A Single-Stage LED Tube Lamp Driver with Power-Factor Corrections and Soft Switching for Energy-Saving Indoor Lighting Applications

Abstract

:1. Introduction

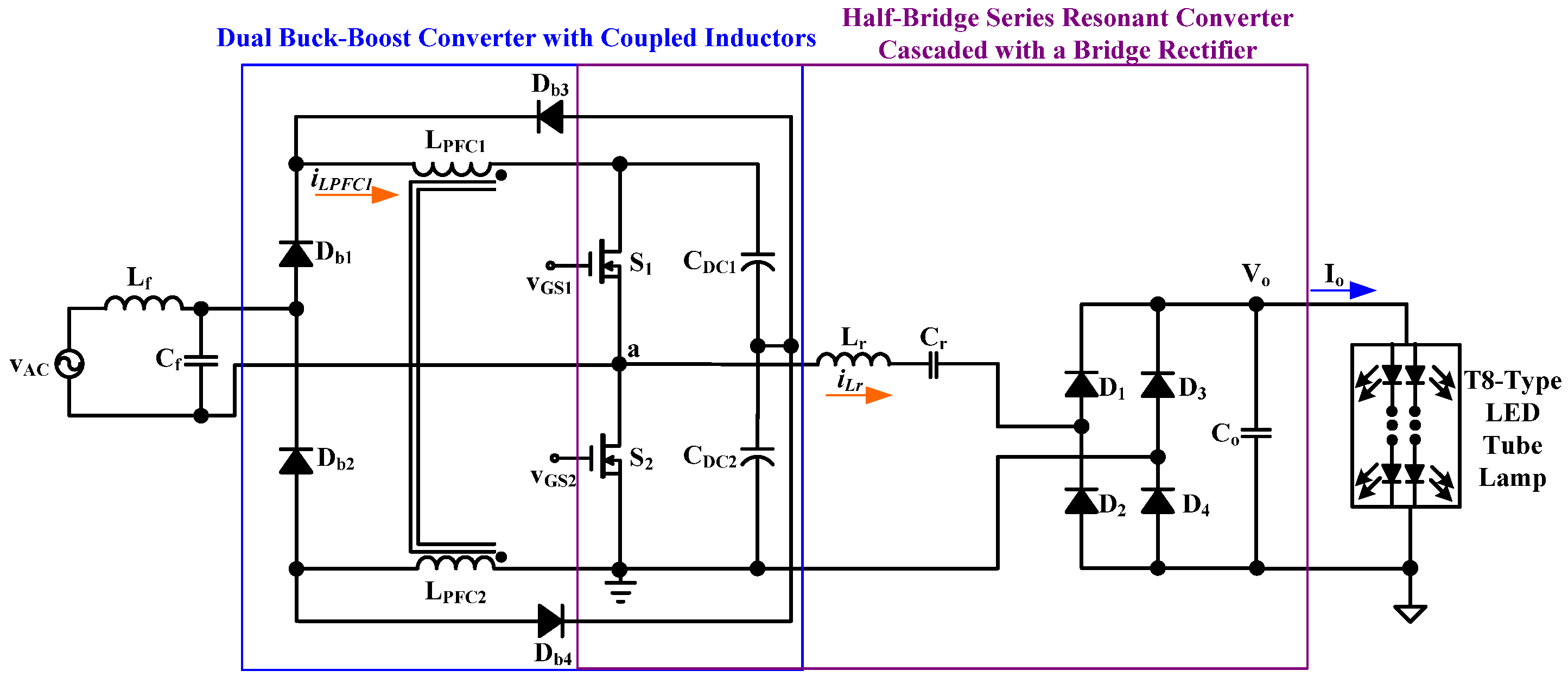

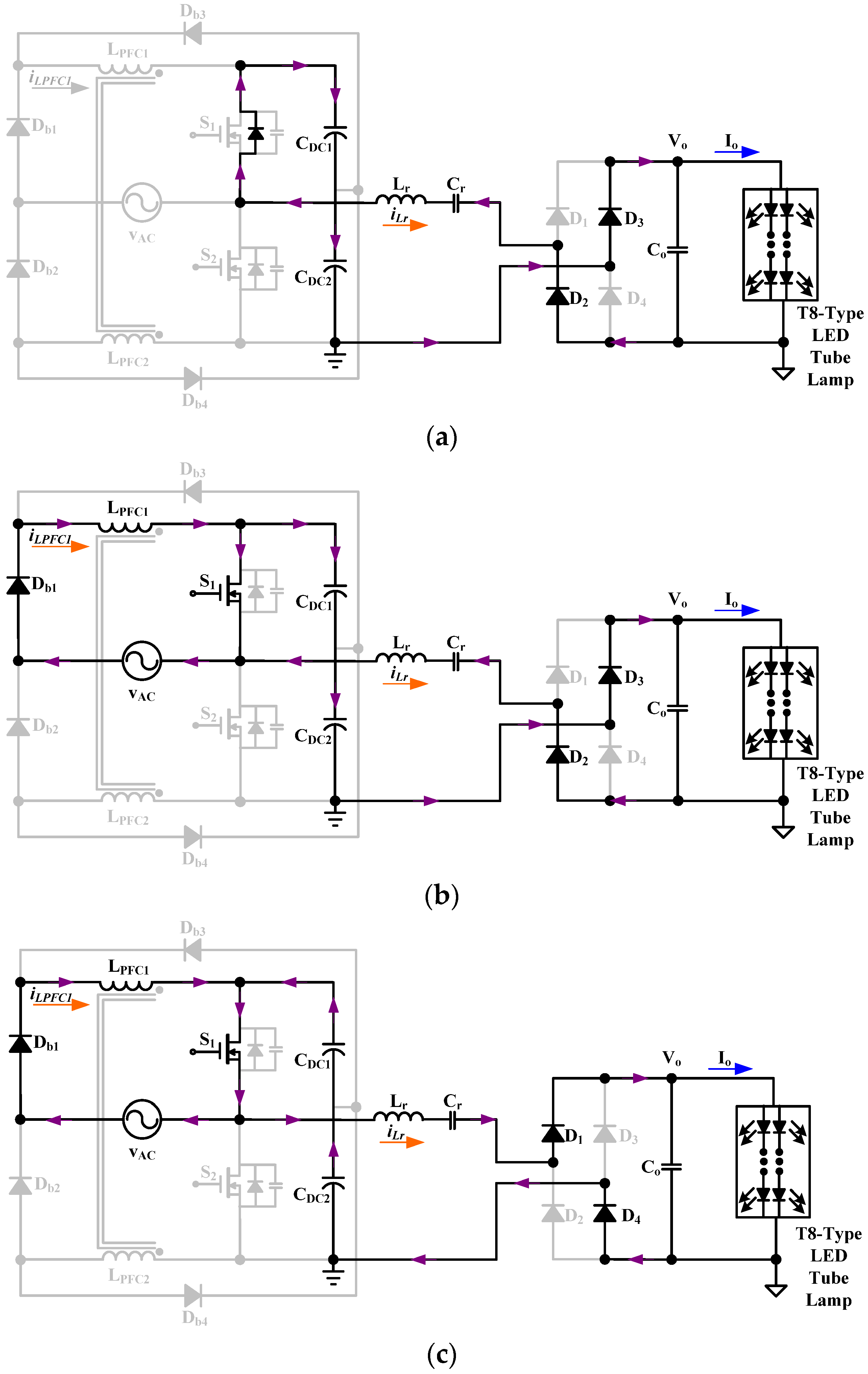

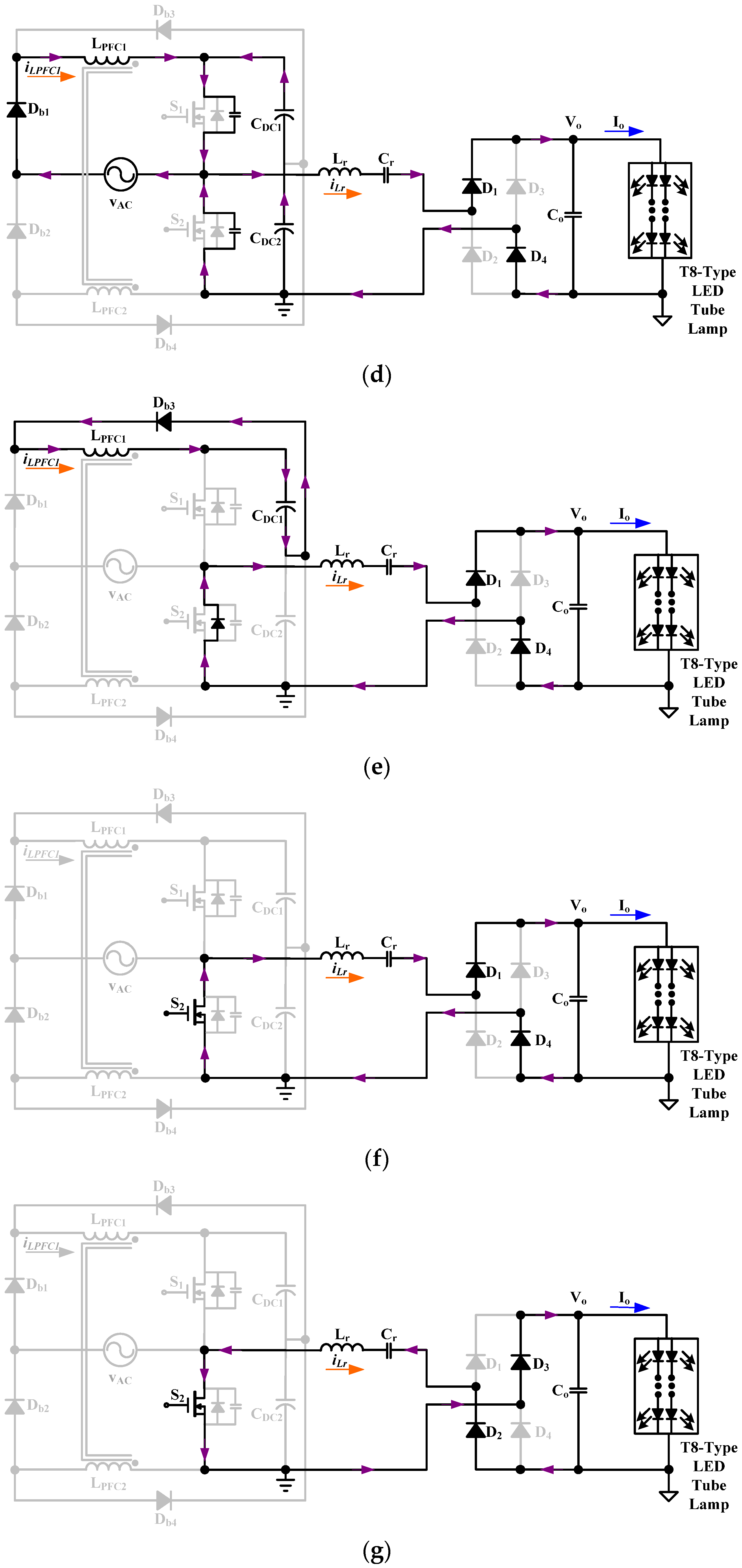

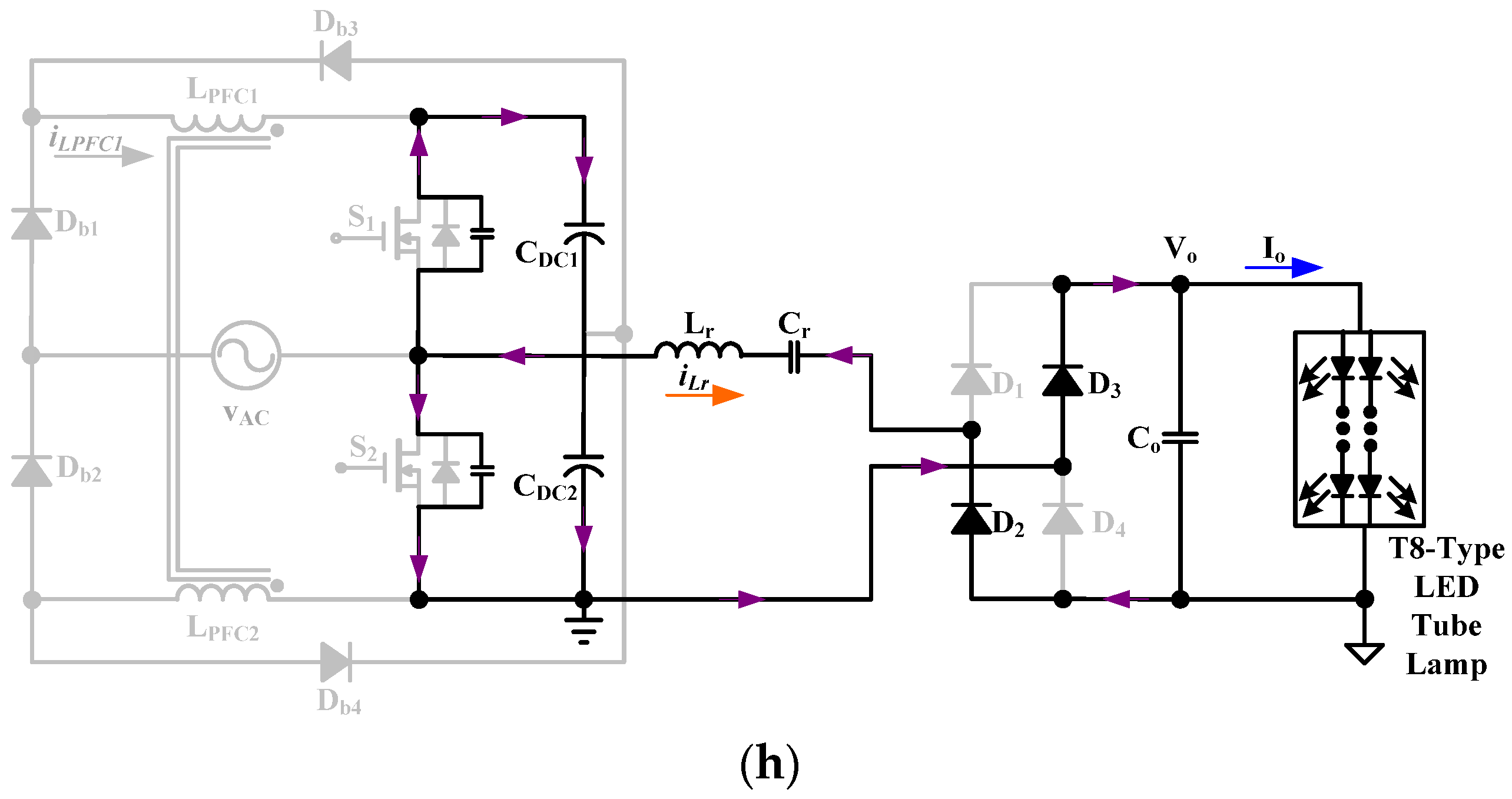

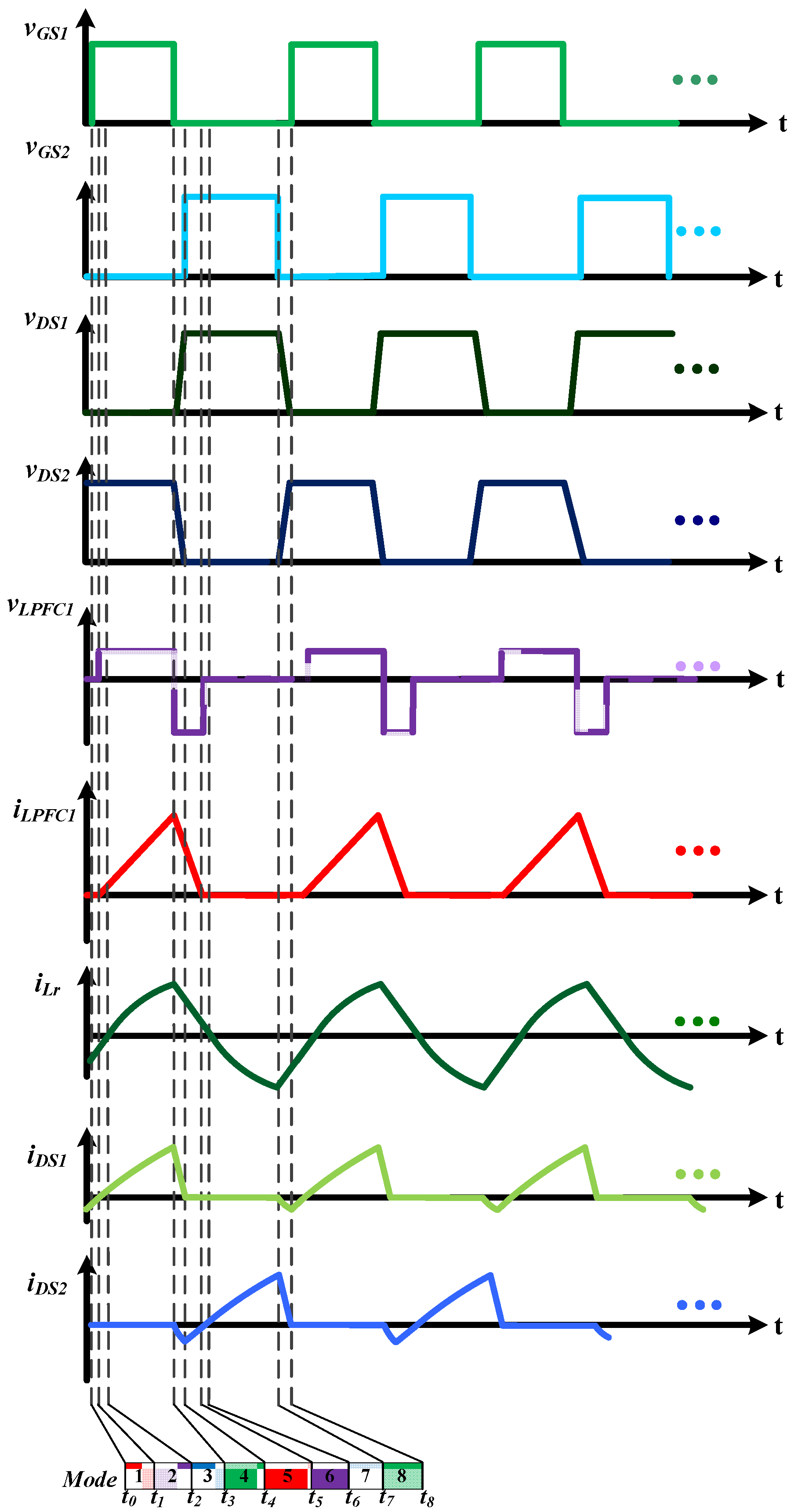

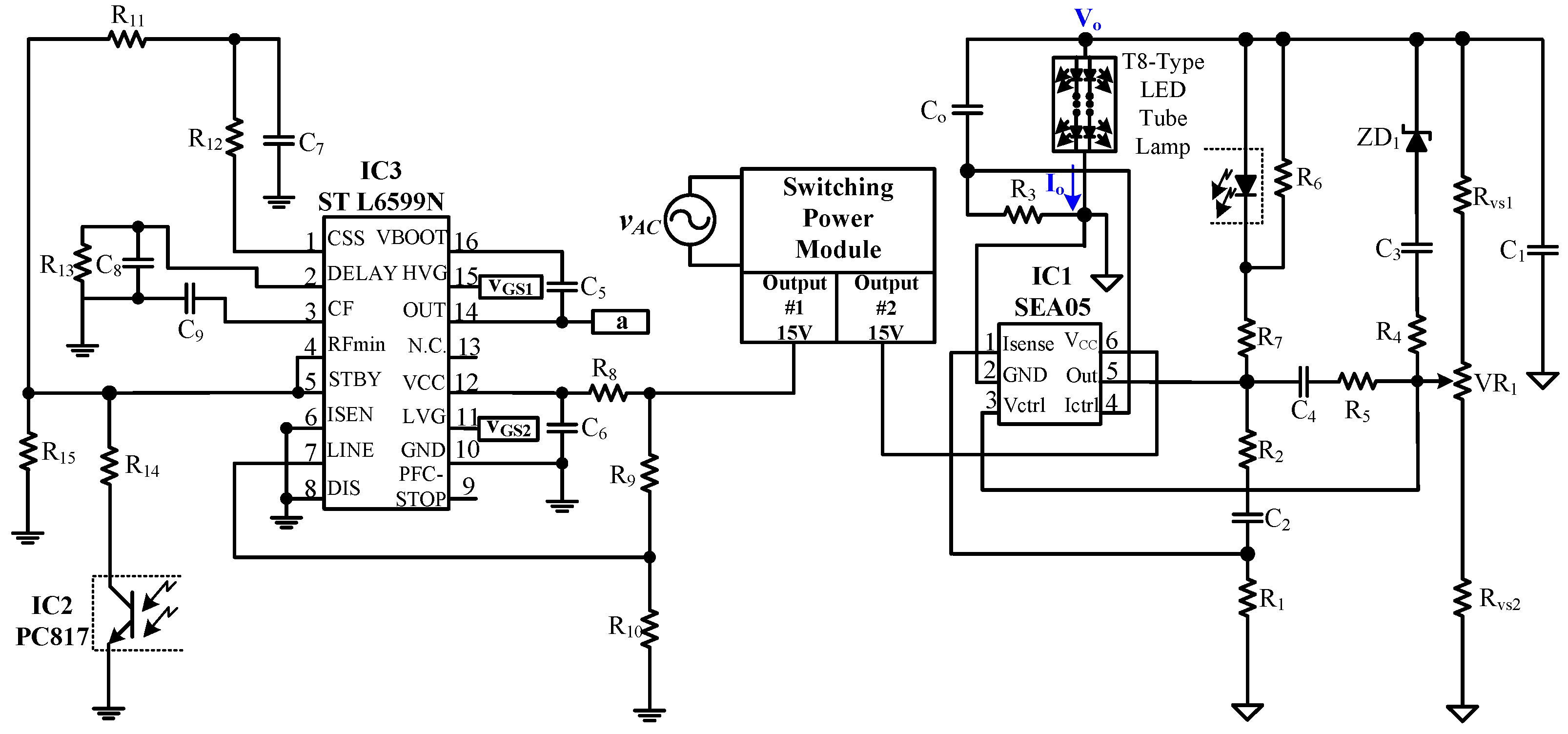

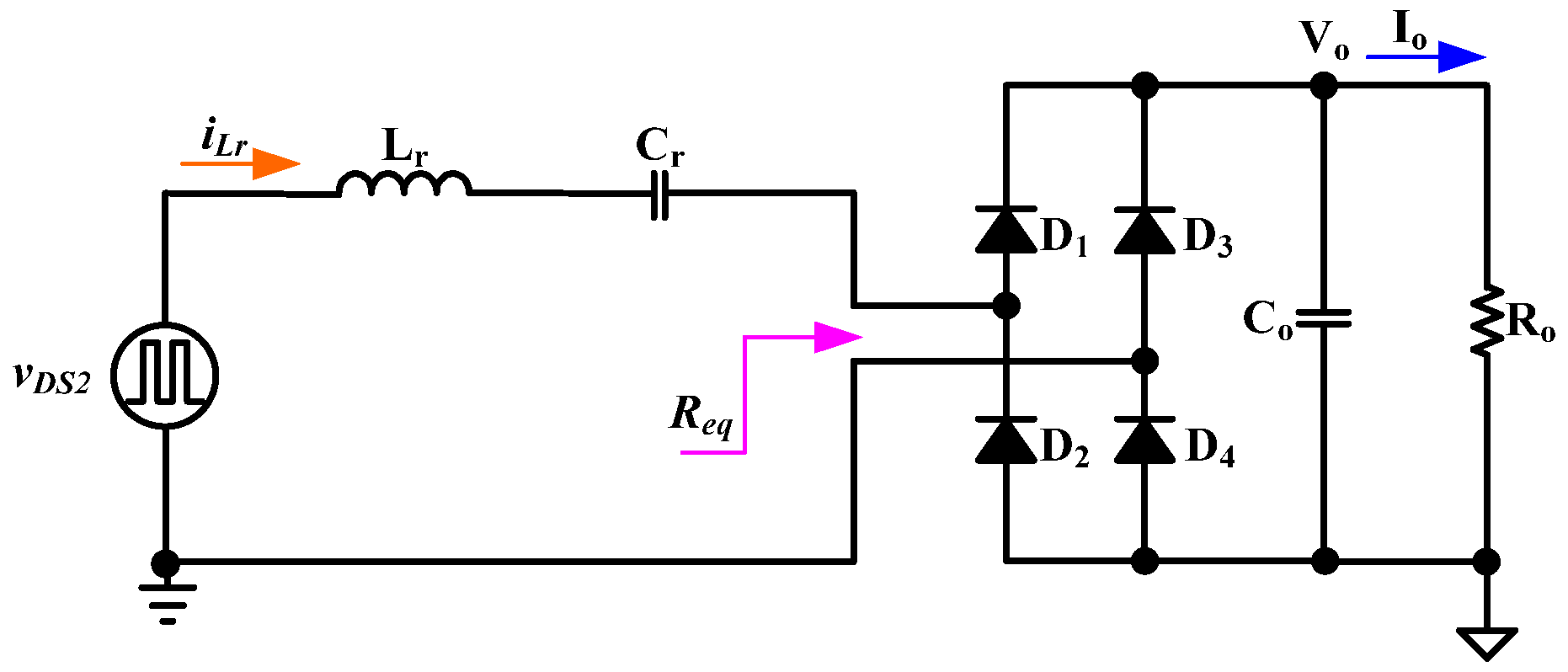

2. The Description and Analysis of the Presented LED Tube Lamp Driver

- (a)

- Since the switching frequencies of the two switches (S1 and S2) are much higher than that of the utility-line voltage vAC, the sinusoidal utility-line voltage can be considered as a constant value for each high-frequency switching period.

- (b)

- Power switches are complementarily operated, and their intrinsic diodes and inherent drain-source capacitors are considered.

- (c)

- The conducting voltage drops of all diodes (including Db1, Db2, Db3, Db4, D1, D2, D3 and D4) are neglected.

- (d)

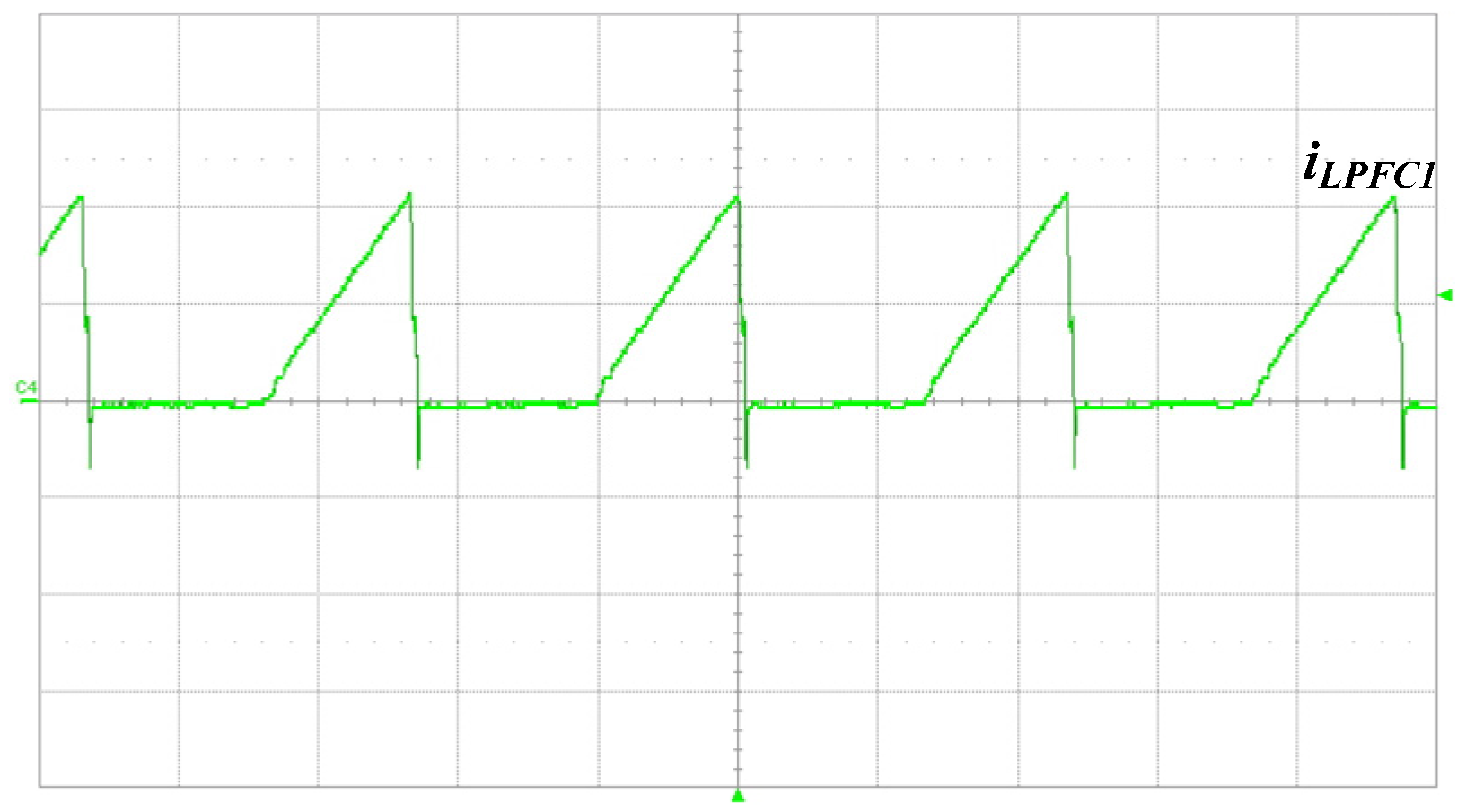

- Two coupled inductors (LPFC1 and LPFC2) are designed to be operated in discontinuous-conduction mode (DCM) for naturally achieving power-factor correction (PFC).

3. Design Equations of Key Components in the Presented LED Tube Lamp Driver

3.1. Design of Coupled Inductors LPFC1 and LPFC2

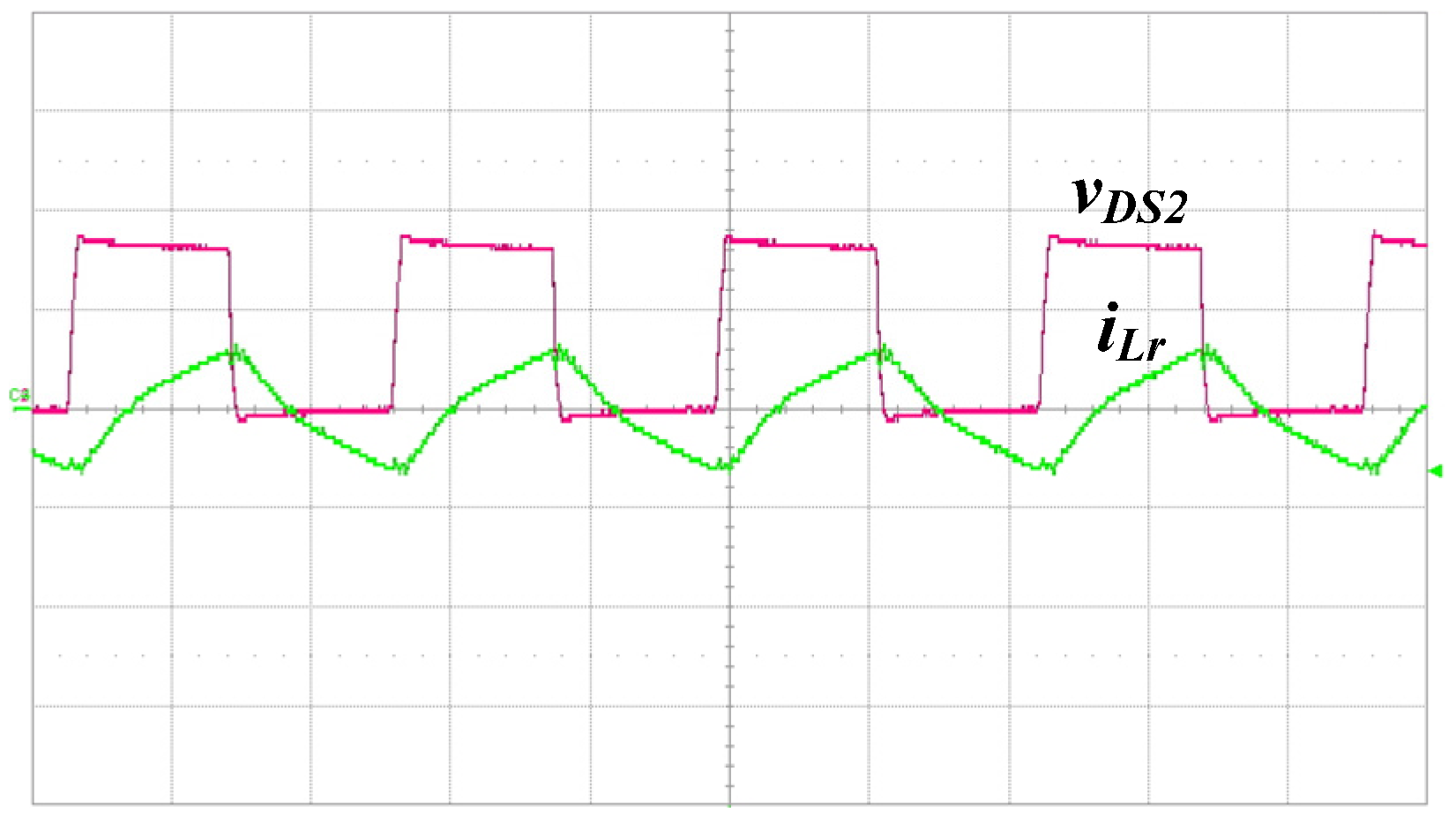

3.2. Design of Series Resonant Tank Lr and Cr

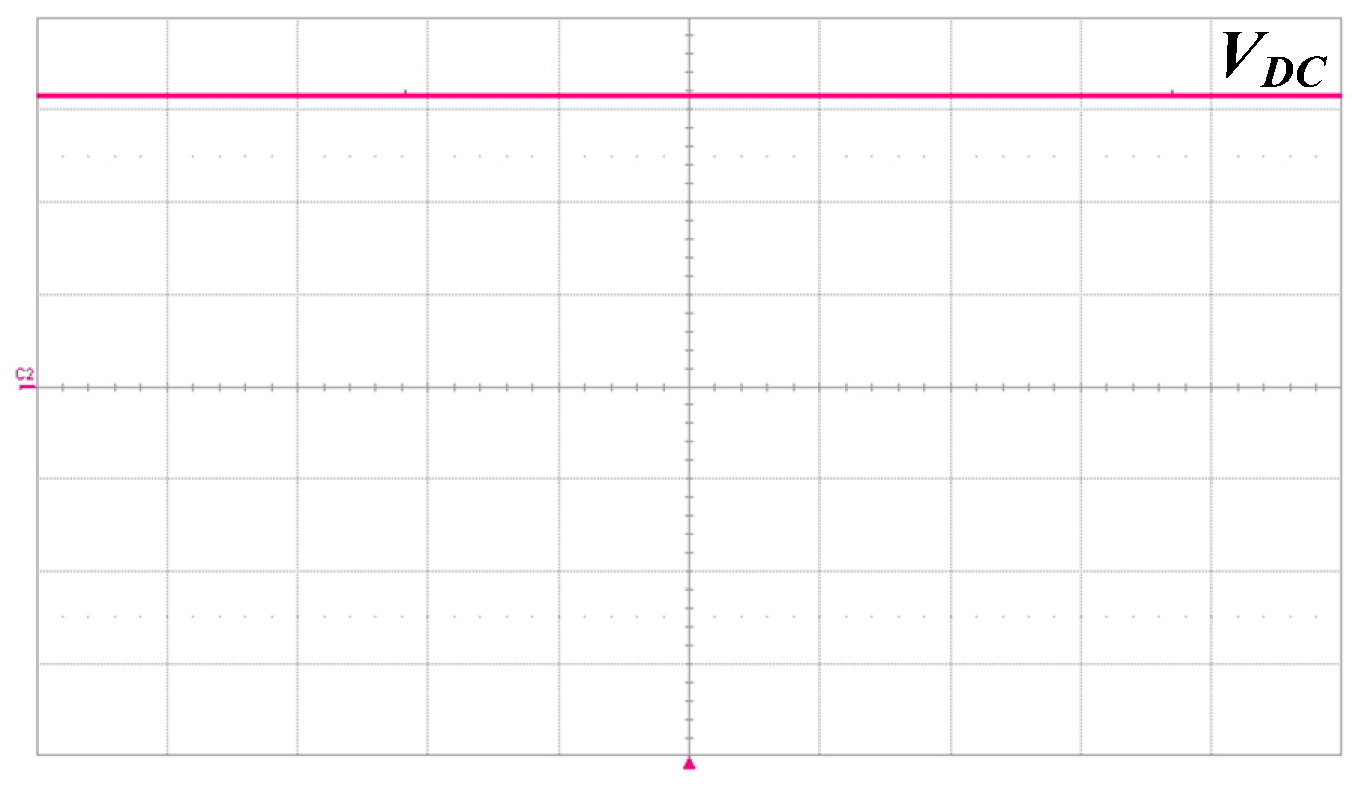

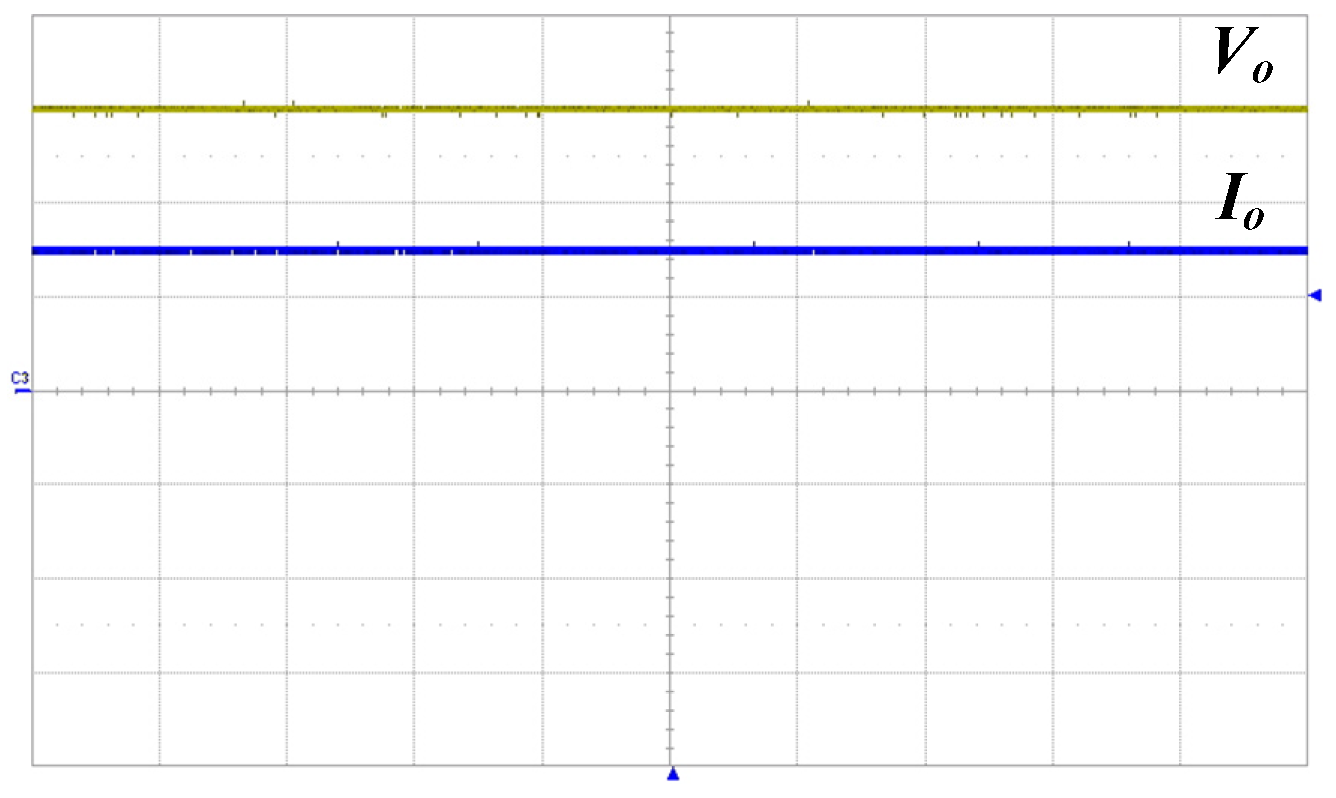

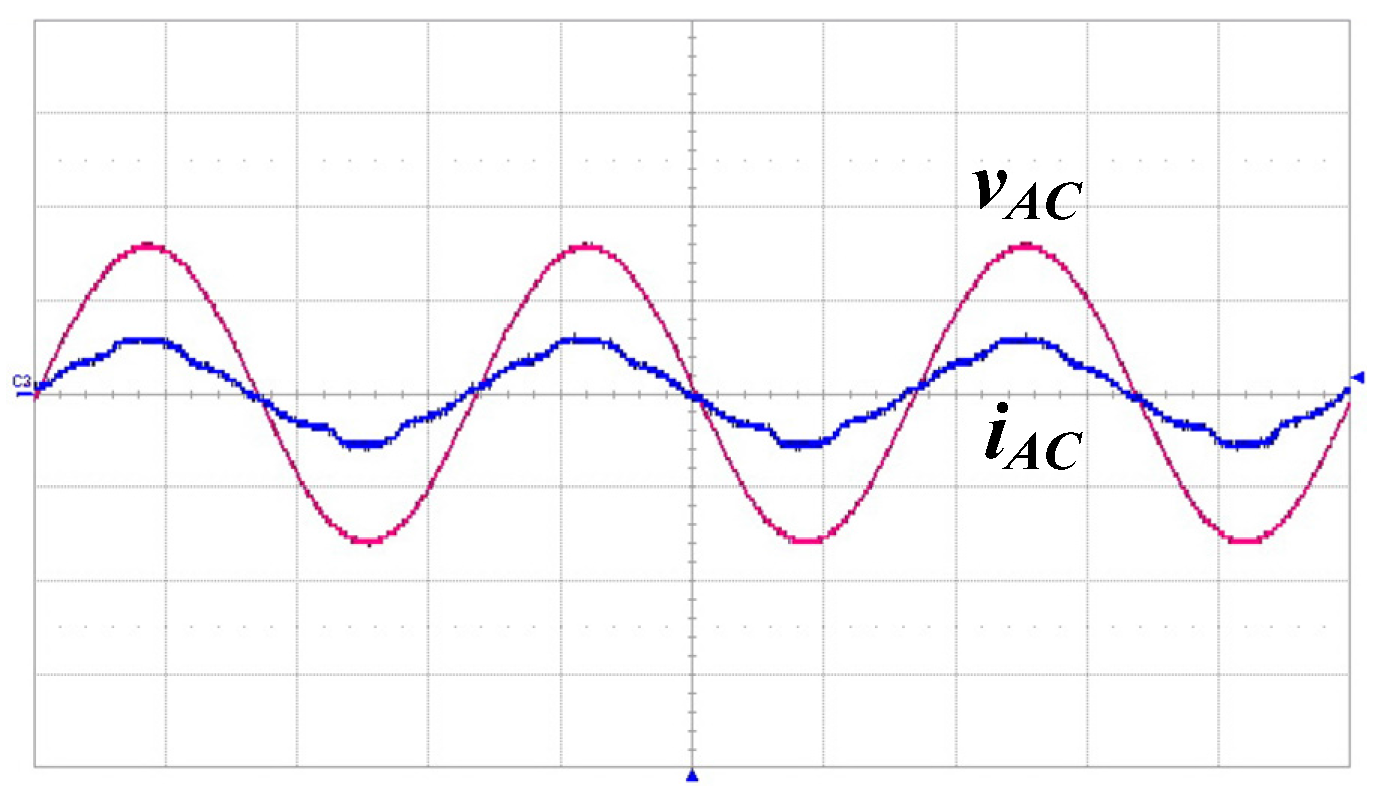

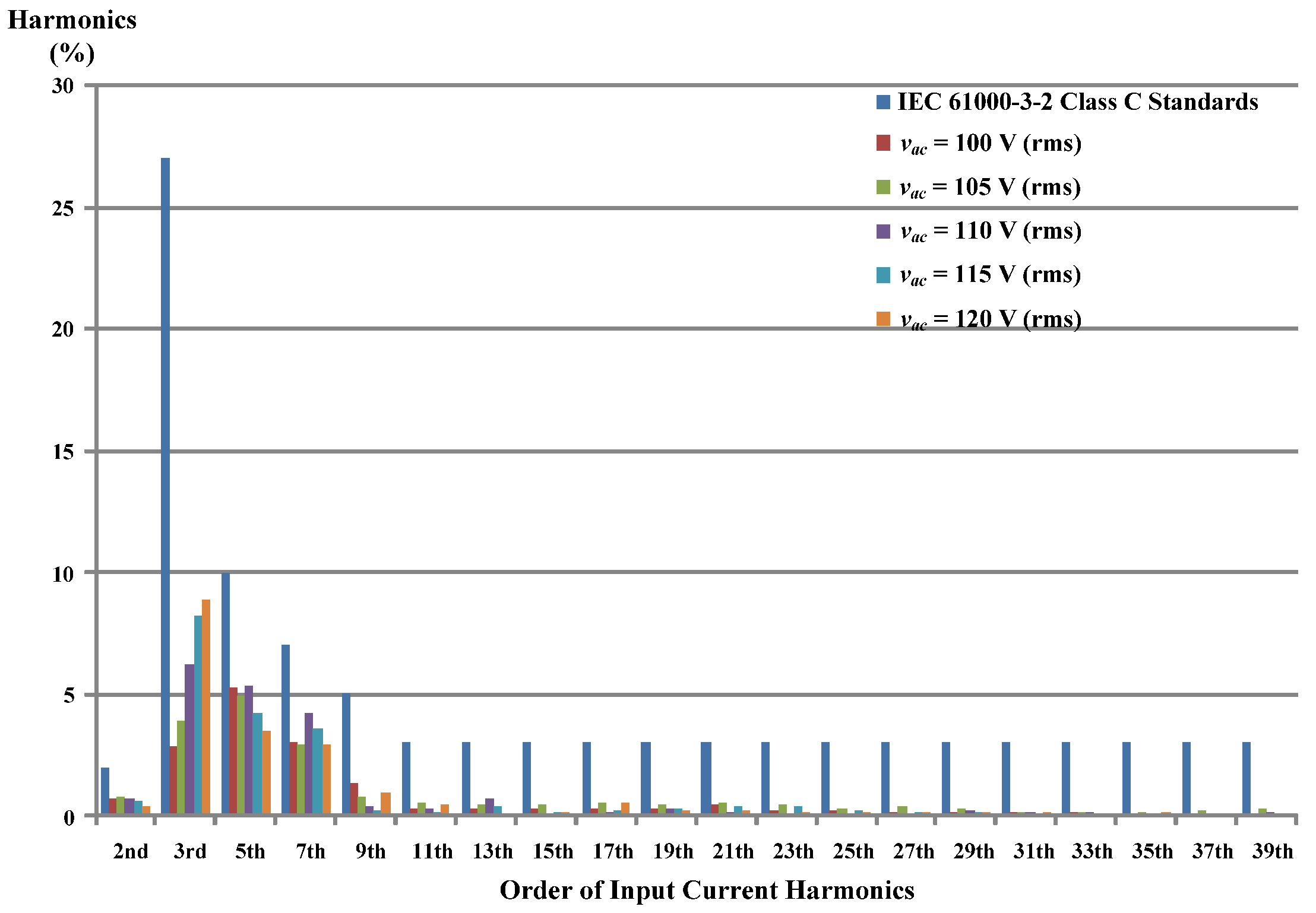

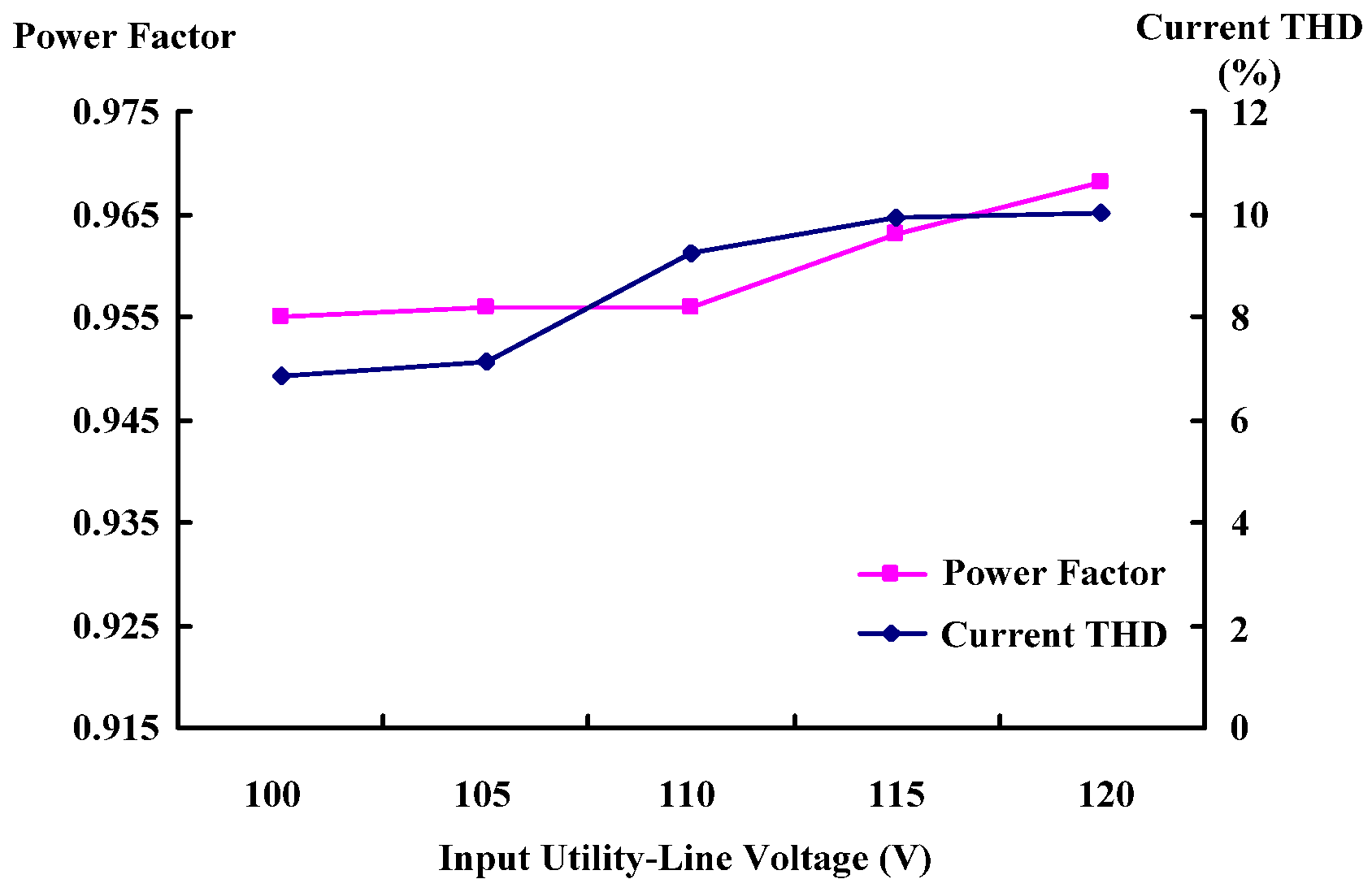

4. Experimental Results

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bender, V.C.; Marchesan, T.B.; Alonso, J.M. Solid-state lighting: A concise review of the state of the art on LED and OLED modeling. IEEE Ind. Electron. Mag. 2015, 9, 6–16. [Google Scholar] [CrossRef]

- Brañas, C.; Azcondo, F.J.; Alonso, J.M. Solid-state lighting: A system review. IEEE Ind. Electron. Mag. 2013, 7, 6–14. [Google Scholar] [CrossRef]

- Liang, T.J.; Tseng, W.J.; Chen, J.F.; Wu, J.P. A novel line frequency multistage conduction LED driver with high power factor. IEEE Trans. Power Electron. 2015, 30, 5103–5115. [Google Scholar] [CrossRef]

- Moo, C.S.; Chen, Y.J.; Yang, W.C. An efficient driver for dimmable LED lighting. IEEE Trans. Power Electron. 2012, 27, 4613–4618. [Google Scholar] [CrossRef]

- Wang, Y.; Guan, Y.; Ren, K.; Xu, D. A single-stage LED driver based on BCM boost circuit and converter for street lighting system. IEEE Trans. Ind. Electron. 2015, 62, 5446–5457. [Google Scholar] [CrossRef]

- Kwak, S.S. Pulse-driven LED circuit with transformer-based current balance technique. Int. J. Electron. 2014, 101, 1683–1693. [Google Scholar] [CrossRef]

- Hsia, S.C.; Sheu, M.H.; Lai, S.Y. Chip implementation of high-efficient light-emitting diode dimming driver for high-power light-emitting diode lighting system. IET Power Electron. 2015, 8, 1043–1051. [Google Scholar] [CrossRef]

- Choi, W.Y.; Yang, M.K. High-efficiency isolated SEPIC converter with reduced conduction losses for LED displays. Int. J. Electron. 2014, 101, 1495–1502. [Google Scholar] [CrossRef]

- Chen, Y.S.; Liang, T.J.; Chen, K.H.; Juang, J.N. Study and implementation of high frequency pulse LED driver with self-oscillating circuit. In Proceedings of the IEEE International Symposium on Circuit and Systems (ISCAS), Rio de Janeiro, Brazil, 15–18 May 2011; pp. 498–501.

- Wang, Y.; Guan, Y.; Zhang, X.; Xu, D. Single-stage LED driver with low bus voltage. Eletron. Lett. 2013, 49, 455–456. [Google Scholar] [CrossRef]

- Hui, S.Y.R.; Li, S.N.; Tao, X.H.; Chen, W.; Ng, W.M. A novel passive off-line light-emitting diode (LED) driver with long lifetime. IEEE Trans. Power Electron. 2010, 25, 2665–2672. [Google Scholar] [CrossRef]

- Qu, X.; Wong, S.C.; Tse, C.K. Resonance-assisted buck converter for offline driving of power LED replacement lamps. IEEE Trans. Power Electron. 2011, 26, 532–540. [Google Scholar]

- Wang, Y.; Guan, Y.; Huang, J.; Wang, W.; Xu, D. A single-stage LED driver based on interleaved buck-boost circuit and LLC resonant converter. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 732–741. [Google Scholar] [CrossRef]

- Chang, Y.N.; Kuo, C.M.; Cheng, H.L.; Lee, C.R. Design of dimmable LED lighting driving circuit for battery power source. In Proceedings of the 10th IEEE International Conference on Power Electronics and Drive Systems (PEDS), Kitakyushu, Japan, 22–25 April 2013; pp. 1168–1172.

- Lin, C.C.; Yang, L.S.; Chang, E.C. Study of a DC-DC converter for solar LED street lighting. In Proceedings of the IEEE International Symposium on Next-Generation Electronics (ISNE), Kaohsiung, Taiwan, 25–26 February 2013; pp. 461–464.

- Chen, N.; Chung, H.S.H. A driving technology for retrofit LED lamp for fluorescent lighting fixtures with electronic ballasts. IEEE Trans. Power Electron. 2011, 26, 588–601. [Google Scholar] [CrossRef]

- Cheng, C.A.; Chang, E.C.; Tseng, C.S.; Chung, T.Y. A novel single-stage LED driver with coupled inductors and interleaved PFC. In Proceedings of the International Symposium on Computer, Consumer and Control, Taichung, Taiwan, 10–12 June 2014; pp. 1287–1290.

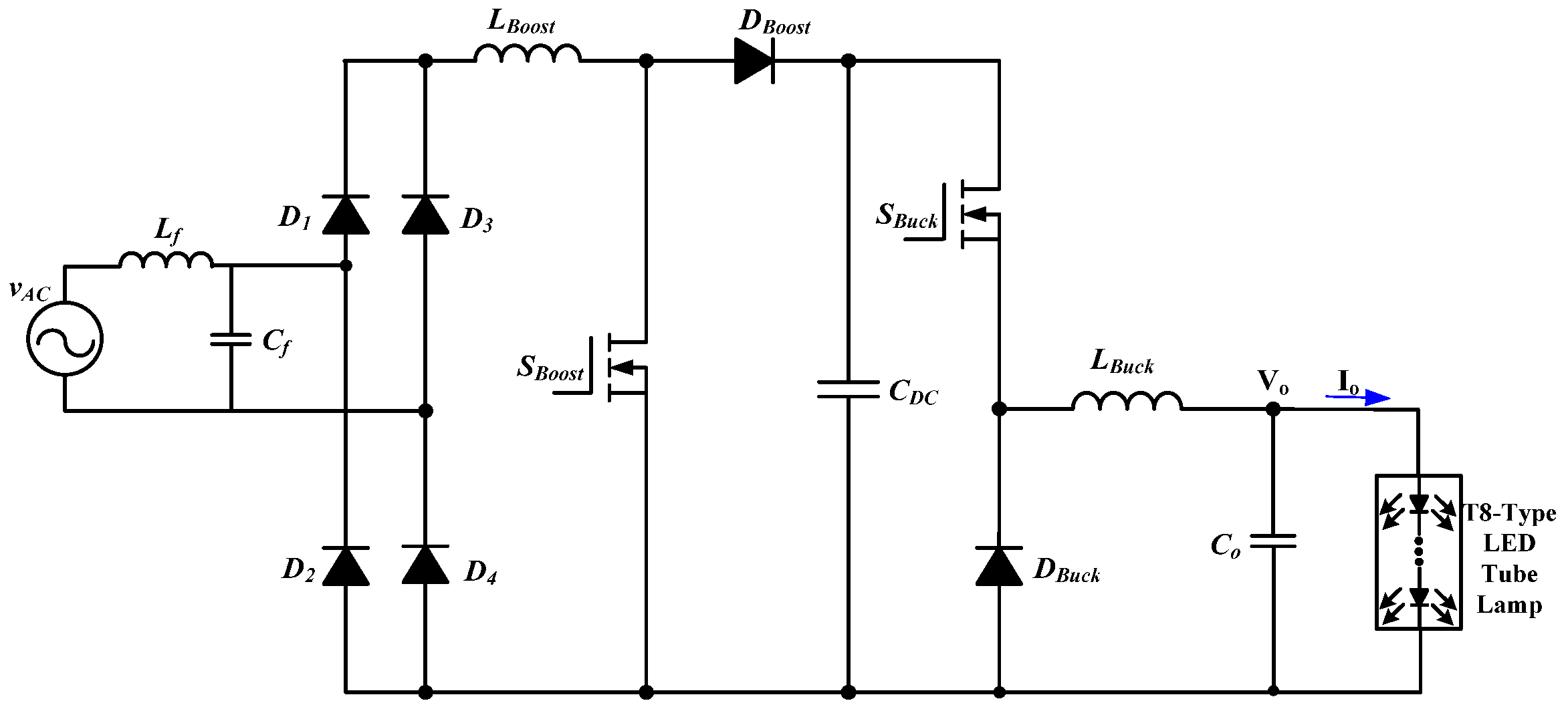

- Texas Instruments. 19 W, Single-Stage AC/DC LED Driver for T8/T10 Fluorescent Lamp Replacement; Texas Instruments: Dallas, TX, USA, 2011; pp. 1–21. [Google Scholar]

- Fairchild Semiconductor. User Guide for FEBFL7701 L34U018A Evaluation Board Universal Input 18.3 W LED Driver; Fairchild Semiconductor: Sunnyvale, CA, USA, 2012; pp. 1–24. [Google Scholar]

- Catalog of Lamps. China Electric MFG. Corporation. Available online: http://ebook.chinaelectric.com.tw/hosts/2/7/files/2712651479460151/book.php (accessed on 9 August2016).

- Catalog of LED Lamps. Everlight Electronics Co., Ltd. Available online: http://www.everlightlighting.com/file/image/files/ELL_2015_Catalogue_dealer.pdf (accessed on 18 May 2015).

- Cheng, C.A.; Cheng, H.L.; Chung, T.Y. A novel single-stage high-power-factor LED street-lighting driver with coupled inductors. IEEE Trans. Ind. Appl. 2014, 50, 3037–3045. [Google Scholar] [CrossRef]

- Steigerwald, R.L. A comparison of half-bridge resonant converter topology. IEEE Trans. Power Electron. 1988, 3, 174–182. [Google Scholar] [CrossRef]

- Kazimierczuk, M.K.; Czarkowski, D. Resonant Power Converters; Wiley: New York, NY, USA, 1995. [Google Scholar]

| Component | Value |

|---|---|

| Filter Inductor (Lf) | 2 mH |

| Filter Capacitor (Cf) | 0.68 μF/250 V |

| Diodes (Db1, Db2) | MUR460 |

| Power Switches (S1, S2) | IRF840 |

| Coupled Inductors (LPFC1, LPFC2) | 1.34 mH |

| DC (direct current)-Linked Capacitors (CDC1, CDC2) | 100 μF/450 V |

| Resonant Inductor (Lr) | 1.68 mH |

| Resonant Capacitor (Cr) | 82 nF |

| Diodes (D1, D2, D3, D4) | MUR460 |

| Output Capacitor (Co) | 200 μF/63 V |

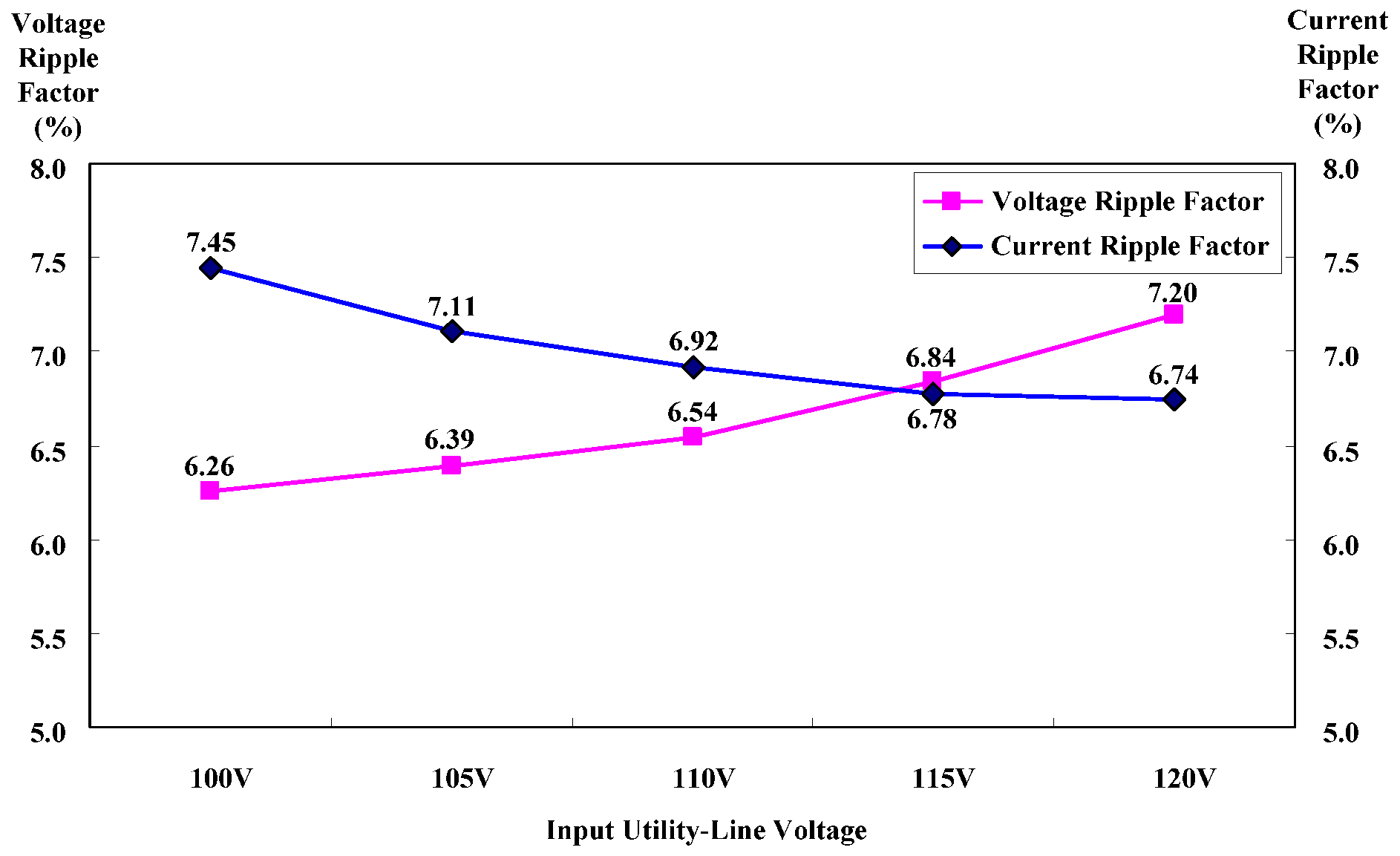

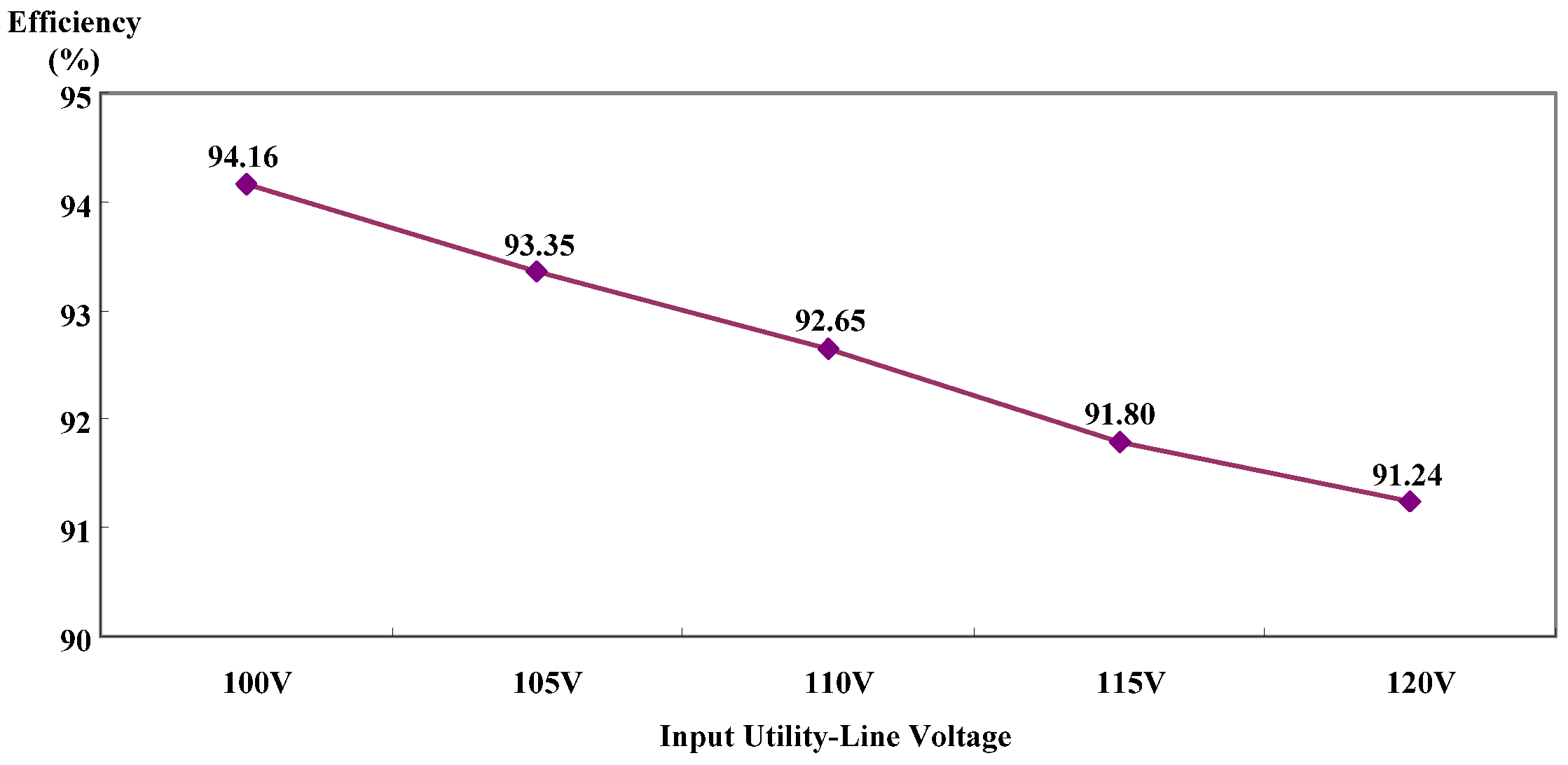

| Input Voltage | 100 V | 105 V | 110 V | 115 V | 120 V |

|---|---|---|---|---|---|

| Parameters | |||||

| Output Voltage (mean) | 60.07 V | 60.1 V | 60.08 V | 60.11 V | 60.16 V |

| Output Voltage (pk–pk) | 3.76 V | 3.84 V | 3.93 V | 4.11 V | 4.33 V |

| Output Current (mean) | 0.321 A | 0.311 A | 0.308 A | 0.304 A | 0.301 A |

| Output Current (pk–pk) | 23.9 mA | 22.1 mA | 21.3 mA | 20.6 mA | 20.3 mA |

| Item | Existing LED (Direct Current) Tube Lamp Driver in [18] | Existing LED Tube Lamp Driver in [19] | Proposed LED Tube Lamp Driver |

|---|---|---|---|

| Circuit Topology | Flyback-type AC-DC (alternating current-direct current) Converter | Buck-type AC-DC Converter | Integration of a Dual Buck-Boost Converter with coupled inductors and a Half-Bridge Series Resonant Converter cascaded with a bridge rectifier |

| Input Utility-Line Voltages | 90~264 V | 90~264 V | 100~120 V |

| Rated Output Power (Rated Output Voltage/Current) | 19 W (42 V/0.45 A) | 18.3 W (39 V/0.47 A) | 18 W (60 V/0.3 A) |

| Required Power Switch | 1 (Without Soft-Switching) | 1 (Without Soft-Switching) | 2 (With Soft-Switching) |

| Measured Maximum Power Factor | 0.99 @ 110 V | 0.96 @ 110 V | 0.97 @ 120 V |

| Measured Minimum Input Current THD (total-harmonic distortion) | 9% @ 180 V | 21.54% @ 110 V | 6.86% @ 100 V |

| Measured Maximum Efficiency | 87.8% @ 180 V | 88.56% @ 180 V | 94.16% @ 100 V |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, C.-A.; Chang, E.-C.; Tseng, C.-H.; Chung, T.-Y. A Single-Stage LED Tube Lamp Driver with Power-Factor Corrections and Soft Switching for Energy-Saving Indoor Lighting Applications. Appl. Sci. 2017, 7, 115. https://doi.org/10.3390/app7020115

Cheng C-A, Chang E-C, Tseng C-H, Chung T-Y. A Single-Stage LED Tube Lamp Driver with Power-Factor Corrections and Soft Switching for Energy-Saving Indoor Lighting Applications. Applied Sciences. 2017; 7(2):115. https://doi.org/10.3390/app7020115

Chicago/Turabian StyleCheng, Chun-An, En-Chih Chang, Ching-Hsien Tseng, and Tsung-Yuan Chung. 2017. "A Single-Stage LED Tube Lamp Driver with Power-Factor Corrections and Soft Switching for Energy-Saving Indoor Lighting Applications" Applied Sciences 7, no. 2: 115. https://doi.org/10.3390/app7020115

APA StyleCheng, C.-A., Chang, E.-C., Tseng, C.-H., & Chung, T.-Y. (2017). A Single-Stage LED Tube Lamp Driver with Power-Factor Corrections and Soft Switching for Energy-Saving Indoor Lighting Applications. Applied Sciences, 7(2), 115. https://doi.org/10.3390/app7020115