Family of Quantum Sources for Improving Near Field Accuracy in Transducer Modeling by the Distributed Point Source Method

Abstract

:1. Introduction

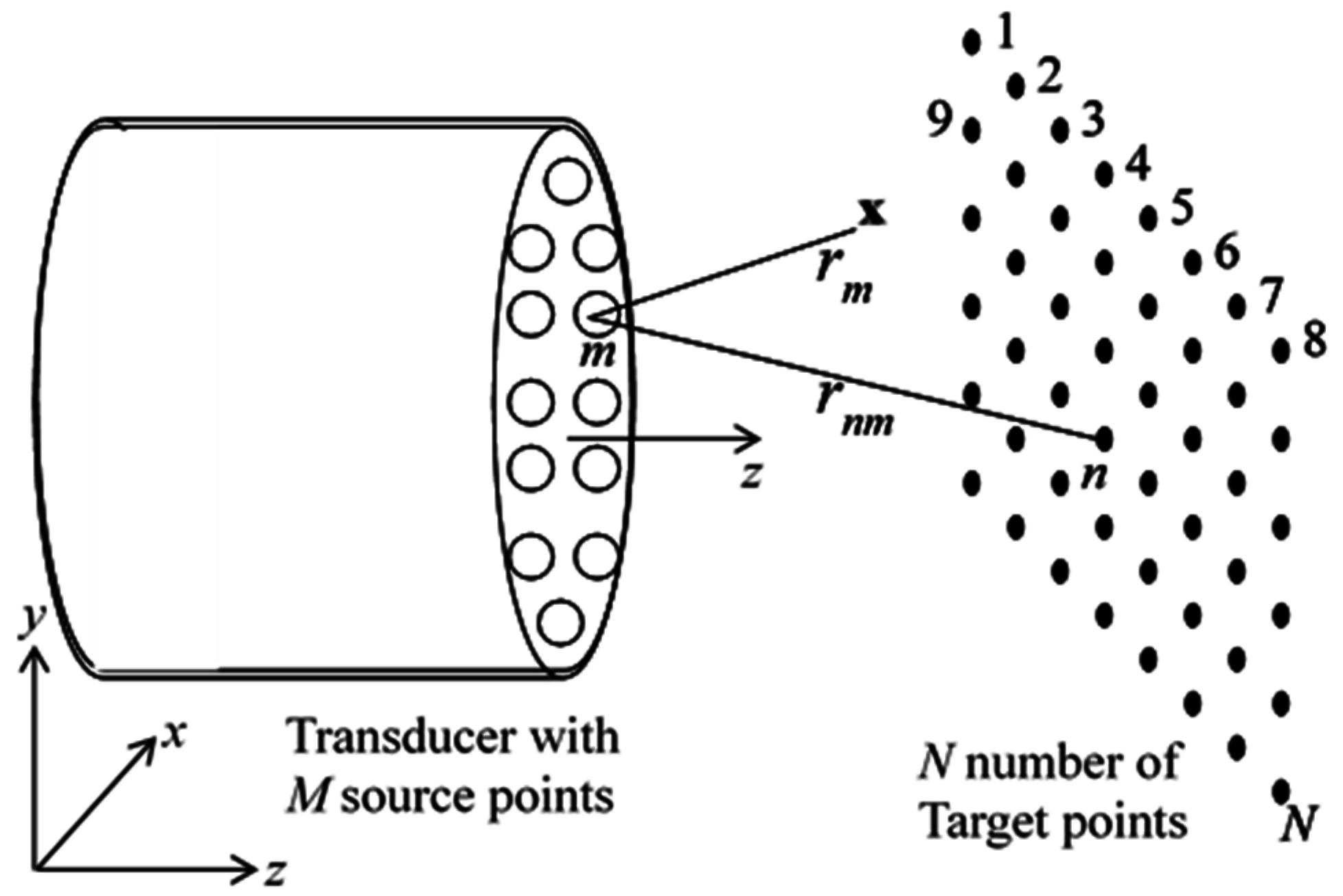

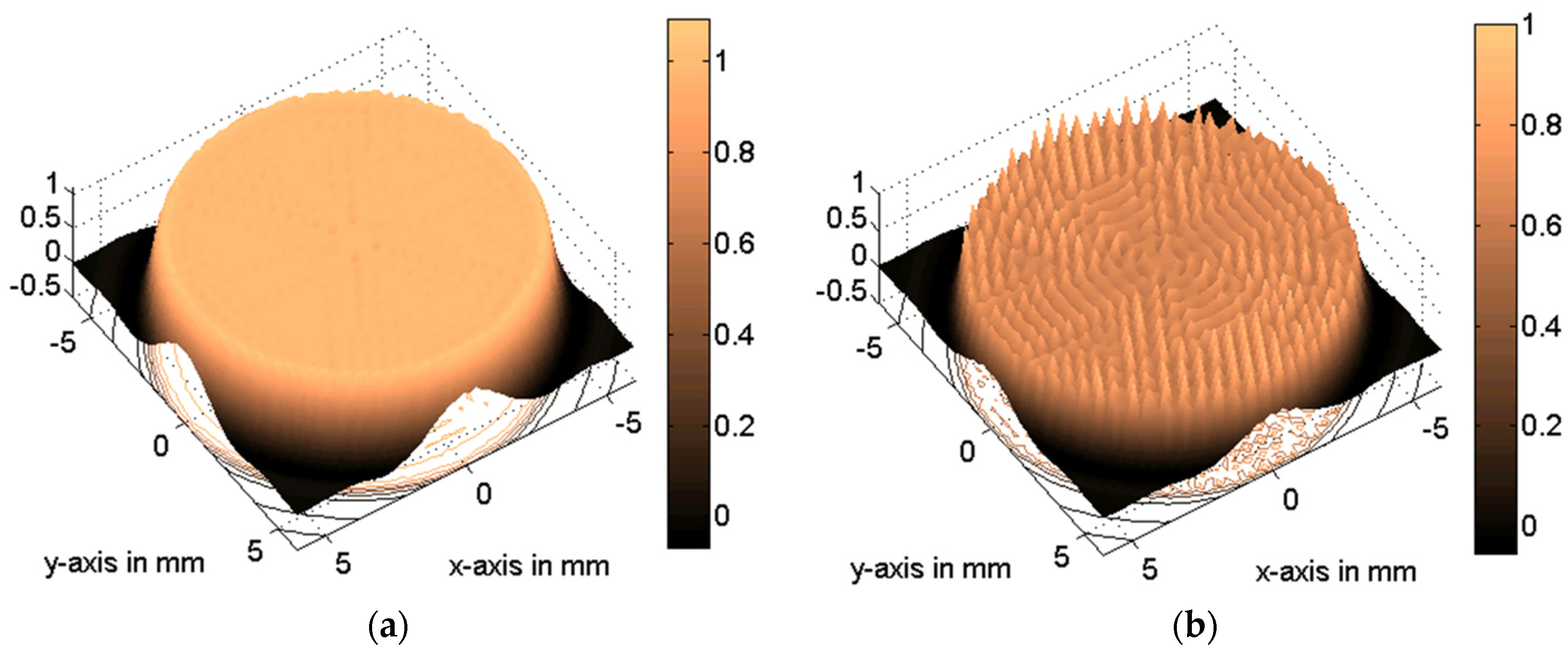

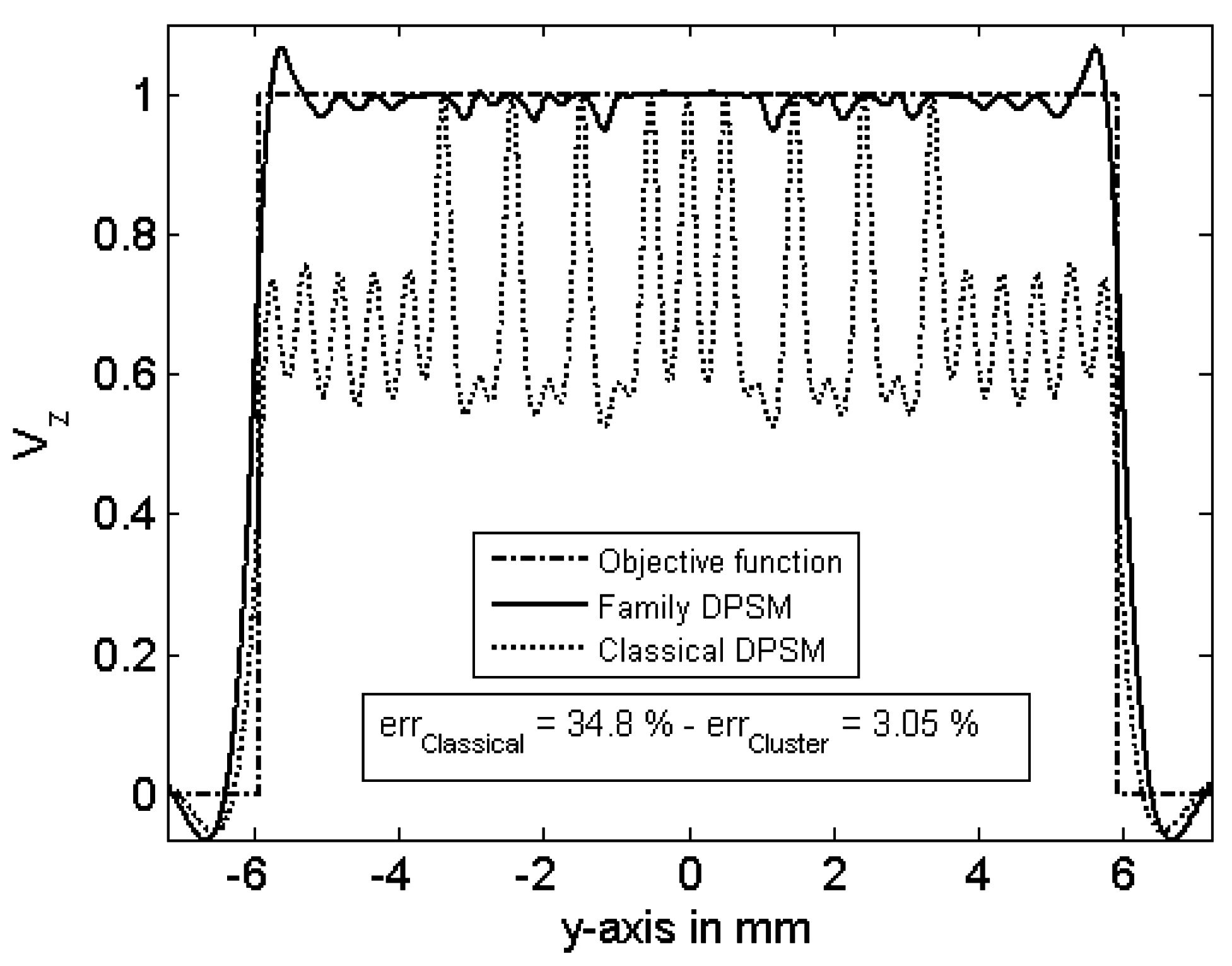

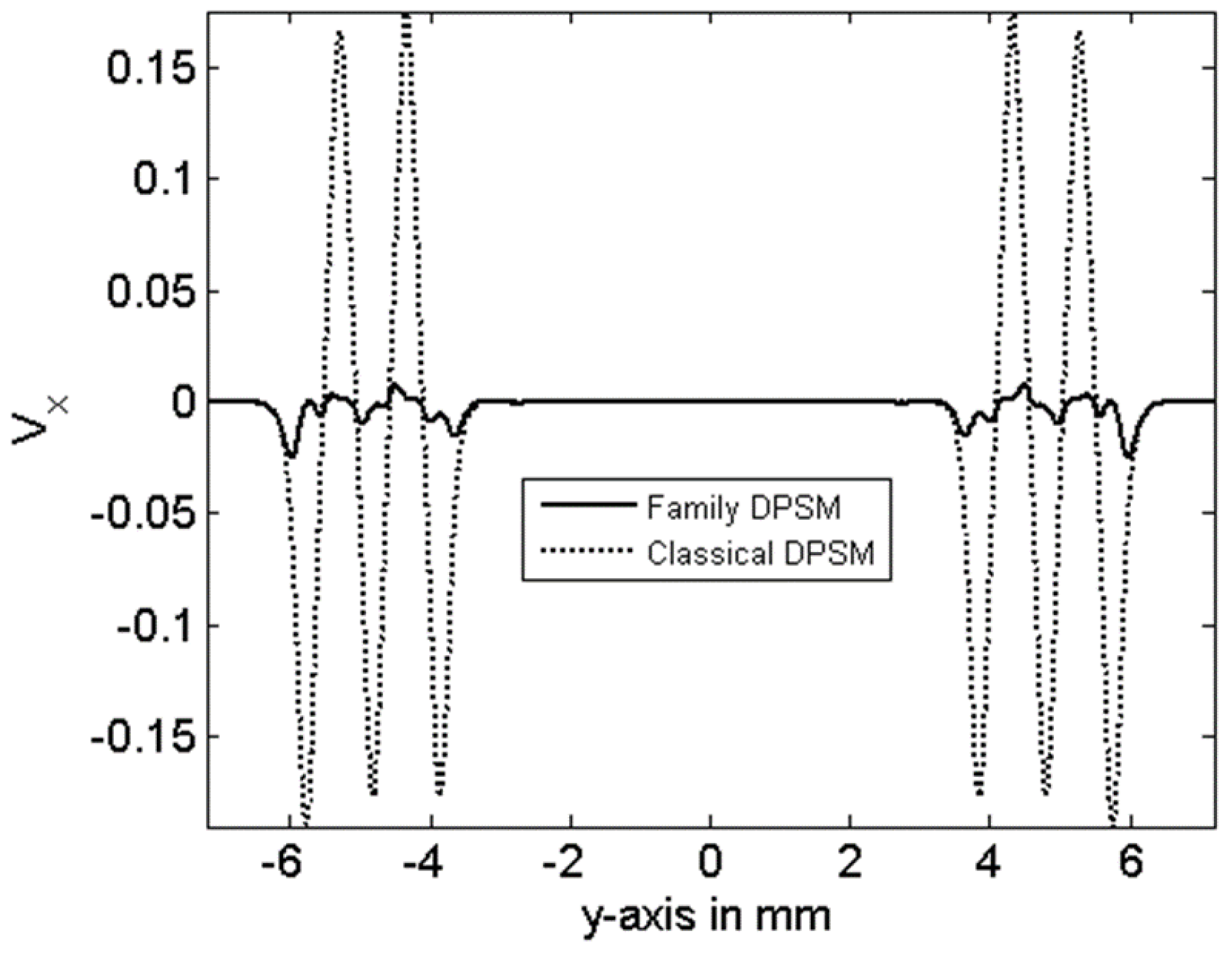

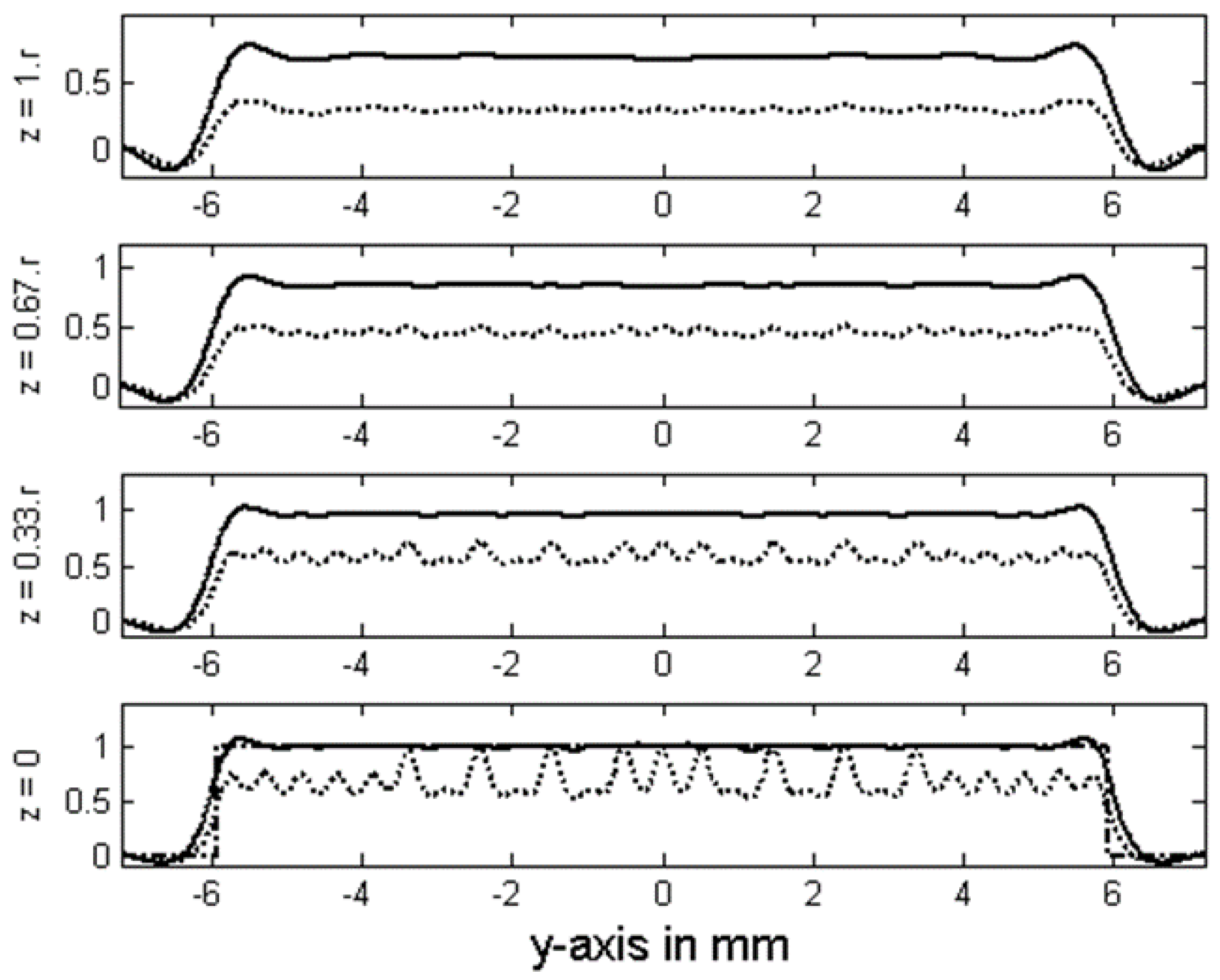

2. Formulations

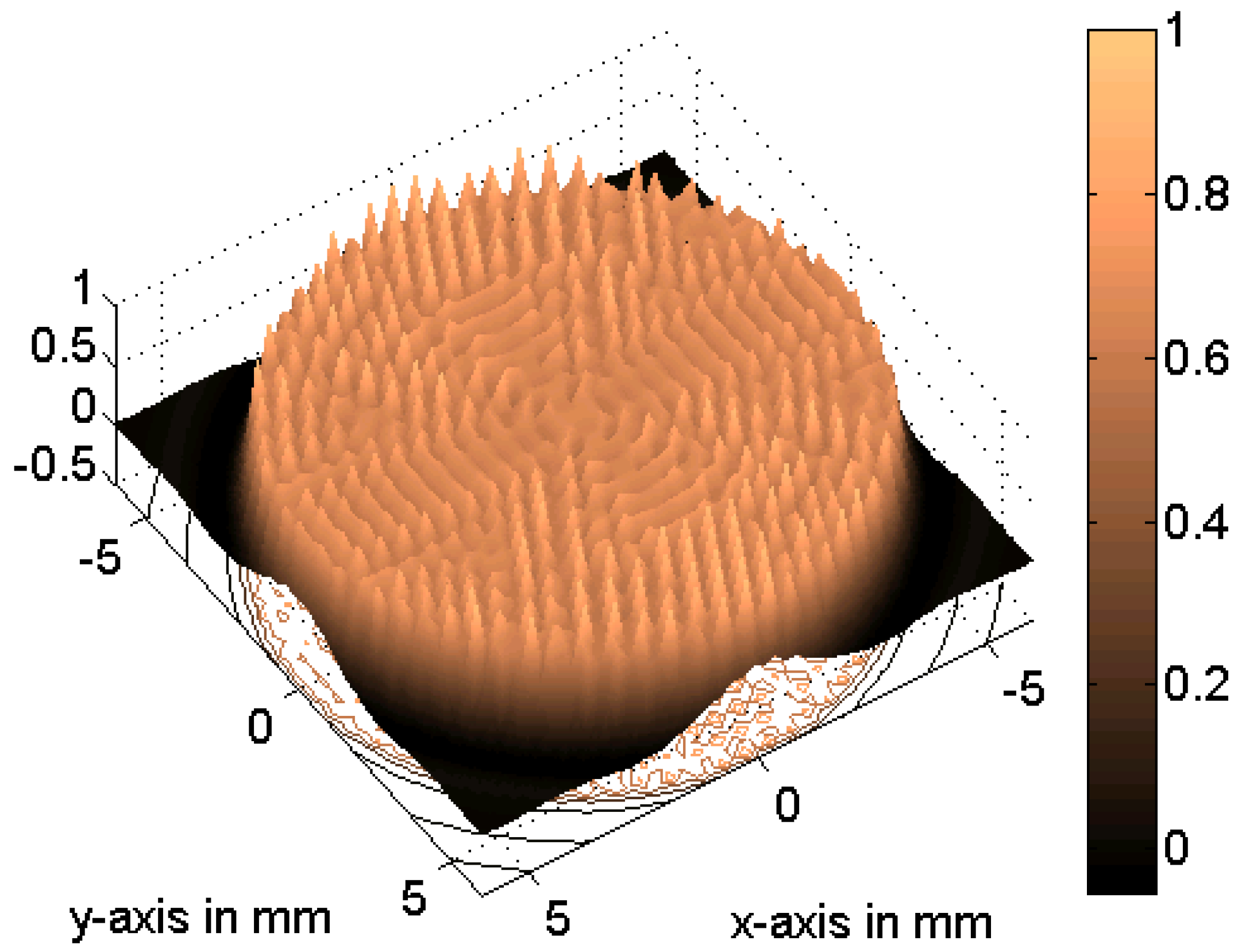

2.1. Classical DPSM Formulation: ESD is a Single Point Source

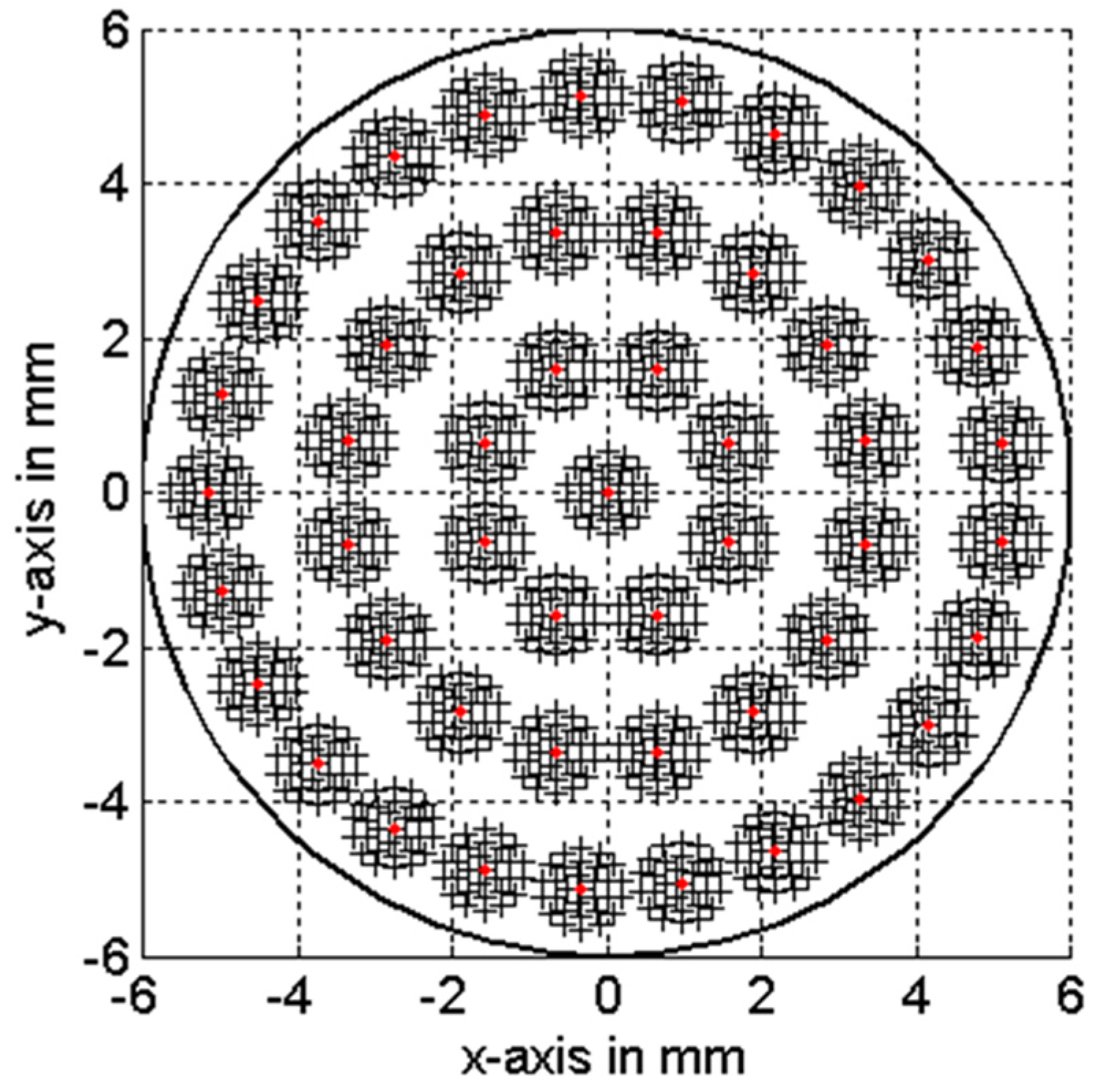

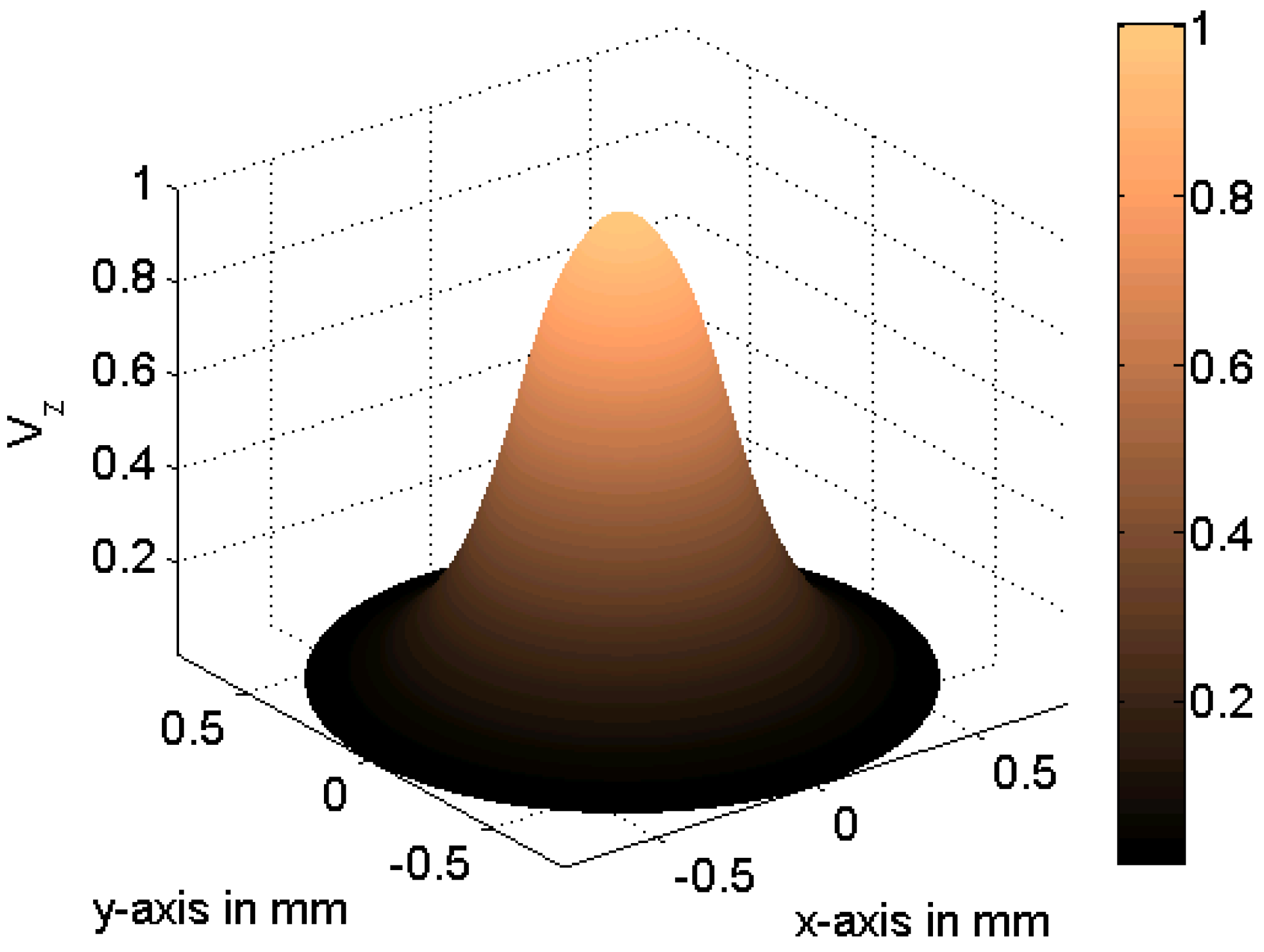

2.2. Formulation with ESD Families

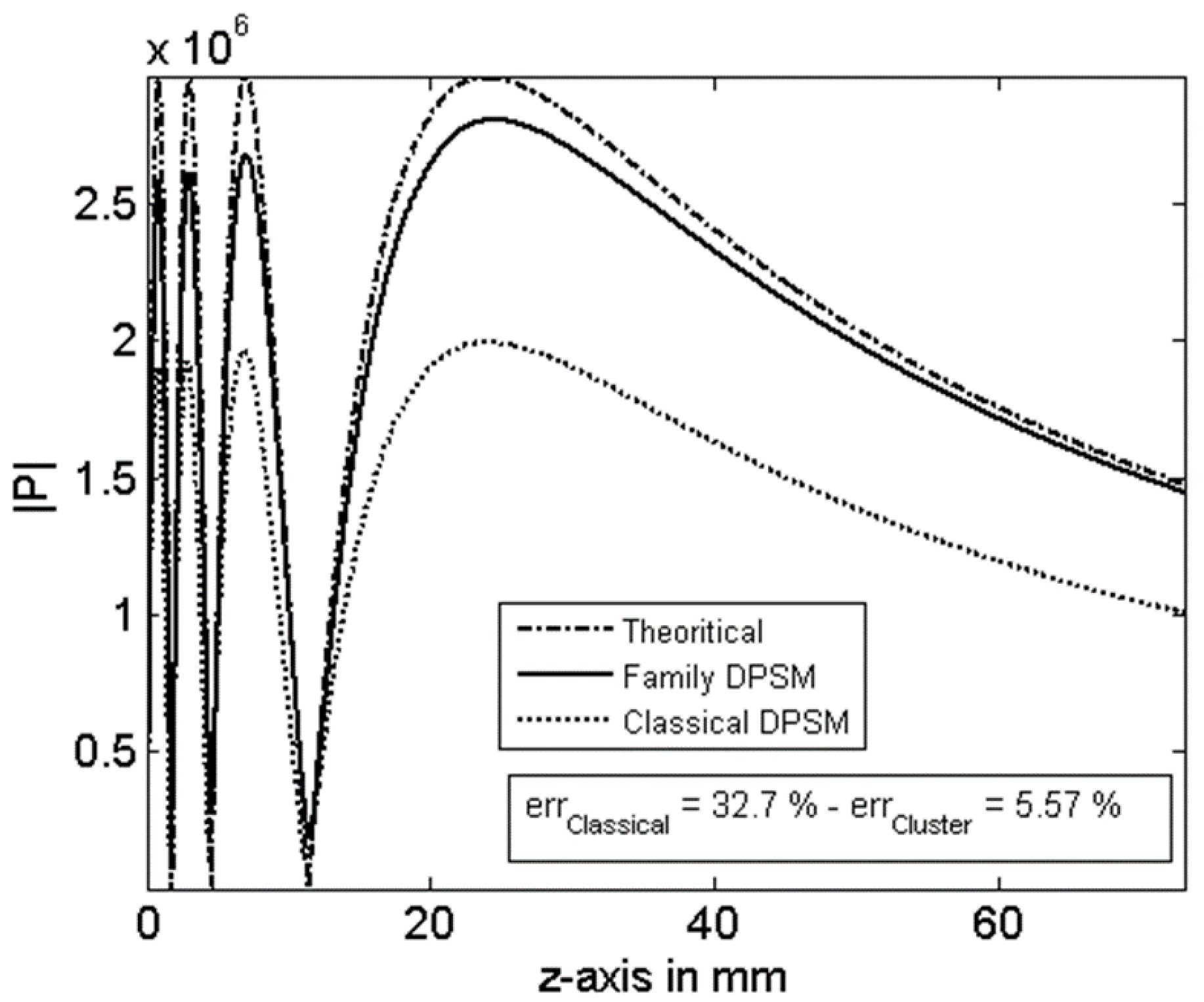

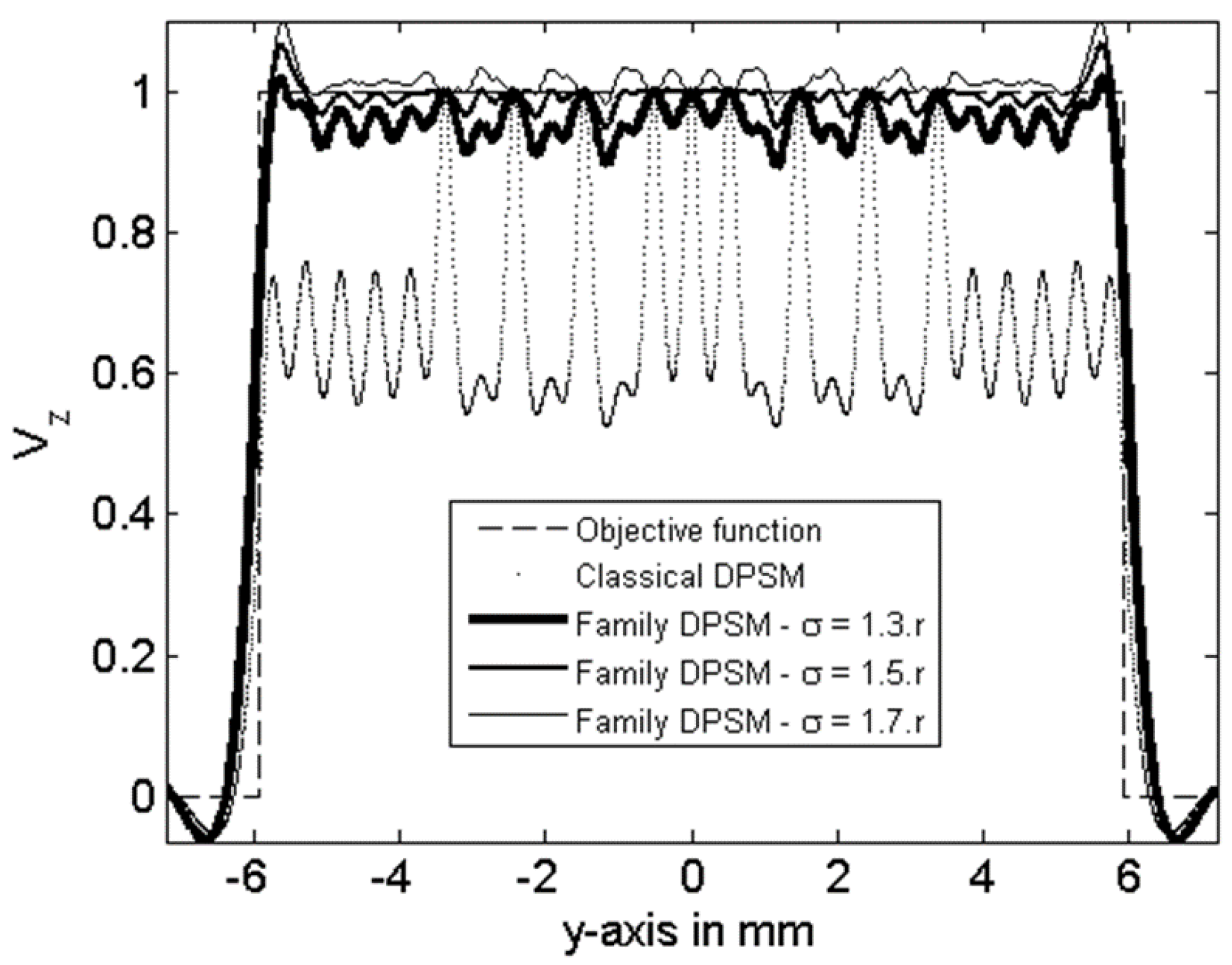

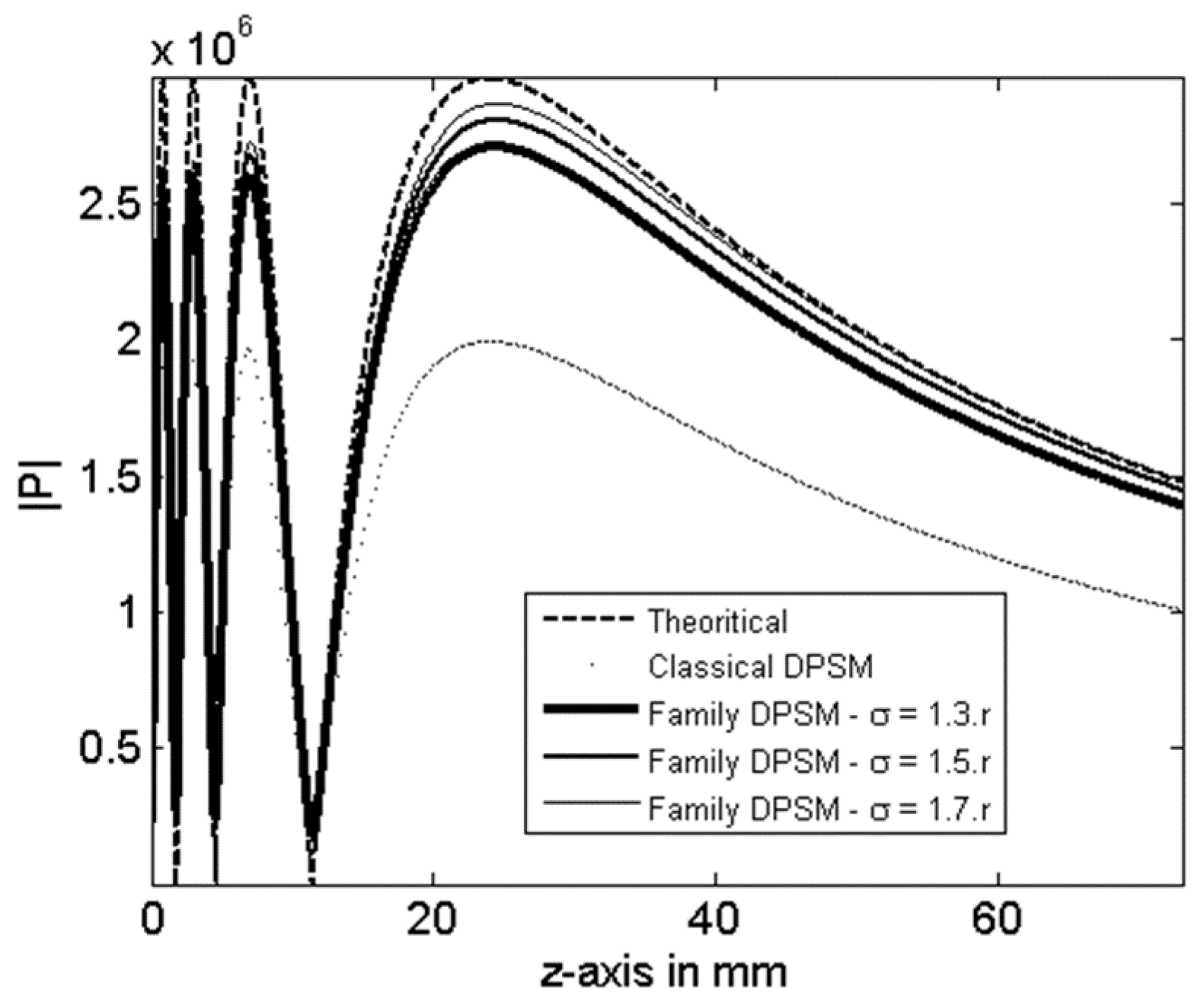

3. Results

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rayleigh, L. Theory of Sound; Dover Publications: New York, NY, USA, 1965; Volume 2, pp. 162–169. [Google Scholar]

- Morse, P.M.; Ingard, U.K. Theoretical Acoustics; McGraw-Hill: New York, NY, USA, 1968. [Google Scholar]

- Schmerr, L.W. Fundamental of Ultrasonic Nondestructive Evaluation—A Modeling Approach; Plenum Press: New York, NY, USA, 1998. [Google Scholar]

- Kundu, T. (Ed.) Ultrasonic Nondestructive Evaluation: Engineering and Biological Material Characterization; CRC Press: Boca Raton, FL, USA, 2004.

- Harris, G.R. Review of transient field theory for a baffled planar piston. J. Acoust. Soc. Am. 1981, 70, 10–20. [Google Scholar] [CrossRef]

- Sha, K.; Yang, J.; Gan, W.S. A complex virtual source approach for calculating the diffraction beam field generated by a rectangular planar source. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2003, 50, 890–895. [Google Scholar] [PubMed]

- Stepanishen, P.R. Transient radiation from piston in an infinite planar baffle. J. Acoust. Soc. Am. 1971, 49, 1627–1638. [Google Scholar] [CrossRef]

- Jensen, J.A.; Svendsen, N.B. Calculation of pressure fields from arbitrary shaped, apodized, and excited ultrasound transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1992, 39, 262–267. [Google Scholar] [CrossRef] [PubMed]

- Ingenito, F.; Cook, B.D. Theoretical investigation of the integrated optical effort produced by sound field radiated from plane piston transducers. J. Acoust. Soc. Am. 1969, 45, 572–577. [Google Scholar] [CrossRef]

- Lockwood, J.C.; Willette, J.G. High-speed method for computing the exact solution for the pressure variations in the near field of a baffled piston. J. Acoust. Soc. Am. 1973, 53, 735–741. [Google Scholar] [CrossRef]

- Scarano, G.; Denisenko, N.; Matteucci, M.; Pappalardo, M. A new approach to the derivation of the impulse response of a rectangular piston. J. Acoust. Soc. Am. 1985, 78, 1109–1113. [Google Scholar] [CrossRef]

- Hah, Z.G.; Sung, K.M. Effect of spatial sampling in the calculation of ultrasonic fields generated by piston transducers. J. Acoust. Soc. Am. 1992, 92, 3403–3408. [Google Scholar] [CrossRef]

- Wu, P.; Kazys, R.; Stepinski, T. Analysis of the numerically implemented angular spectrum approach based on the evaluation of two-dimensional acoustic fields. Part I. Errors due to the discrete Fourier transform and discretization. J. Acoust. Soc. Am. 1995, 99, 1139–1148. [Google Scholar] [CrossRef]

- Lerch, T.P.; Schmerr, L.W.; Sedov, A. Ultrasonic beam models: An edge element approach. J. Acoust. Soc. Am. 1998, 104, 1256–1265. [Google Scholar] [CrossRef]

- Azar, L.; Shi, Y.; Wooh, S.C. Beam focusing behavior of linear phased arrays. NDT E Int. 2000, 33, 189–198. [Google Scholar] [CrossRef]

- Buiochi, F.; Martinez, O.; Ullate, L.G.; Espinosa, F.M. 3D computational method to study the focal laws of transducer arrays for NDE applications. Ultrasonics 2004, 42, 871–876. [Google Scholar] [CrossRef] [PubMed]

- Song, S.J.; Kim, C.H. Simulation of 3-D radiation beam patterns propagated through a planar interface from ultrasonic phased array transducers. Ultrasonics 2002, 40, 519–524. [Google Scholar] [CrossRef]

- Ahmad, R.; Kundu, T.; Placko, D. Modeling of phased array transducers. J. Acoust. Soc. Am. 2005, 117, 1762–1776. [Google Scholar] [CrossRef] [PubMed]

- Park, J.S.; Song, S.J.; Kim, H.J. Calculation of radiation beam field from phased array ultrasonic transducers using expanded Multi-Gaussian beam model. In Advances in Safety and Structural Integrity 2005; Book Series: Solid State Phenomena; Trans Tech Publications: Zürich, Switzerland, 2006; Volume 110, pp. 163–168. [Google Scholar]

- Zhao, X.; Gang, T. A study on non paraxial beam model and ultrasonic measurement model of phased arrays. Ultrasonics 2008, 49, 126–130. [Google Scholar] [CrossRef] [PubMed]

- Placko, D.; Liebeaux, N. Modèle à sources Réparties: Un concept pour le calcul du champ émis par les circuits magnétiques ouverts. In Acte du Deuxième Colloque Interdisciplinaire en Instrumentation (C2I); Hermes: Paris, France, 2001; pp. 523–530. [Google Scholar]

- Placko, D.; Kundu, T. Modeling of ultrasonic field by distributed point source method. In Ultrasonic Nondestructive Evaluation: Engineering and Biological Material Characterization; Kundu, T., Ed.; CRC Press: Boca Raton, FL, USA, 2004; pp. 143–202. [Google Scholar]

- Kundu, T.; Placko, D.; Rahani, E.K.; Yanagita, T.; Dao, C.M. Ultrasonic field modeling: A comparison between analytical, semi-analytical and numerical techniques. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2010, 57, 2795–2807. [Google Scholar] [CrossRef] [PubMed]

- Wada, Y.; Kundu, T.; Nakamura, K. Mesh-free distributed point source method for modeling viscous fluid layer motion between disks vibrating at ultrasonic frequency. J. Acoust. Soc. Am. 2014, 136, 466–474. [Google Scholar] [CrossRef] [PubMed]

- Placko, D.; Rivollet, A.; Bore, T. Procédé et Dispositif de Modélisation D’une Grandeur Physique d’un Écoulement Fluide (Process and set-up for Modeling a Physical Value in a Fuid Flow). French Patent Appl. 1454675, 23 May 2014. [Google Scholar]

- Jarvis, A.J.C.; Cegla, F.B. Scattering of near normal incidence SH waves by sinusoidal and rough surfaces in 3-D: Comparison to the scalar wave approximation. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2014, 61, 1179–1190. [Google Scholar] [CrossRef] [PubMed]

- Bore, T.; Placko, D.; Taillade, F.; Sabouroux, P. Electromagnetic characterization of grouting materials of bridge post tensioned ducts for NDT using capacitive probe. NDT E Int. 2013, 60, 110–120. [Google Scholar] [CrossRef]

- Rahani, E.K.; Kundu, T. Gaussian DPSM (G-DPSM) and Element Source Method (ESM) modifications to DPSM for ultrasonic field modeling. Ultrasonics 2011, 51, 625–631. [Google Scholar] [CrossRef] [PubMed]

- Placko, D.; Bore, T.; Kundu, T. Distributed point source method for modeling and imaging in electrostatic and electromagnetic problems. In Ultrasonic and Electromagnetic NDE for Structure and Material Characterization: Engineering and Biomedical Applications; Kundu, T., Ed.; CRC Press: Boca Raton, FL, USA, 2004; pp. 249–294. [Google Scholar]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Placko, D.; Bore, T.; Kundu, T. Family of Quantum Sources for Improving Near Field Accuracy in Transducer Modeling by the Distributed Point Source Method. Appl. Sci. 2016, 6, 302. https://doi.org/10.3390/app6100302

Placko D, Bore T, Kundu T. Family of Quantum Sources for Improving Near Field Accuracy in Transducer Modeling by the Distributed Point Source Method. Applied Sciences. 2016; 6(10):302. https://doi.org/10.3390/app6100302

Chicago/Turabian StylePlacko, Dominique, Thierry Bore, and Tribikram Kundu. 2016. "Family of Quantum Sources for Improving Near Field Accuracy in Transducer Modeling by the Distributed Point Source Method" Applied Sciences 6, no. 10: 302. https://doi.org/10.3390/app6100302

APA StylePlacko, D., Bore, T., & Kundu, T. (2016). Family of Quantum Sources for Improving Near Field Accuracy in Transducer Modeling by the Distributed Point Source Method. Applied Sciences, 6(10), 302. https://doi.org/10.3390/app6100302