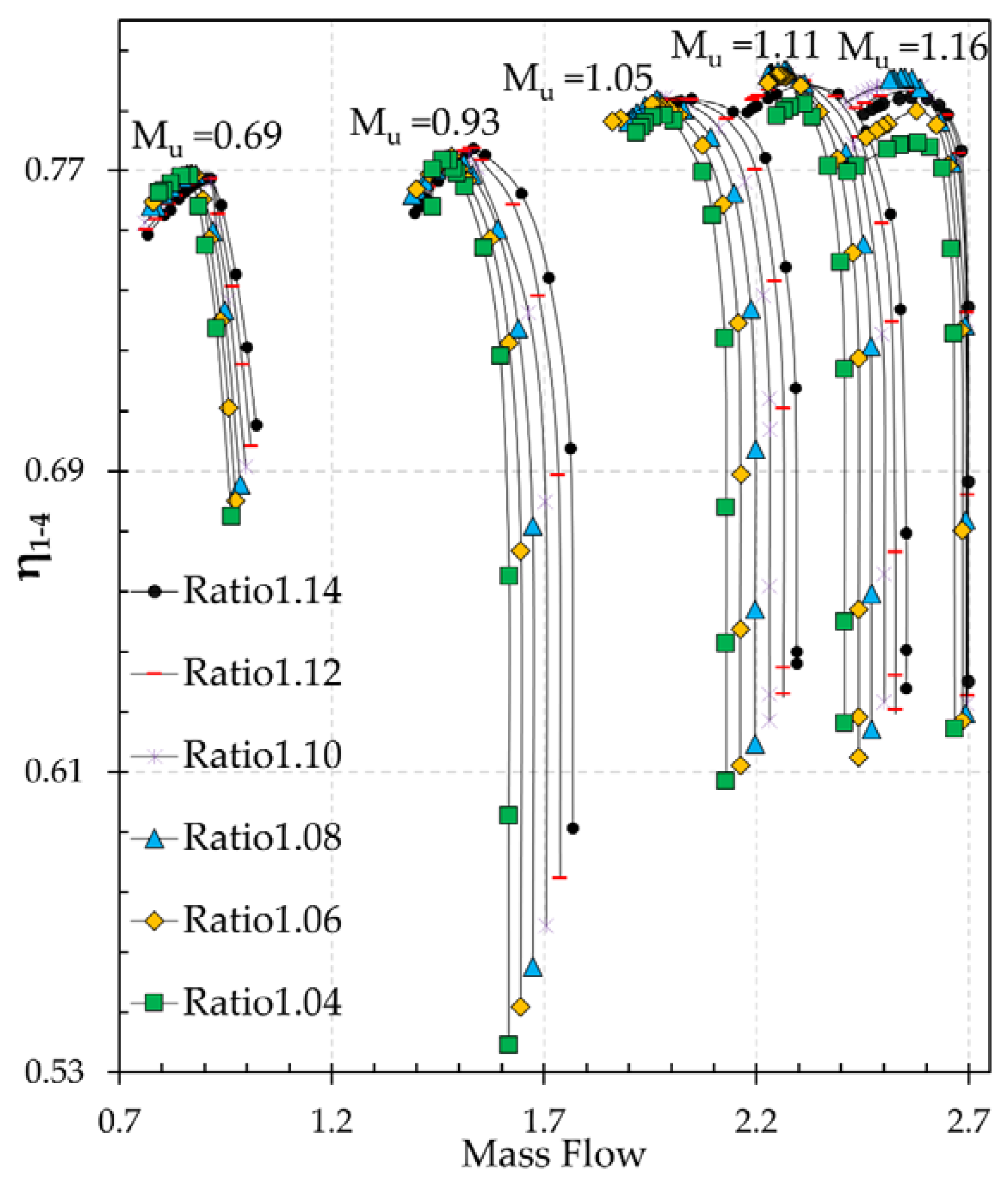

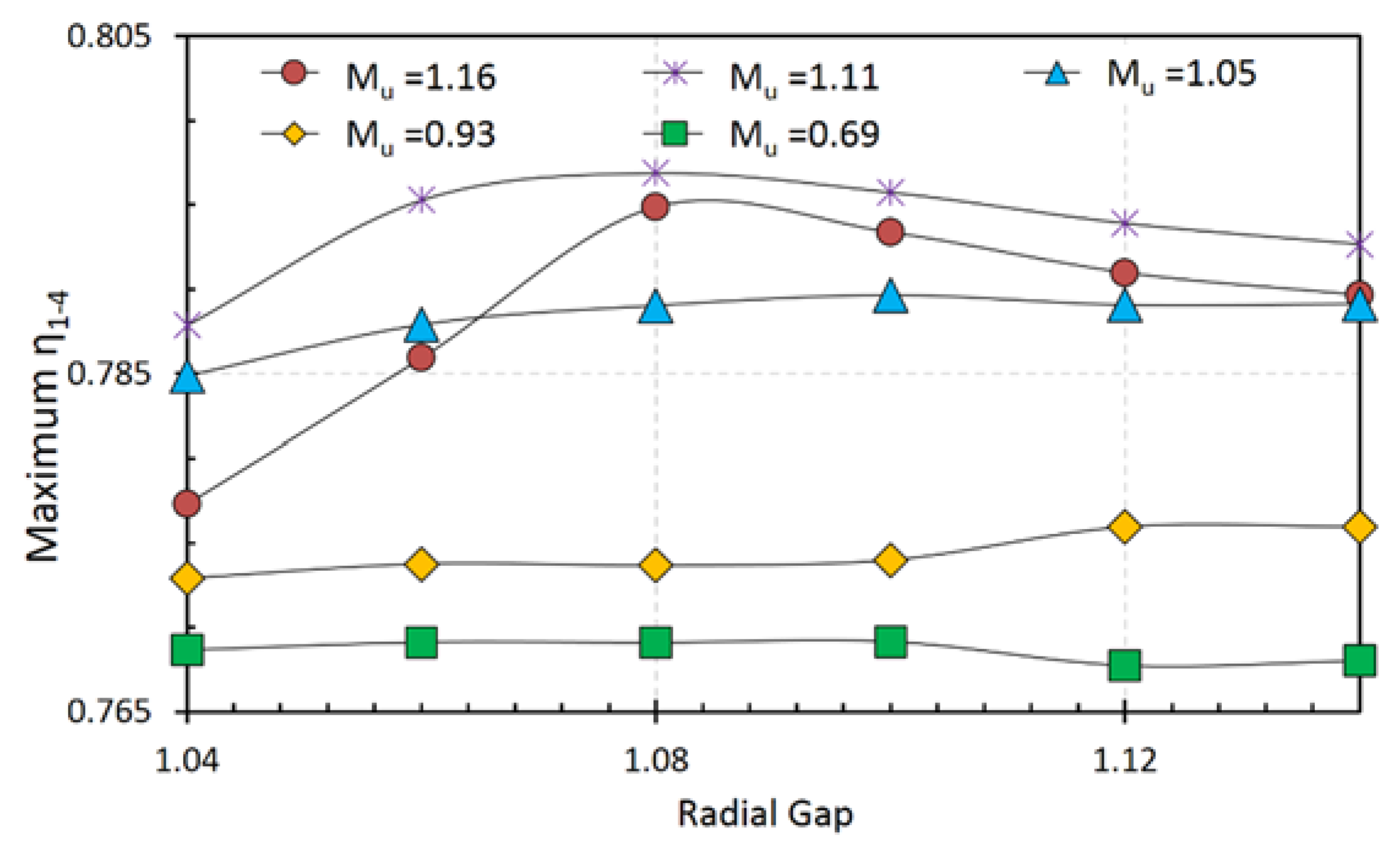

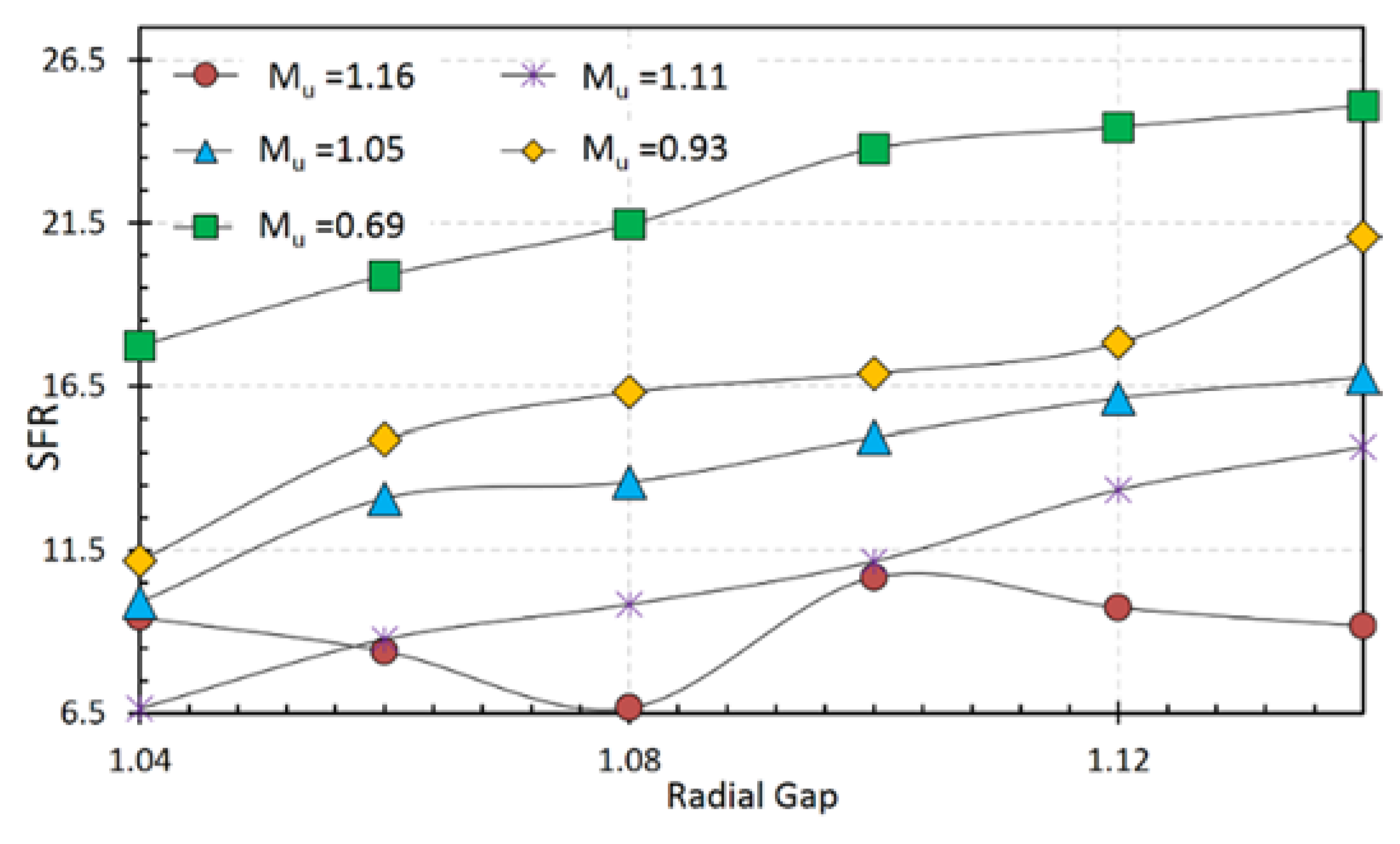

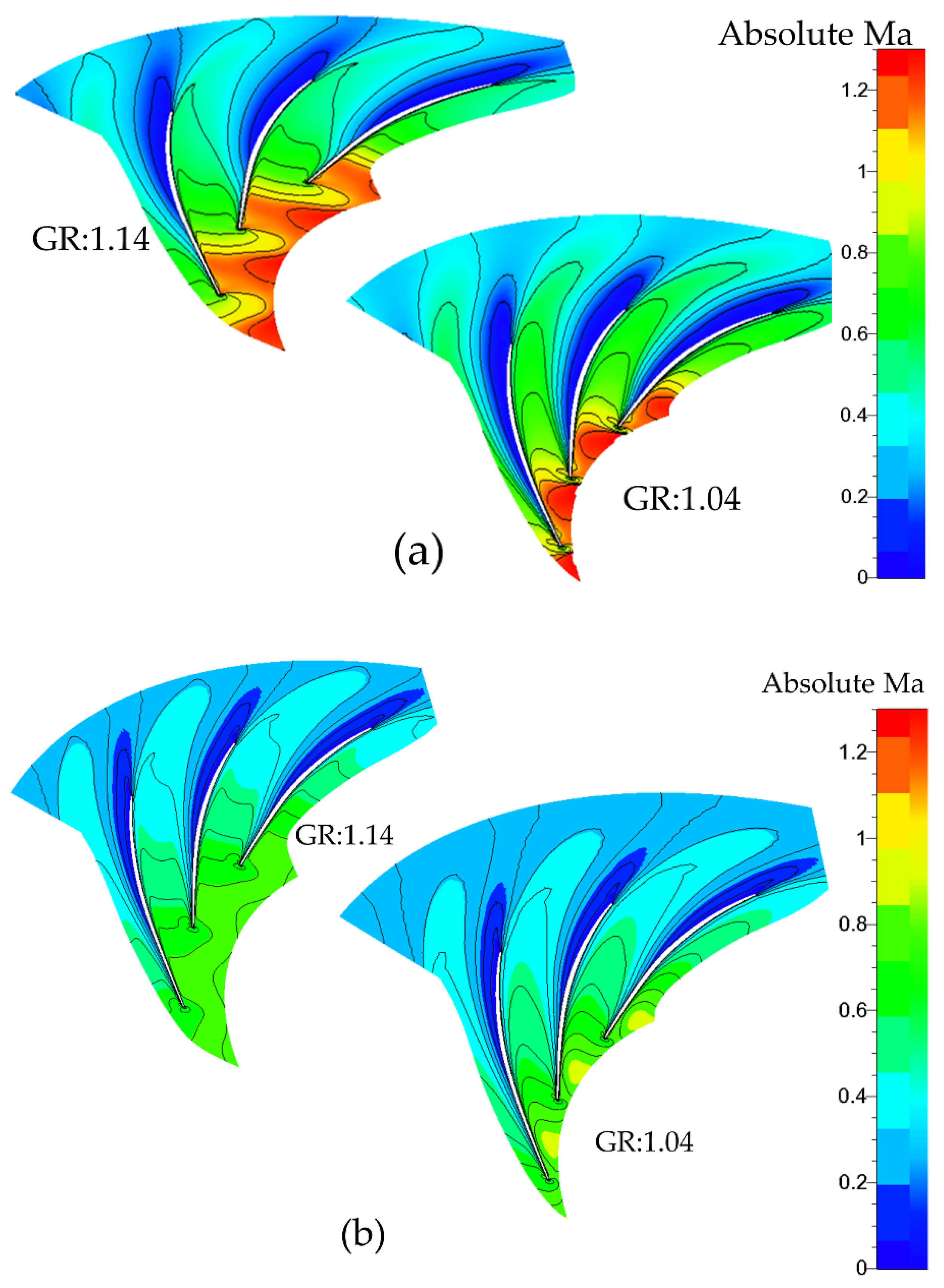

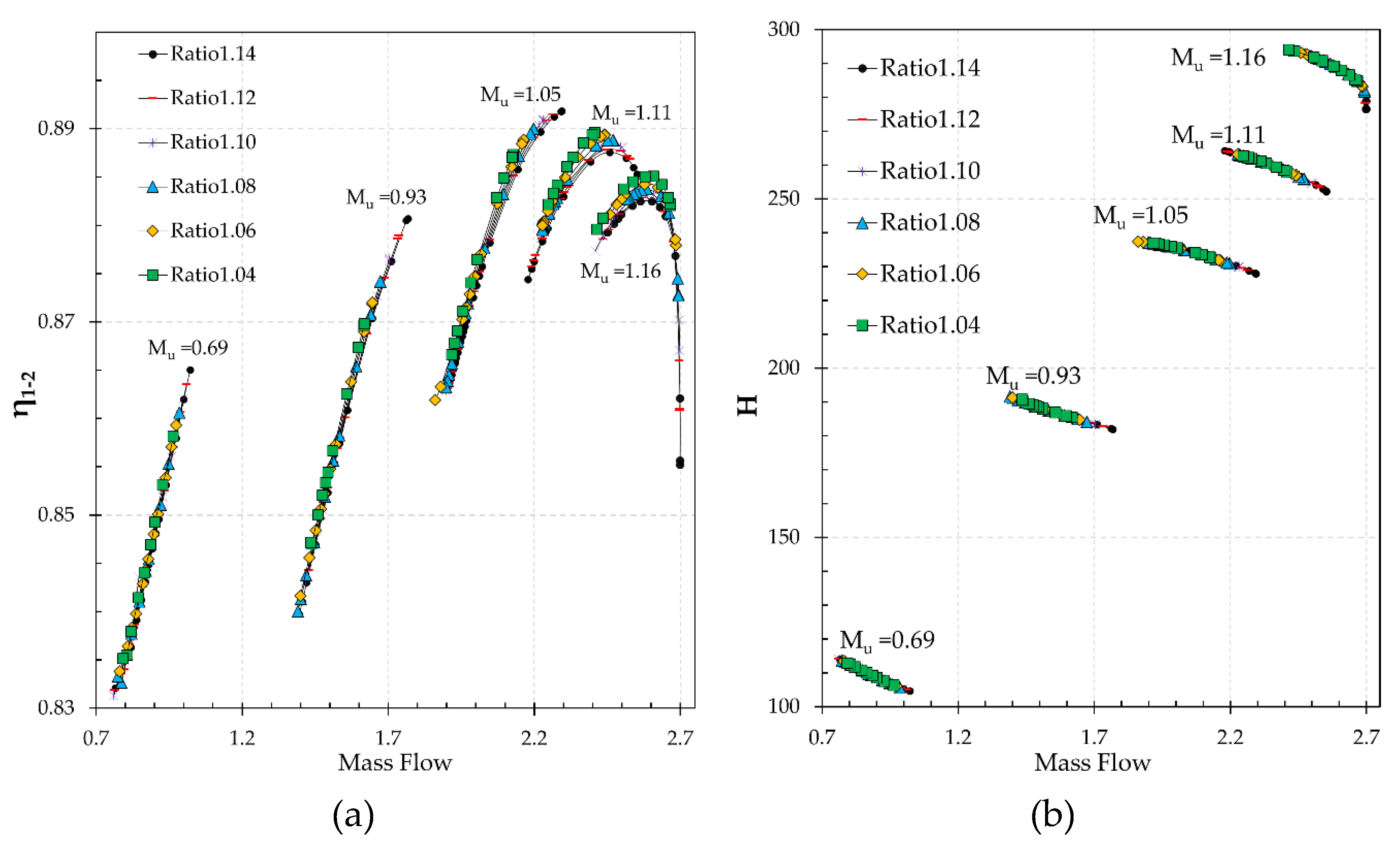

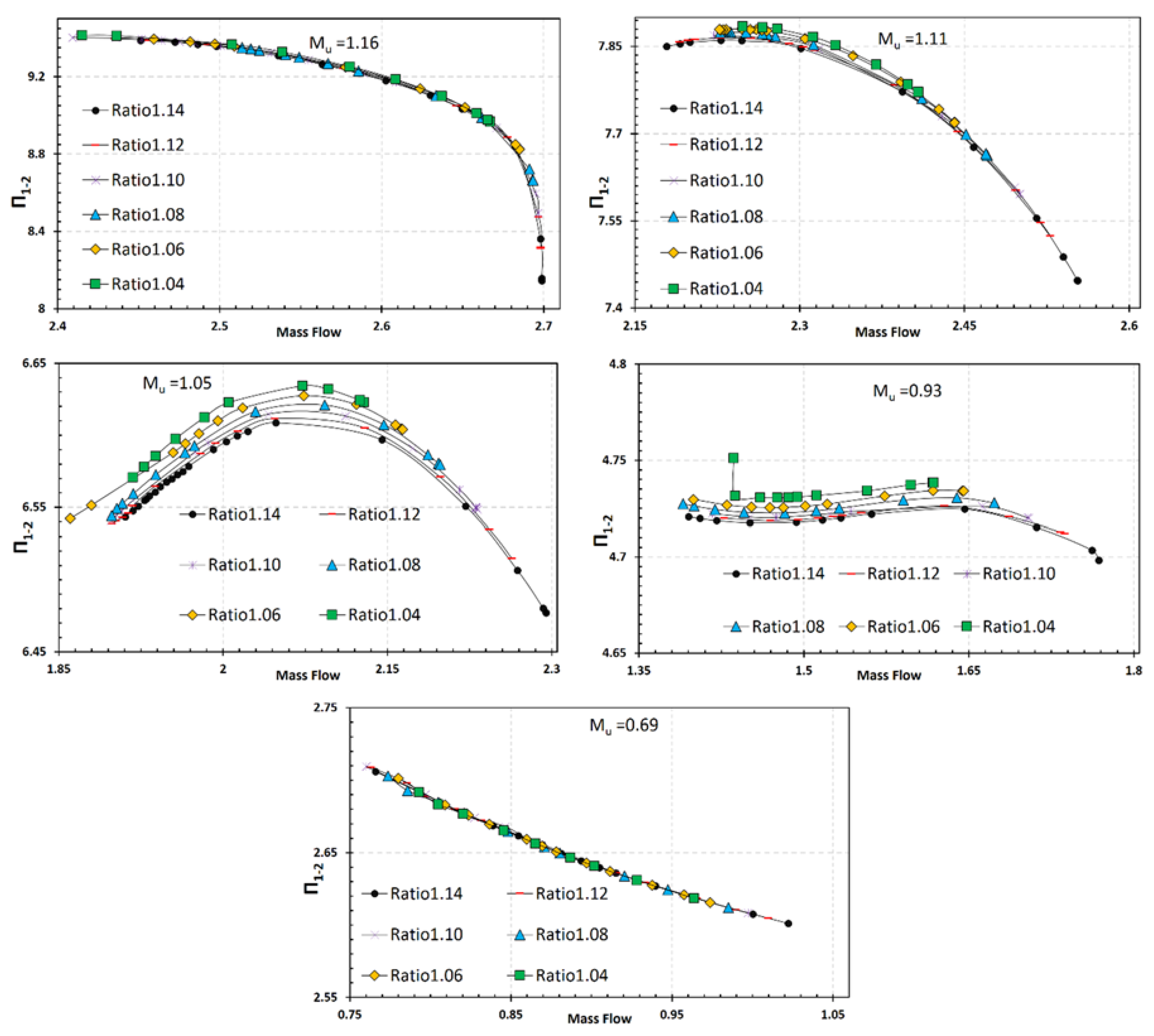

3.2. Effects of Radial Gap Ratio on the Compressor Performance

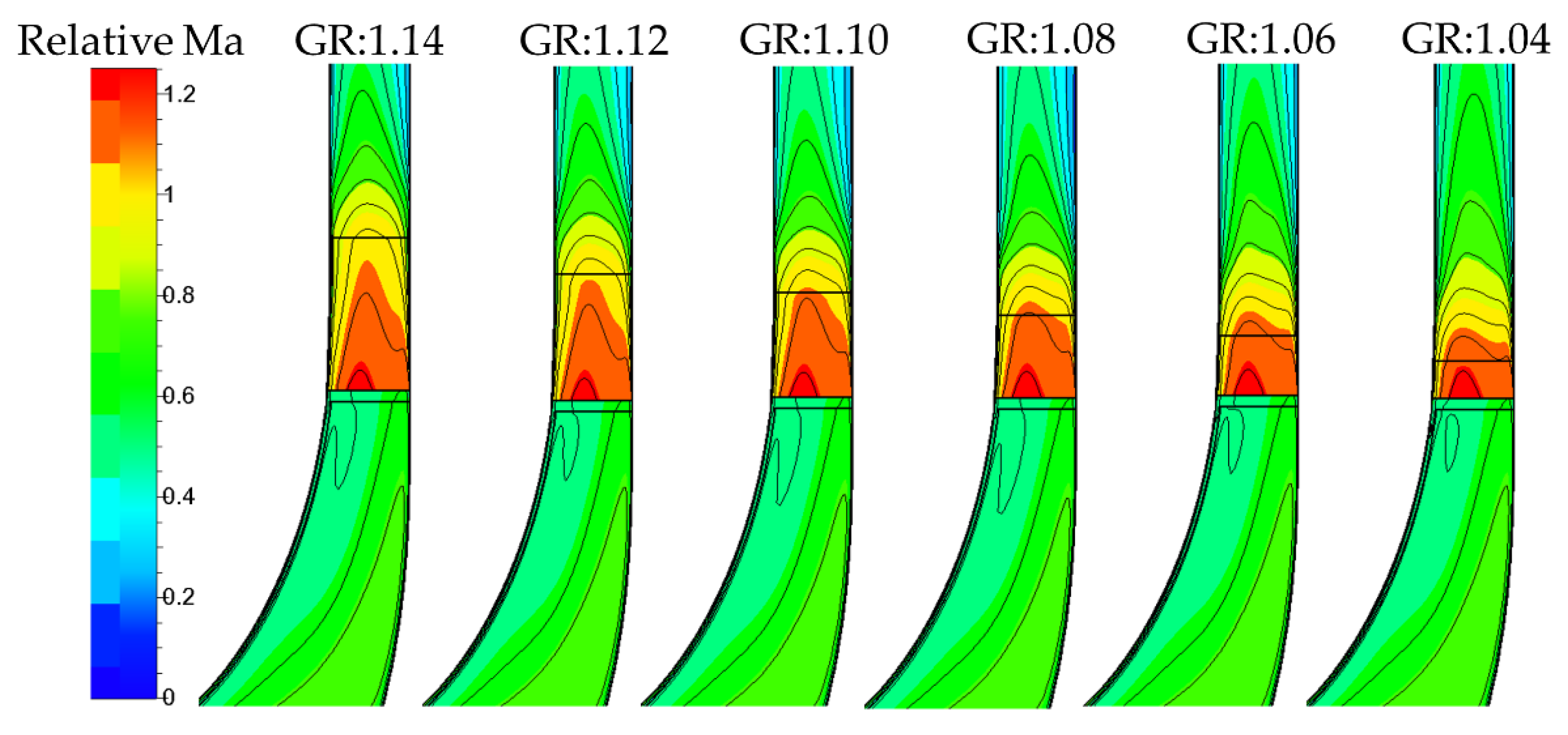

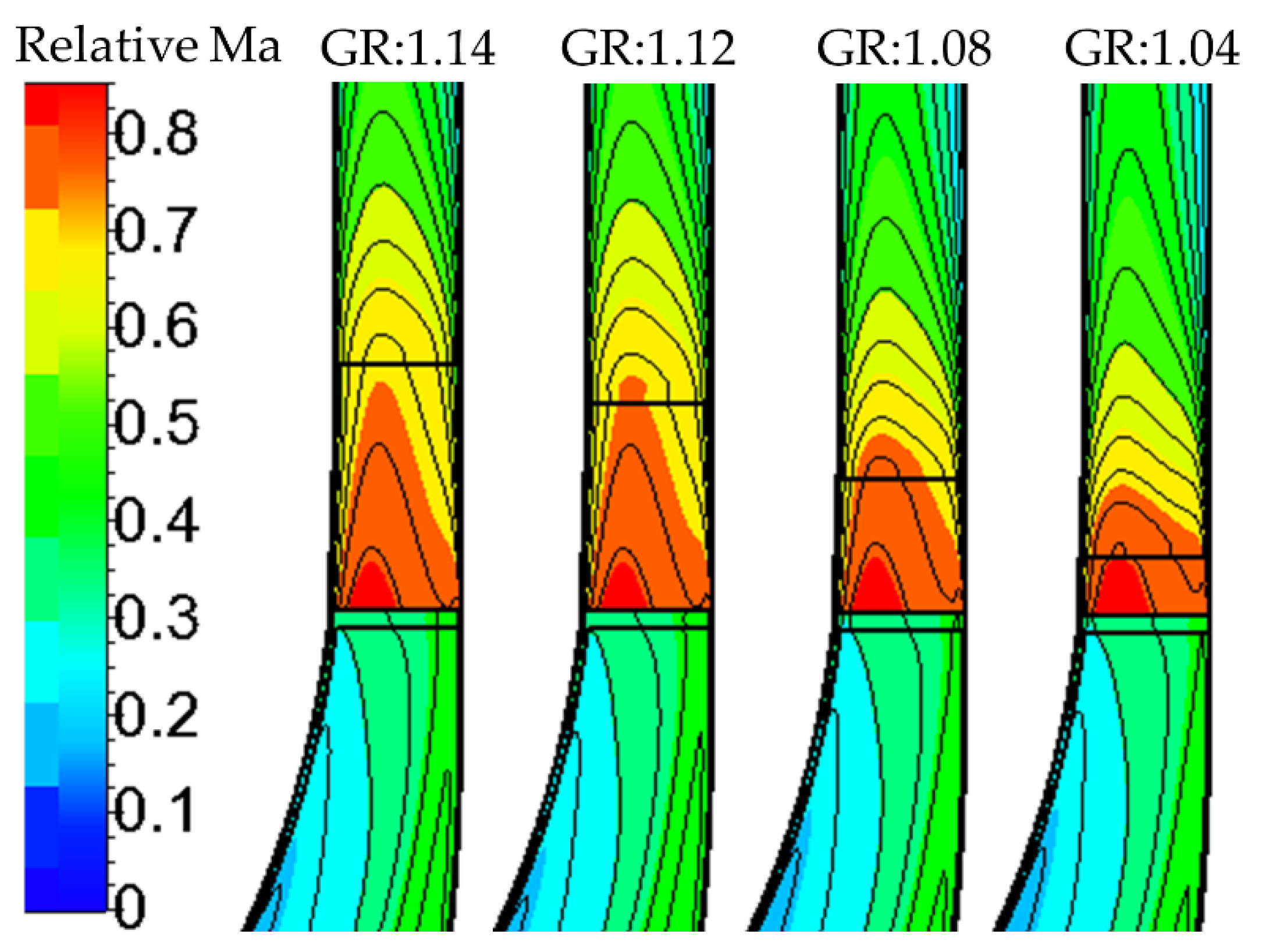

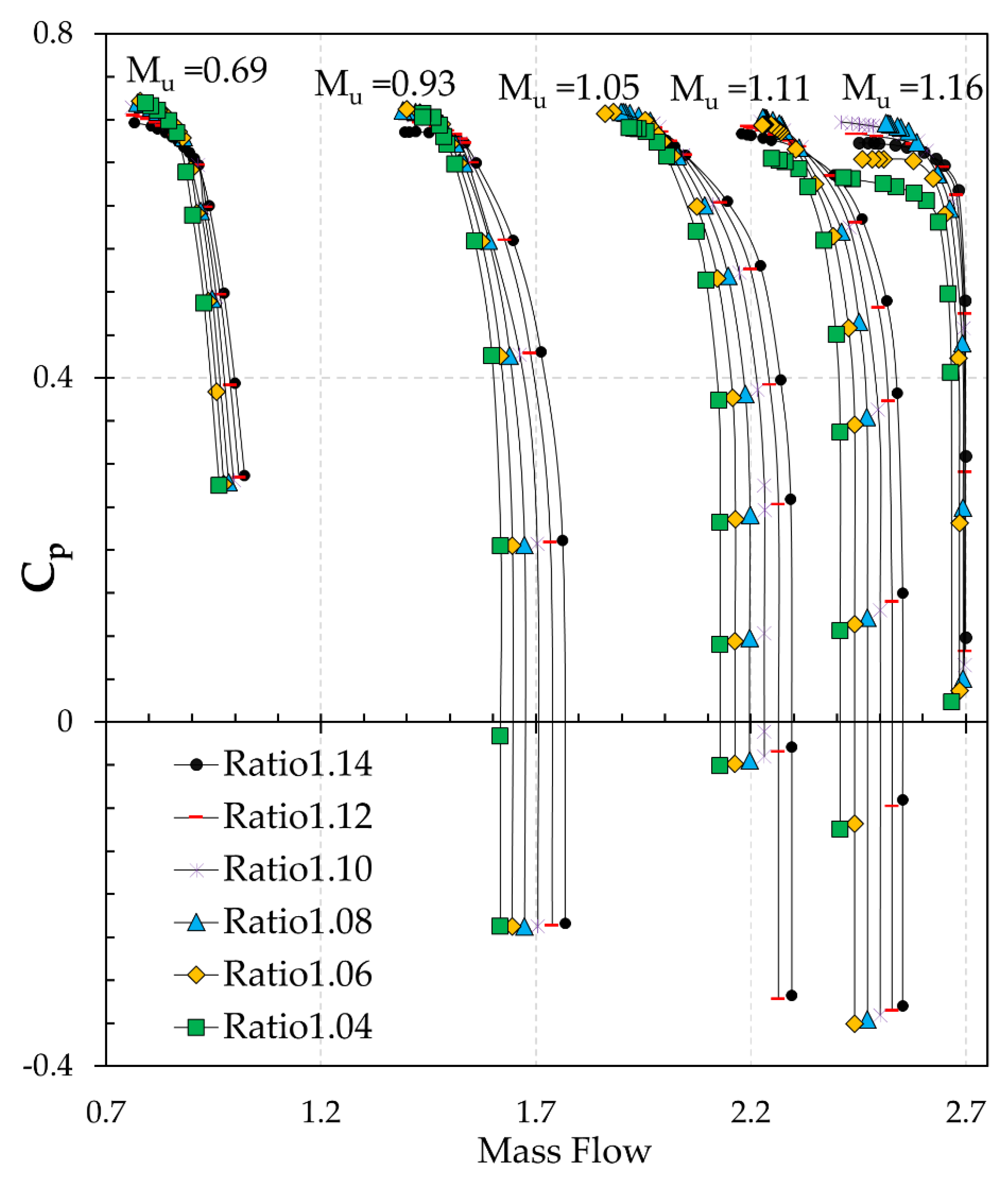

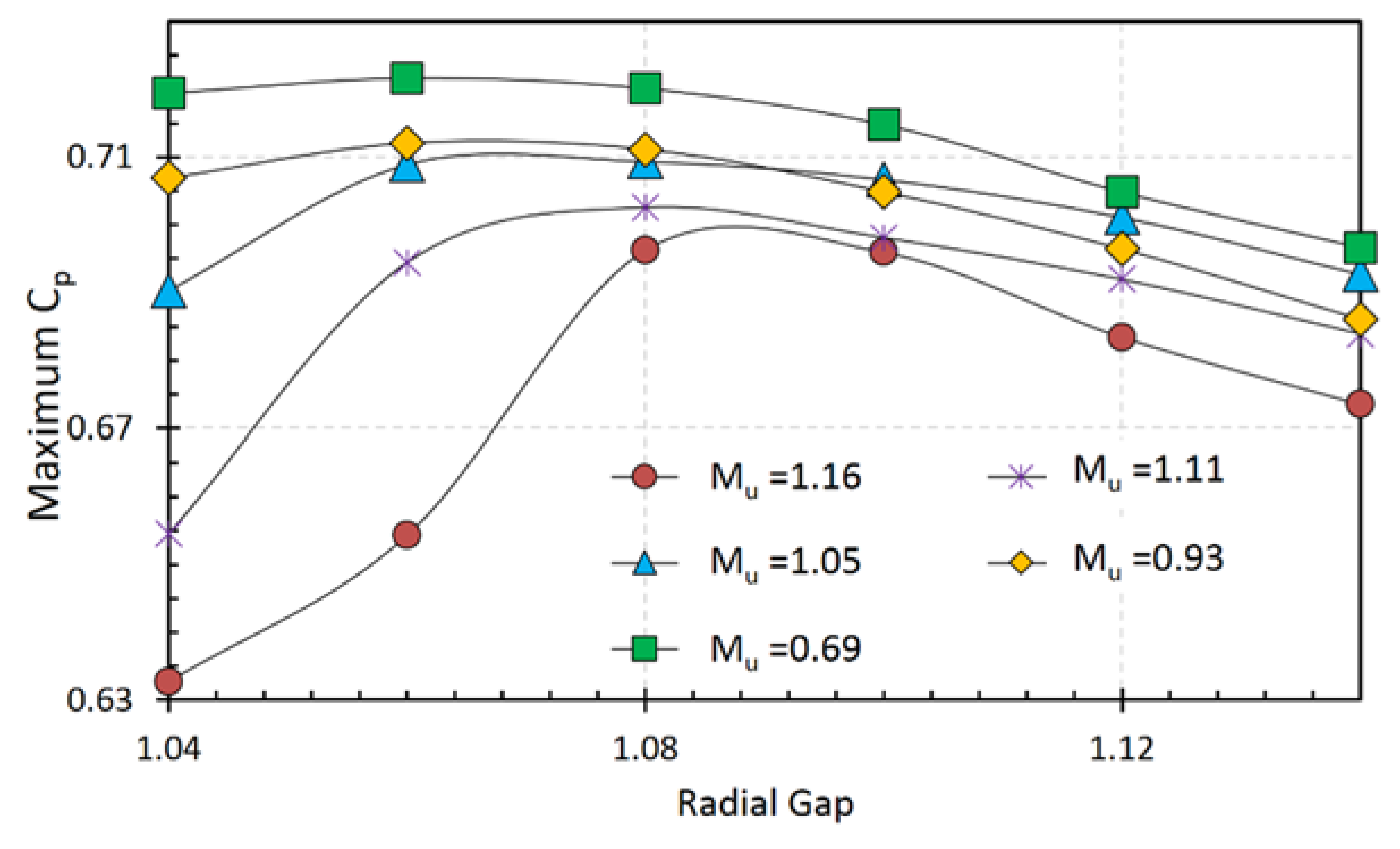

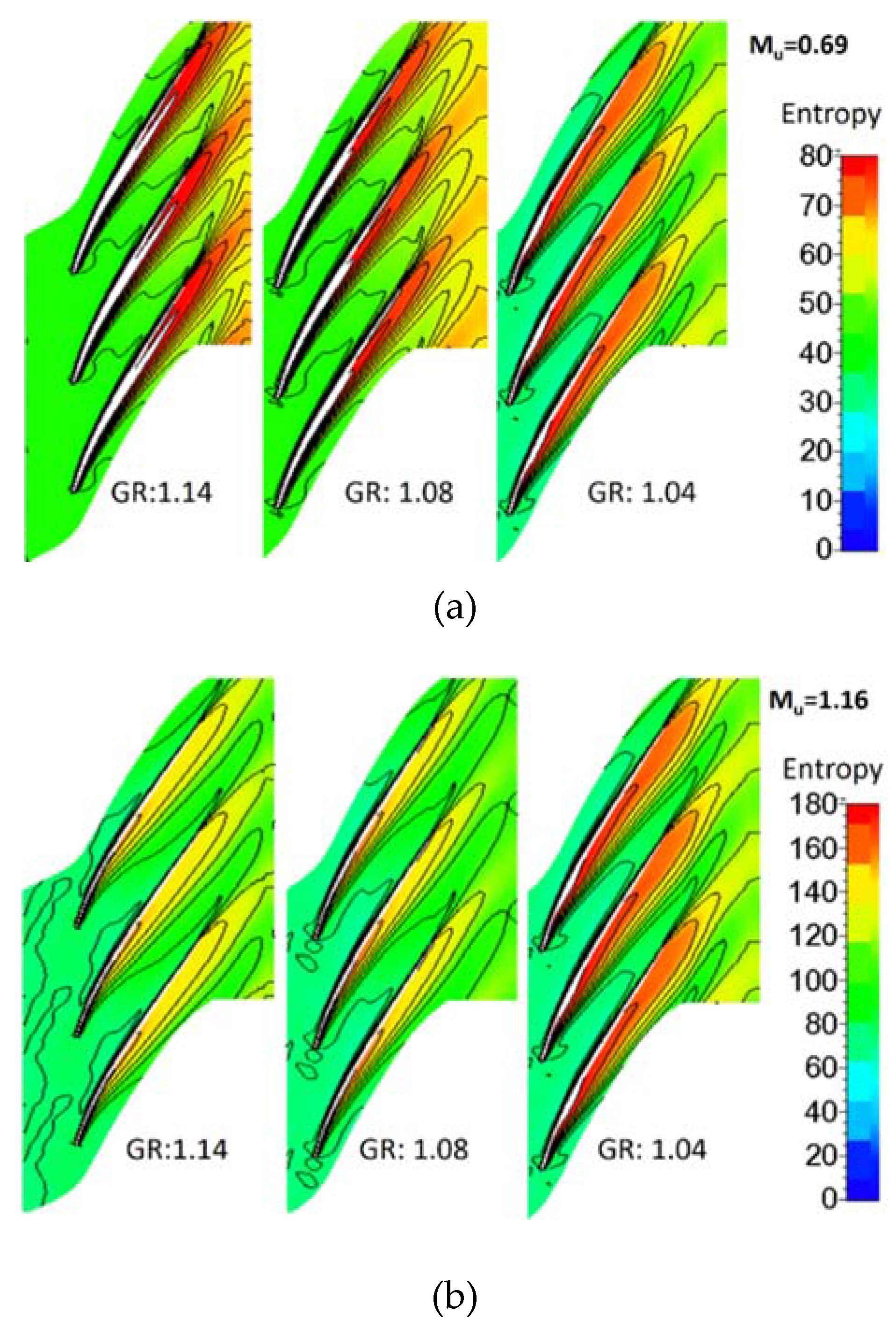

3.3. Effects of Radial Gap Ratio on Vaned Diffuser Performance

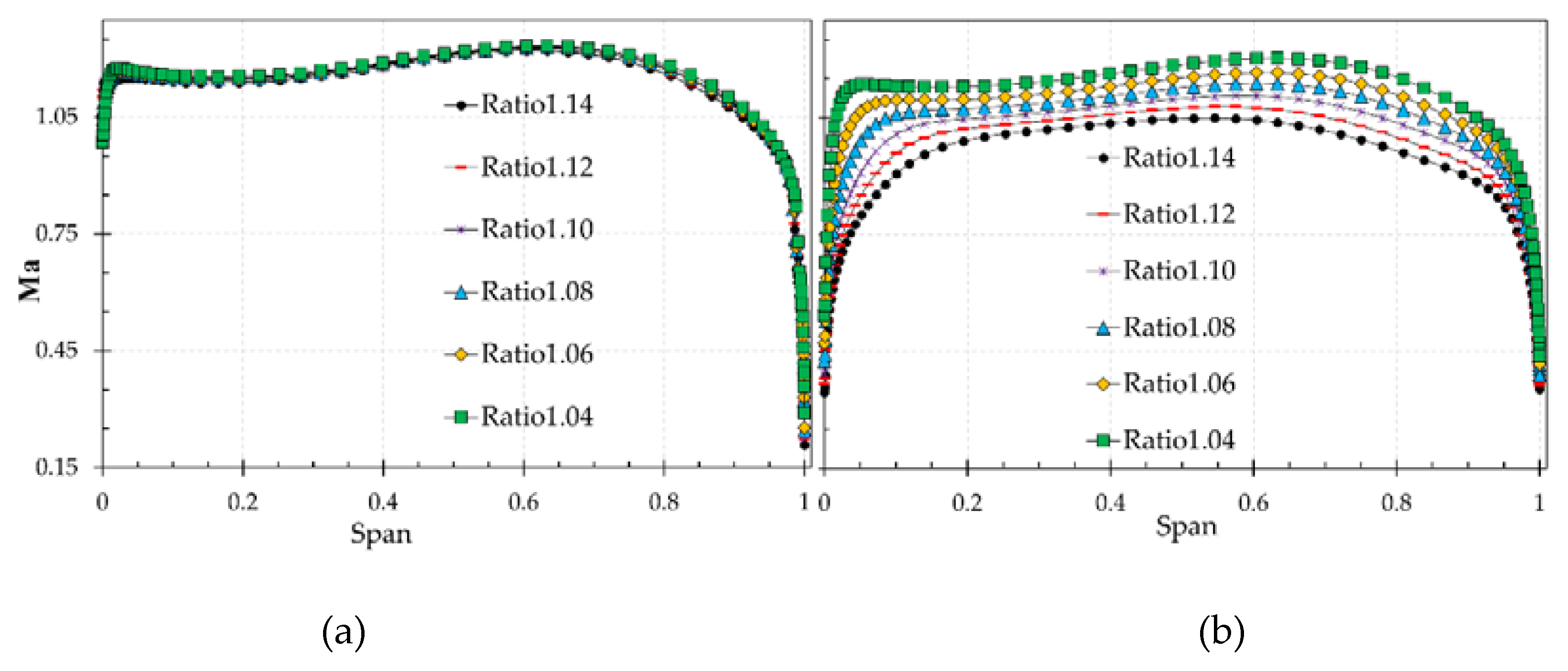

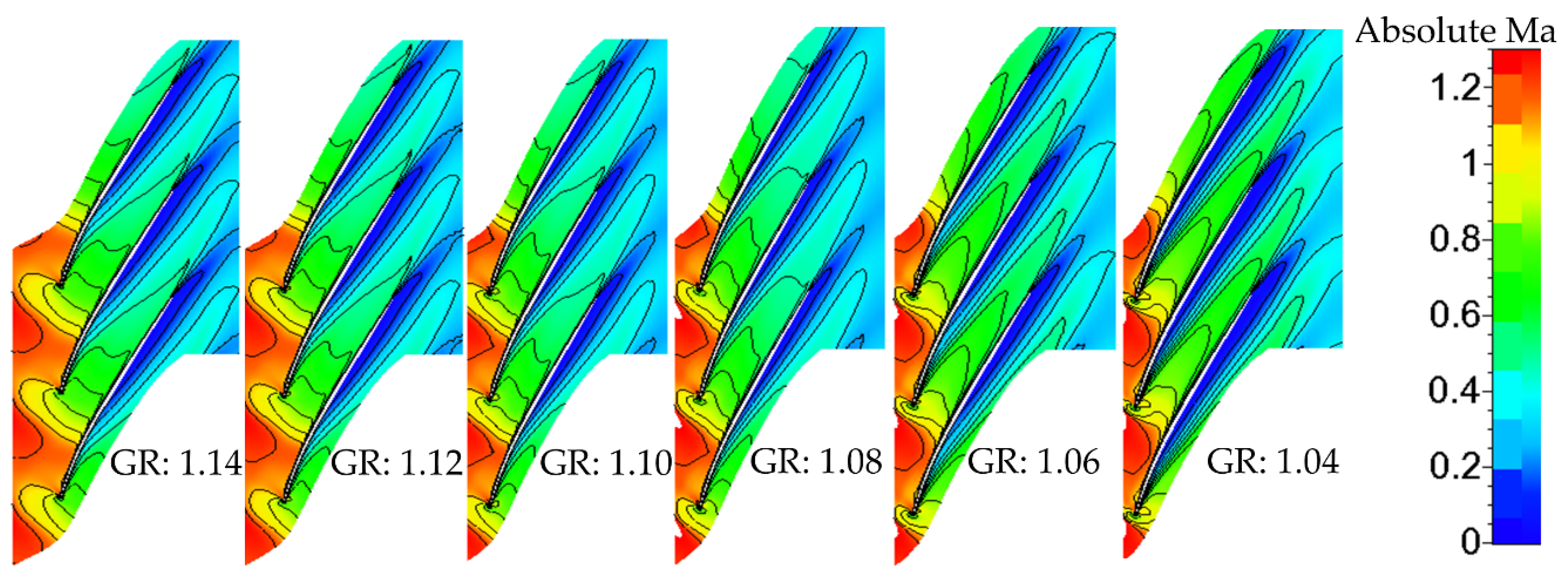

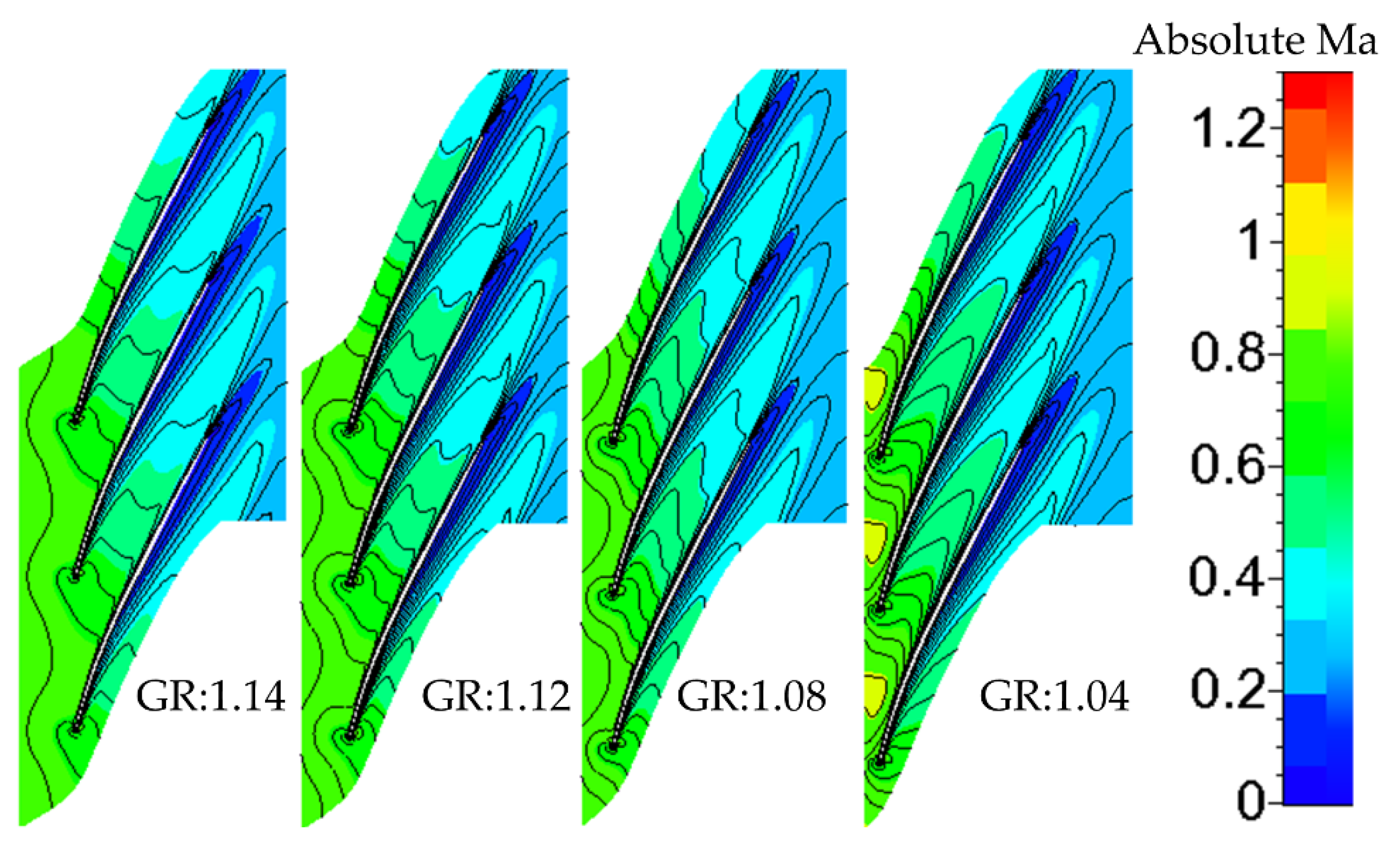

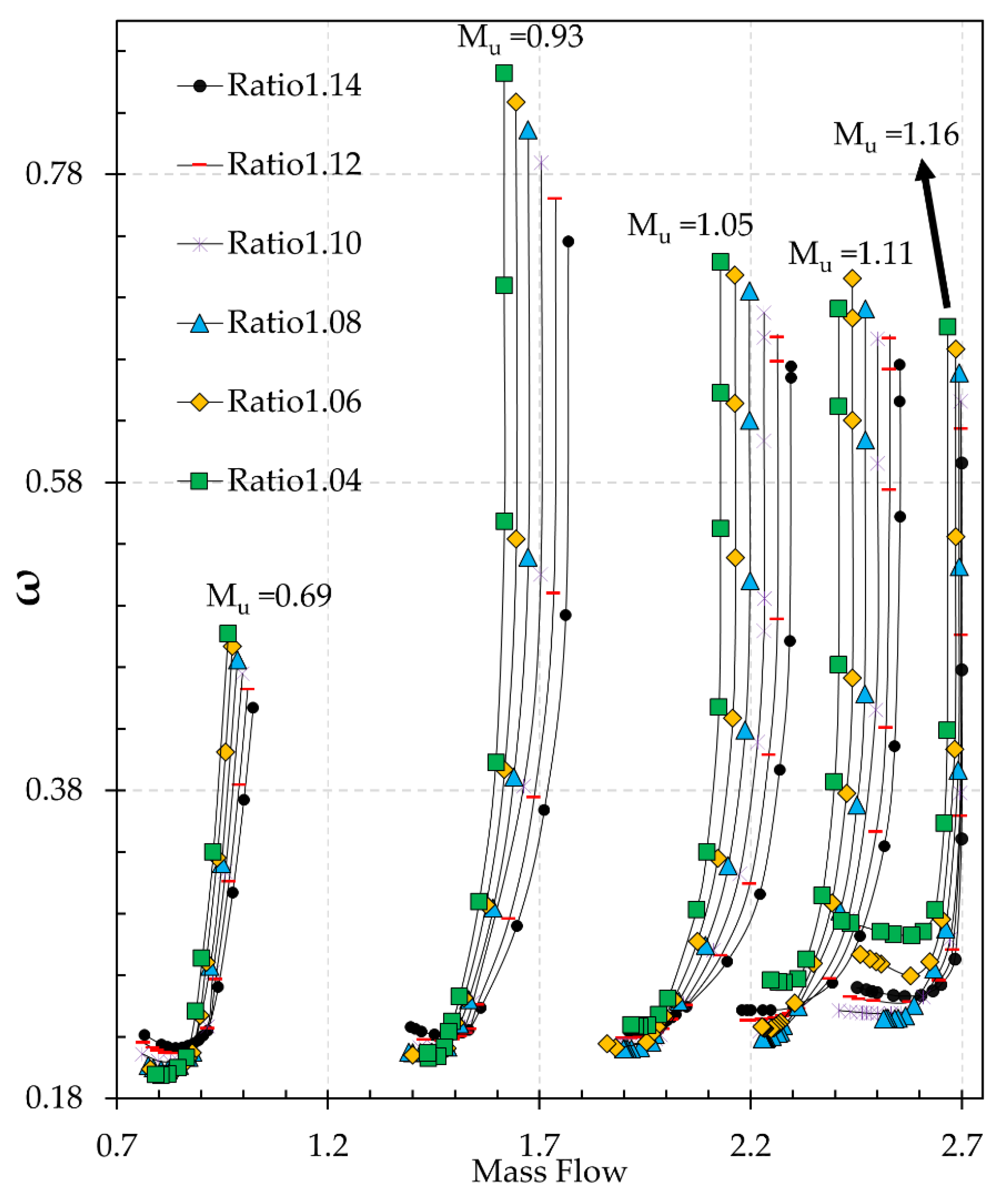

3.4. Effects of Radial Gap Ratio on the Impeller Performance

4. Conclusions and Remarks

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| A | Area |

| Cf | Schlichting empirical formula |

| Cp | Pressure recovery coefficient |

| F | Total skin friction drag force |

| GR | Gap Ratio (Radial gap) (r3/r2) |

| H | Total enthalpy (J/Kg) |

| Mass flow rate | |

| Ma | Absolute Mach number |

| Mu | Tip-speed Mach number (U/) |

| N | Rotational speed |

| P | Pressure |

| R | Gas Constant (J/KgK) |

| T, T0 | Static temperature, Total temperature |

| U | Tip speed (m/s) |

| u | Fluid velocity |

| Swetted | Fluid contacted area |

| Z | Number of blades |

| r2 | Impeller trailing edge radius |

| r3 | Diffuser leading edge radius |

| y+ | Dimensionless Wall Distance |

| Greek symbols | |

| η | Isentropic efficiency |

| π | Total pressure ratio |

| ⍵ | Pressure loss coefficient |

| Fluid density | |

| Subscriptions | |

| 1 | Impeller inlet |

| 2 | Impeller exit |

| 3 | Diffuser inlet |

| 4 | Diffuser exit |

References

- Wang, Y.; Shi, D.; Zhang, D.; Xie, Y. Investigation on Unsteady Flow Characteristics of a SCO2 Centrifugal Compressor. Appl. Sci. 2017, 7, 310. [Google Scholar] [CrossRef]

- Moosania, S.; Zheng, X. Comparison of Cooling Different Parts in a High Pressure Ratio Centrifugal Compressor. Appl. Sci. 2016, 7, 16. [Google Scholar] [CrossRef]

- Krain, H.; Hoffmann, B. Flow Study of a Redesigned High-Pressure-Ratio Centrifugal Compressor. J. Propuls. Power 2008, 24, 1117–1123. [Google Scholar] [CrossRef]

- Higashimori, H.; Hasagawa, K.; Sumida, K.; Suita, T. Detailed Flow Study of Mach Number 1.6 High Transonic Flow With a Shock Wave in a Pressure Ratio 11 Centrifugal Compressor Impeller. J. Turbomach. 2004, 126, 473–481. [Google Scholar] [CrossRef]

- Rodgers, C. Flow Ranges of 8.0:1 Pressure Ratio Centrifugal Compressors for Aviation Applications. In Proceedings of the ASME Turbo Expo 2005: Power for Land, Sea, and Air, Reno, NV, USA, 6–9 June 2005; Volume 6: Turbo Expo 2005, Parts A and B. ASME: New York, NY, USA; pp. 801–811. [Google Scholar]

- Rodgers, C. The Efficiencies of Single-Stage Centrifugal Compressors for Aircraft Applications. In Proceedings of the ASME 1991 International Gas Turbine and Aeroengine Congress and Exposition Conference, Orlando, FL, USA, 3–6 June 1991; Volume 1: Turbomachinery. ASME: New York, NY, USA; p. V001T01A025. [Google Scholar]

- Krain, H. Review of Centrifugal Compressor’s Application and Development. J. Turbomach. 2005, 127, 25. [Google Scholar] [CrossRef]

- Rodgers, C.; Sapiro, L. Design Considerations for High-Pressure-Ratio Centrifugal Compressors. In Proceedings of the ASME 1972 International Gas Turbine and Fluids Engineering Conference and Products Show, San Francisco, CA, USA, 26–30 March 1972; ASME: New York, NY, USA; p. V001T01A090. [Google Scholar]

- Ferrara, G.; Ferrari, L.; Mengoni, C.P.; De Lucia, M.; Baldassarre, L. Experimental Investigation and Characterization of the Rotating Stall in a High Pressure Centrifugal Compressor: Part I—Influence of Diffuser Geometry on Stall Inception. In Proceedings of the ASME Turbo Expo 2002: Power for Land, Sea, and Air, Amsterdam, The Netherlands, 3–6 June 2002; Volume 5: Turbo Expo 2002, Parts A and B. ASME: New York, NY, USA; pp. 613–620. [Google Scholar]

- Ebrahimi, M.; Huang, Q.; He, X.; Zheng, X. Effects of Variable Diffuser Vanes on Performance of a Centrifugal Compressor with Pressure Ratio of 8.0. Energies 2017, 10, 682. [Google Scholar] [CrossRef]

- Zheng, X.; Zhang, Y.; Yang, M.; Bamba, T.; Tamaki, H. Stability Improvement of High-Pressure-Ratio Turbocharger Centrifugal Compressor by Asymmetrical Flow Control-Part II: Non-Axisymmetrical Self-Recirculation Casing Treatment. J. Turbomach. 2013, 135, 0210061–0210069. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.; Zheng, X.; Jin, L.; Tamaki, H.; Kawakubo, T. A novel experimental method to evaluate the impact of volute’s asymmetry on the performance of a high pressure ratio turbocharger compressor. Sci. Chin. Technol. Sci. 2012, 55, 1695–1700. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, J.; Tang, Y.; Lu, L. Effect of Slot at Blade Root on Compressor Cascade Performance under Different Aerodynamic Parameters. Appl. Sci. 2016, 6, 421. [Google Scholar] [CrossRef]

- Klassen, H.A.; Wood, J.R.; Schumann, F. Experimental Performance of a 13.65-Centimeter-Tip-Diameter Tandem-Bladed Sweptback Centrifugal Compressor Designed for a Pressure Ratio of 6; Technical Report; NASA: Washington, DC, USA, 1977.

- Gallier, K. Experimental Characterization of High Speed Centrifugal Compressor Aerodynamic Forcing Function. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2005. [Google Scholar]

- Filipenco, V.G.; Deniz, S.; Johnston, J.M.; Greitzer, E.M.; Cumpsty, N.A. Effects of Inlet Flow Field Conditions on the Performance of Centrifugal Compressor Diffuser. In Volume 1: Turbomachinery; ASME: New York, NY, USA, 1998; Volume 122, p. V001T01A111. [Google Scholar]

- Bonaiuti, D.; Arnone, A.; Hah, C.; Hayami, H. Development of Secondary Flow Field in a Low Solidity Diffuser in a Transonic Centrifugal Compressor Stage. In Proceedings of the ASME Turbo Expo 2002: Power for Land, Sea, and Air, Amsterdam, The Netherlands, 3–6 June 2002; Volume 5: Turbo Expo 2002, Parts A and B. ASME: New York, NY, USA; pp. 445–454. [Google Scholar]

- Ziegler, K.U.; Gallus, H.E.; Niehuis, R. A Study on Impeller-Diffuser Interaction—Part II: Detailed Flow Analysis. J. Turbomach. 2003, 125, 183. [Google Scholar] [CrossRef]

- Sato, K.; He, L. A Numerical Study on Performances of Centrifugal Compressor Stages With Different Radial Gaps. In Proceedings of the ASME Turbo Expo 2000: Power for Land, Sea, and Air, Munich, Germany, 8–11 May 2000; Volume 1: Aircraft Engine; Marine; Turbomachinery; Microturbines and Small Turbomachinery. ASME: New York, NY, USA; p. V001T03A036. [Google Scholar]

- Shum, Y.K.P.; Tan, C.S.; Cumpsty, N.A. Impeller—Diffuser Interaction in a Centrifugal Compressor. J. Turbomach. 2000, 122, 777–786. [Google Scholar] [CrossRef]

- Robinson, C.; Casey, M.; Hutchinson, B.; Steed, R. Impeller-Diffuser Interaction in Centrifugal Compressors. In Proceedings of the ASME Turbo Expo 2012: Turbine Technical Conference and Exposition, Copenhagen, Denmark, 11–15 June 2012; Volume 8: Turbomachinery, Parts A, B, and C. ASME: New York, NY, USA; pp. 767–777. [Google Scholar]

- Ziegler, K.U.; Gallus, H.E.; Niehuis, R. A Study on Impeller-Diffuser Interaction—Part I: Influence on the Performance. J. Turbomach. 2003, 125, 173–182. [Google Scholar] [CrossRef]

- Krishnababu, S.K.; Imregun, M.; Green, J.S.; Hoyniak, D. Aerodynamics and Aeroelasticity of Impeller Vane Interactions in a High Pressure Ratio Centrifugal Compressor. In Proceedings of the ASME Turbo Expo 2010: Power for Land, Sea, and Air, Glasgow, UK, 14–18 June 2010; Volume 6: Structures and Dynamics, Parts A and B. ASME: New York, NY, USA; pp. 1201–1208. [Google Scholar]

- Clements, W.W.; Artt, D.W. The Influence of Diffuser Vane Leading Edge Geometry on the Performance of a Centrifugal Compressor. In Proceedings of the ASME 1989 International Gas Turbine and Aeroengine Congress and Exposition, Toronto, ON, Canada, 4–8 June 1989; Volume 1: Turbomachinery. ASME: New York, NY, USA; p. V001T01A068. [Google Scholar]

- Rodgers, C. The Performance of Centrifugal Compressor Channel Diffusers. In Proceedings of the ASME 1982 International Gas Turbine Conference and Exhibit, London, England, 18–22 April 1982; Volume 1: Turbomachinery. ASME: New York, NY, USA; Volume 82-NaN-10, p. V001T01A003. [Google Scholar]

- He, X.; Zheng, X.; Wei, J.; Zeng, H. Investigation of Vaned Diffuser Splitters on the Performance and Flow Control of High Pressure Ratio Centrifugal Compressors. In Proceedings of the ASME Turbo Expo 2016: Turbomachinery Technical Conference and Exposition, Seoul, South Korea, 13–17 June 2016; Volume 2D: Turbomachinery. ASME: New York, NY, USA; p. V02DT42A008. [Google Scholar]

- NUMECA International NUMECA FINE/Turbo User Manual 10.1. Available online: http://www.numeca.com (accessed on 3 April 2017).

- Spalart, P.R.; Allmaras, S.R. A One-Equation Turbulence Model for Aerodynamic Flows. AIAA Meet. Pap. 1994, 1, 5–21. [Google Scholar]

- Spalart, P.R.; Shur, M. On the sensitization of turbulence models to rotation and curvature. Aerosp. Sci. Technol. 1997, 1, 297–302. [Google Scholar] [CrossRef]

- Hakimi, N. Preconditioning Methods for Time Dependent Navier-Stokes Equations. Ph.D. Thesis, Vrije Universiteit, Brussels, Belgium, 1997. [Google Scholar]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Peyvan, A.; Benisi, A.H. Axial-Flow Compressor Performance Prediction in Design and Off-Design Conditions through 1-D and 3-D Modeling and Experimental Study. J. Appl. Fluid Mech. 2016, 9, 2149–2160. [Google Scholar]

- Mirzaee, S.; Zheng, X.; Lin, Y. Improvement in the stability of a turbocharger centrifugal compressor by tip leakage control. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2017, 231, 700–714. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, B.; Lu, L. Investigation of Unsteady Impeller-Diffuser Interaction in a Transonic Centrifugal Compressor Stage. In Proceedings of the ASME Turbo Expo 2010: Power for Land, Sea, and Air, Glasgow, UK, 14–18 June 2010; Volume 7: Turbomachinery, Parts A, B, and C. ASME: New York, NY, USA; pp. 1961–1971. [Google Scholar]

- Li, P.Y.; Gu, C.W.; Song, Y. A new optimization method for centrifugal compressors based on 1D calculations and analyses. Energies 2015, 8, 4317–4334. [Google Scholar] [CrossRef]

- Liu, B.; Fu, D.; Yu, X. Development of a Preliminary Design Method for Subsonic Splittered Blades in Highly Loaded Axial-Flow Compressors. Appl. Sci. 2017, 7, 283. [Google Scholar] [CrossRef]

- Cumpsty, N.A. Compressor Aerodynamics; Longman Scientific & Technical: London, UK, 1989; p. 509. [Google Scholar]

- Japikse, D. Centrifugal Compressor Design and Performance; Concepts ETI Inc.: Windsor County, VT, USA, 1996. [Google Scholar]

| Datum Compressor TTL-1 | ||

|---|---|---|

| Impeller | ||

| Number of blades | ZI | 24 |

| Maximum rotational speed | Nmax (rpm) | 52,440 |

| Normalized leading edge hub radius | r1h/r2 | 0.26 |

| Normalized leading edge tip radius | r1t/r2 | 0.65 |

| Diffuser | ||

| Number of Vanes | ZD | 19 |

| Area ratio | A4/AThroat | 2.0 |

| Blade turning | β4–β3 | 15° |

| Normalized leading edge radius | r3/r2 | 1.10 |

| Normalized trailing edge radius | r4/r2 | 1.48 |

| Stage performance | ||

| Peak total pressure ratio | max π1-4 | 8.12 |

| Maximum corrected mass flow | ṁ | 2.6982 |

| Peak isentropic efficiency | η1-4 | 79.7% |

| Models | Equation Numbers | Time (10,000 Iterations Per Core) | η1-4 | π1-4 |

|---|---|---|---|---|

| SST | 2 | 23.3 h | 0.8042 | 8.03 |

| k-ε | 2 | 19.5 h | 0.7871 | 7.83 |

| SA | 1 | 17.4 h | 0.7989 | 8.05 |

| SARC | 1 | 27.0 h | 0.7924 | 7.89 |

| Domain Boundary | Imposed Condition | Value |

|---|---|---|

| Inlet | Total Temperature | 288.15 K |

| Total Pressure | 101,300 Pa | |

| Tangential velocity angle | 0 rad | |

| Radial velocity angle | 0 rad | |

| Outlet (mid-operating points) | Averaged static pressure | Increased stepwise |

| Outlet (near surge) | Average mass flow rate | Decreased stepwise |

| Solid walls | Stationary or rotating adiabatic non-slip wall |

| Mu = 1.16 | Mu = 1.11 | Mu = 1.05 | Mu = 0.93 | Mu = 0.69 | |

|---|---|---|---|---|---|

| GR = 1.14 | 8.0297 | 6.8368 | 5.8013 | 4.2286 | 2.4961 |

| GR = 1.12 | 8.0701 | 6.8665 | 5.8184 | 4.2374 | 2.5032 |

| GR = 1.10 | 8.1229 | 6.9012 | 5.8322 | 4.2484 | 2.5104 |

| GR = 1.08 | 8.1039 | 6.9265 | 5.8384 | 4.2587 | 2.5121 |

| GR = 1.06 | 7.9239 | 6.9044 | 5.8373 | 4.2642 | 2.5127 |

| GR = 1.04 | 7.8279 | 6.7734 | 5.8074 | 4.2815 | 2.5079 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hosseini, M.; Sun, Z.; He, X.; Zheng, X. Effects of Radial Gap Ratio between Impeller and Vaned Diffuser on Performance of Centrifugal Compressors. Appl. Sci. 2017, 7, 728. https://doi.org/10.3390/app7070728

Hosseini M, Sun Z, He X, Zheng X. Effects of Radial Gap Ratio between Impeller and Vaned Diffuser on Performance of Centrifugal Compressors. Applied Sciences. 2017; 7(7):728. https://doi.org/10.3390/app7070728

Chicago/Turabian StyleHosseini, Mohammadjavad, Zhenzhong Sun, Xiao He, and Xinqian Zheng. 2017. "Effects of Radial Gap Ratio between Impeller and Vaned Diffuser on Performance of Centrifugal Compressors" Applied Sciences 7, no. 7: 728. https://doi.org/10.3390/app7070728

APA StyleHosseini, M., Sun, Z., He, X., & Zheng, X. (2017). Effects of Radial Gap Ratio between Impeller and Vaned Diffuser on Performance of Centrifugal Compressors. Applied Sciences, 7(7), 728. https://doi.org/10.3390/app7070728