A High-Thrust Screw-Type Piezoelectric Ultrasonic Motor with Three-Wavelength Exciting Mode

Abstract

:1. Introduction

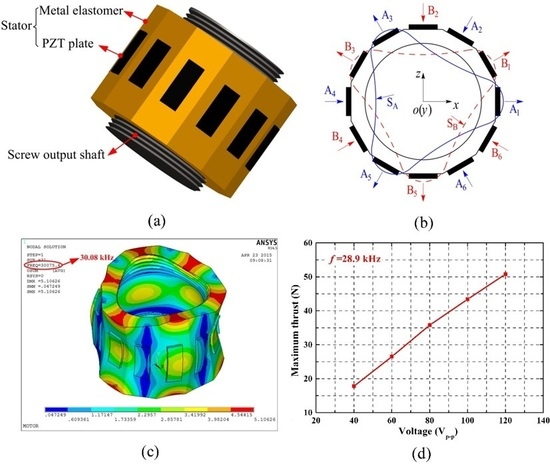

2. Structure and Operating Principle

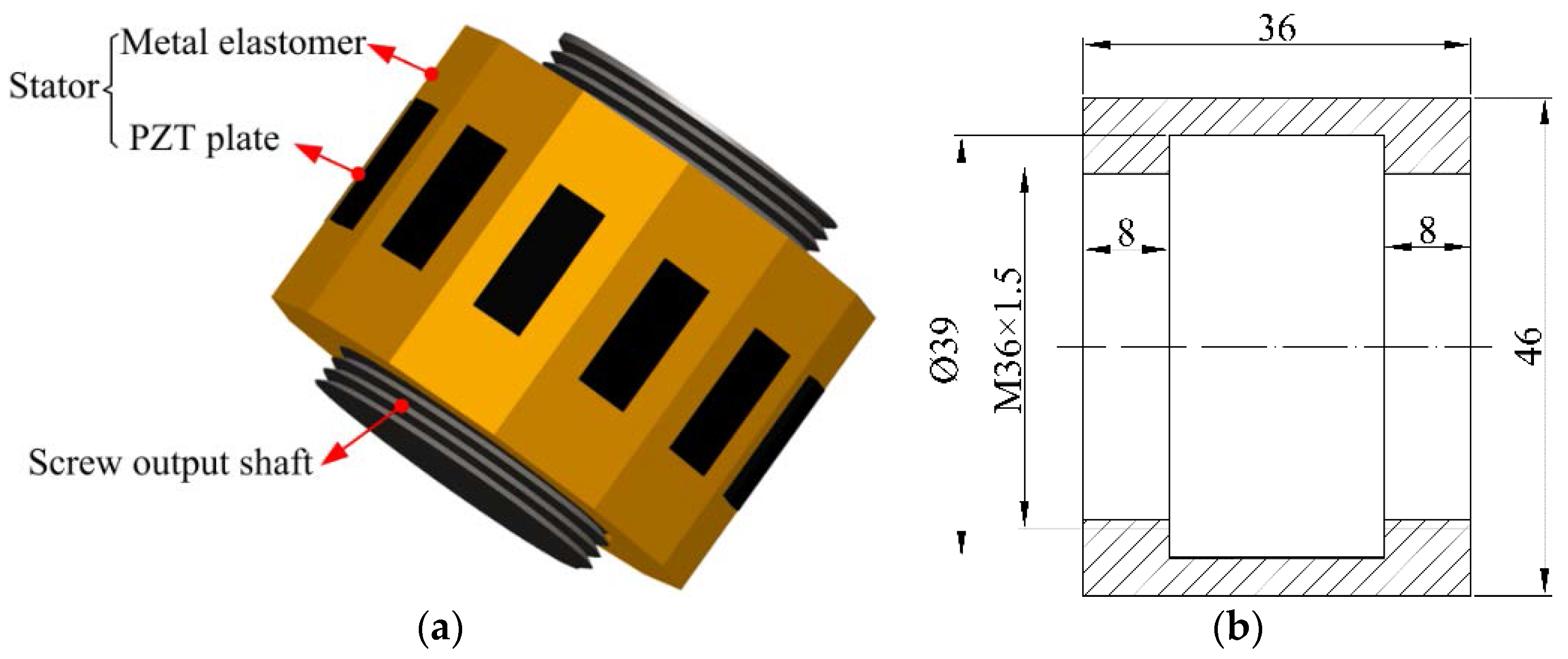

2.1. The Structureof the Screw-Type Ultrasonic Motor

2.2. Operating Principle of ScrewTtype Ultrasonic Motor

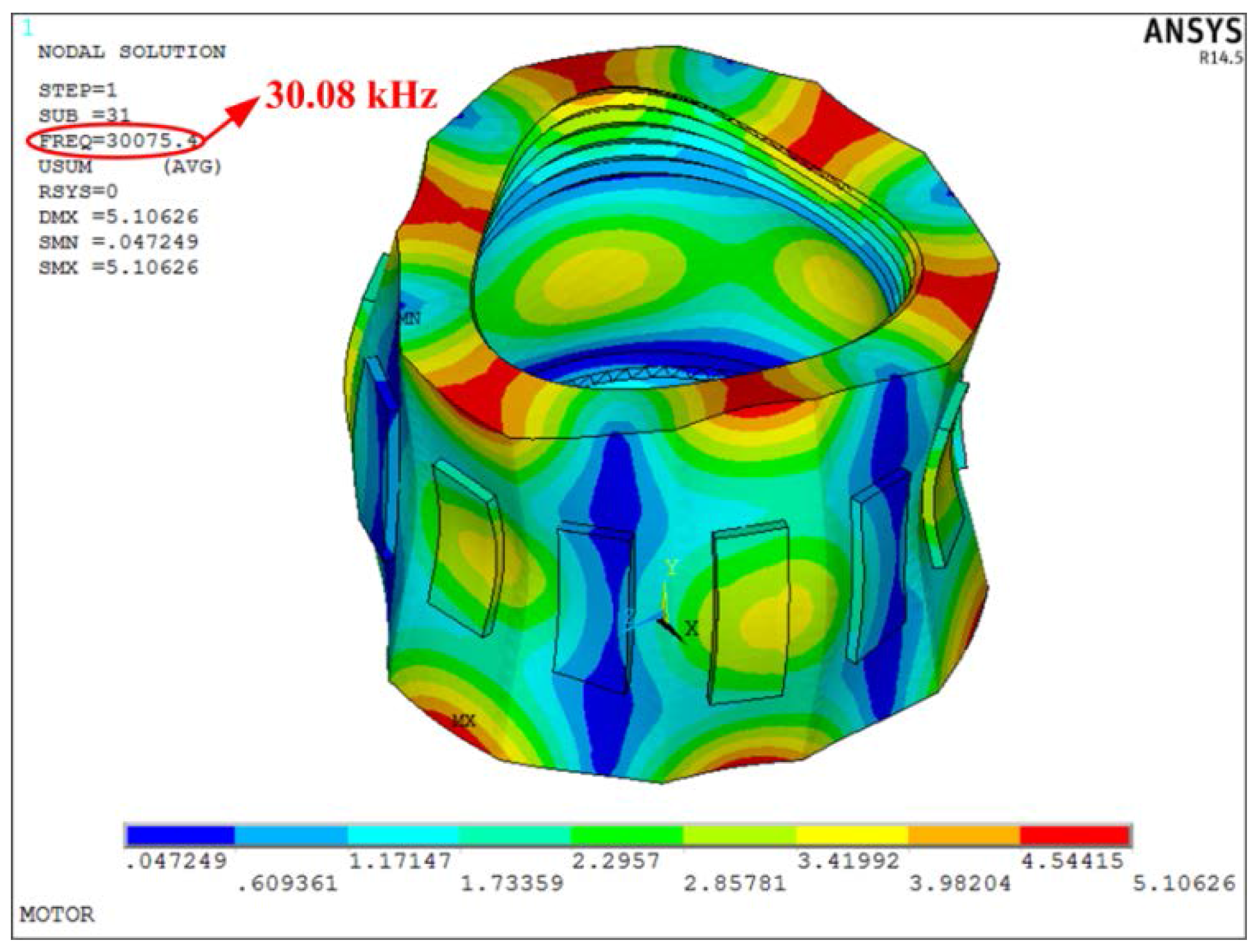

3. Finite Element Analysis

3.1. Modal Simulation of the Stator

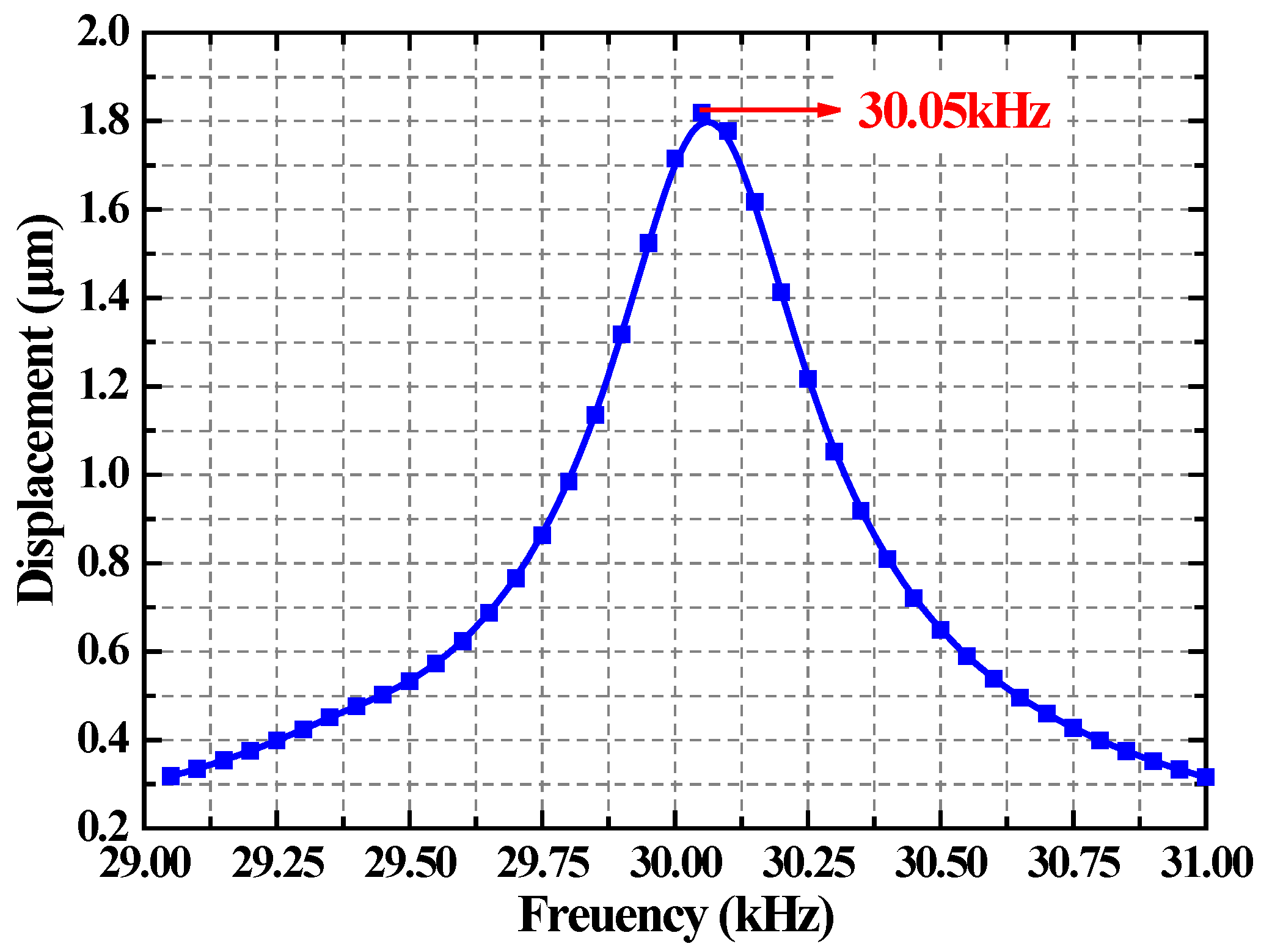

3.2. Harmonic Response Analysis of the Stator

4. Fabrication and Measurement

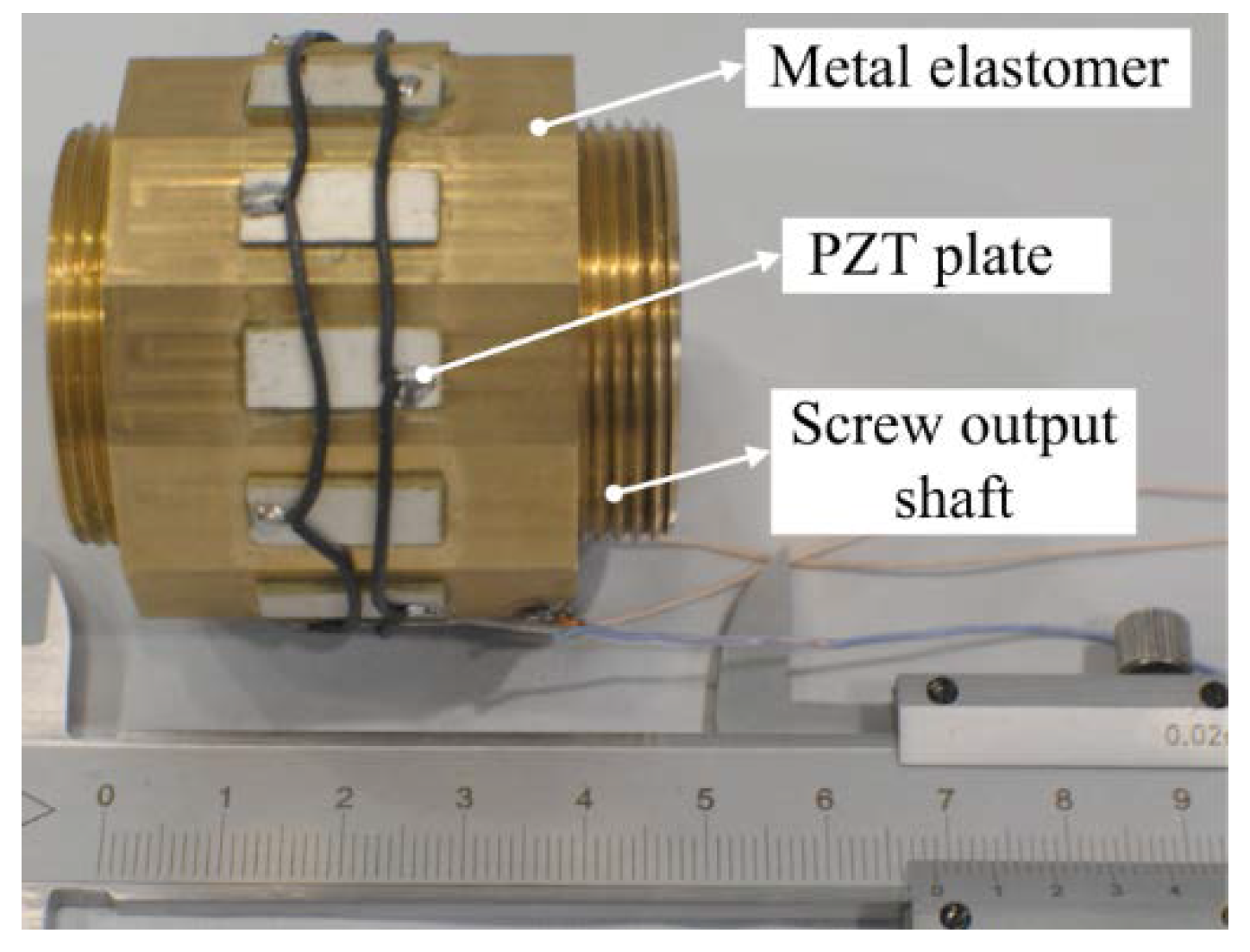

4.1. The Prototype of Screw-Type Ultrasonic Motor

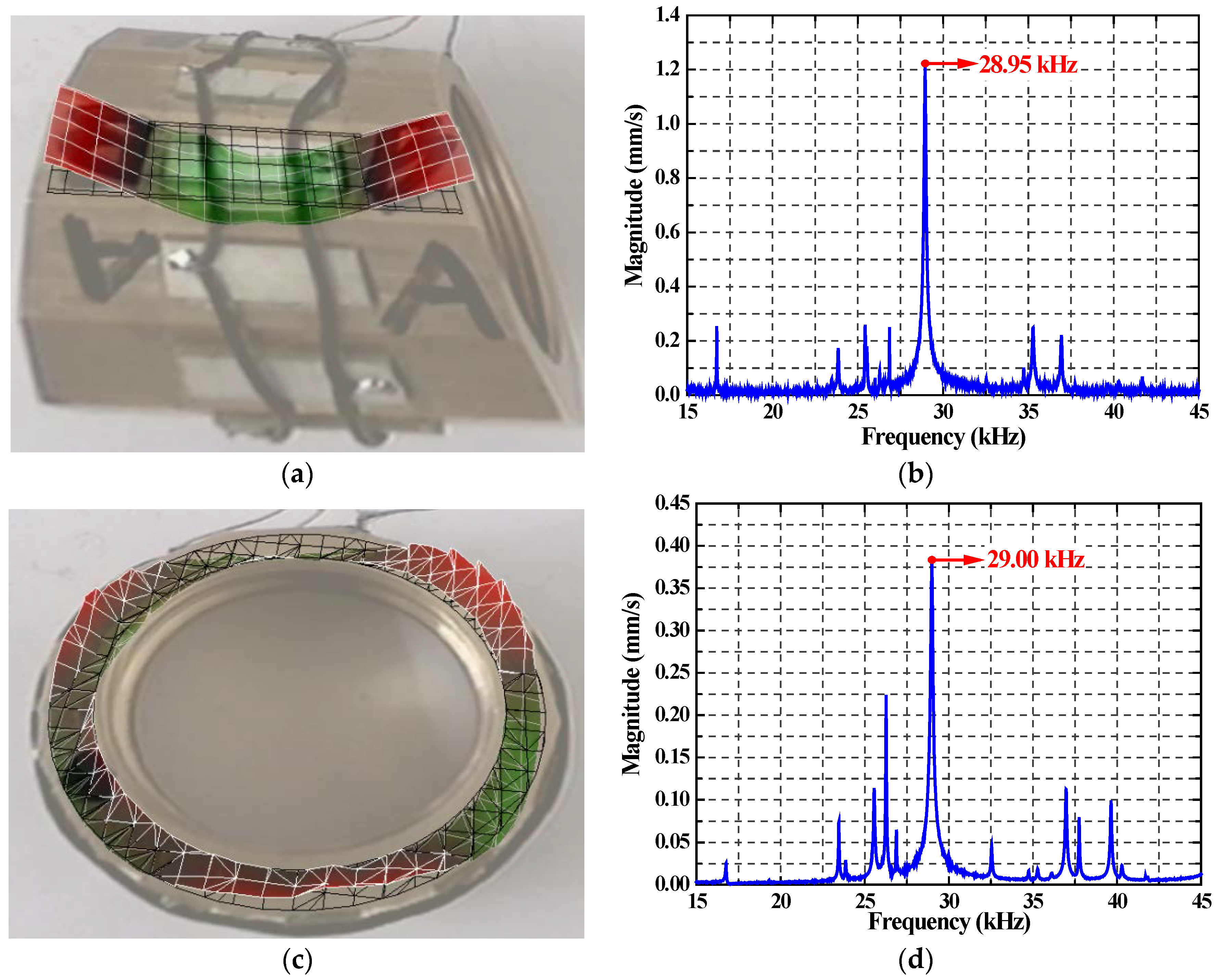

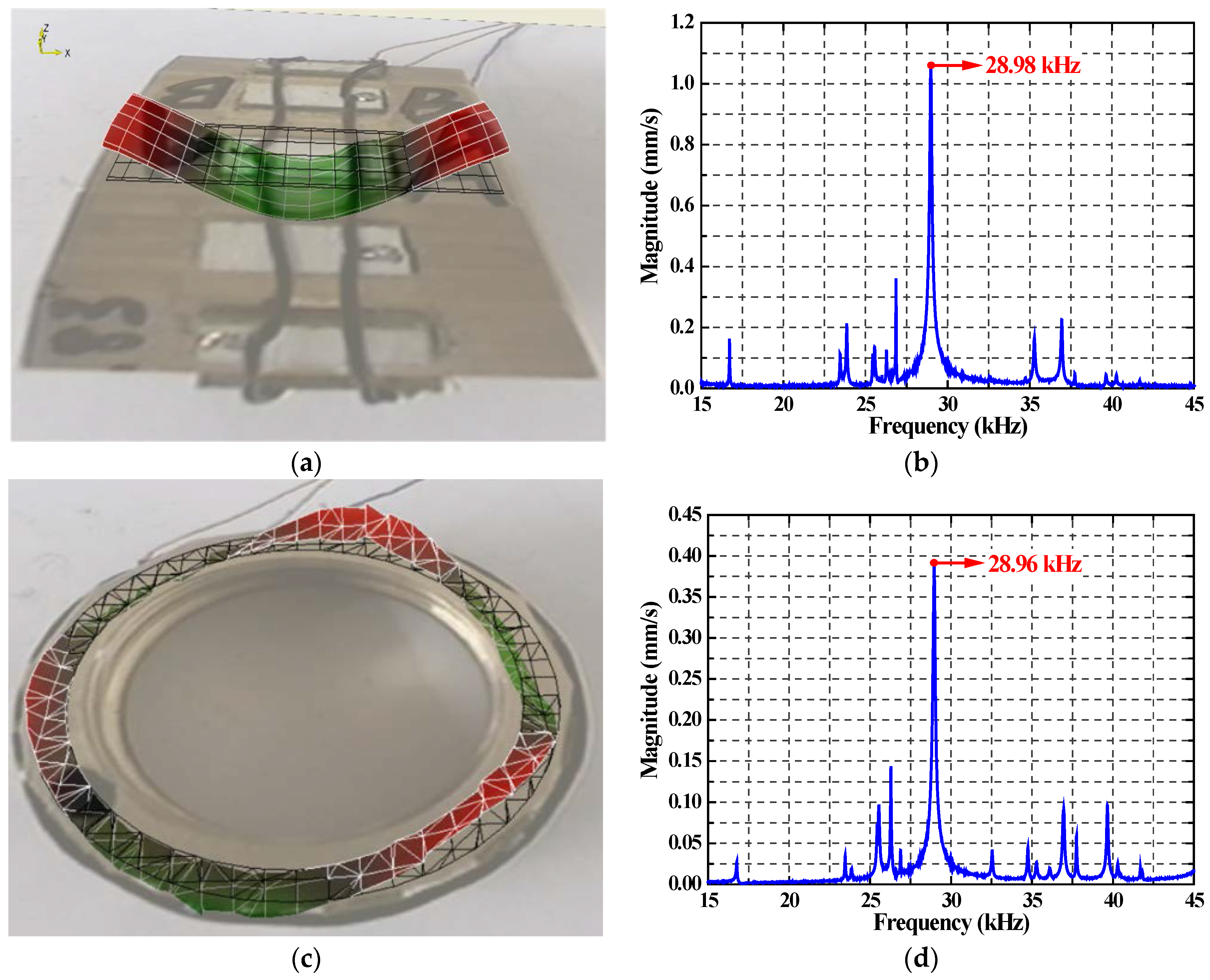

4.2. Vibration CharacteristicsMeasurement

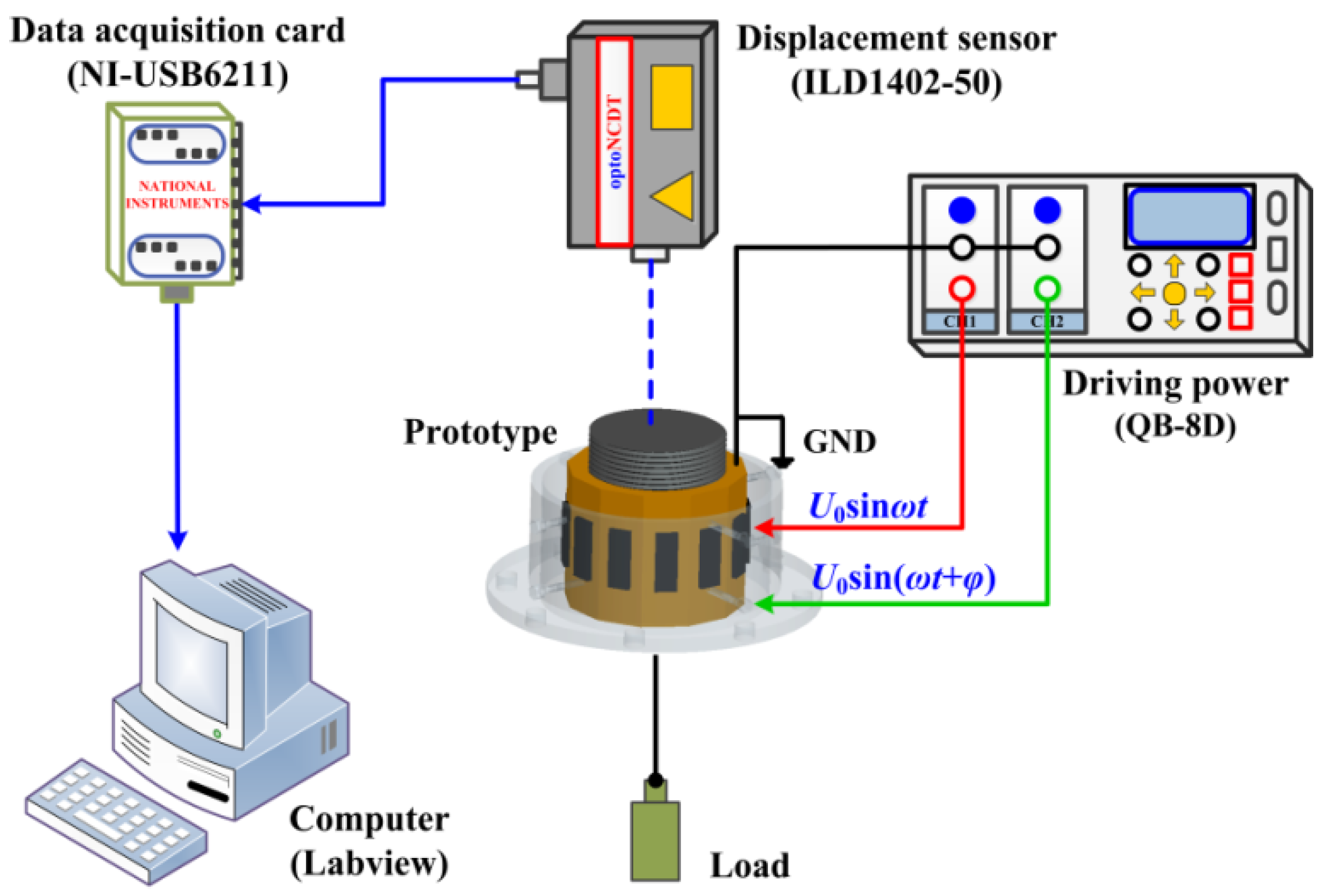

4.3. The Established Experiment System

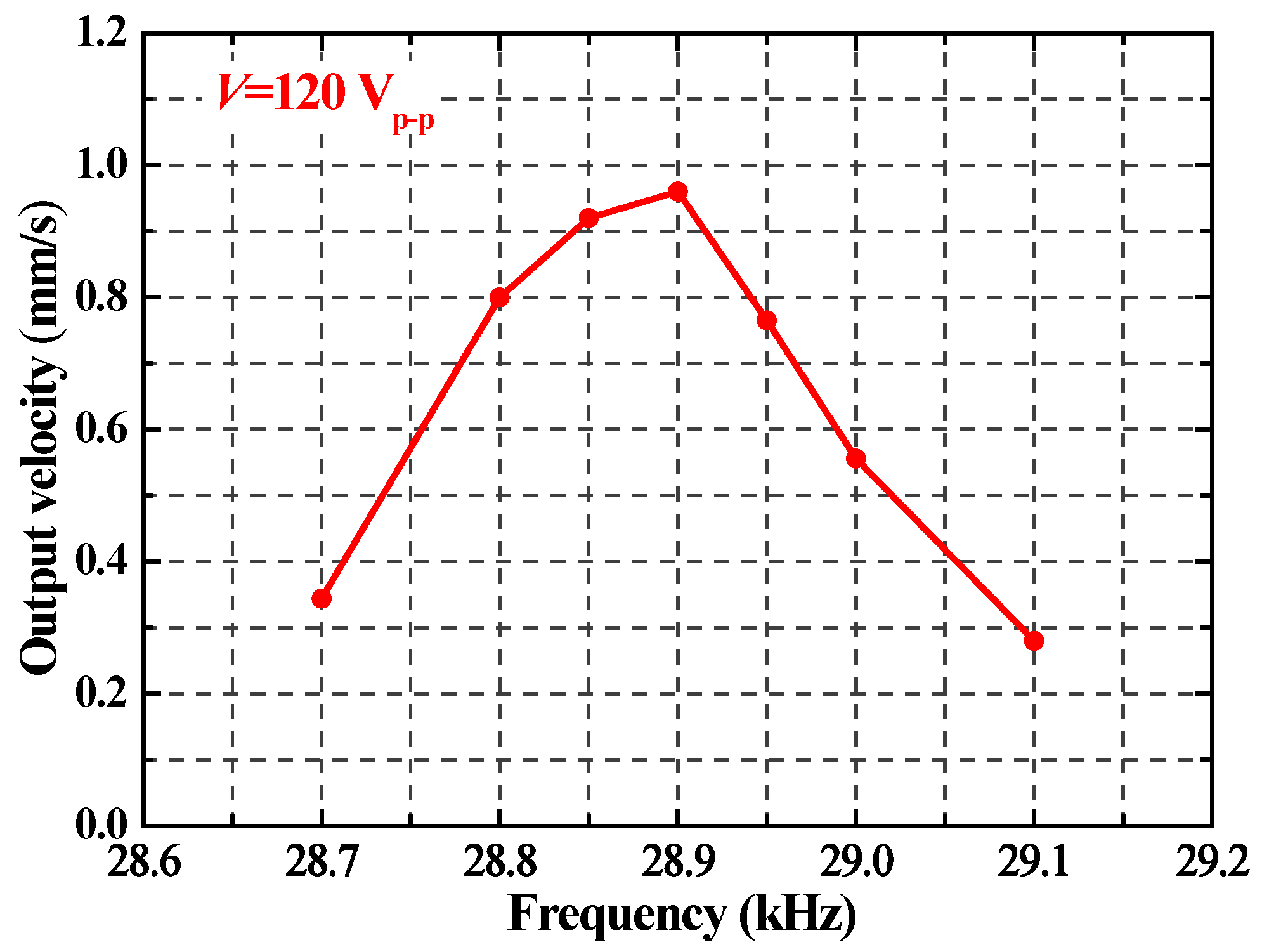

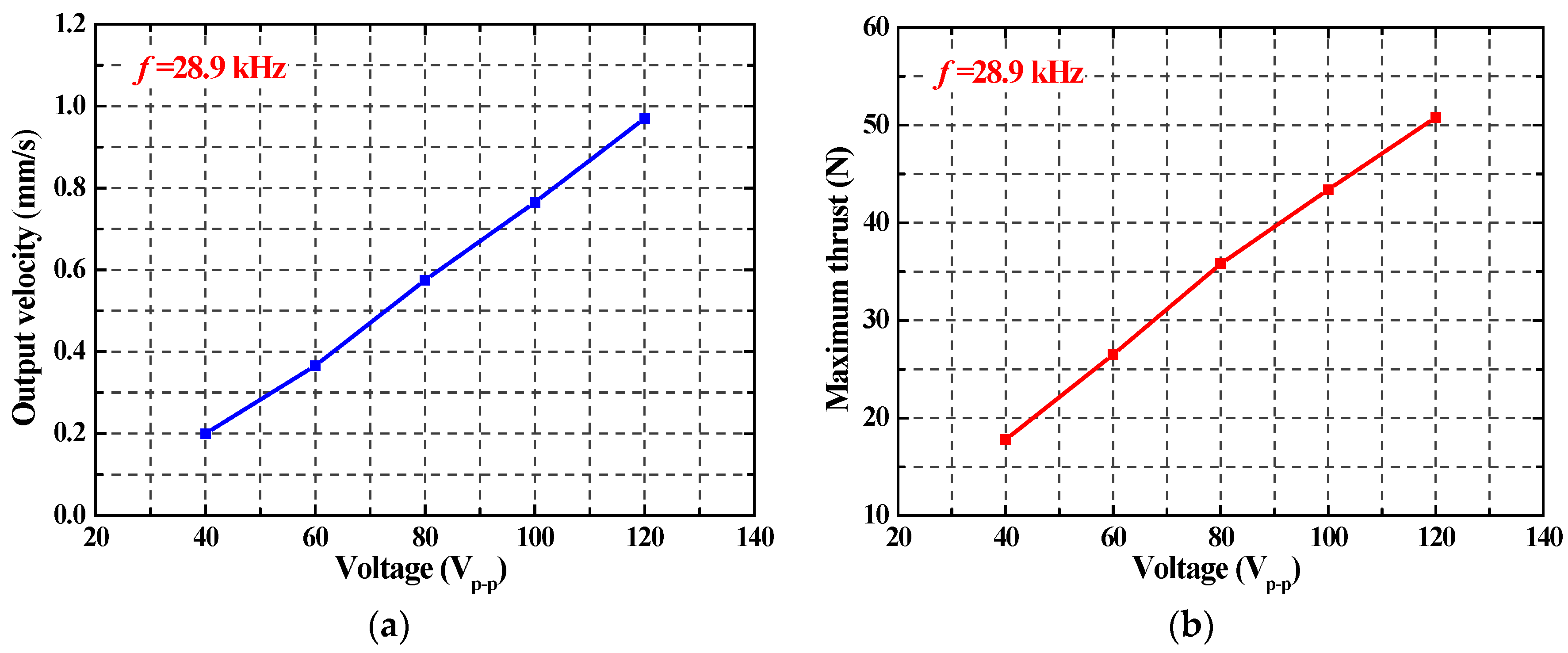

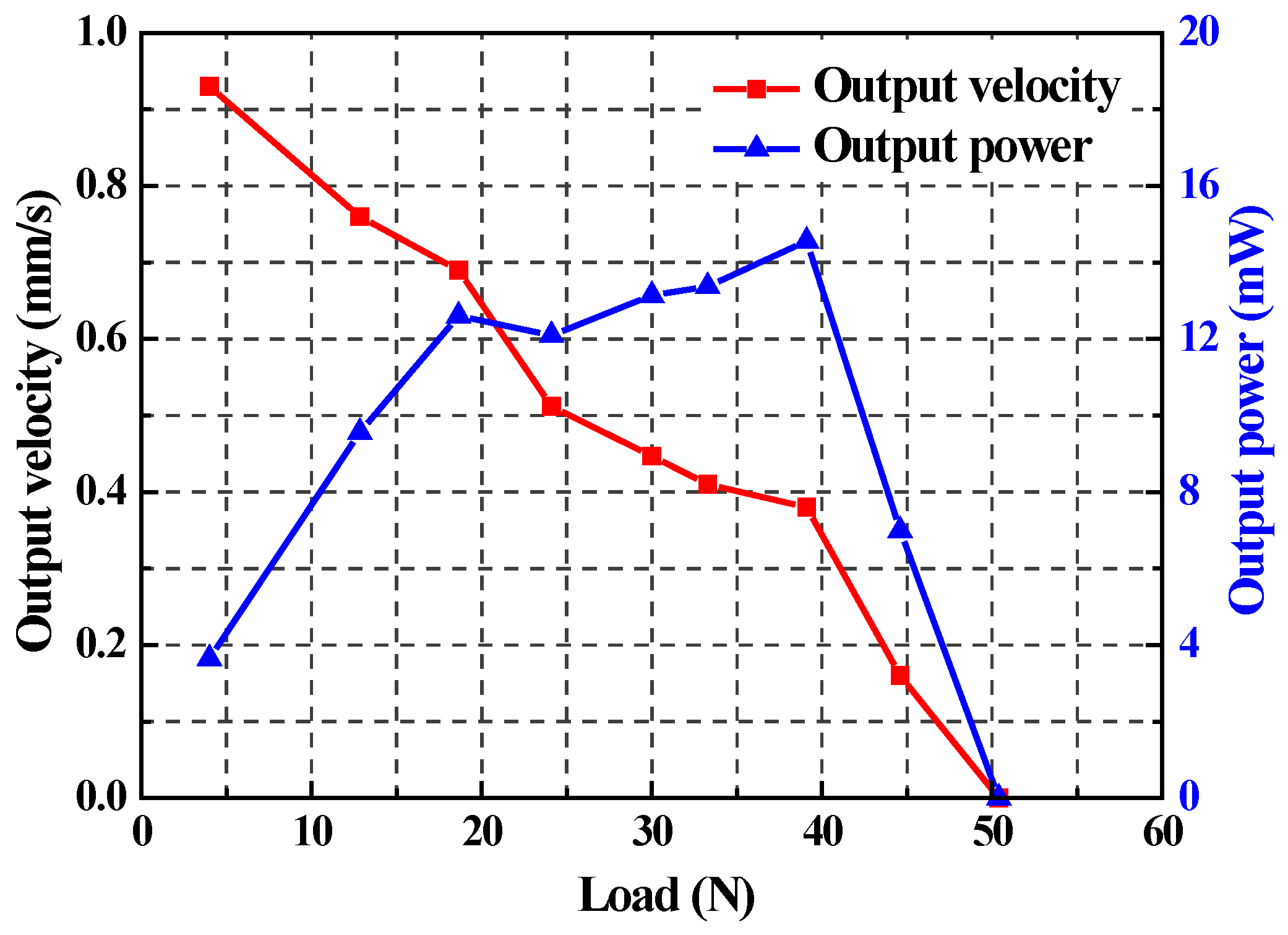

4.4. Results and Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Mashimo, T.; Toyama, S. Rotary-linear piezoelectric micro actuator with a cubic stator of side length 3.5 mm. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2010, 57, 1825–1830. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Xu, D.; Yang, X.; Chen, W. Miniaturized piezoelectric actuator operating in bending hybrid modes. Sens. Actuators A 2015, 235, 015112. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, W.; Yang, X.; Liu, J. A T-shape linear piezoelectric motor with single foot. Ultrasonics 2015, 56, 551–556. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.; Zhao, C. Simple new ultrasonic piezoelectric actuator for precision linear positioning. J. Electroceram. 2012, 28, 233–239. [Google Scholar] [CrossRef]

- Koc, B.; Cagatay, S.; Uchino, K. A piezoelectric motor using two orthogonal bending modes of a hollow cylinder. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2002, 49, 495–500. [Google Scholar] [CrossRef] [PubMed]

- Dong, S.; Lim, S.; Lee, K.; Zhang, J.; Lim, L.; Uchino, K. Piezoelectric ultrasonic micromotor with 1.5 mm diameter. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2003, 50, 361–367. [Google Scholar] [CrossRef] [PubMed]

- Vyshnevskyy, O.; Kovalev, S.; Mehner, J. Coupled tangential-axial resonant modes of piezoelectric hollow cylinders and their application in ultrasonic motors. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2005, 52, 31–36. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Liu, Y.; Yang, X.; Liu, J. Ring-type traveling wave ultrasonic motor using a radial bending mode. Ultrason. Ferroelectr. Freq. Control 2014, 61, 197–202. [Google Scholar] [CrossRef] [PubMed]

- Mashimo, T.; Terashima, K. Experimental verification of elliptical motion model in traveling wave ultrasonic motors. IEEE/ASME Trans. Mech. 2015, 20, 1–9. [Google Scholar] [CrossRef]

- Watson, B.; Friend, J.; Yeo, L. Piezoelectric ultrasonic micro/milli-scale actuators. Sens. Actuators A 2009, 152, 219–233. [Google Scholar] [CrossRef]

- Egashira, Y.; Kosaka, K.; Iwabuchi, T.; Kosaka, T.; Baba, T.; Endo, T.; Hashiguchi, H.; Harada, T.; Nagamoto, K.; Watanabe, M.; et al. Sub-nanometer resolution ultrasonic motor for 300 mm waferlithography precision stage. Jpn. J. Appl. Phys. 2002, 41, 5858–5863. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, W.; Hesselbach, J.; Kerle, H. Development of a two-degree-of-freedom piezoelectric rotary-linear actuator with high driving force and unlimited linear movement. Rev. Sci. Instrum. 2006, 77, 035112. [Google Scholar] [CrossRef]

- Li, H.; Quan, Q.; Deng, Z.; Hua, Y.; Wang, Y.; Bai, D. A novel noncontact ultrasonic levitating bearing excited by piezoelectric ceramics. Appl. Sci. 2016, 6, 280. [Google Scholar] [CrossRef]

- Huang, H.; Fu, L.; Zhao, H.; Shi, C.; Ren, L.; Li, J.; Qu, H. A novel rotary actuator driven by only one piezoelectric actuator. Rev. Sci. Instrum. 2013, 84, 096105. [Google Scholar] [CrossRef] [PubMed]

- Shao, S.; Shi, S.; Chen, W.; Liu, J.; Liu, Y. Research on a linear piezoelectric actuator using T-Shape transducer to realize high mechanical output. Appl. Sci. 2016, 6, 103. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, D.; Yu, Z.; Yan, J.; Yang, X.; Chen, W. A novel rotary piezoelectric motor using first bending hybrid transducers. Appl. Sci. 2015, 5, 472–484. [Google Scholar] [CrossRef]

- Yuan, S.; Zhao, Y.; Chu, X.; Zhu, C.; Zhong, J. Analysis and experimental research of a multilayer linear piezoelectric actuator. Appl. Sci. 2016, 6, 225. [Google Scholar] [CrossRef]

- Zhou, T.; Chen, Y.; Lu, C.; Fu, D.; Hu, X.; Li, Y. A nut-type ultrasonic motor and its application in the focus system. Sci. China Ser. E-Technol. Sci. 2009, 52, 2591–2596. [Google Scholar] [CrossRef]

- Zhou, T.; Chen, Y.; Lu, C.; Fu, D.; Hu, X.; Li, Y.; Tian, B. Integrated lens auto-focus system driven by a nut-type ultrosonic motor (USM). Sci. China Ser. E 2009, 54, 2591–2596. [Google Scholar] [CrossRef]

- Henderson, D. Simple Ceramic Motor, Inspiring Smaller Products. In Proceedings of the International Conference on New Actuators, Bremen, Germany, 14–16 June 2006; pp. 1–4.

- Henderson, D.A. Novel piezo motor enables positive displacement micro fluidic pump. In Proceedings of the 2007 NSTI Nanotechnology Conference and Trade Show, Santa Clara, CA, USA, 20–24 May 2007; pp. 272–275.

- Ho, S.; Chiu, W. A piezoelectric screw-driven motor operating in shear vibration modes. J. Intell. Mater. Syst. Struct. 2016, 27, 134–145. [Google Scholar] [CrossRef]

- Sanguinetti, B.; Varcoe, B. Use of a piezoelectric SQUIGGLE® motor for positioning at 6 K in a cryostat. Cryogenics 2006, 46, 694–696. [Google Scholar] [CrossRef]

- Turowski, S.G.; Seshadri, M.; Loecher, M.; Podniesinski, E.; Spernyak, J.A.; Mazurchuk, R.V. Performance of a novel piezoelectric motor at 4.7 T applications and initial tests. Magn. Reson. Imaging 2008, 26, 426–432. [Google Scholar] [CrossRef] [PubMed]

- Loverich, J.; Koopmann, G.; Lesieutre, G.; Frank, J.; Chen, W. A new piezoelectric actuator using a feed-screw for quasi-static motion accumulation–Part I experimental development. J. Intell. Mater. Syst. Struct. 2008, 19, 73–81. [Google Scholar] [CrossRef]

- Patronik, N.; Ota, T.; Zenati, M.; Riviere, C. Synchronization of epicardial crawling robot with heart beat and respiration for improved safety and efficiency of locomotion. Int. J. Med. Robot. 2012, 8, 97–106. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Zhu, H.; Zhao, C. Contact analysis and modeling of a linear ultrasonic motor with a threaded output shaft. J. Electroceram. 2012, 29, 254–261. [Google Scholar] [CrossRef]

- Chu, X.; Wang, J.; Yuan, S.; Li, L.; Cui, H. A screw-thread-type ultrasonic actuator based on a Langevin piezoelectric vibrator. Rev. Sci. Instrum. 2014, 85, 065002. [Google Scholar] [CrossRef] [PubMed]

- Hua, S.; Meng, Y.; Lou, Y.; Li, Z.; Wang, X. Screw-type actuator driven by piezoelectric transducers. Adv. Mech. Eng. 2015, 7, 1–10. [Google Scholar] [CrossRef]

- Zhu, H.; Chen, C.; Zhao, C. Investigation on a cylindrical ultrasonic micromotor. Proc. CSEE 2006, 26, 128–133. (In Chinese) [Google Scholar] [CrossRef]

- Morita, T.; Kurosawa, M.; Higuchi, T. A cylindrical shaped micro ultrasonic motor utilizing PZT thin film (1.4 mm in diameter and 5.0 mm long stator transducer). Sens. Actuators A 2000, 83, 225–230. [Google Scholar] [CrossRef]

- Cheng, T.; Guo, X.; Bao, G. Research on the excitation modes of PZT element in bending cylindrical transducers. In Proceedings of the 2011 Symposium on Piezoelectricity, Acoustic Waves, and Device Applications, Shenzhen, China, 9–11 December 2011; pp. 305–309.

| DielectricCoefficientMatrix (F/m) | PiezoelectricStressMatrix (C/m2) | ElasticCoefficientMatrix (GPa) |

|---|---|---|

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Wang, L.; Cheng, T.; He, M.; Zhao, H.; Gao, H. A High-Thrust Screw-Type Piezoelectric Ultrasonic Motor with Three-Wavelength Exciting Mode. Appl. Sci. 2016, 6, 442. https://doi.org/10.3390/app6120442

Li H, Wang L, Cheng T, He M, Zhao H, Gao H. A High-Thrust Screw-Type Piezoelectric Ultrasonic Motor with Three-Wavelength Exciting Mode. Applied Sciences. 2016; 6(12):442. https://doi.org/10.3390/app6120442

Chicago/Turabian StyleLi, Hengyu, Liang Wang, Tinghai Cheng, Meng He, Hongwei Zhao, and Haibo Gao. 2016. "A High-Thrust Screw-Type Piezoelectric Ultrasonic Motor with Three-Wavelength Exciting Mode" Applied Sciences 6, no. 12: 442. https://doi.org/10.3390/app6120442

APA StyleLi, H., Wang, L., Cheng, T., He, M., Zhao, H., & Gao, H. (2016). A High-Thrust Screw-Type Piezoelectric Ultrasonic Motor with Three-Wavelength Exciting Mode. Applied Sciences, 6(12), 442. https://doi.org/10.3390/app6120442