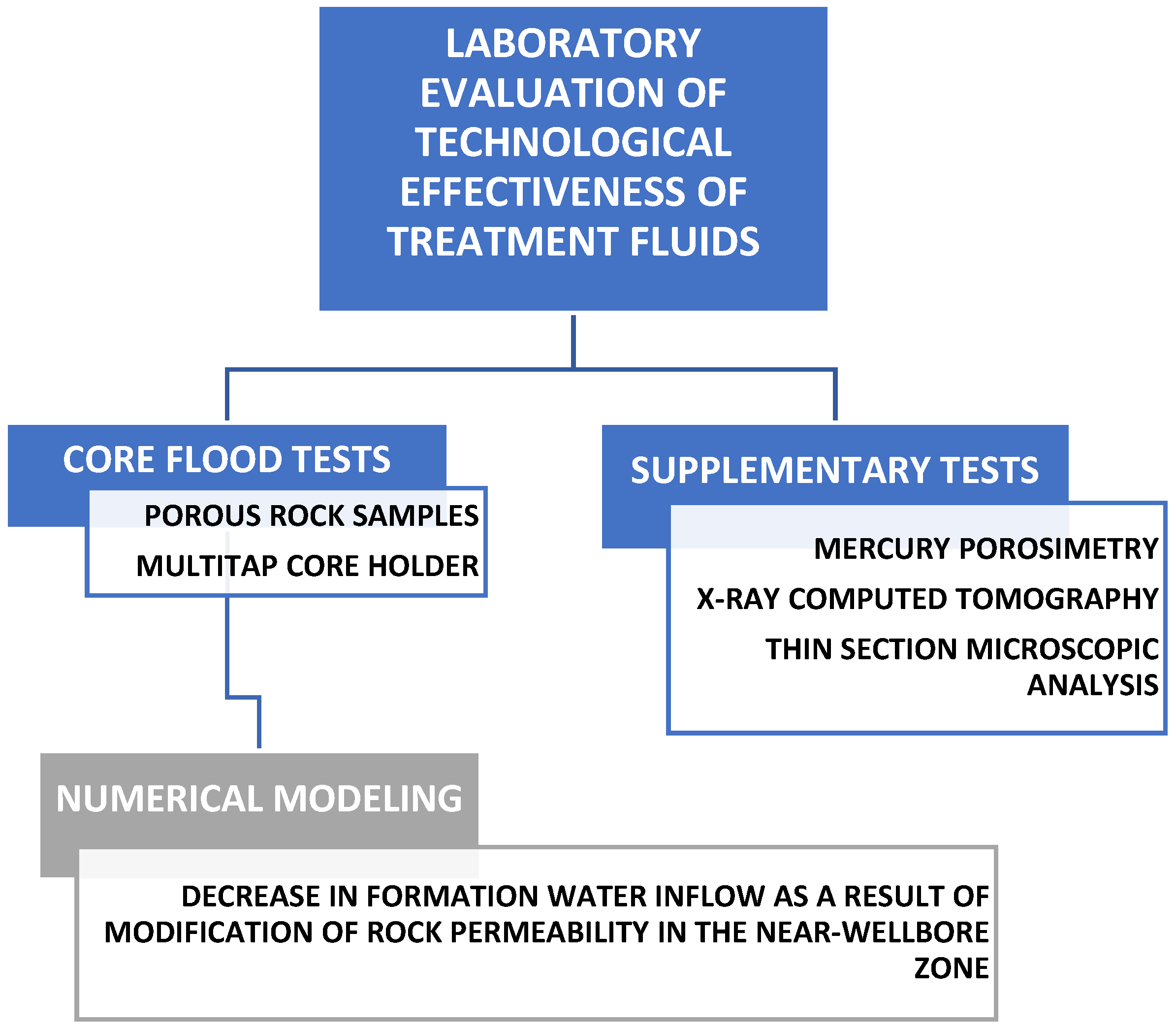

Assessment Methodology for Treatment Fluid Efficiency in Modifying Filtration Properties of Porous Rocks

Abstract

1. Introduction

2. Methods

- Effective permeability for gas, as a simulation of changes in the gas zone (porous rock samples marked as RG);

- Absolute permeability for brine, as a simulation of changes in the water-bearing zone (porous rock samples marked as RW).

2.1. X-Ray Computed Tomography

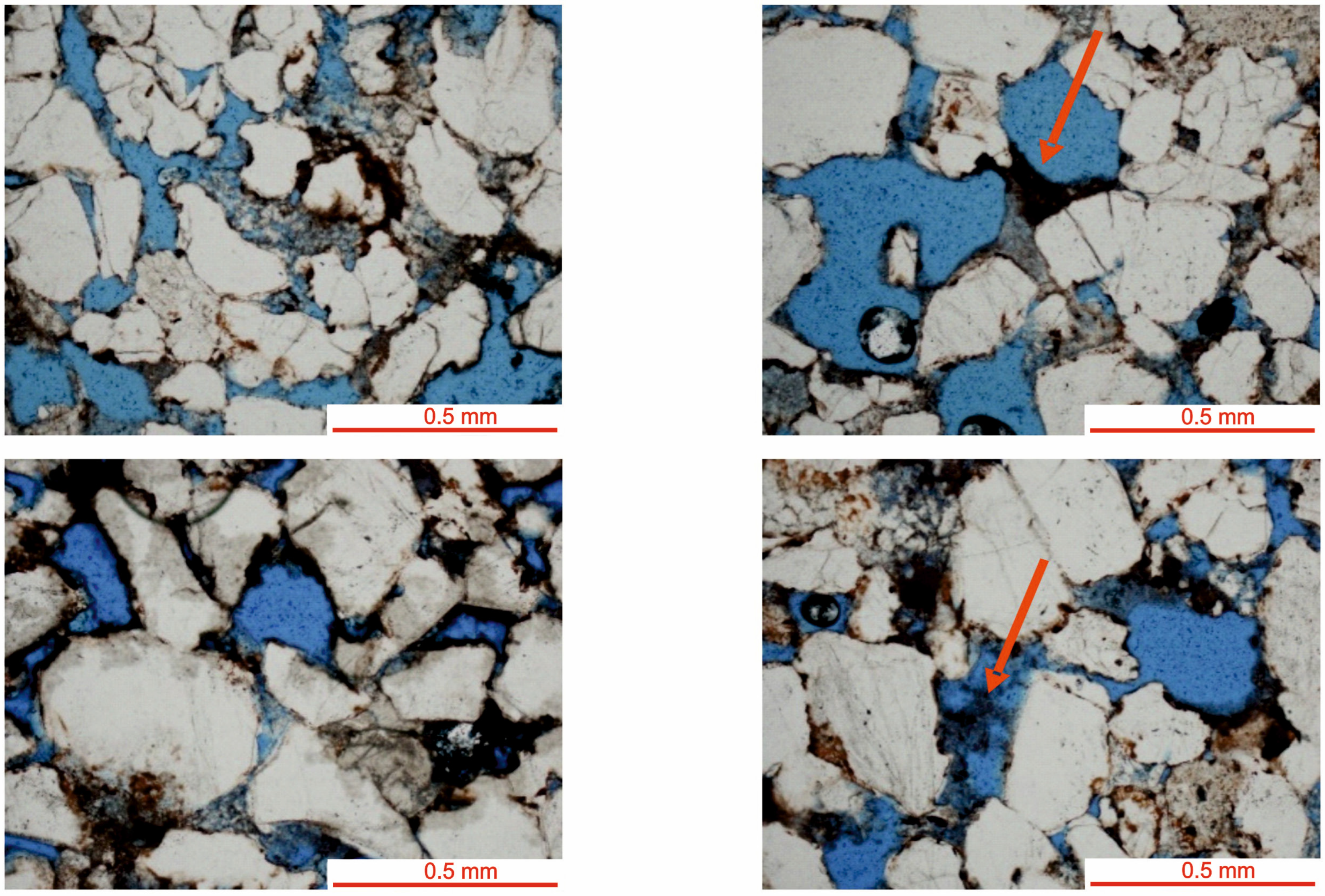

2.2. Microscopic Image Analysis

3. Materials

4. Results

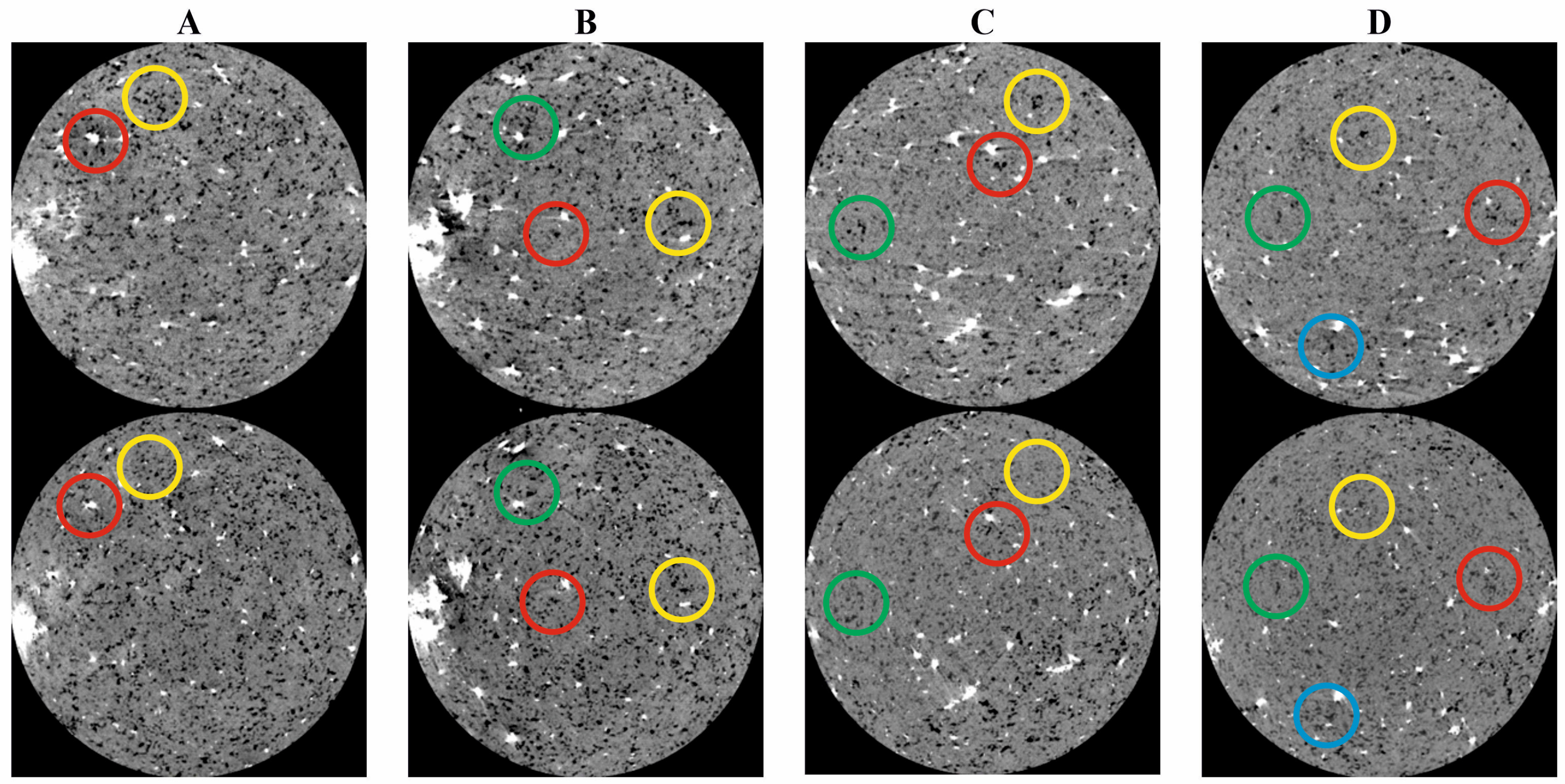

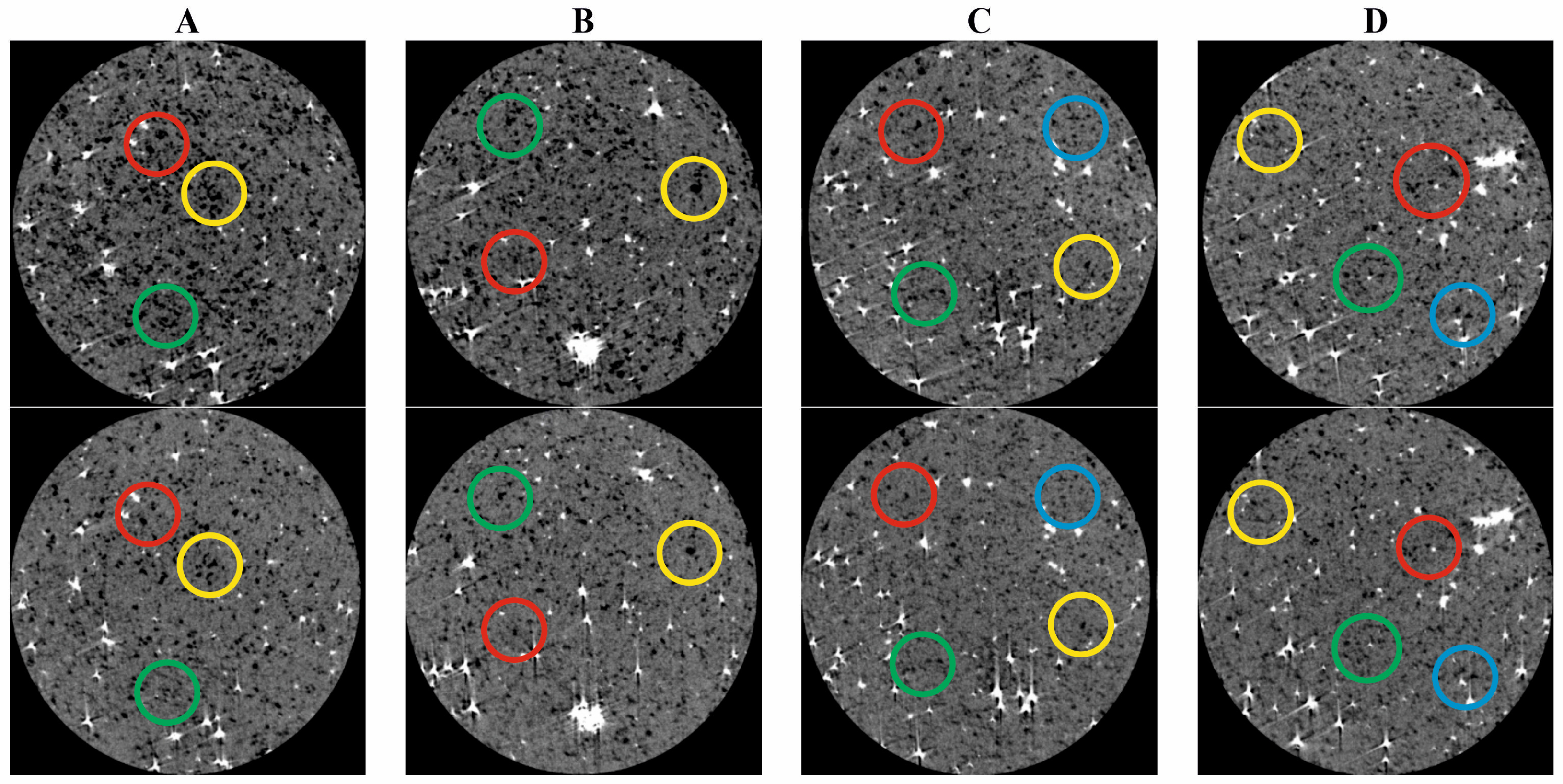

4.1. X-Ray Computed Tomography

4.2. Microscopic Image Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cicha-Szot, R.; Falkowicz, S. Wpływ modyfikatora na właściwości wiskoelastyczne żeli krzemianowych. Naft.-Gaz 2010, 12, 1102–1108. [Google Scholar]

- Dai, C.; You, Q.; Zhao, M.; Zhao, G.; Zhao, F. Profile control and flooding of water injection wells. In Principles of Enhanced Oil Recovery; Springer Nature: Singapore, 2023; pp. 49–78. [Google Scholar] [CrossRef]

- Ma, W.; Li, Y.; Liu, P.; Liu, Z.; Song, T. Progress of research into preformed particle gels for profile control and water shutoff techniques. Gels 2024, 10, 372. [Google Scholar] [CrossRef]

- Falkowicz, S.; Cicha-Szot, R. Iniekcyjna technologia tworzenia horyzontalnych barier izolacyjnych: Z laboratorium do warstwy wodonośnej. Górnictwo Odkryw. 2018, 59, 85–91. [Google Scholar]

- Karpiński, M.; Batko, R.; Kmiecik, E.; Tomaszewska, B.; Zdechlik, R. Czasowa zmienność wielkości dopływu wód dołowych do wyrobisk górniczych. Tech. Poszuk. Geol. Geoterm. Zrównoważony Rozw. 2017, 1, 49–60. [Google Scholar]

- Przybyłek, J. Aktualne problemy odwadniania złóż węgla brunatnego w Wielkopolsce. Górnictwo Odkryw. 2018, 2, 5–14. [Google Scholar]

- Słowikowski, D. Likwidacja przebić hydraulicznych w podłożu gruntowym: Praktyczne doświadczenia z realizacji. GDMT Geoinżynieria Drog. Mosty Tunele 2013, 4, 50–54. [Google Scholar]

- Izak, P.; Wójcik, Ł.; Słowikowski, D. Reologia zawiesin spoiw uszczelniających. Mater. Ceram. 2015, 67, 158–163. [Google Scholar]

- Lubaś, J.; Stopa, J.; Wojnicki, M. Możliwości zastosowania zaawansowanych metod wspomagania wydobycia ropy naftowej ze złóż dojrzałych. Nafta-Gaz 2019, 75, 24–28. [Google Scholar] [CrossRef]

- Seright, R.; Brattekås, B. Water shutoff and conformance improvement: An introduction. Pet. Sci. 2021, 18, 450–478. [Google Scholar] [CrossRef]

- Botermans, C.W.; Dalrymple, E.D.; Dahl, J.; Smith, D. Chemical systems for water and gas control: Terminology, evaluation methods, candidate selection, and expectations. In Proceedings of the SPE International Symposium on Oilfield Chemistry, Houston, TX, USA, 13–16 February 2001. [Google Scholar] [CrossRef]

- Guo, P.; Tian, Z.; Zhou, R.; Chen, F.; Du, J.; Wang, Z.; Hu, S. Chemical water shutoff agents and their plugging mechanism for gas reservoirs: A review and prospects. J. Nat. Gas Sci. Eng. 2022, 104, 104658. [Google Scholar] [CrossRef]

- Falkowicz, S.; Dubiel, S.; Cicha-Szot, R. Problemy ograniczania dopływu wody do odwiertów wydobywczych gazowych i ropnych. Gospod. Surowcami Miner. 2012, 28, 125–136. [Google Scholar]

- Grattoni, C.A.; Jing, X.D.; Zimmerman, R.W. Disproportionate permeability reduction when a silicate gel is formed in-situ to control water production. In Proceedings of the SPE Latin American and Caribbean Petroleum Engineering Conference, Buenos Aires, Argentina, 25–28 March 2001. [Google Scholar] [CrossRef]

- Romero, L.; Ziritt, J.; Marin, A.; Rojas, F.; Mogollon, J.; Paz, F. Plugging of high permeability—Fractured zones using emulsions. In Proceedings of the SPE/DOE Improved Oil Recovery Symposium, Tulsa, OK, USA, 21–24 April 1996. [Google Scholar] [CrossRef]

- Sobanova, O.B.; Fridman, G.B.; Arefyev, Y.N. Laboratory and oil field testing for application of compositions including hydrocarbons and surfactants for restricting water influx into producing wells. In Proceedings of the 7th European Symposium on IOR, Moscow, Russia, 5–7 July 1993; pp. 207–215. [Google Scholar]

- Lakatos, I.; Tóth, J.; Bauer, K.; Lakatos-Szabó, J.; Palásthy, G.; Wöltje, H. Comparative study of different silicone compounds as candidates for restriction of water production in gas wells. In Proceedings of the International Symposium on Oilfield Chemistry, Houston, TX, USA, 5–7 February 2003. [Google Scholar] [CrossRef]

- Pusch, G.; Meyn, R.; Burger, W.; Geck, M. Method for Stabilizing the Gas Flow in Water-Bearing Natural Gas Deposits of Reservoirs. Patent 6.206.102 B1, 27 March 2001. [Google Scholar]

- Lakatos, I.; Szentes, G.; Toro, M.; Karaffa, Z.; Vago, A. Mitigation of formation damage caused by chemical overdosing in water shut-off treatments. In Proceedings of the SPE International Conference and Exhibition on Formation Damage Control, Lafayette, LA, USA, 19–21 February 2020. [Google Scholar] [CrossRef]

- Lakatos, I.; Lakatos-Szabó, J.; Bódi, T.; Vágó, Á. New alternatives of water shutoff treatments: Application of water sensitive metastable systems. In Proceedings of the SPE International Symposium and Exhibition on Formation Damage Control, Lafayette, LA, USA, 13–15 February 2008. [Google Scholar] [CrossRef]

- Lakatos, I.J.; Lakatos-Szabo, J.; Szentes, G.; Vadaszi, M. Mitigation of formation damage caused by macromolecular materials using ‘liquid’ polymers. In Proceedings of the SPE European Formation Damage Conference & Exhibition, Noordwijk, The Netherlands, 5–7 June 2013. [Google Scholar] [CrossRef]

- Lakatos, I.; Lakatos-Szabo, J.; Szentes, G.; Vago, A. Restriction of water production in gas wells by induced phase inversion: Field case studies. In Proceedings of the SPE International Symposium and Exhibition on Formation Damage Control, Lafayette, LA, USA, 26–28 February 2014. [Google Scholar] [CrossRef]

- Lakatos, I.; Szentes, G.; Vago, A.; Karaffa, Z. Application of nanoparticle aided silicate reservoir conformance control method at the Algyo field, Hungary: Fundamentals and case histories. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 13–16 November 2017. [Google Scholar] [CrossRef]

- Falkowicz, S.; Stanik, W.; Czupski, M.; Majkrzak, M. Technologia kontroli produkcji wody w odwiertach gazowych wraz z pozabiegową procedurą stymulacji produkcji. Wiadomości Naft. I Gazow. 2025, 9, 4–11. [Google Scholar]

- Majkrzak, M.; Falkowicz, S.; Stanik, W. Modification of filtration properties of porous media using Multizol micellar treatment fluid. Naft.-Gaz 2023, 9, 567–575. [Google Scholar] [CrossRef]

- Kruczek, J.; Such, P. Pomiary przepuszczalności fazowej i matematyczna ekstrapolacja otrzymanych wyników. Przegląd Geol. 1995, 43, 291–294. [Google Scholar]

- Knobloch, L.O.; Hincapie, R.E.; Födisch, H.; Ganzer, L. Qualitative and quantitative evaluation of permeability changes during EOR polymer flooding using micromodels. World J. Eng. Technol. 2018, 6, 332–349. [Google Scholar] [CrossRef]

- Shi, L.; Ye, Z.Y.; Zhang, Z.; Zhou, C.; Zhu, S.; Guo, Z. Necessity and feasibility of improving the residual resistance factor of polymer flooding in heavy oil reservoirs. Pet. Sci. 2010, 7, 251–256. [Google Scholar] [CrossRef]

- Sowiżdżał, K. Analiza niepewności wyników obliczeń zasobów węglowodorów metodą objętościową, w oparciu o statyczny, przestrzenny model złoża. Naft.-Gaz 2009, 65, 934–941. [Google Scholar]

- Alfarge, D.K.; Wei, M.; Bai, B. Numerical simulation study of factors affecting relative permeability modification for water-shutoff treatments. Fuel 2017, 207, 226–239. [Google Scholar] [CrossRef]

- Łętkowski, P. Automatyczna kalibracja symulacyjnego modelu złożowego w bliskim otoczeniu odwiertu. Naft.-Gaz 2011, 67, 163–170. [Google Scholar]

- Civan, F. Reservoir Formation Damage, 3rd ed.; Gulf Publishing Company: Houston, TX, USA, 2015; pp. 1–1024. [Google Scholar]

- Brian, R.S.; Hisham, K.B.M. Numerical approach for enhanced oil recovery with surfactant flooding using STARS (CMG). Int. J. Pet. Petrochem. Eng. 2017, 3, 4. [Google Scholar] [CrossRef]

- He, W.; Liu, Z. Numerical simulation of formation damage by drilling fluid in low permeability sandstone reservoirs. J. Pet. Explor. Prod. 2021, 11, 1865–1871. [Google Scholar] [CrossRef]

- Dohnalik, M. Zwiększenie Możliwości Wyznaczania Parametrów Zbiornikowych Skał z Wykorzystaniem Rentgenowskiej Mikrotomografii Komputerowej. Ph.D. Thesis, AGH University of Science and Technology, Kraków, Poland, 2013. [Google Scholar]

- Wu, J.; Gong, W.; Wang, Q.; He, Y.; Guo, J.; Bao, Y.; Shao, S.; Li, R. Dynamic characterization of microscopic pore structure in medium-high permeability sandstones during waterflooding. Nanomaterials 2025, 15, 747. [Google Scholar] [CrossRef] [PubMed]

- Stock, S.R. MicroComputed Tomography: Methodology and Applications; CRC Press: Boca Raton, FL, USA, 2009; pp. 1–348. [Google Scholar]

- Fourie, S. The cranial morphology of Thriaxodon liorhinus Seeley. Ann. S. Afr. Mus. 1974, 65, 337–400. [Google Scholar]

- Drabik, K.; Przelaskowska, A.; Skupio, R.; Kubik, B. Obrazowanie przestrzeni porowej skał o zróżnicowanej litologii metodą tomografii komputerowej. Naft.-Gaz 2022, 10, 713–719. [Google Scholar] [CrossRef]

- Krakowska, P.; Dohnalik, M.; Jarzyna, J.; Wawrzyniak-Guz, K. Computed X-ray microtomography as the useful tool in petrophysics: A case study of tight carbonates Modryn formation from Poland. J. Nat. Gas Sci. Eng. 2016, 31, 67–75. [Google Scholar] [CrossRef]

- Wang, B.; Guo, L.; Luo, X.; Jiang, Y.; Li, Q.; Xie, J. Identification and extraction of cementation patterns in sand modified by MICP: New insights at the pore scale. PLoS ONE 2024, 19, e0296437. [Google Scholar] [CrossRef]

- Akin, S.; Schembre, J.M.; Bhat, S.K.; Kovscek, A.R. Spontaneous imbibition characteristics of diatomite. J. Pet. Sci. Eng. 2000, 25, 149–165. [Google Scholar] [CrossRef]

- Iglauer, S.; Rahman, T.; Sarmadivaleh, M.; Al-Hinai, A.; Fernø, M.A.; Lebedev, M. Influence of wettability on residual gas trapping and enhanced oil recovery in three-phase flow: A pore-scale analysis by use of microcomputed tomography. SPE J. 2016, 21, 1916–1929. [Google Scholar] [CrossRef]

- Orlov, M.S.; Roschin, P.V.; Struchkov, I.A.; Litvin, V.T. The application of X-ray micro computed tomography (Micro-CT) of core sample for estimation of physicochemical treatment efficiency. In Proceedings of the SPE Russian Petroleum Technology Conference, Moscow, Russia, 26–28 October 2015. [Google Scholar] [CrossRef]

- Bentz, D.P.; Quenard, D.; Kunzel, H.M.; Baruchel, J.; Peyrin, F.; Martys, N.S.; Garboczi, E.J. Microstructure and transport properties of porous building materials. II: Three-dimensional X-ray tomographic studies. Mater. Struct. 2000, 33, 147–153. [Google Scholar] [CrossRef]

- Geotek. RXCT Rotary and Medical CT Scanner Systems. Available online: https://www.geotek.co.uk (accessed on 21 August 2025).

- Tadeusiewicz, R.; Korohoda, P. Komputerowa Analiza i Przetwarzanie Obrazu; Wydawnictwo Fundacji Postępu Komunikacji: Kraków, Poland, 1997; pp. 1–444. [Google Scholar]

- Leśniak, G. Zastosowanie komputerowej analizy obrazu w badaniach petrofizycznych. Przegląd Geol. 1999, 47, 895–900. [Google Scholar]

- Tiab, D.; Donaldson, E.C. Petrophysics: Theory and Practice of Measuring Reservoir Rock and Fluid Transport Properties, 4th ed.; Gulf Professional Publishing: Oxford, UK, 2016; pp. 1–894. [Google Scholar]

- Dolson, J. Understanding Oil and Gas Shows and Seals in the Search for Hydrocarbons; Springer: Cham, Switzerland, 2016; pp. 1–486. [Google Scholar] [CrossRef]

- Majkrzak, M. Ocena selektywnej redukcji właściwości filtracyjnych skał porowatych w zabiegach ograniczania produkcji wody w odwiertach. Naft.-Gaz 2022, 4, 259–268. [Google Scholar] [CrossRef]

- Stanik, W.; Falkowicz, S.; Majkrzak, M.; Konieczny, R.; Cicha-Szot, R.; Czupski, M. Kompozycja Surfaktantów Przeznaczona do Ograniczania Produkcji Wody w Odwiertach Gazowych; Oil and Gas Institute—National Research Institute: Krakow, Poland, 2023; p. 445682. [Google Scholar]

| No. | Diameter [cm] | Length [cm] | Absolute Permeability for Gas [mD] | Pore Volume [cm3] | Porosity [%] |

|---|---|---|---|---|---|

| RG1 | 2.57 | 12.70 | 14.21 | 11.93 | 18.11 |

| RG2 | 2.56 | 12.23 | 22.67 | 12.04 | 19.41 |

| RW1 | 2.58 | 13.00 | 56.36 | 13.69 | 20.15 |

| RW2 | 2.58 | 11.73 | 40.86 | 11.23 | 18.31 |

| RW3 | 2.58 | 11.87 | 38.36 | 11.72 | 18.89 |

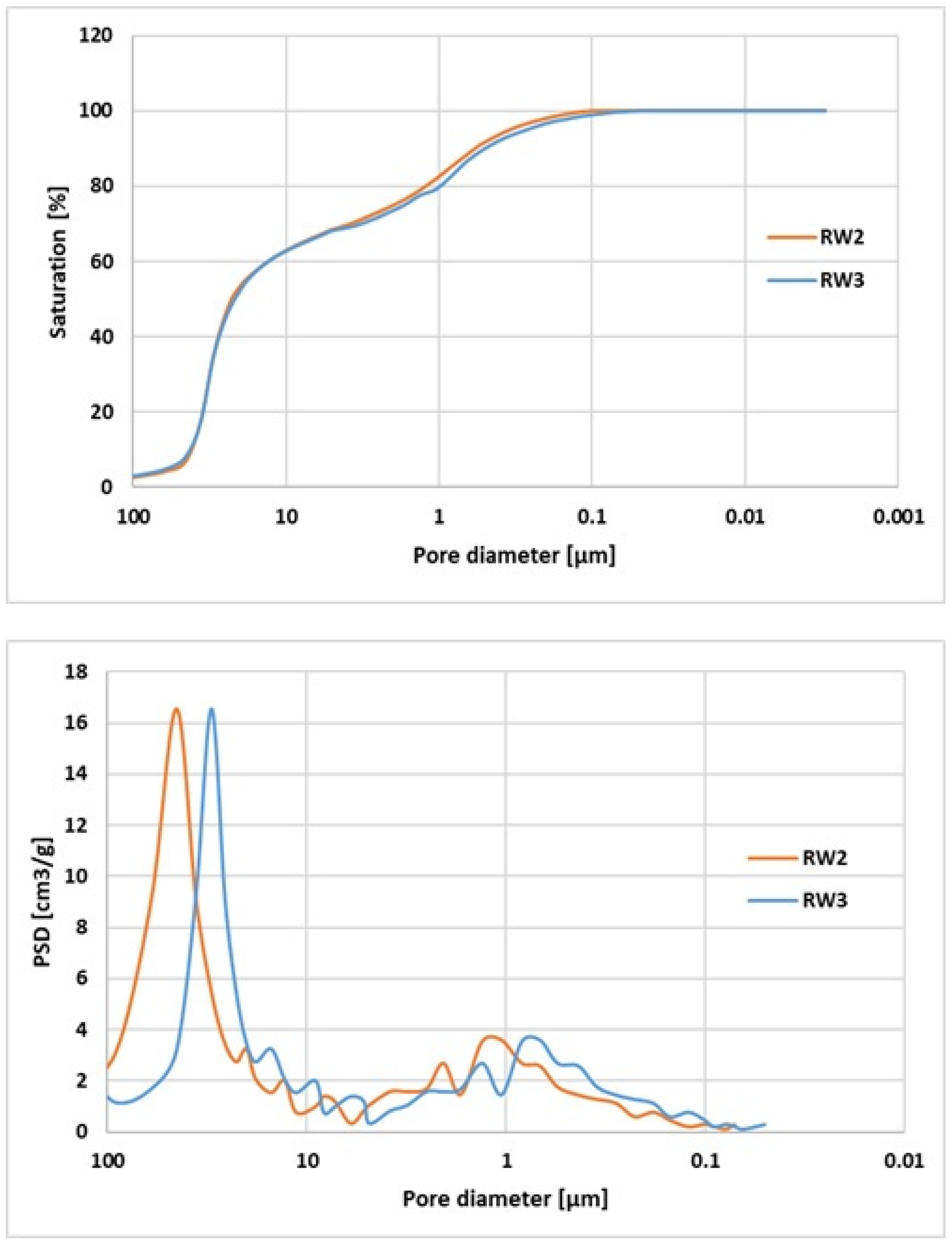

| Parameter | No. | |

|---|---|---|

| RW2 | RW3 | |

| Total helium porosity [%] | 22.94 | 21.79 |

| Effective porosity [%] | 19.20 | 19.75 |

| Skeletal density [g/cm3] | 2.68 | 2.71 |

| Bulk density [g/cm3] | 2.07 | 2.12 |

| Skeletal density from MICP [g/cm3] | 2.56 | 2.64 |

| Entry pressure [psi] | 1.23 | 1.23 |

| Entry diameter [µm] | 150.00 | 150.00 |

| Threshold diameter [µm] | 45.00 | 45.00 |

| Mean diameter [µm] | 1.73 | 1.32 |

| Specific surface area [m2/g] | 0.21 | 0.28 |

| mega [>10 µm] | 62.18 | 62.00 |

| macro [10–2 µm] | 12.24 | 11.01 |

| meso [2–0.5 µm] | 17.13 | 16.85 |

| micro [0.5–0.1 µm] | 8.41 | 9.06 |

| nano [<0.1 µm] | 0.04 | 1.09 |

| k_Swanson [mD] | 529.05 | 529.17 |

| Measurement Temperature [°C] | Density [g/cm3] | Dynamic Viscosity [cP] | |

|---|---|---|---|

| 15% NaCl | 25 | 1.11 | 1.24 |

| No. | FRR Coefficient [-] in Consecutive Sample Zones | Irreducible Saturation for Brine Swi [%] | FRR Coefficient [-] for Entire Sample | |||

|---|---|---|---|---|---|---|

| I | II | III | IV | |||

| RG1 | 1.35 | 1.25 | 1.37 | 1.33 | 9.14 | 1.32 |

| RG2 | 1.15 | 1.21 | 1.22 | 1.28 | 10.72 | 1.24 |

| RW1 | 1.03 | 1.26 | 28.12 | 13.67 | 100 | 11.69 |

| RW2 | 0.97 | 1.00 | 26.64 | - | 100 | 9.55 |

| RW3 | 2.65 | 14.73 | 38.91 | - | 100 | 15.46 |

| No. Classes | Volume Fraction Before the Injection of the Treatment Fluid [%] | Volume Fraction After the Injection of the Treatment Fluid [%] | ∆ [%] |

|---|---|---|---|

| RW2 | |||

| I | 0.6 | 0.3 | 0.3 |

| II | 5.4 | 3.3 | 2.1 |

| III | 31.3 | 21.7 | 9.6 |

| IV | 60.6 | 63.2 | −2.6 |

| V | 2.1 | 11.5 | −9.4 |

| VI | 0 | 0 | 0 |

| VII | 0 | 0 | 0 |

| RW3 | |||

| I | 1.4 | 0.6 | 0.8 |

| II | 16.3 | 10.2 | 6.1 |

| III | 56.3 | 47.8 | 8.5 |

| IV | 25.3 | 40.6 | −15.3 |

| V | 0.6 | 0.8 | −0.2 |

| VI | 0 | 0 | 0 |

| VII | 0 | 0 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Majkrzak, M.; Falkowicz, S.; Cicha-Szot, R.; Leśniak, G. Assessment Methodology for Treatment Fluid Efficiency in Modifying Filtration Properties of Porous Rocks. Appl. Sci. 2025, 15, 12415. https://doi.org/10.3390/app152312415

Majkrzak M, Falkowicz S, Cicha-Szot R, Leśniak G. Assessment Methodology for Treatment Fluid Efficiency in Modifying Filtration Properties of Porous Rocks. Applied Sciences. 2025; 15(23):12415. https://doi.org/10.3390/app152312415

Chicago/Turabian StyleMajkrzak, Marcin, Sławomir Falkowicz, Renata Cicha-Szot, and Grzegorz Leśniak. 2025. "Assessment Methodology for Treatment Fluid Efficiency in Modifying Filtration Properties of Porous Rocks" Applied Sciences 15, no. 23: 12415. https://doi.org/10.3390/app152312415

APA StyleMajkrzak, M., Falkowicz, S., Cicha-Szot, R., & Leśniak, G. (2025). Assessment Methodology for Treatment Fluid Efficiency in Modifying Filtration Properties of Porous Rocks. Applied Sciences, 15(23), 12415. https://doi.org/10.3390/app152312415