Finite Element Simulation Analyses of Load-Bearing Capacity of RPP Material-Based Shoe Box

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Properties

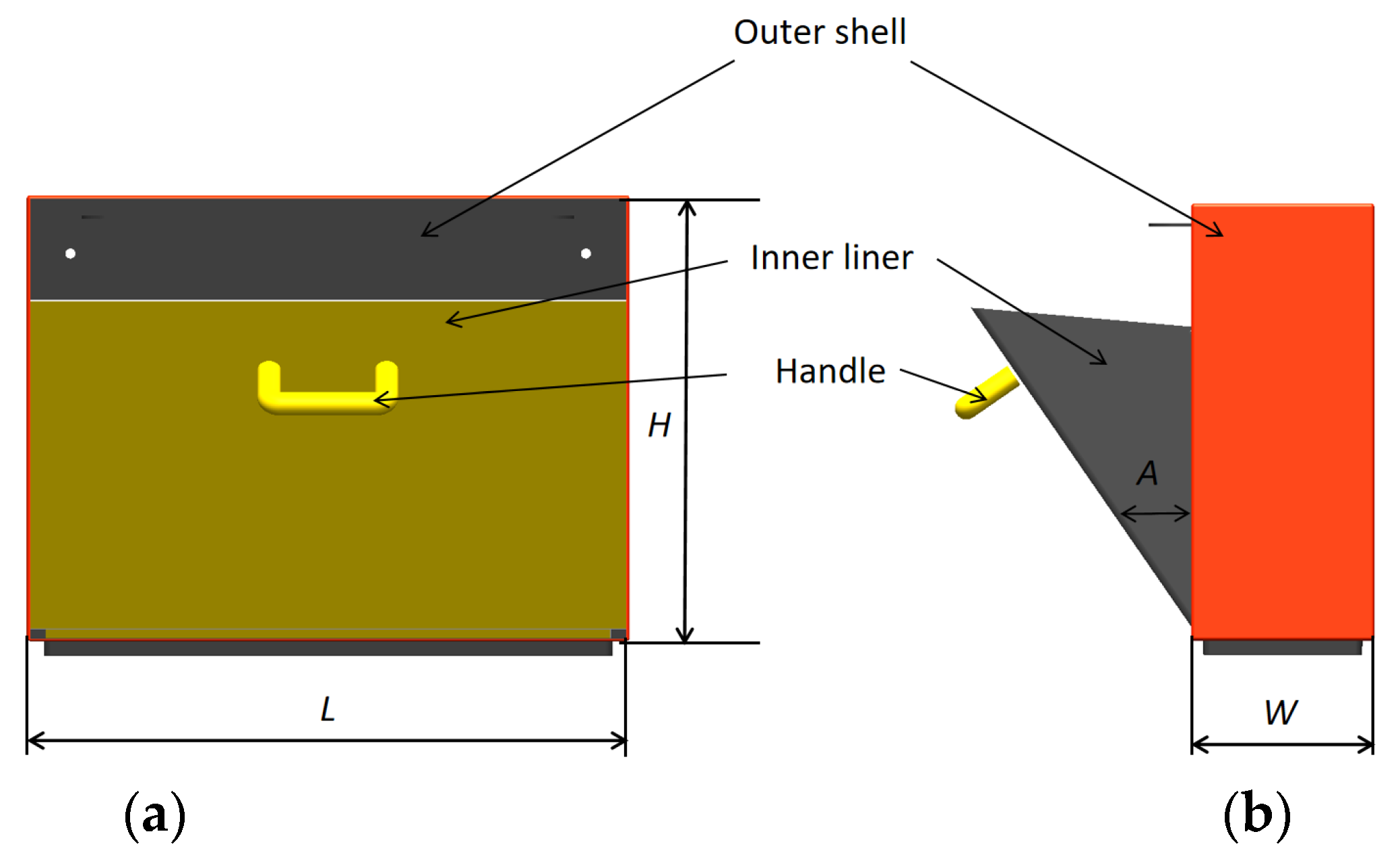

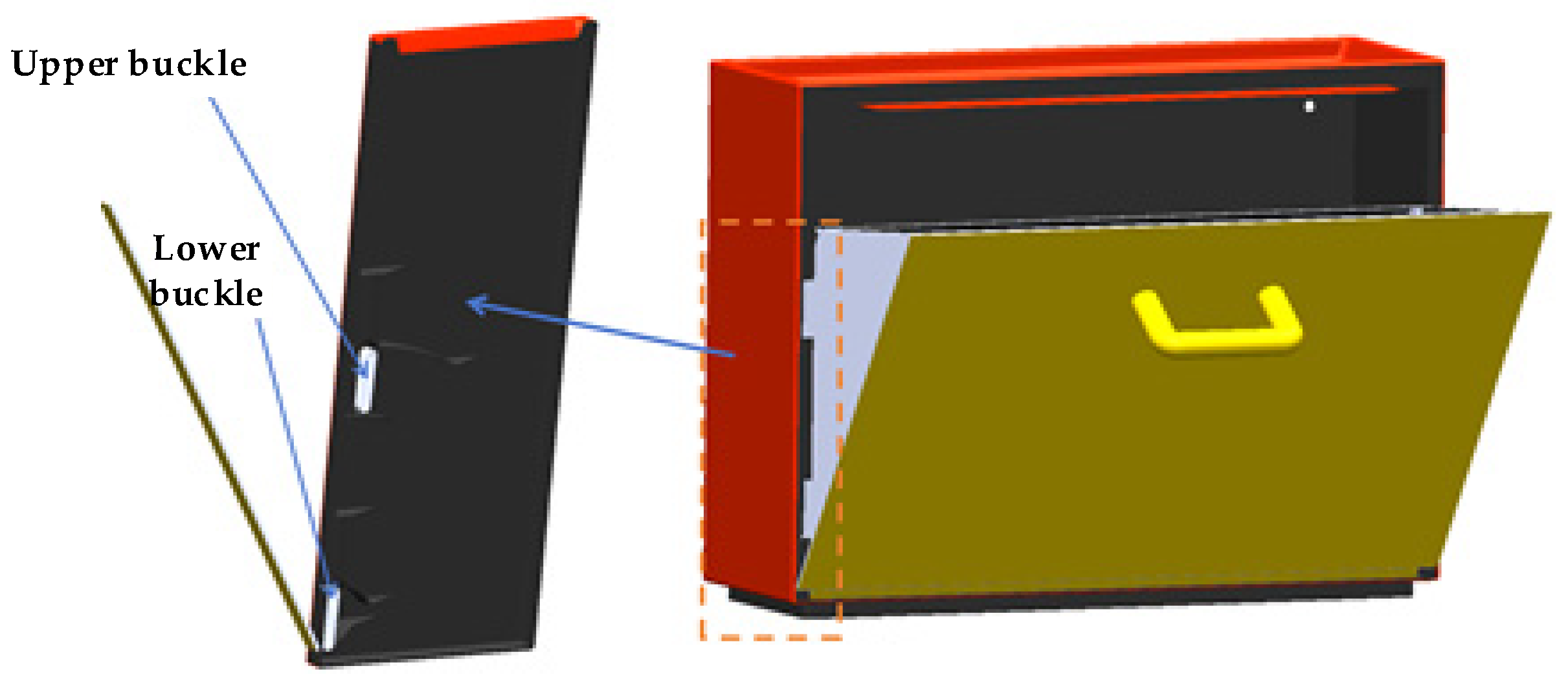

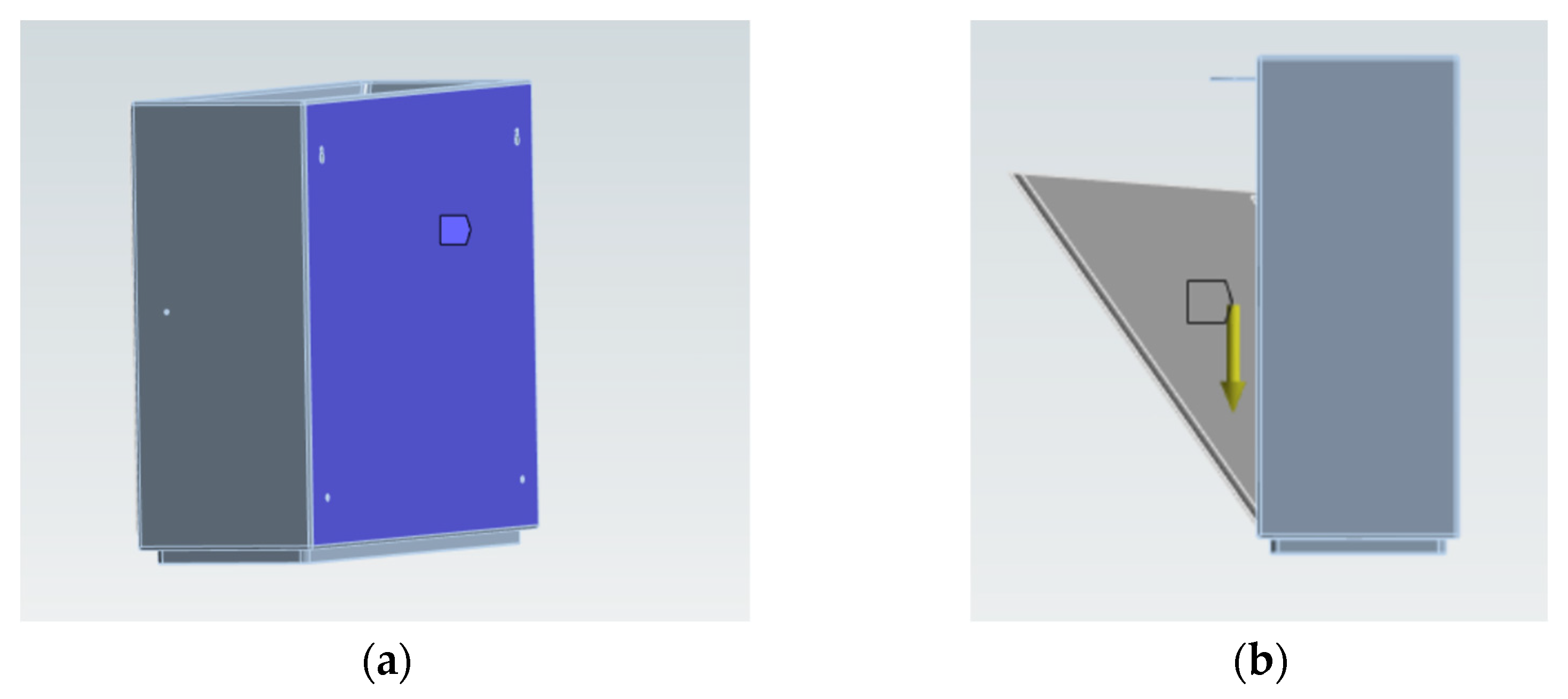

2.2. Structural Model

2.3. Experimental Overview

2.3.1. Experimental Purpose

2.3.2. Experimental Setup and Conditions

2.3.3. Experimental Procedures

2.3.4. Experimental Results

2.4. Finite Element Modeling

2.4.1. Basic Equations of Elastic Mechanics

2.4.2. Stress–Strain Constitutive Relation

2.4.3. Finite Element Discretization Principle

- (1)

- Element Displacement Interpolation and Stiffness Matrix

- (2)

- Assembly and Solution of the Overall Equation

2.4.4. Material Nonlinearity and Limitations of Linear–Elastic Approximation

- (1)

- Bilinear plasticity model: Elastic up to yield stress , then plastic deformation with tangent modulus . as follows (Equation (8)):

- (2)

- Damage mechanics model: Quantifies microcrack evolution via scalar damage variable (0 = undamaged, 1 = fully damaged) as follows (Equation (10)):

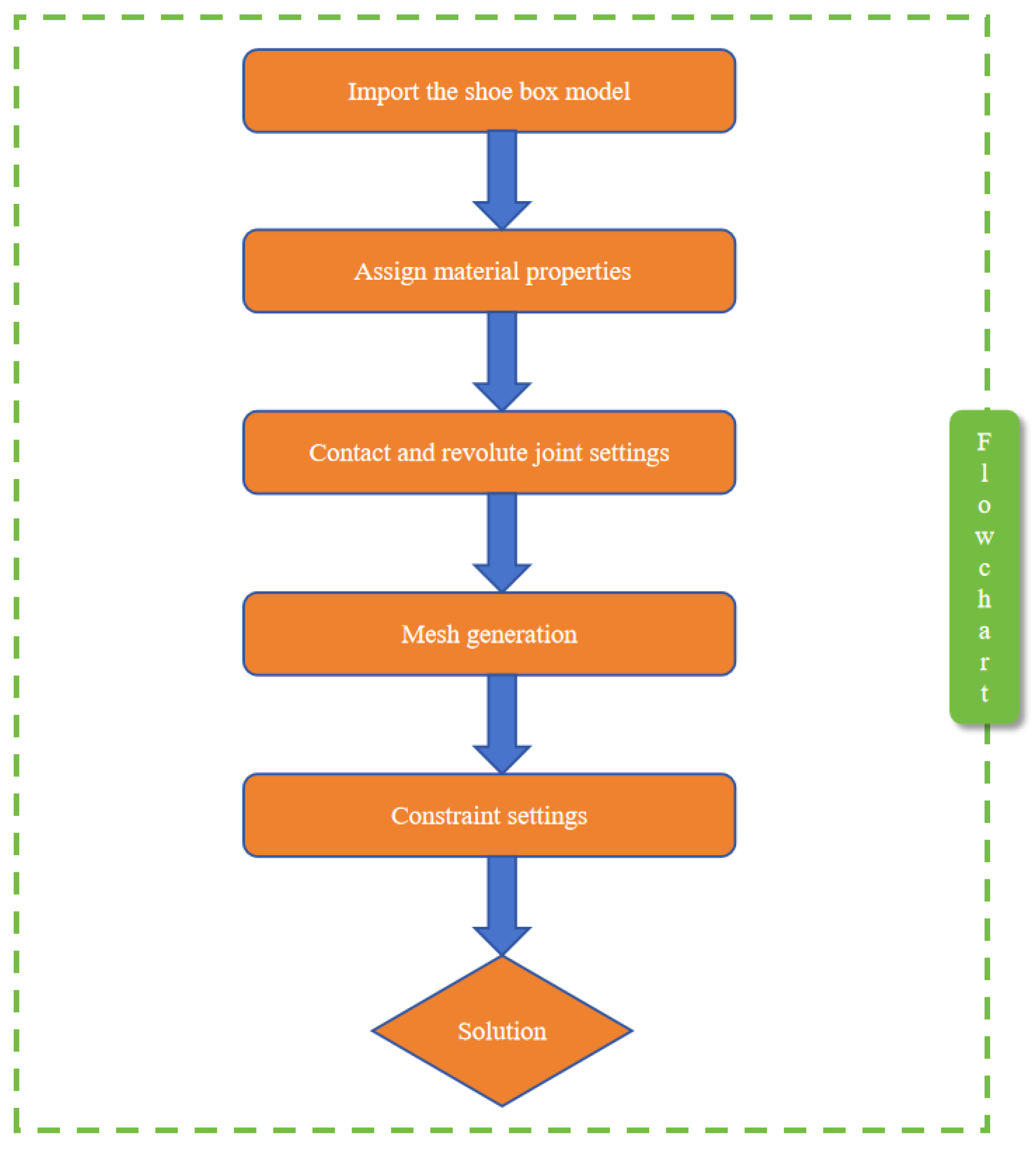

3. Finite Element Software Settings

3.1. Analysis Purpose

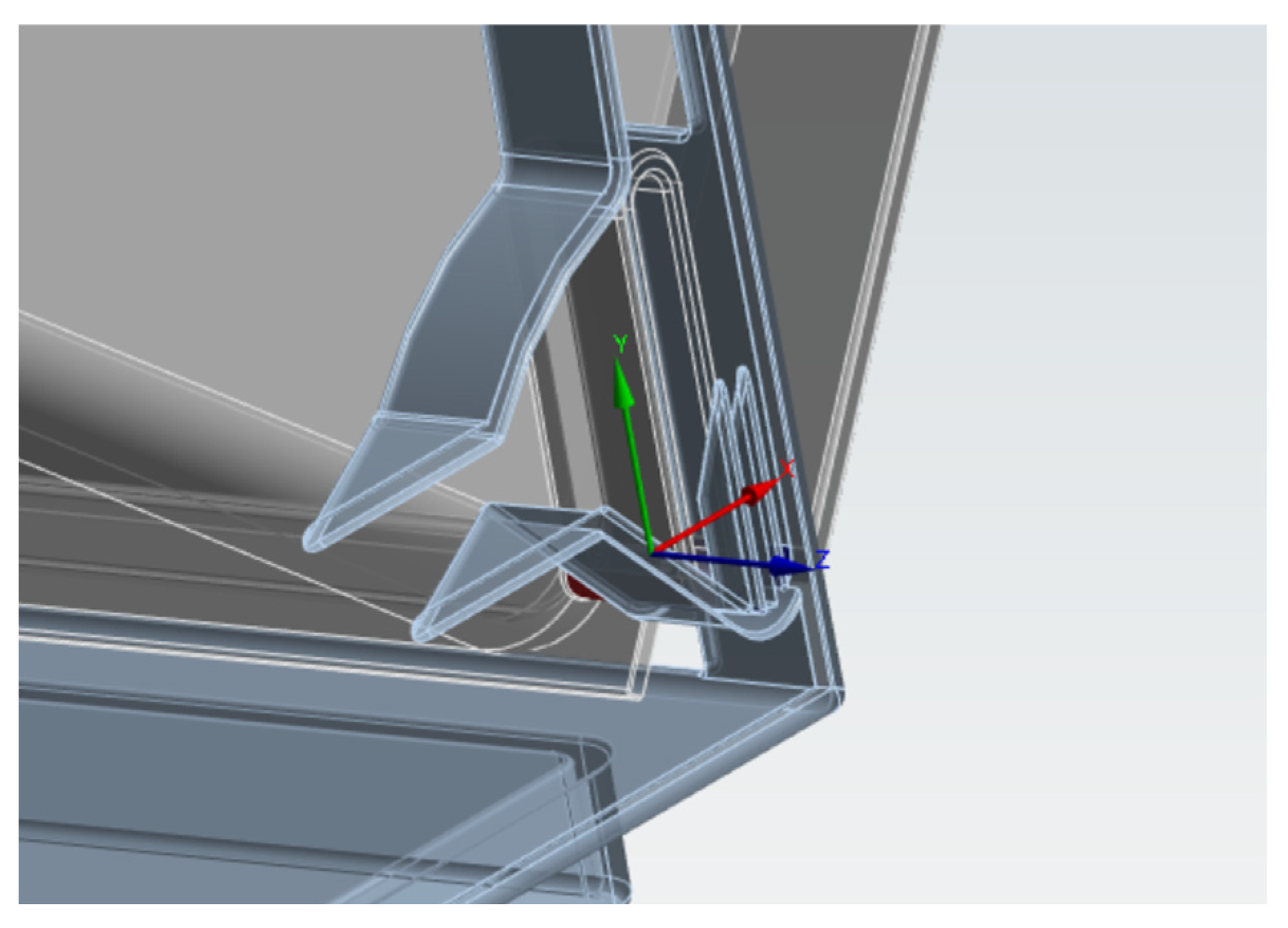

3.2. Establishment of the Simulation Model

3.2.1. Material Assignment

3.2.2. Contact Setting: Closed State

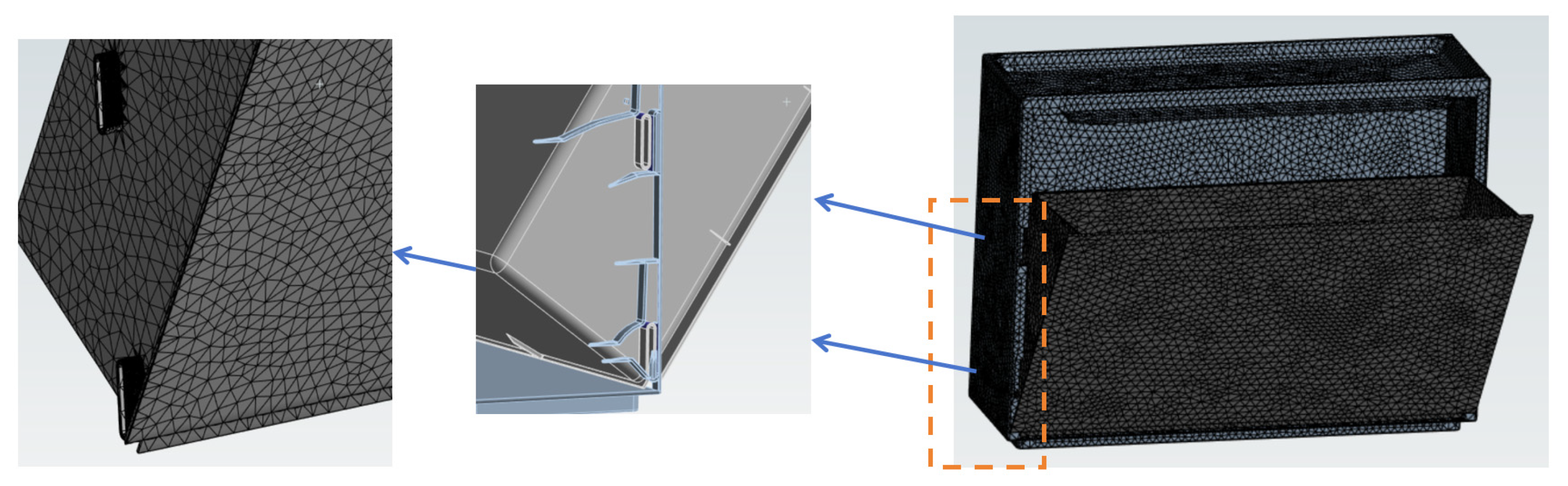

3.2.3. Mesh Generation

4. Results

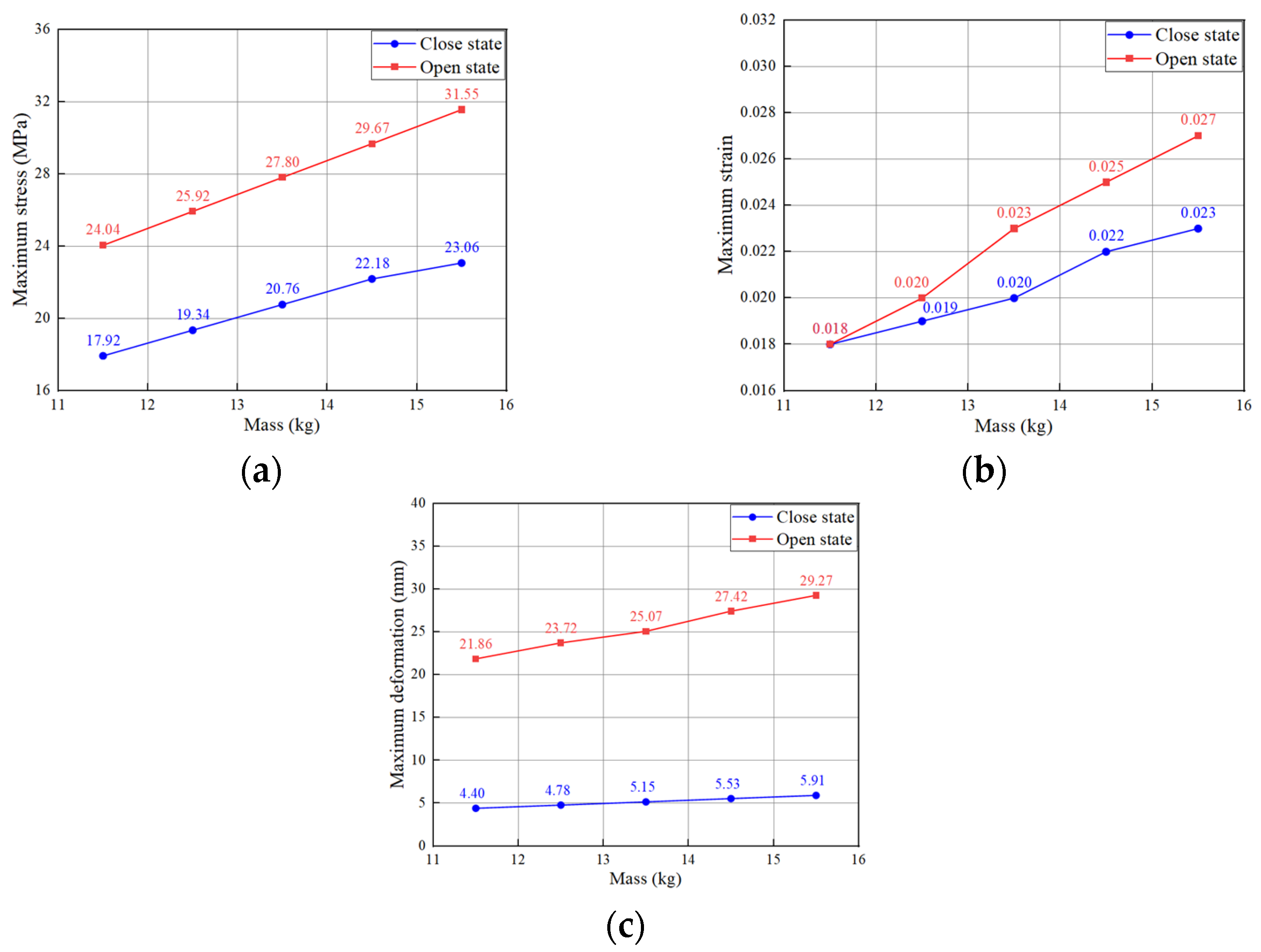

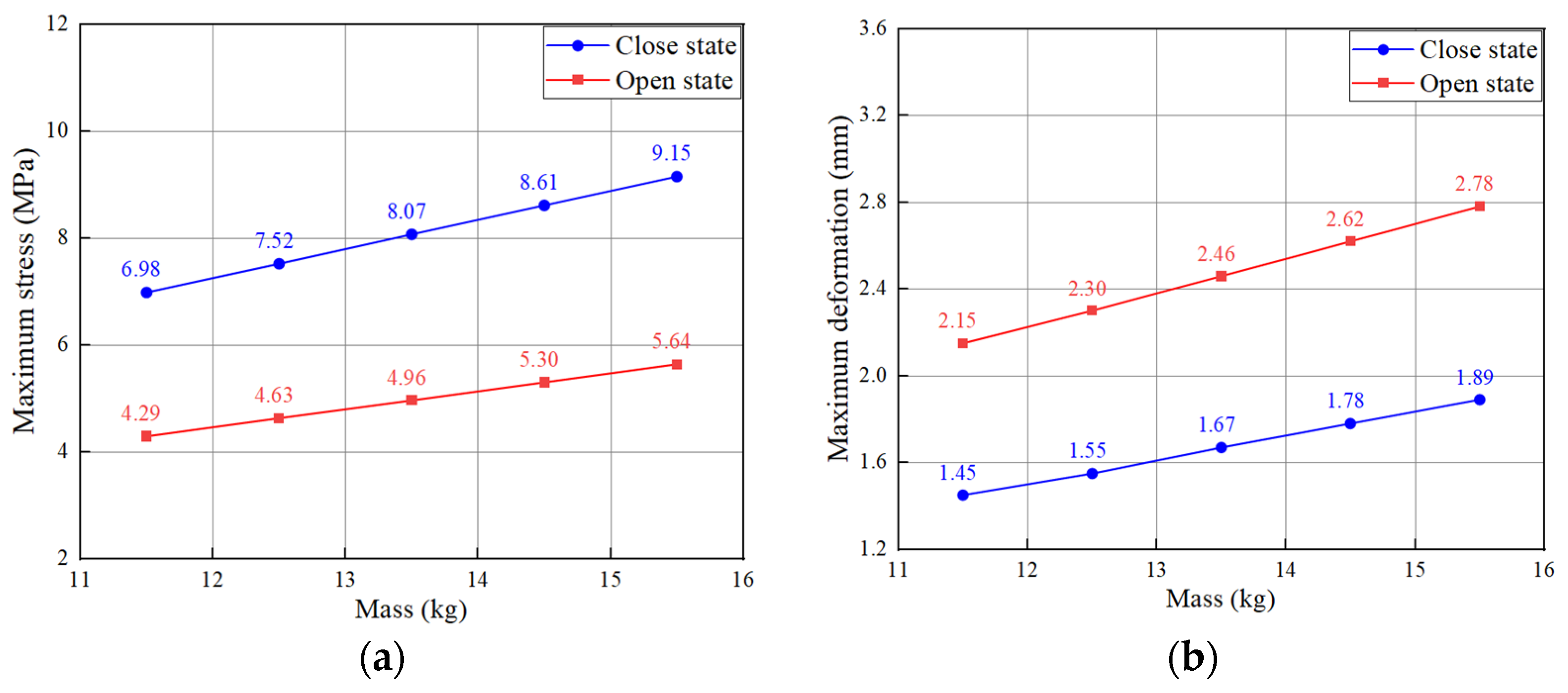

4.1. Stress and Strain Responses Under Different Working States

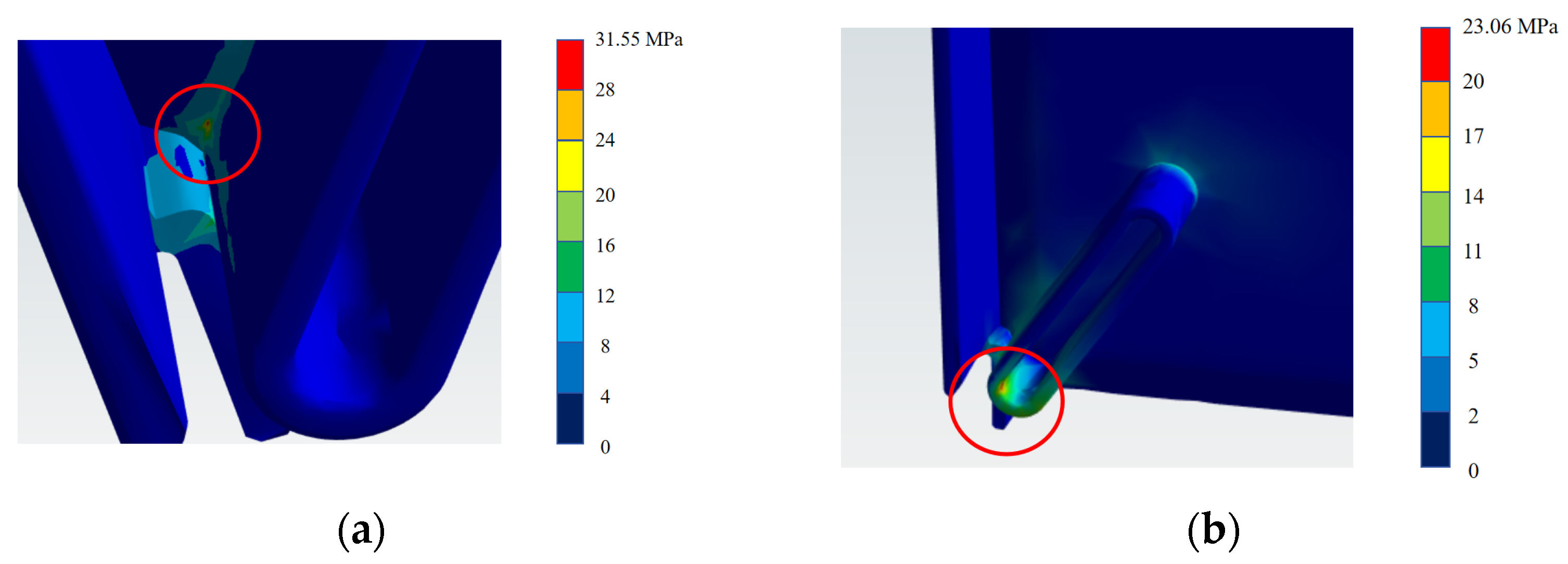

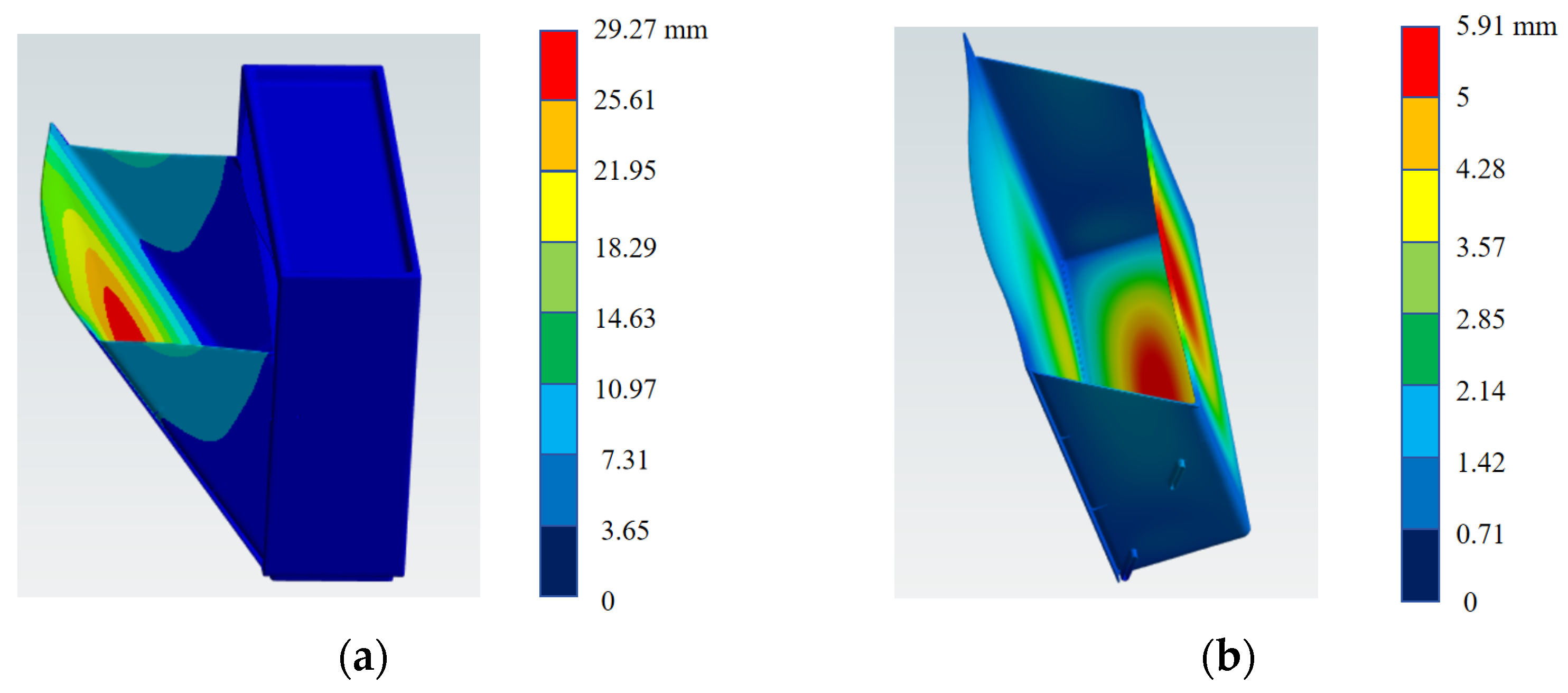

4.2. Mechanical Response Analysis of the Upper Buckle in the Open State

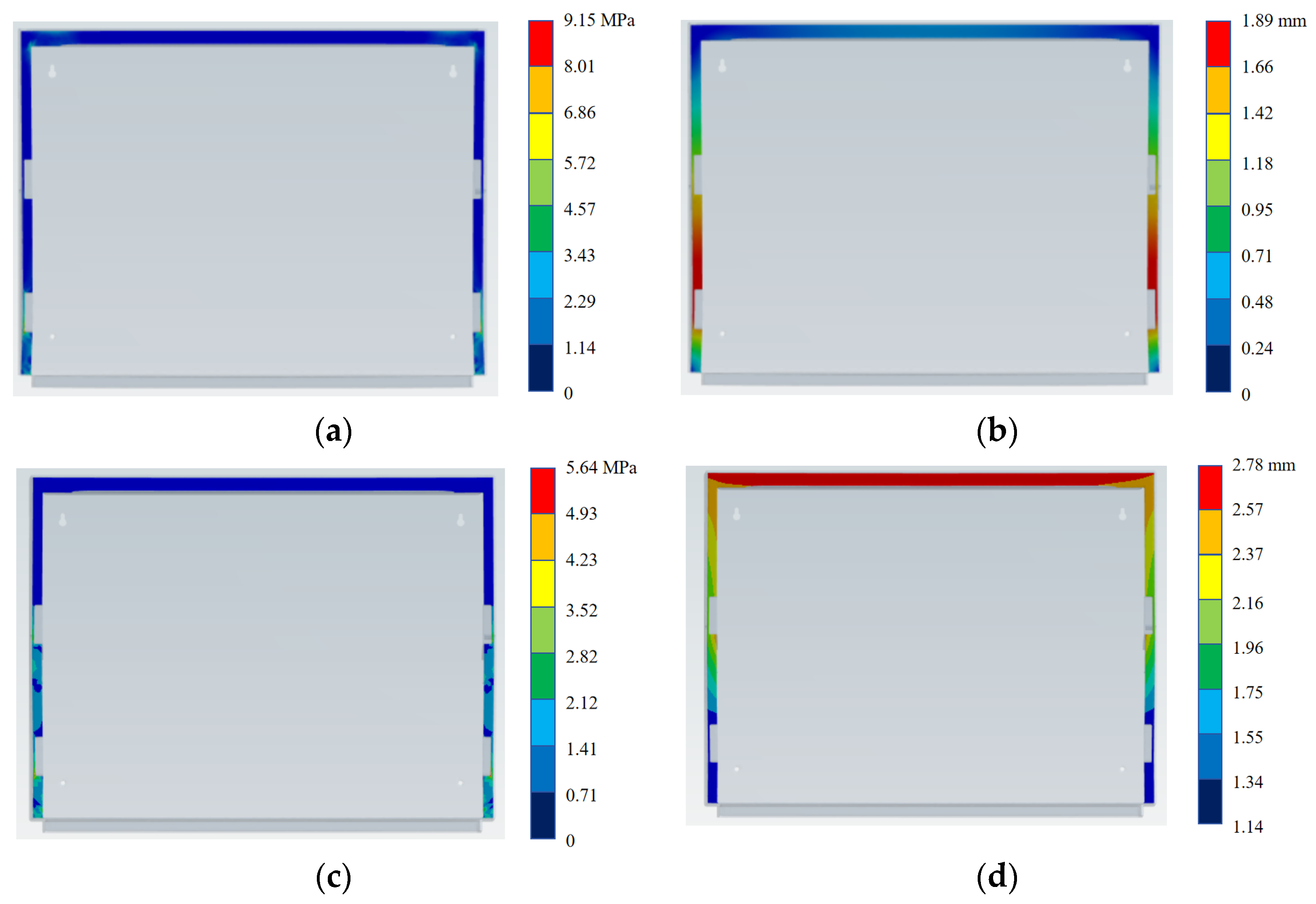

4.3. Mechanical Response of the Outer Shell Surface in Closed and Open States

5. Conclusions

- (1)

- The experimental results of the load-bearing limit of the shoe box show that the failure load in the open state is 13.2–15.4 kg, which is manifested as the fracture of the lower buckle and the slipping of the inner liner. In the finite element simulation, when the load reaches 13.5 kg, the stress of the lower buckle is close to the flexural strength of RPP, and the local strain exceeds the fracture elongation. The possible reasons for the slight discrepancies between the experimental results and the finite element results are as follows:

- (i)

- Load resolution: Differences in how the load is incremented between experimental tests and numerical simulations.

- (ii)

- Weighing error: Inherent variability in experimental weight measurements.

- (iii)

- Contact conditions: Variations in friction, contact area, or component fit between physical tests and finite element models.

- (2)

- The flexural strength and fracture elongation of RPP are the core parameters for judging the fracture of the shoe box. When the local strain exceeds the fracture elongation but the stress does not reach the flexural strength, the material does not fracture immediately due to “excessive plastic deformation but remaining strength redundancy”, but there is a risk of “delayed fracture”. When the stress reaches the flexural strength and the strain exceeds the limit, “stress–strain coupled fracture” is triggered, which is the main failure mode of the shoe box in the open state.

- (3)

- Closed state: Due to the “contact cooperative load bearing between the outer shell and the inner liner”, the stress distribution is more uniform, the deformation is limited by the support of the inner liner, the overall load-bearing capacity is stronger, and there is no risk of local strain exceeding the limit. Open state: After losing the support of the inner liner, the lower buckle becomes a “stress-dominated high-risk fracture part”, and both the upper and lower buckles are “strain-dominated potential deformation parts”, so the overall mechanical performance is significantly weaker than that in the closed state.

- (4)

- Based on the research results, the structural optimization of the shoe box can focus on two directions: For the open state, strengthen the “stress fracture resistance” design of the lower buckle and optimize the “strain deformation resistance” design of both the upper and lower buckles. For the closed state, utilize the “contact synergy effect between the outer shell and the inner liner” and improve the overall load-bearing efficiency by optimizing the contact part between the inner liner and the outer shell.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- GB/T 36975-2018; General Technical Requirements for Footwear. Standards Press of China: Beijing, China, 2018.

- Beghetto, V.; Sole, R.; Buranello, C.; Al-Abkal, M.; Facchin, M. Recent Advancements in Plastic Packaging Recycling: A Mini-Review. Materials 2021, 14, 4782. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.T.; Liang, Y.F.; Pu, Z.C.; He, J.; Yang, S.Q. Transforming waste to treasure: Superhydrophobic coatings from recycled polypropylene for high-value application. Prog. Org. Coat. 2024, 188, 108248. [Google Scholar] [CrossRef]

- Bowen, N.; Guyer, C.; Rippon, T.; Daly, M.; Gao, P.; Galati, V.; Lograsso, S.; Johnston, S.; Masato, D. Mechanical and crystallization properties of hot runner injection molded virgin and recycled polypropylene. Polym. Eng. Sci. 2024, 64, 2241–2255. [Google Scholar] [CrossRef]

- Shahroodi, Z.; Krempl, N.; Zidar, D.; Mayrhofer, T.; Kirschnick, U.; Arbeiter, F.; Duretek, I.; Holzer, C. Waste-to-Value Feasibility Study: Assessing the Viability and Quality of Incorporating Different Postindustrial Glass-Fiber Composites into Postconsumer Recycled Polypropylene. ACS Sustain. Chem. Eng. 2024, 12, 12619–12631. [Google Scholar] [CrossRef]

- Zheng, Y.T.; Gu, F.; Wang, B.; Wang, Z.; Gao, C.; Zhou, Y.; Hall, P. Thermal and mechanical behaviour of recycled short milled carbon fibre reinforced polypropylene and recycled polypropylene composites: A comparative study. J. Mater. Res. Technol. 2024, 32, 4221–4233. [Google Scholar] [CrossRef]

- Albedah, A.; Abdo, H.S.; Mohammed, S.; Bouiadjra, B.A.B.; Al-Ghurabi, E.H.; Alothman, O.Y. Potential of recycled polypropylene: A study on effect of natural fiber on the morphology and properties of biocomposite. J. King Saud Univ. Sci. 2024, 36, 103167. [Google Scholar] [CrossRef]

- Zhang, W.C.; Shen, J.; Guo, X.G.; Wang, K.; Jia, J.; Zhao, J.T.; Zhang, J.S. Comprehensive Investigation into the Impact of Degradation of Recycled Polyethylene and Recycled Polypropylene on the Thermo-Mechanical Characteristics and Thermal Stability of Blends. Molecules 2024, 29, 4499. [Google Scholar] [CrossRef]

- Krantz, J.; Nieduzak, Z.; Licata, J.; O’Meara, S.; Gao, P.; Masato, D. In-mold rheology and automated process control for injection molding of recycled polypropylene. Polym. Eng. Sci. 2024, 64, 4112–4127. [Google Scholar] [CrossRef]

- Li, X.K.; Wang, J.Q.; Chan, S.P.; Teong, S.P.; Zhang, Y.G. Scalable superhydrophobic coatings with recycled polypropylene. Green Chem. 2024, 26, 4493–4497. [Google Scholar] [CrossRef]

- Dananjaya, V.; Abeykoon, C. Thermo-mechanical and electrical properties of graphene nanoplatelets reinforced recycled polypropylene nanocomposites. Int. J. Lightweight Mater. Manuf. 2025, 8, 374–384. [Google Scholar] [CrossRef]

- Yu, C.H.; Ye, L.D.; Li, D.C.; Liu, H.B.; Wei, Q.Y.; Huang, Y.Y.; Wu, Z.J.; Zhang, L.L.; Li, Z.W.; Lu, S.R. Synergistic effect of tannic acid/stearic acid/calcium carbonate/recycled polypropylene polymer composites and molecular dynamics simulation study. Polym. Compos. 2025, 46, 9134–9147. [Google Scholar] [CrossRef]

- Teklemuz, T.G.; Gerezgiher, A.G.; Tesfay, A.G. Enhancing the machinability of recycled polypropylene composites reinforced with waste cotton and pine sawdust through milling parameters optimization. J. Thermoplast. Compos. Mater. 2025, 38, 4122–4140. [Google Scholar] [CrossRef]

- Marrocco, V.; Surace, R.; Brandonisio, E.; Marasco, I.; Pagano, C.; Tonetti, C.; Errico, V.; Calò, G.; Campanelli, S.L.; Fassi, I. Investigating EMI shielding performance of recycled polypropylene (PP) composite foams with reused metal powders. Mater. Des. 2025, 254, 114106. [Google Scholar] [CrossRef]

- Alzebdeh, K.; Alsafy, M.; Al-Kindi, K.; Al-Anqoodi, A.; Al-Alawi, A.; Al-Hinai, N. Optimization and Characterization of Recycled Polypropylene and Date Palm Nanocomposites for 3D Printing Applications. J. Mater. Eng. Perform. 2025, 34, 24073–24089. [Google Scholar] [CrossRef]

- Frankenbach, L.A.; Lukoschek, S.; Kruppke, I.; Cherif, C. Multifilament spinning of mechanically recycled polypropylene from post-consumer sources for a circular economy in textile applications. Sci. Rep. 2025, 15, 14047. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Cao, Y.M.; He, X.Y.; Su, Y.; Wang, Y.J.; Wang, W.T.; Yang, C.; Jin, Z.H.; Fan, M.; Liu, Z.H.; et al. Preparation and ageing resistance enhancement of RP/SBS composite asphalt by heterostructure copper oxalate nanoparticles/recycled polypropylene fiber. Constr. Build. Mater. 2025, 473, 140992. [Google Scholar] [CrossRef]

- Belabed, Z.; Tounsi, A.; Bousahla, A.A.; Tounsi, A.; Khedher, K.M.; Salem, M.A. Mechanical behavior analysis of FG-CNTRC porous beams resting on Winkler and Pasternak elastic foundations: A finite element approach. Comput. Concr. 2024, 34, 447–476. [Google Scholar] [CrossRef]

- Li, H.L.; Yan, H. Refined finite element analysis of helical wire ropes under multi-axial dynamic loading. Adv. Eng. Softw. 2025, 200, 103823. [Google Scholar] [CrossRef]

- Liu, Z.; Liang, J.L.; He, Z.F.; Liu, X.; Liu, H.D.; Shao, Z.J. A developed fatigue analysis approach for composite wind turbine blade adhesive joints using finite-element submodeling technique. Eng. Fail. Anal. 2024, 164, 108701. [Google Scholar] [CrossRef]

- Wu, Y.C.; Chen, J.B.; Zhu, P.; Zhi, P. Finite Element Analysis of Perforated Prestressed Concrete Frame Enhanced by Artificial Neural Networks. Buildings 2024, 14, 3215. [Google Scholar] [CrossRef]

- Özcan, C.; Lestriez, P.; Özcan, M.; Josset, Y. Finite element analysis of dental structures: The role of mandibular kinematics and model complexity. Front. Dent. Med. 2024, 5, 1461909. [Google Scholar] [CrossRef]

- Shen, X.; Guo, H.; Chen, G.X.; Lian, H.Y.; Guo, W.; Wang, Z.; Xu, Z.H.; Li, Z.T. Finite element analysis of proximal femur bionic nail for treating intertrochanteric fractures in osteoporotic bone. Comput. Methods Biomech. Biomed. Eng. 2025, 28, 1991–2002. [Google Scholar] [CrossRef] [PubMed]

- Kundakcioglu, A.; Gedik, B. Comparison of Screws with Different Diameters in Subperiosteal Implant Application with Finite Element Analysis. Int. J. Med. Sci. 2024, 21, 2595–2602. [Google Scholar] [CrossRef] [PubMed]

- Xian, C.; Zhang, H.; Kim, Y.C.; Zhang, H.; Liu, Y. Programmed system for fatigue life prediction of excavator turntables based on multi-body dynamics and finite element analysis. Heliyon 2024, 10, e33126. [Google Scholar] [CrossRef] [PubMed]

- Satonkar, N.; Venkatachalam, G.; Pitchumani, S.V. Finite Element Analysis of Electromagnetic Forming Process and Optimization of Process Parameters Using RSM. Mathematics 2024, 12, 1622. [Google Scholar] [CrossRef]

- Kim, S.W.; Song, J.W.; Hong, J.P.; Kim, H.J.; Kang, J.H. Finite Element Analysis and Validation of Wind Turbine Bearings. Energies 2024, 17, 692. [Google Scholar] [CrossRef]

- Wang, B.; Bai, J.T.; Lu, S.B.; Zuo, W.J. An open source MATLAB solver for contact finite element analysis. Adv. Eng. Softw. 2025, 199, 103798. [Google Scholar] [CrossRef]

- Faraji, T.; Irani, M.; Korpala, G.; Ostwald, C.; Hatscher, A.; Prahl, U. Modeling the influence of bainite transformation on the flow behavior of steel using a macroscale finite element analysis. Int. J. Plast. 2025, 184, 104189. [Google Scholar] [CrossRef]

- Sahu, O.; Das, P.; Muni, M.K.; Pradhan, N.; Basa, B.; Sahu, S.K. Frequency-Based Crack Effect Study on Beams Under Free Vibration Using Finite Element Analysis. Eng. Trans. 2024, 72, 95–114. [Google Scholar] [CrossRef]

- Maier, W.; Möhring, H.C.; Feng, Q.; Wunderle, R. Augmented reality to visualize a finite element analysis for assessing clamping concepts. Int. J. Adv. Manuf. Technol. 2024, 133, 2293–2302. [Google Scholar] [CrossRef]

| Name/Unit | Value |

|---|---|

| Elastic modulus/MPa | 1250 |

| Density/(kg/m3) | 950 |

| Poisson’s ratio | 0.4 |

| Flexural strength (MPa) | 28 |

| Fracture elongation | 0.02 |

| Parameter | Symbol | Value | Tolerance |

|---|---|---|---|

| Total length of the shoe box | L | 513 mm | ±1 mm |

| Total width of the shoe box | W | 159 mm | ±1 mm |

| Total height of the shoe box | H | 392 mm | ±1 mm |

| Maximum opening angle of the shoe box | A | 35° | ±1° |

| Outer shell thickness | 5 mm | ±0.1 mm | |

| Inner liner thickness | 3 mm | ±0.1 mm | |

| Filet Radius | 2 mm | ±0.1 mm | |

| Stiffener | 3 mm | ±0.1 mm |

| Shoe Mass/kg | Force Load/N |

|---|---|

| 11.5 | 112.7 |

| 12.5 | 122.5 |

| 13.5 | 132.3 |

| 14.5 | 142.1 |

| 15.5 | 151.9 |

| Note | Force load = shoe mass × 9.8 m/s2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tu, Y.; Zhang, H.; Luo, J.; Fan, J. Finite Element Simulation Analyses of Load-Bearing Capacity of RPP Material-Based Shoe Box. Appl. Sci. 2025, 15, 12314. https://doi.org/10.3390/app152212314

Tu Y, Zhang H, Luo J, Fan J. Finite Element Simulation Analyses of Load-Bearing Capacity of RPP Material-Based Shoe Box. Applied Sciences. 2025; 15(22):12314. https://doi.org/10.3390/app152212314

Chicago/Turabian StyleTu, Yongqiang, Haoran Zhang, Jie Luo, and Jianyu Fan. 2025. "Finite Element Simulation Analyses of Load-Bearing Capacity of RPP Material-Based Shoe Box" Applied Sciences 15, no. 22: 12314. https://doi.org/10.3390/app152212314

APA StyleTu, Y., Zhang, H., Luo, J., & Fan, J. (2025). Finite Element Simulation Analyses of Load-Bearing Capacity of RPP Material-Based Shoe Box. Applied Sciences, 15(22), 12314. https://doi.org/10.3390/app152212314