A Micro-Processor-Based Feedback Stabilization Scheme for High-Q, Non-Linear Silicon Resonators

Abstract

:1. Introduction

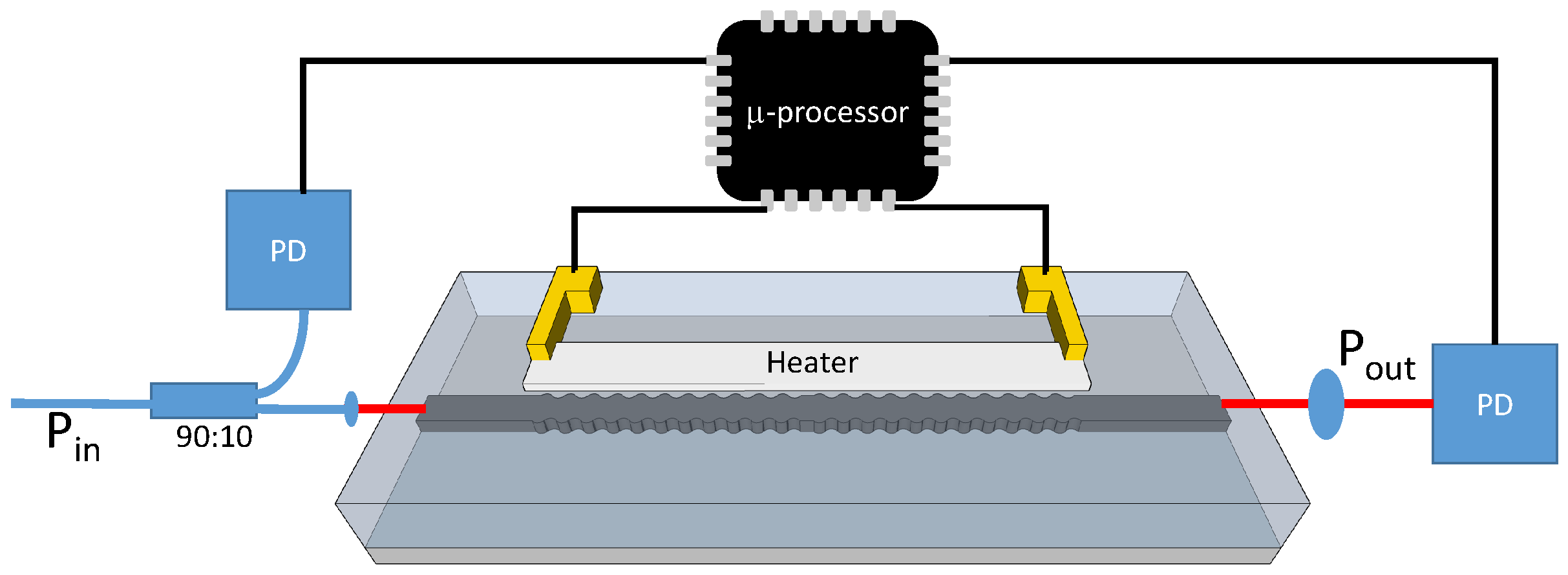

2. Materials and Methods

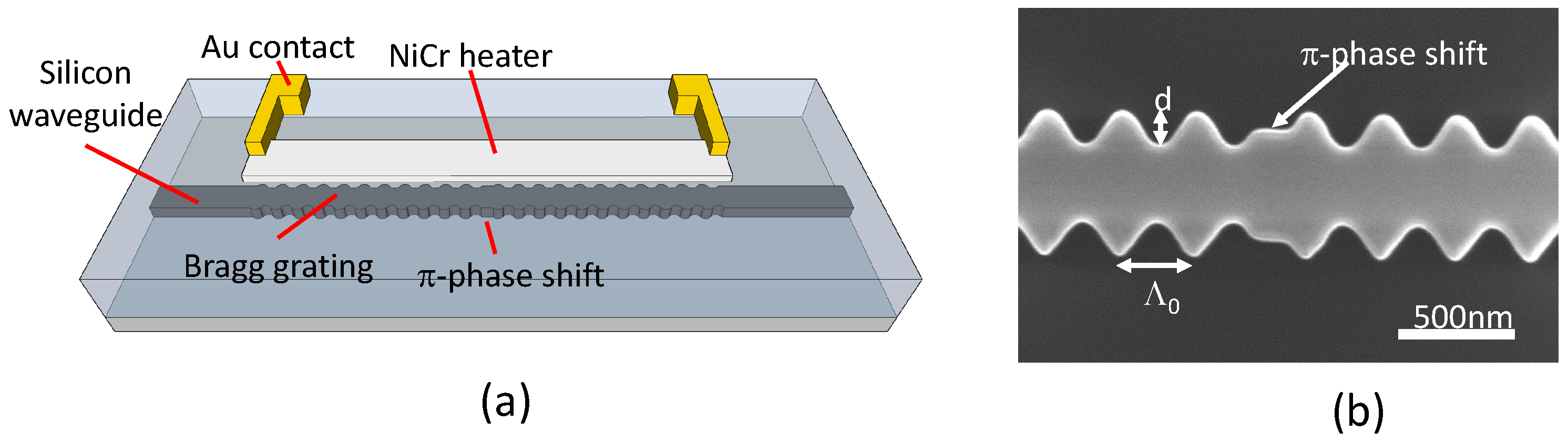

2.1. -Phase Shifted Bragg Grating Design and Fabrication

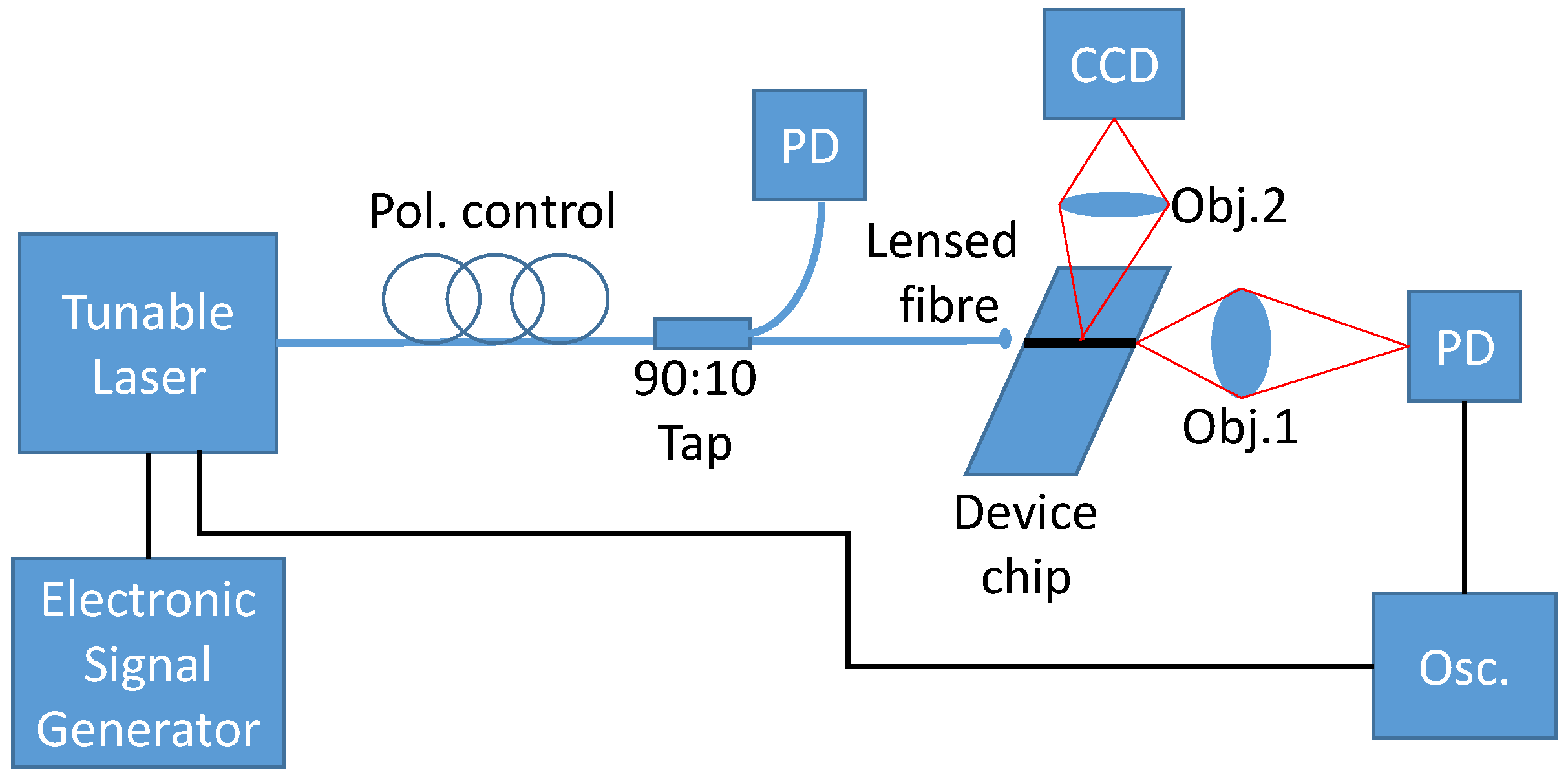

2.2. Optical Transmission Measurement Setup

2.3. Cavity Stabilization Scheme

3. Results and Discussion

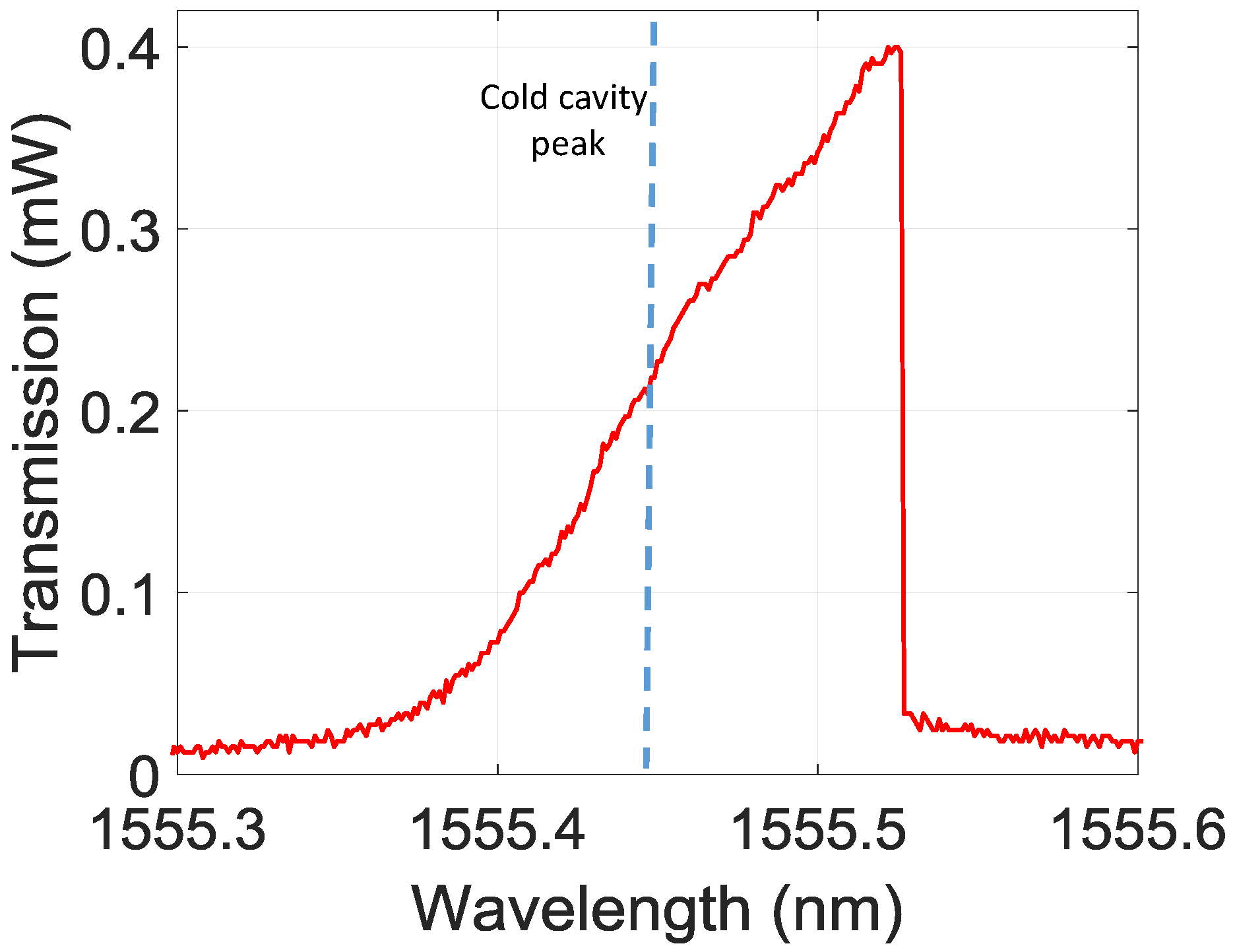

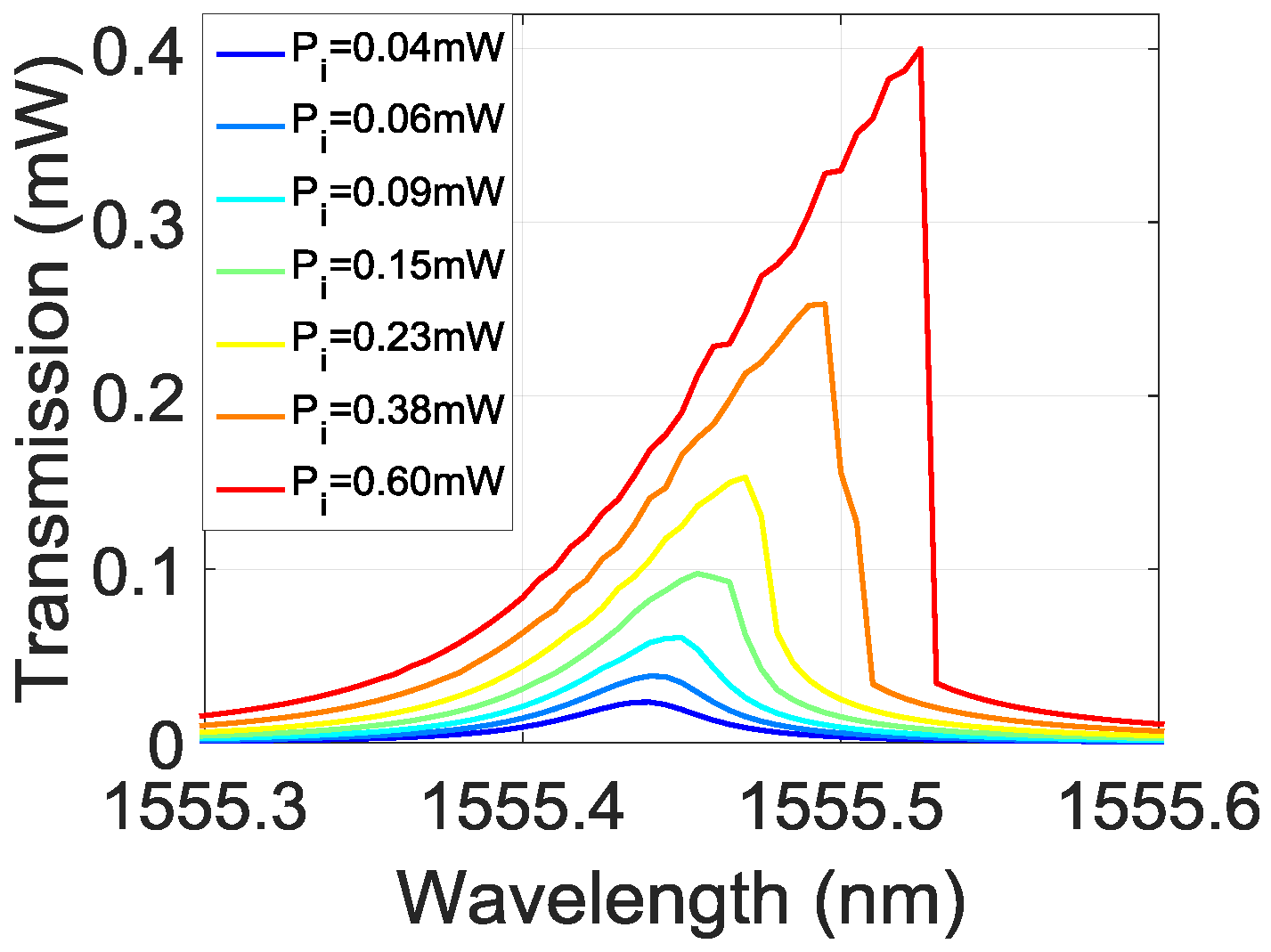

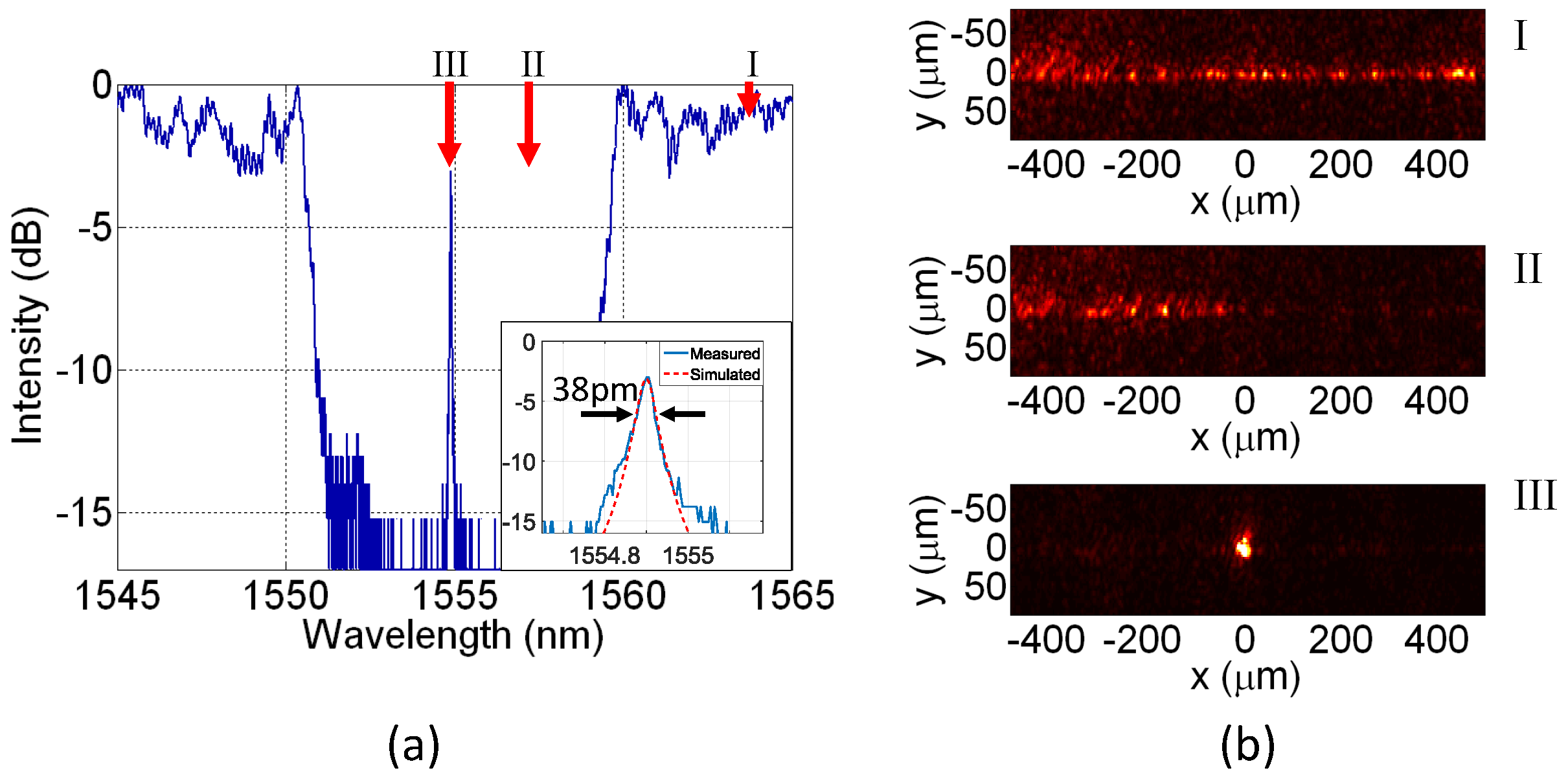

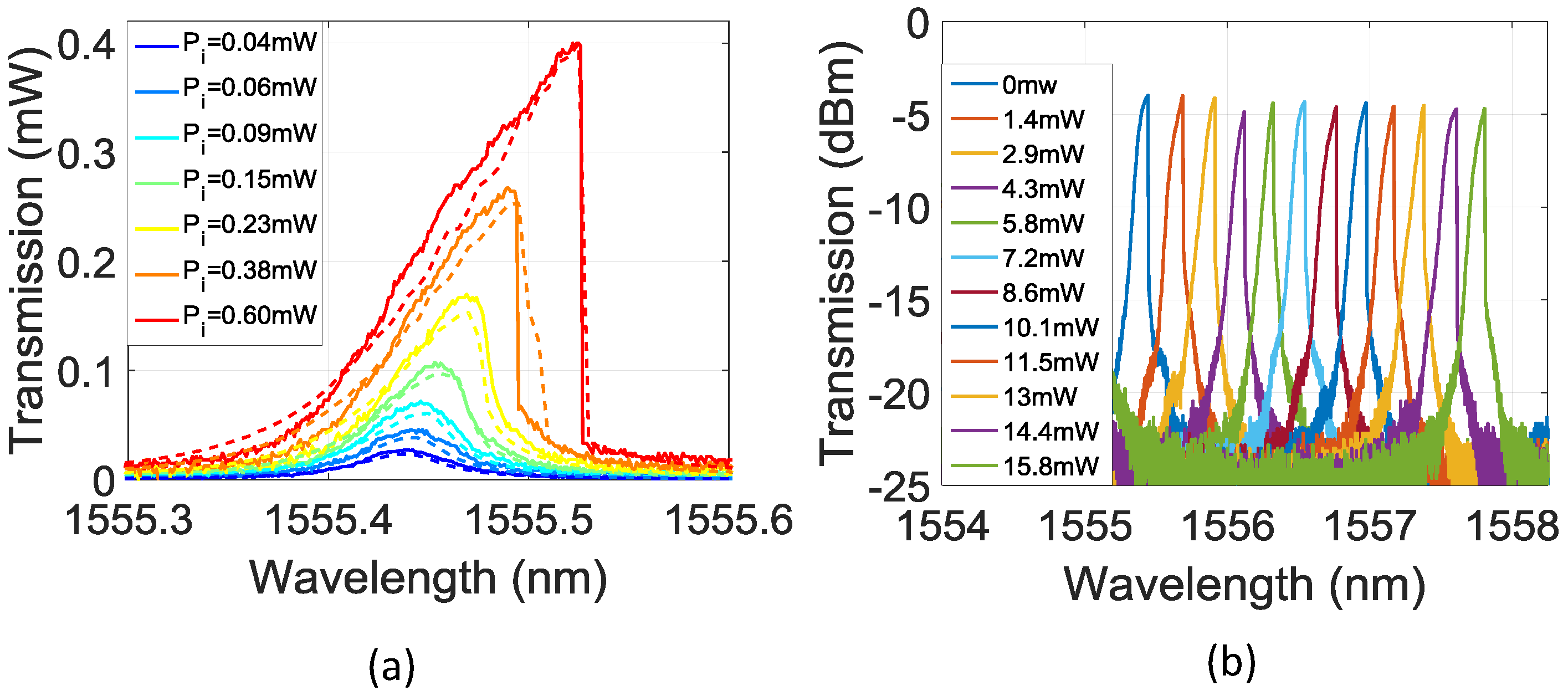

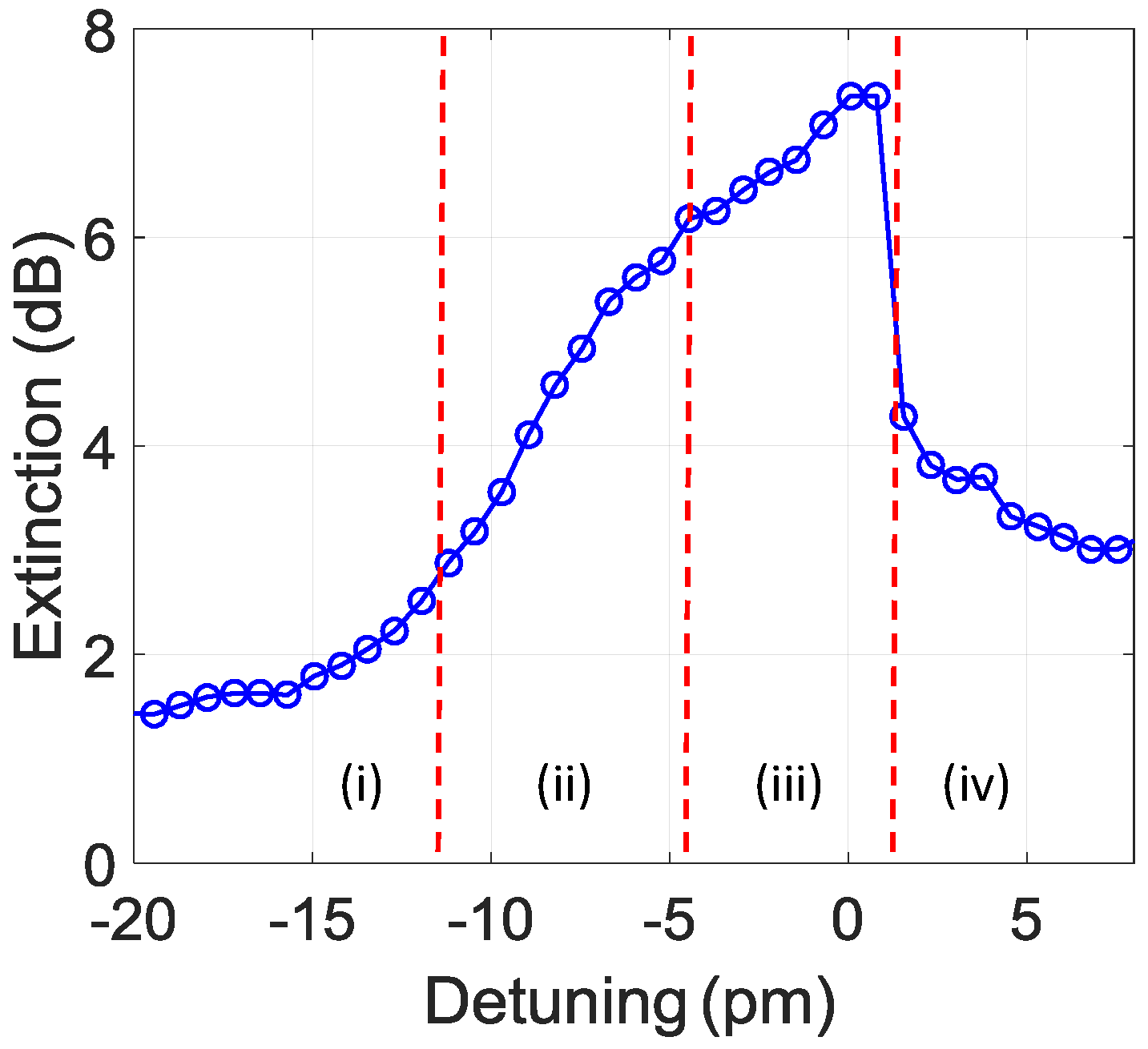

3.1. -Phase Shifted Grating Response

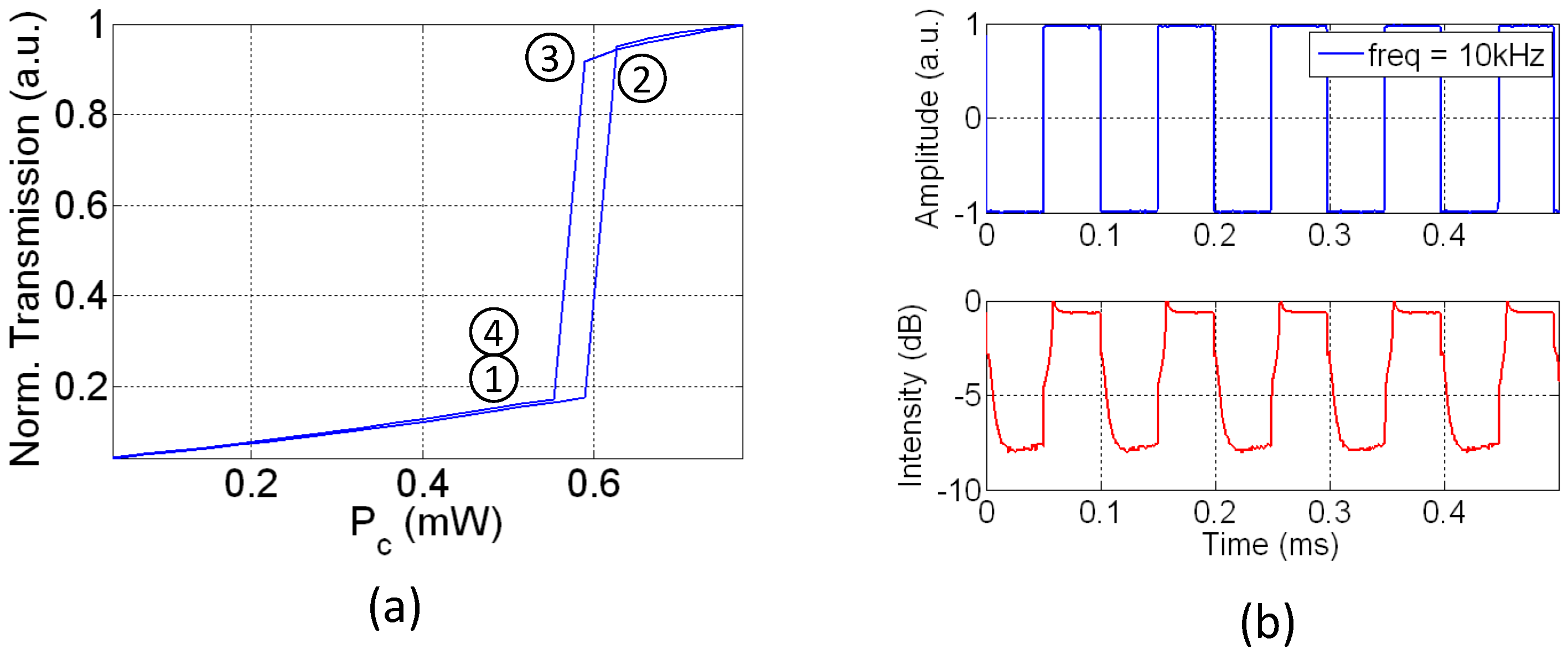

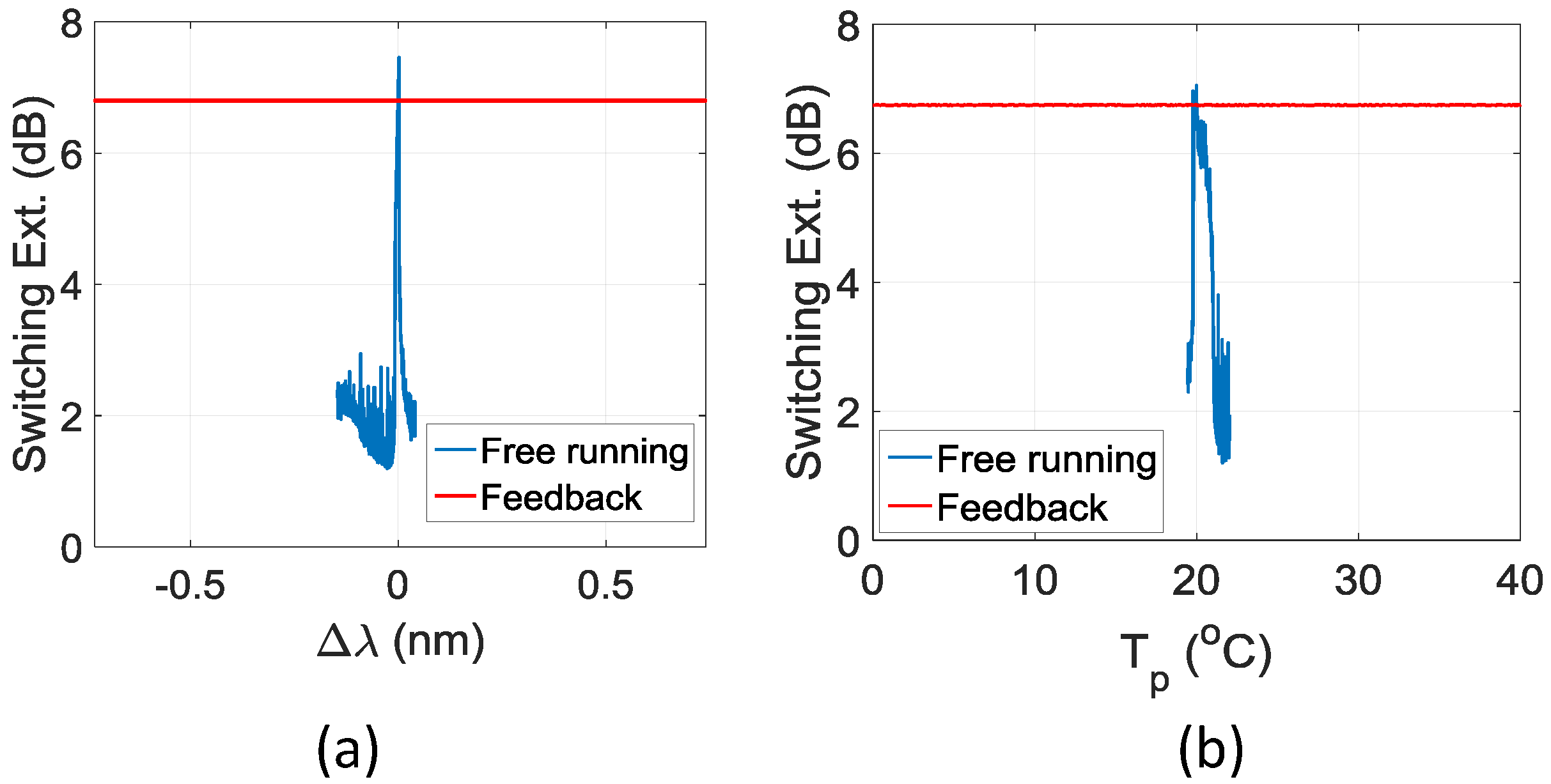

3.2. Cavity Stabilization

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Leuthold, J.; Koos, C.; Freude, W. Nonlinear silicon photonics. Nat. Photonics 2010, 4, 535–544. [Google Scholar] [CrossRef]

- Foster, M.A.; Turner, A.C.; Salem, R.; Lipson, M.; Gaeta, A.L. Broad-band continuous-wave parametric wavelength conversion in silicon nanowaveguides. Opt. Express 2007, 15, 12949–12958. [Google Scholar] [CrossRef] [PubMed]

- Ong, J.R.; Member, S.; Kumar, R. Efficient CW Four-Wave Mixing in Silicon-on-Insulator Micro-Rings With Active Carrier Removal. IEEE Photonics Technol. Lett. 2013, 25, 1699–1702. [Google Scholar] [CrossRef]

- Wu, C.; Lin, Y.; Su, S.; Huang, B.; Lin, G.-R. Degenerate Four-Wave Mixing in Si Quantum Dot doped Si-rich SiNx Channel Waveguide. J. Light. Technol. 2016, 34, 4111–4120. [Google Scholar] [CrossRef]

- Kuyken, B.; Liu, X.; Osgood, R.M.; Baets, R.; Roelkens, G.; Green, W.M.J. Mid-infrared to telecom-band supercontinuum generation in highly nonlinear silicon-on-insulator wire waveguides. Opt. Express 2011, 19, 20172–20181. [Google Scholar] [CrossRef] [PubMed]

- Grassani, D.; Azzini, S.; Liscidini, M.; Galli, M.; Strain, M.J.; Sorel, M.; Sipe, J.E.; Bajoni, D. Micrometer-scale integrated silicon source of time-energy entangled photons. Optica 2015, 2, 88–94. [Google Scholar] [CrossRef]

- Almeida, V.R.; Lipson, M. Optical bistability on a silicon chip. Opt. Lett. 2004, 29, 2387–2389. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.-L.; Lin, Y.-H.; Cheng, C.-H.; Su, S.-P.; Huang, B.-J.; Chang, J.-H.; Wu, C.-I.; Lee, C.-K.; Lin, G.-R. Enriching Si quantum dots in a Si-rich SiNx matrix for strong χ(3) optical nonlinearity. J. Mater. Chem. C 2016, 4, 1405–1413. [Google Scholar] [CrossRef]

- Turner, A.C.; Foster, M.A.; Gaeta, A.L.; Lipson, M. Ultra-low power parametric frequency conversion in a silicon microring resonator. Opt. Express 2008, 16, 4881–4887. [Google Scholar] [CrossRef] [PubMed]

- Morichetti, F.; Canciamilla, A.; Ferrari, C.; Samarelli, A.; Sorel, M.; Melloni, A. Travelling-wave resonant four-wave mixing breaks the limits of cavity-enhanced all-optical wavelength conversion. Nat. Commun. 2011, 2, 296. [Google Scholar] [CrossRef] [PubMed]

- Strain, M.J.; Lacava, C.; Merrigi, L.; Cristiani, I.; Sorel, M. Tunable Q-factor silicon micro-ring resonators for ultra-low power parametric processes. Opt. Lett. 2014, 40, 4–7. [Google Scholar]

- Grieco, A.; Slutsky, B.; Tan, D.T.H.; Zamek, S.; Nezhad, M.P.; Fainman, Y. Optical Bistability in a Silicon Waveguide Distributed Bragg Reflector Fabry-Pérot Resonator. IEEE J. Light. Technol. 2012, 30, 2352–2355. [Google Scholar] [CrossRef]

- Komma, J.; Schwarz, C.; Hofmann, G.; Heinert, D.; Nawrodt, R. Thermo-optic coefficient of silicon at 1550 nm and cryogenic temperatures. Appl. Phys. Lett. 2012, 101, 4–8. [Google Scholar] [CrossRef]

- Padmaraju, K.; Logan, D.F.; Shiraishi, T.; Ackert, J.J.; Knights, A.P.; Bergman, K. Wavelength locking and thermally stabilizing microring resonators using dithering signals. J. Light. Technol. 2014, 32, 505–512. [Google Scholar] [CrossRef]

- Padmaraju, K.; Logan, D.F.; Zhu, X.; Ackert, J.J.; Knights, A.P.; Bergman, K. Integrated thermal stabilization of a microring modulator. Opt. Express 2013, 21, 14342–14350. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Shi, W.; Grist, S.; Yun, H.; Jaeger, N.A.F.; Chrostowski, L. Narrow-band transmission filter using phase-shifted Bragg gratings in SOI waveguide. In Proceedings of the IEEE Photonics Conference, Arlington, VA, USA, 9–13 October 2011.

- Rutkowska, K.A.; Duchesne, D.; Strain, M.J.; Morandotti, R.; Sorel, M.; Azaña, J. Ultrafast all-optical temporal differentiators based on CMOS-compatible integrated-waveguide Bragg gratings. Opt. Express 2011, 19, 19514–19522. [Google Scholar] [CrossRef] [PubMed]

- Strain, M.J.; Thoms, S.; MacIntyre, D.S.; Sorel, M. Multi-wavelength filters in silicon using superposition sidewall Bragg grating devices. Opt. Lett. 2014, 39, 413–416. [Google Scholar] [CrossRef] [PubMed]

- Strain, M.J.; Sorel, M. Design and fabrication of integrated chirped Bragg gratings for on-chip dispersion control. IEEE J. Quantum Electron. 2010, 46, 774–782. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cantarella, G.; Strain, M.J. A Micro-Processor-Based Feedback Stabilization Scheme for High-Q, Non-Linear Silicon Resonators. Appl. Sci. 2016, 6, 316. https://doi.org/10.3390/app6110316

Cantarella G, Strain MJ. A Micro-Processor-Based Feedback Stabilization Scheme for High-Q, Non-Linear Silicon Resonators. Applied Sciences. 2016; 6(11):316. https://doi.org/10.3390/app6110316

Chicago/Turabian StyleCantarella, Giuseppe, and Michael J. Strain. 2016. "A Micro-Processor-Based Feedback Stabilization Scheme for High-Q, Non-Linear Silicon Resonators" Applied Sciences 6, no. 11: 316. https://doi.org/10.3390/app6110316

APA StyleCantarella, G., & Strain, M. J. (2016). A Micro-Processor-Based Feedback Stabilization Scheme for High-Q, Non-Linear Silicon Resonators. Applied Sciences, 6(11), 316. https://doi.org/10.3390/app6110316