Prediction of Water Inrush Hazard in Fully Mechanized Coal Seams’ Mining Under Aquifers by Numerical Simulation in ANSYS Software

Abstract

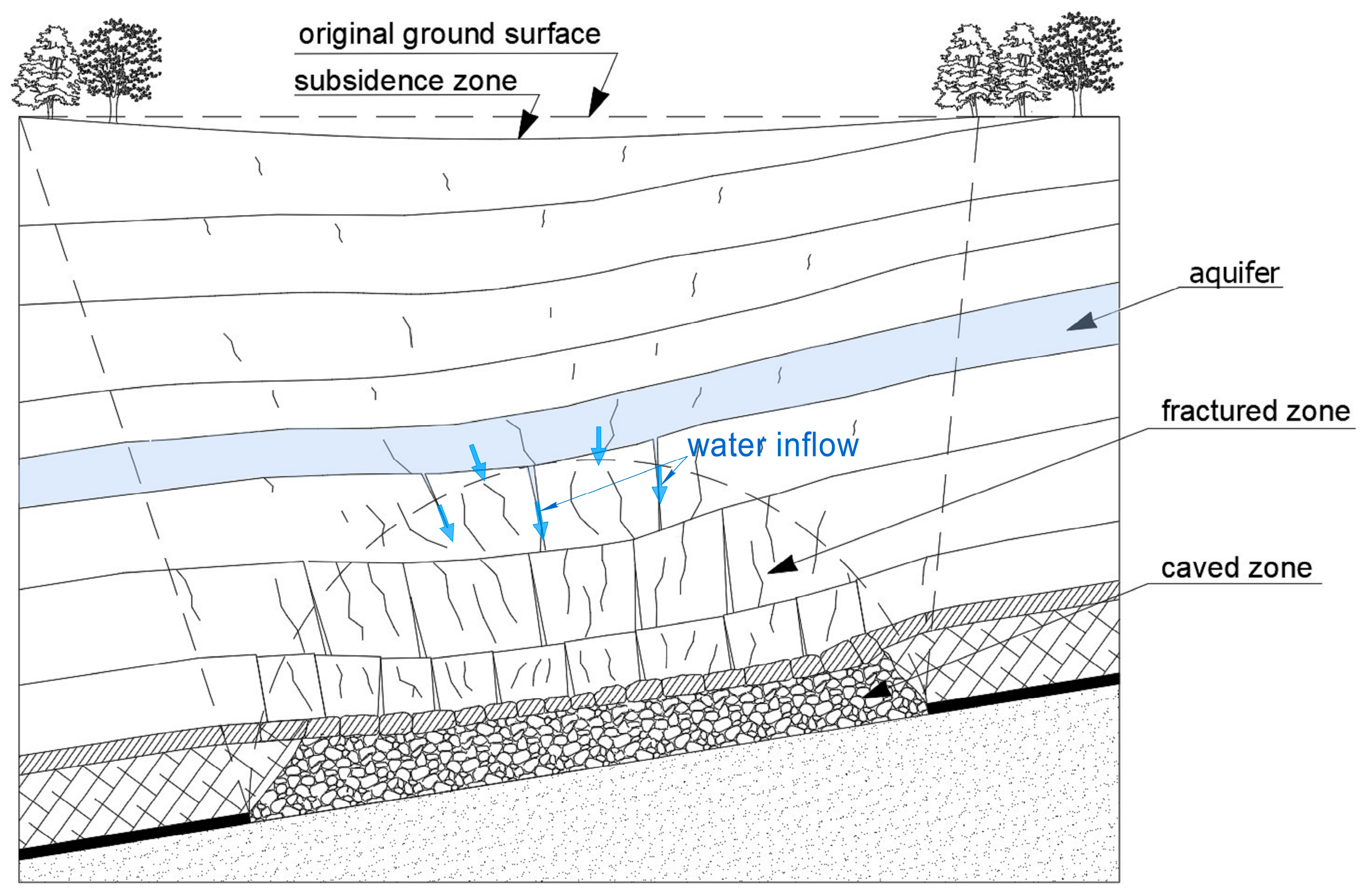

1. Introduction

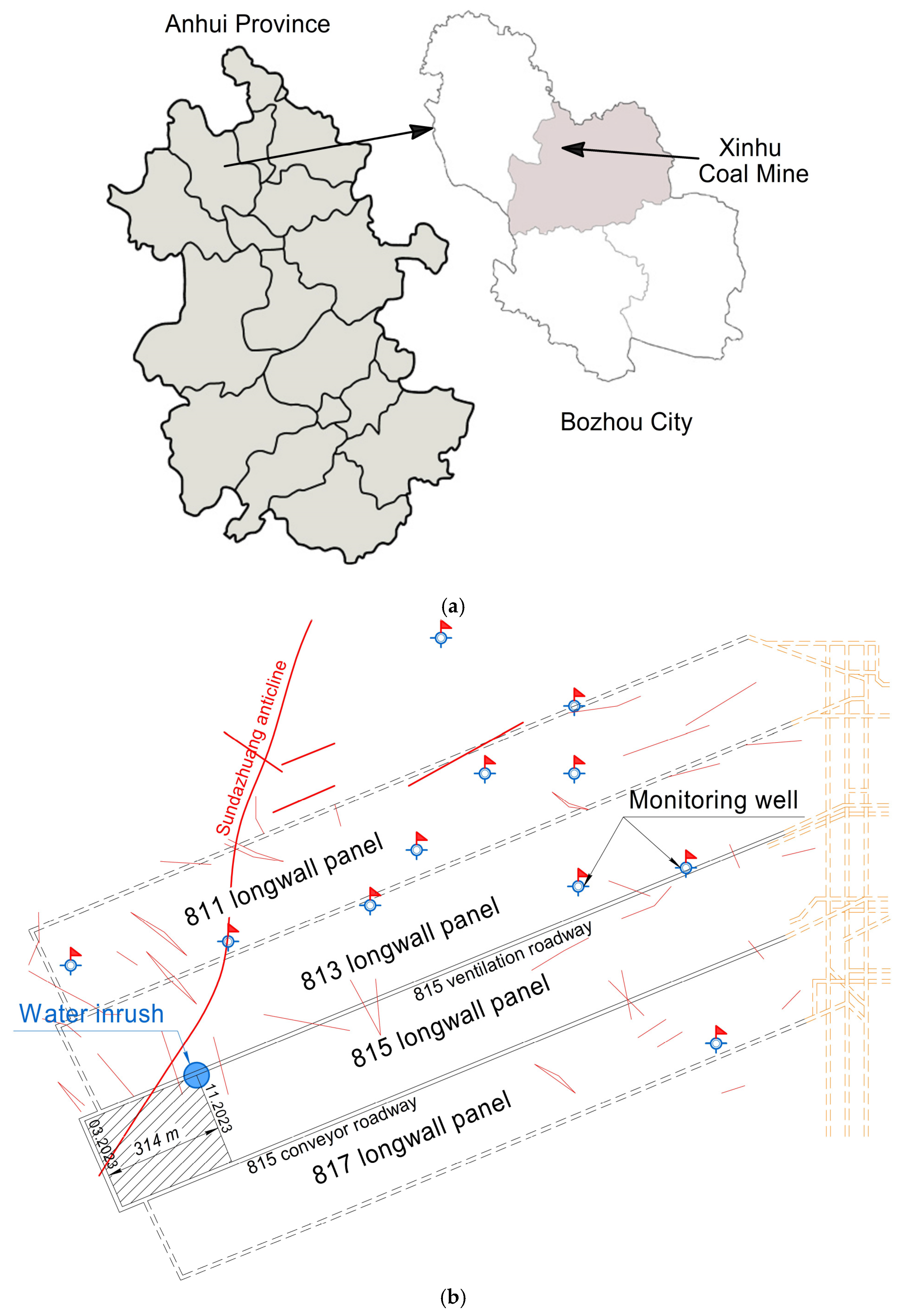

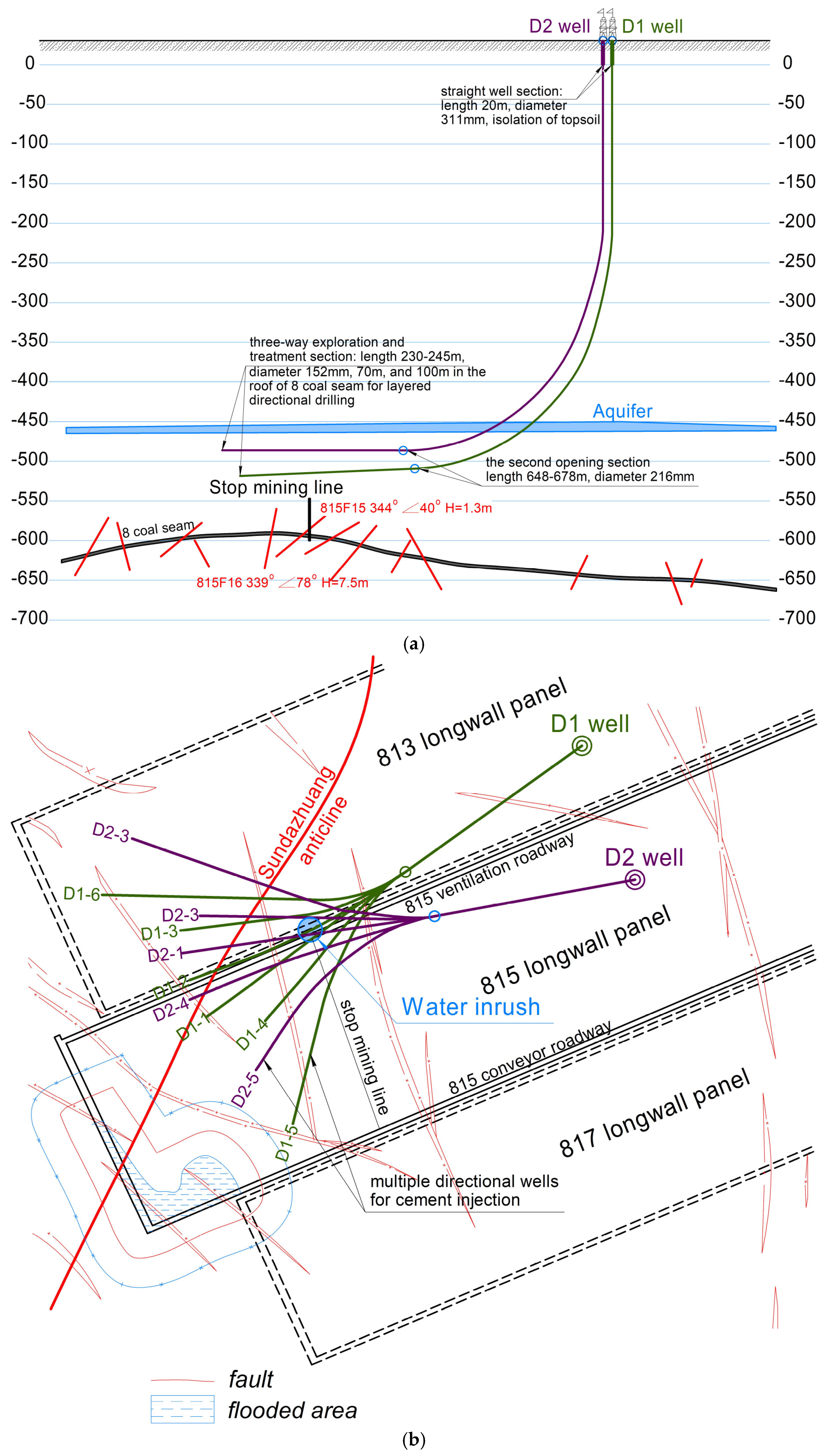

2. Engineering Background

3. Materials and Methods

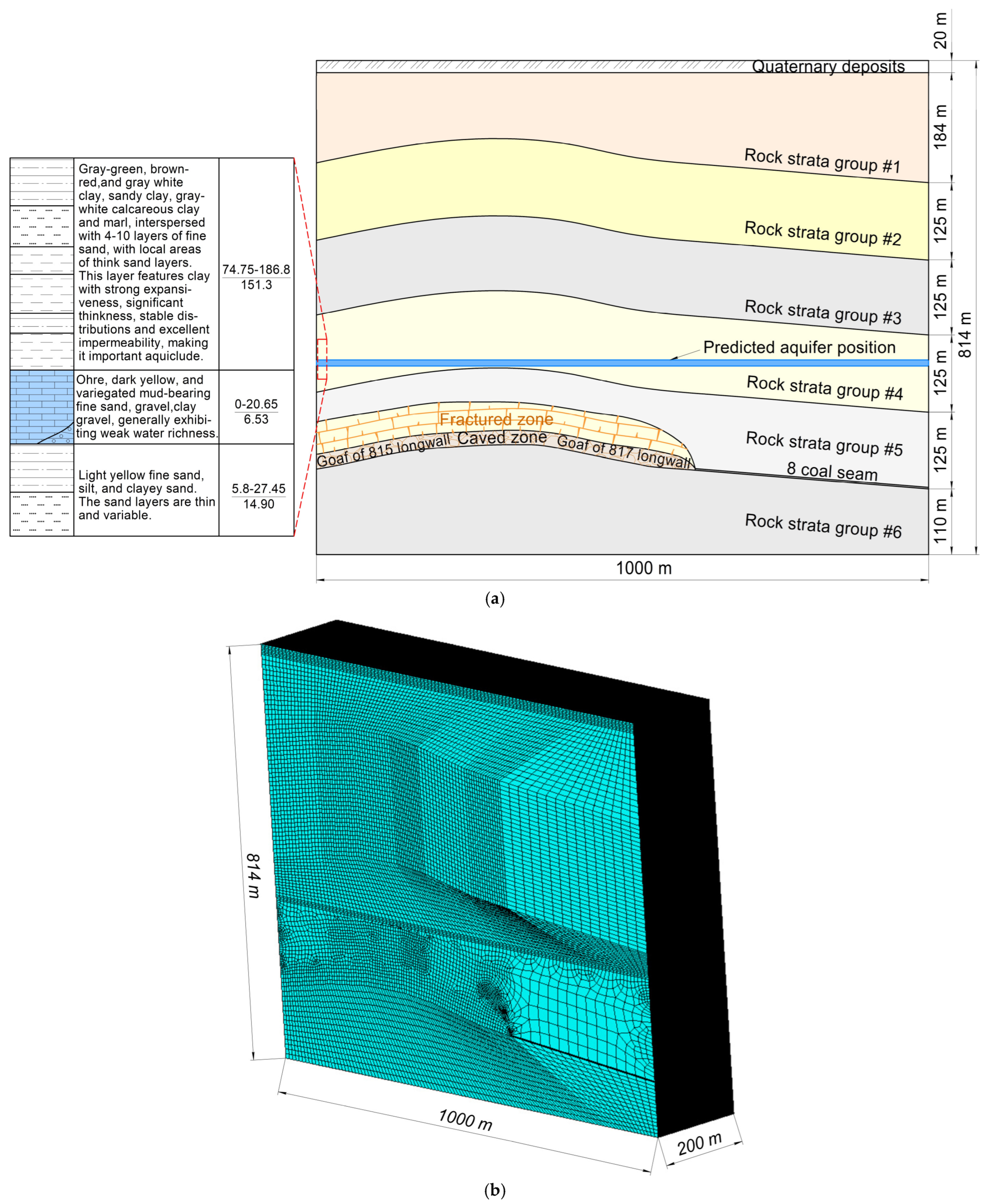

3.1. Geological and Engineering Conditions

3.2. Numerical Model

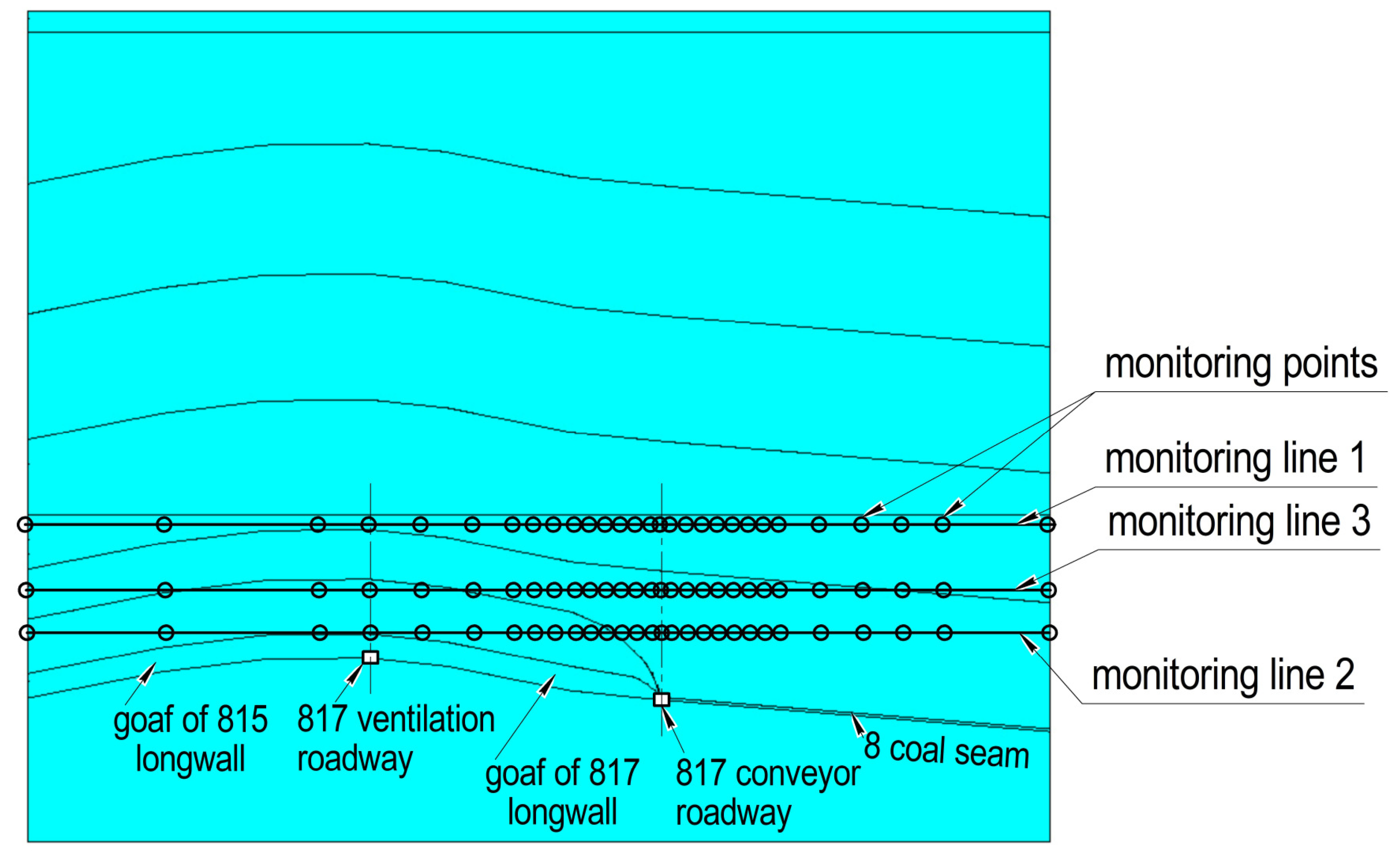

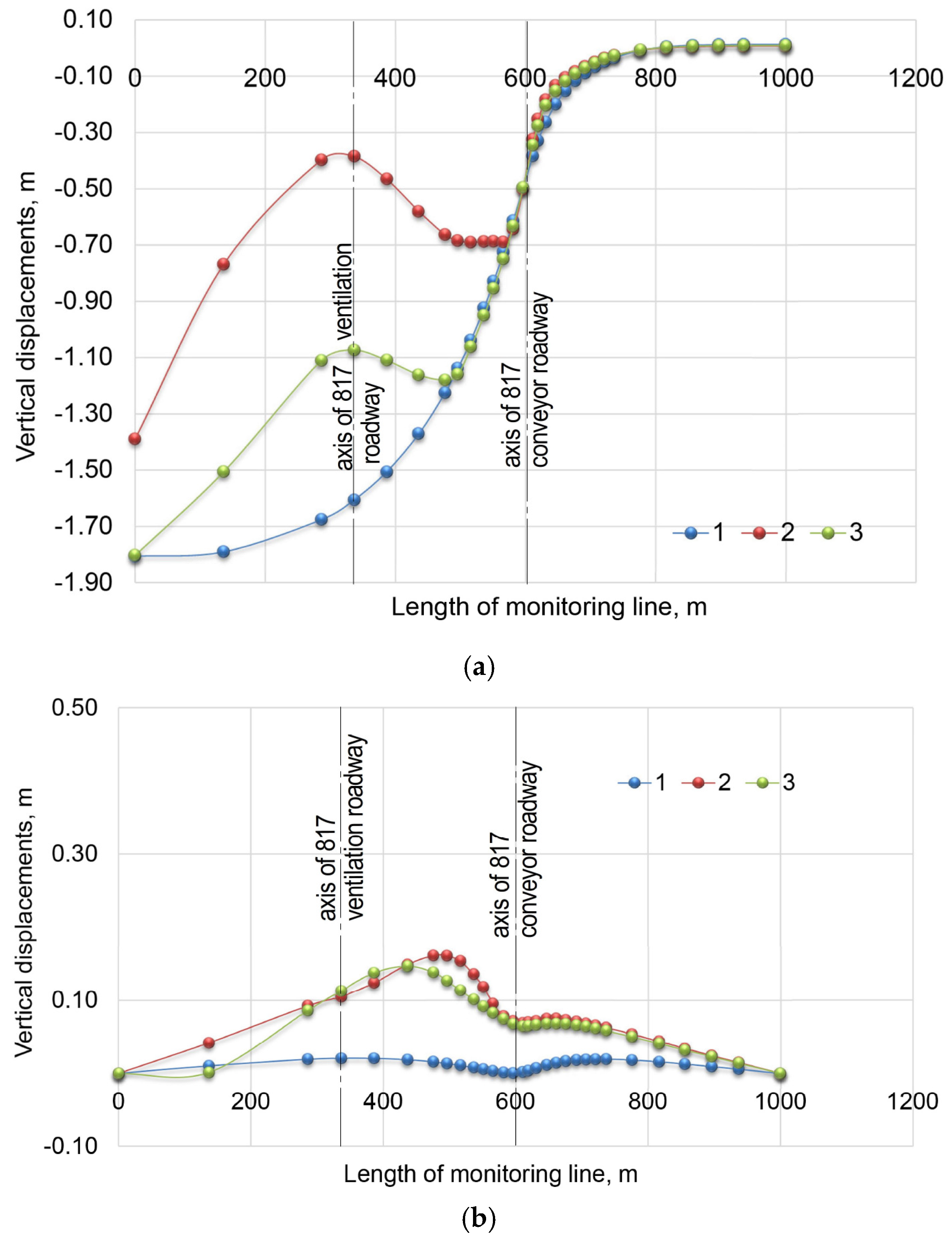

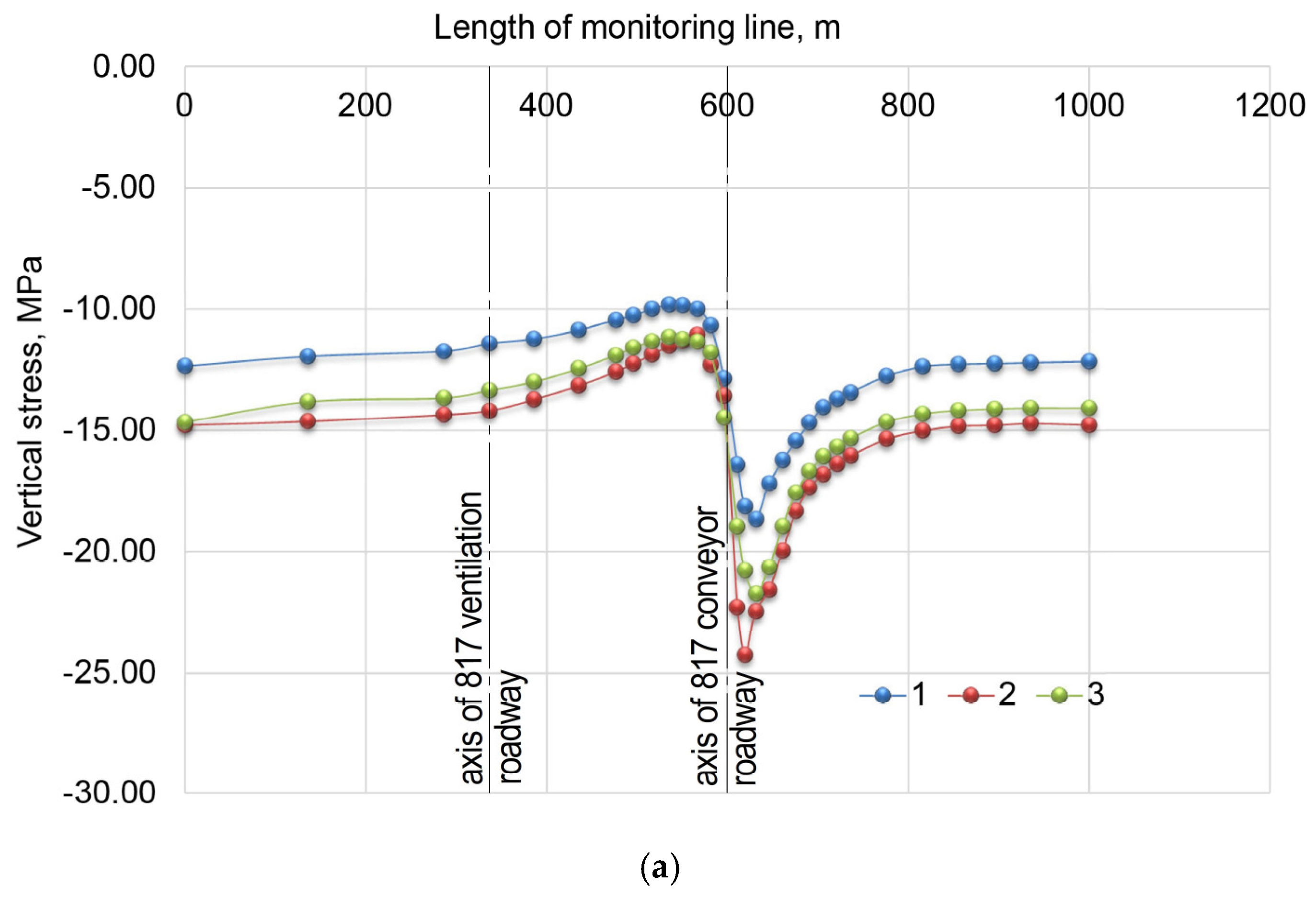

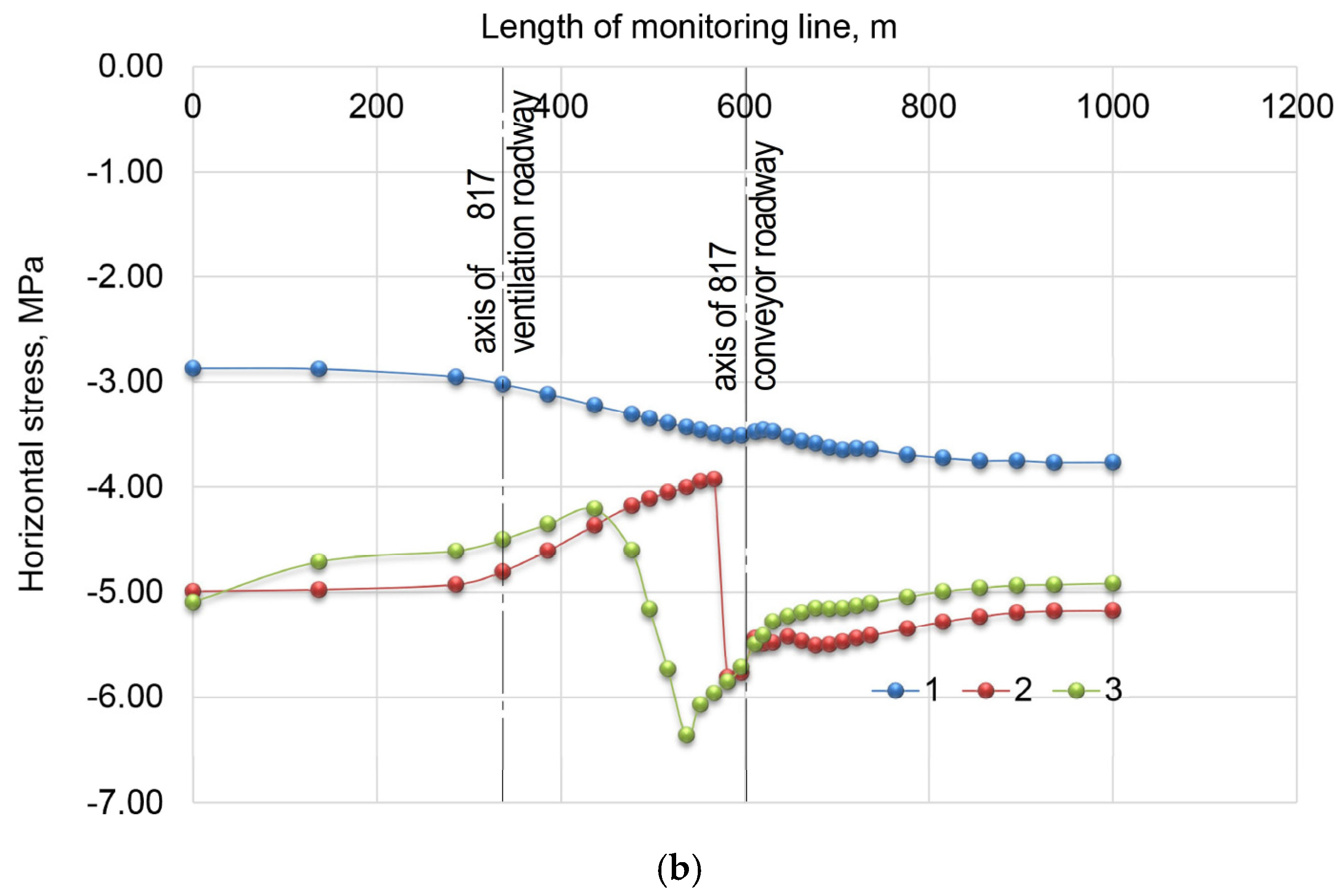

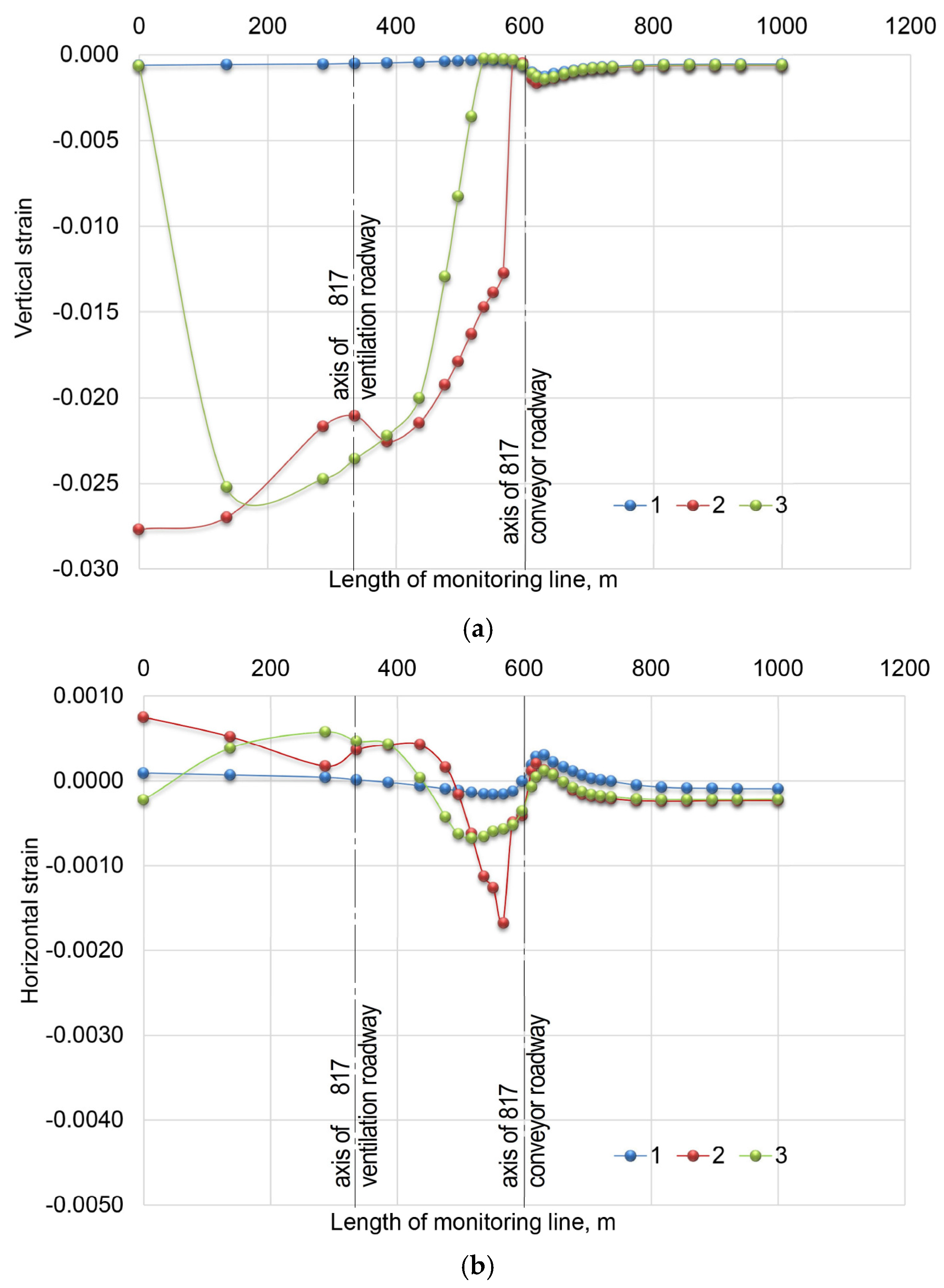

3.3. Simulation Results

- -

- The center of the goaf of the 817 longwall panel, where maximum vertical and horizontal displacements are observed;

- -

- The edge of the 817 longwall panel, where significant horizontal deformations occur.

4. Discussion

- Construction of a numerical model based on geological exploration data.

- Calibration of the model and verification of its adequacy.

- Calculation of the stress–strain state of the rock mass.

- Analysis of the stresses and strains at the lower boundary of the aquifer.

- Calculation of safety factor (Stress) and safety factor (Strain) by mathematical expressions (4), (5).

- Determination of the probabilities of rock mass failure (Figure 15).

- Estimating inrush risk (Table 4).

- Additional assessment of the influence of faults with steep dip angles and large displacement.

5. Conclusions

- (1)

- The stress–strain analysis highlights where two potentially hazardous zones of rock mass failure near the aquifer may be found:

- -

- Above the goaf of the longwall panel, where maximum vertical and horizontal displacements and strain are observed;

- -

- Above the edge of the longwall panel, where maximum vertical stress occurs.

- (2)

- Safety factors, based on the stress and strain parameters, can be used as criteria for the risk of rock failure in the aquifer zone. The result of numerical simulation indicates that the risk of failure of surrounding rock near the aquifer based on the calculation of the strain safety factor is extremely low. The safety factor by stress indicates a conditionally stable state of rock mass near the aquifer zone. Based on current geotechnical engineering studies, it is possible to recalculate safety factors to probabilities of rock failure. For example, for the edge of the 817 longwall panel, a safety factor of 1.15 corresponds to probabilities of rock failure of 0.12–0.25.

- (3)

- The algorithm for determining the risk of water inflow from aquifer is proposed. The proposed algorithm has been tested for the conditions of 817 longwall panel of the Xinhu Coal Mine.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, D.; Sui, W.; Ranville, J.F. Hazard identification and risk assessment of groundwater inrush from a coal mine: A review. Bull. Eng. Geol. Environ. 2022, 81, 421. [Google Scholar] [CrossRef]

- Liang, S.; Zhang, X.; Ke, F.; Liu, J.; Yao, Q.; Luo, H.; Li, X.; Xu, Y. Evolution of Overlying Strata Bed Separation and Water Inrush Hazard Assessment in Fully Mechanized Longwall Top-Coal Caving of an Ultra-Thick Coal Seam. Water 2025, 17, 850. [Google Scholar] [CrossRef]

- Zhang, J.; He, M.; Yang, G.; Wang, Y.; Hou, S. N00 Method with Double-Sided Roof Cutting for Protecting Roadways and Surface Strata. Rock Mech. Rock Eng. 2024, 57, 1629–1651. [Google Scholar] [CrossRef]

- Kuznetsov, G.N. Investigation of Deformations and Pressures Arising in a Multistratified Roof Cantilever, and Its Interaction with the Supports; USSR: Saint Petersburg, Russia, 1960; pp. 3–34. (In Russian) [Google Scholar]

- Qian, M.G.; Li, H.C. The law of overlying strata movement and its influence on the pressure of mine. Coal 1982, 2, 1–8. [Google Scholar]

- Song, Z. Rules for the stope bearing pressure and its application. J. Shandong Inst. Min. Technol. 1982, 1, 1–25. (In Chinese) [Google Scholar]

- Qian, M.; Miao, X.; Xu, J. Key Stratum Theory in Ground Control; China University of Mining and Technology Press: Xuzhou, China, 2003; p. 120. (In Chinese) [Google Scholar]

- Xu, J.L.; Qian, M.G. Study and application of dominant stratum theory for control of strata movement. China Min. Mag. 2001, 10, 54–56. [Google Scholar]

- Gao, Y. Four-zone model of rockmass movement and back analysis of dynamic displacement. J. China Coal Soc. 1996, 21, 51–56. (In Chinese) [Google Scholar]

- Xuan, D.; Xu, J.; Wang, B.; Teng, H. Borehole investigation of the effectiveness of grout injection technology on coal mine subsidence control. Rock Mech. Rock Eng. 2015, 48, 2435–2445. [Google Scholar] [CrossRef]

- Zhang, D.L. Strata control in fully-Mechanized sub-level caving face. Shandong Univ. Sci. Technol. 2000, 19, 8–11. [Google Scholar]

- Sakhno, I.; Sakhno, S.; Petrenko, A.; Barkova, O.; Kobylianskyi, B. Numerical simulation of the surface subsidence evolutioncaused by the flooding of the longwall goaf during excavation of thin coal seams. IOP Conf. Ser. Earth Environ. Sci. 2023, 1254, 012057. [Google Scholar] [CrossRef]

- Budryk, W.; Knothe, S. The influence of the underground coals excavation for the surface. Przeglqd Gorniczy 1950, 11. (In Polish) [Google Scholar]

- Buczek, M.; Nguyen, Q.L.; Bui, X.N.; Nguyen, H. Application of Knothe-Budryk Theory and Rigid Body Condition forAssesment of Subsidence. Sustain. Dev. Mt. Territ. 2018, 10, 595–603. [Google Scholar] [CrossRef]

- Bazaluk, O.; Kuchyn, O.; Saik, P.; Soltabayeva, S.; Brui, H.; Lozynskyi, V.; Cherniaiev, O. Impact of ground surface subsidence caused by underground coal mining on natural gas pipeline. Sci. Rep. 2023, 13, 19327. [Google Scholar] [CrossRef]

- Fan, K.; Li, W.; Wang, Q.; Liu, S.; Xue, S.; Xie, C.; Wang, Z. Formation mechanism and prediction method of water inrush from separated layers within coal seam mining: A case study in the Shilawusu mining area, China. Eng. Fail. Anal. 2019, 103, 158–172. [Google Scholar] [CrossRef]

- Anisimova, L.; Babyi, K.; Pihulevskyi, P. Some Hydrochemical Features of Water Filtration Sources from under the Left-bank Dumps. In Proceedings of the 16th International Conference Monitoring of Geological Processes and Ecological Condition of the Environment, Kyiv, Ukraine, 15–18 November 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Zhang, S.; Shen, B.; Li, Y.; Zhou, S. Modeling rock fracture propagation and water inrush mechanisms in underground coal mine. Geofluids 2019, 2019, 1796965. [Google Scholar] [CrossRef]

- Lu, X.; Jiang, J.; Wang, W.; Cao, H. Study on the “Two-Zone” Heights in Lower Slice Mining Under Thick Alluvium and Thin Bedrock. Appl. Sci. 2024, 14, 10128. [Google Scholar] [CrossRef]

- Jiang, D.; Tang, Y.; Huang, W.; Hou, K.; Luo, Y.; Liu, J. Research on the Height of the Water-Conducting Fracture Zone in Fully Mechanized Top Coal Caving Face under Combined-Strata Structure. Sustainability 2022, 14, 13781. [Google Scholar] [CrossRef]

- Wu, F.; Gao, Z.; Liu, H.; Yu, X.; Gu, H. Theoretical Discrimination Method of Water-Flowing Fractured Zone Development Height Based on Thin Plate Theory. Appl. Sci. 2024, 14, 6284. [Google Scholar] [CrossRef]

- He, J.; Li, W.; Fan, K.; Qiao, W.; Wang, Q.; Li, L. A method for predicting the water-flowing fractured zone height based on an improved key stratum theory. Int. J. Min.Sci. Technol. 2023, 33, 61–71. [Google Scholar] [CrossRef]

- Zheng, L.; Liu, X.; Qiu, Q.; Tian, Y.; Ren, W.; Xu, J.; Wang, X. Failure and development height of overlying rock of a water flowing fracture in goaf under a karst aquifer. Sci. Rep. 2025, 15, 2473. [Google Scholar] [CrossRef]

- Li, C.; Lu, C.; Xu, J.; Zhang, K.; Liu, S.; Zhao, H. Diffusion Mechanism of Variable-Rate Grouting in Water Prevention and Control of Coal Mine. Water 2024, 16, 2814. [Google Scholar] [CrossRef]

- Xing, M.; Wang, Q.; Xu, J.; Li, W. Application of NIPOS-SVM Model for Evaluation of Water Richness of Coal Seam Roof Aquifer—A Case Study of the Xinhu Coal Mine in Huaibei, China. Water 2024, 16, 3670. [Google Scholar] [CrossRef]

- Cazacu, O.; Cristescu, N.D.; Shao, J.F.; Henry, J.P. A new anisotropic failure criterion for transversely isotropic solids. Mech. Cohesive-Frict. Mater. 1998, 3, 89–103. [Google Scholar] [CrossRef]

- Oka, F.; Kimoto, S.; Kobayashi, H.; Adachi, T. Anisotropic behaviorof soft sedimentary rock and a constitutive model. Soils Found. 2002, 42, 59–70. [Google Scholar] [CrossRef] [PubMed]

- Khanlari, G.; Rafiei, B.; Abdilor, Y. Evaluation of strength anisotropy and failure modes of laminated sandstones. Arab. J. Geosci. 2015, 8, 3089–3102. [Google Scholar] [CrossRef]

- Sakhno, I.G.; Molodetskyi, A.V.; Sakhno, S.V. Identification of material parameters for numerical simulation of the behavior ofrocks under true triaxial conditions. Nauk. Visnyk NHU 2018, 5, 48–53. [Google Scholar] [CrossRef]

- Sakhno, I.; Sakhno, S.; Vovna, O. Surface Subsidence Response to Safety Pillar Width Between Reactor Cavities in the Underground Gasification of Thin Coal Seams. Sustainability 2025, 17, 2533. [Google Scholar] [CrossRef]

- MFEU 2004 Pravyla Pidrobky Budivel’, Sporud i Pryrodnyx Objektiv pry Vydobuvanni Vuhillja Pidzemnym Sposobom MFEU 101.00159226.001-2003. Available online: https://zakon.isu.net.ua/sites/default/files/normdocs/pravila_pidrobki_budivel_sporud_i_prirodnikh_obektiv_pri_vido.pdf (accessed on 10 April 2025). (In Ukrainian).

- MacRobert, C.J. Factors of safety and probabilities of failure in geotechnical engineering: What do we mean? Civ. Eng. 2018, 26, 45–50. [Google Scholar]

- Zhou, H.; Zhang, C.; Li, Z.; Hu, D.; Hou, J. Analysis of mechanical behavior of soft rocks and stability control in deep tunnels. J. Rock Mech. Geotech. Eng. 2014, 6, 219–226. [Google Scholar] [CrossRef]

- Josh, M.; Esteban, L.; Delle Piane, C.; Sarout, J.; Dewhurst, D.N.; Clennell, M.B. Laboratory characterisation of shale properties. J. Pet. Sci. Eng. 2019, 88, 107–124. [Google Scholar] [CrossRef]

- Almisned, O.A.; Alqahtani, N. Rock analysis to characterize Saudi soft sandstone rock. J. Pet. Explor. Prod. Technol. 2021, 11, 2381–2387. [Google Scholar] [CrossRef]

- Liu, Q.; Liang, B.; Sun, W.; Zhao, H. Experimental Study on the Difference of Shale Mechanical Properties. Adv. Civ. Eng. 2021, 2021, 6677992. [Google Scholar] [CrossRef]

- Sakhno, I.; Sakhno, S.; Vovna, O. Assesing a risk of roof fall in the development mine workings in the process of longwall coal mining in terms of Ukrainian mines. Min. Miner. Depos. 2020, 14, 72–80. [Google Scholar] [CrossRef]

| Coal Mine Name | Sudden Water Time | Maximum Surge Capacity (m3/h) | Hydrogeological Features | Impact |

|---|---|---|---|---|

| Cuimu Mine | 2013 | 1300 | Water in the Yijun formation sandstone and Luohe formation sandstone aquifers | Discontinued |

| Guojiahe Coal Mine | 2016 | 2300 | Water in the Yijun formation sandstone and Luohe formation sandstone aquifers | Discontinued |

| Yuanzigou Coal Mine | 2019 | 570 | Water in the Yijun formation sandstone and Luohe formation sandstone aquifers | Discontinued |

| Gaojiabao Coal Mine | 2015 | 3000 | Low river formation sandstone aquifer | Discontinued |

| Zhaojin Coal Mine | 2013 2016 | - | Rock river formation sandstone fissure aquifer | 11 deaths |

| Yangliu Coal Mine | 2017 | - | Water in the sandstone aquifer of the stone box formation | Potential threats |

| Fangezhuang Coal Mine | 2016 | 60 | Hydraulic fracture zones, sandstone fracture-bearing aquifers | No impact |

| Daliu Coal Mine | 2013 | 430 | Water-conducting fracture zones, geological for-mations | Discontinued |

| Wanglou Coal Mine | 2013 | 1345.7 | Jurassic sand and conglomerate fissure aquifer | Discontinued |

| Lijialou Coal Mine | 2016 | 3158 | Water-conductive rift zone | Discontinued |

| Shajihai Coal Mine | 2016 | - | Water from the Headunhe formation aquifer, water from the Xishangyao formation medium-coarse sandstone aquifer | Discontinued |

| Shilawusu Coal Mine | 2018 | 921.4 | Cretaceous Luohe formation sandstone aquifer | Discontinued |

| , (GPa) | , (GPa) | , (GPa) | , (GPa) | , (GPa) | , (GPa) | Density, kg/m3 | |||

|---|---|---|---|---|---|---|---|---|---|

| Quaternary sediments | |||||||||

| 1.4 | 6.3 | 1.4 | 0.27 | 0.1 | 0.25 | 0.55 | 2.86 | 0.56 | 2000 |

| Rock strata group #1 | |||||||||

| 2.1 | 19.2 | 2.1 | 0.23 | 0.12 | 0.22 | 0.85 | 8.57 | 0.86 | 2350 |

| Rock strata group #2 | |||||||||

| 2.9 | 24 | 2.9 | 0.23 | 0.12 | 0.22 | 1.18 | 10.71 | 1.19 | 2550 |

| Rock strata group #3 | |||||||||

| 2.45 | 19.2 | 2.45 | 0.23 | 0.12 | 0.22 | 1.00 | 8.57 | 1.00 | 2450 |

| Rock strata group #4 | |||||||||

| 2.6 | 22.8 | 2.6 | 0.23 | 0.12 | 0.22 | 1.06 | 10.18 | 1.07 | 2500 |

| Rock strata group #5 | |||||||||

| 2.1 | 19.2 | 2.1 | 0.23 | 0.12 | 0.22 | 0.85 | 8.57 | 0.86 | 2350 |

| Rock strata group #6 | |||||||||

| 2.45 | 19.2 | 2.45 | 0.23 | 0.12 | 0.22 | 1.00 | 8.57 | 1.00 | 2450 |

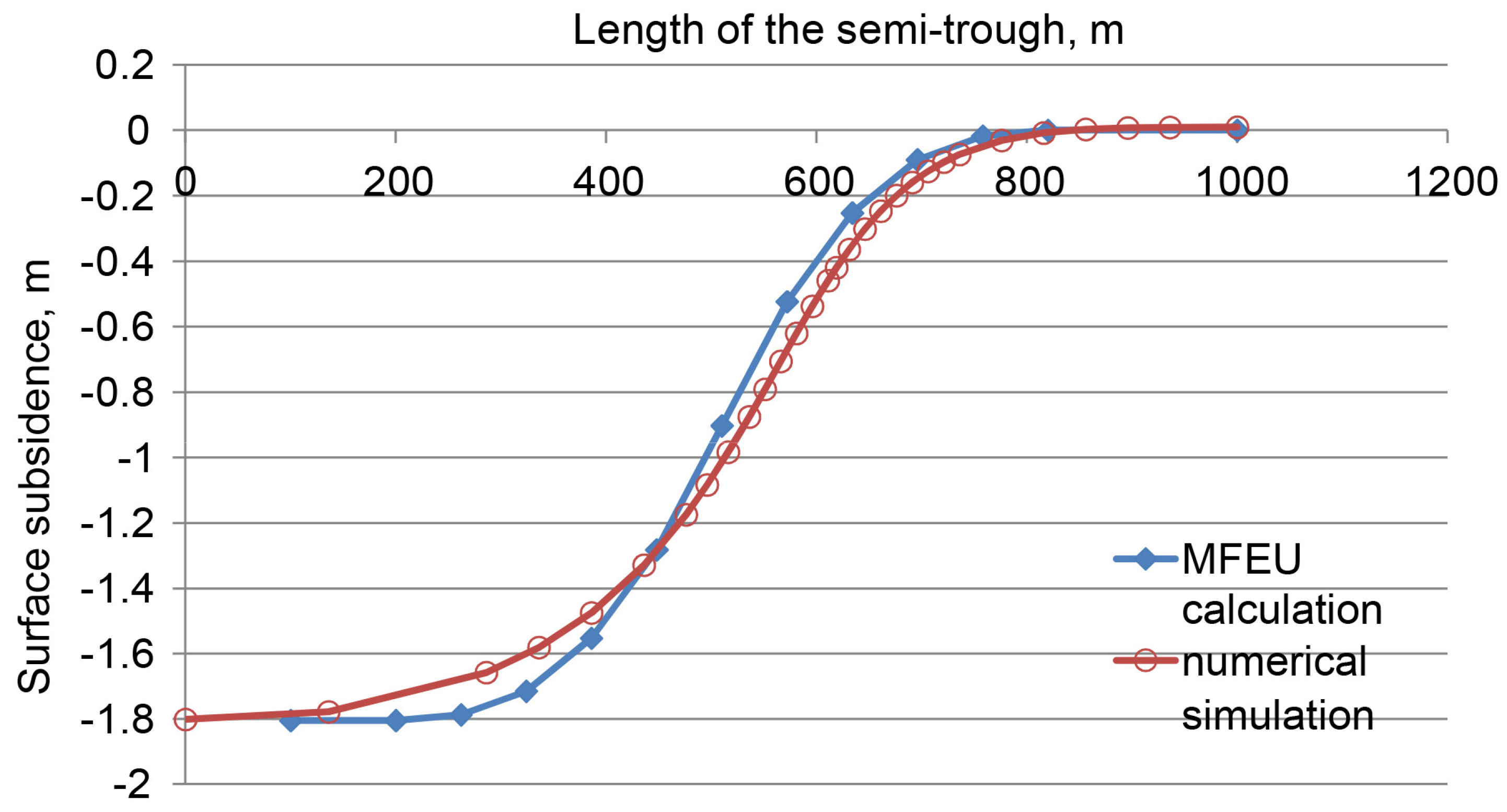

| Length of the Semi-Trough, m | Subsidence, m |

|---|---|

| 0.00 | −1.80524 |

| 62.00 | −1.78719 |

| 124.00 | −1.71498 |

| 186.00 | −1.55251 |

| 248.00 | −1.28172 |

| 310.00 | −0.90262 |

| 372.00 | −0.52352 |

| 434.00 | −0.25273 |

| 496.00 | −0.09026 |

| 558.00 | −0.01805 |

| 620.00 | 0 |

| Length of the Semi-Trough, m | Subsidence According to | Absolute Error, mm | Percentage Error, % | |

|---|---|---|---|---|

| MFEU, mm | FEM (Finite Element Method), mm | |||

| 0 | 1800 | 1810 | −10 | −0.5556 |

| 50 | 1800 | 1810 | −10 | −0.5556 |

| 100 | 1792.5 | 1810 | −17.5 | −0.9763 |

| 150 | 1772.5 | 1810 | −37.5 | −2.1157 |

| 200 | 1742.2 | 1810 | −67.8 | −3.8916 |

| 250 | 1699 | 1797.5 | −98.5 | −5.7975 |

| 300 | 1639.2 | 1755.7 | −116.5 | −7.1071 |

| 350 | 1557.6 | 1671.5 | −113.9 | −7.3125 |

| 400 | 1443.8 | 1523.6 | −79.8 | −5.5271 |

| 450 | 1280 | 1280 | 0 | 0.0000 |

| 500 | 991.9 | 1066 | −74.1 | −7.4705 |

| 550 | 665.8 | 809.1 | −143.3 | −21.5230 |

| 600 | 403.5 | 532.5 | −129 | −31.9703 |

| 650 | 218.4 | 305.3 | −86.9 | −39.7894 |

| 700 | 98.6 | 158.9 | −60.3 | −61.1562 |

| 750 | 36.6 | 69.9 | −33.3 | −90.9836 |

| 800 | 6.7 | 26.1 | −19.4 | −289.5522 |

| Total | 18,948.3 | 20,046.1 | −1097.8 | |

| Inrush Risk Level | Probability of Failure, % | Probability of Failure Level | Accident Risk Caused by Rock Failure |

|---|---|---|---|

| Low | 16.0–36.9 | Very low | Acceptable |

| Average | 37.0–57.9 | Possible | Acceptable in case of supervision and repetitive monitoring |

| High | 58.0–78.9 | Expectable | Nonacceptable without regular control measures |

| Critical | 79.0–100.0 | Very expectable | Nonacceptable |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sakhno, I.; Zuievska, N.; Xiao, L.; Zuievskyi, Y.; Sakhno, S.; Semchuk, R. Prediction of Water Inrush Hazard in Fully Mechanized Coal Seams’ Mining Under Aquifers by Numerical Simulation in ANSYS Software. Appl. Sci. 2025, 15, 4302. https://doi.org/10.3390/app15084302

Sakhno I, Zuievska N, Xiao L, Zuievskyi Y, Sakhno S, Semchuk R. Prediction of Water Inrush Hazard in Fully Mechanized Coal Seams’ Mining Under Aquifers by Numerical Simulation in ANSYS Software. Applied Sciences. 2025; 15(8):4302. https://doi.org/10.3390/app15084302

Chicago/Turabian StyleSakhno, Ivan, Natalia Zuievska, Li Xiao, Yurii Zuievskyi, Svitlana Sakhno, and Roman Semchuk. 2025. "Prediction of Water Inrush Hazard in Fully Mechanized Coal Seams’ Mining Under Aquifers by Numerical Simulation in ANSYS Software" Applied Sciences 15, no. 8: 4302. https://doi.org/10.3390/app15084302

APA StyleSakhno, I., Zuievska, N., Xiao, L., Zuievskyi, Y., Sakhno, S., & Semchuk, R. (2025). Prediction of Water Inrush Hazard in Fully Mechanized Coal Seams’ Mining Under Aquifers by Numerical Simulation in ANSYS Software. Applied Sciences, 15(8), 4302. https://doi.org/10.3390/app15084302