Off-Line Optimization Based Active Control of Torsional Oscillation for Electric Vehicle Drivetrain

Abstract

1. Introduction

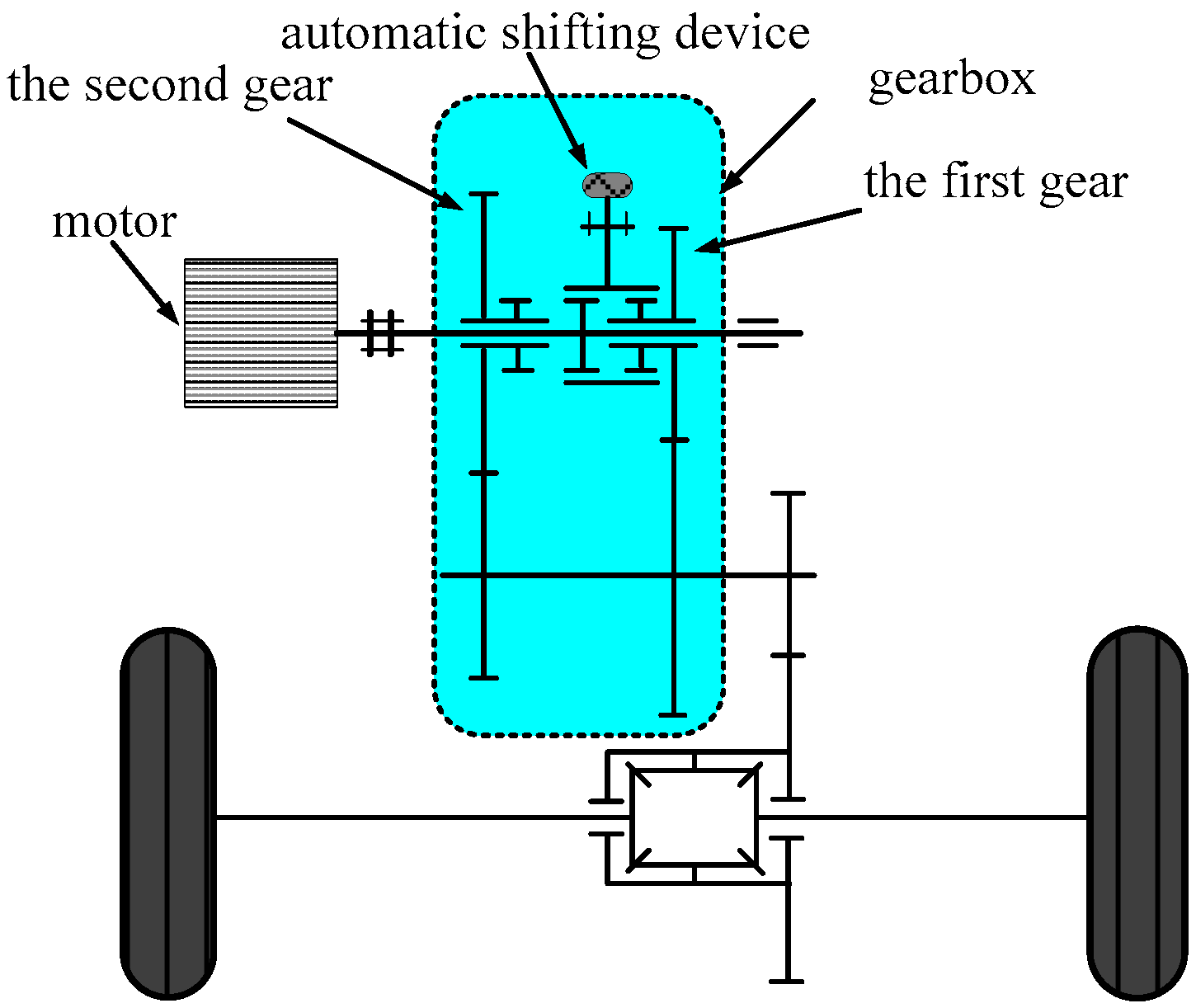

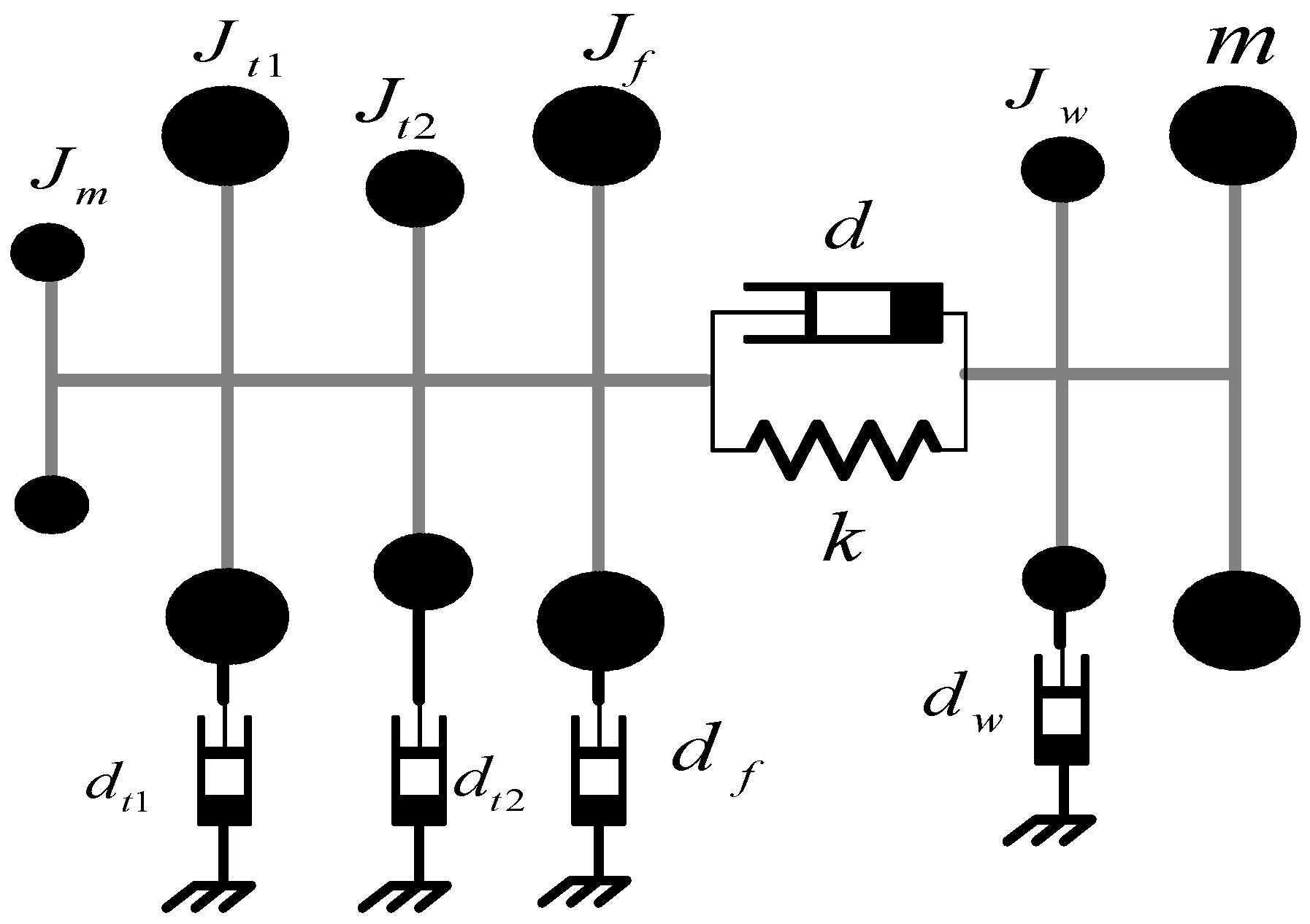

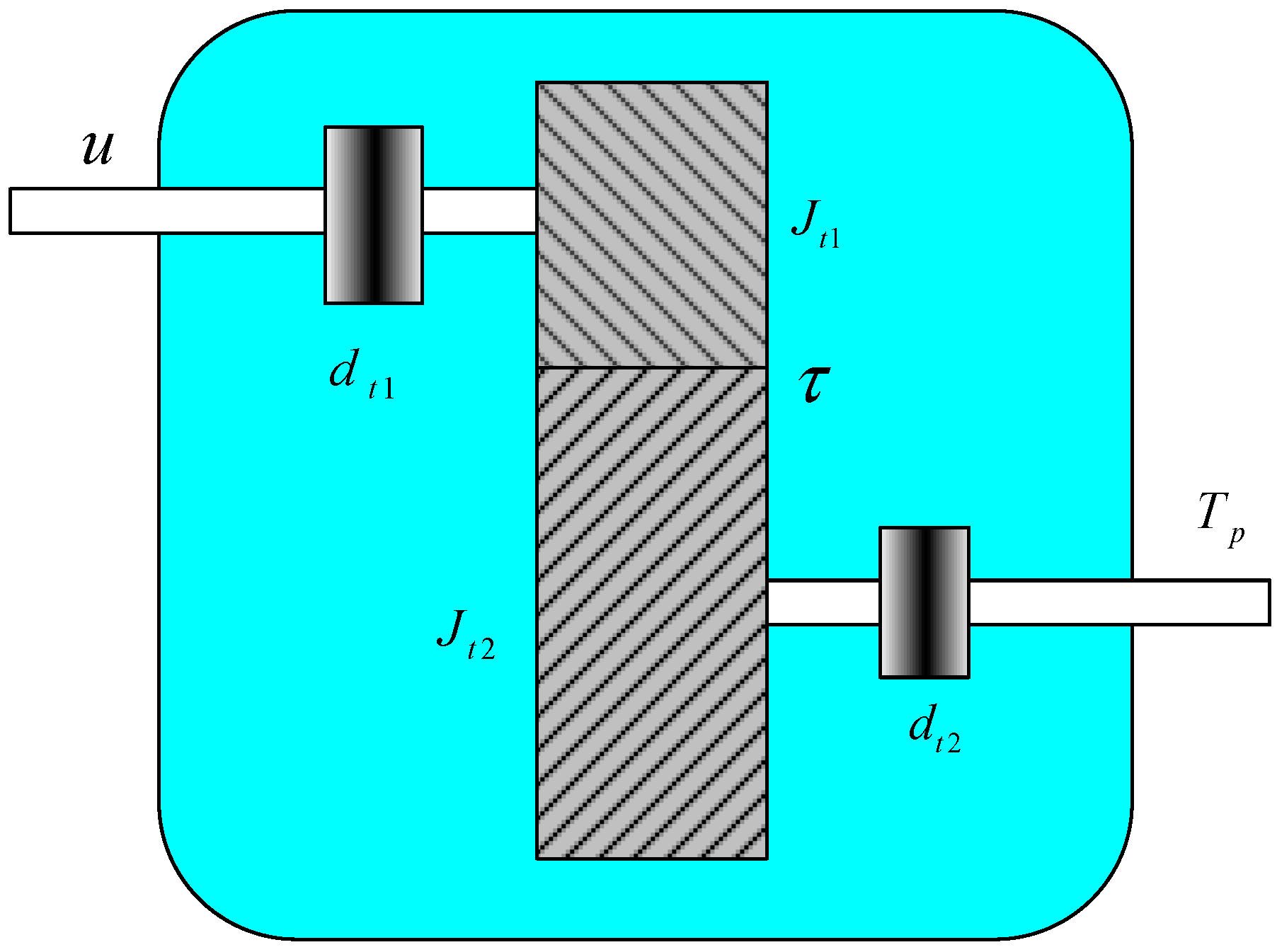

2. Drivetrain Modelling

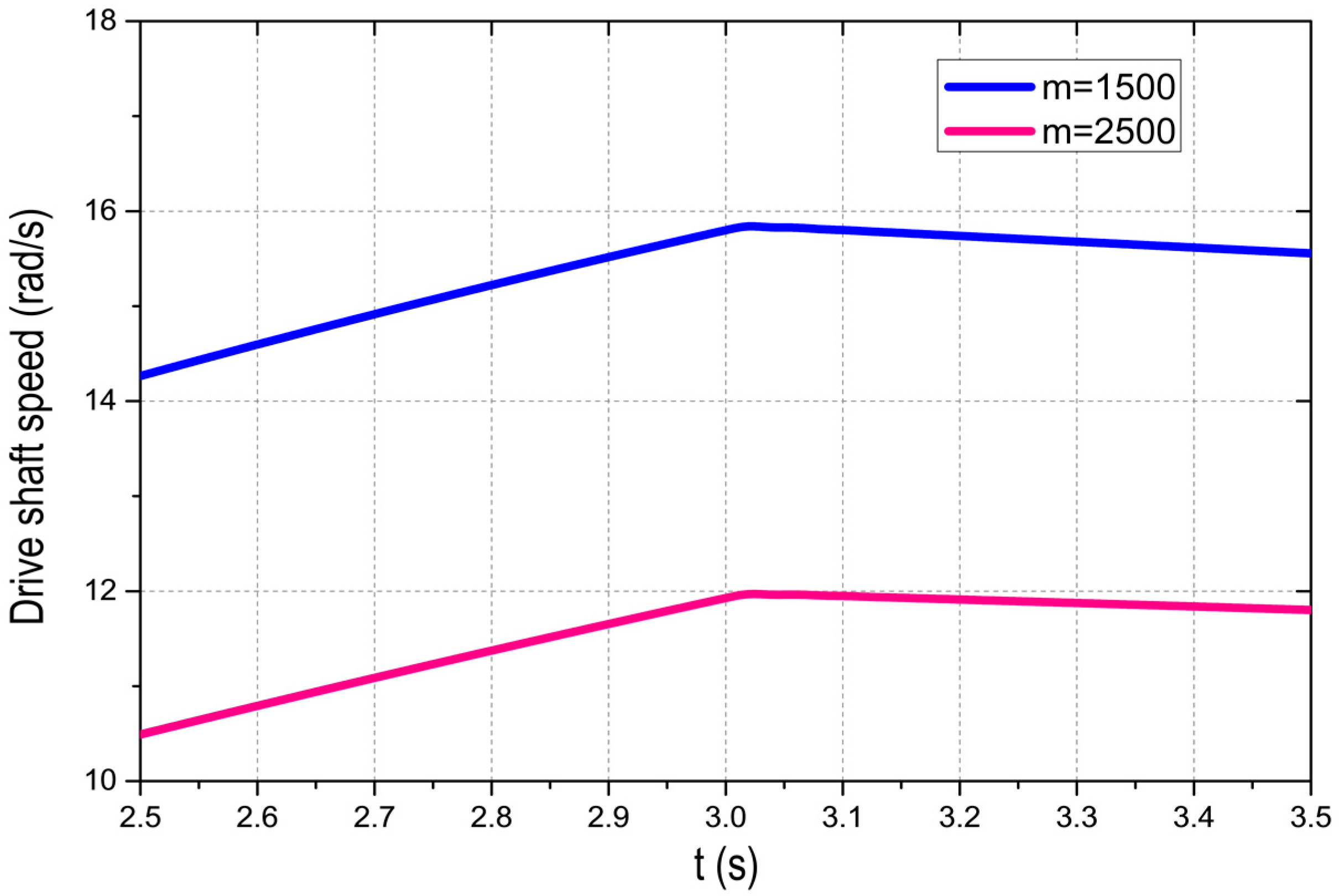

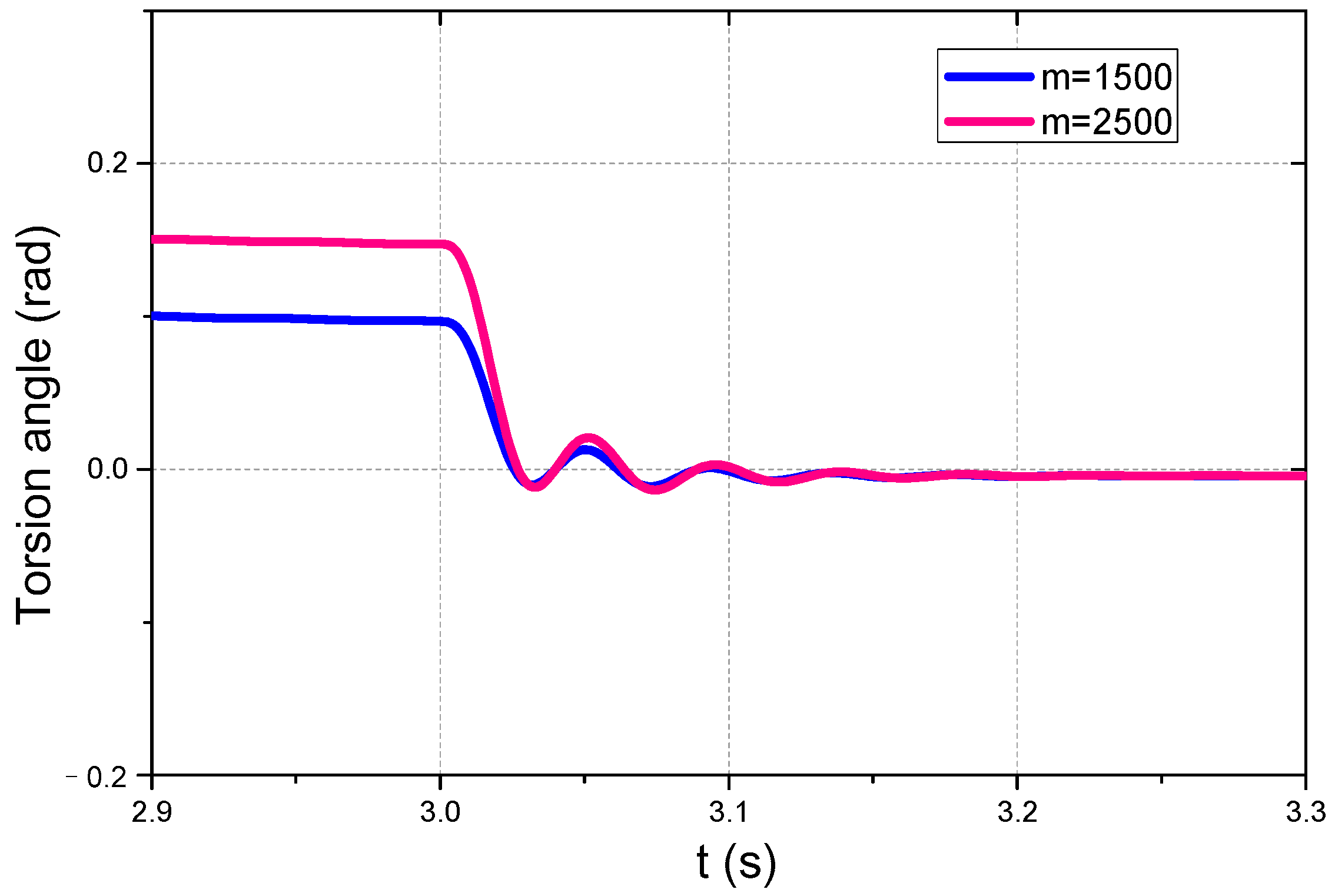

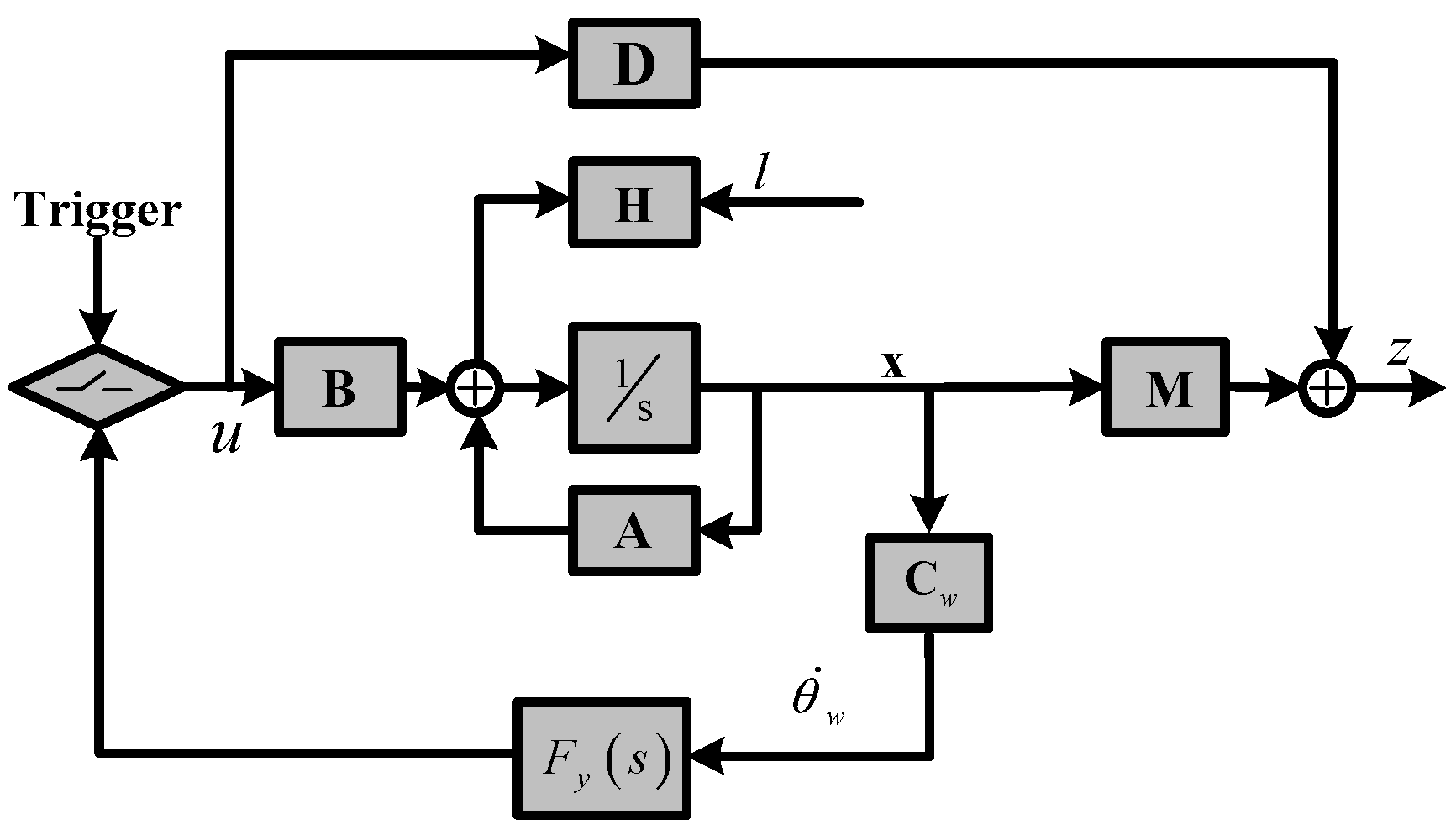

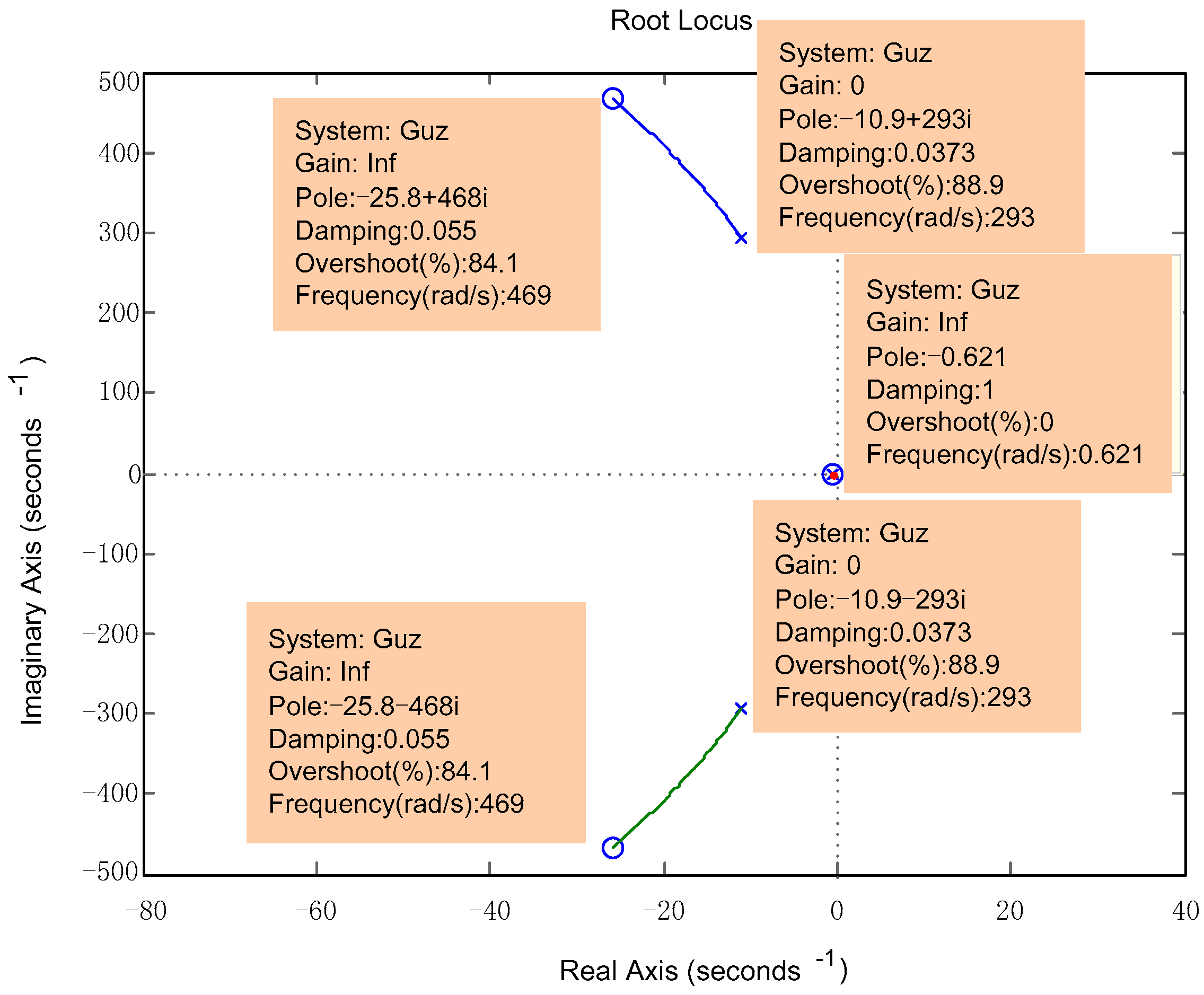

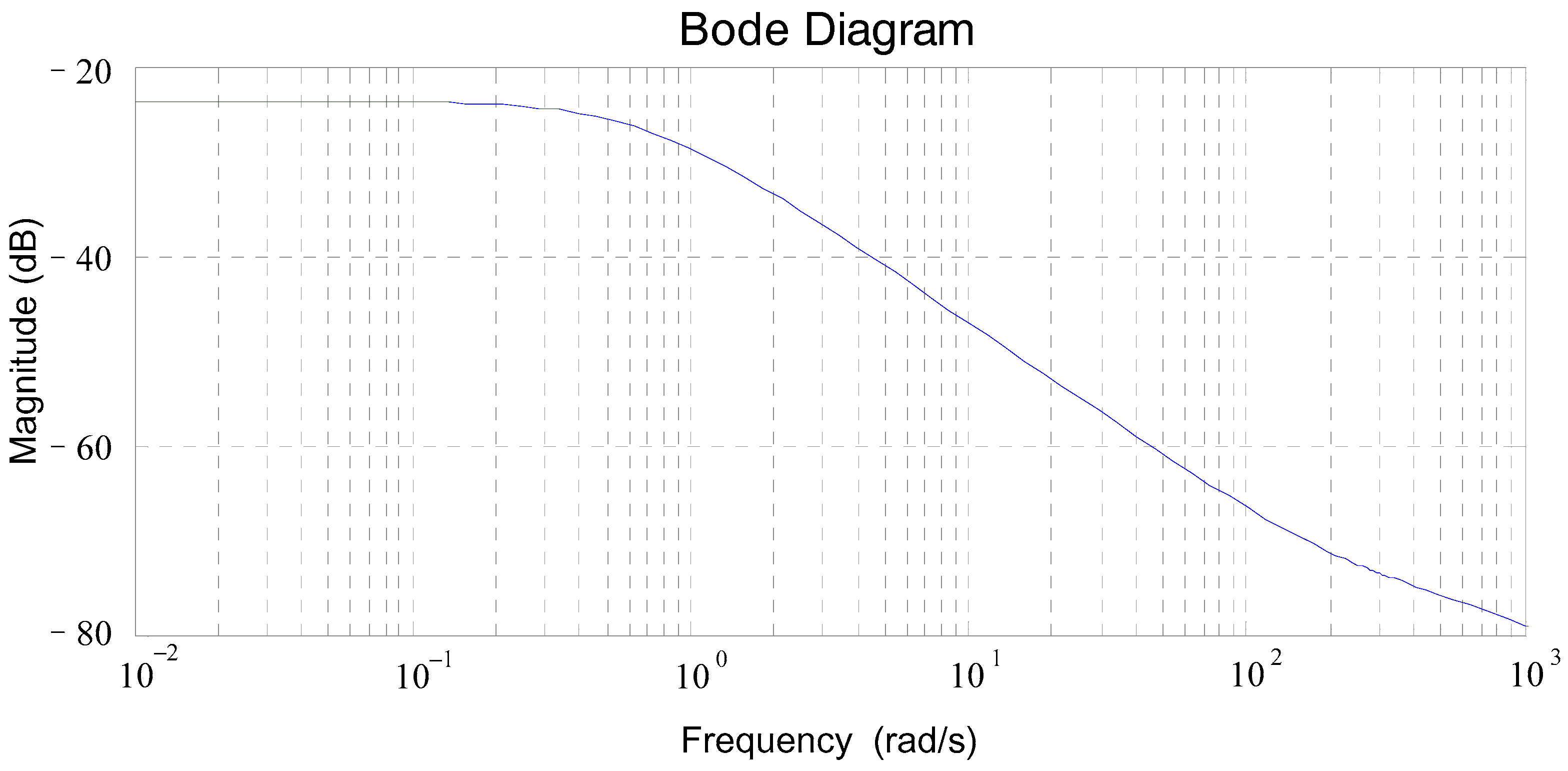

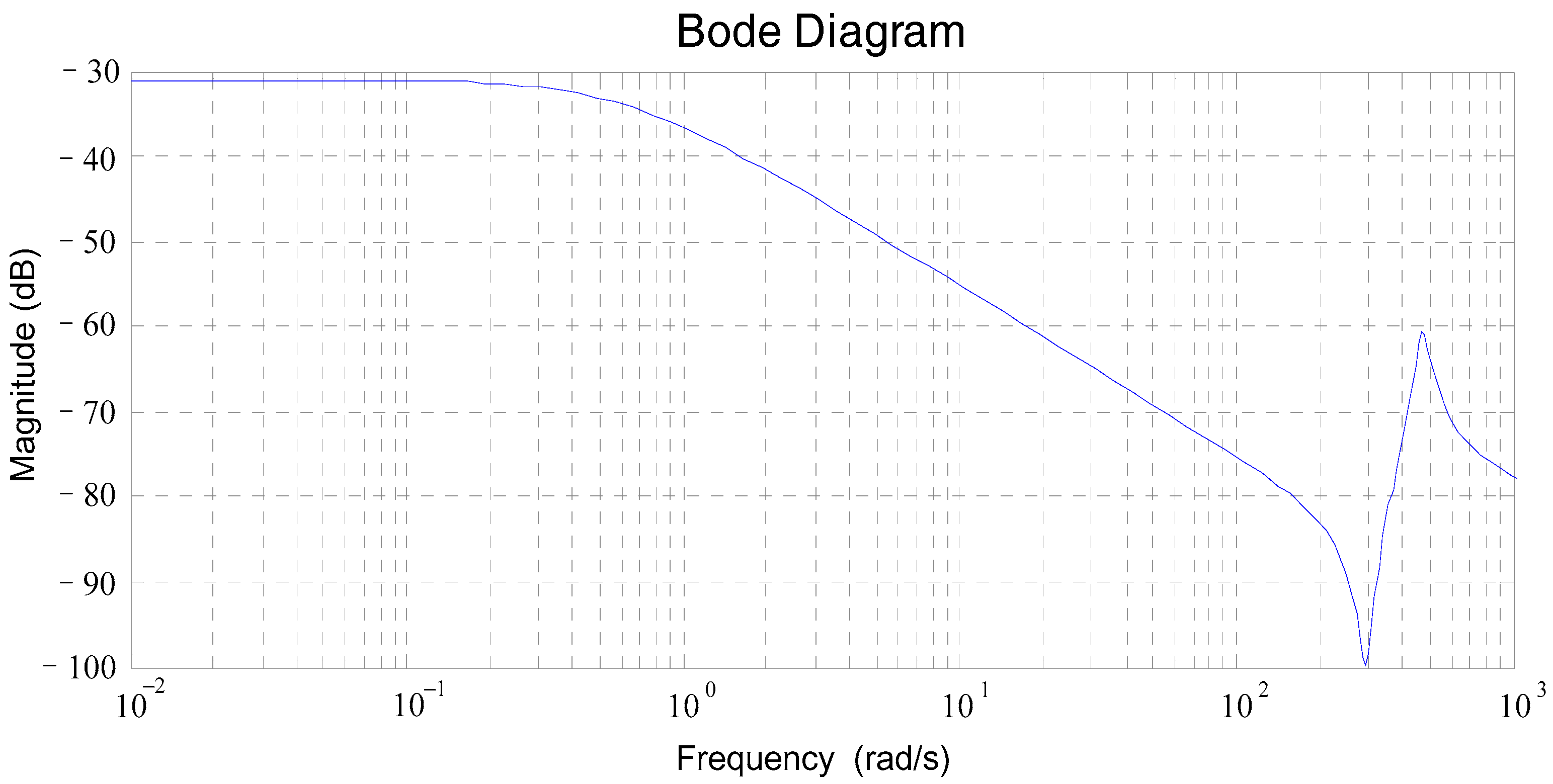

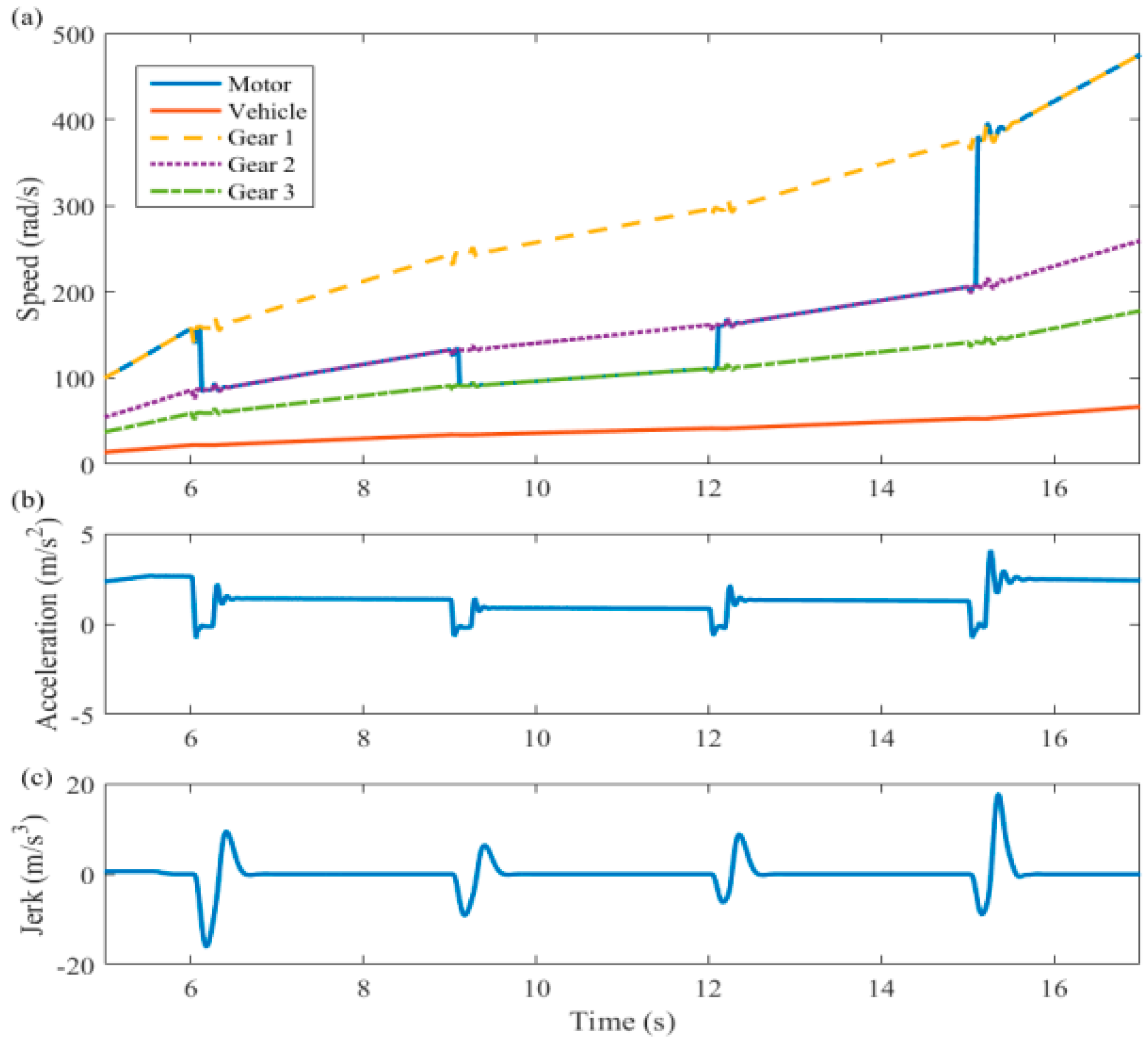

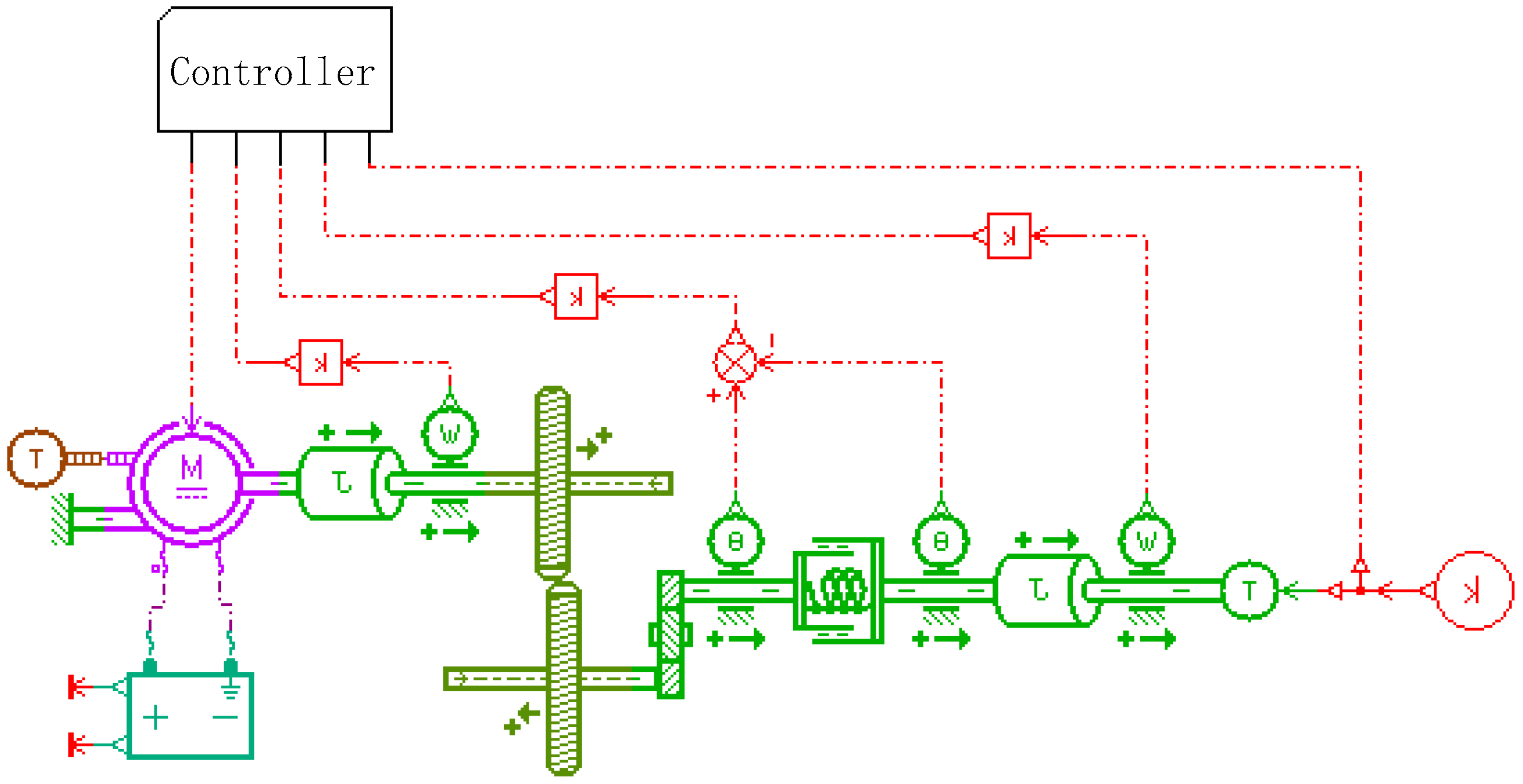

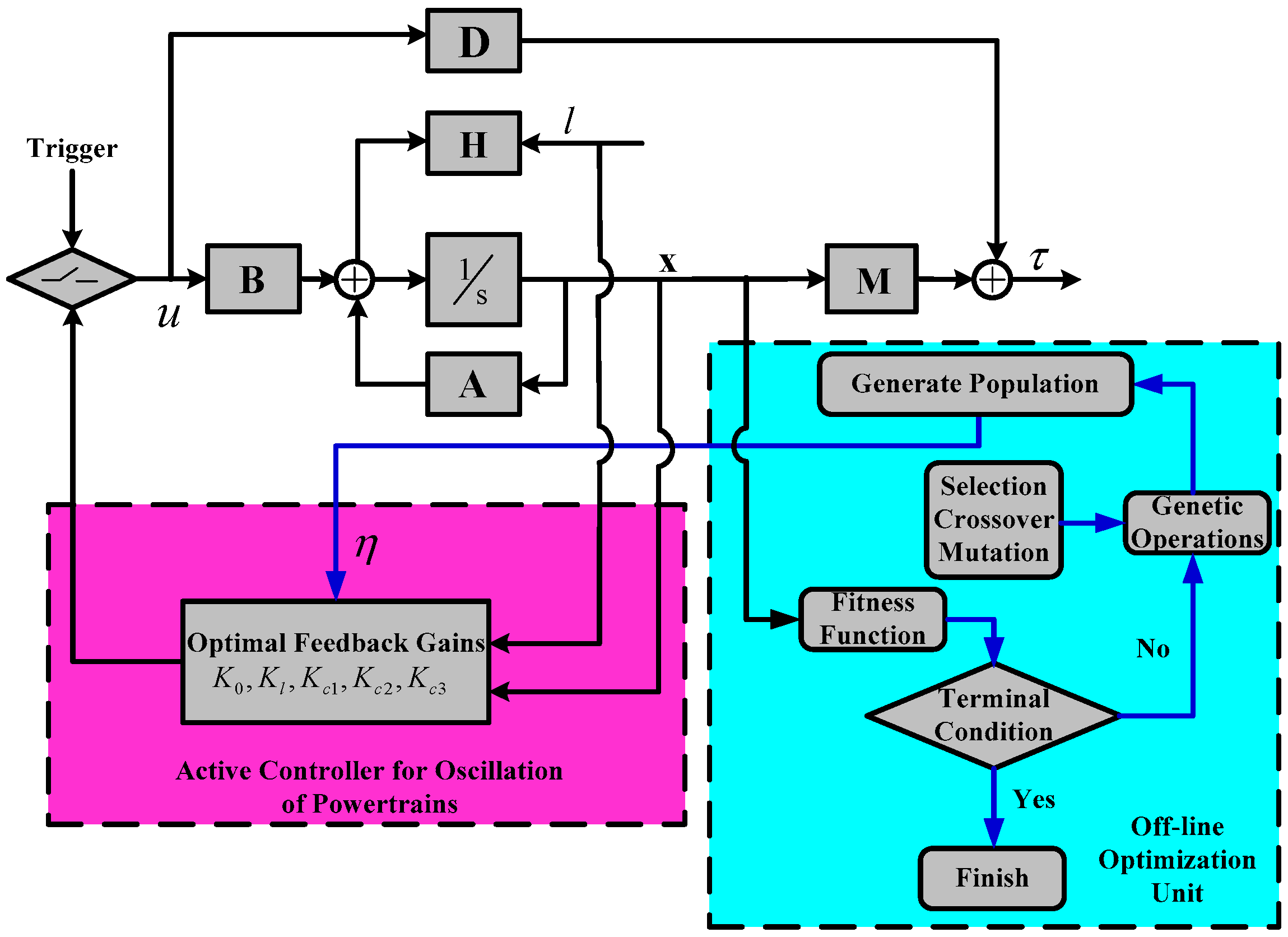

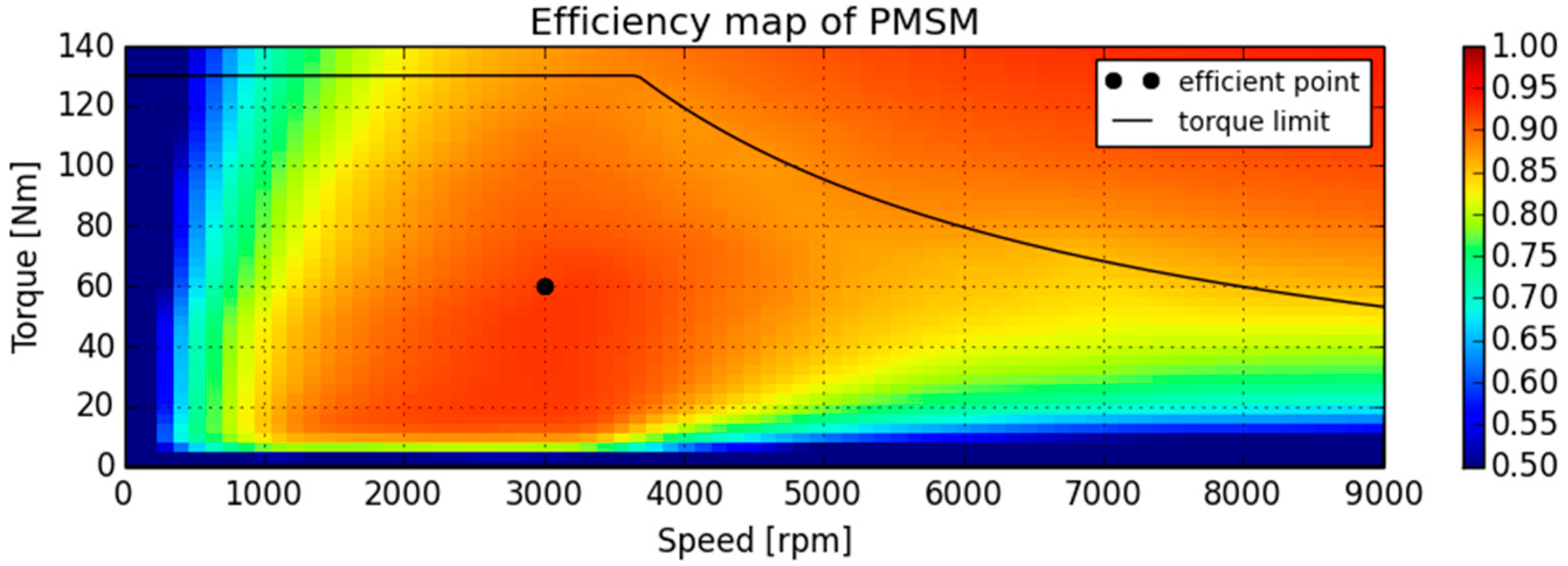

3. Active Control System

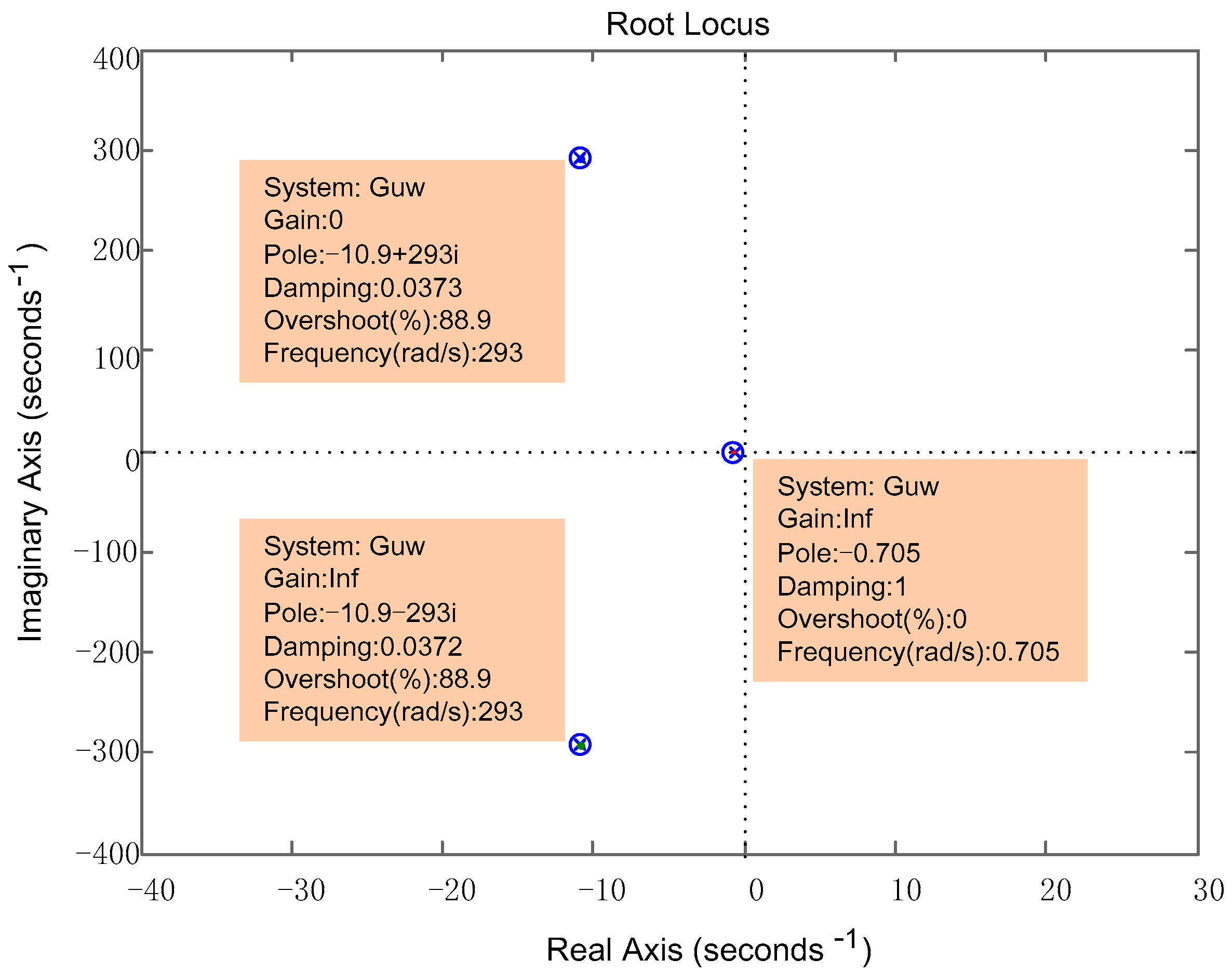

3.1. Controller Design

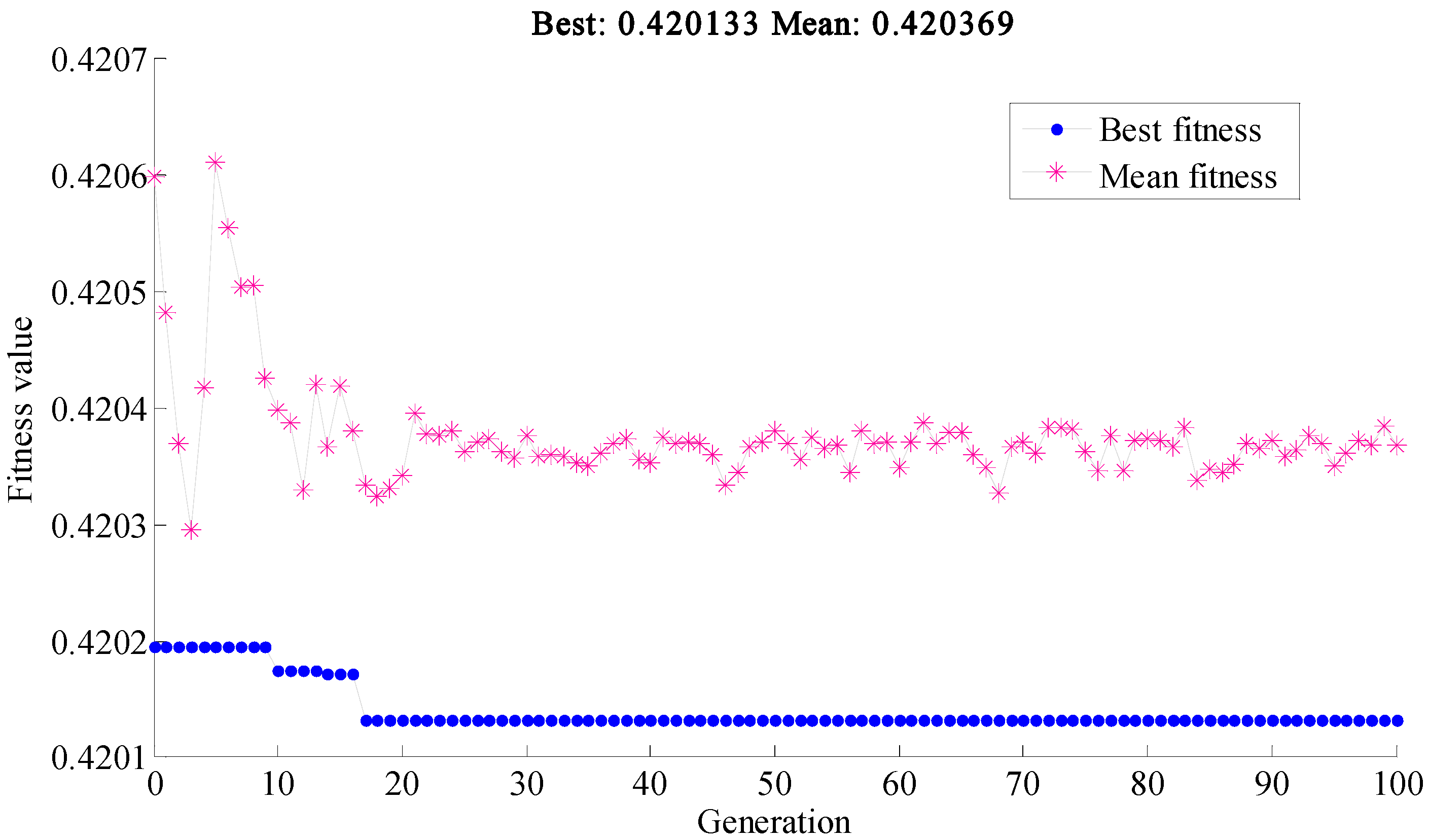

3.2. Off-Line Optimization with Real-Coded Genetic Algorithm

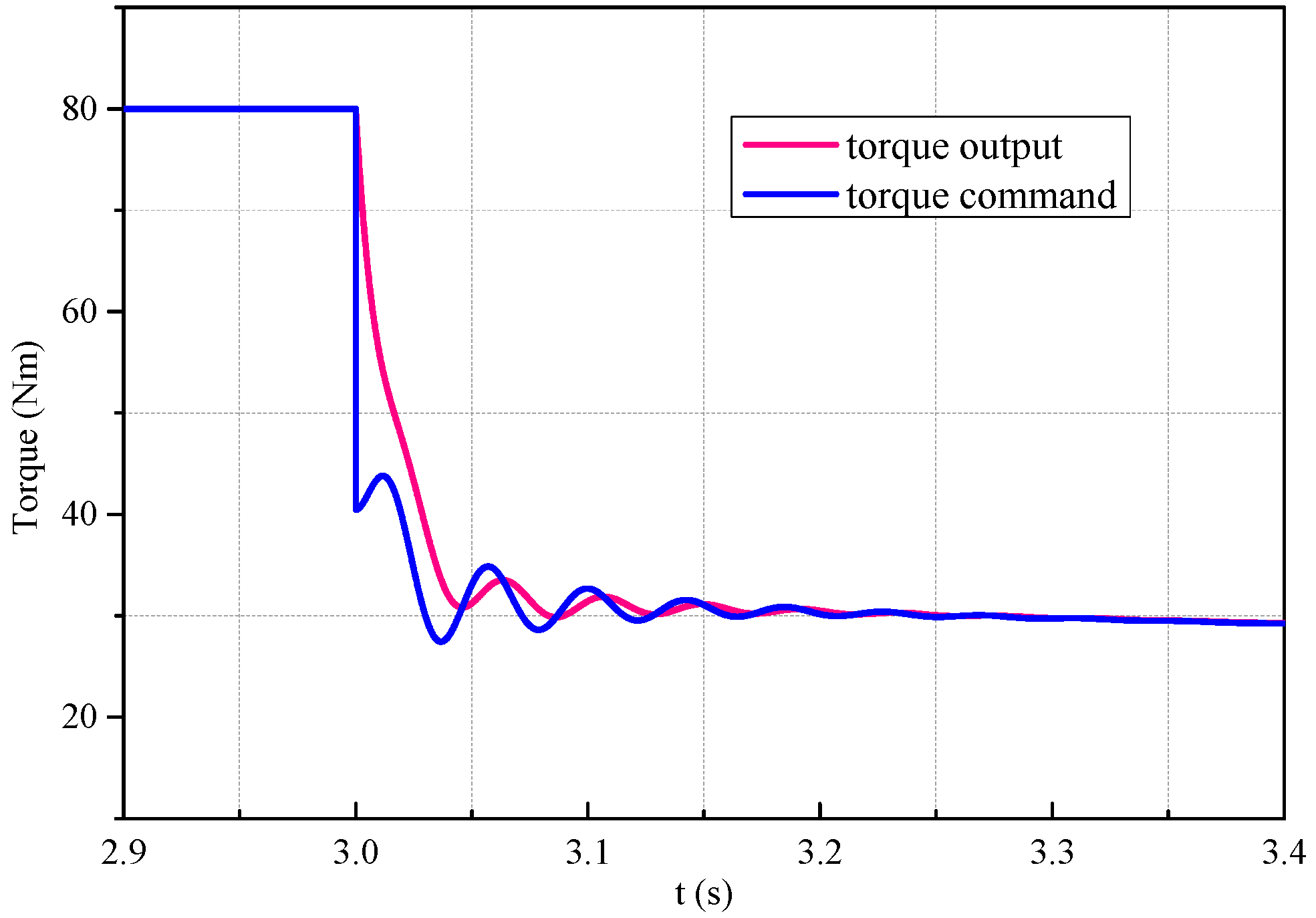

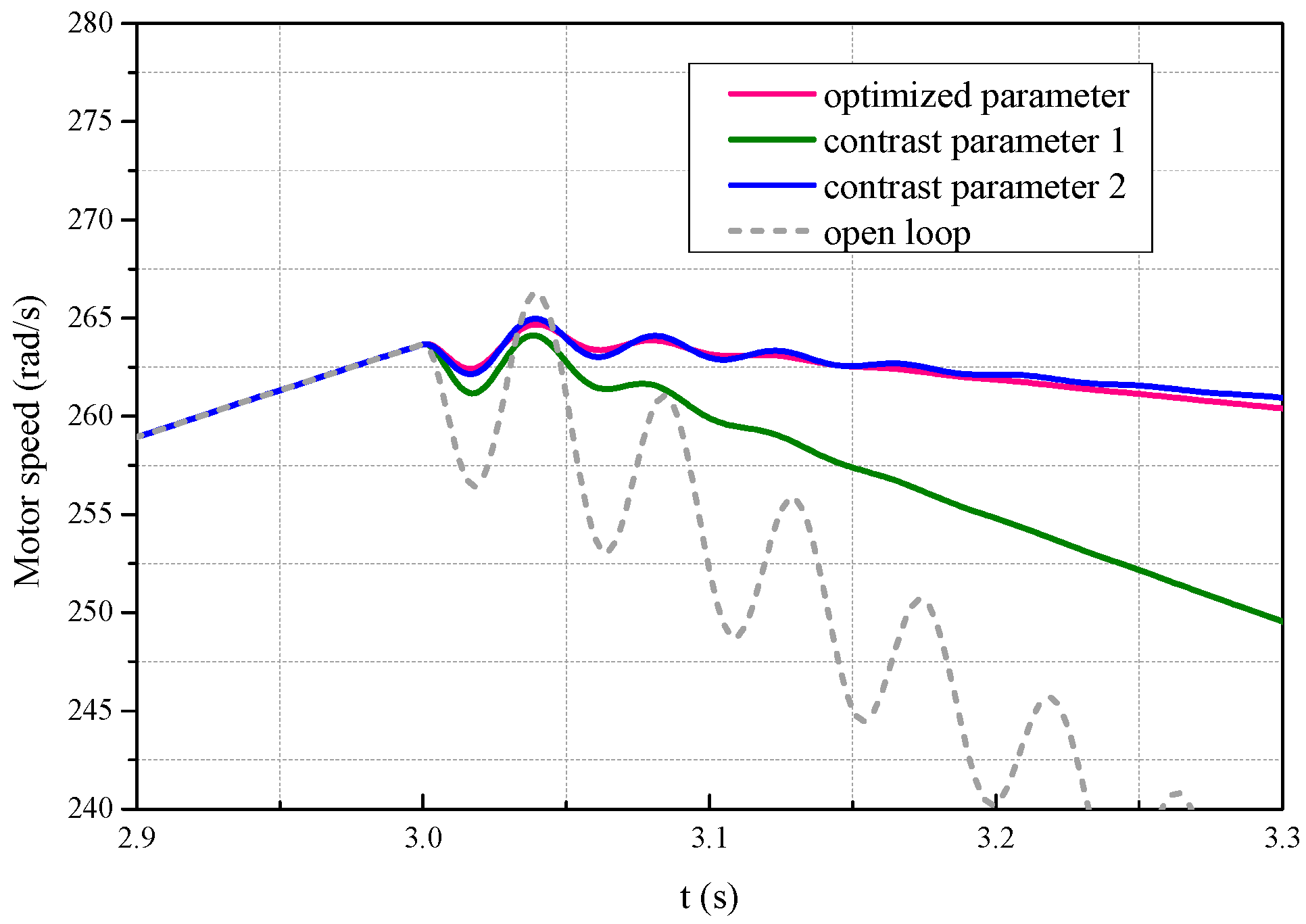

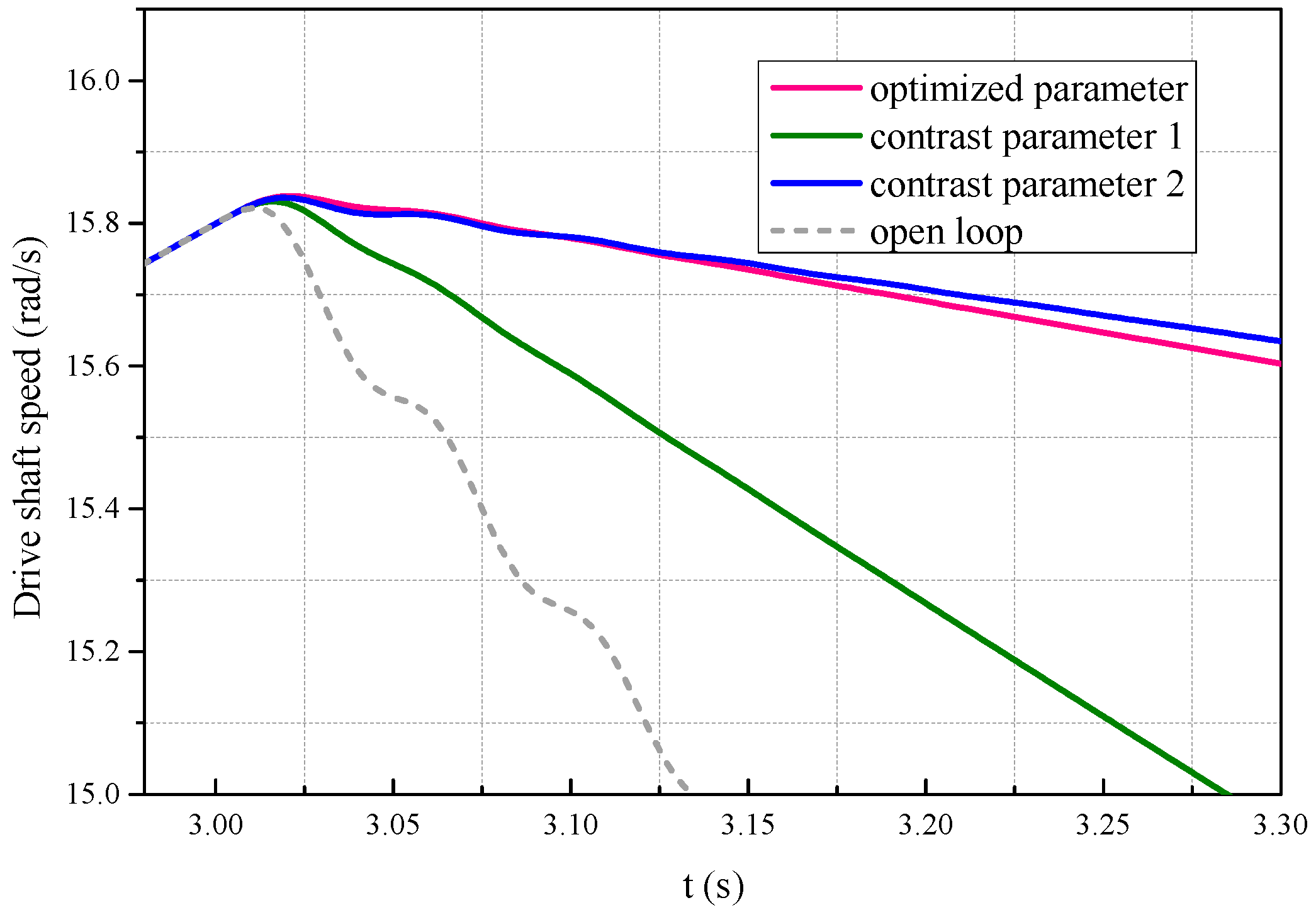

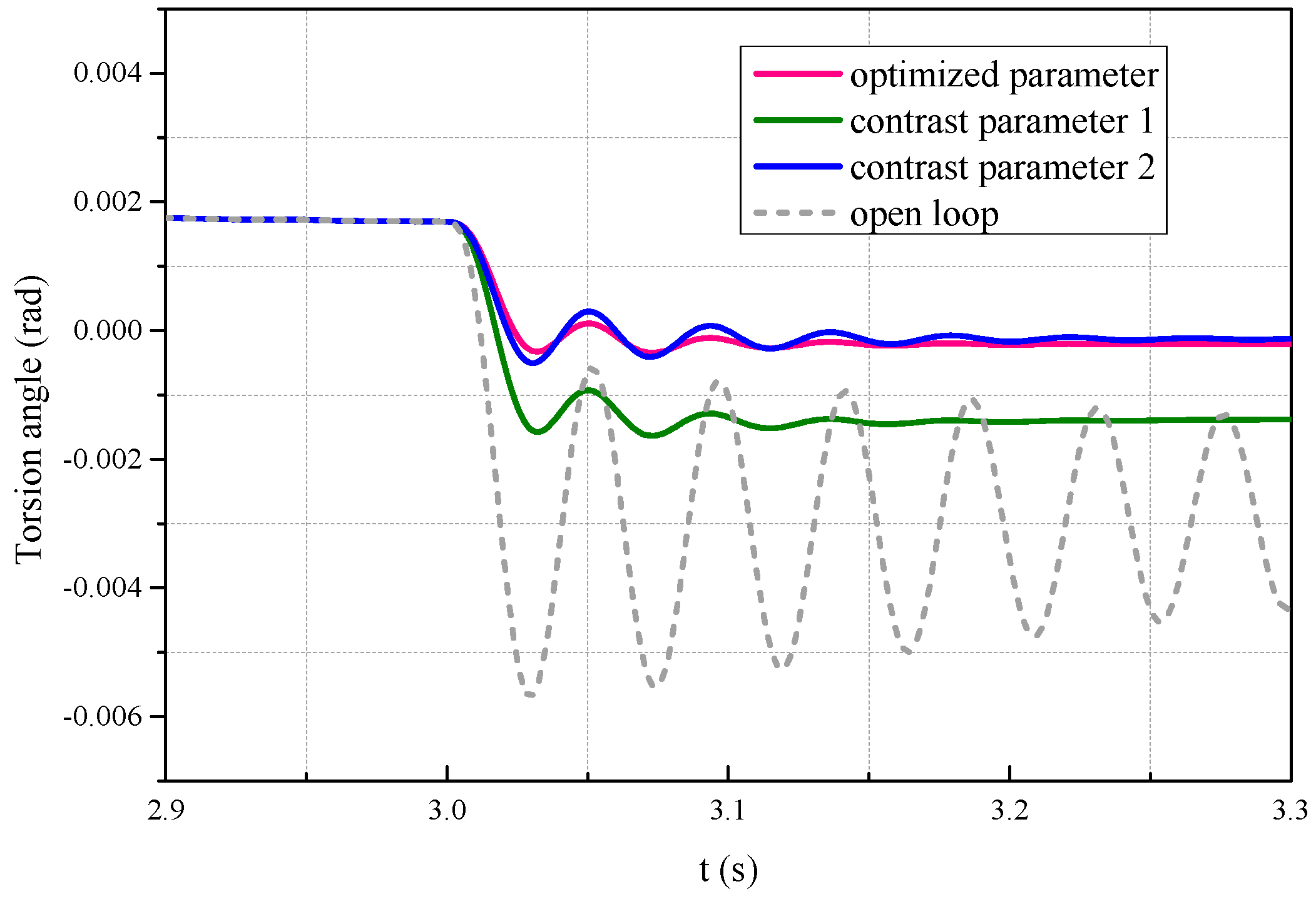

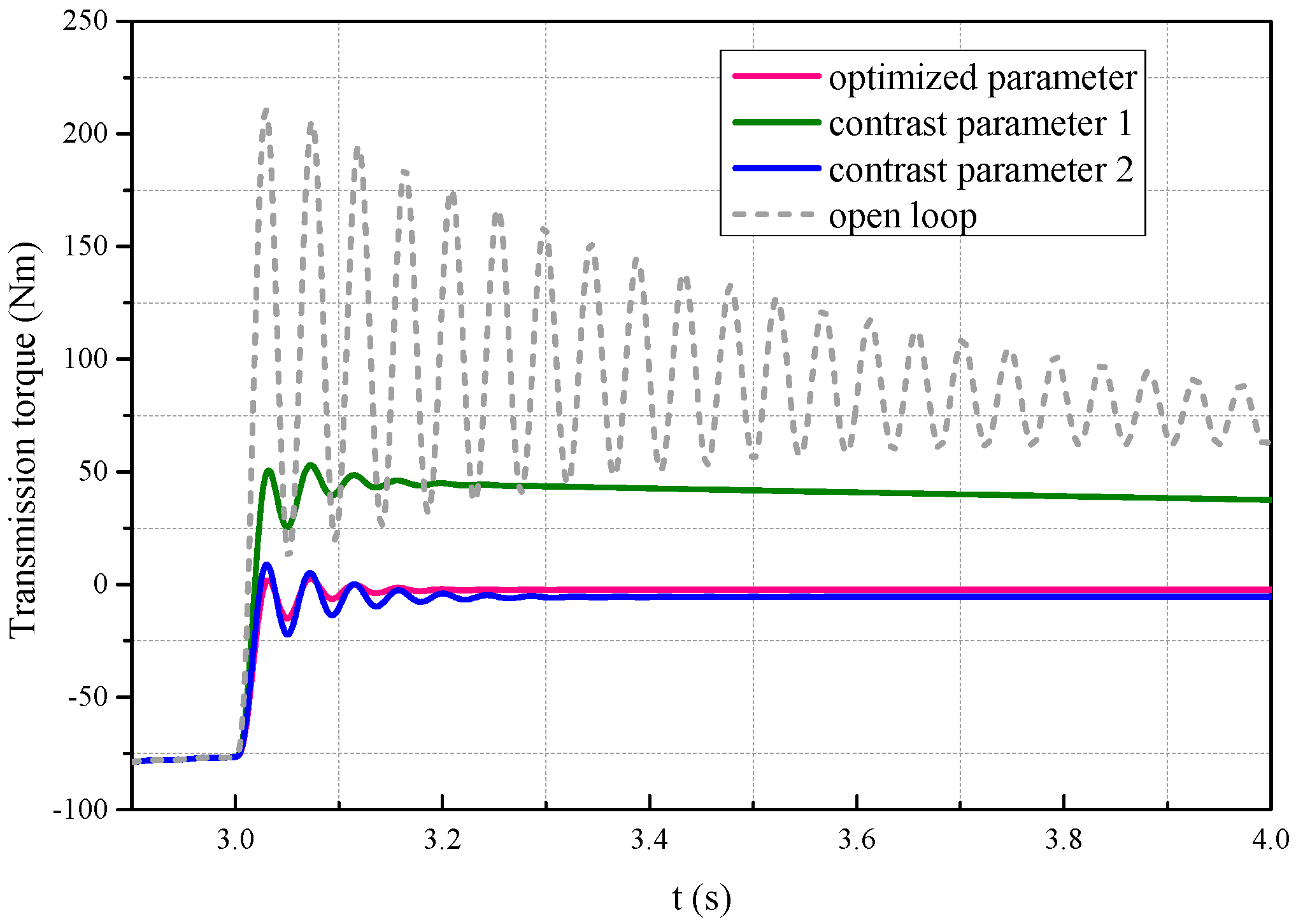

4. Results and Discussion

5. Conclusions and Future Work

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

Appendix B

References

- Shin, M.; Kim, H.; Kim, H.; Jang, H. Building an interoperability test system for electric vehicle chargers based on iso/iec 15118 and iec 61850 standards. Appl. Sci. 2016, 6, 165. [Google Scholar] [CrossRef]

- Llaria, A.; Terrasson, G.; Curea, O.; Jiménez, J. Application of wireless sensor and actuator networks to achieve intelligent microgrids: A promising approach towards a global smart grid deployment. Appl. Sci. 2016, 6, 61. [Google Scholar] [CrossRef]

- Chan, C.C.; Chau, K. An overview of power electronics in electric vehicles. IEEE Trans. Ind. Electron. 1997, 44, 3–13. [Google Scholar] [CrossRef]

- Walker, P.D.; Fang, Y.; Zhang, N. Dynamics and control of clutchless automated manual transmissions for electric vehicles. J. Vib. Acoust. 2017, 139, 061005. [Google Scholar] [CrossRef]

- Theodossiades, S.; Tangasawi, O.; Rahnejat, H. Gear teeth impacts in hydrodynamic conjunctions promoting idle gear rattle. J. Sound Vib. 2007, 303, 632–658. [Google Scholar] [CrossRef]

- Haris, A.; Motato, E.; Theodossiades, S.; Rahnejat, H.; Kelly, P.; Vakakis, A.; Bergman, L.A.; McFarland, D.M. A study on torsional vibration attenuation in automotive drivetrains using absorbers with smooth and non-smooth nonlinearities. Appl. Math. Model. 2017, 46, 674–690. [Google Scholar] [CrossRef]

- Zhang, L.; Si, Y.; Yu, Z. Numerical investigation into nonlinear dynamical characteristics of fuel cell vehicle powertrain system. Chin. J. Mech. Eng. 2009, 45, 62–67. [Google Scholar] [CrossRef]

- Pettersson, M.; Nielsen, L. Gear shifting by engine control. IEEE Trans. Control Syst. Technol. 2000, 8, 495–507. [Google Scholar] [CrossRef]

- Pham, T.; Bushnell, L. Two-degree-of-freedom damping control of driveline oscillations caused by pedal tip-in maneuver. In Proceedings of the American Control Conference (ACC) 2015, Chicago, IL, USA, 1–3 July 2015; pp. 1425–1432. [Google Scholar]

- Berriri, M.; Chevrel, P.; Lefebvre, D. Active damping of automotive powertrain oscillations by a partial torque compensator. Control Eng. Pract. 2008, 16, 874–883. [Google Scholar] [CrossRef]

- Fredriksson, J.; Weiefors, H.; Egardt, B. Powertrain control for active damping of driveline oscillations. Veh. Syst. Dyn. 2002, 37, 359–376. [Google Scholar] [CrossRef]

- Baumann, J.; Torkzadeh, D.D.; Ramstein, A.; Kiencke, U.; Schlegl, T. Model-based predictive anti-jerk control. Control Eng. Pract. 2006, 14, 259–266. [Google Scholar] [CrossRef]

- Caruntu, C.F.; Balau, A.E.; Lazar, M.; Bosch, P.P.; Di Cairano, S. Driveline oscillations damping: A tractable predictive control solution based on a piecewise affine model. Nonlinear Anal. Hybrid Syst. 2016, 19, 168–185. [Google Scholar] [CrossRef]

- Lefebvre, D.; Chevrel, P.; Richard, S. An h-infinity-based control design methodology dedicated to the active control of vehicle longitudinal oscillations. IEEE Trans. Control Syst. Technol. 2003, 11, 948–956. [Google Scholar] [CrossRef]

- Siami, M.; Khaburi, D.A.; Rivera, M.; Rodríguez, J. An experimental evaluation of predictive current control and predictive torque control for a pmsm fed by a matrix converter. IEEE Trans. Ind. Electron. 2017, 64, 8459–8471. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, X.; Xie, W.; Wang, F.; Dou, M.; Kennel, R.M.; Lorenz, R.D.; Gerling, D. Deadbeat model-predictive torque control with discrete space-vector modulation for pmsm drives. IEEE Trans. Ind. Electron. 2017, 64, 3537–3547. [Google Scholar] [CrossRef]

- Yang, H.; Zhang, Y.; Yuan, G.; Walker, P.D.; Zhang, N. Hybrid synchronized pwm schemes for closed-loop current control of high-power motor drives. IEEE Trans. Ind. Electron. 2017, 64, 6920–6929. [Google Scholar] [CrossRef]

- Kommuri, S.K.; Defoort, M.; Karimi, H.R.; Veluvolu, K.C. A robust observer-based sensor fault-tolerant control for pmsm in electric vehicles. IEEE Trans. Ind. Electron. 2016, 63, 7671–7681. [Google Scholar] [CrossRef]

- Song, Z.; Li, J.; Shuai, Z.; Xu, L.; Ouyang, M. Fuzzy logic torque control system in four-wheel-drive electric vehicles for active damping vibration control. Int. J. Veh. Des. 2015, 68, 55–80. [Google Scholar] [CrossRef]

- Bang, J.S.; Ko, Y.-K.; Jung, T.-H. The Active Damping Control to Reduce Driveline Oscillations for Electric Vehicles Using Wheel Speeds; SAE Technical Paper 0148-7191; SAE: Detroit, MI, USA, 2015. [Google Scholar]

- Orlowska-Kowalska, T.; Szabat, K. Damping of torsional vibrations in two-mass system using adaptive sliding neuro-fuzzy approach. IEEE Trans. Ind. Inform. 2008, 4, 47–57. [Google Scholar] [CrossRef]

- Lv, C.; Zhang, J.; Li, Y.; Yuan, Y. Mode-switching-based active control of a powertrain system with non-linear backlash and flexibility for an electric vehicle during regenerative deceleration. Proc. Inst. Mech. Eng. D J. Automob. Eng. 2015, 229, 1429–1442. [Google Scholar] [CrossRef]

- Fu, H.; Tian, G.; Chen, H.A.; University, C.Q. A study on the torsional vibration control of motor-transmission integrated drive system. Automot. Eng. 2010, 32, 597–600. [Google Scholar]

- Roy, T.; Chakraborty, D. Optimal vibration control of smart fiber reinforced composite shell structures using improved genetic algorithm. J. Sound Vib. 2009, 319, 15–40. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, Z.; Jiao, Y. A hybrid vibration isolator: Design, control, and experiments. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2016, 230, 2982–2995. [Google Scholar] [CrossRef]

- Prabakar, R.S.; Sujatha, C.; Narayanan, S. Response of a half-car model with optimal magnetorheological damper parameters. J. Vib. Control 2016, 22, 784–798. [Google Scholar] [CrossRef]

- Nagarkar, M.; Vikhe, G. Optimization of the linear quadratic regulator (LQR) control quarter car suspension system using genetic algorithm. Ing. Investig. 2016, 36, 23–30. [Google Scholar] [CrossRef]

- Das, S.; Pan, I.; Das, S. Multi-objective lqr with optimum weight selection to design fopid controllers for delayed fractional order processes. ISA Trans. 2015, 58, 35–49. [Google Scholar] [CrossRef] [PubMed]

- Ufnalski, B.; Kaszewski, A.; Grzesiak, L.M. Particle swarm optimization of the multioscillatory lqr for a three-phase four-wire voltage-source inverter with an LC output filter. IEEE Trans. Ind. Electron. 2015, 62, 484–493. [Google Scholar] [CrossRef]

- Yu, S.; Dong, G.; Li, L. Transient characteristics of emissions during engine start/stop operation employing a conventional gasoline engine for HEV application. Int. J. Automot. Technol. 2008, 9, 543–549. [Google Scholar] [CrossRef]

- Mitschke, M.; Wallentowitz, H. Dynamik der Kraftfahrzeuge; Springer: Berlin/Heidelberg, Germany, 2004. [Google Scholar]

- Kiencke, U.; Nielsen, L. Automotive Control Systems: For Engine, Driveline, and Vehicle; Springer: Berlin, Germany, 2005. [Google Scholar]

- Kuo, C.-C.; Liu, C.-H.; Chang, H.-C.; Lin, K.-J. Implementation of a motor diagnosis system for rotor failure using genetic algorithm and fuzzy classification. Appl. Sci. 2017, 7, 31. [Google Scholar] [CrossRef]

- Perez-Ramirez, C.; Jaen-Cuellar, A.; Valtierra-Rodriguez, M.; Dominguez-Gonzalez, A.; Osornio-Rios, R.; Romero-Troncoso, R.; Amezquita-Sanchez, J. A two-step strategy for system identification of civil structures for structural health monitoring using wavelet transform and genetic algorithms. Appl. Sci. 2017, 7, 111. [Google Scholar] [CrossRef]

- Cam, E.; Gorel, G.; Mamur, H. Use of the genetic algorithm-based fuzzy logic controller for load-frequency control in a two area interconnected power system. Appl. Sci. 2017, 7, 308. [Google Scholar] [CrossRef]

| Symbols | Indication | Subscripts | Indication |

|---|---|---|---|

| mass moment of inertia | Motor | ||

| torsional stiffness | transmission | ||

| torsional damping | propeller shaft | ||

| gear ratio | final drive | ||

| torsion angle of drive shaft | drive shaft | ||

| torque include friction | wheel | ||

| resisting moment | - | - | |

| gross mass of vehicle | - | - | |

| wheel radius | - | - |

| Parameter | Configuration | Parameter | Configuration |

|---|---|---|---|

| Encoding | real code | Crossover Fraction | 0.4 |

| Population Size | 100 | Generations | 100 |

| Elite Amount | 10 | Mutation Function | constrained mutation |

| Parameter | Configuration | Parameter | Configuration |

|---|---|---|---|

| maximum power | 60 kW | maximum torque | 150 Nm |

| maximum speed | 9000 rev/min | - | - |

| Parameter | Configuration | Parameter | Configuration |

|---|---|---|---|

| 1500 kg | 0.29 m | ||

| 3.4545 | 4.831 | ||

| 246,371 Nm/rad | 0.05 kg·m2 | ||

| 0.01055 kg·m2 | 128.15 kg·m2 | ||

| 9.549 Nm/(rad/s) | 0.2 Nm/(rad/s) | ||

| 31.17 Nm/(rad/s) | - | - |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, C.; Sun, S.; Walker, P.; Zhang, N. Off-Line Optimization Based Active Control of Torsional Oscillation for Electric Vehicle Drivetrain. Appl. Sci. 2017, 7, 1261. https://doi.org/10.3390/app7121261

Lin C, Sun S, Walker P, Zhang N. Off-Line Optimization Based Active Control of Torsional Oscillation for Electric Vehicle Drivetrain. Applied Sciences. 2017; 7(12):1261. https://doi.org/10.3390/app7121261

Chicago/Turabian StyleLin, Cheng, Shengxiong Sun, Paul Walker, and Nong Zhang. 2017. "Off-Line Optimization Based Active Control of Torsional Oscillation for Electric Vehicle Drivetrain" Applied Sciences 7, no. 12: 1261. https://doi.org/10.3390/app7121261

APA StyleLin, C., Sun, S., Walker, P., & Zhang, N. (2017). Off-Line Optimization Based Active Control of Torsional Oscillation for Electric Vehicle Drivetrain. Applied Sciences, 7(12), 1261. https://doi.org/10.3390/app7121261