The Impact of Air Velocity on the Formation of Methane Concentration Fields in Excavated Workings

Abstract

1. Introduction

2. Methods

2.1. The Site

- Methane Meter MM4

- Measurement range: 0–100% CH4 in two subranges:

- 0–5% CH4—pellistor sensor

- 5–100% CH4—thermoconductometric sensor

- Measurement error:

- ±0.1% CH4 for concentrations of 0–2% CH4

- ±5% of the reading for concentrations of 2–5% CH4

- ±3% CH4 for concentrations of 5–60% CH4

- ±5% of the reading for concentrations of 60–100% CH4

- Sampling frequency: 5 s

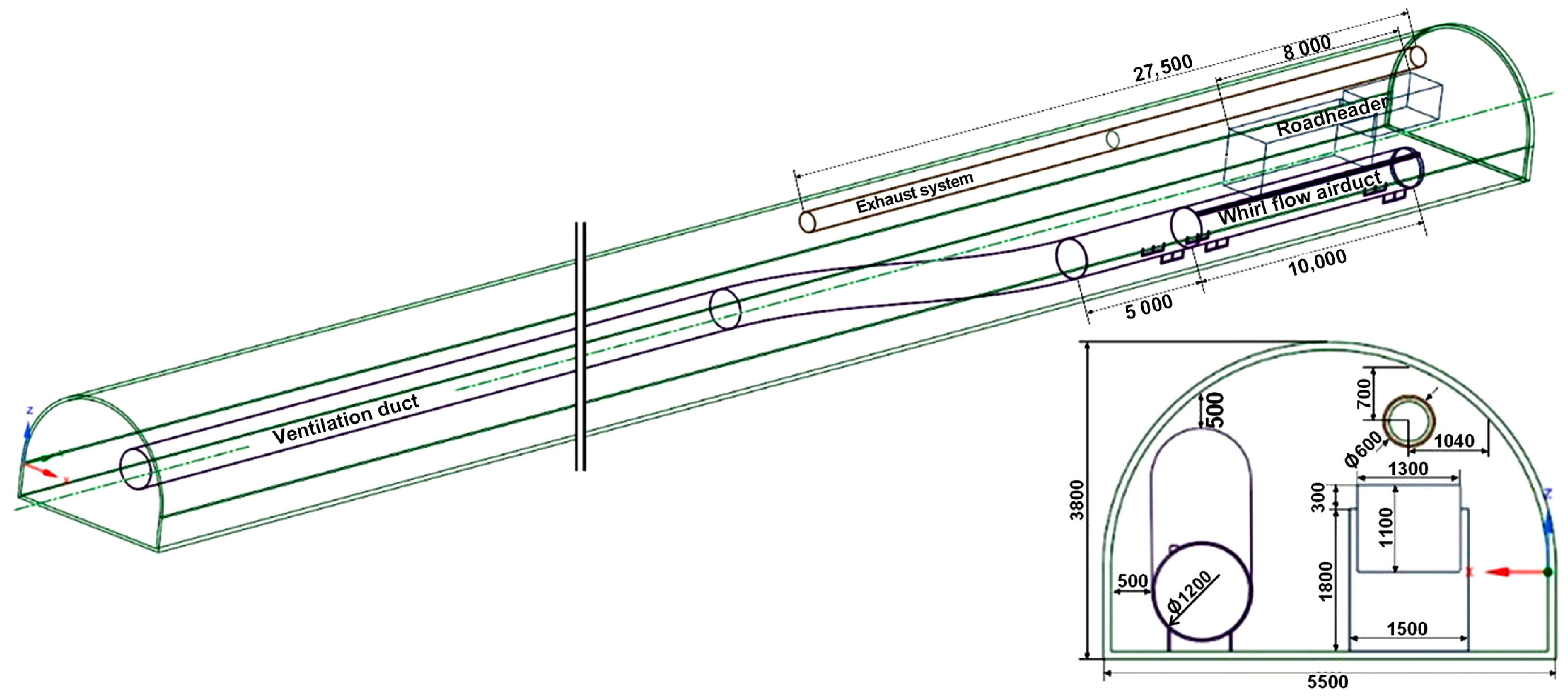

2.2. Numerical Model

- -

- inlet_duct—the airflow located in the whirl flow airduct at the model’s boundary, supplying air to the face of the working; the inflow velocity was the subject of the analysis,

- -

- inlet_methane—methane inflow from the face of the working, based on actual observations, covering 80% of the cross-sectional area of the excavation; velocity inlet—0.00494 m/s (based on measurement data), CH4—100%.

3. Results and Discussion

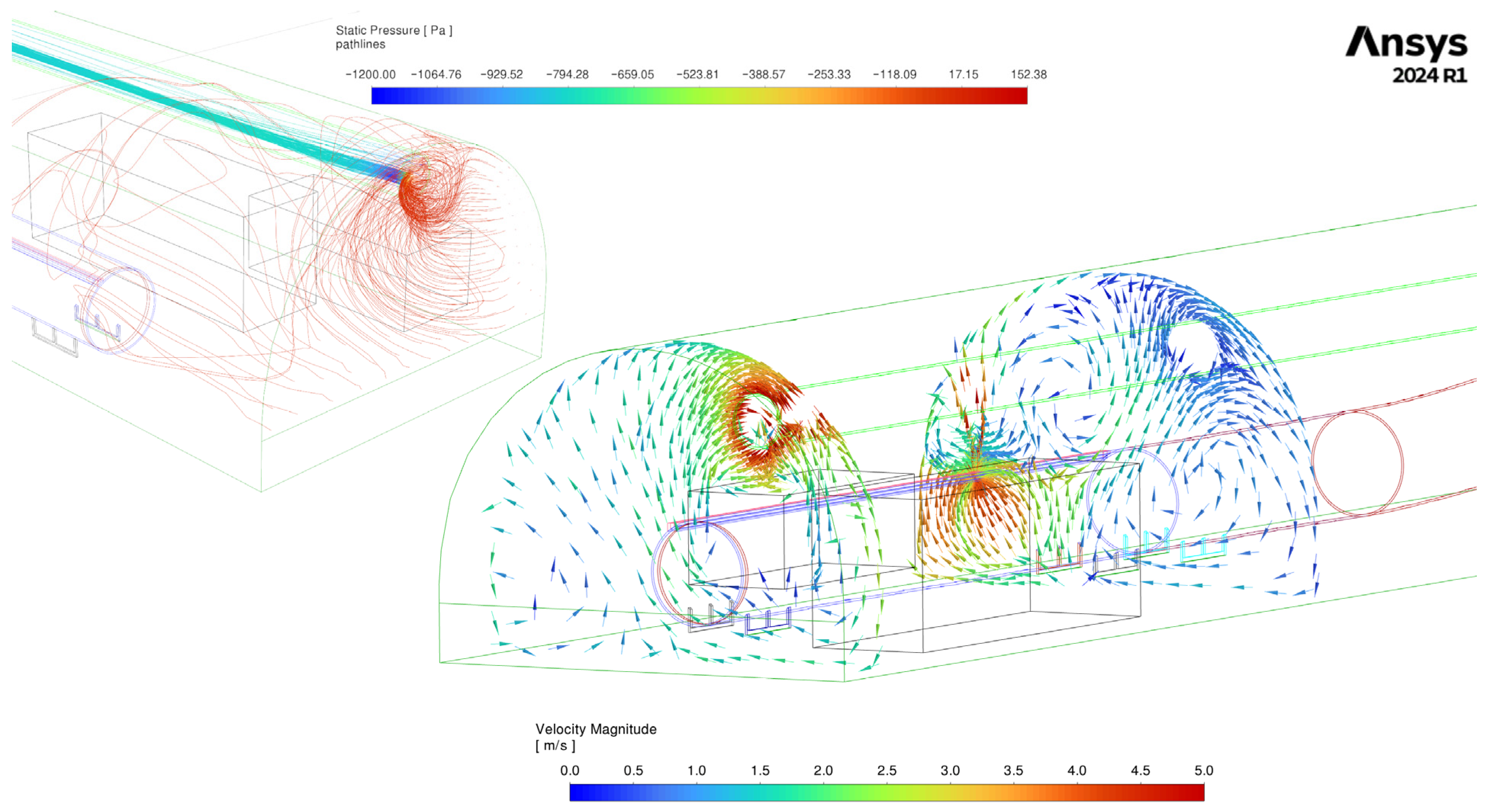

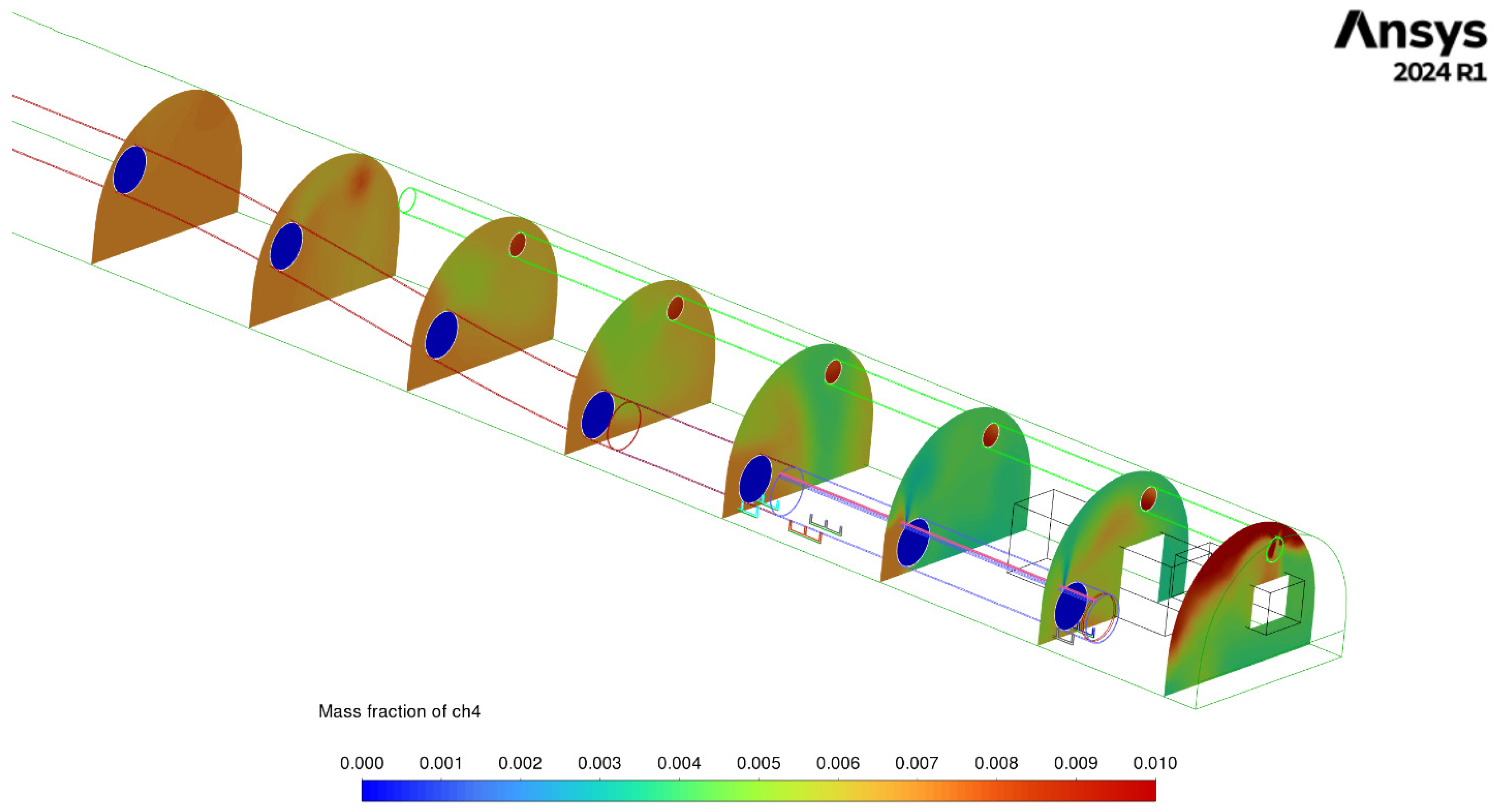

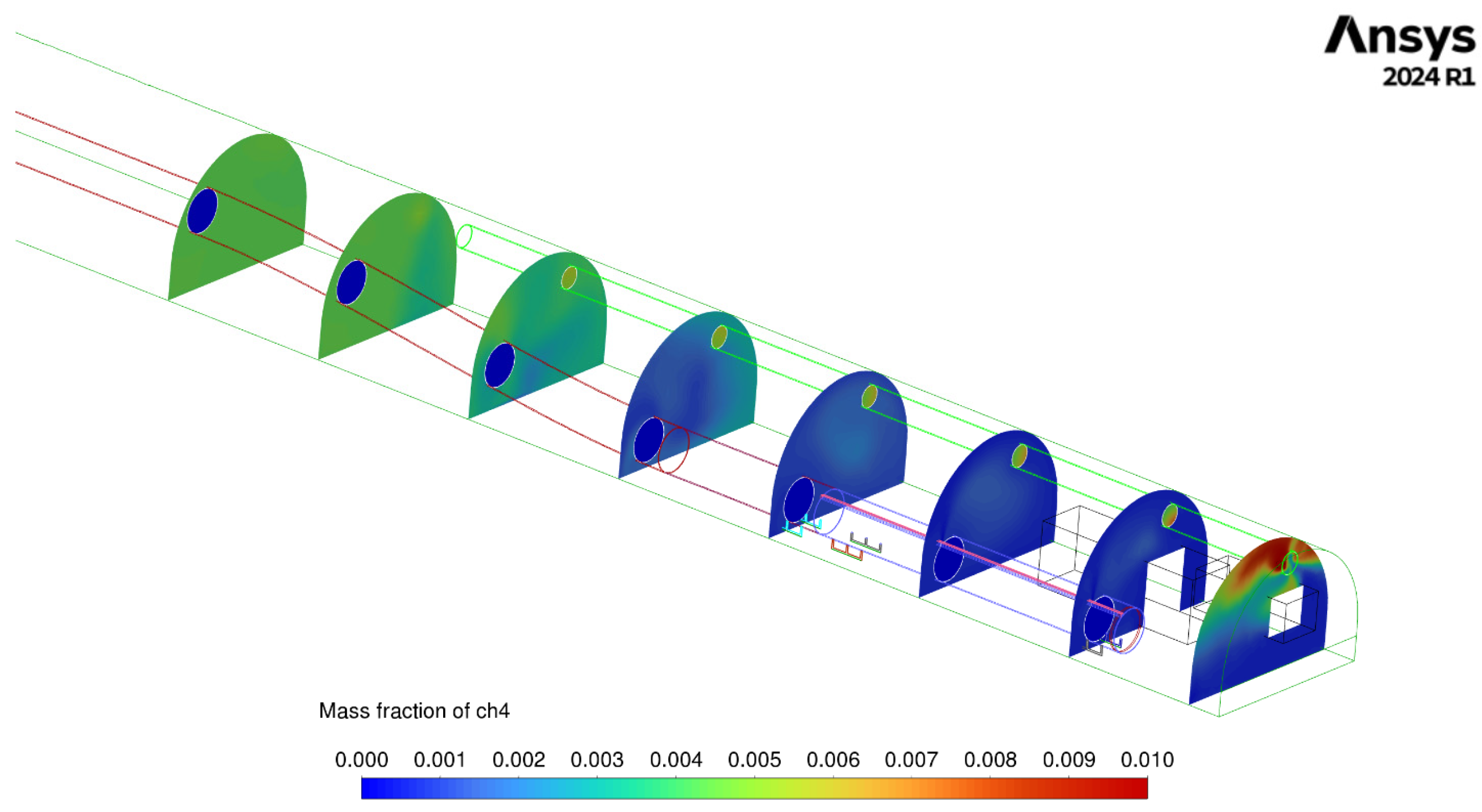

3.1. Variant I—Analysis for a Velocity of 4.72 m/s

3.2. Variant II—Analysis for a Velocity of 7.60 m/s

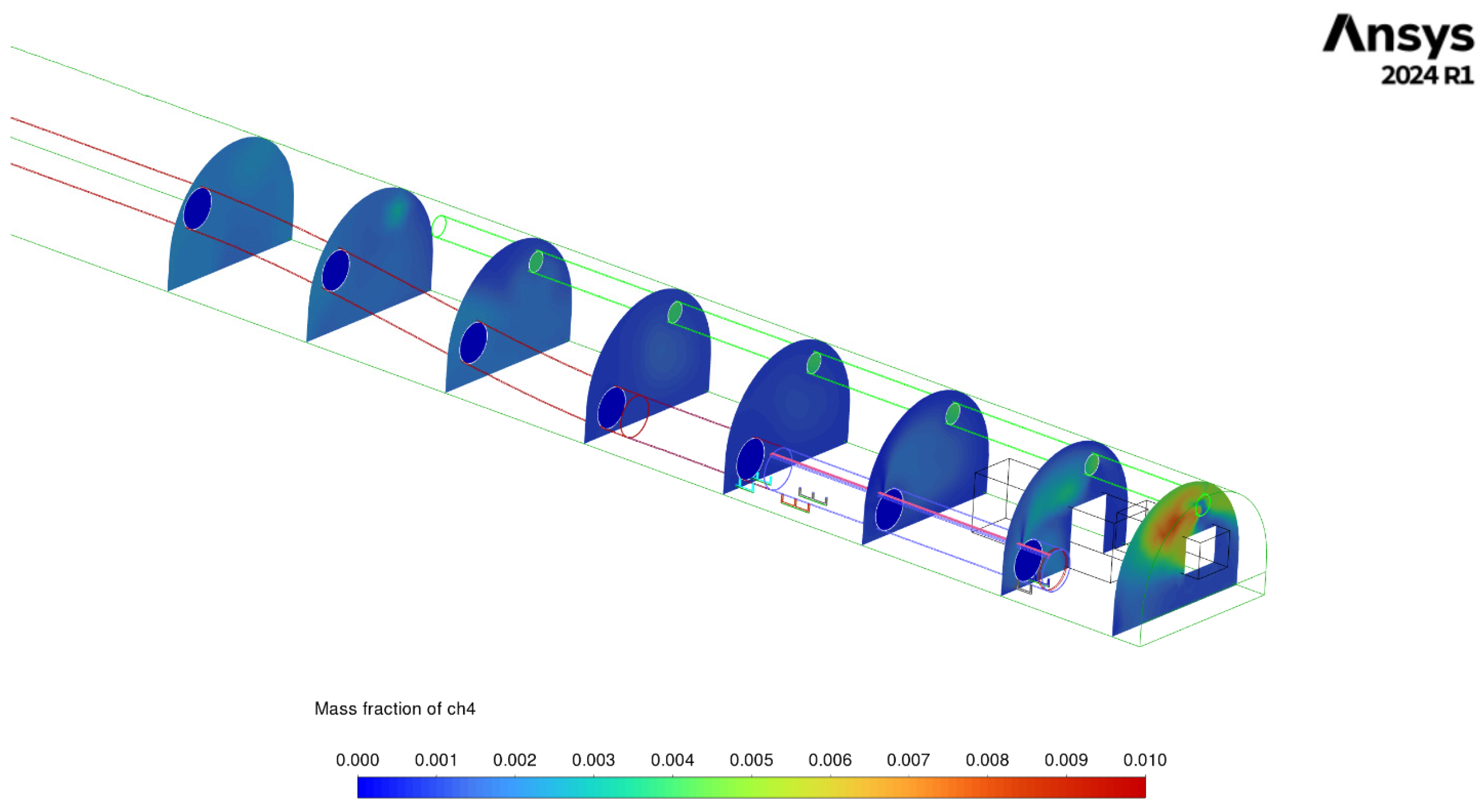

3.3. Variant III—Analysis for a Velocity of 15.74 m/s

3.4. Comparative Analysis of Variants

4. Conclusions

- For the variant with the lowest air velocity, a zone of elevated methane concentration was observed in the space between the whirl flow airduct and the adjacent wall of the excavation (10 m cross-section). Local methane accumulations are a significant safety issue for the crew. In variants II and III, due to the high air velocity, this phenomenon is not noticeable in the diagrams.

- As the air velocity in the ventilation duct increases, along with a constant dust collector throughput, the volumetric airflow directed from the face into the excavation space increases. As a result, the proportion of methane flowing in the excavation relative to the dust collector increases. This increase corresponds to the air velocity supplied by the duct. This is visible in cross-sections located behind the dust collector inlet (5 m and 10 m cross-sections). The authors of the publication plan to continue research in this area.

- A small recirculation of air–methane mixture was observed in the zone of the dust collector outlet toward the face. This phenomenon is most visible in variant II. The cause of the recirculation is the change in the height of the duct’s position in the mixing zone of the two airflow streams from the dust collector and the excavation.

- The conducted analysis showed no impact of air velocity on the homogeneity of the mixture beyond 30 m from the face of the excavation. This conclusion is also confirmed by the obtained values of methane concentration variance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ji, Z.M.; Chen, Z.J.; Pan, J.N.; Niu, Q.H. A novel method for estimating methane emissions from underground coal mines: The Yanma coal mine, China. Atmos. Environ. 2017, 170, 96–107. [Google Scholar] [CrossRef]

- Roshchanka, V.; Evans, M.; Ruiz, F.; Kholod, N. A strategic approach to selecting policy mechanisms for addressing coal mine methane emissions: A case study on Kazakhstan. Environ. Sci. Policy 2017, 78, 185–192. [Google Scholar] [CrossRef]

- Ghorbani, Y.; Nwaila, G.T.; Zhang, S.E.; Bourdeau, J.E.; Cánovas, M.; Arzua, J.; Nikadat, N. Moving towards deep underground mineral resources: Drivers, challenges and potential solutions. Resour. Policy 2023, 80, 103222. [Google Scholar] [CrossRef]

- Obracaj, D.; Korzec, M.; Deszcz, P. Study on methane distribution in the face zone of the fully mechanized roadway with overlap auxiliary ventilation system. Energies 2021, 14, 6379. [Google Scholar] [CrossRef]

- Huiuk, Y.; Kim, M.; Lee, D.; Park, J. Applications of computational fluid dynamics for mine ventilation in mineral development. Energies 2022, 15, 8405. [Google Scholar] [CrossRef]

- Whirl Flow Air Duct LW-SIGMA 800. Available online: https://www.sigmasa.pl/en/offer/mining/ventilation-and-dedusting-systems/whirl-flow-air-duct-lw-sigma-800 (accessed on 13 November 2025).

- Liu, Z.; Zhong, Q.; Lu, Y. Study on the propagation characteristics of methane-air explosion under the promotion of crushed gangue. Sci. Rep. 2024, 14, 2087. [Google Scholar] [CrossRef]

- Kundu, S.; Zanganeh, J.; Moghtaderi, B. A review on understanding explosions from methane–air mixture. J. Loss Prev. Process Ind. 2016, 40, 507–523. [Google Scholar] [CrossRef]

- Rao, S.; Mishra, D.P.; Mishra, A. Methane migration and explosive fringe localisation in retreating longwall panel under varied ventilation scenarios: A numerical simulation approach. Environ. Sci. Pollut. Res. 2023, 30, 66705–66729. [Google Scholar] [CrossRef]

- Brune, J.F.; Grubb, J.W.; Bogin, G.E.; Marts, J.A.; Gilmore, R.C.; Saki, S.A. Lessons learned from research about methane explosive gas zones in coal mine gobs. Int. J. Min. Miner. Eng. 2016, 7, 155–169. [Google Scholar] [CrossRef]

- Trzop, K.; Palka, D.; Szurgacz, D.; Sobik, L. Preventive measures to minimize natural hazards in the Polish underground mining industry. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; Volume 684, p. 012009. [Google Scholar]

- Szlązak, N.; Obracaj, D.; Borowski, M.; Swolkień, J.; Korzec, M. Monitoring and controlling methane hazard in excavations in hard coal mines. AGH J. Min. Geoengin. 2013, 37, 105–116. [Google Scholar] [CrossRef]

- Ostrogórski, P.; Skotniczny, P.; Pucka, M. Measurements of the methane concentration along the longwall excavations and longwall. Arch. Min. Sci. 2022, 67, 195–204. [Google Scholar]

- Ostrogórski, P.; Skotniczny, P. Methane emission measurements along underground galleries of coal mine. Arch. Min. Sci. 2024, 68, 107–114. [Google Scholar] [CrossRef]

- Sidorenko, S.; Trushnikov, V.; Sidorenko, A. Methane emission estimation tools as a basis for sustainable underground mining of gas-bearing coal seams. Sustainability 2024, 6, 3457. [Google Scholar] [CrossRef]

- Gong, W.; Hu, J.; Wang, Z.; Wei, Y.; Li, Y.; Zhang, T.; Zhang, Q.; Liu, T.; Ning, Y.; Zhang, W.; et al. Recent advances in laser gas sensors for applications to safety monitoring in intelligent coal mines. Front. Phys. 2022, 10, 1058475. [Google Scholar] [CrossRef]

- Wu, X.; Cui, J.; Tong, R.; Li, Q. Research on methane measurement and interference factors in coal mines. Sensors 2022, 22, 5608. [Google Scholar] [CrossRef]

- Chen, D.; Xie, J.; Wang, Y.; Sun, X.; Du, H.; Li, G. CFD modeling of optimal airflow rates for safe production in isolated mining faces with high methane concentration and coal spontaneous combustion. J. Clean. Prod. 2023, 423, 138835. [Google Scholar] [CrossRef]

- Nemati-karaviq, R.; Abdollahisharif, J.; Abbasalizadeh, M.; Gilani, S.O. Investigation of Methane Recovery in Coal Mines During Ventilation Operations Through CFD Simulation. Geotech. Geol. Eng. 2024, 42, 6549–6559. [Google Scholar] [CrossRef]

- Palka, D. Modeling and simulation of the methane risk in the mining production process. Multidiscip. Asp. Prod. Eng. 2021, 4, 1–13. [Google Scholar] [CrossRef]

- Torno, S.; Toraño, J. Methane Emission Outbursts in the Mine Face of Two Galleries: Computational Fluid Dynamics Analysis and On-Site Calibration. Energies 2023, 16, 7298. [Google Scholar] [CrossRef]

- Daloğlu, G.; Önder, M.; Parra, T. Modeling of methane and air velocity behavior in an auxiliary ventilated coal heading. Arch. Min. Sci. 2021, 66, 69–84. [Google Scholar]

- Niewiadomski, A.; Badura, H.; Ivanova, T.N.; Repko, A.; Yury, N.R. Analysis of methane concentration distribution at U-ventilated longwall outlet-case study. New Trends Prod. Eng. 2020, 3, 149–168. [Google Scholar] [CrossRef]

- Kumar, P.; Mishra, D.P.; Panigrahi, D.C.; Sahu, P. Numerical studies of ventilation effect on methane layering behaviour in underground coal mines. Curr. Sci. 2017, 112, 1873–1881. [Google Scholar] [CrossRef]

- Juganda, A.; Strebinger, C.; Brune, J.F.; Bogin, G.E., Jr. Computational fluid dynamics modeling of a methane gas explosion in a full-scale, underground longwall coal mine. Min. Metall. Explor. 2022, 39, 897–916. [Google Scholar] [CrossRef]

- Arrieta-Gomez, M.; Vélez-García, S.; Zuluaga, D.H.; Tejada, J.C.; Sanin-Villa, D. Efficiency optimization of a hybrid Savonius-Darrieus hydrokinetic turbine via regression modeling and CFD-based design of experiments. Results Eng. 2025, 27, 105751. [Google Scholar] [CrossRef]

- Trybała, P.; Rigon, S.; Remondino, F.; Banasiewicz, A.; Wróblewski, A.; Macek, A.; Kujawa, P.; Romańczukiewicz, K.; Redondo, C.; Espada, F. Optimizing Mining Ventilation Using 3D Technologies. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2024, 48, 427–434. [Google Scholar] [CrossRef]

- Demirkan, D.C.; Duzgun, H.S.; Juganda, A.; Brune, J.; Bogin, G. Real-time methane prediction in underground longwall coal mining using AI. Energies 2022, 15, 6486. [Google Scholar] [CrossRef]

- Rahimi, S.; Ataee-pour, M.; Madani, H. CFD modeling of impact of gas content uncertainty on methane distribution in underground coal mine roadways. J. Min. Environ. 2022, 13, 493–502. [Google Scholar]

- Wrona, P.; Różański, Z.; Pach, G.; Domagała, L. The application of a jet fan for the control of air and methane streams mixing at the excavations cross-the results of numerical simulation. Manag. Syst. Prod. Eng. 2016, 23, 156–162. [Google Scholar] [CrossRef]

- Cao, Z.; Liu, X. Study on the characteristics of flow field and gas migration in gas tunnels. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 741, p. 012039. [Google Scholar]

- Wesołowski, M.; Badura, H.; Kołodziejczyk, P.; Bańka, P. Numeryczna symulacja wypływu metanu do wyrobiska korytarzowego. Syst. Wspomagania Inżynierii Prod. 2018, 7, 443–456. [Google Scholar]

- Regulation of the Polish Minister of Energy on Detailed Requirements for the Operation of Underground Mining Plants Dated 23 November 2016. (Dz.U. z 2017 r. poz. 1118). Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20170001118 (accessed on 12 October 2025).

| Parameter | Value |

|---|---|

| Cross-sectional area of the excavation | 17.80 m2 |

| Excavation length | 1430 m |

| Portion of the cross-section composed of coal | 80% |

| Air density in the excavation | 1.31 kg/m3 |

| Ventilation duct diameter | 1.20 m |

| Ventilation duct efficiency | 87% |

| Dust collector fan airflow rate | 360 m3/min |

| Absolute methane inflow to the excavation | 2.90 m3/min |

| Solver | Pressure-Based |

|---|---|

| time discretization | steady state |

| sub-models | turbulent flow RANS (SST k-epsilon turbulence mode), species transport (methane–air mixture) |

| computational scheme | coupled |

| scheme of the analysis | all sub-models as second-order |

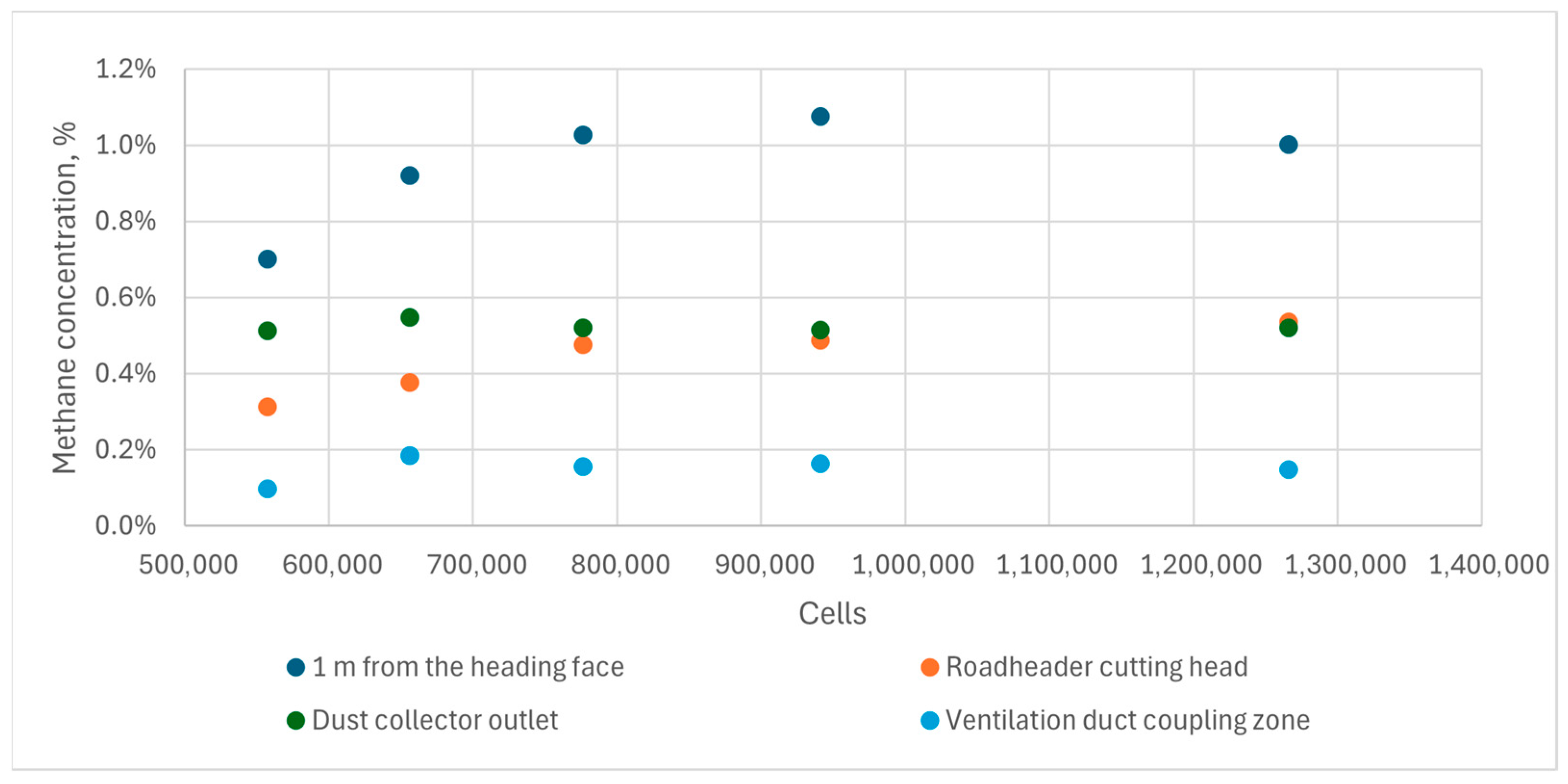

| No. of Cells | Orthogonal Quality | Skewness | Methane Concentration at Sensor Locations | |||

|---|---|---|---|---|---|---|

| 1 m from the Heading Face | Roadheader Cutting Head | Dust Collector Outlet | Ventilation Duct Coupling Zone | |||

| 557,693 | 0.16584 | 0.83416 | 0.70% | 0.31% | 0.51% | 0.10% |

| 656,338 | 0.151533 | 0.84847 | 0.92% | 0.38% | 0.55% | 0.18% |

| 776,439 | 0.16834 | 0.83166 | 1.03% | 0.48% | 0.52% | 0.16% |

| 941,317 | 0.16749 | 0.83251 | 1.08% | 0.49% | 0.51% | 0.16% |

| 1,265,946 | 0.16637 | 0.83363 | 1.00% | 0.54% | 0.52% | 0.15% |

| Cross- Section | Variants of Air Velocity | Methane Concentration, % | |||||

|---|---|---|---|---|---|---|---|

| Min | Max | Value Range | Arithmetic Mean | Median | Var [-] | ||

| 1 m | V1 | 0.38 | 1.39 | 1.01 | 0.61 | 0.50 | 5.86 × 10−6 |

| V2 | 0.04 | 1.08 | 1.04 | 0.28 | 0.16 | 7.30 × 10−6 | |

| V3 | 0.10 | 0.78 | 0.68 | 0.31 | 0.23 | 3.97 × 10−6 | |

| 5 m | V1 | 0.28 | 0.67 | 0.39 | 0.49 | 0.50 | 8.26 × 10−7 |

| V2 | 0.03 | 0.15 | 0.12 | 0.07 | 0.06 | 5.70 × 10−8 | |

| V3 | 0.08 | 0.35 | 0.27 | 0.16 | 0.15 | 4.31 × 10−7 | |

| 10 m | V1 | 0.10 | 0.71 | 0.61 | 0.42 | 0.40 | 6.67 × 10−7 |

| V2 | 0.01 | 0.15 | 0.14 | 0.09 | 0.08 | 8.56 × 10−8 | |

| V3 | 0.04 | 0.18 | 0.14 | 0.12 | 0.12 | 1.08 × 10−7 | |

| 15 m | V1 | 0.41 | 0.71 | 0.30 | 0.53 | 0.53 | 8.73 × 10−7 |

| V2 | 0.07 | 0.20 | 0.14 | 0.13 | 0.12 | 8.69 × 10−8 | |

| V3 | 0.09 | 0.12 | 0.03 | 0.10 | 0.10 | 7.91 × 10−9 | |

| 20 m | V1 | 0.48 | 0.71 | 0.23 | 0.60 | 0.60 | 3.52 × 10−7 |

| V2 | 0.09 | 0.30 | 0.21 | 0.18 | 0.16 | 3.68 × 10−7 | |

| V3 | 0.09 | 0.15 | 0.06 | 0.11 | 0.11 | 2.34 × 10−8 | |

| 25 m | V1 | 0.54 | 0.71 | 0.17 | 0.63 | 0.63 | 1.99 × 10−7 |

| V2 | 0.20 | 0.46 | 0.26 | 0.34 | 0.35 | 2.14 × 10−7 | |

| V3 | 0.10 | 0.21 | 0.11 | 0.16 | 0.17 | 9.43 × 10−8 | |

| 30 m | V1 | 0.61 | 0.79 | 0.18 | 0.66 | 0.66 | 1.08 × 10−7 |

| V2 | 0.33 | 0.49 | 0.16 | 0.42 | 0.43 | 1.06 × 10−7 | |

| V3 | 0.11 | 0.30 | 0.19 | 0.17 | 0.17 | 2.22 × 10−7 | |

| 35 m | V1 | 0.67 | 0.72 | 0.05 | 0.70 | 0.70 | 4.54 × 10−9 |

| V2 | 0.42 | 0.46 | 0.04 | 0.44 | 0.44 | 3.15 × 10−9 | |

| V3 | 0.16 | 0.23 | 0.07 | 0.20 | 0.20 | 1.77 × 10−8 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niewiadomski, A.P.; Musioł, D.; Pach, G.; Różański, Z.; Wrona, P.; Koch, N.; Šofranko, M. The Impact of Air Velocity on the Formation of Methane Concentration Fields in Excavated Workings. Appl. Sci. 2025, 15, 12352. https://doi.org/10.3390/app152312352

Niewiadomski AP, Musioł D, Pach G, Różański Z, Wrona P, Koch N, Šofranko M. The Impact of Air Velocity on the Formation of Methane Concentration Fields in Excavated Workings. Applied Sciences. 2025; 15(23):12352. https://doi.org/10.3390/app152312352

Chicago/Turabian StyleNiewiadomski, Adam P., Dariusz Musioł, Grzegorz Pach, Zenon Różański, Paweł Wrona, Natalia Koch, and Marian Šofranko. 2025. "The Impact of Air Velocity on the Formation of Methane Concentration Fields in Excavated Workings" Applied Sciences 15, no. 23: 12352. https://doi.org/10.3390/app152312352

APA StyleNiewiadomski, A. P., Musioł, D., Pach, G., Różański, Z., Wrona, P., Koch, N., & Šofranko, M. (2025). The Impact of Air Velocity on the Formation of Methane Concentration Fields in Excavated Workings. Applied Sciences, 15(23), 12352. https://doi.org/10.3390/app152312352